Jon Burk, California State License #31053

The Scope and Purpose of a Home Inspection

PROVIEW Professional Home Inspections is proud to include our SAFE HOME BOOK as part of your home inspection report. This publication is a compilation of well-researched articles especially for homeowners. They include valuable information and tips for helping keep families safe and their homes in top condition. Please enjoy it with our compliments.

This inspection was performed in accordance with the current Standards of Practice and Code of Ethics of InterNACHI (International Association of Certified Home Inspectors). The Standards contain certain and very important limitations, expectations and exclusions to the inspection. A copy is available prior to, during and after the inspection and it is part of the report.

©2013 International Association of Certified Home Inspectors & Master Inspector Certification Board.

💲Purchasing property involves risk

The purpose of a home inspection is to help reduce the risk associated with the purchase of a structure by providing a professional opinion about the overall condition of the structure. A home inspection is a limited visual inspection and it cannot eliminate this risk. Some homes present more risks than others. We cannot control this, but we try to help educate you about what we don’t know during the inspection process. This is more difficult to convey in a report and one of many reasons why we recommend that you attend the inspection.

Occasional typographical errors and other minor errors and omissions will occur in the report. I apologize in advance for these. If any of these typos make the report unclear, confusing or incomplete, please contact me immediately for clarification/correction.

A home inspection is not an insurance policy

This report does not substitute for or serve as a warranty or guarantee of any kind. Home warranties can be purchased separately from insuring firms that provide this service.

A home inspection is visual and not destructive

The descriptions and observations in this report are based on a visual inspection of the structure. We inspect the aspects of the structure that can be viewed without dismantling, damaging or disfiguring the structure and without moving furniture and interior furnishings. Areas that are concealed, hidden or inaccessible to view are not covered by this inspection. Some systems cannot be tested during this inspection as testing risks damaging the building. For example, overflow drains on bathtubs are generally not tested because if they were found to be leaking they could damage the finishes below. Our procedures involve non-invasive investigation and non-destructive testing which will limit the scope of the inspection.

☠️Environmental/Suspected bio-growth Exclusions

The reported or actual health effects of many potentially harmful, toxic or environmentally hazardous elements that may be found in building materials or in the air, soil, water in and/or around any house are varied, and, in some cases controversial. A home inspection does not include the detection, identification or analysis of any such elements or related concerns such as, but not limited to, suspected bio-growth, allergens, legal/illegal drugs and other biological contaminants, radon, , bed bugs, cockroaches, fleas, lice, formaldehyde, asbestos, lead, electromagnetic fields, carbon monoxide, insecticides, Chinese drywall, refrigerants and fuel oils. Furthermore, no evaluations are performed to determine the effectiveness or appropriateness of any method or system (e.g., water filter, radon mitigation, etc.), designed to prevent or remove any hazardous or unwanted materials or elements. An environmental health specialist should be contacted for evaluation of any potential health or environmental concerns. The noting of the presence of materials commonly considered to contain asbestos, formaldehyde, lead, suspected bio-growth etc in the inspection report, should not be construed to mean the inspector is inspecting for these things but instead should be seen as a "heads-up" regarding these materials and further evaluation by qualified professionals may be warranted.

This is not an inspection for code compliance

This inspection and report are not intended for city / local code compliance. During the construction process structures are inspected for code compliance by municipal inspectors. Framing is open at this time and conditions can be fully viewed. Framing is not open during inspections of finished homes, and this limits the inspection. All houses fall out of code compliance shortly after they are built, as the codes continually change. National codes are augmented at least every three years for all of the varying disciplines. Municipalities can choose to adopt and phase in sections of the codes on their own timetables. There are generally no requirements to bring older homes into compliance unless substantial renovation is being done.

This is just my opinion and just for you

The contents of this report are for the sole use of the client named above and no other person or party may rely on this report for any reason or purpose whatsoever without the prior written consent of the inspector who authored the report. Any person or party who chooses to rely on this report for any reason or purpose whatsoever without my express written consent does so at their own risk and by doing so waives any claim of error or deficiency in this report.

Construction techniques and standards vary. There is no one way to build a house or install a system in a house. The observations in this report are my opinions based on my training and experience. Other inspectors and contractors are likely to have differing opinions. You are welcome to seek opinions from other professionals in the context of doing your due diligence.

The scope of this inspection

This inspection will include the following systems: exterior, roof, structure, drainage, foundation, attic, interior, plumbing, electrical and heating. The evaluation will be based on limited observations that are primarily visual and non-invasive. This inspection and report are not intended to be technically exhaustive.

All homes are likely to have some faults which may range from cosmetic defects to major safety hazards. Not all defects will be found. While some minor deficiencies may be mentioned, the emphasis of this report is to inform the buyer of the property condition by detecting deficiencies or circumstances that may affect the structural integrity of the building and its components and its safe use as a residence.

You are encouraged to obtain competitive estimates for major repair needs. Safety and health issues should be addressed promptly. It is recommended that all corrective work, other than routine maintenance activities, be performed by qualified licensed contractors.

It is beyond the scope of the Standard Home Inspection to identify components within the home that may have been part of a "manufacturer's recall". Mention of specific recalls within this report must not be construed to mean that all such items have been identified, or that such identification is part of a Standard Home Inspection. When possible, appliance Model Numbers and Serial Numbers are included in the report and can be used to check for recall related issues. If you have any question about specific appliances, information can be found at the CPSC (Consumer Products Safety Commission) website or contact the manufacturer directly.

I recommend you obtain as much history as is available concerning this property. This historical information may include copies of any seller's disclosures, previous inspection or engineering reports, reports performed for or by relocation companies, municipal inspection departments, lenders, insurers and appraisers. You should attempt to determine whether repairs, renovation, remodeling, additions or other such activities have taken place at this property, and this report will attempt to identify such items when possible.

Ranges, Dish Washers, and Refrigerators, Microwaves (and the like) are typically tested for basic function (Do they turn on). No assertions are made as to how well they function. Clothes washers/dryers are typically not operated.

Throughout this report, comments will be made as to the presence or absence of components or parts of components. This must not be construed to mean that these components or parts of components exist (or don't exist) in concealed areas or behind finished surfaces. For example: if foundation bolting was seen in one area, it does not mean that the bolting exists (or doesn't exist) in areas that are concealed. Also if an item was noted as "not being visible," that should not be construed to mean that none of whatever was "not visible" does not exist on the premises---it just means none was noted at the time of inspection and should be seen as a "heads-up" that the concern or condition might be present but hidden, or that the conditions that would allow its presence to be known was not replicated at the time of inspection.

Many of the non-narrative observations/documentation detailed in the report that are related to more "cosmetic" issues should not be construed as "all inclusive" but should instead be seen in as "suggestive" or a "guideline" of conditions that may exist elsewhere in the home. It is not the focus of the report to comment extensively on cosmetic issues, but I do make note of them at times to help complete the "snap-shot" of the home at the time of inspection. For example, "nail-pops" seen in one room are likely to be seen (and should be anticipated) in other rooms even though I may not have noted them in the report.

Throughout the report I may make recommendations as to possible repairs. These recommendations are not intended to be substitutes or construed to be more appropriate than the recommendations of the professionals making the repairs. Conflicts in recommendations should be resolved prior to repairs being made.

Your expectations

The overall goal of a home inspection is to help ensure that your expectations are appropriate with the house you are proposing to buy. To this end we assist with discovery by showing and documenting observations during the home inspection. This should not be mistaken for a technically exhaustive inspection designed to uncover every defect with a building. Such inspections are available but they are generally cost-prohibitive to most home-buyers.

Who should make repairs and what should their qualifications be?

Worker qualifications: In the text of the report, in some instances, I recommend that work be done by a "qualified" persons or "qualified" parties. I consider qualified parties, in licensed trades, to be those individuals who hold the necessary licenses to legally work in their profession -- licensed electricians, licensed pest control applicators, licensed plumbers, licensed HVAC professionals, licensed engineers, licensed general contractors, etc. In instances where a task may not, typically, need to be done by a person with a professional license, my recommendation is to hire an individual to do the work who is, based on past training, experience or expertise, qualified to further evaluate the condition or problem listed in the report and to then make appropriate repairs.

For additional fees, I can perform invasive inspection of concealed areas if desired. Please contact me for more information regarding this service.

Your participation is requested

Your presence is requested during this inspection. A written report will not substitute for all the possible information that can be conveyed verbally by a shared visual observation of the conditions of the property.

How to Read This Report

Getting the Information to You

This report is designed to deliver important and technical information in a way that is easy for anyone to access and understand. If you are in a hurry, you can take a quick look at our "Summary Page” and quickly get critical information for important decision making. However, we strongly recommend that you take the time to read the full Report, which includes digital photographs, captions, diagrams, descriptions, videos and hot links to additional information.

The best way to get the layers of information that are presented in this report is to read your report online, which will allow you to expand your learning about your house. You will notice some words or series of words highlighted in blue and underlined – clicking on these will provide you with a link to additional information.

This report can also be printed on paper or to a PDF document.

Chapters and Sections

This report is divided into chapters that parcel the home into logical inspection components. Each chapter is broken into sections that relate to a specific system or component of the home. You can navigate between chapters with the click of a button on the left side margin.

Most sections will contain some descriptive information done in black font. Observation narrative, done in colored boxes, will be included if a system or component is found to be significantly deficient in some way or if we wish to provide helpful additional information about the system or the scope of our inspection. If a system or component of the home was deemed to be in satisfactory or serviceable condition, there may be no narrative observation comments in that section and it may simply say “tested,” or “inspected.”

Observation Labels

All narrative observations are colored, numbered and labeled to help you find, refer to, and understand the severity of the observation. Observation colors and labels used in this report are:

- Major Concern:Repair items that may cost significant money to correct now or in the near future, or items that require immediate attention to prevent additional damage or eliminate safety hazards.

- Repair:Repair and maintenance items noted during inspection. Please note that some repair items can be expensive to correct such as re-finishing hardwood floors, but are considered simply repair items due to their cosmetic nature.

- Recommended Maintenance:These are repair items that should be considered "routine home ownership items," such as servicing the furnace, cleaning the gutters or changing the air filters in the furnace.

- Improve:Observations that are not necessarily defects, but which could be improved for safety, efficiency, or reliability reasons.

- Monitor:Items that should be watched to see if correction may be needed in the future.

- Due Diligence:Observation such as a buried oil tank that may require further investigation to determine the severity and / or urgency of repair.

- Efficiency:Denotes observations that are needed to make the home more energy efficient as well as to bring the home up to modern insulation standards. This category typically includes windows and insulation. Other items, such as lighting and appliances, are not inspected for their energy status.

- Note:Refers to aside information and /or any comments elaborating on descriptions of systems in the home or limitations to the home inspection.

- Description:Detailed description of various aspects of the property noted during the inspection.

Summary Page

The Summary Page is designed as a bulleted overview of all the observations noted during inspection. This helpful overview is not a substitution for reading the entire inspection report. The entire report must be read to get a complete understanding of this inspection report as the Summary Page does not include photographs or photo captions.

Summary

Major Concerns

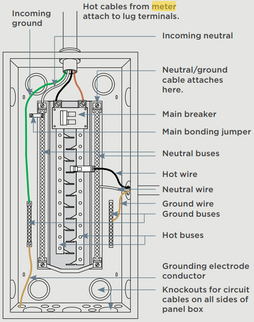

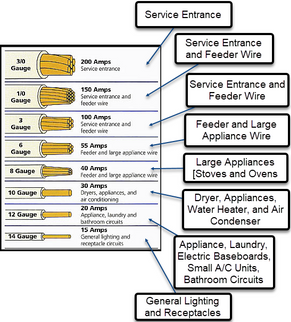

- E-6 ELECTRICAL:

The electrical panel has numerous issues that will require a Lic. Electrical contractor to evaluate and correct. Red flags exist of non-professional workmanship, defective components, brand/s of a panel such as Zinsco, or needed updating of the panel. Issues such as missing screws at the exterior dead cover, open gaps at the dead cover, missing grommets inside the panel, Dbl lugging at the breaker/s neutral bus bar, overheated circuits, and service conductors not properly sized for this panel or other issues will require repairs. Recommend consulting an Electrical Contractor for evaluation, possible replacement, and or repairs concerning this panel.

- The house has a Zinsco brand electrical panel. These panels have a reputation for failing and malfunctioning breakers as well as a unique aluminum bus bar design that can allow breakers to make loose connections which can lead to arcing and fires. These panels are considered a latent fire hazard. Full electric panel replacement is recommended for improved safety. Please note that CA state home inspector standards of practice require us to report on these panels.

- E-9 ELECTRICAL:

Aluminum single strand or solid conductor wiring was noted in the main electrical panel for some of the 15 and 20 amp circuits in this building. Solid strand aluminum wiring that was used for 15 and 20 amp circuits during the Vietnam war era has proven a problematic fire hazard. I recommend hiring a licensed electrical contractor who specializes in aluminum wiring to further evaluate these circuits and all termination points and make repairs as recommended. Recommended repair options include using a CPSC approved crimping system or fully replacing the circuits. The aluminum alloys used prior to 1972 are generally more problematic and this wiring should be replaced. Post 1972 single strand aluminum should employ an improved alloy that can be safely kept in service when properly installed. For more information on solid strand aluminum wiring see:

- https://dylanchalk.com/single-strand-aluminum-wiring-safe/

- http://structuretech1.com/aluminum-wiring/

- https://www.cpsc.gov/s3fs-public/516.pdf

- https://inspectapedia.com/electric/Old-Fabric-Insulated-Electrical-Wire-ID.php

- https://www.alwirerepair.com/photo-gallery/burned-purples

Examples of specific observations noted during inspection today include:

Repairs

- E1-2 EXTERIOR/GROUNDS:

Typical cracks were noted in the flatwork. No immediate repair appears necessary, though water will continue to deteriorate the surface until the concrete is repaired. Consult a general contractor or other licensed professional for repair methods and options.

- E1-9 EXTERIOR/GROUNDS:

The exterior paint job requires localized touch-up due to peeling paint and bare wood exposed. This is typical on older homes. Be prepared to make repairs such as wood putty to fill in areas that need it. Have the exterior paint job touched up and completed by the painter. During inspection today, I noted:

- E1-12 EXTERIOR/GROUNDS:

The front porch has a header beam that is twisting under load. This requires repair to avoid damage to the roofing above and the patio structure below. Consult a licensed contractor for repairs.

- E1-15 EXTERIOR/GROUNDS:

The sealant around the exterior of the windows are showing signs of failure was visible. Sealants can help prevent possible moisture-related issues. Numerous products are available, but stay away from silicone; using GEOCEL or Lexsel is recommended. I recommend having all of these areas further investigated by a qualified general contractor and repair failing areas of a sealant as needed to ensure a waterproof envelope.

- E1-21 EXTERIOR/GROUNDS:

The garage slab has a staining pattern on it that could indicate seasonal moisture / dampness. This is usually not a major concern in a garage as this is outdoor space but could limit the uses of this space. High moisture content in a garage slab could make it difficult to store cardboard on the floor for example, or finish this space, or could even lead to condensation problems on the overhead door. You can use concrete sealers to better seal the concrete and slow water wicking through to the surface. It is common on garage slabs to prepare them with less vigorous water proofing techniques as they are outside the thermal envelope.

- R-5 ROOF/ATTIC:

Repair all of the loose / poorly secured downspouts. Many of the downspouts are not well secured to the home and are vulnerable to disconnecting. This could lead to water damage. Tune up all downspouts to insure they are reliably secured.

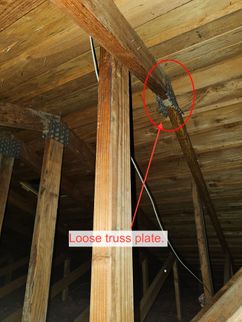

- R-11 ROOF/ATTIC:

One of the metal connections plates that connect the components of the engineered wood truss in the roof frame appears to be damaged. This could compromise an engineered truss system. In general, trusses should not be cut, notched, drilled or spliced or otherwise damaged without approval from a registered design professional. Have this further evaluated and repaired as recommended to ensure reliable performance.

- R-13 ROOF/ATTIC:

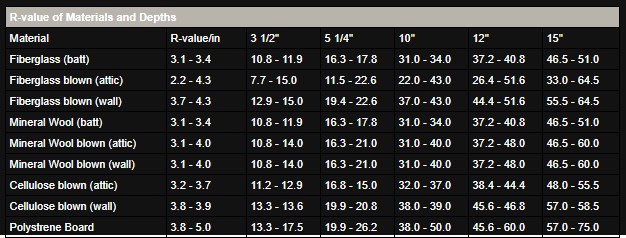

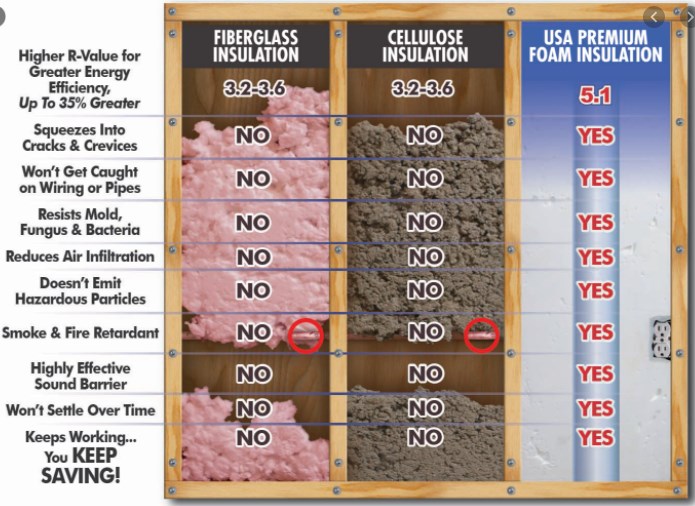

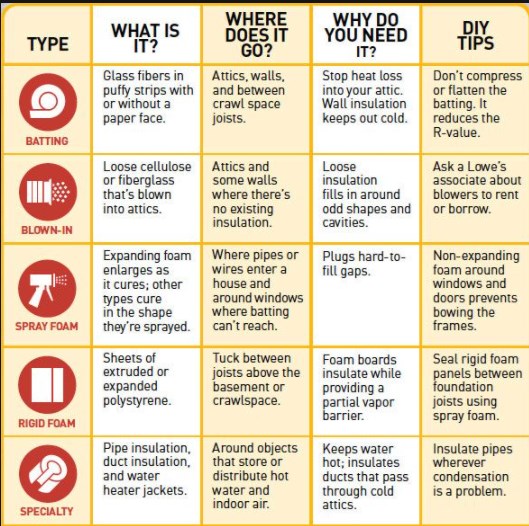

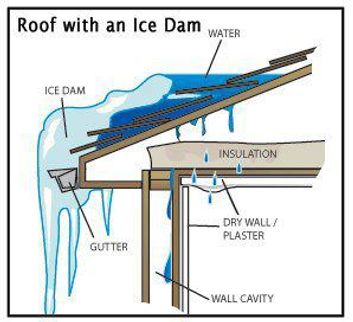

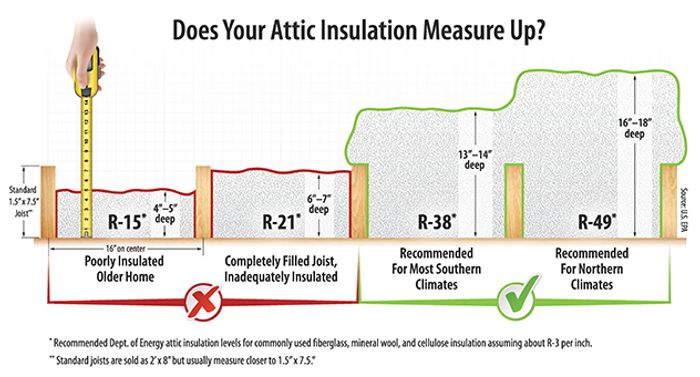

The attic was missing insulation in a localized area. This condition can result in increased heating and cooling costs, reduced comfort levels and may contribute to ice damming of the roof during the winter. Uneven amounts and old insulation will cause higher energy cost. The Inspector recommends that insulation be properly distributed to cover all portions of the attic located above the home living space and add additional coverage. All work should be performed by a qualified contractor.

- R-14 ROOF/ATTIC:

The insulation is old, damaged, and installed in a substandard manner. We recommend it be reworked or replaced in accordance with accepted standards. I recommend consulting a Contractor for evaluation and repairs concerning this issue.

- HS-2 HEATING/COOLING SYSTEMS:

At the time of the inspection, the safety switch in the blower compartment failed to shut down the blower when the compartment cover was removed. We do not remove the tape, but you may inquire from the seller why the tape is present. Recommend that you consider repairing this for safety reasons.

- HS-7 HEATING/COOLING SYSTEMS:

Annual servicing of the gas log fireplace is recommended to ensure safe and reliable performance. No recent service records were noted. Have this appliance cleaned and serviced by a qualified gas appliance specialist. Examples of observations noted during inspection include:

- E-2 ELECTRICAL:

The electric meter base is corroded and requires replacement. Have this further investigated by the electric utility and replaced as recommended.

- E-14 ELECTRICAL:

The loose switch needs to be secured to prevent accidental damage to the wiring connections - see video taken near laundry room.

- P-2 PLUMBING:

Evidence of electrolysis was noted on the supply pipe. Make sure all connections of dissimilar metals are protected with dielectric fittings to prevent corrosion. Hire a licensed plumber to further evaluate and repair.

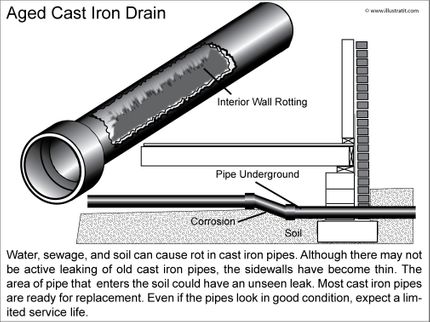

- P-3 PLUMBING:

Cast iron drain pipes present. Maintenance concern. Cast iron drain pipes typically indicate an older sewer system. Cast iron also is subject to excessive deterioration from the inside out or tree roots may intrude into the pipes through joints or breaks in the pipe. These types of sewer pipes can fail or clog at any time. Proview Professional Home Inspections is aware of some sellers who use commercial drain cleaners to solve clogging problems prior to home inspections, only to have the clogging problems return a short time into the future. Consider having a plumber run a camera through the drain lines (sewer scope) to determine the condition of the underground drain lines and look for potential blockages. Follow their advice after the sewer scope. Note that replacing main sewer lines is likely to be expensive and now is the time to find out if that is needed.

- P-4 PLUMBING:

Some of the waste plumbing has been updated, while some of the old waste plumbing remains and is considered old and unreliable. Old metal pipes are subject to internal corrosion, which can cause problems at any time. During repairs and renovations to the plumbing system, be sure to have this old piping immediately evaluated and updated as a licensed plumber recommends.

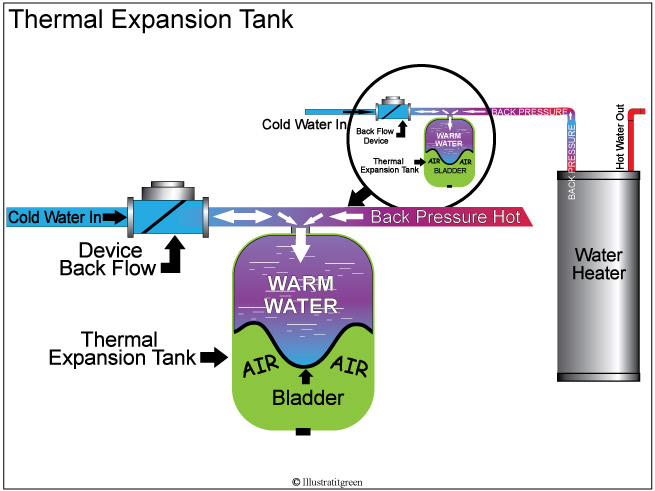

- P-5 PLUMBING:

An expansion tank is recommended for the water heater; these are required if the house has a closed plumbing system. This helps reduce pressure on the plumbing system when the pipes and water expand from thermal expansion during water heating. Installation of expansion or pressure tanks is modern installation practice and will be required if a pressure reducing valve has been installed. Consult with a qualified plumber to install if the water heater is aged and recommended replacement then one should make sure this is installed at that time.

- P-8 PLUMBING:

The water heater is missing a drip-leg/sediment trap. I recommend contacting a licensed plumber to install this fixture.

- P-10 PLUMBING:

The sump pump in the crawl space is missing a cover. It is a requirement that the sump pump have a proper cover for safety. Repair may be performed by a qualified person.

- P-11 PLUMBING:

The discharge pipe for the sump pump has inadequate support. Have this further investigated and repaired by a qualified contractor to ensure reliable discharge from the sump pump system.

- P-12 PLUMBING:

The sump pump appears to be connected to an open non-GFCI outlet. This is a fire hazard. I recommend contacting an electrician to update this outlet.

- P-15 PLUMBING:

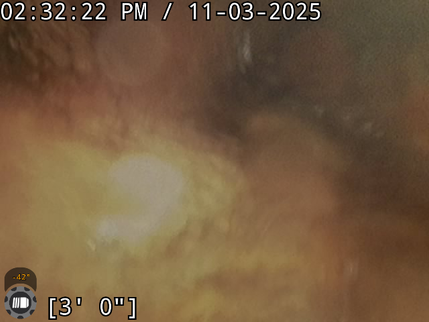

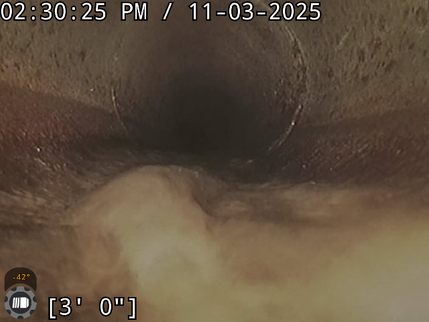

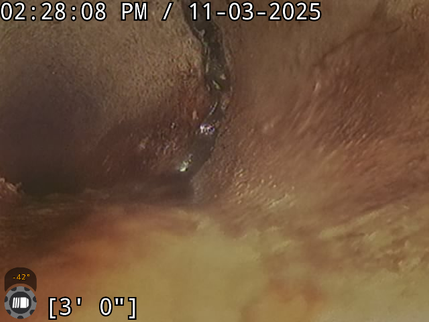

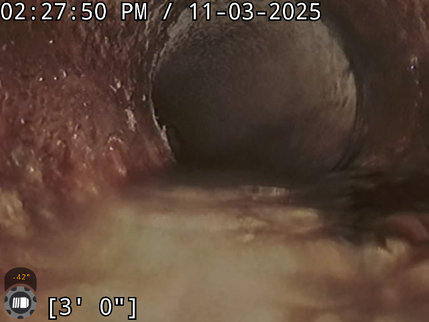

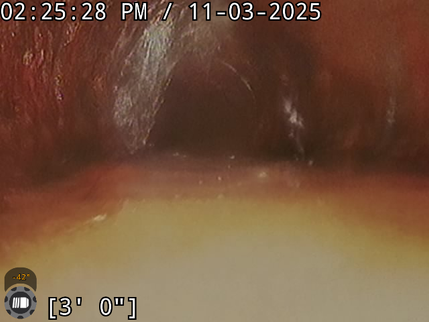

*** Important note - During the inspection the photos captured were not accurately displaying the counter in the bottom left. ***

All photos and video show severe corrosion of the cast iron piping throughout the home. Around 67' the cast iron transitions to PVC Schedule 40 piping which continued another 30' to the city tap.

This is likely where there have been previous repairs made at the home (see photo near water shut-off valve and brick siding).

Corrosion occurs in cast iron piping due to prolonged blockages, chemical reactions, and exposure to moisture from surrounding soils likely from the crawl space.

Typical life span of cast iron piping is anywhere from 50-100 years if properly maintained, but usually in my inspections I find around 30 years to be more accurate due to corrosion.

The cap to access the lateral line from the garage was improperly fitting and needs to be reinstalled correctly. Hose clamps and gasket are not a proper seal for the pipe. Note the backwash and corrosion on the cap.

Ultimately, I am going to recommend the whole cast iron section of the sewer lateral line to be replaced. It is at the end of it's life span, there are sections that appeared to be leaking, sections that had intrusion from roots which likely indicates moisture from outside the pipe allowing plants to find the pipe,

and the severity of the corrosion which is a tell tale sign of failure. Sewer lateral replacement typically begins around $1,000.00 per linear foot. I recommend consulting a licensed plumber for a second opinion and job costing. This line likely cannot be saved by a cutting blade as it is too corroded.

- I-3 INTERIOR:

The carpeting in the most of the house is loose and has a rolled appearance. This indicates that the carpet should be stretched for a proper finish. Have this further evaluated and repaired by a carpet installer.

- I-4 INTERIOR:

Squeaking floors (when walked upon) are common in all types of construction, show up under different conditions and are not always apparent during inspection. Newer construction utilizes adhesives to reduce the likelihood of squeaks. Their presence sometimes indicates that adhesive has been omitted. There are many other causes of squeaks as well. Sometimes squeaks can be minimized by removal of carpeting and screwing the subfloor to the joists. Recommend consulting a qualified person for this repair and repair as desired.

- I-5 INTERIOR:

Some cracks were noted in the plaster walls and ceilings. This is typical in older plaster walls. As a general rule, repairs should be made as desired. Repair becomes necessary when the keys that bond the plaster to the lath begin to fail. Cracking at the time of inspection did not seem in need of urgent attention.

- I-7 INTERIOR:

Some of the interior doors are rubbing or hitting the jamb and were difficult to close. The door may be out of square and will need to be adjusted or trimmed. The Inspector recommends correction by a qualified contractor.

- B-5 BATHROOM(S):

The hall bath shower diverter, which diverts water from the tub fill spigot to the shower head, is leaky and requires repair to prevent wasting water and to improve flow to the shower head.

- S-2 STRUCTURE/BASEMENT:

Minor to moderate settlement was noted in the home during inspection today. Be sure to correct any and all drainage recommendations to prevent further settlement (see Drainage section of this report) and monitor for signs of on-going movement. If conditions get worse, a structural engineer should be consulted for repair advice. The hope in older homes is that soils that were poorly compacted at construction have compacted with the weight of the building and may not continue to move as long as they stay dry.

- S-3 STRUCTURE/BASEMENT:

The structural beam in the crawl space appears to have inadequate bearing. Minimum 1.5 inch bearing onto other wood framing is needed or 3 inches onto concrete. Hire a qualified general contractor to further investigate and repair as recommended.

- CS-1 CRAWL SPACE:

The access hatch for the crawl space has been carpeted over. I recommend cutting the carpet around the access hatch and installing a pull handle so the carpet does not have to be removed to access the crawl space.

- CS-2 CRAWL SPACE:

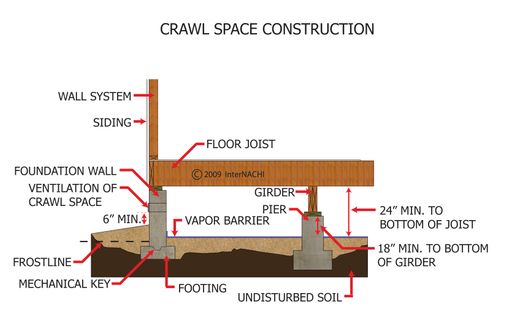

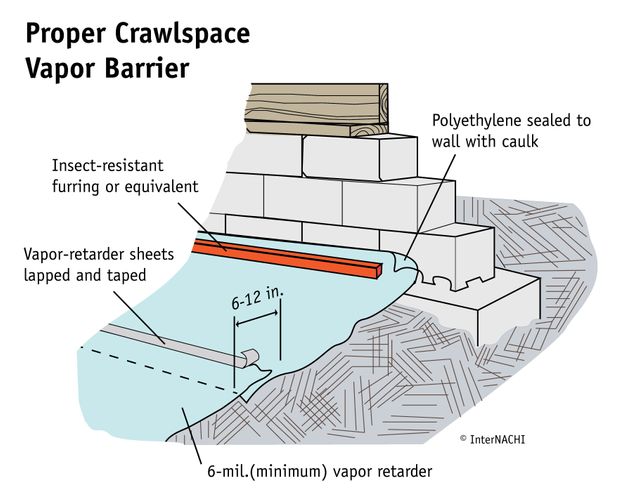

A vapor barrier has been installed and is missing in larger areas on the soils of this crawl space to contain the moisture in the ground. This is a conducive pest condition and can lead to high moisture conditions. Install a 6 mil. black plastic vapor barrier to cover all exposed earth.

- CS-3 CRAWL SPACE:

No sub-floor insulation was noted. Sub-floors should be insulated to R-30 or better to conserve energy. Hire an insulation specialist to evaluate and repair. Prior to repair, use spray expanding foam to seal all gaps and holes in the sub-floor. When insulating be sure to implement cohesive rodent exclusion work to ensure new thermal barriers do not get damaged.

- CS-4 CRAWL SPACE:

Evidence of prior water entry into the crawl space was noted at one of the crawl space vents or silt stains along the foundation walls - see water stains. Inquire with the seller for any history here and monitor. This may be signs of past issues or may be an existing problem during heavy rain cycles. Take every precaution to make sure of drainage issues are addressed and improvements made. Recommend consulting a Contractor for evaluation and repairs concerning this issue.

- CS-5 CRAWL SPACE:

Minor to moderate water was noted in the crawl space at the time of inspection. This condition can change seasonally so it is difficult to gauge the scope and urgency of a needed repair. Ideally, no water should ever be above the plastic vapor barrier as is the case now. I recommend additional inspection by a qualified drainage contractor. Minor moisture can often be handled with some gravel and a new vapor barrier. More persistent problems may require a sump pump or additional drainage work.

Recommended Maintenance Items

- E1-6 EXTERIOR/GROUNDS:

Trimming the shrubs and vegetation is recommended to maintain a 12" minimum clearance. This will prevent damage to the exterior finishes as well as prevent mildew or algae growth due to moisture entrapment. Maintaining proper clearance will also eliminate a condition conducive to wood destroying insects and a path for rodent entry. Overgrown vegetation can:

* Cause structural damage by putting pressure on foundation walls or roofing materials

* Allow water intrusion through compromised seals and joints

* Create an invitation for pests and rodents to inhabit the area

* Reduce energy efficiency by blocking sunlight and air circulation

To maintain a safe and well-maintained exterior, it's crucial to regularly trim and prune vegetation to ensure a minimum of 1 foot clearance between plants and walls. This simple task can go a long way in preserving the integrity and appearance of your property."

- R-6 ROOF/ATTIC:

The gutters are clogged with organic debris and require cleaning to ensure proper control of roof runoff. Clean the gutters and ensure they are unobstructed, leak free and properly sloped to drain. This is routine house maintenance; I would expect the need to clean gutters and downspouts regularly.

- FD-1 FUEL & DISTRIBUTION:

Gas pipes at the meter exhibited moderate corrosion. This condition has the potential for an eventual gas leak. The inspector recommends that this condition be evaluated by the public utility responsible for supplying gas to the property.

Improves

- E1-5 EXTERIOR/GROUNDS:

Downspouts are discharging adjacent to the foundation. This can cause foundation settlement or basement / crawl space moisture problems. Make sure all downspouts discharge into a proper tight-line system or at least 5 feet away from the foundation.

- E1-8 EXTERIOR/GROUNDS:

Obvious repairs have been performed to the stucco siding. The owner may have information about the original condition, the repairs and any permits required, issued and completed.

Monitors

- I-2 INTERIOR:

Minor to moderate floor settlement was noted in the house. Inquire with the seller for any history of repairs or movement. No signs of recent movement were visible at the time of inspection.

Due Diligences

- E1-16 EXTERIOR/GROUNDS:

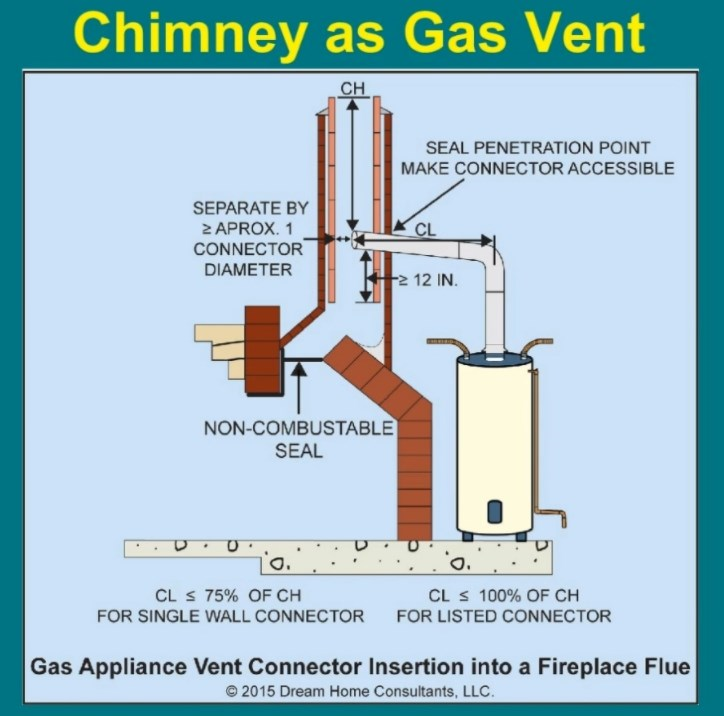

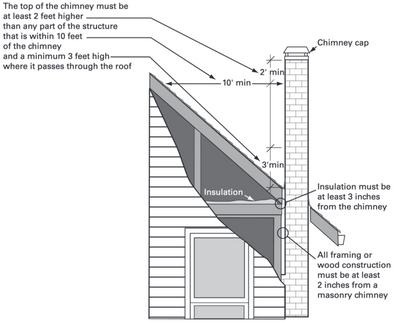

The NFPA (National Fire Protection Association) recommends an annual inspection of all chimneys, fireplaces, solid fuel-burning appliances, and vents. They also recommend an NFPA 211 Standard, Level II inspection upon sale or transfer of the property. A Level II inspection includes, not only cleaning the interior of the chimney pipe, but also the use of specialized tools and testing procedures such as video cameras, etc. to thoroughly evaluate the serviceability of the entire flue lining and fireplace/chimney system. Level II inspections are not always needed, especially for short simple flues that can be inspected visually after a cleaning. If a chimney cleaning has not been performed over the past 12 months, such an inspection is recommended before home changes ownership---for fire safety reasons. Effectiveness of the chimney draw is not determined during or as part of a home inspection. Implement any repairs as recommended.

- R-4 ROOF/ATTIC:

The roofing material on this building is a recently installed dimensional or architectural grade shingle. These are often rated as 30-40 year shingles. In practice, as a roof assembly, these tend to last about 18-23 years depending on the quality of the installation, the steepness of the roof and the exposure. The installation appears neat and professional. Inquire with the seller about any warranty information for this roof. Many professional roofing companies will offer limited workmanship warranties. Please note that roofs are not a shingle. they are an assembly and they require regular cleaning and maintenance to keep them performing reliably. Examples of observations noted during inspection include:

- P-9 PLUMBING:

A sump pump system was noted for this building. Inquire with the seller for more information about this pump system; is it needed to keep the building dry? Some sump pumps are installed as a prophylactic measure, other systems are critical for keeping a building dry. The importance of this system is impossible to determine during a one-time inspection. Sump pumps always require maintenance. If it is determined that the pump is critical to maintain a dry basement or crawl space, I recommend installing back up power systems so the pump will work in a power outage, have a back-up pump and an alarm to alert the occupants in case of a pump failure.

- CS-6 CRAWL SPACE:

Floor joists, subfloor area/s or ductwork in the crawlspace were partially covered in a few areas with a substance resembling suspected bio-growth. This condition indicates moisture intrusion of the crawlspace. Suspected bio-growth can only be positively identified through sampling and analysis by taking samples with testing from a lab. Growing spore colonies can cause bio-growth spore concentrations in indoor air to rise to unhealthy levels. Conditions that encourage bio-growth can also cause structural damage from wood decay. Proview Professional Home Inspections can perform testing for an additional fee.

- CS-7 CRAWL SPACE:

The crawl space was dry at the time of inspection but I did note signs of a prior moisture condition. Disclose any additional information about any prior moisture issues or drainage work done to date. I recommend inspecting this space for water during the rainy season to check for water. Mild dampness in the wet weather is pretty normal but there should be no significant standing water or pooling above the vapor barrier. The plastic vapor barrier should never be floating on water.

Efficiencies

- R-9 ROOF/ATTIC:

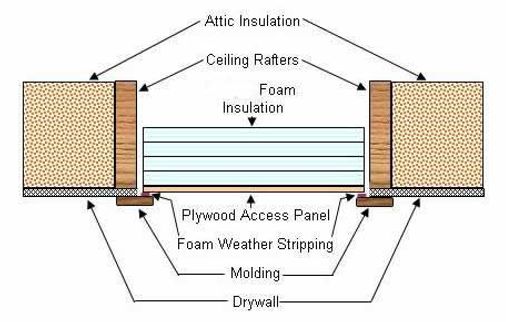

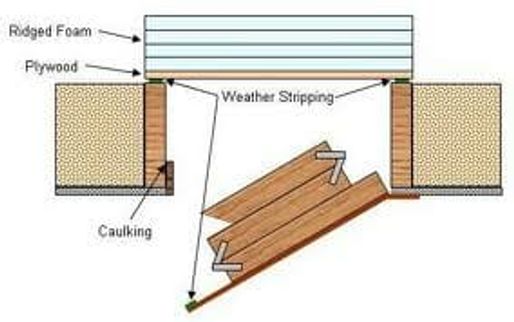

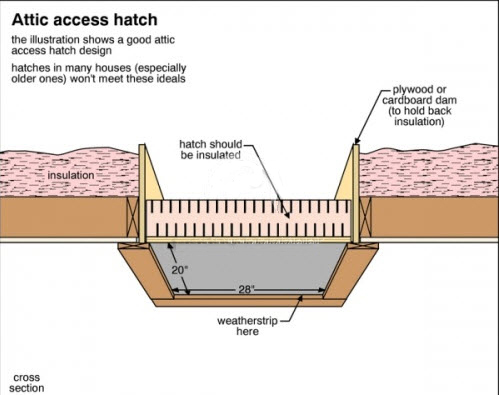

The weather strip for the attic access hatch is missing and the hatch is leaking air. This should be better air sealed to prevent heat migration into the attic.

Notes

- E1-20 EXTERIOR/GROUNDS:

Typical cracks were noted in the concrete garage slab. No control joints were used in the pour here so the concrete will crack. You can fill the cracks with a masonry rated caulking, but no repair is needed at this time; this is a cosmetic defect.

- E-7 ELECTRICAL:

This is provided for your information concerning the main panel and it's location

- E-8 ELECTRICAL:

Permit stickers were noted on the electric panel.

- E-13 ELECTRICAL:

Photos/Videos of GFCI testing.

- I-8 INTERIOR:

Ten Things You Should Know About Suspected Bio-Growth(from the EPA):

1. Potential health effects and symptoms associated with Suspected Bio-Growth exposures include allergic reactions, asthma, and other respiratory complaints.

2. There is no practical way to eliminate all Suspected Bio-Growth and spores in the indoor environment; the way to control indoor Suspected Bio-Growth is to control moisture.

3. If Suspected Bio-Growth is a problem in your home or school, you must clean up the Suspected Bio-Growth and eliminate sources of moisture.

4. Fix the source of the water problem or leak to prevent Suspected Bio-Growth growth.

5. Reduce indoor humidity (to 30‐60% ) to decrease Suspected Bio-Growth by: venting bathrooms, dryers, and other moisture‐generating sources to the outside; using air conditioners and de‐humidifiers; increasing ventilation; and using exhaust fans whenever cooking, dishwashing, and cleaning.

6. Clean and dry any damp or wet building materials and furnishings within 24‐48 hours to prevent Suspected Bio-Growth growth.

7. Clean Suspected Bio-Growth off hard surfaces with water and detergent, and dry completely. Absorbent materials such as ceiling tiles, that are moldy, may need to be replaced.

8. Prevent condensation: Reduce the potential for condensation on cold surfaces (i.e., windows, piping, exterior walls, roof, or floors) by adding insulation.

9. In areas where there is a perpetual moisture problem, do not install carpeting (i.e., by drinking fountains, by classroom sinks, or on concrete floors with leaks or frequent condensation).

10. Suspected Bio-Growth can be found almost anywhere; they can grow on virtually any substance, providing moisture is present. There are Suspected Bio-Growth's that can grow on wood, paper, carpet, and foods.

Localized Suspected Bio-Growth-like substances were noted in crawl space. Please note that Bio-Growth is beyond the scope of this home inspection. If you are concerned about Suspected Bio-Growth or indoor air quality, I recommend having it tested to determine the type and if it is active. Proview Professional Home Inspections also provide testing as an ancillary service.

- B-4 BATHROOM(S):

) While the tub and shower drainage was tested at the time of inspection and no leaking was noted, this should not be construed to mean the tub and shower will not leak in the future or that even current leaking might be concealed. This is especially true of recent repairs/installations where work was done in a less than professional manner. Functional testing of the tub and shower during the inspection will not duplicate normal use. Any leaking noted should be properly repaired as soon as practical and hidden damage is always possible.

Descriptions

- GC-1 GENERAL COMMENTS:

The following applies to vacant properties. Most often, vacant properties have little to no historical property condition report, and the problems/risk of repair is often increased by how a home performs when not in normal use. Also recognized that no disclosure data has been shared with us prior to the inspection.

Some systems and components of vacant and/or abandoned homes, such as piping, wiring and appliances that have not been used during real-life conditions, could fail without warning. Know that while some systems and components are reported as "working at the time of inspection," may, in fact, fail. It is difficult to know how they will respond to regular use after having sat for extended periods of time. Septic systems may initially function and then fail under a live load. Plumbing traps may operate with no signs of leaks and then let go when being actively used for a few days. Drains that operated during an inspection after real-life conditions may indicate blockage. Component seals may dry up and later leak. Sewer lines could take a few days to backup because of roots or other elements that allow test water to flow, only to fail when waste and tissue are flushed through the system.

For these and similar reasons - be aware that the risk of component failure is greater in these type homes.

- GC-2 GENERAL COMMENTS:

👉The photos included in this home inspection report are representative examples only and may not capture every condition or defect present in the property. Please refer to the full written report for a comprehensive understanding of the inspection results.

- GC-3 GENERAL COMMENTS:

This report is proofread before sending it out, but typographical errors may be present. If any errors are noticed, please feel free to contact me for clarification.

- GC-4 GENERAL COMMENTS:

In the report, there may be specific references to areas and items that were inaccessible or only partly accessible. Suspended ceilings for example would be one of those conditions. I can make no representations regarding conditions that may be present in these areas but were concealed or inaccessible for review. With access and an opportunity for inspection, reportable conditions or hidden damage may be found in these areas. If a request is made by the client for a second inspection, an additional fee will be charged.

✒️

- crawlspace or sections of the crawlspace

- GC-5 GENERAL COMMENTS:

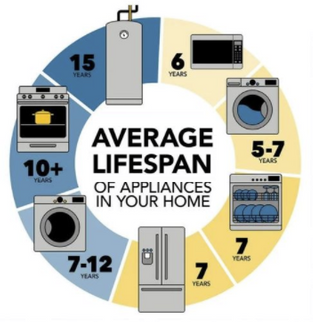

Components may be listed as having no deficiencies at the time of inspection, but may fail at any time due to their age or lack of maintenance, that couldn't be determined by the inspector. A life expectancy chart can be viewed by visiting http://prohitn.com/component-life-expectancies/

- GC-6 GENERAL COMMENTS:

We do not guarantee the presence or extent of any code violations, nor can we assure you of the legal compliance of this building. For specific information regarding these matters, it is recommended that you contact the appropriate local building and zoning department.

- GC-7 GENERAL COMMENTS:

No determination was made regarding any damage and/or lingering odors/waste that may exist from pest infestation or household pet activity unless specifically noted. Such conditions may not surface or become apparent for some time or until carpeting or other obstructions are removed. If pets have been kept in the house, there are likely some resultant conditions or residue.

- GC-8 GENERAL COMMENTS:

When repairs are made on the building, I recommend that I be called back to verify that corrections have been satisfactorily made. An extra fee will be applied based on the quantity and type of structure. . Additional charges will accrue for anything in writing travel time—these costs are to be agreed upon at the time of the request for further evaluation. REMEDIAL WORK - For any element or condition requiring attention, quotes should be obtained from qualified specialists or contractors before closing to determine actual repair/replacement costs. Any cost estimates provided, whether oral or written, represent only an approximation of possible costs. Also, any cost estimates do not reflect all possible remedial needs or costs for the property; latent concerns or consequential damage may exist. If the need for remedial work develops or is uncovered after the inspection, contact Proview Professional Home Inspections to arrange an inspection to assess conditions before performing any repairs.

IF THERE ARE ITEMS WITHIN THIS REPORT THAT REQUIRE RE-INSPECTION, YOU ARE ENCOURAGED TO HAVE ME COMMUNICATE DIRECTLY WITH THOSE HIRED TO MAKE THE CORRECTIONS TO ENSURE THAT REPAIRS ARE PROPERLY MADE.

There are many things that can be done to improve safety and living conditions within any building. While many of these issues come to light in the course of the Standard Home Inspection there are likely to be other things that can be done to improve the building.

- GC-10 GENERAL COMMENTS:

🧭For this report, all directions are given as if you are facing the front of the building unless further noted. Items listed as multiple locations may not directly reference all affected locations. Examples may be given that should not be construed as the only affected areas. Further evaluation will need to take place to determine every affected location.

- E1-3 EXTERIOR/GROUNDS:

Driveways, sidewalks, stoops, etc., that slope to the house are likely to saturate the soil around the foundation or drain water directly into foundation cracks. Even if the flatwork originally drained away from the house, the soil next to the house usually is uncompacted backfill and is likely to settle. Water draining toward the house can lead to foundation instability, deterioration, and basement moisture problems. Or perhaps it would allow water cascading down the surface in a torrential rain to wash under a garage door or into basement window wells.

- E1-7 EXTERIOR/GROUNDS:

This building has a Hardcoat stucco siding system. When installed over a wood building, stucco should be installed with two layers of underlayment below the plaster and a weep screed system which allows air to dry any accumulated water behind the plaster. Stucco is one of the nicest and lowest maintenance siding systems but it is installation sensitive. Poor installation can lead to expensive repairs. The most critical element to a stucco siding system, the weather barrier, is not visible to inspection, which limits the inspectors' ability to see how the system is performing. During the inspection, we look for clues in the installation to make an educated guess about the future reliability of this system. More detailed information can be gained through destructive testing. This involves drilling holes in the plaster and using a moisture probe to determine if any sections of the building have failed moisture control. Destructive testing like this is beyond the scope of this inspection.

- E1-10 EXTERIOR/GROUNDS:

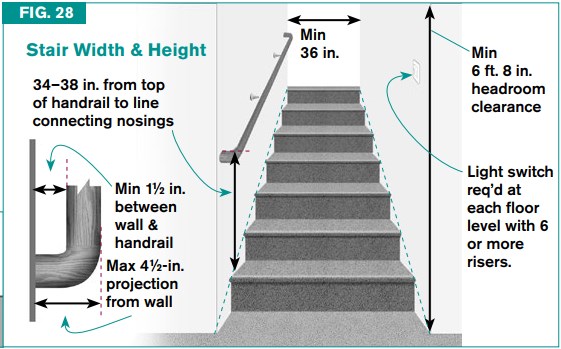

Like fences and other exposed wood construction, decks have a finite service life. Even the best maintained deck will need repair and eventual replacement. We urge regular treatment with combination wood preservative/UV inhibiting sealers. A stoop/deck/porch that is higher than 30 inches above the ground (within 36 inches of the stoop/deck/porch ) should have a railing that is at least 36 inches in height and baluster spaces should be no greater than 4 inches in width.

- E1-11 EXTERIOR/GROUNDS:

To see a prescriptive guide for residential wood deck construction click this link:

- E1-13 EXTERIOR/GROUNDS:

The 'Security' of any home is never absolute. At the time of inspection I assess the 'basic functionality' of door and window locking mechanisms. No assessment of the individual or overall effectiveness of security is implied. Glass, frames, locks and other elements can be prone to 'tampering’ and are 'limiting factors' of locking mechanisms/systems. All security devices and systems must be balanced against the ease of escape in the event of emergency. Concerns about the home s overall security system should be addressed by a licensed home security company. It is our advice to you that once you move in is to replace all exterior locks for your safety.

- E1-14 EXTERIOR/GROUNDS:

All surfaces of the envelope of the house should be inspected at least semi-annually, and maintained as needed. Any exterior element defect can result in leakage and/or subsequent damage. Exterior wood elements and wood composites are particularly susceptible to water-related damage, including decay, insect infestation, and mold. The use of proper treated lumber or alternative products may help minimize these concerns, but will not eliminate them altogether. While some areas of decay or damage may be reported, additional areas of concern may exist, subsequently develop, or be discovered during repair or maintenance work.

- E1-19 EXTERIOR/GROUNDS:

Complimentary photos provided when at the inspection.

- E1-22 EXTERIOR/GROUNDS:

The overhead garage door is the largest and heaviest moving object in a house. According to the U.S. Consumer Product Safety Commission (CPSC), approximately 4 children die each year from accidents caused by garage doors. Many more children have suffered brain damage or other serious injuries when the closing garage door contacts them, and fails to stop/reverse its direction. A typical garage door weighs anywhere from 155 to 400 pounds, but wooden garage doors can weigh even more. During times of wet weather, wooden garage doors can even absorb about 50 pounds of water from the air. This extra weight can cause additional wear and tear on the garage door opener. As the occupant, you will become accustomed to the noises associated with the operation of your garage door and opener. If any changes occur with the squeaks and chattering most garage door systems make, it is essential to take action promptly. Consult a qualified service technician and never attempt to make adjustments to the door springs and cables yourself.

- R-3 ROOF/ATTIC:

A gable roof is the classic, most commonly occurring roof shape in those parts of the world with cold or temperate climates. It consists of two roof sections sloping in opposite directions and placed such that the highest, horizontal edges meet to form the roof ridge.

- R-7 ROOF/ATTIC:

An attic access opening should be provided to all attics of combustible roof construction. The opening should be not less than 22 inches x 30 inches, should be located in a readily accessible location, and should have at least 30 inches of headroom above the access opening.

- R-10 ROOF/ATTIC:

Roof Inspection Limitations [Includes attic spaces, Some areas not walked on, Steepness, No access to some attic spaces, No access to some knee-wall spaces, Roof structures with no access (Knee-wall Attics, Overlaying roof structures/dormers, Dormers, All vaulted ceiling areas, Front entryway porch, Gas fireplace extension), Miscellaneous Information]

This report provides an opinion of the general condition of the roof system based on a visual inspection of representative areas. The inspector does not offer an opinion or warranty as to whether the roof leaks or is subject to future leakage. If it is dry, has been dry for a long time, or is not the rainy season the possibility of leaks not showing up at the time of inspection is not unusual. Water stains on ceilings, walls, and soffits that tested dry at the time of inspection may very well test elevated for moisture under other conditions or at another time.

Specific notation of leakage or stains does not preclude additional areas of leakage and/or hidden damage. Monitor attic for any changes; ongoing or questionable situations should be assessed and corrected. Leakage can lead to Mold or Mold-like/Fungal Growth.

Due to typical design/accessibility constraints (insulation, storage, etc.), evaluation of attic areas, including structural components, is usually limited. Any specifically noted limitations/obstructions are intended to highlight these limitations beyond the norm. A complete check of the attic should be made when non-permanent limitations are resolved.

- R-15 ROOF/ATTIC:

The primary purpose for attic ventilation is heat reduction. With the ventilation necessary to accomplish this it will also remove very minor amounts of moisture that may find its way into the space as well. Its overall purpose is NOT TO REMOVE MOISTURE. We want to reduce heat to reduce cooling loads and improve indoor comfort. Ventilation of the home is examined by looking for eave, soffit, gable, roof and ridge vents. A properly ventilated attic/roof cavity keeps the house more comfortable in the summer, and prevents condensation that can damage roofing components.

Newer homes that are well insulated should have no less than one square foot of free vent area for each 150 square feet of ventilated area. The amount can be reduced to one square foot for each 300 square feet if the ventilation is equally divided between the lower and upper portions of the area being vented, or if a vapor barrier is installed on the warm side of the insulation. Determination of how or if vaulted ceilings are vented can be beyond the scope of the Standard Home Inspection.

- HS-3 HEATING/COOLING SYSTEMS:

This photo shows the most recent service records found on the heating equipment during inspection.

- HS-4 HEATING/COOLING SYSTEMS:

These photos show the most recent service records on the furnace.

- HS-5 HEATING/COOLING SYSTEMS:

Temperatures at supply registers are taken with infrared camera but it must be noted the instrument measures grill surface temperature and not the air temperature. Different register materials and textures will show different temperatures than the actual air temperature (Thermometers would be more accurate but take considerable time to take). The infrared temperatures should therefor only be seen as a rough guestimate of temperatures. It is the "relative" difference in temperatures that is of interest to the inspector to determine some level of consistent function of the system at the time of inspection and to find registers that are not delivering heat consistent with other locations.

- Basically the only thing a home inspector can verify is that warn air flowed from the supply registers.

- Adequacy can be affected by many factors including seasonal extremes and personal methods of use of the system

- E-11 ELECTRICAL:

A representative number of receptacles were tested with a polarity tester to confirm proper wiring. No wiring deficiencies were reported by the tester unless otherwise noted in this report.

- E-15 ELECTRICAL:

During the home inspection, smoke detectors are not tested as it would not be an accurate test. For reliability, fire marshals recommended updating smoke alarms every 10 years and changing batters bi-annually. The latest data indicate that we should be using photo-electric technology in our smoke alarms for improved fire detection and to reduce problems with false alarms which can lead to disabling of this important safety system. Unfortunately, the alarms have to be removed to determine if they are photo-electric or ionization types. It is surprisingly complex to accurately test a smoke alarm system and determine the reliability, age, and type of sensor technology used, especially as many homes can have half a dozen or more alarms throughout the house. A complete evaluation of smoke alarms is beyond the scope of this inspection. For optimal fire safety, I recommend taking control of these important safety devices and learning about how to service and maintain your smoke alarm system to keep the building occupants safe. For more information, please read this link.For more information, please read this link.

- P-14 PLUMBING:

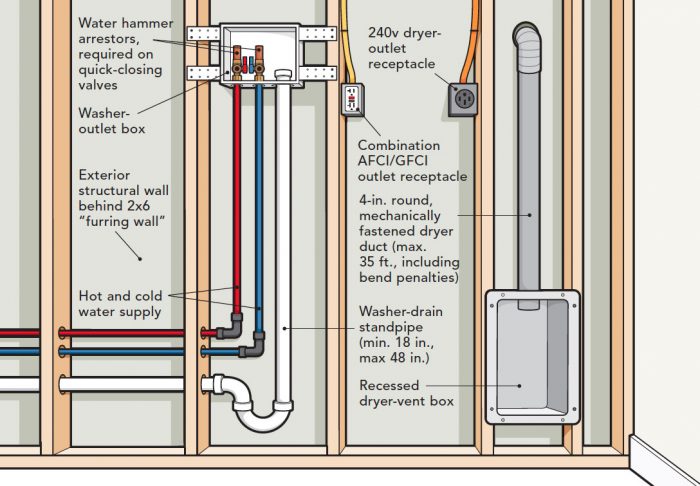

Proper dryer exhaust venting is critical for safe and reliable performance from the dryer. Here are some basic rules of thumb for dryer exhaust duct installation: Unless a vent-free appliance is being used, the dryer exhaust vent must terminate outdoors. It should be no more than 25 feet long and for every 90 degree turn subtract 5 feet and for every 45 degree bend subtract 2.5 feet. Use only smooth-wall metal vent pipe @ 4 inch pipe diameter. Do not use plastic pipe and plastic flex pipe. If a flexible connector is needed behind the dryer use a short amount of corrugated metal pipe. If the exhaust duct is getting pinched behind dryer, consider use of a dryer vent box, pictured here. Flex and corrugated pipes should never be used in concealed spaces such as through walls or in attic or crawl spaces. Insulate dryer exhaust duct where it passes through unconditioned spaces to prevent condensation that could hasten lint build-up inside the pipe. Do not use screws to connect pipe as these can trap lint. Secure duct with foil tape as needed. Be sure duct is sleeved properly so that it will not trap lint and clean the vent regularly, especially if it is a long exhaust run.

- B-6 BATHROOM(S):

Exhaust fans are recommended in all bathrooms, and are more important where a bathroom does not have an operable window.

- The fan should discharge directly to the building exterior. In many cases, the fan terminates inside the house or roof space. This can add considerable moisture to a house, leading to condensation and rot problems.

- The exhaust fan should provide at least 12 air changes per hour. That means it should replace all the air In the room every 5 minutes. For example, in a bathroom that is 320 cubic feet (five feet by eight feet by eight feet high) the exhaust fan should have a capability of more than 64 cfm (cubic feet per minute).

- FC-1 FINAL CHECKLIST:

Thermostat settings provided at the time of the inspection.

The Full Report

GENERAL COMMENTS

Disclaimers

Recommended Contractors Information/Re-Inspections

Building Characteristics / Conditions

EXTERIOR/GROUNDS

Inclusions and Restrictions of Exterior/Grounds/Garage Inspection

Driveways/Walkways/Flatwork

Drainage and Topography

Grounds, Trees and Vegetation

Siding and Trim

Exterior Stairs/Decks/Balconies/Porches

Eaves/Soffits

Exterior Doors

Exterior Window and Frames

Chimneys

Garage / Carport

ROOF/ATTIC

Inclusion & Restrictions of the Roof/Attic Inspection

Roofing Materials & Flashings

Gutters & Downspouts

Attic Access

Observations & Limitations of the Attic

Roof Framing & Sheathing

Attic Insulation

Attic & Roof Cavity Ventilation

HEATING/COOLING SYSTEMS

Inclusions and Restrictions of Heating/Cooling Inspection

Heating System

Heating / Cooling Distribution Systems

Inclusions and Restrictions of Gas/Solid Fuel Fireplace Inspection

Gas Fireplaces

ELECTRICAL

Inclusions and Restrictions of Electrical Inspection

Service Equipment-Main Panel

Branch Wiring

Receptacles and Fixtures

Smoke and CO Alarm Systems

PLUMBING

Inclusions and Restrictions for Pluming Inspection

Water Service Supply

Distribution Pipe

Waste Pipe and Discharge

Water Heater

Exterior Hose Bibs

Sump Pumps and Drains

Laundry and Additional Plumbing

Sewer Lateral Observations

INTERIOR

Inclusions and Restrictions of Interior Inspection

Floors

Walls, Ceilings, Trim and Closets

Windows

Stairs and Railings

Interior Doors

Indoor Air Quality

BATHROOM(S)

General Bath Condition and Overview

Sinks and Cabinets

Toilet

Bathtub / Shower

Bathroom Ventilation

KITCHEN

Limitations/Exclusions Related to Kitchen

Sinks and Faucets

Cabinets and Countertops

Ventilation Method

STRUCTURE/BASEMENT

Inclusions and Restrictions of Structure/Basement/Crawlspace Inspection

Foundation

Floor, Wall and Ceiling Framing

GENERAL COMMENTS

Disclaimers

PHOTOGRAPHS-: Include

👉The photos included in this home inspection report are representative examples only and may not capture every condition or defect present in the property. Please refer to the full written report for a comprehensive understanding of the inspection results.

TYPOGRAPHICAL ERRORS-: Errors

This report is proofread before sending it out, but typographical errors may be present. If any errors are noticed, please feel free to contact me for clarification.

INACCESSIBLE AREA'S-: YES

In the report, there may be specific references to areas and items that were inaccessible or only partly accessible. Suspended ceilings for example would be one of those conditions. I can make no representations regarding conditions that may be present in these areas but were concealed or inaccessible for review. With access and an opportunity for inspection, reportable conditions or hidden damage may be found in these areas. If a request is made by the client for a second inspection, an additional fee will be charged.

✒️

- crawlspace or sections of the crawlspace

COMPONENT LIFE EXPECTANCY-: YES

Components may be listed as having no deficiencies at the time of inspection, but may fail at any time due to their age or lack of maintenance, that couldn't be determined by the inspector. A life expectancy chart can be viewed by visiting http://prohitn.com/component-life-expectancies/

DRAINAGE SYSTEMS SURFACE OR BELOW: The surface water drainage system is below grade and cannot be viewed. Designs and materials for these systems vary widely, making it impossible to evaluate the integrity of the system with any certainty. Because it is inaccessible for inspection, we are unable to determine the presence, extent, or condition of any curtain drainage system that may have been installed.

CODE VIOLATIONS-: Code Violation Issues

We do not guarantee the presence or extent of any code violations, nor can we assure you of the legal compliance of this building. For specific information regarding these matters, it is recommended that you contact the appropriate local building and zoning department.

PEST/PETS-: Odors/Signs

No determination was made regarding any damage and/or lingering odors/waste that may exist from pest infestation or household pet activity unless specifically noted. Such conditions may not surface or become apparent for some time or until carpeting or other obstructions are removed. If pets have been kept in the house, there are likely some resultant conditions or residue.

PERSONS PRESENT DURING THE INSPECTION: Client, Realtor Professional

The following applies to vacant properties. Most often, vacant properties have little to no historical property condition report, and the problems/risk of repair is often increased by how a home performs when not in normal use. Also recognized that no disclosure data has been shared with us prior to the inspection.

Some systems and components of vacant and/or abandoned homes, such as piping, wiring and appliances that have not been used during real-life conditions, could fail without warning. Know that while some systems and components are reported as "working at the time of inspection," may, in fact, fail. It is difficult to know how they will respond to regular use after having sat for extended periods of time. Septic systems may initially function and then fail under a live load. Plumbing traps may operate with no signs of leaks and then let go when being actively used for a few days. Drains that operated during an inspection after real-life conditions may indicate blockage. Component seals may dry up and later leak. Sewer lines could take a few days to backup because of roots or other elements that allow test water to flow, only to fail when waste and tissue are flushed through the system.

For these and similar reasons - be aware that the risk of component failure is greater in these type homes.

Recommended Contractors Information/Re-Inspections

CONTRACTORS / FURTHER EVALUATION: It is recommended that licensed professionals be used for repair issues as it relates to the comments in this report, and copies of receipts are kept for warranty purposes. The use of the term "Qualified Person" in this report relates to an individual, company, or contractor who is either licensed or certified in the field of concern. If I recommend evaluation or repairs by contractors or other licensed professionals, it is possible that they will discover additional problems since they will be invasive with their evaluation and repairs. Any listed items in this report concerning areas reserved for such experts should not be construed as a detailed, comprehensive, and / or exhaustive list of problems or areas of concern.

RE-INSPECTION Concerns: YES

When repairs are made on the building, I recommend that I be called back to verify that corrections have been satisfactorily made. An extra fee will be applied based on the quantity and type of structure. . Additional charges will accrue for anything in writing travel time—these costs are to be agreed upon at the time of the request for further evaluation. REMEDIAL WORK - For any element or condition requiring attention, quotes should be obtained from qualified specialists or contractors before closing to determine actual repair/replacement costs. Any cost estimates provided, whether oral or written, represent only an approximation of possible costs. Also, any cost estimates do not reflect all possible remedial needs or costs for the property; latent concerns or consequential damage may exist. If the need for remedial work develops or is uncovered after the inspection, contact Proview Professional Home Inspections to arrange an inspection to assess conditions before performing any repairs.

IF THERE ARE ITEMS WITHIN THIS REPORT THAT REQUIRE RE-INSPECTION, YOU ARE ENCOURAGED TO HAVE ME COMMUNICATE DIRECTLY WITH THOSE HIRED TO MAKE THE CORRECTIONS TO ENSURE THAT REPAIRS ARE PROPERLY MADE.

There are many things that can be done to improve safety and living conditions within any building. While many of these issues come to light in the course of the Standard Home Inspection there are likely to be other things that can be done to improve the building.

Building Characteristics / Conditions

STYLE OF HOME: Traditional

Photos provide views of all elevations of the home at the time of the inspection.

TYPE OF BUILDING-: Residential (Single Family (2-story))

APPROXIMATE SQUARE FOOTAGE: 1,907

#BEDROOMS: 5

#FULL BATHROOMS: 3

APPROXIMATE YEAR OF CONSTRUCTION-Per the MLS listing or the DCPVA-: 1969

ANIMALS PRESENT-: No

WEATHER DURING INSPECTION-: Clear

GROUND/SOIL SURFACE CONDITIONS: Damp

LOCATION REFERENCE: Complimentary Photos of Elevations

🧭For this report, all directions are given as if you are facing the front of the building unless further noted. Items listed as multiple locations may not directly reference all affected locations. Examples may be given that should not be construed as the only affected areas. Further evaluation will need to take place to determine every affected location.

EXTERIOR/GROUNDS

Inclusions and Restrictions of Exterior/Grounds/Garage Inspection

For the exterior inspection the inspector SHALL inspect:

- The exterior wall-covering materials;

- the eaves, soffits and fascias;

- A representative number of windows;

- All exterior doors;

- Flashing and trim;

- Adjacent walkways and driveways;

- Stairs, steps, stoops, stairways, and ramps;

- Porches, patios, decks, balconies, and carports;

- Railings, guards and handrails;

- Vegetation, surface drainage, retaining walls, and grading of the property, where they may adversely affect the structure due to moisture intrusion; and

- Garage vehicle doors and the operation of garage vehicle door openers, using normal operating controls

The inspector SHALL describe:

- The type of exterior wall-covering materials

- A garage vehicle door as manually-operated or installed with a garage opener

The inspector SHALL report as in need of correction:

- Any improper spacing between intermediate balusters, spindles, and rails

- Photo-electric safety sensors that did not operate properly

The inspector is NOT required to:

- Inspect or operate screens, storm windows, shutters, awnings, fences, outbuildings, or exterior accent lighting

- Inspect items that are not visible or readily accessible from the ground, including window and door flashing

- Inspect or identify geological, geotechnical, hydrological, or soil conditions

- Inspect erosion-control or earth-stabilization measures

- Inspect recreational facilities or playground equipment

- Inspect seawalls, breakwalls, or docks

- Inspect for safety-type glass

- Inspect underground items such as wells, springs, or utilities

- Inspect solar, wind, or geothermal systems

- Inspect wastewater treatment systems, septic systems, or cesspools

- Inspect irrigation or sprinkler systems

- Inspect drain fields or dry wells

- Determine the integrity of multiple-pane window glazing or thermal window seals

- Inspect or operate equipment housed in the garage, except as otherwise noted

- Verify or certify the proper operation of any pressure-activated auto-reverse or related safety feature of a garage door

- Operate or evaluate any security bar release and opening mechanism, whether interior or exterior, including their compliance with local, state, or federal standards

- Inspect pools, spas, or fountains

- Determine the structural integrity or leakage of pools or spas

Driveways/Walkways/Flatwork

DRIVEWAY/WALKWAY/PATIO FLATWORK: Concrete

Concrete Gravel

Gravel Asphalt

Asphalt Pavers

Pavers Brick

Brick Deck On Ground Surface

Deck On Ground Surface Dirt

Dirt None Noted

None Noted

Drainage and Topography

LOT DESCRIPTION-: Flat

MONITOR DRAINAGE AROUND THE HOUSE-: Description

Description

Driveways, sidewalks, stoops, etc., that slope to the house are likely to saturate the soil around the foundation or drain water directly into foundation cracks. Even if the flatwork originally drained away from the house, the soil next to the house usually is uncompacted backfill and is likely to settle. Water draining toward the house can lead to foundation instability, deterioration, and basement moisture problems. Or perhaps it would allow water cascading down the surface in a torrential rain to wash under a garage door or into basement window wells.

DRAINAGE/TOPOGRAPHY OBSERVATIONS📝: 🔹DOWNSPOUTS AND DISCHARGE (Downspouts--Discharge by Foundation [Erosion/Ponding])

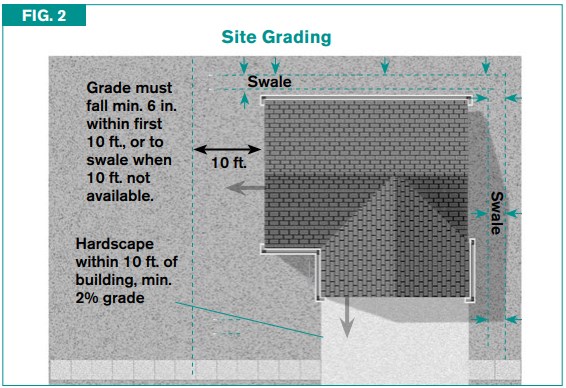

Soils, Grading & Drainage 18 IRC

- [0 Grading from foundation min. 6 in. fall in 1st 10 ft. EXC F2 401.3

- Use drains or swales when lot lines, walls, etc. prevent 6 in./10 ft. __401.3X

- Hardscape min 2% slope away from building within 10 ft. F2 401.3X

- Graded sites top of foundation min 12 in. + 2% above street drain 403.1.7.3

- Drain system req'd for foundations enclosing usable space below grade unless well-drained ground or sand/gravel mixture F3 405.1

- Walls retaining earth & enclosing interior space req dampproofing F3 to finished grade EXC 406.1 If high water table, waterproofing to finished grade 406.2

- Expansive soil req design per IBC 1808.6 or waiver by BO 403.1.8

- Trenching parallel to footings may not undermine footing — stay outside line extending out 45° out from outside bottom edge of footing F3 _ 2604.4

Grounds, Trees and Vegetation

TREES / VEGETATION NEAR TO BUILDING: YES

TREE & SHRUB OBSERVATIONS📝: 🔹TREE & SHRUB OBSERVATIONS (Prune Vegetation Off House)

Trimming the shrubs and vegetation is recommended to maintain a 12" minimum clearance. This will prevent damage to the exterior finishes as well as prevent mildew or algae growth due to moisture entrapment. Maintaining proper clearance will also eliminate a condition conducive to wood destroying insects and a path for rodent entry. Overgrown vegetation can:

* Cause structural damage by putting pressure on foundation walls or roofing materials

* Allow water intrusion through compromised seals and joints

* Create an invitation for pests and rodents to inhabit the area

* Reduce energy efficiency by blocking sunlight and air circulation

To maintain a safe and well-maintained exterior, it's crucial to regularly trim and prune vegetation to ensure a minimum of 1 foot clearance between plants and walls. This simple task can go a long way in preserving the integrity and appearance of your property."

Siding and Trim

EXTERIOR ENVELOPE MATERIALS: 🔹SIDING MATERIAL (Stucco)

This building has a Hardcoat stucco siding system. When installed over a wood building, stucco should be installed with two layers of underlayment below the plaster and a weep screed system which allows air to dry any accumulated water behind the plaster. Stucco is one of the nicest and lowest maintenance siding systems but it is installation sensitive. Poor installation can lead to expensive repairs. The most critical element to a stucco siding system, the weather barrier, is not visible to inspection, which limits the inspectors' ability to see how the system is performing. During the inspection, we look for clues in the installation to make an educated guess about the future reliability of this system. More detailed information can be gained through destructive testing. This involves drilling holes in the plaster and using a moisture probe to determine if any sections of the building have failed moisture control. Destructive testing like this is beyond the scope of this inspection.

SIDING OBSERVATIONS📝: Previous Repairs Made

TRIM/FLASHING OBSERVATIONS📝: 🔹TRIM (Wood Trim--Old House Touch Up)

The exterior paint job requires localized touch-up due to peeling paint and bare wood exposed. This is typical on older homes. Be prepared to make repairs such as wood putty to fill in areas that need it. Have the exterior paint job touched up and completed by the painter. During inspection today, I noted:

Exterior Stairs/Decks/Balconies/Porches

EXTERIOR STAIRS/DECKS/BALCONIES/PORCHES: 🔹DECKS (Present), 🔹PORCHES (Present)

Like fences and other exposed wood construction, decks have a finite service life. Even the best maintained deck will need repair and eventual replacement. We urge regular treatment with combination wood preservative/UV inhibiting sealers. A stoop/deck/porch that is higher than 30 inches above the ground (within 36 inches of the stoop/deck/porch ) should have a railing that is at least 36 inches in height and baluster spaces should be no greater than 4 inches in width.

COMMON OBSERVATIONS📝: No Issues

To see a prescriptive guide for residential wood deck construction click this link:

Eaves/Soffits

MATERIALS USED and TYPE: 🔹MATERIAL USED (Plywood)

OVERHANG & SOFFIT ISSUES📝: No Issues

Exterior Doors

HOME SECURITY-: Description

The 'Security' of any home is never absolute. At the time of inspection I assess the 'basic functionality' of door and window locking mechanisms. No assessment of the individual or overall effectiveness of security is implied. Glass, frames, locks and other elements can be prone to 'tampering’ and are 'limiting factors' of locking mechanisms/systems. All security devices and systems must be balanced against the ease of escape in the event of emergency. Concerns about the home s overall security system should be addressed by a licensed home security company. It is our advice to you that once you move in is to replace all exterior locks for your safety.

TYPE/STYLE OF UNITS: 🔹TYPE/STYLE (Sliding-Vinyl, Solid Wood)

DOOR OBSERVATIONS📝: No Issues

Exterior Window and Frames

MATERIAL: Vinyl

WINDOW OBSERVATIONS📝: 🔹SEALANTS (Failed- needs NEW)

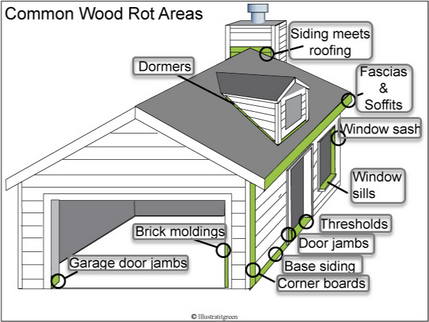

All surfaces of the envelope of the house should be inspected at least semi-annually, and maintained as needed. Any exterior element defect can result in leakage and/or subsequent damage. Exterior wood elements and wood composites are particularly susceptible to water-related damage, including decay, insect infestation, and mold. The use of proper treated lumber or alternative products may help minimize these concerns, but will not eliminate them altogether. While some areas of decay or damage may be reported, additional areas of concern may exist, subsequently develop, or be discovered during repair or maintenance work.

The sealant around the exterior of the windows are showing signs of failure was visible. Sealants can help prevent possible moisture-related issues. Numerous products are available, but stay away from silicone; using GEOCEL or Lexsel is recommended. I recommend having all of these areas further investigated by a qualified general contractor and repair failing areas of a sealant as needed to ensure a waterproof envelope.

Chimneys

Present

Present None noted

None noted

CHIMNEY MATERIAL: Masonry

CHIMNEY FLUE LINERS: Present

CHIMNEY OBSERVATIONS📝: 🔹GENERAL COMMENTS (Level II Inspection Recommended)