The Summary provides a quick view of important defects but be sure to read the entire Detailed Report. There are minor repairs and improvements noted throughout.

Navigation

On a desktop browser, the left side of the screen is the navigation panel. Selecting any of the displayed text selects that section. You will see larger text "Introduction", "Summary" and "Detailed Report", explained below. Selecting Introduction, Summary or Detailed Report will toggle between those 3 areas of this report. Although all browsers are compatible, the best experience is using Chrome on desktop.

On a Mobile device, because of the smaller screen, the Navigation panel is hidden until you display it. To display it, scroll up until you see the "hamburger" icon on the top right of the screen. This resembles 3 horizontal lines. By pressing this icon, the navigation panel will appear.

Throughout the report you may notice bright blue underlined text. These are links to more details either found in the report, or elsewhere on the internet. For example, in the summary section you may see "E-9 EXTERIORS:" By selecting the link (E-9) you will be taken to the 9th observation in the Exterior chapter where further details will be found about it including any photos/videos, notes etc.

The Summary Report

The Summary section presents observations of most importance in a brief view. The Summary report is meant as a quick look of important areas of concern or awareness. This is not a substitute for reading the entire report where additional details to the observations noted in the summary can be found as well as additional observation types.

The Detailed Report

The detailed report section is organized by Chapters and Sections and provides expanded details on observations noted in the Summary as well as additional minor repairs, improvements and knowledge. When selecting Detailed Report, the Chapters will appear in the navigation panel and are grouped by locations of importance (kitchens, bathrooms etc.) and systems (electrical, hvac, plumbing etc.).

Chapters are logically grouped observations, photographs, captions, diagrams, descriptions, videos and hot links to additional information. For example the "Electrical" chapter will present all electrical observations noted, "Plumbing" will show all plumbing observations etc. In this way, it is easier to know which skilled trades to hire, and to provide them with the information they need when repairing, improving and maintaining.

I encourage you to read the Detailed Report in it's entirety and keep it handy for future reference as there are improvements, suggestions, guidance and maintenance issue noted throughout.

How to Convert to PDF

This report can be converted to PDF and printed, saved and emailed. You can convert the entire report (Report PDF), the Summary section only (Summary PDF), or selective areas of concern (Create Request List). Using the latter feature is a great way to share specific information when negotiating a sale/purchase and providing to contractors, insurance companies, realtors etc. The buttons to achieve these are located at the top of this page when viewing on desktop and at the bottom of the left side Navigation panel when viewing on Mobile.

How to Make a Payment

Payment can be made by

- Etransfer to payment@walkerhomeinspection.ca or

- Credit card at https://walkerhomeinspection.ca

Final Note

Be sure to click on the photo when you want a closer look. Doing so will expand the photos to full screen. In fact, additionally double click on the photo and get really up close! Photos are generally of high resolution.

Reviews are always appreciated with thanks: Please click here to record a review, and help my business grow and thank you for choosing me to perform your home inspection

Steven Walker, (613) 813-9713 steven@walkerhomeinspection.ca

This report is effectively a snapshot of the property, recording the conditions on a given date and time. Home inspectors cannot predict future behavior, and as such cannot be responsible for things that occur after the inspection.

Category Definitions

All narrative observations are colored, numbered and labeled to help you find, refer to, and understand the severity of the observation. Only defect type observations are included in the Summary; Red Flags, Hazards, Repairs, Future Expenses, Due Diligence as well as Shutoff Locations and the Insurance Brief. All other categories are included in the Detailed Report as well as the categories previously noted, along with photos and further information. Observation colors and labels used in this report are:

Equipment that may be at the end of, or close to the end of it's usual lifespan. Budgeting for replacement is usually advised.

Recommendations to request (or provide) disclosure with another parties. Examples include, information about a possible buried oil tank, an unused well, a dry water stain or hot water tank rental agreement.

These are repair items that should be considered "routine home ownership items," such as servicing the furnace, cleaning the gutters, changing the air filters in the furnace or re-staining the deck. These are listed in the summary to assist the home owner with achieving these regular activities.

Summary

👍🏼Positive Attributes

- I-1 INTERIOR:

The interior finishes are generally very good with many classic attributes retained however there is some cracking plaster which should be repaired.

- UI-1 UNFINISHED INTERIOR:

The unfinished basement is dry and clean with structural reinforcements applied.

- E-1 ELECTRICAL:

The electrical system (panel, outlets/switches & wires) appears to be fully updated to modern standards. There are relatively minor corrections to be made but overall the electrical system is very good.

- P-1 PLUMBING:

The plumbing system is up to modern standards however a potential leaking toilet was detected which should be addressed immediately.

- S-1 STRUCTURE:

The foundation appears to be solid and has received new framing support beams in the basement. The second floor is warped however due to the building's construction and age.

👎🏼Items of Concern

- BE-1 BUILDING EXTERIOR:

The building siding is wood which requires scraping and repainting. The siding is too close to the ground and the soffit requires some repair.

- H-1 HVAC:

The heating system works well however the furnace is toward the end of it's life and the associated duct work at the furnace requires some repair. The air conditioning unit is well beyond it's normal lifespan and may need to be replaced.

- A-1 ATTIC:

The attic structure has been reinforced and is in acceptable condition however the insulation level is very poor, there is no attic ventilation and an uninsulated vent is located in the unconditioned space.

Alerts

No Alerts notedHazards

- O2-1 OUTBUILDING:

An older model garage door opener was noted with no laser eyes in use as a safety feature.

These are less safe than modern openers which will reverse when the laser beam is broken. This safety feature is especially important for children and pets. Updating the garage door opener is recommended for improved safety.

Repairs

- BE-4 BUILDING EXTERIOR:

The soffit on the west side is damaged and requires repair.

Also note that no soffit vents are in place. This negatively affects the attic ventilation. I recommend installing soffit vents as well as roof vents.

- BE-5 BUILDING EXTERIOR:

The gutters on the east side appear to be coming loose as they are twisting away from the roof.

I recommend repairing these as soon as possible to prevent further damage to the gutters and potential additional damage to the roof fascia and soffit.

- I-3 INTERIOR:

A larger than normal plaster cracks was noted in a corner.

This is characteristic of old plaster walls and ceilings and appears to indicate a failure of the bonding between the plaster keys and lath. This crack is fairly sizeable and may need more extensive repairs than a normal light crack.

- I-6 INTERIOR:

The loose guardrail to the 2nd floor needs to be secured for improved safety.

This is an important safety item. The guardrail should be stiff enough to stop a falling adult. Hire a licensed general contractor to further evaluate and repair.

- P-7 PLUMBING:

Temperature Pressure Release (TPR) valve on the water heater terminates incorrectly and may be leaking

The discharge tube for the water heater temperature and pressure relief valve (TPRV) is not correctly installed. This is a potential safety hazard. Ideally, the discharge tube for a relief valve:

- Terminates to an exterior location or above a drain, though this is not always possible

- Terminates between 6 and 24-inches off the ground (UPC)

- Slopes to drain to prevent water pooling inside the discharge tube

- Is not made from pipe with an inside diameter less than 3/4 on an inch

- Terminates to a visible location that can be monitored for leaks and discharges

- Does not have a threaded termination point which would prevent accidental capping of this important discharge

- Does not terminate into a drain pan

I recommend having this relief valve discharge tube further investigated and repaired as recommended by a licensed plumber.

- P-13 PLUMBING:

A high moisture reading was taken around the 2nd floor Common bathroom toilet, indicating there is likely leakage and possibly concealed water damage.

I also noted water stains around the toilet and thermal imaging appears to confirm the high moisture level. It is difficult to determine the extent of the needed repair at this time. Repairs can be simple or more complex depending on the moisture source and the condition of materials below the toilet. Further investigation is required to determine an accurate scope of repair. Hire a licensed plumbing contractor to further evaluate and repair the toilet and the finish floor and sub-floor as needed.

- H-11 HVAC:

The furnace return air plenum is corroded.

The plenum should be cleaned or repaired and all joints sealed using duct mastic. Hire a qualified heating contractor to further evaluate and repair.

- A-5 ATTIC:

The exhaust ductwork for the laundry vent is uninsulated in the attic space.

This can lead to seasonal condensation problems. Replace these exhaust vents with insulated exhaust ducts or insulate to R-8 or better.

Future Expenses

- I-9 INTERIOR:

Most of the windows are more than 30 years old.

The average lifespan of residential windows is 15 to 30 years if well maintained. I recommend budgeting for window replacements as they may begin to fail.

- H-8 HVAC:

The air conditioning system was not tested due to cold temperatures and it is old and should be considered unreliable.

Air conditioning compressors have fairly unreliable service lives that can range from as little as 7 to as many as 30 years. Service life can depend on keeping a proper refrigerant charge and reliable return air flow as well as the amount the system has been used. I recommend having this old system serviced by a licensed heating and cooling professional and have the refrigerant charge checked. Given the age of this unit I would budget to replace at any time.

Disclosures

- P1-1 PROPERTY:

This building is located near a stream. This presents risks for seasonal flooding problems

and should be further investigated to see if any history of flooding has occurred on the property. Be sure to inquire with the seller about any flooding history. At the time of inspection I found no red flags to indicate regular flood damage in the home.

- E-10 ELECTRICAL:

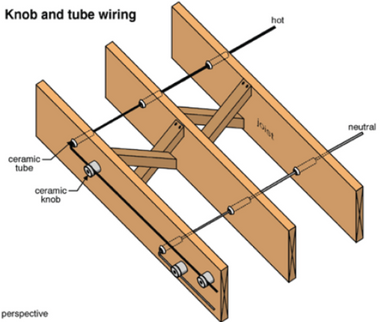

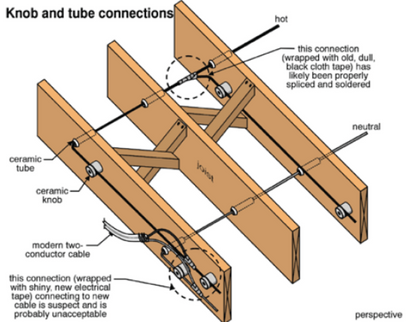

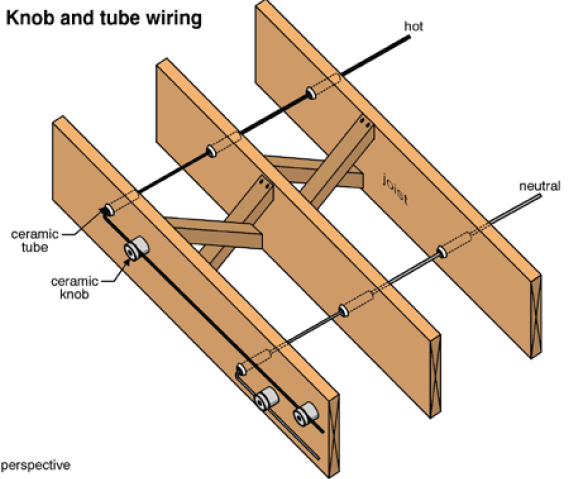

Evidence of Knob and tube (K&T) wiring is noted indicating that it was previously used in the building.

Knob & Tube wiring is an old style of wiring where conductors are run outside of a sheathed cable and supported on ceramic knobs and protected by ceramic tubes where the wire passes through framing. Knob and tube wiring does not meet today's standards and alterations and extensions to this wiring are seldom done correctly and tend to produce safety hazards. I was unable to visually locate any active K&T wiring in the home, so it may have all been upgraded. There is a possibility that some K&T wiring is still employed however and it is simply not visible. Evaluation by a licensed electrician and an ESA certificate is recommend and possibly required in order to insure the home. If the upgrade documents including an ESA certificate is already available then be sure to keep it for your records.

- P-9 PLUMBING:

A video camera sewer scope is recommended.

An evaluation of the sewer line below the ground is beyond the scope of this inspection. Due to the age of the building, a sewer scope is recommended to further evaluate the sewer line and the below ground connections between the house and the municipal sewer line. Sewer scopes are done using video cameras and can reveal the materials, condition and reliability of the sewer line. If that has not been done recently, I recommend having a sewer scope performed.

- A-6 ATTIC:

A rodent bait station was noted in the attic.

This is evidence of prior rodent control work. I recommend inquiring with the seller about the extent and scope of prior rodent control work.

Maintenance

- BE-3 BUILDING EXTERIOR:

The exterior siding and trim needs to be re-painted to preserve and maintain the siding system.

Budget for re-painting the exterior in the near term. This is routine maintenance, but can be costly.

- E-2 ELECTRICAL:

Trees and vegetation are impacting the overhead electric service drop.

This can fray through insulation and cause damage to the conductors and even arcing and fires. I recommend additional inspection of this drop by the utility. Remove trees, limbs and vegetation as needed and repair conductors if needed.

- E-8 ELECTRICAL:

Excessive insect buildup is noted in the electrical panel.

I recommend having these cleaned out.

- P-12 PLUMBING:

Older hose faucets were noted on this building which must be winterized.

Updating the hose faucets is recommended. Modern hose faucets are typically "frost free," which are (arguably) more resistant to bursting in cold weather. In the meantime, be sure to winterize your hose faucets during cold weather (shutting the interior tap) to prevent from freezing, including disconnecting any attached hose.

- H-3 HVAC:

Annual servicing of central heating equipment is recommended

Records indicate that this furnace has not been serviced in the last year. The furnace was tested during inspection and was operational. The design life of these forced air furnaces is 15-20 years. Hire a licensed heating contractor to service and further evaluate the furnace.

- H-10 HVAC:

Heating ductwork cleaning is recommended.

The heating ductwork is moderately clean however I always recommend duct cleaning whenever home owners change for sanitary reasons.

- H-12 HVAC:

A WETT (Wood Energy Technology Transfer) inspection is recommended.

This may be required by your lender and/or insurance company before use of the wood stove. An annual inspection and cleaning of all chimneys, fireplaces, solid fuel-burning appliances, and vents is also recommend. This inspection includes, not only cleaning the interior of the chimney pipe, but also the use of specialized tools and testing procedures such as video cameras, etc. to thoroughly evaluate the serviceability of the entire flue lining and fireplace/chimney system. If a chimney cleaning has not been performed over the past 12 months, such an inspection is recommended before the home changes ownership---for fire safety reasons. Implement any repairs as recommended.

Improvements

- BE-2 BUILDING EXTERIOR:

The wood siding has been installed too close to grade.

It is recommended that wood siding has a 6-inch clearance to soils. This can be difficult to correct. Remove soils away from the siding as feasible. Where a full 6-inches cannot be achieved, consider using gravel between the soils and siding to act as a capillary break.

- BE-6 BUILDING EXTERIOR:

The downspout on the north west corner appears to have been blocked, backed up, frozen and burst.

I recommend replacing the lower section of this downspout and extension to ensure roof runoff is discharged well away from the building.

- B-1 BATHROOMS:

The toilets have not been caulked to the floor.

Caulking the toilet to the floor is recommended and even required though opinions on this can vary. Best practice is to caulk the toilet to the floor, but leave a gap on the back of the toilet that remains un-caulked so if the toilet leaks, water has an escape route and is quickly observed for repair. The biggest risks of not caulking the toilet to the floor is that the toilet can become loose, and it is difficult to completely clean into the gap and as such is unsanitary. Here is a site that details the process. www

- L-1 LAUNDRY:

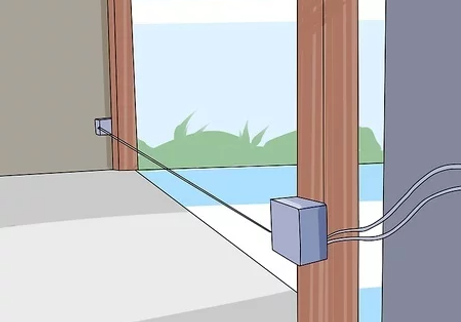

A moisture alarm with water shut-off feature is recommended under the washing machine to protect against accidental leaks in the supply hoses.

Pans can be effective when there is a drain, but even these will not protect against a burst supply connector. A moisture alarm with automatic shut-off will turn off the water and alert occupants of the leak.

- L-2 LAUNDRY:

No ventilation fan was found for the laundry room.

This is common in older homes and may be required in newer buildings (based on local standards). Installing a ventilation fan is recommended to help control indoor relative humidity.

- I-5 INTERIOR:

Smoke alarms are missing in all bedrooms.

Modern standards recommend smoke alarms in all bedrooms, in all hallways outside bedrooms and at least one on each floor of the building. At the time of inspection smoke alarms were missing in the bedrooms.

- E-14 ELECTRICAL:

The kitchen is missing GFCI protected outlets.

Not all kitchen receptacles need to be GFCI protected, but they are required to be if they’re within six feet of a kitchen sink or if they serve a countertop.

- E-15 ELECTRICAL:

The garage should have GFCI protected receptacles installed

as there is often wet floors from melting snow and/or electric garden equipment operated in wet environments.

- P-5 PLUMBING:

The water temperature reading at the kitchen faucet is lower than normal: 41.1 C (106 F).

The temperature may need to be turned up at the water heater so that it is in the range of 46-52 C (115-125 F) at the faucet. There is some evidence that hot water temperatures in the tank water heater should be greater than 54.5 C (130 F) to prevent Legionaries' disease from developing. I recommend installing a mixing valve at the hot water tank. A mixing valve at the tank allows the tank temperature to be set as high as 60 C (140 F) to ensure all bacteria is neutralized while providing 49 C (120 F) temperature at the faucets.

- P-6 PLUMBING:

An expansion tank is recommended for the water heater.

Expansion tanks help reduce pressure on the plumbing system by creating a buffer or a place for water to expand into as water swells during thermal expansion. Installation of expansion or pressure tanks is modern installation practice and will be required if a pressure reducing valve has been installed on a public water supply or if for any reason the plumbing system is closed. Open systems do not require an expansion device though they can still be an excellent way to help prevent build-up of pressures in the piping system. Consult with a qualified plumber to install.

- P-10 PLUMBING:

The AAV (Automatic Air Vent) used should in the kitchen sink should be CSA approved

(these are usually white, see example). Poor quality AAV's may get stuck in the open position allowing sewer gas to enter the home. I recommend installing a CSA certified AAV.

- P-11 PLUMBING:

This building has a sump pump installed and should have a redundant backup system installed.

It appears that this sump pump is critical in keeping the basement dry as it was wet, and active at the time of the inspection. I recommend one of the following backup solutions:

- Install a back-up battery in case of a power outage (especially when on private well)

- Install a water driven redundant pump (when on public water supply)

- Have a backup pump in case of pump failure

- Install a high water alarm to warn occupants of a failing sump system.

Quick Inventory Snapshot

- O-1 ORIENTATION:

Approximate Year of Construction: Earlier than 1900

- R-1 ROOF:

Roofing Material: Shingles

- R-2 ROOF:

Approximate Age of Roof Covering: 10-20 years

- E-3 ELECTRICAL:

Main Panel Amperage: 200 Amp

- E-4 ELECTRICAL:

Main Electrical Panel Type: Breakers

- E-5 ELECTRICAL:

Age of Main Electrical Panel: More than 30 years

- E-11 ELECTRICAL:

Electrical Wiring Material: Copper

- E-12 ELECTRICAL:

Electrical Wiring Type: Non-metallic sheathed cable

- P-3 PLUMBING:

Water Distribution Plumbing: Copper

- P-8 PLUMBING:

Waste Water Plumbing: ABS

- S-2 STRUCTURE:

Foundation Type: Basement

- S-3 STRUCTURE:

Foundation Material: Stone

- A-3 ATTIC:

Attic Insulation Material: Fiberglass

Shutoff Locations

Detailed Report

BUILDING EXTERIOR

Assessment

Siding

Soffit & Fascia

Gutters

Downspouts & Rain Barrels

Doors (Exterior)

Outlets, Fixtures

Window wells

Stairwells

Deck

Vegetation Growth

Garage (Attached)

KITCHEN

General Photos

Countertops

Cabinets

Windows

Outlets

Switches

Lights

Ceiling Fan

Sink & Faucet

Plumbing - Supply & Waste

Water Filters

Dishwasher

Refrigerators

Ovens, Cooktops

Exhaust/Ventilation

Disposers

Floor

BATHROOMS

General Photos

Countertops

Cabinets

Outlets

Switches

Lights

Sink & Faucet

Plumbing - Supply & Waste

Toilet

Bathtub / Shower

Ventilation

Doors

Floor

LAUNDRY

General Photos

Countertops

Cabinets

Washer

Dryer

Outlets

Switches

Lights

Sink & Faucet

Plumbing - Supply & Waste

Ventilation

Doors

Floor

INTERIOR

Assessment

General Photos

Ceiling

Walls

Floors

Outlets

Smoke & CO Alarms

Stairs and Railings

Wall Insulation

Windows

PLUMBING

Assessment

Water Meter

Water Supply

Distribution Pipe

Water Heater

Waste

Waste Water/Sewage Ejector Pumps

Sump Pumps and Drains

Exterior Faucet

Toilets

HVAC

Assessment

Primary Heating

Heating Exhaust

Central Cooling

Ventilation

Natural Gas Meter

Oil Storage

Distribution

Solid Fuel Fireplaces

ATTIC

Assessment

Access

Framing

Attic Insulation

Attic Ventilation

Venting

Outlets, Fixtures

Rodents & Birds

ORIENTATION

Property Specs

Inspection Type: Pre-Purchase

Style of Building: Traditional Multi Story

Building Use: Residential Single Family

Approximate Square Footage: 2,000-2,499

The approximate square footage and the approximate year of construction listed here is listed as a courtesy and is based off of public records, disclosure or a visual estimation. An evaluation of square footage and age of the buildings and property lines is beyond the scope of this inspection.

Approximate Year of Original Construction: Pre-1900

The approximate year of construction listed here is listed as a courtesy and is based off of public records, disclosure or a visual estimation. An evaluation of the year of construction is beyond the scope of this inspection.

Unless the wiring in the building has been fully updated, this building likely has wiring that predates the late 1980's.

In the late 1970's, laws were past to prohibit use of lead and asbestos in building materials. Manufacturers of building materials were allowed to sell existing stocks of materials that were manufactured with lead and asbestos, so even buildings constructed as late as the mid-1980's could possibly contain lead or asbestos. Common building materials include but are not limited to wall plaster, drywall, floor coverings and insulation. Identification and testing for lead and asbestos and other environmental testing is beyond the scope of this home inspection. If you wish to seek additional information and/or plan to perform destructive renovations, I recommend contacting an environmental lab or industrial hygienist.

Environment

On Site During the Inspection: Seller's Agent

Occupancy: Occupied

Animals Present: No

Weather: Partly cloudy

Temperature: Below 0[C]

Ground/Soil surface conditions: Frozen, Snow-covered

This home was occupied at the time of the inspection. Inspection of occupied homes presents some challenges as occupant belongings can obstruct visual inspection of and access to parts of the building. I do my best during inspection to work around belongings to discover as much as possible about the house without moving or damaging personal property, however, the presence of personal items does limit the inspection.

Please note that snow and ice limits the scope of the inspection. Typically, a visual inspection of the roof, grounds and structure on the outside of the house is severely limited when snow and ice are present. For example roof covering and flashing, patios, walkways, driveways etc. are not visible.

General Limitations

Please note that while I do look for and report suspected mould, identification of mould, mould testing and indoor air quality are beyond the scope of this inspection. If you are concerned about mould or indoor quality, I recommend additional inspection by a specialist. As a general rule, localized mould problems can often be easily repaired by eliminating the moisture source and removing or sealing the localized area that got wet. Best practices to control mould in buildings are to spend limited resources diagnosing and repairing water problems. Where water problems are chronic, mould problems can be more complex and expensive to correct. Where water problems are seasonal or localized, repairs tend to be more limited in scope and less complex to repair. Mould problems in attics are generally unlikely to affect indoor air quality because homes experience the stack effect where warm air escapes out the top of the house like a chimney. However, at the very least repairs should be made to diagnose and understand attic moisture problems to prevent on-going water damage in this space.

Asbestos was used in many materials up until the late 1970's. While I do look for and report suspected asbestos materials, testing and confirmation of these products is beyond the scope of the inspection.

Homes built up to about 1930 had knob and tube wiring and even those built in the 1940's and 1950's may have also. This is an old style of wiring where conductors are run outside of a sheathed cable and supported on ceramic knobs and protected by ceramic tubes where the wire passes through framing. Knob and tube wiring does not meet today's standards and alterations and extensions to this wiring are seldom done correctly and tend to produce safety hazards. Many homeowners insurance companies will not insure homes with this type of wiring and many electricians will recommend complete removal and replacement of this older wiring. Homes of this age may continue to use knob and tube circuits, occasionally even after electrical upgrades are visible and appear extensive. I look for knob and tube wiring during my inspection, however sometimes this wiring is hidden from view, for example under insulation or in wall cavities.

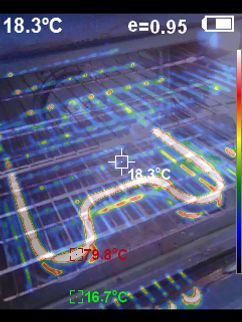

During this inspection, a thermal imaging camera was used to check walls and ceilings for thermal anomalies and also to check specific appliances for verification of proper function. Thermal imaging cameras use the infrared light spectrum to build a picture of the house. Experienced thermographers look for clues in these thermal images that could lead us to otherwise concealed water leaks or missing air or thermal barriers. In older homes, incomplete air and thermal barriers are so common, we will only report on items that look significantly deficient and are worthy of correction. This service is included with our home inspection; it is limited and is not a complete thermal mapping of the house. The use of an infrared camera is well beyond the minimum standards for a home inspection, but I offer this service because I know it is valuable and can help us help my clients by improving our inspection services. Relevant thermal images are included in this report.

PROPERTY

Driveway

Gravel

Walkway

Concrete

Site Drainage

Flat

This building is located near a stream. This presents risks for seasonal flooding problems

and should be further investigated to see if any history of flooding has occurred on the property. Be sure to inquire with the seller about any flooding history. At the time of inspection I found no red flags to indicate regular flood damage in the home.

Retaining Walls

Brick

Fences

None noted

Irrigation

None Noted

Outbuildings, Structures

Detached garage

BUILDING EXTERIOR

Assessment

The building siding is wood which requires scraping and repainting. The siding is too close to the ground and the soffit requires some repair.

Siding

Wood

Clearance to Grade: Unacceptable, Wood Siding too close to grade

The wood siding has been installed too close to grade.

It is recommended that wood siding has a 6-inch clearance to soils. This can be difficult to correct. Remove soils away from the siding as feasible. Where a full 6-inches cannot be achieved, consider using gravel between the soils and siding to act as a capillary break.

Soffit & Fascia

Gutters

Seamless Aluminum

Downspouts & Rain Barrels

Downspout Discharge: Above grade, Below grade

Rain Barrels: None Noted

The downspout on the south east corner discharges to an underground pipe. I was unable to locate the discharge point of the underground pipe. These are prone to becoming clogged or frozen and backup which would discharge water at the foundation base. Monitor this and correct as required.

Doors (Exterior)

Noted

Outlets, Fixtures

Tested

An exterior outlet covers are an older style - updating to a modern "in-use cover" is recommended for improved safety.

Window wells

None Noted

Stairwells

None Noted

Deck

None Noted

Vegetation Growth

Acceptable

Garage (Attached)

None Noted

ROOF

Roof Covering

Roof Covering Materials: Architectural grade composition shingle

Architectural style shingles can replicate the appearance of slate or tile roofing, while remaining closer in cost to more common asphalt or wood shingle materials. The usual life expectancy is 25-30 years.

Roof Style: Gable

Flashings: Not Visible

Approximate Age of Roof Covering: 10-20 Years

The estimated age of the roof is the inspector's educated guess only based on visible clues. This estimate is meant only to provide some guidance to the reader and may be incorrect. Gross inaccuracy is possible when snow or other limitations are present.

Method of Roof Inspection: Viewed with camera from ground

Skylights

None Noted

KITCHEN

Countertops

Granite, Wood

Cabinets

Wood

Windows

Noted

Outlets

Tested, Defects Noted - refer to the Electrical Chapter

Switches

Tested

Lights

Tested

Ceiling Fan

None Noted

Sink & Faucet

Tested

Plumbing - Supply & Waste

Tested, Defects Noted - refer to the Plumbing Chapter

Water Filters

None Noted

Dishwasher

Tested, Noted

Refrigerators

Ovens, Cooktops

Exhaust/Ventilation

Exterior Exhaust Fan

Disposers

None Noted

Floor

Wood

BATHROOMS

General Photos

Countertops

Quartz

Cabinets

Wood

Outlets

Tested

Switches

Tested

Lights

Tested

Sink & Faucet

Tested

Plumbing - Supply & Waste

Tested

Toilet

Tested, Plumbing defects noted - refer to the Plumbing chapter

The toilets have not been caulked to the floor.

Caulking the toilet to the floor is recommended and even required though opinions on this can vary. Best practice is to caulk the toilet to the floor, but leave a gap on the back of the toilet that remains un-caulked so if the toilet leaks, water has an escape route and is quickly observed for repair. The biggest risks of not caulking the toilet to the floor is that the toilet can become loose, and it is difficult to completely clean into the gap and as such is unsanitary. Here is a site that details the process. www

Bathtub / Shower

Tested

Ventilation

Ceiling/Wall Exhaust Fan

Doors

Acceptable

Floor

Wood

LAUNDRY

Countertops

None Noted

Cabinets

None Noted

Washer

Tested

A moisture alarm with water shut-off feature is recommended under the washing machine to protect against accidental leaks in the supply hoses.

Pans can be effective when there is a drain, but even these will not protect against a burst supply connector. A moisture alarm with automatic shut-off will turn off the water and alert occupants of the leak.

Dryer

Tested

Power Source: Electric

Exhaust Duct: Noted

Outlets

Tested

Switches

Tested

Lights

Tested

Sink & Faucet

None Noted

Plumbing - Supply & Waste

None Noted

Ventilation

None noted

No ventilation fan was found for the laundry room.

This is common in older homes and may be required in newer buildings (based on local standards). Installing a ventilation fan is recommended to help control indoor relative humidity.

Doors

Noted

Floor

Vinyl composite tiles

INTERIOR

Assessment

The interior finishes are generally very good with many classic attributes retained however there is some cracking plaster which should be repaired.

Ceiling

Drywall

Cracks were noted in the ceiling. These are straight line cracks and no other indications were found to indicate settlement. Cracking lines like these can be due to routine settlement or moderate seasonal expansion and contraction of the structure. Cracks like these can also be related to workmanship and nailing of framing and drywall or deflection from the framing. The seasonal types of cracking can be most problematic as they will tend to re-open after repair. Repair and paint cracks as needed and monitor.

Walls

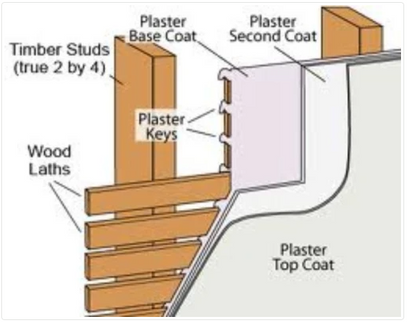

Plaster

A larger than normal plaster cracks was noted in a corner.

This is characteristic of old plaster walls and ceilings and appears to indicate a failure of the bonding between the plaster keys and lath. This crack is fairly sizeable and may need more extensive repairs than a normal light crack.

Floors

Carpet, Wood

The floors in the house are not level. They tend to sag toward the center on the second floor. This is not unusual with a house of this era. It is likely that the exterior wall framing uses the balloon framing construction which is susceptible to slumping. Some signs of cracking is noted in the plaster walls (note comments in the Walls and Ceiling sections), but it is difficult to get a sense of the history of movement here or predict future movement. Inquire with the seller for more information and monitor.

Options include:

- Seek additional opinions from a structural engineer or qualified general contractor regarding the scope and urgency of any needed repairs to prevent continued movement.

- Monitor for movement to see if any additional repairs become needed.

Outlets

Defects Noted - refer to the Electrical Chapter

Smoke & CO Alarms

Smoke Alarms: No Smoke Alarms in Bedrooms

CO Alarms: Second Floor (Noted), First Floor (Noted), Furnace Room (Missing)

Smoke alarms are missing in all bedrooms.

Modern standards recommend smoke alarms in all bedrooms, in all hallways outside bedrooms and at least one on each floor of the building. At the time of inspection smoke alarms were missing in the bedrooms.

Stairs and Railings

Noted

The loose guardrail to the 2nd floor needs to be secured for improved safety.

This is an important safety item. The guardrail should be stiff enough to stop a falling adult. Hire a licensed general contractor to further evaluate and repair.

Wall Insulation

Insulation Type: Unknown

Windows

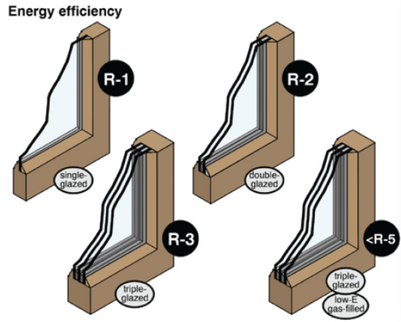

Single pane

Approximate Age: More than 30 years

Most of the windows are more than 30 years old.

The average lifespan of residential windows is 15 to 30 years if well maintained. I recommend budgeting for window replacements as they may begin to fail.

Most of the single pane windows are either sealed shut, or do not stay open on their own (no counter balance sash).

I try to determine the age of most windows by looking for a date stamp in the window frame and/or the home. When this is not possible or a date stamp does not exist, any comment about window age is purely based on visible observation to be confirmed by a window specialist as desired.

UNFINISHED INTERIOR

Assessment

The unfinished basement is dry and clean with structural reinforcements applied.

Floor/Slab

Cement

Wall & Floor Insulation

Insulation Type: None noted

Moisture

None Noted

Rodents & Birds

None Noted

ELECTRICAL

Assessment

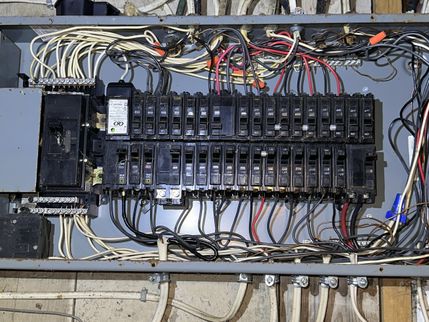

The electrical system (panel, outlets/switches & wires) appears to be fully updated to modern standards. There are relatively minor corrections to be made but overall the electrical system is very good.

Electric Service

Service Entrance/Drop: Above Ground

Trees and vegetation are impacting the overhead electric service drop.

This can fray through insulation and cause damage to the conductors and even arcing and fires. I recommend additional inspection of this drop by the utility. Remove trees, limbs and vegetation as needed and repair conductors if needed.

Main Panel

Manufacturer: Square D

Panel Amperage: 200 amps

Type: Breakers

Approximate Age: More than 30 years

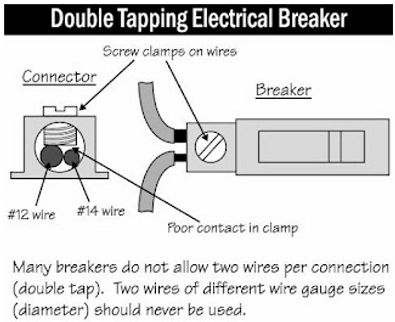

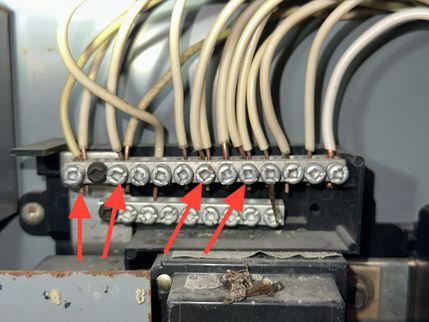

Double-tapped (double-lugged) circuits are noted in the electric panel; this is when two conductors share the same breaker. Most circuit breaker manufacturers do not allow two conductors / breaker. The breakers here do not look rated for two conductors. This condition risks poorly protected circuits and is a possible fire hazard. Please note that a pigtail is often used as a simple repair for this condition - see the attached illustration.

Hire a licensed electrician to correct the double lugged neutral or grounded conductors in the electric panel - this is when two conductors share the same lug. Double lugged conductors risk poorly protected conductors that are more vulnerable to arcing and overheating. This requires additional evaluation by an electrician.

Branch Wiring

Wire Material: Copper

Wiring Type: Non-metallic sheathed cable

Evidence of Knob and tube (K&T) wiring is noted indicating that it was previously used in the building.

Knob & Tube wiring is an old style of wiring where conductors are run outside of a sheathed cable and supported on ceramic knobs and protected by ceramic tubes where the wire passes through framing. Knob and tube wiring does not meet today's standards and alterations and extensions to this wiring are seldom done correctly and tend to produce safety hazards. I was unable to visually locate any active K&T wiring in the home, so it may have all been upgraded. There is a possibility that some K&T wiring is still employed however and it is simply not visible. Evaluation by a licensed electrician and an ESA certificate is recommend and possibly required in order to insure the home. If the upgrade documents including an ESA certificate is already available then be sure to keep it for your records.

Outlets, Switches & Fixtures

Outlet Types: 3 Prong (grounded)

Limitations: Random Testing

While I do my best to test as many outlets as I can during the inspection, the scope of a home inspection is to test a random and representative number of outlets, not all and some outlets are not accessible. As a result, some outlets with problems may not be specifically identified or noted in this report.

The GFCI protected outlet in the the 2nd floor bedroom did not respond to testing and may be defective - it did not trip when tested. Have this outlets repaired or replaced.

PLUMBING

Assessment

The plumbing system is up to modern standards however a potential leaking toilet was detected which should be addressed immediately.

Water Supply

Pipe Material: Plastic

Water Supply: Public water

Water Pressure: Average

Pressure Reducing Valve: None noted

Distribution Pipe

Pipe Materials: Copper, Galvanized Steel

Copper pipes have been in use residentially since approximately 1950 and continues to be used successfully.

Functional Flow: Average

Water Heater

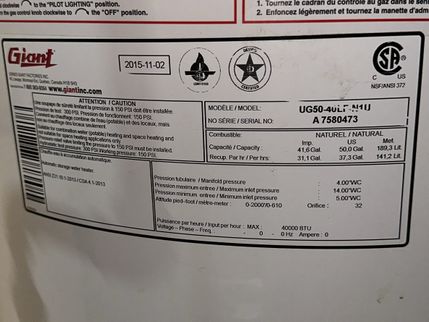

System Type: Tank

Manufacturer: Giant

Year of Manufacture: 2015

Size (litres): 189

TPR Valve: Present - Not Tested, Inadequate Discharge - General Note

A temperature and pressure relief valve (TPRV) is required on all water heaters to discharge any excessive pressure within the tank. A discharge pipe should be attached to the valve and directed to a safe location away from body contact. Newer installations must be directed to the building exterior or to an approved indoor drain receptor. Most manufacturers suggest that homeowners test these valves at least once a year by lifting the lever to ensure the valve discharges properly and also recommend inspection of these safety devices every three years. The picture here shows a typical TPRV. They may also be found on the side of the heater on some models. I do not test these valves due to the possibility that they may leak after testing. A leaking or inoperative TPRV should be replaced immediately by a licensed plumber.

Due to inconsistencies between both UPC and IPC Plumbing codes, and water heater manufacturer's instructions, and TPRV manufacturer instructions, it is not actually possible to install the drain from the Water Heater TPRV "properly." There are conflicts with distance of termination to the floor/ground, types of pipes approved, and diameters of pipes approved. Additional confusion is added when jurisdictional inspectors approve installations/materials specifically not allowed by both codes and manufacturers. My recommendations will vary depending on the installation and will be included in the applicable narratives below.

Most codes defer to manufacturer instructions and I favor those recommendations. The yellow tag on the valve states clearly the termination should be 6" above the floor which is more consistent with the UPC code requirements.

Energy Source: Gas

Pad: None Needed

Drain Pan: Not Needed

Water Temperature: Below 115 (46.1) - Too Low

The water temperature was tested at the kitchen sink during inspection. It is common for water temperatures to fluctuate throughout the house depending on the distance from the water heater, the water heater settings, the type of water heater and any thermostatic controls used in the plumbing fixtures and mixing valves.

Temperature Pressure Release (TPR) valve on the water heater terminates incorrectly and may be leaking

The discharge tube for the water heater temperature and pressure relief valve (TPRV) is not correctly installed. This is a potential safety hazard. Ideally, the discharge tube for a relief valve:

- Terminates to an exterior location or above a drain, though this is not always possible

- Terminates between 6 and 24-inches off the ground (UPC)

- Slopes to drain to prevent water pooling inside the discharge tube

- Is not made from pipe with an inside diameter less than 3/4 on an inch

- Terminates to a visible location that can be monitored for leaks and discharges

- Does not have a threaded termination point which would prevent accidental capping of this important discharge

- Does not terminate into a drain pan

I recommend having this relief valve discharge tube further investigated and repaired as recommended by a licensed plumber.

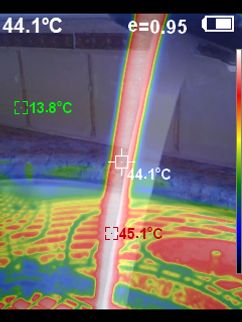

The water temperature reading at the kitchen faucet is lower than normal: 41.1 C (106 F).

The temperature may need to be turned up at the water heater so that it is in the range of 46-52 C (115-125 F) at the faucet. There is some evidence that hot water temperatures in the tank water heater should be greater than 54.5 C (130 F) to prevent Legionaries' disease from developing. I recommend installing a mixing valve at the hot water tank. A mixing valve at the tank allows the tank temperature to be set as high as 60 C (140 F) to ensure all bacteria is neutralized while providing 49 C (120 F) temperature at the faucets.

An expansion tank is recommended for the water heater.

Expansion tanks help reduce pressure on the plumbing system by creating a buffer or a place for water to expand into as water swells during thermal expansion. Installation of expansion or pressure tanks is modern installation practice and will be required if a pressure reducing valve has been installed on a public water supply or if for any reason the plumbing system is closed. Open systems do not require an expansion device though they can still be an excellent way to help prevent build-up of pressures in the piping system. Consult with a qualified plumber to install.

Waste

Discharge Type: Public Sewer

Waste and Vent Pipe Materials: ABS plastic

Backflow Valve: None Noted

A video camera sewer scope is recommended.

An evaluation of the sewer line below the ground is beyond the scope of this inspection. Due to the age of the building, a sewer scope is recommended to further evaluate the sewer line and the below ground connections between the house and the municipal sewer line. Sewer scopes are done using video cameras and can reveal the materials, condition and reliability of the sewer line. If that has not been done recently, I recommend having a sewer scope performed.

Waste Water/Sewage Ejector Pumps

None Noted

Sump Pumps and Drains

Sump Pump: Present, Tested

Floor Drain: None noted

This building has a sump pump installed and should have a redundant backup system installed.

It appears that this sump pump is critical in keeping the basement dry as it was wet, and active at the time of the inspection. I recommend one of the following backup solutions:

- Install a back-up battery in case of a power outage (especially when on private well)

- Install a water driven redundant pump (when on public water supply)

- Have a backup pump in case of pump failure

- Install a high water alarm to warn occupants of a failing sump system.

Exterior Faucet

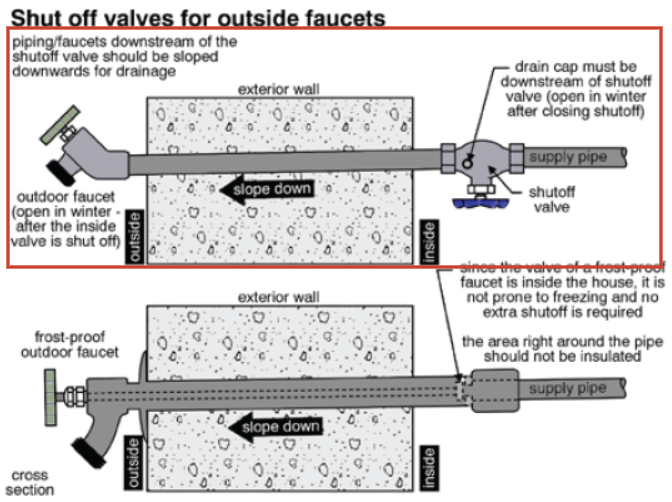

Style: Standard

Older hose faucets were noted on this building which must be winterized.

Updating the hose faucets is recommended. Modern hose faucets are typically "frost free," which are (arguably) more resistant to bursting in cold weather. In the meantime, be sure to winterize your hose faucets during cold weather (shutting the interior tap) to prevent from freezing, including disconnecting any attached hose.

Toilets

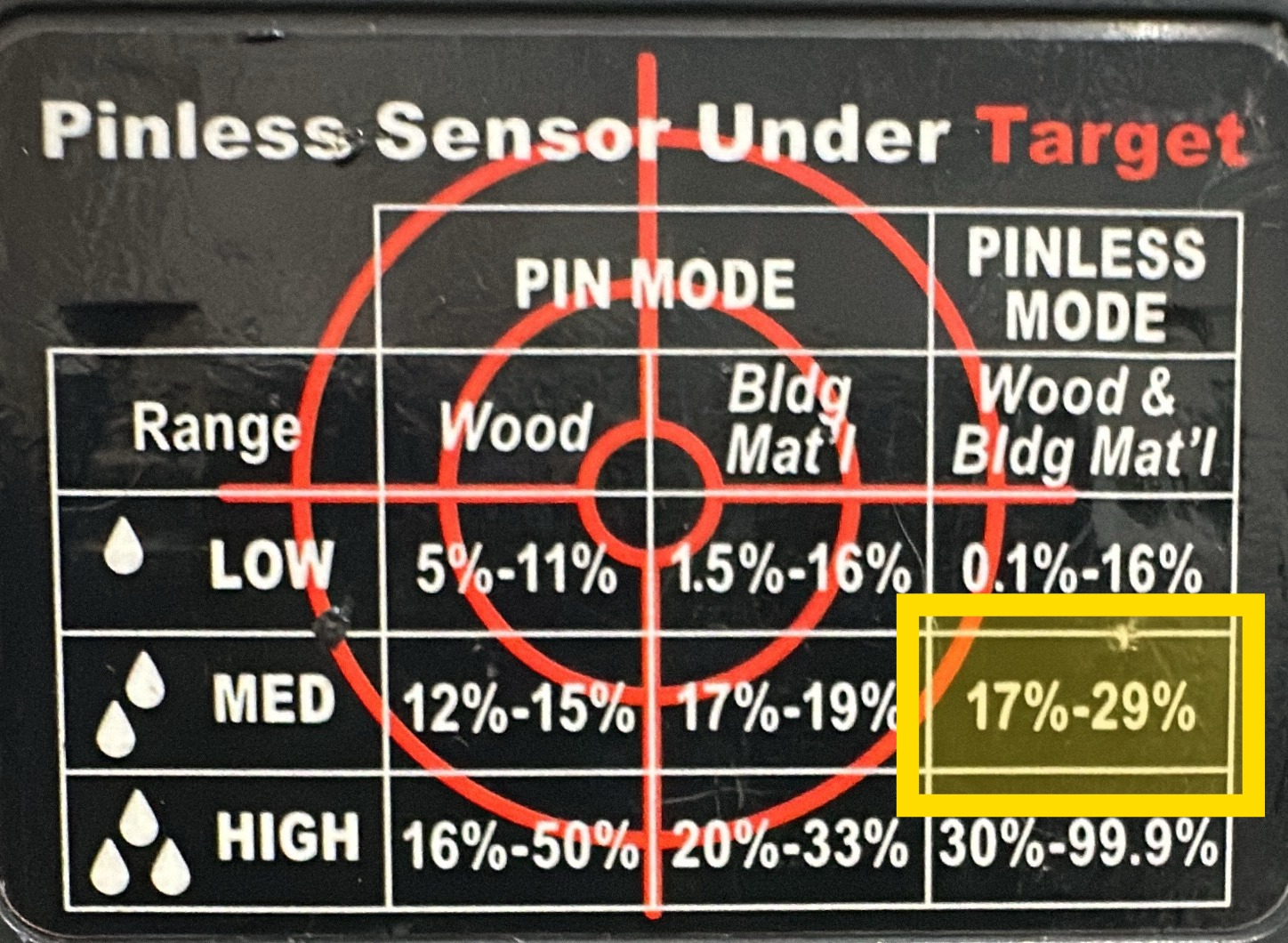

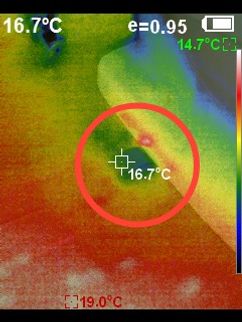

A high moisture reading was taken around the 2nd floor Common bathroom toilet, indicating there is likely leakage and possibly concealed water damage.

I also noted water stains around the toilet and thermal imaging appears to confirm the high moisture level. It is difficult to determine the extent of the needed repair at this time. Repairs can be simple or more complex depending on the moisture source and the condition of materials below the toilet. Further investigation is required to determine an accurate scope of repair. Hire a licensed plumbing contractor to further evaluate and repair the toilet and the finish floor and sub-floor as needed.

HVAC

Assessment

The heating system works well however the furnace is toward the end of it's life and the associated duct work at the furnace requires some repair. The air conditioning unit is well beyond it's normal lifespan and may need to be replaced.

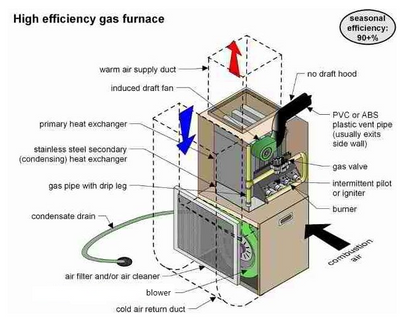

Primary Heating

Manufacturer: Gibson

Year of Manufacture: 2007

Efficiency: High

Energy Source: Natural gas

Filter Size: 16 x 25 x 1"

Annual servicing of central heating equipment is recommended

Records indicate that this furnace has not been serviced in the last year. The furnace was tested during inspection and was operational. The design life of these forced air furnaces is 15-20 years. Hire a licensed heating contractor to service and further evaluate the furnace.

You can expect a gas furnace to last anywhere between 15 and 30 years, with many furnaces being replaced around the 17-year mark. Be sure to regularly schedule annual maintenance and consider budgeting for replacement in the coming years.

A critical component to all combustion equipment is the heat exchanger. Heat exchangers on modern furnaces have an average life expectancy of 15-20 years. Heat exchangers are concealed inside of heating equipment; are not visible and are specifically excluded from a home inspection.

Heating Exhaust

Acceptable

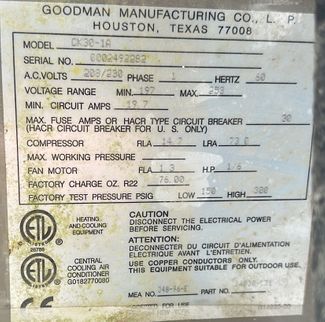

Central Cooling

Air Conditioning / Heat Pump: Air Conditioning

System Type: Air Source Electric

Manufacturer: Goodman

Size: 2.5 Tons

Age: 2000

The air conditioning system was not tested due to cold temperatures and it is old and should be considered unreliable.

Air conditioning compressors have fairly unreliable service lives that can range from as little as 7 to as many as 30 years. Service life can depend on keeping a proper refrigerant charge and reliable return air flow as well as the amount the system has been used. I recommend having this old system serviced by a licensed heating and cooling professional and have the refrigerant charge checked. Given the age of this unit I would budget to replace at any time.

Ventilation

Whole Home Ventilation: None Noted

Natural Gas Meter

Noted

Gas Shutoff Location: North side of structure

Oil Storage

None Noted

None Noted

No oil storage was noted on the property

Distribution

Heat Source in Each Room: Present

Distribution Method: Forced Air / Ducts

Heating ductwork cleaning is recommended.

The heating ductwork is moderately clean however I always recommend duct cleaning whenever home owners change for sanitary reasons.

Solid Fuel Fireplaces

Noted

A WETT (Wood Energy Technology Transfer) inspection is recommended.

This may be required by your lender and/or insurance company before use of the wood stove. An annual inspection and cleaning of all chimneys, fireplaces, solid fuel-burning appliances, and vents is also recommend. This inspection includes, not only cleaning the interior of the chimney pipe, but also the use of specialized tools and testing procedures such as video cameras, etc. to thoroughly evaluate the serviceability of the entire flue lining and fireplace/chimney system. If a chimney cleaning has not been performed over the past 12 months, such an inspection is recommended before the home changes ownership---for fire safety reasons. Implement any repairs as recommended.

A solid fuel fireplace is noted. Inspection or WETT certification of the fireplace and/or chimney is not in the scope of this home inspection. Any comments or photos provided are for your awareness only and should not be construed as advice or professional certification.

STRUCTURE

Assessment

The foundation appears to be solid and has received new framing support beams in the basement. The second floor is warped however due to the building's construction and age.

Foundation

% of Foundation Not Visible: 80%

Foundation Type: Basement

Foundation Material: Stone

Framing

Floor Framing: 2x10

Sub-Floor Material: Tongue and groove

Wall Framing: Not visible

Wall Sheathing: Not visible

Ceiling Framing: Not visible

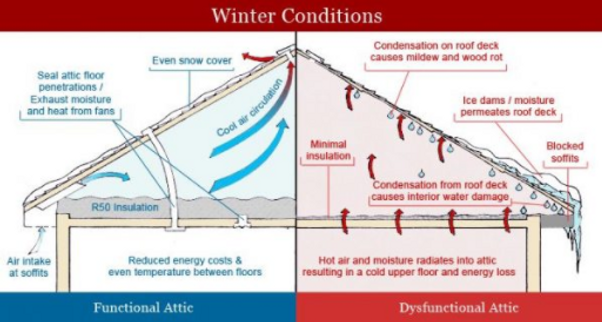

ATTIC

Assessment

The attic structure has been reinforced and is in acceptable condition however the insulation level is very poor, there is no attic ventilation and an uninsulated vent is located in the unconditioned space.

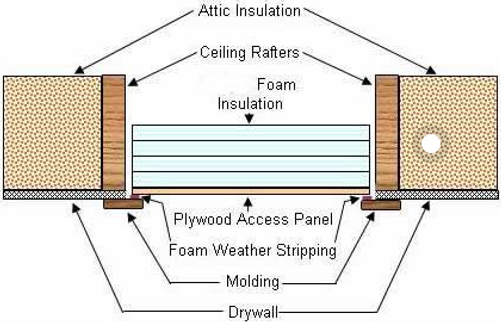

Access

Access Method: Viewed at access

Attic Insulation

Insulation Type: Fiberglass

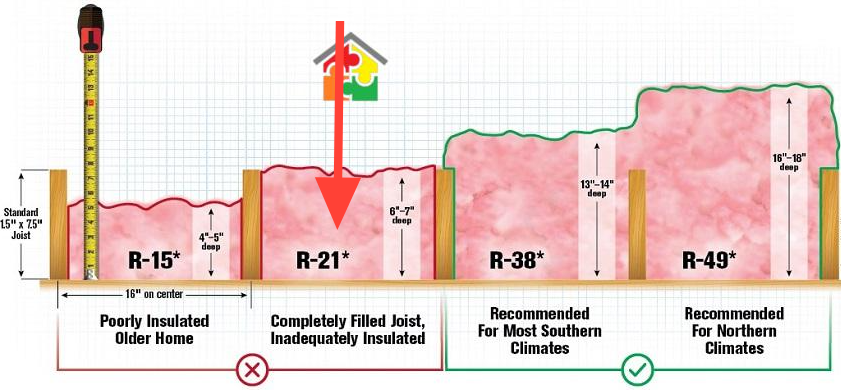

Approximate Insulation R-Value: 20-25

Vapour Barrier: Paper

The attic insulation could be improved to modern standards, which recommend R-60 on the attic floor and R-30 on the house walls. R-value is the measure of resistance to heat loss; the higher the R-value the better the insulation. During insulation repairs it is best practices to implement any air seal-up repairs to seal air leakage. Also, be sure you have completed any wiring or other projects that are needed in the attic. Then, hire an insulation contractor to improve thermal barriers.

Attic Ventilation

Type: None noted

Venting

Outlets, Fixtures

None Noted

OUTBUILDING

Building Use

Garage

Siding & Walls

Roof Covering

Roof Covering Materials: Same as House

Method of Roof Inspection: Viewed with camera from ground

Roof Style: Gable

Gutters

Type: Same as House

Chimney

None Noted

Skylights

None Noted

Framing

Floor Framing: 2x6

Sub-Floor Material: Plywood

Wall Framing: 2x4

Roof Framing

Rafters: 2x6

Sheathing: Plywood

Doors

Equipment/Vehicle Door Type: Wood

Automatic Door Opener: Inspected

Occupant Door: Inspected

An older model garage door opener was noted with no laser eyes in use as a safety feature.

These are less safe than modern openers which will reverse when the laser beam is broken. This safety feature is especially important for children and pets. Updating the garage door opener is recommended for improved safety.

Outlets, Fixtures

Defects Noted - refer to the Electrical Chapter

Insulation

Insulation Type: This building is not insulated

CONTRACTORS

Many of these contractors I have contracted either personally to me and/or in business however I have no affiliation with any, nor do I receive any compensation for their entry on this list or guarantee their work. This list is provided for your convenience only

ASBESTOS/MOLD TESTING & ABATEMENT

Mold Buster | Belleville, Kingston | (888) 605-0816 | https://www.bustmold.com/

First Response | Ottawa, Kingston | (613) 702-6701 | https://www.firstresponsecleaning.ca/

Paracel Laboraties | Ottawa, Kingston | (800) 749-1947 | https://www.paracellabs.com/home

ELECTRICAL

Terry Shortt Electrical Services |Trenton | (613) 394-6359 | http://www.shorttelectric.ca/

Roberts Electric Ltd | Cobourg | (905) 372-4421 | http://www.bgrobertselectric.ca/

Bertoia Electric | Kingston | (613) 634-9450| https://www.bertoiaelectric.com/

Briden Electrical Services | Belleville| (613) 922-0743 | https://bridenelectric.ca/

ENGINEERING / FOUNDATION REPAIR

Elliot Tee | Napanee | (613) 483-4125

Three Hills Engineering |Belleville | (613) 902-0036 | http://www.threehillsengineering.com/

LANDSCAPING

The Tree Medic | Cobourg | (905) 396-6632 | http://www.thetreemedic.ca/

MASONRY

Holmes Custom Masonry | Trenton | (613) 920-1616 | https://www.holmescustommasonry.com/

RENOVATION, CARPENTRY AND PAINT

Knock on Wood (Journeyman Carpenter) | Prince Edward County | (613) 813-4789

Bread & Hammer | Belleville | (613) 214-9040 | https://www.breadandhammer.com/

Alair | Belleville | (613) 707-1793 | https://www.alairhomes.ca/belleville/home-renovations/

Slabinski Carpentry | Cobourg | (905) 269-7307 | https://www.facebook.com/slabinskicarpentry/

ROOFING

Robert Miller Construction (Amish) | Sterling | Call John Davies (613) 395-5546

Advanced Roofing | Belleville | (613) 243-1083 | http://advancedroofingquinte.com/

Salama roofing inc. | Trenton | (647) 528-0361 | https://salamaroofinginc.business.site/

Moffatt Bros. Roofing Ltd. | Cobourg | (905) 373-0071 | https://moffattbrosroofing.ca/

WATER (WELL, SEPTIC, PLUMBING)

Professional Pumps & Water Treatment (well and water testing) | Kingston | (613) 561-7867 | https://www.ppwt.ca/

Storing Septic (septic inspection only) | Tamworth | (613) 379-2192

MacLellan Water Treatment and Pumps (well inspection only) | Odessa | (613) 777-9121 | https://www.mwater.ca/

QLogic Water Solutions (well & water inspection) | Trenton | (613) 922-7474 | https://qlogicwatersolutions.com/

A1 Plumbing Services (well & septic inspection) | Frankford | (613) 398-0599 | https://a1plumbingquinte.com/

D.Koets Plumbing & Heating (plumbing only) | Brighton | (613) 392-9820 | https://www.koetsplumbing.com/

Reids Plumbing (plumbing only) | Belleville | (613) 968-9344 | https://reids-plumbing-heating-and-air-conditioning.business.site/

Stadtke Plumbing & Heating Ltd. (plumbing only) | Cobourg | (905) 377-9214 | http://www.stadtkeplumbingheating.com/

WATERPROOFING/BASEMENT LEAK

Upper Canada Water Proofing | Quinte West | (613) 392-1485 | https://www.uppercanadawaterproofing.ca/

.jpg)

.png)

.png)

.png)

.png)

(3).png)

(1) (1).jpg)