The Scope and Purpose of a Home Inspection

Purchasing property involves risk

The purpose of a home inspection is to help reduce the risk associated with the purchase of a structure by providing a professional opinion about the overall condition of the structure. A home inspection is a limited visual inspection and it cannot eliminate this risk. Some homes present more risks than others. We cannot control this, but we try to help educate you about what we don’t know during the inspection process. This is more difficult to convey in a report and one of many reasons why we recommend that you attend the inspection.

A home inspection is not an insurance policy

This report does not substitute for or serve as a warranty or guarantee of any kind. Home warranties can be purchased separately from insuring firms that provide this service.

A home inspection is visual and not destructive

The descriptions and observations in this report are based on a visual inspection of the structure. We inspect the aspects of the structure that can be viewed without dismantling, damaging or disfiguring the structure and without moving furniture and interior furnishings. Areas that are concealed, hidden or inaccessible to view are not covered by this inspection. Some systems cannot be tested during this inspection as testing risks damaging the building. For example, overflow drains on bathtubs are generally not tested because if they were found to be leaking they could damage the finishes below. Our procedures involve non-invasive investigation and non-destructive testing which will limit the scope of the inspection.

This is not an inspection for code compliance

This inspection and report are not intended for city / local code compliance. During the construction process structures are inspected for code compliance by municipal inspectors. Framing is open at this time and conditions can be fully viewed. Framing is not open during inspections of finished homes, and this limits the inspection. All houses fall out of code compliance shortly after they are built, as the codes continually change. National codes are augmented at least every three years for all of the varying disciplines. Municipalities can choose to adopt and phase in sections of the codes on their own timetables. There are generally no requirements to bring older homes into compliance unless substantial renovation is being done.

This is just our opinion

Construction techniques and standards vary. There is no one way to build a house or install a system in a house. The observations in this report are the opinions of the home inspector. Other inspectors and contractors are likely to have some differing opinions. You are welcome to seek opinions from other professionals.

The scope of this inspection

This inspection will include the following systems: exterior, roof, structure, drainage, foundation, attic, interior, plumbing, electrical and heating. The evaluation will be based on limited observations that are primarily visual and non-invasive. This inspection and report are not intended to be technically exhaustive.

Your expectations

The overall goal of a home inspection is to help ensure that your expectations are appropriate with the house you are proposing to buy. To this end we assist with discovery by showing and documenting observations during the home inspection. This should not be mistaken for a technically exhaustive inspection designed to uncover every defect with a building. Such inspections are available but they are generally cost-prohibitive to most homebuyers.

Your participation is requested

Your presence is requested during this inspection. A written report will not substitute for all the possible information that can be conveyed verbally by a shared visual observation of the conditions of the property.

How to Read This Report

Getting the Information to You

This report is designed to deliver important and technical information in a way that is easy for anyone to access and understand. If you are in a hurry, you can take a quick look at our "Summary Page” and quickly get critical information for important decision making. However, we strongly recommend that you take the time to read the full Report, which includes digital photographs, captions, diagrams, descriptions, videos and hot links to additional information.

The best way to get the layers of information that are presented in this report is to read your report online (the HTML version), which will allow you to expand your learning about your house. You will notice some words or series of words highlighted in blue and underlined – clicking on these will provide you with a link to additional information. The HTML version of this report also contains streaming videos. Short video clips often contain important information and critical context and sounds that can be difficult to capture in words and still pictures.

For the most reliable viewing experience, I recommend viewing the report on as large a screen as practical, as much detail can be lost on small devices like smart phones. For similar reasons, reports should only be printed in color to retain as much detail as possible and minimize misinterpretation of photographs.

This report can also be printed on paper or to a PDF document.

Chapters and Sections

This report is divided into chapters that parcel the home into logical inspection components. Each chapter is broken into sections that relate to a specific system or component of the home. You can navigate between chapters with the click of a button on the left side margin.

Most sections will contain some descriptive information done in black font. Observation narrative, done in colored boxes, will be included if a system or component is found to be significantly deficient in some way or if we wish to provide helpful additional information about the system or the scope of our inspection. If a system or component of the home was deemed to be in satisfactory or serviceable condition, there may be no narrative observation comments in that section and it may simply say “tested,” or “inspected.”

Observation Labels

All narrative observations are colored, numbered and labeled to help you find, refer to, and understand the severity of the observation. Observation colors and labels used in this report are:

- Major Concern:Repair items that may cost significant money to correct now or in the near future, or items that require immediate attention to prevent additional damage or eliminate safety hazards.

- Repair:Repair and maintenance items noted during inspection. Please note that some repair items can be expensive to correct such as re-finishing hardwood floors, but are considered simply repair items due to their cosmetic nature.

- Recommended Maintenance:These are repair items that should be considered "routine home ownership items," such as servicing the furnace, cleaning the gutters or changing the air filters in the furnace.

- Improve:Observations that are not necessarily defects, but which could be improved for safety, efficiency, or reliability reasons.

- Monitor:Items that should be watched to see if correction may be needed in the future.

- Due Diligence:Observation such as a buried oil tank that may require further investigation to determine the severity and / or urgency of repair.

- Efficiency:Denotes observations that are needed to make the home more energy efficient as well as to bring the home up to modern insulation standards. This category typically includes windows and insulation. Other items, such as lighting and appliances, are not inspected for their energy status.

- Completed:Items that were initially an issue but have since been completed.

- Note:Refers to aside information and /or any comments elaborating on descriptions of systems in the home or limitations to the home inspection.

- Description:Detailed description of various aspects of the property noted during the inspection.

Pest Inspection

All items with the bug logo () are part of a structural pest inspection. If your inspector included a structural pest inspection as a part of the scope of your home inspection, you can distinguish pest inspection items by this logo. You can also go to the pest inspection summary page to see a summary of the items that are part of a pest inspection.

Summary Page

The Summary Page is designed as a bulleted overview of all the observations noted during inspection. This helpful overview is not a substitution for reading the entire inspection report. The entire report must be read to get a complete understanding of this inspection report as the Summary Page does not include photographs or photo captions.

Moisture Meter Testing

Where moisture meter testing is indicated in this report a Protimiter Survey Master Dual Function was used.

Summary

Major Concerns

- HCFV-3 Heating, Cooling, Fireplaces and Ventilation:

The ductwork for the heating delivery system is in generally poor condition and requires repairs. The ductwork should be cleaned and all joints sealed using duct mastic. Areas that are poorly supported should be re-supported and where they are outside the conditioned space, they should be insulated to R-8 or better. Hire a qualified heating contractor to further evaluate and repair.

- MB-3 Master Bathroom:

The master bathroom in this home is in marginal condition and will be unreliable until updated. Remodeling this bathroom is recommended for safe, sanitary and reliable performance. Please note that this visible condition risks concealed water damage.

Repairs

- G1-6 Grounds:

Localized wood decay was noted in the storage shed. Repair wood decay as needed and all conditions conducive to wood decay.

- ESDW-1 Exterior Siding, Doors and Windows:

Localized rot repairs are needed to the exterior trim and siding. Hire a licensed general contractor to further evaluate and repair the exterior siding system. Repair and replace all damaged and decaying exterior wood as needed. Please note that this condition can indicate additional concealed damage that is not visible to inspection. During inspection. I noted:

- ESDW-2 Exterior Siding, Doors and Windows:

Localized paint failure was noted at the exterior see especially where exposed to the weather. Implement localized painting as needed.

- ESDW-5 Exterior Siding, Doors and Windows:

Opening were noted in the eaves of the house that need to be sealed up to exclude rodents from getting into the attic.

- ESDW-6 Exterior Siding, Doors and Windows:

The fascia around the roof needs to be cleaned and painted and repair any localized wood decay.

- ESDW-7 Exterior Siding, Doors and Windows:

Bees were noted swarming around the roof eaves. The nest was not visible but clearly there is one in the roof here. Have this nest treated and removed to eliminate a safety hazard.

- G-1 Garage:

An unprotected opening was found in the garage wall and ceiling finishes. This should be repaired to complete the fire separation between the house and the garage. Large holes should be repaired with the proper sheetrock materials. Small holes and openings should be sealed with mud or high temperature of "fire stop" caulking. Openings with doors should employ listed fire-rated doors.

- G-3 Garage:

The overhead garage door is damaged and requires repair or replacement. Hire a garage door specialist to further evaluate and repair.

- G-4 Garage:

Repair the damaged weather stripping on the bottom of the garage door. This is important to prevent water and rodent entry.

- ES-4 Electric Service:

Openings were noted in the electric panel that have not been covered. This is unsafe as it does not adequately protect the energized area of the electric panel. Cover all open knock-outs with listed covers.

- ES-5 Electric Service:

Shelving been installed in front of the electric panel. This presents an inadequate working clearance and a potential safety hazard for people working on or inspecting the electric panel. A 30-inch wide and 36-inch deep unobstructed working clearance is recommended for improved safety. Consult with a general contractor to further evaluate this condition and relocate the panel or improve access as needed.

- EDFW-3 Electric Distribution and Finish Wiring:

The loose electric receptacles in the building should be secured to prevent accidental damage to the wiring connections. Securing loose receptacles can often be done by just tightening some set screws between the receptacle and the junction box, though sometimes it can get more complex if the box itself is loose. Repair as needed.

- EDFW-4 Electric Distribution and Finish Wiring:

An inoperative light was noted at the exterior garage door. Have this further investigated an repaired as needed. If a new bulb does not correct the problem, consult with a licensed electrical contractor.

- EDFW-6 Electric Distribution and Finish Wiring:

Dust came flying off the ceiling fan(s) during testing. Clean the fan as needed.

- EDFW-7 Electric Distribution and Finish Wiring:

The installation of carbon monoxide alarms is recommended for all homes that have fuel burning appliances such as gas or oil furnaces, gas water heaters, gas ovens and cook-tops, gas fireplaces and wood stoves. Carbon monoxide is a colorless, odorless gas that can cause sickness, nausea and even death. For more information, consult the Consumer Product Safety Commission at 1-800-638-2772 (C.P.S.C.) Modern standards in many states now recommend one CO alarm outside of all bedrooms and at least 1 per floor of the house.

- EDFW-8 Electric Distribution and Finish Wiring:

No smoke alarms were noted anywhere. Smoke alarms are an important safety feature and are recommended inside all bedrooms and in hallways outside of all sleeping areas. It is also recommended that there be at least one smoke alarm on each floor of the house. I recommend having smoke alarms installed to meet modern safety standards.

- HCFV-1 Heating, Cooling, Fireplaces and Ventilation:

The insulation for the refrigerant lines for the AC is damaged and requires repair. This should be done to ensure reliable and efficient performance from this unit. .

- HCFV-2 Heating, Cooling, Fireplaces and Ventilation:

A number of problems were noted with the heating and cooling ducts during inspection. I recommend additional inspection and repair of the heating ductwork system by a qualified heating and cooling contractor. Implement repairs as recommended to ensure reliable performance.

Examples of Observations Noted During Inspection Include

- The ductwork insulation is damaged and requires repair

- HCFV-4 Heating, Cooling, Fireplaces and Ventilation:

The exhaust ductwork for the bathroom fans are disconnected in the attic and requires repair to ensure fan exhaust is properly venting to the exterior. Having exhaust fans venting into the attic can cause lead to seasonal condensation and moisture controls problems and could damage the attic building materials. Repair to ensure proper discharge of air to the exterior and be sure exhaust ductwork is insulated to R-8 or better to reduce risks of seasonal condensation.

- P-4 Plumbing:

No drain pan has been installed below the water heater here. A drain pan is recommended under water heaters that are located in finished spaces or where a leak could damage finishes. Where a pan does not already exist, the tricky part is providing a drain to the outside. A pan without a drain is often of limited benefit / protection. For improved protection from accidental water heater leaks, and where a drain is difficult to install, consider a pan with a moisture alarm and a flood-safe device such as this: Watts Water Heater Leak Prevention.

- P-5 Plumbing:

No thermal expansion device was found for the water heating system. Some type of thermal expansion device is required for closed plumbing systems. This is typically provided by an expansion tank at the water heater. Thermal expansion devices help prevent unwanted pressure build-up in piping systems.

Recommended Contractor: Plumber

- P-7 Plumbing:

The discharge tube for the water heater relief valve is installed too high off the ground. Discharge tubes should always terminate by pointing toward the ground to eliminate a scald hazard and should terminate between 6-inches and 24-inches (UPC) off the ground, though specific requirements can vary by manufacturer and jurisdiction. Ideally, the discharge tube for a relief valve:

- Terminates to an exterior location or above a drain, though this is not always possible

- Slopes to drain to prevent water pooling inside the discharge tube

- Is not made from pipe with an inside diameter less than 3/4 on an inch

- Terminates to a visible location that can be monitored for leaks and discharges

- Does not have a threaded termination point which would prevent accidental capping of this important discharge

- Does not terminate into a drain pan

I recommend having this relief valve discharge tube further investigated and repaired as recommended by a licensed plumber.

- I-2 Interior:

The wood laminate floors are damaged in places. Have all damaged flooring further evaluated and repaired by a qualified contractor as needed.

- I-3 Interior:

Water stains were noted on the ceiling in the bedroom Disclose any history of prior leakage to get a better sense if repairs may be needed to prevent another leak. Many water leaks are intermittent or related to specific weather conditions or occupant behavior; it is impossible for us to distinguish these conditions during a one-time inspection or to know if repairs could be needed to prevent future leaks. Repair damaged finishes and paint as needed for a proper cosmetic appearance and implement additional repairs as needed to prevent future leaks.

- K-1 Kitchen:

Kitchen cabinet door and drawer adjustment is needed for proper operation of the kitchen cabinets. Examples of observations noted during inspection include:

- K-2 Kitchen:

Repair or replace the water damaged base of the kitchen cabinet below the kitchen sink. This was dry at the the time of inspection, but seems to have been damaged by a prior moisture condition.

- K-3 Kitchen:

The kitchen cabinets are old and close to the end of their useful service life. I would budget to update soon, though the urgency of this update is subjective.

- K-5 Kitchen:

Overall, the kitchen finishes and appliances are old and in the last phase of their useful service life. While only minor repairs are needed at the moment, a complete kitchen remodel would be logical in the near term to update this kitchen. Urgency depends on desire for cosmetic appearance and reliability.

- MB-2 Master Bathroom:

The tile in the bathroom shower surround is old and may require updating at any time. The reliability of tile depends on what the tile is mounted on and what it is mounted with: this is not visible to inspection. Hire a tile specialist to further evaluate and repair this tile as recommended. Additional inspection could reveal an easy repair or concealed water damage and the need for full replacement, a significant expense. Examples of observations and red flags found during inspection include:

- GB-1 Guest Bathroom:

The stopper to the guest bathroom sink is missing - install proper stopper system.

- GB-2 Guest Bathroom:

The toilet in the guest bath has not been caulked to the floor. Caulking the toilet to the floor is recommended and even required though opinions on this can vary. I prefer caulking the toilet to the floor, but leaving a gap on the back of the toilet that remains un-caulked so if the toilet leaks, water has an escape route. The biggest risk of not caulking the toilet to the floor is that the toilet can become loose which is the biggest problem here. Repair as recommended by a licensed plumber.

- GB-3 Guest Bathroom:

The shower head in the guest bathroom shower needs to be cleaned or replaced. Calcium build-up and scaling is causing the shower head to spray in right angles and water is spraying out of the shower. If the house is on a well system, this can also indicate that sediment is entering the water supply.

- GB-4 Guest Bathroom:

The faucet handle and fill valve in the guest bathroom tub is leaking and requires repair or replacement. Hire a licensed plumber to further evaluate and repair.

- GB-5 Guest Bathroom:

The caulking around the shower enclosure is old and failing and should be replaced.

- GB-6 Guest Bathroom:

The tub fill spigot is leaking and requires repair or replacement.

- A-1 Attic:

The attic access hatch requires insulation and weather stripping to prevent heat loss and heat migration into the attic.

- A-5 Attic:

The exhaust ductwork for the bathroom fan is disconnected in the attic and requires repair to ensure fan exhaust is properly venting to the exterior. Having exhaust fans venting into the attic can cause lead to seasonal condensation and moisture controls problems and could damage the attic building materials. Repair to ensure proper discharge of air to the exterior and be sure exhaust ductwork is insulated to R-8 or better to reduce risks of seasonal condensation.

Recommended Maintenance Items

- G1-3 Grounds:

Trim back bushes in contact with house

- G1-4 Grounds:

Stain the fence to prolong its life

- ESDW-4 Exterior Siding, Doors and Windows:

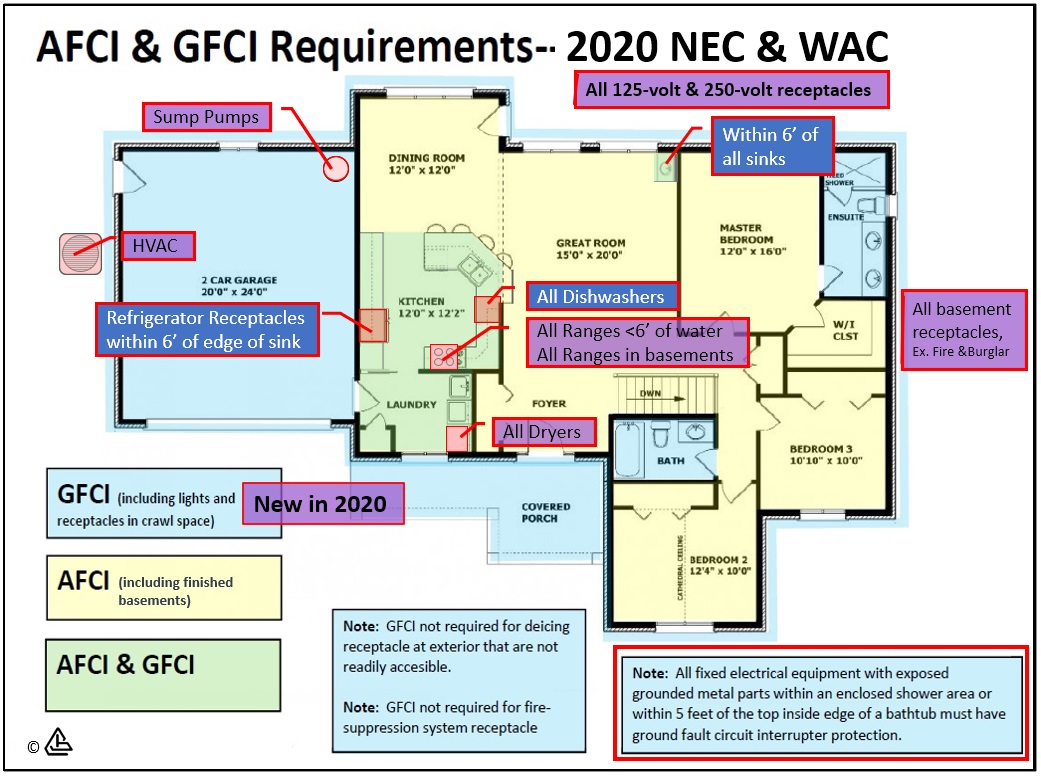

- EDFW-2 Electric Distribution and Finish Wiring:

Since the 1970s, requirements for GFCI (Ground Fault Circuit Interruption) protection have changed, and locations requiring GFCI protection seem to get added with every code cycle. It is common for older residential buildings to have some or even many electric receptacles that do not meet modern safety standards. GFCIs have proven successful at reducing electrocutions, and it seems likely that someday, every circuit, receptacle, and appliance in the building will require GFCI protection. The first chart below shows how successful GFCIs have been at reducing risks from electrocution. The second illustration shows where GFCI protection is required as of the 2020 NEC and WAC. As a general best practice for safety. For improved safety, I always recommend bringing GFCI protection up to modern safety standards.

During inspection today, I noted that GFCI protection is inconsistent with modern minimum standards for safety in the following locations:

- P-6 Plumbing:

An expansion tank is recommended for the water heater. Expansion tanks help reduce pressure on the plumbing system by creating a buffer or a place for water to expand into as water swells during thermal expansion. Installation of expansion or pressure tanks is modern installation practice and will be required if a pressure reducing valve has been installed on a public water supply or if for any reason the plumbing system is closed. Open systems do not require an expansion device though they can still be an excellent way to help prevent build-up of pressures in the piping system. Consult with a qualified plumber to install.

- LF-3 Laundry Facilities:

The dryer exhaust ductwork is dirty and needs to be cleaned for improved safety. This is important, regular maintenance to eliminate a potential fire hazard.

Improves

- G-2 Garage:

You will likely want to install an automatic garage door opener as none has been installed for the garage door.

- EDFW-1 Electric Distribution and Finish Wiring:

This building is under-wired by modern standards, which means the wiring system may not respond well to modern electrical demands. This can present safety issues as it tends to encourage overloading of circuits and use of power strips and extension cords. This can also be inconvenient - think two prong receptacles. I recommend hiring a licensed electrician to further evaluate the wiring in this building and add circuits as needed for improved safety, reliability and convenience. Consider adding more circuits for the kitchen, office and media areas in particular. The scope and extent of updating the wiring is subjective and depends on desires and expectations for the wiring system. Examples of some of the guidelines for minimum wiring standards in modern houses include:

- No point along a wall in habitable rooms should be more than 6-feet from an electric receptacle

- No point along kitchen countertops should be more than 2-feet from an electric receptacle

- Two 20-amp circuits for the kitchen receptacles

- One 20-amp circuit for the laundry receptacles

- One 20-amp circuit for the bathroom receptacles

- One separate, individual branch circuit for central heating equipment

- An electric receptacle should be provided for the exterior of the house at both the front and the back of the house

- K-4 Kitchen:

There is no dishwasher for the kitchen and no space in which to install a dishwasher. If you wish to have a dishwasher here you will need to have one installed including provisions for electricity, drain lines and water supply.

- LF-1 Laundry Facilities:

A moisture alarm with water shut-off features is recommended under the washing machine to protect against accidental leaks in the supply hoses. Pans can be effective when there is a drain, but even these will not protect against a burst supply connector. A moisture alarm with automatic shut-off will. Watts is a brand I have seen installed: Link.

- LF-2 Laundry Facilities:

For improved reliability, update the old water supply connectors to the washing machine. These are old and should be regularly swapped out to prevent accidental leaks from bursting hoses. Consider improving the reliability of this water supply by installing a flood safe hose system.

- LF-4 Laundry Facilities:

No ventilation fan was found for the laundry room. This is common in older homes and required in newer buildings. Installing a ventilation fan is recommended to help control indoor relative humidity. This fan can be run during operation of the laundry and/or placed on a timer to come on automatically throughout the day using a timer. Hire a qualified contractor to further evaluate and repair.

Monitors

- ES-3 Electric Service:

Sealant used around service entrance mast. Sealant can and will fail. Monitor the sealant and replace as needed to prevent roof leaks

Due Diligences

- RCG-2 Roof, Chimney and Gutters:

The roofing material on this building is a recently installed dimensional or architectural grade shingle. These are often rated as 30-40 year shingles. In practice, as a roof assembly, these tend to last about 18-23 years depending on the quality of the installation, the steepness of the roof and the exposure. The installation appears neat and professional. Many professional roofing companies will offer limited workmanship warranties. Please note that roofs are not a shingle. they are an assembly and they require regular cleaning and maintenance to keep them performing reliably. Examples of observations noted during inspection include:

Recommendation

Inquire with the seller about any warranty and/or installer information for this new roof covering installation.

- ES-1 Electric Service:

No permit stickers or paper work related to electrical work were found on the electric panel. Inquire with the seller for any additional information about this installation.

- P-1 Plumbing:

No water meter was found. This house seems to be on a public water system, which should have a metering device. Inquire with the seller or the utility as needed to locate the water meter.

- P-3 Plumbing:

No cleanout was noted for the sewer line. It is possible there is an accessible cleanout for the sewer line that is concealed behind finishes or belongings. Sewer line cleanouts are necessary for clearing drain obstructions and for inspecting the building sewer with a sewer camera. While code allows cleanouts to be in crawl spaces, a preferred method is to extend them to an area that is more readily accessible. The UPC requires that underfloor cleanouts be no farther than 20 ft. from the access opening, with a 30 in. wide, 18 in. high path from the access to the cleanout. When those conditions cannot be met, the cleanout must be extended to the exterior. Inquire with the seller for additional information and install an adequate accessible cleanout as recommended by a qualified plumbing contractor. Please note that many older buildings do not have sewer line cleanouts; these are often added when sewer line work becomes necessary.

Efficiencies

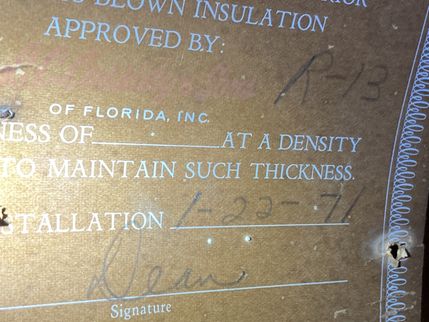

- A-4 Attic:

The attic insulation could be improved to modern standards, which recommend R-30 on the floor and R-13 on walls for insulation Zone 2. R-value is the measure of resistance to heat loss; the higher the R-value the better the insulation. During insulation repairs it is best practices to implement any air seal-up repairs to seal air leakage. Also, be sure you have completed any wiring or other projects that are needed in the attic. Then, hire an insulation contractor to improve thermal barriers.

Completed Items

- RCG-1 Roof, Chimney and Gutters:

The roofing material on this building is a recently installed architectural grade shingle. These are often rated as 30-40 year shingles. In practice, as a roof assembly, I find these last closer to 18-23 years, depending on the quality of the installation, the steepness of the roof, and the amount of exposure. The installation appears neat and professional. Many professional roofing companies will offer limited workmanship warranties. Please note that roofs are not a shingle, they are an assembly, and they require regular cleaning and maintenance to keep them performing reliably. Examples of observations noted during the inspection include:

Recommendation

Disclose any warranty and/or installer information for this new roof installation.

- EDFW-9 Electric Distribution and Finish Wiring:

This house has a smart doorbell installed. These are often tied into an internet connection and may include a camera and other features. I recommend disclosing any needed information about using this system and changing access and passwords that may be needed to control this house feature.

- P-2 Plumbing:

An evaluation of the sewer line below the ground is beyond the scope of this inspection. Due to the age and location of the building, a sewer scope is recommended to further evaluate the sewer line and the below ground connections between the house and the municipal sewer line. Sewer scopes are done using video cameras and can reveal the materials, condition and reliability of the sewer line. If that has been done recently, I recommend disclosing available information. If this has not been done recently, this would be valuable information to disclose to a buyer.

Notes

- GC-2 General Comments:

This hot link provides access to the National Association of Home Builders: Residential Construction Performance Guide.

- G1-2 Grounds:

Common cracks (¼-inch or less) were visible in the driveway at the time of the inspection. Cracks exceeding ¼ inch should be filled with an appropriate sealant to avoid continued damage to the driveway surface from moisture.

- G-5 Garage:

Personal belongings and storage were obstructing a full view of the concrete garage floor.

- RCG-3 Roof, Chimney and Gutters:

There is currently no gutter and downspout system for this building. This seems to be performing well to date. Often houses with this design have drainage installed in the ground to collect and control roof and site runoff. Disclose any information about this drainage system.

- AP-1 Additional Plumbing:

This house has a Koi pond. Inspection of water features is beyond the scope of this inspection. Disclose any installed and maintenance information as needed.

- A-3 Attic:

I did not crawl the crawl space for the attic where there was no ramp or safe way to access the space. Crawling in the V of trusses or on top of framing risks damaging thermal barriers and ceiling finishes and is not a safe way to access an attic. This limited inspection of this space.

📃 The Complete Inspection Report

General Comments

Building Characteristics, Conditions and Limitations

Style of Home: Ranch

Type of Building : Residential Single Family (1 story)

Approximate Square Footage: 900

The approximate square footage (952) listed here is listed as a courtesy and is based off of public records and disclosure. An evaluation of square footage of the buildings and property lines is beyond the scope of this inspection.

Approximate Year of Original Construction: 1971

Unless the wiring in the building has been fully updated, this building likely has wiring that predates the late 1980's. Branch circuit wiring installed in buildings built prior to the late 1980s is typically rated for a maximum temperature of only 60 degrees Celsius. This includes non-metallic sheathed (Romex) wiring, and both BX and AC metal-clad flexible wiring. Knob and tube wiring, typically installed in homes built prior to 1950, may be rated for even lower maximum temperatures. Newer electric fixtures including lighting and fans typically require wiring rated for 90 degrees Celsius. Connecting newer fixtures to older, 60-degree-rated wiring is a potential fire hazard. Repairs for such conditions may involve replacing the last few feet of wiring to newer fixtures with new 90-degree-rated wire, and installing a junction box to join the old and new wiring. It is beyond the scope of this inspection to determine if any such incompatible components are installed. Based on the age of this building, be aware that such components may be present.

In 1978, federal laws were passed to prohibit use of lead and asbestos in building materials. Manufacturers of building materials were allowed to sell existing stocks of materials that were manufactured with lead and asbestos, so even buildings constructed as late as the mid-1980's could possibly contain lead or asbestos. Identification and testing for lead and asbestos and other environmental testing is beyond the scope of this home inspection. If you wish to seek additional information, I recommend contacting an environmental lab or industrial hygienist.

Solid conductor aluminum wiring was used in residential construction for 15 and 20-amp circuits in the 1960's through the 1970's. This wiring has proven to be problematic and a fire hazard, primarily due to problems with loose connections and metal fatigue. I looked hard to find any signs of solid conductor aluminum here. No signs were found. There is always a chance that solid conductor aluminum wiring exists and is concealed from view. If this wiring is ever uncovered during subsequent renovation work, I recommend removal and replacement.

Attending the Inspection: Owner

Occupancy: Occupied

Animals Present: No

Weather during the inspection: Hot and Humid

Approximate temperature during the inspection: Over 90[F]

Ground/Soil surface conditions: Dry

For the Purposes of This Report, the Front Door Faces: North

This hot link provides access to the National Association of Home Builders: Residential Construction Performance Guide.

This home was occupied at the time of the inspection. Inspection of occupied homes presents some challenges as occupant belongings can obstruct visual inspection of and access to parts of the building. We do our best during inspection to work around belongings to discover as much as possible about the house without moving or damaging personal property, however, the presence of personal items does limit the inspection.

Grounds

Drainage and Site

Clearance to Grade: Standard

Downspout Discharge: No downspouts noted

Site Description: Flat

Driveways/Walkways/Flatwork

Driveway: Concrete

Patios: Concrete, Brick

Grounds, Trees and Vegetation

Trees/Vegetation too near building: Yes - Prune Vegetation off House

Trim back bushes in contact with house

Fences

Exterior Fencing: Present, Stain The Fence - Recommended

Exterior Siding, Doors and Windows

Siding and Trim

Trim Material: Wood

Siding Material: Concrete block, Wood

Localized rot repairs are needed to the exterior trim and siding. Hire a licensed general contractor to further evaluate and repair the exterior siding system. Repair and replace all damaged and decaying exterior wood as needed. Please note that this condition can indicate additional concealed damage that is not visible to inspection. During inspection. I noted:

Localized paint failure was noted at the exterior see especially where exposed to the weather. Implement localized painting as needed.

Eaves

Plywood

Bees were noted swarming around the roof eaves. The nest was not visible but clearly there is one in the roof here. Have this nest treated and removed to eliminate a safety hazard.

Exterior Doors

Exterior Door Styles: Glass panel doors

Exterior Window Frames

Window Frames: Vinyl

Recently updated windows. Hurricane rated except for 2 windows at the rear of the house. Caulking was in good condition at the time of the inspection.

Garage

Garage General

Garage Type: Attached

An unprotected opening was found in the garage wall and ceiling finishes. This should be repaired to complete the fire separation between the house and the garage. Large holes should be repaired with the proper sheetrock materials. Small holes and openings should be sealed with mud or high temperature of "fire stop" caulking. Openings with doors should employ listed fire-rated doors.

Garage Doors and Automatic Openers

Overhead Garage Door Type: Metal

Automatic Garage Opener: None needed

Repair the damaged weather stripping on the bottom of the garage door. This is important to prevent water and rodent entry.

Garage Floor

Garage Slab: Concrete

Personal belongings and storage were obstructing a full view of the concrete garage floor.

Extensive storage in the garage inhibited the view of most of the garage and limited visual inspection of this space.

Roof, Chimney and Gutters

Roof Materials

Method of Roof Inspection: Walked on roof

Roof Style: Gable

Flashings, Valleys and Penetrations: Present and Visually Standard

Roof flashings are used to keep a roofing system waterproof where the roofing material starts, stops, changes direction, or is penetrated. During the inspection, we look for standard flashing techniques that could be considered normal or standard in our region. Damaged, incomplete or non-standard flashings can be a sign of an older or less reliable roofing system and may require repair. Any non-standard flashings noted during the inspection will be reported below if found.

Roof Covering Materials: Architectural grade composition shingle

Approximate Age of Roof Covering: 2-5 Years

Overlay Roof: No

Shingle Fastening Accessible For Inspection : No

Please note that when inspecting composition roof installations, I try and look under shingles to see how the shingles have been fastened. Proper fastening is critical for successful roof performance. Often the shingles are bonding so well, they cannot be lifted to inspect the fastening. In this case, I was unable to lift the shingles and see the fastening pattern - they are bonded well and I do not use a flat bar to pry them apart as part of a visual inspection unless there is a reason to start chasing visible leaks. While this limits my visual inspection, this is a good sign, as loose, un-bonded shingles can lead to wind damage and would be written up as a defect.

The roofing material on this building is a recently installed dimensional or architectural grade shingle. These are often rated as 30-40 year shingles. In practice, as a roof assembly, these tend to last about 18-23 years depending on the quality of the installation, the steepness of the roof and the exposure. The installation appears neat and professional. Many professional roofing companies will offer limited workmanship warranties. Please note that roofs are not a shingle. they are an assembly and they require regular cleaning and maintenance to keep them performing reliably. Examples of observations noted during inspection include:

Recommendation

Inquire with the seller about any warranty and/or installer information for this new roof covering installation.

The roofing material on this building is a recently installed architectural grade shingle. These are often rated as 30-40 year shingles. In practice, as a roof assembly, I find these last closer to 18-23 years, depending on the quality of the installation, the steepness of the roof, and the amount of exposure. The installation appears neat and professional. Many professional roofing companies will offer limited workmanship warranties. Please note that roofs are not a shingle, they are an assembly, and they require regular cleaning and maintenance to keep them performing reliably. Examples of observations noted during the inspection include:

Recommendation

Disclose any warranty and/or installer information for this new roof installation.

Gutters and Downspouts

Gutter and Downspout Materials: None

There is currently no gutter and downspout system for this building. This seems to be performing well to date. Often houses with this design have drainage installed in the ground to collect and control roof and site runoff. Disclose any information about this drainage system.

Electric Service

Electric Service Permits Found

No permit stickers or paper work related to electrical work were found on the electric panel. Inquire with the seller for any additional information about this installation.

Electric Service Voltage Tested

Service Voltage: 120/240

Electric Service

Service Entrance: Above Ground

Meter Base Amperage: 200

Electric Service Equipment

Service Entrance (SE) conductor Size: Aluminum, 4/0, 200 amps

Main Panel Amperage: 200 amps

Electric Service Amperage: Unable to determine

Main Electric Panel Location: Garage, Utility room

Panel Manufacturer: Square D

Shelving been installed in front of the electric panel. This presents an inadequate working clearance and a potential safety hazard for people working on or inspecting the electric panel. A 30-inch wide and 36-inch deep unobstructed working clearance is recommended for improved safety. Consult with a general contractor to further evaluate this condition and relocate the panel or improve access as needed.

Electrical Grounding System

Present - Could Not Confirm

During a home or property inspection, every effort is made to inspect the visible components of the electrical system grounding. The grounding system is critical for safely discharging electrical surges, especially in the case of lightning strikes. There is no way in the context of a home inspection to verify the "effectiveness" of the grounding system as much of the system is not visible, and there are no practical tests one can perform in the way we can test a furnace or a plumbing fixture. However, many things can lead me to recommend further evaluation of the grounding system by a licensed electrical contractor, and they will be documented in the observations below if discovered.

Electrical Bonding System

Present - Could Not Confirm

During the inspection, I attempt to visually document electrical system bonding. There is no way in the context of a home inspection to verify the "effectiveness" of system bonding. All metallic systems in the building are required to be "bonded" (connected) to the the building's electrical grounding system. Bonding creates a pathway to shunt static charges (that would otherwise build up on the system) to earth, and to provide a pathway to trip a breaker in the event that these bonded metallic components became energized. There are many things that can lead me to recommend further evaluation of this system by a licensed electrical contractor and they will be documented as repair items in the observations below if discovered.

Electric Distribution and Finish Wiring

Branch Wiring

Wire Material: Copper

Wiring Method: Non-metallic sheathed cable

This building is under-wired by modern standards, which means the wiring system may not respond well to modern electrical demands. This can present safety issues as it tends to encourage overloading of circuits and use of power strips and extension cords. This can also be inconvenient - think two prong receptacles. I recommend hiring a licensed electrician to further evaluate the wiring in this building and add circuits as needed for improved safety, reliability and convenience. Consider adding more circuits for the kitchen, office and media areas in particular. The scope and extent of updating the wiring is subjective and depends on desires and expectations for the wiring system. Examples of some of the guidelines for minimum wiring standards in modern houses include:

- No point along a wall in habitable rooms should be more than 6-feet from an electric receptacle

- No point along kitchen countertops should be more than 2-feet from an electric receptacle

- Two 20-amp circuits for the kitchen receptacles

- One 20-amp circuit for the laundry receptacles

- One 20-amp circuit for the bathroom receptacles

- One separate, individual branch circuit for central heating equipment

- An electric receptacle should be provided for the exterior of the house at both the front and the back of the house

Receptacles and Fixtures

Inspection Method: Representative Testing

A representative number of receptacles and switches were tested during inspection. Any defects found during inspection are noted in this report. Only visible and accessible receptacles and switches were tested during inspection and personal items and furnishings are not moved to access any receptacles or fixtures. Inspection/testing of the electrical system can be challenging. It should be anticipated that not all defects will be discovered and that some issues found may actually not be defects at all. Tools used to verify proper wiring and function can vary wildly in reliability/consistency. The kinds of tools that could be used to confidently analyze the system and its function cannot typically be done in the context of a Standard Home Inspection. I look for indications of issues, based on the age of the home, types of wiring systems used etc, as well as personal experience and by testing with a variety of common tools. Issues identified, will be further discussed with recommendations in the electrical section below.

Electric Receptacles: Three wire receptacles

The loose electric receptacles in the building should be secured to prevent accidental damage to the wiring connections. Securing loose receptacles can often be done by just tightening some set screws between the receptacle and the junction box, though sometimes it can get more complex if the box itself is loose. Repair as needed.

An inoperative light was noted at the exterior garage door. Have this further investigated an repaired as needed. If a new bulb does not correct the problem, consult with a licensed electrical contractor.

Since the 1970s, requirements for GFCI (Ground Fault Circuit Interruption) protection have changed, and locations requiring GFCI protection seem to get added with every code cycle. It is common for older residential buildings to have some or even many electric receptacles that do not meet modern safety standards. GFCIs have proven successful at reducing electrocutions, and it seems likely that someday, every circuit, receptacle, and appliance in the building will require GFCI protection. The first chart below shows how successful GFCIs have been at reducing risks from electrocution. The second illustration shows where GFCI protection is required as of the 2020 NEC and WAC. As a general best practice for safety. For improved safety, I always recommend bringing GFCI protection up to modern safety standards.

During inspection today, I noted that GFCI protection is inconsistent with modern minimum standards for safety in the following locations:

Ceiling Fans

Ceiling Fans: Present and Tested, Dusty

Dust came flying off the ceiling fan(s) during testing. Clean the fan as needed.

The ceiling fans were tested and operating during the inspection.

Smoke and Carbon Monoxide Alarm Systems

CO Alarms: None Noted

The installation of carbon monoxide alarms is recommended for all homes that have fuel burning appliances such as gas or oil furnaces, gas water heaters, gas ovens and cooktops, gas fireplaces and wood stoves. In addition, Washington State law (WAC 51-51-0315) now requires UL 2034 approved carbon monoxide alarms in ALL homes and condominiums being sold in Washington State. The location should be: at least one alarm outside of all sleeping areas and one on each floor of the house. Best practices are to have these alarms hardwired with a battery back-up - though requirements are for the installation to meet manufacturer's specifications. Carbon monoxide is a colorless, odorless gas that can cause sickness, nausea and even death. Alarms have a useful service life of roughly 6 years, so changing them more frequently than smoke alarms is recommended.

Smoke Alarms: None Anywhere

During the home inspection, I try and test a representative sample of the smoke alarms by using the test button on the alarms. This is NOT an accurate test of the sensor, just a test to see if the unit is powered. For reliability, fire marshals recommended updating smoke alarms every ten years and changing batteries bi-annually. The latest data indicate that we should be using photoelectric technology in our smoke alarms for improved fire detection and reducing problems with false alarms, which can lead to disabling of this critical safety system. Unfortunately, the alarms must be removed to determine if they are photo-electric or ionization types. It is surprisingly complex to accurately test a smoke alarm system and determine the reliability, age, and type of sensor technology used, especially as many homes can have half a dozen or more alarms throughout the house. A complete evaluation of smoke alarms is beyond the scope of this inspection. For optimal fire safety, I recommend taking control of these critical safety devices and learning about how to service and maintain your smoke alarm system to keep the building occupants safe. For more information, please read this link. For more information, please read this link.

The installation of carbon monoxide alarms is recommended for all homes that have fuel burning appliances such as gas or oil furnaces, gas water heaters, gas ovens and cook-tops, gas fireplaces and wood stoves. Carbon monoxide is a colorless, odorless gas that can cause sickness, nausea and even death. For more information, consult the Consumer Product Safety Commission at 1-800-638-2772 (C.P.S.C.) Modern standards in many states now recommend one CO alarm outside of all bedrooms and at least 1 per floor of the house.

No smoke alarms were noted anywhere. Smoke alarms are an important safety feature and are recommended inside all bedrooms and in hallways outside of all sleeping areas. It is also recommended that there be at least one smoke alarm on each floor of the house. I recommend having smoke alarms installed to meet modern safety standards.

Low Voltage Wiring

This house has a smart doorbell installed. These are often tied into an internet connection and may include a camera and other features. I recommend disclosing any needed information about using this system and changing access and passwords that may be needed to control this house feature.

Heating, Cooling, Fireplaces and Ventilation

Heating Systems

Air Filters

Filtration Systems: Disposable

Cooling Systems and Heat Pumps

Air Conditioning Present, Heat Pump Present

The following list is a minimum set of requirements to be expected of heat pump or air conditioning servicing. I provide these as a courtesy to show they types of check-ups that should be expected from a professional servicing.

- Check compressor efficiency

- Check refrigerant level

- Clean the condenser coil

- Change or clean air filters

- Inspect contactors and wiring

- Inspect drive-sheaves, pulleys and belts

- Check and adjust for proper air flow

- Clean the blower motor as needed

- Lubricate all motors and shaft bearings

- Check, calibrate and program the thermostats and be sure the thermostat has adequate batteries as needed

- Check unit smoke detector, clean filter if applicable

- Check safety disconnect, laser-temp -- check across contacts

Manufacturer: GrandAire

System Type: Air Source

Listed Nominal Capacity: 2.5 Tons

Energy Source: Electric

Age: 2019

The insulation for the refrigerant lines for the AC is damaged and requires repair. This should be done to ensure reliable and efficient performance from this unit. .

Heating and Cooling Distribution Systems

Heat Source in Each Room: Present

Distribution Method: Forced Air / Ducts

The ductwork for the heating delivery system is in generally poor condition and requires repairs. The ductwork should be cleaned and all joints sealed using duct mastic. Areas that are poorly supported should be re-supported and where they are outside the conditioned space, they should be insulated to R-8 or better. Hire a qualified heating contractor to further evaluate and repair.

A number of problems were noted with the heating and cooling ducts during inspection. I recommend additional inspection and repair of the heating ductwork system by a qualified heating and cooling contractor. Implement repairs as recommended to ensure reliable performance.

Examples of Observations Noted During Inspection Include

- The ductwork insulation is damaged and requires repair

Mechanical Ventilation Systems

Bath Fan Ducting: Disconnected in Attic

Kitchen Fan Ducting: Ductwork not visible

Determining proper ventilation to the exterior from kitchen, bath, and laundry fans can be tricky as exhaust fan ductwork is often concealed behind finishes and fan terminations can be all over the house from the roof to the foundation, presenting difficulties for systematically checking every fan termination. During inspection, every effort is made to verify proper terminations of fan vents to the exterior, but it is possible to miss something here that is latent or concealed.

The exhaust ductwork for the bathroom fans are disconnected in the attic and requires repair to ensure fan exhaust is properly venting to the exterior. Having exhaust fans venting into the attic can cause lead to seasonal condensation and moisture controls problems and could damage the attic building materials. Repair to ensure proper discharge of air to the exterior and be sure exhaust ductwork is insulated to R-8 or better to reduce risks of seasonal condensation.

Gas Fireplaces

Fireplace Types: No gas fireplaces or woodstoves noted

Solid Fuel Fireplaces

Fireplace Types: No wood burning fireplaces or appliances noted

Plumbing

Water Meter

Not Found - Inquire With Seller

No water meter was found. This house seems to be on a public water system, which should have a metering device. Inquire with the seller or the utility as needed to locate the water meter.

Water Service Supply

Pipe Material: Copper

Water Supply: Public water

Pressure Reducing Valve: None noted

Main Water Shut-off Location: Water Shut Off Location Noted

This shows the location of the main water shut off located at the exterior.

Distribution Pipe

Pipe Insulation: Not visible

Supply Pipe Materials: Copper

Copper water supply pipes were installed. Copper pipes installed prior to the late 1980's may be joined with solder that contains lead, which is a known health hazard especially for children. Laws were passed in 1985 prohibiting the use of lead in solder, but prior to that solder normally contained approximately 50% lead. Note that testing for toxic materials such as lead, is beyond the scope of this inspection. Consider having a qualified lab test for lead, and if necessary take steps to reduce or remove lead from the water supply. Various solutions include:

- Flush water taps or faucets. Do not drink water that has been sitting in the plumbing lines for more than 6 hours

- Install appropriate filters at points of use

- Use only cold water for cooking and drinking, as hot water dissolves lead more quickly than cold water

- Treat well water to make it less corrosive

- Have a qualified plumber replace supply pipes and/or plumbing components as necessary

Functional Flow: Average

Circulation Pump: None Noted

Waste Pipe and Discharge

Discharge Type: Public Sewer - Seller

Waste and Vent Pipe Materials: Cast Iron

Location of Sewer Cleanout: Not Found

No cleanout was noted for the sewer line. It is possible there is an accessible cleanout for the sewer line that is concealed behind finishes or belongings. Sewer line cleanouts are necessary for clearing drain obstructions and for inspecting the building sewer with a sewer camera. While code allows cleanouts to be in crawl spaces, a preferred method is to extend them to an area that is more readily accessible. The UPC requires that underfloor cleanouts be no farther than 20 ft. from the access opening, with a 30 in. wide, 18 in. high path from the access to the cleanout. When those conditions cannot be met, the cleanout must be extended to the exterior. Inquire with the seller for additional information and install an adequate accessible cleanout as recommended by a qualified plumbing contractor. Please note that many older buildings do not have sewer line cleanouts; these are often added when sewer line work becomes necessary.

An evaluation of the sewer line below the ground is beyond the scope of this inspection. Due to the age and location of the building, a sewer scope is recommended to further evaluate the sewer line and the below ground connections between the house and the municipal sewer line. Sewer scopes are done using video cameras and can reveal the materials, condition and reliability of the sewer line. If that has been done recently, I recommend disclosing available information. If this has not been done recently, this would be valuable information to disclose to a buyer.

Water Heater

System Type: Tank

Manufacturer: Bradford-White

Size: 40 gal

Energy Source: Electricity

Pad: None Needed

Drain Pan: None Noted - Recommended

Expansion Tank: None Noted - Recommended

Relief Valve: Present - Not Tested, Terminates Too High

A temperature and pressure relief valve (TPRV) is required on all water heaters to discharge any excessive pressure within the tank. A discharge pipe should be attached to the valve and directed to a safe location away from body contact. Newer installations must be directed to the building exterior or to an approved indoor drain receptor. Most manufacturers suggest that homeowners test these valves at least once a year by lifting the lever to ensure the valve discharges properly and also recommend inspection of these safety devices every three years. The picture here shows a typical TPRV. They may also be found on the side of the heater on some models. I do not test these valves due to the possibility that they may leak after testing. A leaking or inoperative TPRV should be replaced immediately by a licensed plumber.

Due to inconsistencies between both UPC and IPC Plumbing codes, and water heater manufacturer's instructions, and TPRV manufacturer instructions, it is not actually possible to install the drain from the Water Heater TPRV "properly." There are conflicts with distance of termination to the floor/ground, types of pipes approved, and diameters of pipes approved. Additional confusion is added when jurisdictional inspectors approve installations/materials specifically not allowed by both codes and manufacturers. My recommendations will vary depending on the installation and will be included in the applicable narratives below.

Most codes defer to manufacturer instructions and I favor those recommendations. The yellow tag on the valve states clearly the termination should be 6" above the floor which is more consistent with the UPC code requirements.

No drain pan has been installed below the water heater here. A drain pan is recommended under water heaters that are located in finished spaces or where a leak could damage finishes. Where a pan does not already exist, the tricky part is providing a drain to the outside. A pan without a drain is often of limited benefit / protection. For improved protection from accidental water heater leaks, and where a drain is difficult to install, consider a pan with a moisture alarm and a flood-safe device such as this: Watts Water Heater Leak Prevention.

No thermal expansion device was found for the water heating system. Some type of thermal expansion device is required for closed plumbing systems. This is typically provided by an expansion tank at the water heater. Thermal expansion devices help prevent unwanted pressure build-up in piping systems.

Recommended Contractor: Plumber

The discharge tube for the water heater relief valve is installed too high off the ground. Discharge tubes should always terminate by pointing toward the ground to eliminate a scald hazard and should terminate between 6-inches and 24-inches (UPC) off the ground, though specific requirements can vary by manufacturer and jurisdiction. Ideally, the discharge tube for a relief valve:

- Terminates to an exterior location or above a drain, though this is not always possible

- Slopes to drain to prevent water pooling inside the discharge tube

- Is not made from pipe with an inside diameter less than 3/4 on an inch

- Terminates to a visible location that can be monitored for leaks and discharges

- Does not have a threaded termination point which would prevent accidental capping of this important discharge

- Does not terminate into a drain pan

I recommend having this relief valve discharge tube further investigated and repaired as recommended by a licensed plumber.

An expansion tank is recommended for the water heater. Expansion tanks help reduce pressure on the plumbing system by creating a buffer or a place for water to expand into as water swells during thermal expansion. Installation of expansion or pressure tanks is modern installation practice and will be required if a pressure reducing valve has been installed on a public water supply or if for any reason the plumbing system is closed. Open systems do not require an expansion device though they can still be an excellent way to help prevent build-up of pressures in the piping system. Consult with a qualified plumber to install.

Exterior Hose Bibs

Operating

Additional Plumbing

Interior

Floors and Floor Materials

Floor Materials: Wood Laminate

Floor Settlement: None noted

Walls, Ceilings, Trim, Hallways and Closets

Wall and Ceiling Materials: Drywall

Water stains were noted on the ceiling in the bedroom Disclose any history of prior leakage to get a better sense if repairs may be needed to prevent another leak. Many water leaks are intermittent or related to specific weather conditions or occupant behavior; it is impossible for us to distinguish these conditions during a one-time inspection or to know if repairs could be needed to prevent future leaks. Repair damaged finishes and paint as needed for a proper cosmetic appearance and implement additional repairs as needed to prevent future leaks.

Wall Insulation and Air Bypass

Wall Insulation: Not Visible

Stairs and Railings

None

Interior Doors

Interior Doors: Hollow Core

Windows

Window Glazing: Double pane

Interior Window Frame: Vinyl

Window Styles: Double hung

Kitchen

Sinks and Faucets

Tested

Cabinets and Countertops

Countertop Material: Plastic laminate

Cabinet Material: Wood

Disposers

Disposer: None noted

Dishwasher

Dishwasher: None Noted - No Plumbing and No Location for One

There is no dishwasher for the kitchen and no space in which to install a dishwasher. If you wish to have a dishwasher here you will need to have one installed including provisions for electricity, drain lines and water supply.

Ventilation Method

Not visible

Ranges, Ovens and Cooktops

Range/ Oven /Cook-tops: Electric, Unable to test oven due to contents but the stove top was functioning

Refrigerators

Refrigerator: Operating

General Kitchen Condition

Remodeling needed soon

Overall, the kitchen finishes and appliances are old and in the last phase of their useful service life. While only minor repairs are needed at the moment, a complete kitchen remodel would be logical in the near term to update this kitchen. Urgency depends on desire for cosmetic appearance and reliability.

Laundry Facilities

Washer

Tested, Hoses (Old and Unreliable)

During inspection, I try and run the clothes washing machine. This is mostly so that I can push water down the drain to test the waste piping system. Running the clothes washer during an inspection is not a reliable test of the appliance. I am not actually doing a load of laundry, so please note the limitations of this test.

A moisture alarm with water shut-off features is recommended under the washing machine to protect against accidental leaks in the supply hoses. Pans can be effective when there is a drain, but even these will not protect against a burst supply connector. A moisture alarm with automatic shut-off will. Watts is a brand I have seen installed: Link.

Dryer

Tested

Proper dryer exhaust venting is critical for safe and reliable performance from the dryer. Here are some basic rules of thumb for dryer exhaust duct installation: Unless a vent-free appliance is being used, the dryer exhaust vent must terminate outdoors. It should be no more than 25 feet long and for every 90 degree turn subtract 5 feet and for every 45 degree bend subtract 2.5 feet. Use only smooth-wall metal vent pipe @ 4 inch pipe diameter. Do not use plastic pipe and plastic flex pipe. If a flexible connector is needed behind the dryer use a short amount of corrugated metal pipe. If the exhaust duct is getting pinched behind dryer, consider use of a dryer vent box, pictured here. Flex and corrugated pipes should never be used in concealed spaces such as through walls or in attic or crawl spaces. Insulate dryer exhaust duct where it passes through unconditioned spaces to prevent condensation that could hasten lint build-up inside the pipe. Do not use screws to connect pipe as these can trap lint. Secure duct with foil tape as needed. Be sure duct is sleeved properly so that it will not trap lint and clean the vent regularly, especially if it is a long exhaust run.

Power Source: Electric

Exhaust Duct: Ducted to Exterior, Cleaning Needed

Laundry Ventilation

Type: None noted

No ventilation fan was found for the laundry room. This is common in older homes and required in newer buildings. Installing a ventilation fan is recommended to help control indoor relative humidity. This fan can be run during operation of the laundry and/or placed on a timer to come on automatically throughout the day using a timer. Hire a qualified contractor to further evaluate and repair.

Master Bathroom

Sinks and Cabinets

Tested

Please note that storage below the sink in the cabinet is restricting inspection of this space. I tried to look around these personal items, but some of the cabinet and finishes were not visible.

Toilet

Tested

Bathtub / Shower

Tested

Shower Type: Tile

The tile in the bathroom shower surround is old and may require updating at any time. The reliability of tile depends on what the tile is mounted on and what it is mounted with: this is not visible to inspection. Hire a tile specialist to further evaluate and repair this tile as recommended. Additional inspection could reveal an easy repair or concealed water damage and the need for full replacement, a significant expense. Examples of observations and red flags found during inspection include:

Bathroom Ventilation

Type: Fan and window

General Bath Condition

Renovation needed - One

Guest Bathroom

Sinks and Cabinets

Tested

Toilet

Tested

The toilet in the guest bath has not been caulked to the floor. Caulking the toilet to the floor is recommended and even required though opinions on this can vary. I prefer caulking the toilet to the floor, but leaving a gap on the back of the toilet that remains un-caulked so if the toilet leaks, water has an escape route. The biggest risk of not caulking the toilet to the floor is that the toilet can become loose which is the biggest problem here. Repair as recommended by a licensed plumber.

Bathtub / Shower

Tested

Tub Type: Cast Iron

The shower head in the guest bathroom shower needs to be cleaned or replaced. Calcium build-up and scaling is causing the shower head to spray in right angles and water is spraying out of the shower. If the house is on a well system, this can also indicate that sediment is entering the water supply.

The caulking around the shower enclosure is old and failing and should be replaced.

The tub fill spigot is leaking and requires repair or replacement.

Bathroom Ventilation

Type: Bath fan

General Bath Condition

Standard

Attic

Attic Access

Viewed at access

I did not crawl the crawl space for the attic where there was no ramp or safe way to access the space. Crawling in the V of trusses or on top of framing risks damaging thermal barriers and ceiling finishes and is not a safe way to access an attic. This limited inspection of this space.

There is no ramp or safe way to access the attic space. Crawling through insulation and on top of framing risks damaging thermal barriers and ceiling finishes and is not a safe way to access an attic. This limited inspection of this space.

Roof Framing and Sheathing

Rafters: Truss

Sheathing: Plywood

Attic Insulation

Insulation Type: Fiberglass

Approximate Insulation R-Value on Attic Floor: Inconsistent

The attic insulation could be improved to modern standards, which recommend R-30 on the floor and R-13 on walls for insulation Zone 2. R-value is the measure of resistance to heat loss; the higher the R-value the better the insulation. During insulation repairs it is best practices to implement any air seal-up repairs to seal air leakage. Also, be sure you have completed any wiring or other projects that are needed in the attic. Then, hire an insulation contractor to improve thermal barriers.

Attic Fan Exhaust Vents

The exhaust ductwork for the bathroom fan is disconnected in the attic and requires repair to ensure fan exhaust is properly venting to the exterior. Having exhaust fans venting into the attic can cause lead to seasonal condensation and moisture controls problems and could damage the attic building materials. Repair to ensure proper discharge of air to the exterior and be sure exhaust ductwork is insulated to R-8 or better to reduce risks of seasonal condensation.

Attic and Roof Cavity Ventilation

Attic Ventilation Method: Soffit vents, Ridge vents

Attic and roof cavity ventilation is a frequently misunderstood element of residential construction. All roof cavities are required to have ventilation. The general default standard is 1 to 150 of the attic area and ideally, this comes from at least 60% lower roof cavity ventilation and 40% upper, but this is a wild over-simplifications of the subject. As a good guiding principle the most important elements for healthy attic spaces, which are traditionally insulated and ventilated are:

- Make sure the ceiling between the living space and the attic is airtight

- Ventilate consistently across the whole lower part of the roof cavity with low, intake soffit venting

- Upper roof cavity venting is less important and if over-installed can exacerbate air migration into the attic from the living space.

- Avoid power ventilators which can depressurize the attic and exacerbate air migration from the house into the attic.

For more information, please see: Link

Structure and Basement

Foundation

% of Foundation Not Visible: 90%

Building Configuration: Slab on grade

Foundation Description: Poured concrete

Floor, Wall and Ceiling Framing

Wall Framing: Not visible, 2x4

Ceiling Framing: 2x4

Checking Out Procedure

Check Out List

Oven: Off

Off

Lights: Off

Off Client Still in House

Client Still in House

Heating and Cooling: Restored to Pre-inspection temperatures

Restored to Pre-inspection temperatures

Appliances: Off / finishing cycle

Off / finishing cycle

Wind Mitigation Form

Wind Mitigation Form

Invoice -- 📃 The Complete Inspection Report

8300 76th Ave N

| Inspection Fee | $0.00 |

| $0.00 | |

| $0.00 | |

| DUE |

-700x500%20(1)%20(1).jpg)

.jpg)

.png)

(1) (1).jpg)

.png)

.png)