The Scope and Purpose of a Home Inspection

Standards of Practice

INSPECT LV performs all home inspections in conformity with NAC 645D.

Purchasing Property Involves Risk

The purpose of a home inspection is to help reduce the risk associated with the purchase of a structure by providing a professional opinion about the overall condition of the structure. A home inspection is a limited visual inspection, and it cannot eliminate this risk. Some homes present greater risk than others, which we cannot control.

This report does not endeavor to document superficial imperfections recognizable to a layperson, nor does it serve as an exhaustive list of items necessitating repair or routine upkeep. The purpose of this report is to identify "Material Defects". The International Association of Certified Home Inspectors (InterNACHI) defines Material Defect as a "specific issue with a system or component of a residential property that may have a significant, adverse impact on the value of the property, or that poses an unreasonable risk to people”. This report contains many Property deficiencies as well as some informational aspects and positive attributes that were observed by the inspector. However, the report will not encompass every existing or potential deficiency. This report only represents the condition of the visually inspected areas of the Property while the Inspector was on site. The photographs depicted in this report are only representative photographs and may not represent the totality of all conditions. Property conditions may change between the conclusion of this inspection and the title transfer date. A thorough final walk-through prior to title transfer helps protect against unexpected surprises and is highly recommended. Please download a complimentary copy of our Final Walkthrough Checklist.

A Home Inspection is Visual and Non-destructive

The descriptions and observations in this report are based on a visual inspection of the structure. We inspect the aspects of the structure that can be viewed without dismantling, damaging, or disfiguring the structure and without moving furniture and interior furnishings. Areas that are concealed, hidden, or inaccessible to view are not covered by this inspection. Some systems cannot be tested during this inspection as testing risks damaging the building. For example, overflow drains on bathtubs are generally not tested because the seals are often compromised, and if leaking, they could damage components and finishes below. Our procedures involve non-invasive investigation and non-destructive testing, which will limit the scope of the inspection. Our inspection service strictly abides the limitations defined by NAC645D.470, emphasizing non-invasive, non-destructive visual assessment. Certain components may have latent defects not immediately visible during the inspection.

This is Not a Code Compliance Inspection

This inspection and report are not intended for city/county code compliance. During the construction process, structures are inspected for code compliance by municipal inspectors. Framing is open at this time, and conditions can be fully viewed. However, during inspections of finished homes, Framing is not open and conditions cannot be fully viewed. All houses fall out of code compliance shortly after they are built, as the codes continually change. National building standards and practices are augmented at least every three years for all disciplines. Municipalities can adopt and phase in sections of the codes on their timetables. There are generally no requirements to bring older homes into compliance unless substantial renovation is being done. You are encouraged to ensure that all relevant installations were accomplished by a licensed and skilled contractor, leveraging the advantages of the permit process, and adhering to manufacturer's installation guidelines.

This is Just Our Opinion

Construction techniques and standards vary. The observations in this report are the opinions of a licensed Nevada Inspector of Structures. Other inspectors and contractors are likely to have some differing opinions. You are welcome to seek opinions from other professionals. The overall goal of a home inspection is to help ensure that your expectations are appropriate for the house you are proposing to buy. To this end, we assist with the discovery by showing and documenting observations during the home inspection. This should not be mistaken for a technically exhaustive inspection designed to uncover every defect in a building. Such inspections are available, but they are generally cost-prohibitive to most homebuyers.

This report does not substitute for or serve as a warranty or guarantee of any kind. Home warranties can be purchased separately from insuring firms that provide this service. The purchase of a home warranty, where applicable, is also recommended. It is important to research the home warranty companies available to ensure adequate coverage will be provided and available when needed. INSPECT LV does not provide contractor referrals to address items noted in this report. Were we to do that, the perception exists of impropriety. INSPECT LV views the perception of impropriety to be an impropriety. If this inspection was performed in conjunction with a sale of the Property, it is recommended the Client seek specific recommendations from their Agent. It is always advised the Client uses a licensed and qualified contractor to further review or repair any items noted in this report. Whether deemed necessary or not, all contractor recommendations should be abided during your due diligence / contingency period. Always verify the licensing status of any contractor with the Nevada State Contractors Board by calling (702) 486-1100 or visiting their website.

INSPECT LV is a privately held Nevada Corporation, a member of the Southern Nevada Association of Professional Property Inspectors (SNAPPI), Better Business Bureau of Southern Nevada (BBB), International Association of Certified Home Inspectors (NACHI), and Las Vegas REALTORS (LVR).

__________________________________________________________________________________________________________________________________________________________________________________________________

How to Read This Report

Getting the Information to You

This report is designed to deliver important and technical information in a way that is easy for anyone to access and understand. If you are in a hurry, you can take a quick look at our "Summary Page” and quickly get the critical information for important decision-making. However, we strongly recommend that you take the time to read the full Report, which includes digital photographs, captions, diagrams, descriptions, videos, and hot links to additional information.

The best way to get the layers of information presented in this report is to read your report online, which will allow you to expand your learning about your house. You will notice some words or series of words highlighted in blue and underlined – clicking on these will provide you with additional information.

This report can also be printed to a PDF file and printed on paper as desired.

Chapters and Sections

This report is divided into chapters that parcel the home into logical inspection components. Each chapter is broken into sections that relate to a specific system or component of the home. You can navigate between chapters with the click of a button on the left-side margin.

Most sections will contain some descriptive information in black font. Observation narrative, done in colored boxes, will be included if a system or component is found to be significantly deficient in some way or if we wish to provide helpful additional information about the system or the scope of our inspection. If a system or component of the home was deemed to be in satisfactory or serviceable condition, there might be no narrative observation comments in that section, and it may simply say “tested” or “inspected.”

Observation Labels

All narrative observations are colored, numbered, and labeled to help you find, refer to, and understand the severity of the observation. Observation colors and labels used in this report are:

- Material Defect:Specific issue with a system or component that may have a significant, adverse impact on the value of the property, or that poses an unreasonable risk to people- Enlisting the services of a licensed and qualified contractor is necessary.

- Repair:Conditions that appeared to deviate from their original design and/or function- Enlisting the services of a licensed and qualified contractor would be the most suitable course of action.

- Maintenance:Deferred maintenance concerns, requiring suitable action to restore the components to optimal condition.

- Monitor:Regularly observe this discovery. If or when needed, enlist a qualified and licensed contractor.

- Efficiency:Repair, modification or replacement typically enhances component or system efficiency and may reduce utility costs- Enlisting the services of a licensed and qualified contractor would be the most suitable course of action.

- Upgrade:Improvement can enhance aesthetics, safety, or efficiency; often reflecting changes to building standards and practices.

- Due Diligence:Significance of the discovery remains uncertain, suggesting further investigation is warranted so that buyers can better understand recent servicing, repairs or maintenance, or even construction history and building/site design.

- Informational:Provided for informational purposes or to benchmark the property condition during the inspection.

- Positive:Favorable property characteristic.

- Limitations:Conditions present at the time of inspection which limited the scope of this visual inspection.

- 📃:Supplementary disclosures

Summary Page

The Summary Page is designed as a bulleted overview of all the observations noted during the inspection. This helpful overview is not a substitute for reading the entire inspection report. The entire report must be read to get a complete understanding of this inspection report, as the Summary Page does not include photographs or photo captions.

The Uniform Building Inspection Report

🌵 Grounds

Water Meter

Irrigation

Site Elements, Grading, Drainage

Retaining Walls

Fences and Gates

Grounds, Trees and Vegetation

Grounds / Parking Lighting

Driveways/Walkways/Flatwork

Exterior Stairs

Outbuildings, Trellises, Storage Sheds, Barns

🛟 Pools and Spas

Pool / Spa

Heating Equipment

Filters, Skimmers, Drains, & Cleaning Systems

Pump Equipment, Plumbing & Electrical Systems

Decks, Steps, & Coping

Safety Devices

🔥❄️ Heating, Cooling, Fireplaces and Ventilation

Heating System 1

Heating System 2

Heating System 3

Heating System 4

Heating System 5

Vents and Flues

Air Filters

A/C 1

A/C 2

A/C 3

A/C 4

A/C 5

A/C 6

AC Refrigerant Lines

Condensate Drains

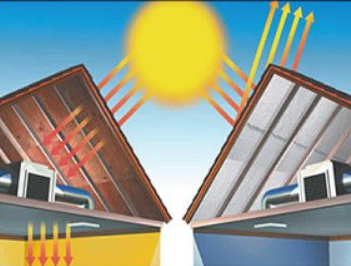

▲T (Delta T)

Heating and Cooling Distribution Systems

Mechanical Ventilation Systems

Non-solid Fuel Fireplaces

🪠 Plumbing

Exterior Hose Bibs

Water Service Supply

Distribution Pipe

Waste Pipe and Discharge

Additional Sinks

Sump Pumps and Drains

Sewage Ejector Pumps

⚡ Electric Service

Electric Service

Electrical Bonding System

Electrical Grounding System

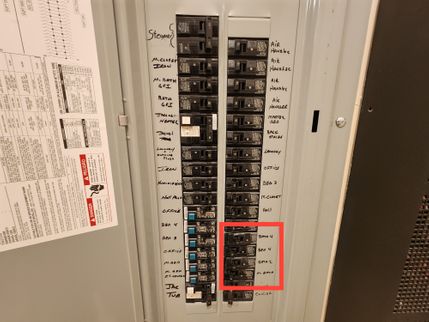

Main Electric Panel

Sub Electrical Panel (Laundry Room)

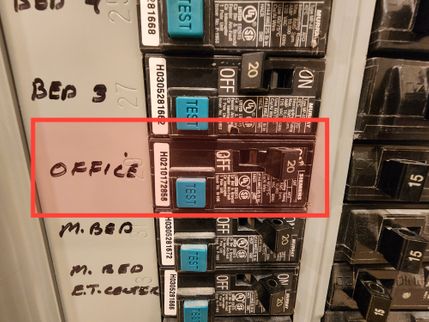

Sub Electrical Panel (Kitchen Pantry)

Sub Electrical Panel (Pool Equipment Area)

Appliance Disconnects

🔌 Electric Distribution and Finish

Branch Wiring

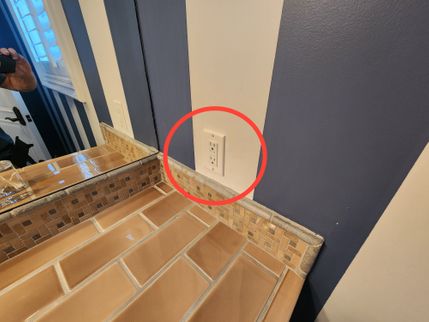

Switches, Receptacles and Fixtures

Ceiling Fans

Low Voltage Wiring

🛁 2nd Floor SW Guest Bathroom (Casita)

Sinks and Cabinets

Water Closet

Bathtub / Shower

Bathroom Ventilation

General Bath

🛁 1st Floor SW Guest Bathroom (Ensuite)

Sinks and Cabinets

Water Closet

Bathtub / Shower

Bathroom Ventilation

General Bath

🛁 2nd Floor NE Guest Bathroom (Ensuite)

Sinks and Cabinets

Water Closet

Bathtub / Shower

Bathroom Ventilation

General Bath

🛁 2nd Floor SE Guest Bathroom (Ensuite)

Sinks and Cabinets

Water Closet

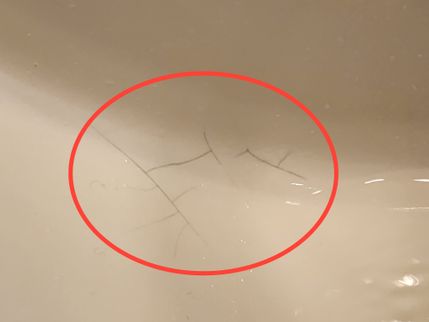

Bathtub / Shower

Bathroom Ventilation

General Bath

🛁 1st Floor SE Guest Bathroom (Ensuite)

Sinks and Cabinets

Water Closet

Bathtub / Shower

Bathroom Ventilation

General Bath

🛋️ Interior

General Interior Photos

Walls, Ceilings, Trim, Hallways and Closets

Wall Insulation and Air Bypass

Interior Doors

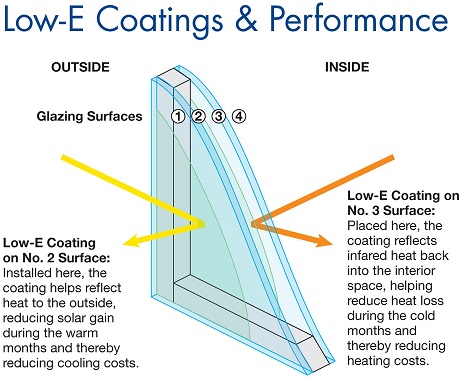

Windows

Smoke and Carbon Monoxide Alarm Systems

Floors and Floor Materials

Stairs and Railings

Misc. Systems

🍴 Kitchen

Sinks and Faucets

Cabinets / Countertops

Garbage Disposal

Dishwasher

Ventilation Method

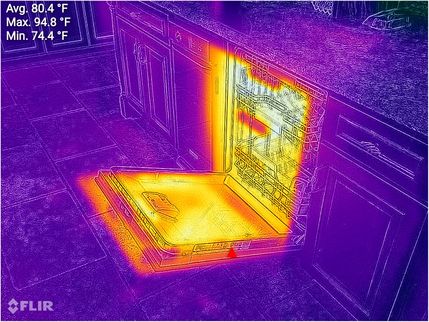

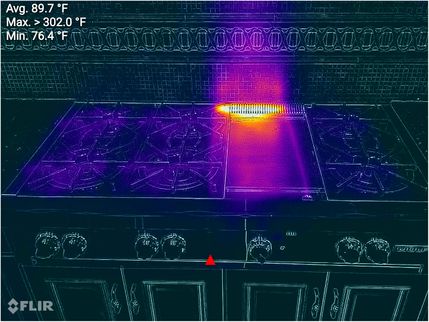

Ranges, Ovens and Cooktops

Microwave

Refrigerators

General Appliances

General Kitchen Condition

🏗️ General Comments

Building Characteristics, Conditions and Limitations

Approximate Year of Original Construction: 2004

Building Type: Single family (2-story)

Approximate Square Footage: 7657

Attendance (%): Inspector(s), Buying agent (At Conclusion), Homeowner(s) (100%), Listing agent (50%)

Occupancy: Occupied

Occupied

PERSONAL PROPERTY NOTE

The client is reminded that this is a "Real Property" inspection. Real property components are those fixtures or appurtenances physically attached to the property that cannot be removed without causing significant disturbance or damage. Personal property components are not included in the scope of this inspection. Several specific examples are cited in our Agreement such as washer, dryer and refrigerator.

Animals Present: No

Weather Conditions: Hot, Clear

Approximate Temperature: 90° F

Ground/Soil surface conditions: Dry

Front Door Faces: Northerly

Northerly

Sub Area: No

No

Outbuilding(s): No

No

Pool/Spa: Yes

Yes

Utilities Present: Electric

Electric Water

Water Natural Gas (NG)

Natural Gas (NG)

Renovations: Original/mostly original

Original/mostly original

New Construction: No

No

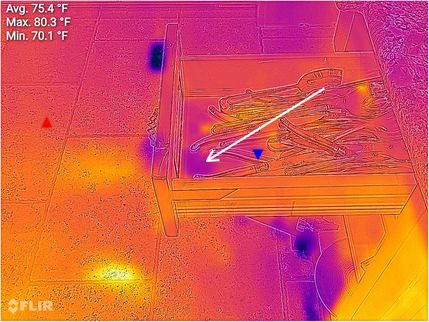

OCCUPIED / FURNISHED

This home was occupied at the time of the inspection. Inspection of occupied homes presents some challenges as occupant belongings can obstruct visual inspection of and access to parts of the building. We do our best during inspection to work around belongings to discover as much as possible about the house without moving or damaging personal property, however, the presence of personal items does limit the inspection.

🌦️ Roof and Chimney

Roof Materials

Roof Inspection Method: Viewed with drone

The client is advised the inspector did not traverse the roof. Any time there is foot traffic on the roof the potential for damaged exists. Robotic drones significantly increase the viewable area and the potential for damage is negated. The level of detail is increased significantly and the potential for damage is negated. Only the pertinent photographs are included in this report.

Roof Penetrations: Roof fully reviewed

Roof fully reviewed

Roof fully viewed from roof level, which allowed full view of the roof and all roof penetrations whether traversed or not.

Roof Style: Gable, Hip, Valley, Shed

Approximate Roof Pitch: 4/12 to 6/12

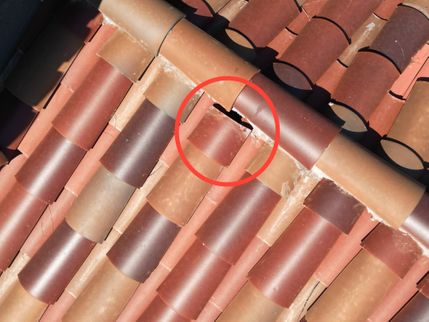

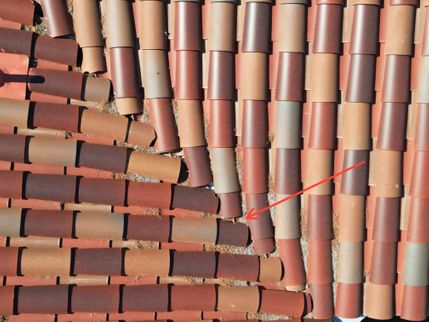

Roof Covering Materials: Clay tile (Cracked, Slipped), Concrete tile (Slipped)

Clay tiles can last up to 100 years; however, no roof is maintenance free. INSPECT LV will not walk a clay tile roof. Repairing slipped or damaged or tiles is a recurring preventive maintenance issue. Roof underlayment typically lasts from 10 to 25 years depending on the materials, weather, and other conditions. Roofs should be inspected annually and after major weather events.

Concrete tiles can last 50 years or more. However, the roof is not maintenance free. Repairing slipped or damaged or tiles is a recurring preventive maintenance issue. Roof underlayment typically lasts from 10 to 25 years depending on the materials, weather, and other conditions. Roofs should be inspected annually and after major weather events.

Roof Flashings and Valleys: Present and Visually Standard

Roof flashings are used to keep a roofing system waterproof where the roofing material starts, stops, changes direction, or is penetrated. During the inspection, we look for standard flashing techniques that could be considered normal or standard in our region. Damaged, incomplete or non-standard flashings can be a sign of an older or less reliable roofing system and may require repair. Any apparent non-standard flashings noted during the inspection will be reported below, if observed.

CRACKED CLAY TILES

On a typical inspection of a typical Las Vegas home our inspection firm generally identifies three to five cracked roof tiles on a 2000 square foot home. Cracked roof tiles are typical because wind causes the tiles to shudder, crack, and chip. Contrary to popular belief concrete roof tiles do very little to provide water tight integrity to the roof. The water tight integrity is provided by the oil impregnated tar paper located beneath the tiles (known as "felt" in the building industry). The concrete tiles act as an insulator and protect the felt from direct exposure to the sun to prevent the felt from drying out.

CLEAN ORGANIC DEBRIS FROM ROOF

Clean organic debris from the roof to ensure unrestricted paths for roof drainage. This discovery is conducive to damming water, which increases the likelihood of moisture intrusion issues. This is routine maintenance that should be part of a regular maintenance schedule. Because accessing a roof is inherently dangerous, this maintenance action should be performed by a licensed and qualified Roofing Contractor.

Eaves, Soffits, and Fascia

None noted

None noted

📝: Covered soffit

Staining: No

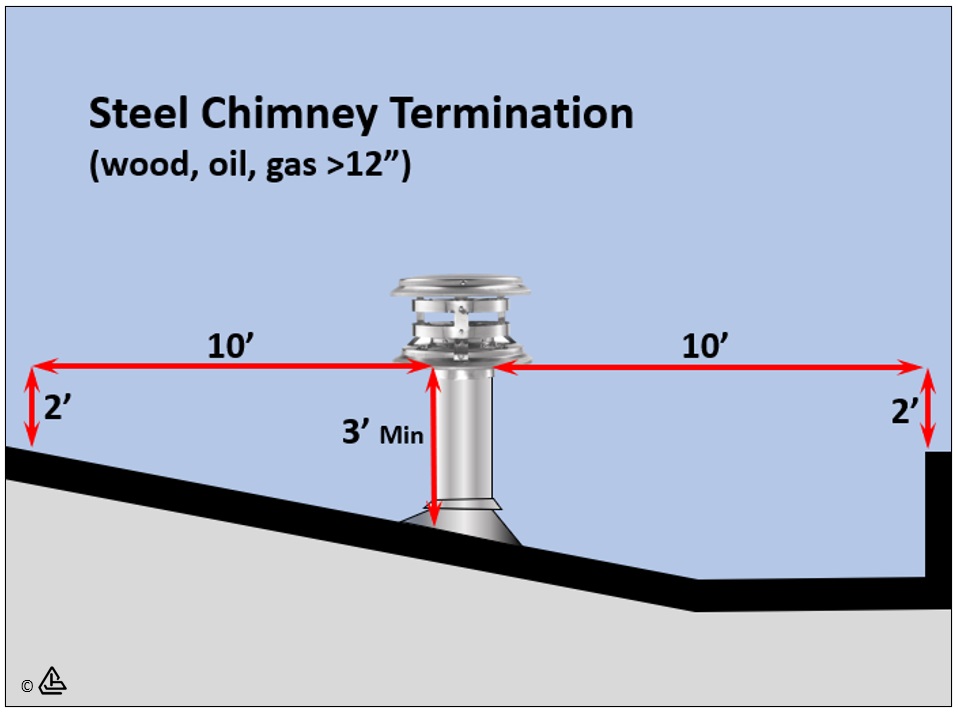

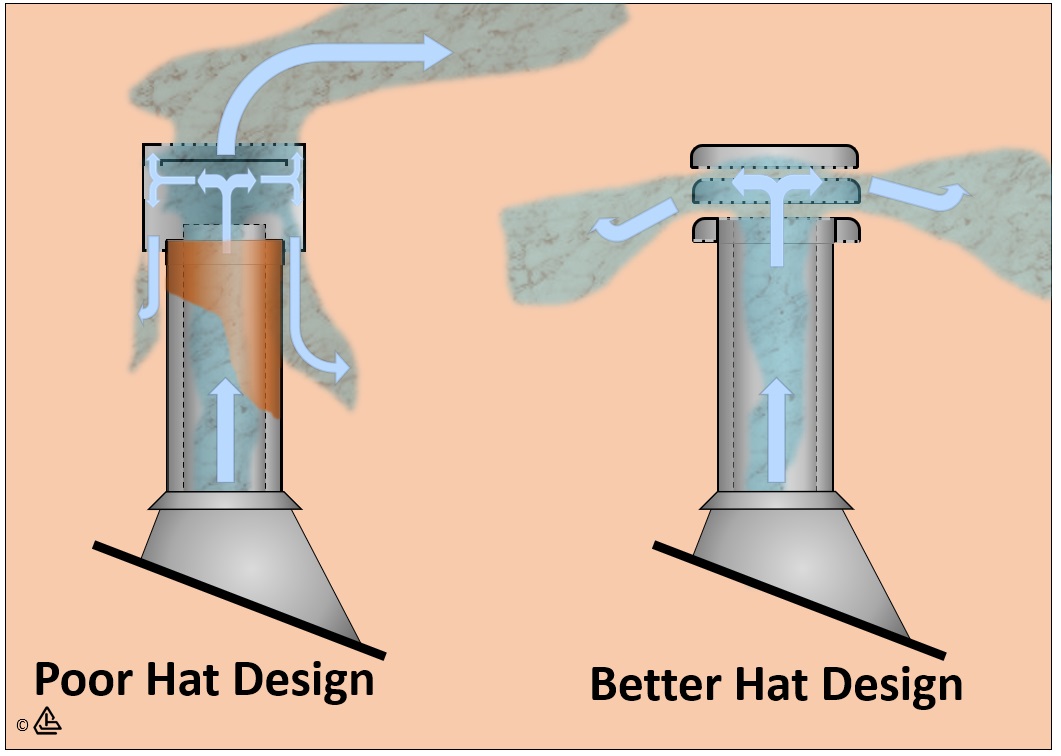

Chimneys

✏️: Present

Chimney Interior Review Method: Partially reviewed from the roof

Chimney Material: Metal

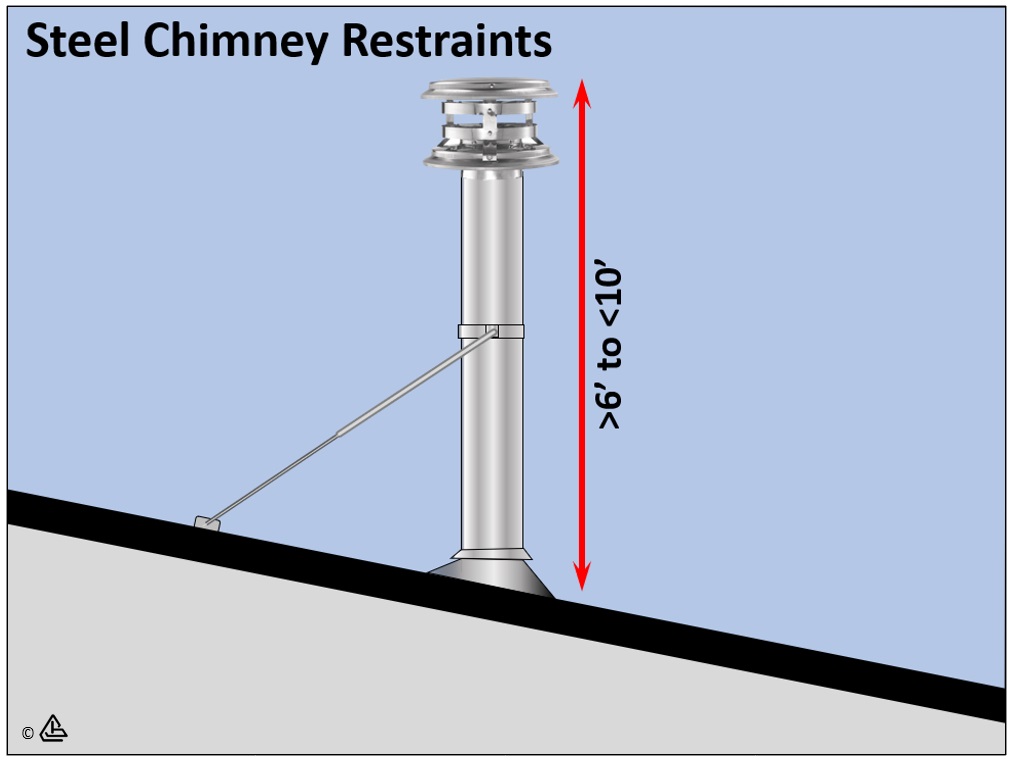

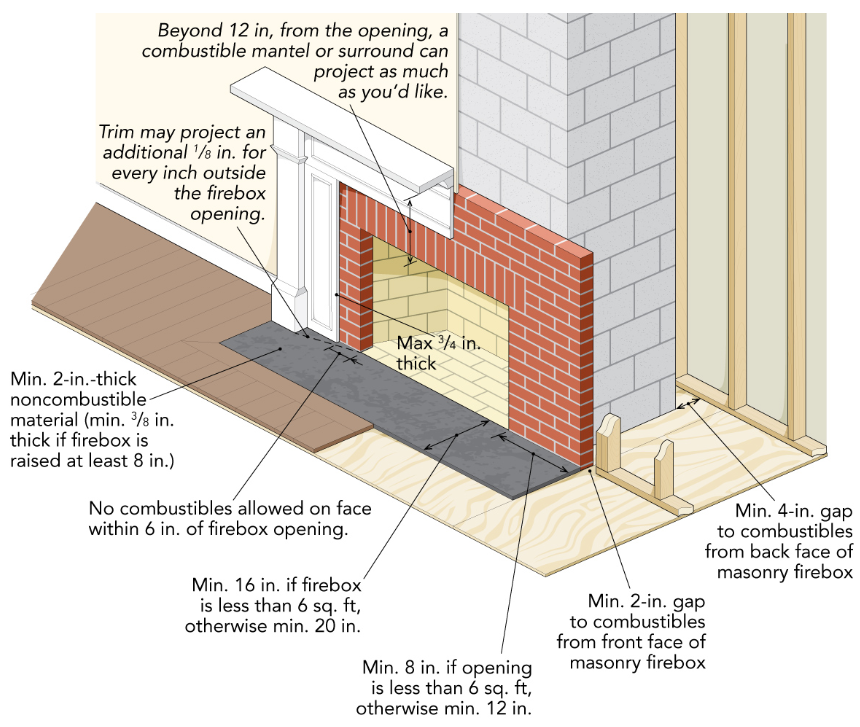

Metal chimneys are constructed from materials such as stainless steel or galvanized steel, known for their durability and resistance to weathering. They provide efficient venting for fireplaces, stoves, or heating appliances, offering a sleek and modern appearance compared to traditional masonry chimneys. Regular maintenance is essential to ensure proper function and prevent issues like corrosion or blockages. Below are examples of proper installations:

CHIMNEY CLEANING AND INSPECTION IS RECOMMENDED

The NFPA (National Fire Protection Association) recommends an annual inspection of all chimneys, fireplaces, solid fuel-burning appliances, and vents. They also recommend an NFPA 211 Standard, Level II inspection upon sale or transfer of the property. A Level II inspection includes, not only cleaning the interior of the chimney pipe, but also the use of specialized tools and testing procedures such as video cameras, etc. to thoroughly evaluate the serviceability of the entire flue lining and fireplace/chimney system. Level II inspections are not always needed, especially for short simple flues that can be inspected visually after a cleaning. If a chimney cleaning has not been performed over the past 12 months, such an inspection is recommended before the home changes ownership---for fire safety reasons. Implement any repairs as recommended.

☔ Gutters and Roof Drains

Gutters and Roof Drains

Materials: Metal, Plastic

Types: Scupper drain, Piped drain

🌵 Grounds

Water Meter

🕐: No Movement

WATER METER REVIEWED WITH NO MOVEMENT OBSERVED

This shows the location of the water meter at the street side of the house. The client is advised that one of the first actions taken by the inspector is to review the flow indicator on the water meter for movement. No movement was noted on the flow indicator.

- The client is advised that upon initial review of the meter minor movement was observed; however, after shutting off the pool auto fill system no movement was observed.

Irrigation

Not inspected

Not inspected

Pressure Vacuum Breaker (PVB): Present

PRESSURE VACUUM BREAKER (PVB) NOTE

These are mechanical devices designed to prevent backflow, capable of functioning under continuous pressure. They consist of two spring-loaded valves: one functions as a check valve and the other as an air inlet valve. Typically situated on the grounds near pool equipment or on the exterior of buildings, PVBs ensure water flows in one direction to safeguard water quality.

IRRIGATION SYSTEM OBSERVED

The property had one or more irrigation systems, which fall outside the scope of our inspection services. Based on my experience, these systems often need regular maintenance, repairs, and servicing. Inquire with the seller for any relevant details about the irrigation system. Proper maintenance is essential to ensure that the system doesn’t affect the structure and to extend the lifespan of the siding.

INLINE FERTILIZER INSTALLED

These components allow the homeowner to add fertilizer liquid to the tank and fertilize all the vegetation on the entire property. It is beyond the scope to determine if this system is functional and operating. For further information regarding this system the client is encouraged to inquire with the seller.

Site Elements, Grading, Drainage

Above grade (with respect to road)

Above grade (with respect to road)

Low slope

Low slope

Soil: Rocky

Rocky Sandy

Sandy Clay (expansive)

Clay (expansive)

CLAY SOIL NOTE

Clay is a predominant soil type in the Las Vegas Valley, alongside sand and caliche, known for its hardness and poor nutrient content. It often exhibits high pH levels or alkalinity. Clay-rich soils undergo shrink-swell cycles due to moisture changes, leading to potential heaving and lifting of structures from swelling pressures, as well as settlement or subsidence from shrinkage, which can vary across different areas.

Planters: None noted

None noted

Drainage / Downspouts: Above grade

Retaining Walls

None noted

None noted

Retaining Wall Material: None Noted

Fences and Gates

Exterior Fencing: Present

Present Concrete Masonry Unit (CMU)

Concrete Masonry Unit (CMU)

FENCING NOTE

The property has a fencing system in place. Inspection and evaluation of fencing is beyond the scope of a home inspection. If the fencing system is important for your use of this property, I recommended a self-examination to see how it will meet your needs. I may make cursory comments about fencing as a courtesy.

MASONRY FENCE / WALL NOTE

Water-soluble salts may be deposited on stucco, masonry fences or concrete materials as efflorescence. Practically any building materials in direct contact with the earth are potential sources for water-soluble salts. This may be due to high pH in the soil or excessive moisture due to poor drainage. The white residue can be cleaned off with white vinegar and a stiff bristle brush. Stucco coated fences and/or walls may need to be repeatedly patched.

Exterior gate(s): Metal

Metal

Grounds, Trees and Vegetation

Trees/Vegetation: Yes - Prune vegetation off house

Yes - Prune vegetation off house

PRUNE VEGETATION OFF STRUCTURE

As a general guideline, tree limbs should be kept a minimum of 6 to 8 feet away from the house to prevent damage from branches rubbing against the siding, roof, or windows during windy conditions. For larger trees, especially those with heavy branches, a greater clearance of 10 to 15 feet may be advisable to reduce the risk of limb breakage and potential damage to the house during storms. Regular pruning and maintenance by a qualified arborist can help ensure proper clearance and minimize the risk of tree-related damage to the house. Smaller vegetation, including grasses, flowers and shrubs should be kept 1-foot off the house to eliminate contact which could trap moisture against the building.

Grounds / Parking Lighting

Low voltage

Low voltage Limited review

Limited review Line voltage

Line voltage Timer, photocell, motion, etc.

Timer, photocell, motion, etc.

LOW VOLTAGE LIGHTING REVIEW LIMITED

Landscape lighting is outside the scope of our services. However, I performed a cursory review of the system as a courtesy to the client. Generally, any inoperative fixtures can be attributed to missing or burned-out bulbs but it is prudent to have all lighting made operable and all lighting be verified at the final walk-through inspection with the client's agent.

Driveways/Walkways/Flatwork

Driveway: Pavers

Walkways: Concrete, Pavers

Patios: Pavers

TREE ROOTS DAMAGING FLATWORK

The paver patio and walkway flatwork has been damaged by tree roots. This has created a trip hazard due to the un-level surface. Repair can be complicated as the tree grows and long term proper repair may necessitate removal of the trees in question as well as repair of the flatwork.

Exterior Stairs

Exterior Stairs: Standard

Stair Material: Metal

Outbuildings, Trellises, Storage Sheds, Barns

Not inspected

Not inspected

⛽ Fuel Storage and Distribution

Gas Meter

Present

Present

Gas Shutoff Location: East side of structure

Gas Piping

Gas Piping Material: Steel, Flex supply lines

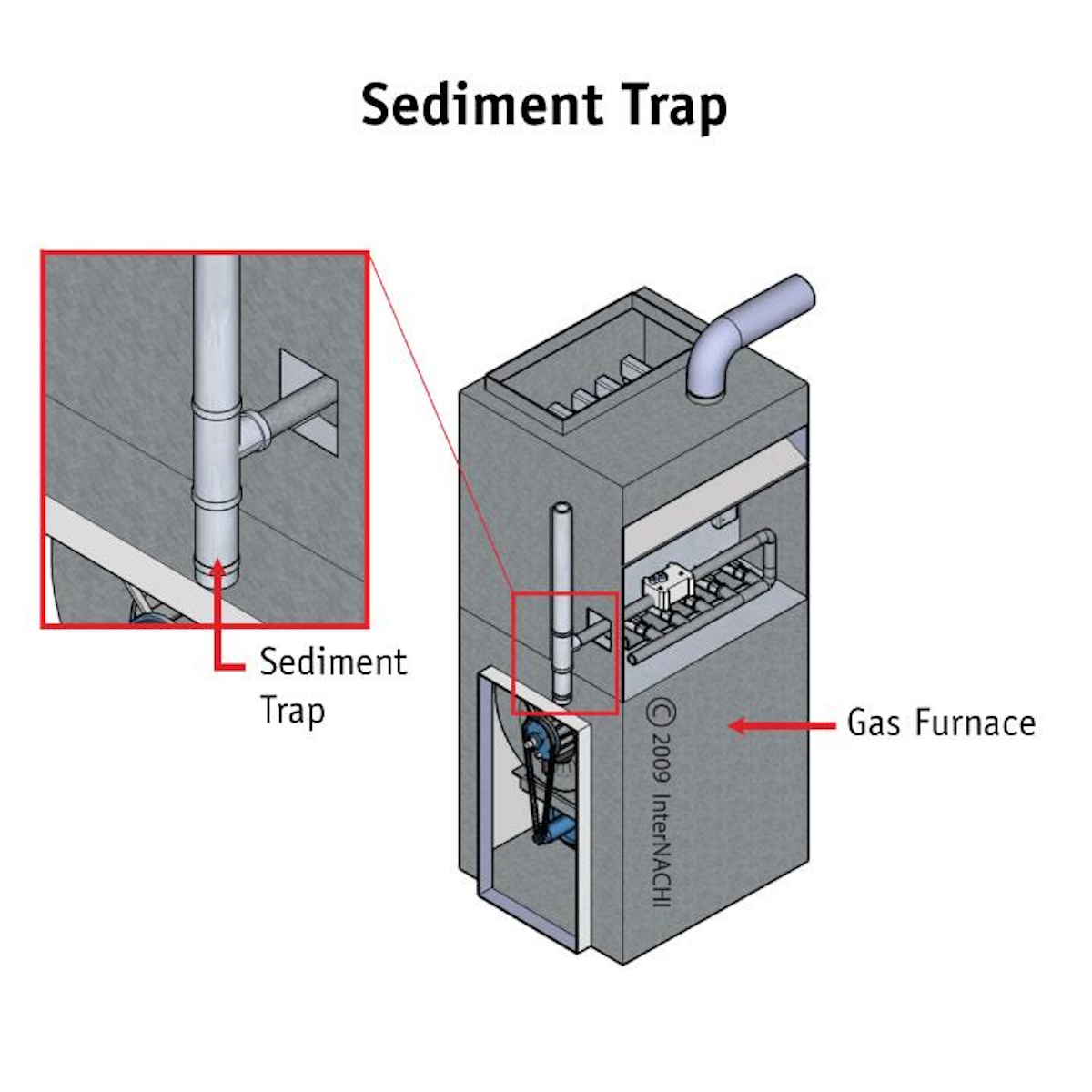

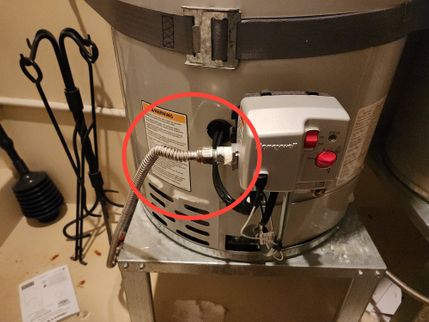

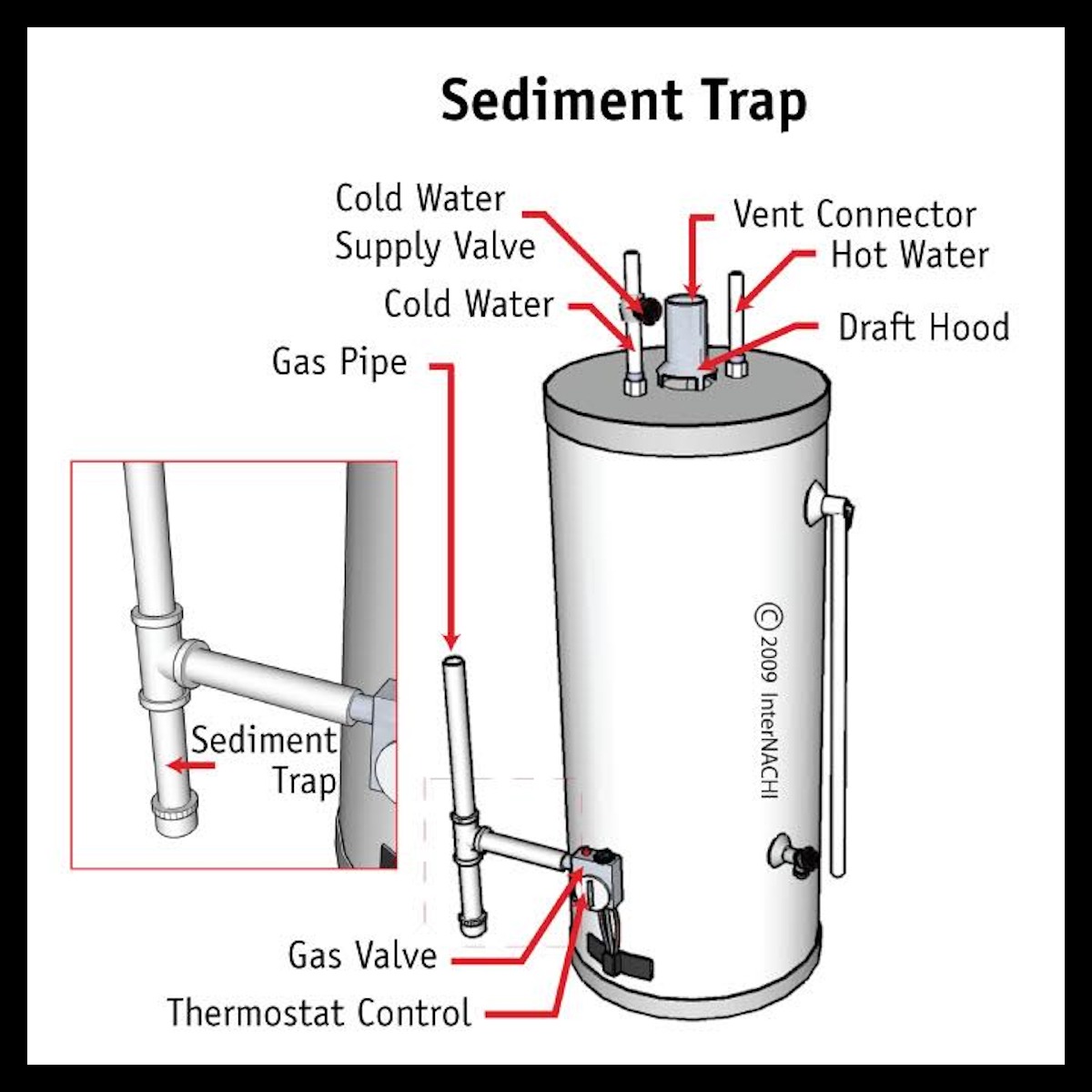

SEDIMENT TRAP ORIENTATED INCORRECTLY

Sediment traps are also known as a "dirt leg" or a "drip leg", and the pipe configuration includes a tee, nipple and a cap. Generally, the pipe nipple is at least 3 inches long and is intended to trap any water or foreign material that may be in the gas before entering the appliance, ensuring a clean unobstructed flow of gas. An attempt at a sediment trap is present; however, it was not oriented properly. Corrections advised.

Propane Storage

Storage Types: None noted

None noted

🏠 Exterior

Siding and Trim

Trim Material: Foam stucco, Masonry

Siding Material: Stucco, Stone

This building has a hardcoat stucco siding system. When installed over a wood building, stucco should be installed with two layers of underlayment below the plaster and a weep screed system which allows air to dry any accumulated moisture behind the plaster. Stucco is one of the nicest and lowest-maintenance siding systems but it is installation-sensitive. Poor installation can lead to expensive moisture control problems. The critical weather barrier, which is installed beneath the plaster is not visible to inspection, limiting the inspectors' ability to see how the system is performing. During our visual inspection, we look for clues to help make an educated guess about the future reliability of this system. More detailed information can be gained through destructive testing. This involves drilling holes in the plaster and using a moisture probe to determine if any sections of the building have moisture control problems. Destructive testing such as this is the only way to get reliable information on how the system is performing and it is beyond the scope of this inspection. Please also note that destructive testing is also limited and should be scheduled for times of year with the most precipitation: if it has been dry for an extended period, moisture probe testing may be worthless as building materials would be dry.

Wall Flashing: Partially visible

Partially visible

GENERAL CAULKING AND SEALING

Caulking may deteriorate or crack over time. Caulking breaks in the bead should not have any gaps or pulling-away from surface. Caulking is commonly used throughout the interior and exterior of the home as sealant or cosmetic filler. Even properly installed caulking will deteriorate, shrink and crack with normal exposure to the elements, wear, and aging or from movement of the materials it is adhered to. Damage to the home can be slow and difficult to detect. Water intrusion can become a costly repair if the caulk is not properly maintained.

Exterior Vent and Exhaust Terminations

Exterior Exhaust and Vent Terminations: Present, Natural draft vents noted, Direct vents noted

Exterior Doors

Exterior Door Styles: French doors, Glass panel doors

Security Door / Gate: No

No

Exterior Window Frames

Frame material: Metal

None noted

None noted

🛟 Pools and Spas

Pool / Spa

Inspected

Inspected

Type: Pool / spa combo

Pool / Spa Body: In-ground (Marcite / plaster)

MARCITE PLASTER NOTE

Marcite plaster is a durable and cost-effective pool finish made from white Portland cement and marble dust. It creates a smooth, classic white surface that enhances water clarity with a light blue hue. Known for its resistance to stains, algae, and chemical imbalances, Marcite can last 8-10 years with proper maintenance like brushing and chemical balancing. Installation involves applying layers of the plaster mix and smoothing it out, typically done by professional pool plasterers. Overall, Marcite plaster remains a popular choice for its longevity, aesthetic appeal, and practicality in both residential and commercial pools. Maintaining proper pool chemistry is essential to longevity of the finish.

Shape: Rectangle

Drain Covers: Anti-vortex

Anti-vortex drain covers are engineered to prevent strong whirlpools that can trap swimmers underwater by using designs that disrupt water flow. In contrast, non-anti-vortex covers lack these safety features, potentially increasing the risk of suction accidents if not installed or maintained properly.

Water Features: Waterfall (Non-functional), Fountain (Non-functional)

POOL WATER FEATURE NOTE

Please note that plumbing for pool water features is often not visible during routine inspections, and our ability to conduct a comprehensive review may be limited. Hidden components such as underground pipes or concealed fittings may not be fully assessable without specialized equipment or additional inspection methods.

Diving Board: No

CONTRACTOR REVIEW AND COST-TO-CURE

Numerous conditions and defects were observed. Given the volume of issues noted, it is probable that further repairs may be necessary to address latent or concealed issues. The client is advised to obtain a written cost-to-cure estimate from the contractor detailing the scope of work and proposed corrective actions. Several specific observations noted during the inspection include:

- Seized water feature pump that trips the breaker when operated

- Pool equipment not properly bonded to the electrical system

- Lighting system repeatedly trips GFCI and requires repair

- Significant pool system leaks with standing water observed

- Valves not labeled and identified for easier operation and maintenance

- PVC piping in need of paint maintenance as paint is faded in areas

- Abandoned pool equipment and features such as waterfalls or fountains

- Electrical conduit separated at blower

- Numerous doors around the home allow access to the pool and our not alarmed

- Worn pool finish throughout the pool

- Possible algae build up in areas of the pool, indicating an improper chemical balance

POOL SAFETY RESOURCES

You should check with your local municipality to verify your pool is within their safety requirements. Every municipality is different and changes and updates may be necessary to keep up with the standards of safety and compliance. There are state statute requirements, and there are requirements for each city. The more restrictive requirement will always apply.

Resources:

LIMITED REVIEW OF POOL FINISH

When inspecting the interior shell of the pool, we do our best to inspect as thoroughly as possible. However, like many other systems or components of a home or building, there can be limits that make inspections difficult, inaccessible, or not visible. Please understand that some conditions can manipulate or distort the view of the pools finish making it difficult to see defects. The way sun light or light of any kind can reflect off the water, or windy days can cause the water to ripple making it very difficult to see the finish are examples of limitations that could be present during an inspection.

Heating Equipment

Heater: Gas

Gas Functional

Functional

GAS POOL HEATER NOTE

Gas pool heaters are known for their rapid heating capabilities by burning natural gas or propane, making them ideal for quickly raising water temperatures. However, they can be less energy-efficient compared to heat pumps or solar heaters, and operating costs will vary depending on fuel prices. Regular maintenance and proper sizing are important to ensure efficient operation and longevity.

Bonded: Yes

Yes

POOL BONDING NOTE

All metallic parts of the pool structure, including reinforcing metal, must be bonded using solid copper conductors of at least 8 AWG, or rigid metal conduit made of corrosion-resistant metals like brass. This bonding ensures compliance with current building standards, providing a safe path for electrical currents. Underwater metal-formed lighting shells, metal fittings within or attached to the pool, and electrical equipment such as pumps, motors, and pool covers must also be bonded. Additionally, fixed metal parts like metal-sheathed cables, piping, awnings, fences, doors, and window frames must be bonded. Bonding to the conductive pool shells is required. All concrete materials must be considered conductive, with structural reinforcing steel either tied together with tie wires or installed in a copper conductor grid conforming to the pool's shape, secured within 6 inches of the pool's outer contour. Perimeter surfaces extending 3 feet beyond the pool walls must be bonded to the reinforcing steel or copper grid at least every 4 points around the pool. Much of this is not visible; however, I will comment on apparently improper bonding and advise further evaluation.

Filters, Skimmers, Drains, & Cleaning Systems

Pool Filter: Cartridges/Pleated Filters

Cartridges/Pleated Filters

CARTRIDGE FILTER NOTE

The filter system for this pool is a cartridge filter system. Cartridge filters are an excellent filtration system being the most effective method of filtration. The cartridges need to be removed, on average, 2-4 times a year for cleaning They can be cleaned by a high-pressure nozzle on a water hose. Speak with a qualified pool technician to learn how to properly open the housing and remove the cartridges for cleaning. Most filter systems are designed to operate in the 5-15 psi or 10-20 psi range with empty pump and skimmer baskets.

Cleaning Systems: In-Floor Pop-Up Cleaning System, Skimmer(s)

AUTOMATIC IN-FLOOR CLEANING SYSTEM NOTE

An in-floor pool cleaning system uses pop-up cleaners to help clean the pool floor of debris and dirt. There are small heads that sit flush with the pool floor, recessed in their pocket. They are automatic and will pop up as scheduled to spray water under pressure to help move the debris toward the drain or stir it up so it can be picked by the other cleaning systems and components. Some are controlled by an automatic valve, but most have a small actuator housing that cycles the heads in groups or sections. You speak with your local pool professional to learn how to set and control your cycle speed duration, as this may need to be changed during times of storms and seasons. The system should be routinely inspected to be sure that all the heads of the system are properly functioning. One head failing can affect the rest of the system. A section that appears unusually dirty can be a sign of repair/maintenance needed.

SKIMMER NOTE

This pool, like most pools, has one or more skimmer cleaning systems. A skimmer helps to clean the pool by using suction to create a current that pulls the surface water towards to skimmer opening, capturing floating debris such as leaves, flower petals, dirt, twigs, dead insects, oil (sunblock), etc., before the waste can sink to the pool's bottom. The debris is collected in the basket in the well accessed from the deck's surface. This basket should be routinely checked and emptied to maintain optimal results.

Pump Equipment, Plumbing & Electrical Systems

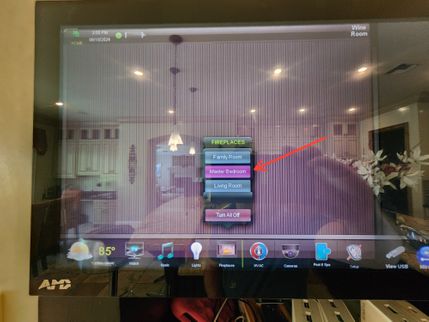

Pumps / Lighting / Electrical: Pumps (Air, Filter), Lighting system (Pool, Spa, Non-functional), Controls (Remote controlled switching), Conduit (Plastic)

Pumps Bonded: No

No

POOL BONDING NOTE

All metallic parts of the pool structure, including reinforcing metal, must be bonded using solid copper conductors of at least 8 AWG, or rigid metal conduit made of corrosion-resistant metals like brass. This bonding ensures compliance with current building standards, providing a safe path for electrical currents. Underwater metal-formed lighting shells, metal fittings within or attached to the pool, and electrical equipment such as pumps, motors, and pool covers must also be bonded. Additionally, fixed metal parts like metal-sheathed cables, piping, awnings, fences, doors, and window frames must be bonded. Bonding to the conductive pool shells is required. All concrete materials must be considered conductive, with structural reinforcing steel either tied together with tie wires or installed in a copper conductor grid conforming to the pool's shape, secured within 6 inches of the pool's outer contour. Perimeter surfaces extending 3 feet beyond the pool walls must be bonded to the reinforcing steel or copper grid at least every 4 points around the pool. Much of this is not visible; however, I will comment on apparent improper bonding and advise further evaluation.

Plumbing: Piping

Piping Painted

Painted Yes

Yes Labeled

Labeled No

No Valves

Valves Fill-valve

Fill-valve Automatic

Automatic Remote controlled

Remote controlled Yes

Yes Ball valve

Ball valve

Pressure Vacuum Breaker (PVB) Present: Yes

Yes

PRESSURE VACUUM BREAKER (PVB) NOTE

These are mechanical devices designed to prevent backflow, capable of functioning under continuous pressure. They consist of two spring-loaded valves: one functions as a check valve and the other as an air inlet valve. Typically situated on the grounds near pool equipment or on the exterior of buildings, PVBs ensure water flows in one direction to safeguard water quality.

Decks, Steps, & Coping

Pool Deck: Yes (Pavers)

Pool Cover Present: No

Safety Devices

Gates and Doors with Direct Pool Access: Gates

Gates Self-closing and Self latching

Self-closing and Self latching Yes - outward swing, away from pool

Yes - outward swing, away from pool Doors

Doors Self-closing and Self latching

Self-closing and Self latching No

No

Alarms: Doors (No)

Lockable Spa Cover: N/A

N/A

Fence: Yes

🔩 Decks, Porches and Balconies

Wood Decks Porches and Balconies

Present

To see a prescriptive guide for residential wood deck construction click this link:

Structure: Not visible

Ledger Board: Not visible

Guardrail: Standard

Decking Material: Not visible

Posts, Beams and Footings: Not Visible

🚘 Garage

Garage General

Garage Type: Attached

Garage Doors and Automatic Openers

Overhead Garage Door Type: Sectional

Overhead Garage Door Material: Metal

Automatic Garage Opener: Tested

Tested

Safety: Laser Eyes

Laser Eyes OK

OK Pressure Sensor

Pressure Sensor OK

OK Needs adjustment

Needs adjustment

Garage Occupant Door: Solid Wood, Fails to latch

FIRE DOOR NOT LATCHING

There are the requisite number of spring loaded hinges on this door, and it did fully self-close. However, it did not reliably self-latch. This appeared to deviate from acceptable building standards and practices in effect at the time of construction or installation. Exercise caution. This discovery could be or could become hazardous under certain circumstances.

MINOR VEHICLE DOOR DAMAGE

Over time, cracks in garage door panels can worsen, possibly requiring panel replacement. Experience has shown that often the cost of a panel is not substantially different than the cost of an entire door. An economical means for addressing this issue is to drill a hole at the end(s) of the crack to prevent it from propagating further. The crack can then be repaired with a liquid steel product such as "JB-Weld" which is an epoxy-like substance available online and at most major home improvement warehouses.

OVERHEAD DOOR SENSITIVITY

The overhead garage door opener did not reverse under resistance while closing. Adjustment of the sensitivity is recommended for improved safety. This typically involves adjusting a small plastic screw on the opener labeled "Closing Force", although newer openers may have other means for this simple but critical adjustment. Guidance is generally contained in the garage door opener manual or can likely be obtained online

Garage Floor

Garage Slab: Concrete

Concrete

Garage Stairs

Garage Stairs: None noted

Vehicle Chargers

None noted

🛢️ Water Heaters

Water Heater

Energy Source: Gas

System Type: Tank

Tank

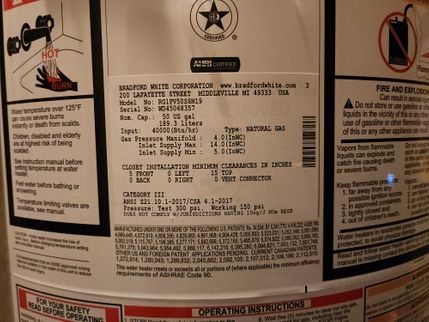

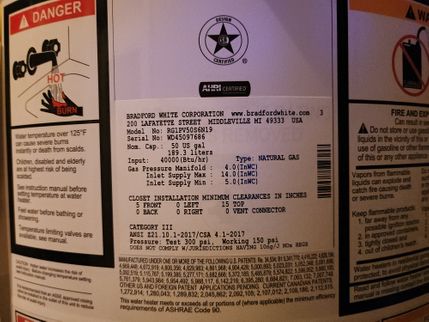

Manufacturer: Bradford-White

Size: 50 gal

Age: 2020

Full-way Valve: Yes

Yes

Mixing Valve: No

No

Supply Lines / Nipples: Corrosion free

Corrosion free

Straps : Present

Drip Pan: None Noted - Recommended

Expansion Tank: None Noted - Recommended

TPRV: Present - Not Tested

TPRV NOTE

All water heaters need a temperature and pressure relief valve (TPRV) to manage excess pressure, with a discharge pipe directing water to a safe location. New installations should direct the pipe to the building exterior or an approved indoor drain. It’s advisable to test the valve annually and have it inspected every three years. The provided image shows a typical TPRV, which may be mounted on the side of the heater in some models. I don’t test these valves due to the risk of leaks, so any malfunctioning TPRV should be replaced by a licensed plumber. For installation specifics, follow the manufacturer’s instructions, which generally recommend a discharge termination 6 inches above the floor.

Bollard: None Required

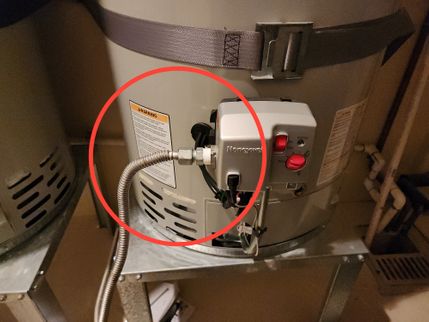

🔥Gas Water Heater🔥: Sediment Trap Issue

Combustion Air: Appeared sufficient

Min. 18" Platform: Yes

Service Disconnect: No

No

NO DRAIN PAN FOR WATER HEATER

No drain pan has been installed below the water heater here. A drain pan is recommended under water heaters that are located in finished spaces or where a leak could damage finishes. Where a pan does not already exist, the tricky part is providing a drain to the outside. A pan without a drain is often of limited benefit / protection. For improved protection from accidental water heater leaks, and where a drain is difficult to install, consider a pan with a moisture alarm and a flood-safe device such as this: Watts Water Heater Leak Prevention.

GAS SEDIMENT TRAP ISSUE

Sediment traps, often called "dirt legs," are designed to capture sediment and water in gas lines before it reaches an appliance. The assembly includes a tee, a nipple, and a cap, with careful attention to orientation. The purpose is to force a 90° shift in gas flow, which helps keep sediment from bypassing the trap. Typically, the nipple is at least 3 inches long, allowing it to effectively trap any water or debris in the gas, ensuring a clean and unobstructed flow into the appliance.

THERMAL EXPANSION DEVICE ADVISED

An expansion tank is recommended for the water heater. Expansion tanks help reduce pressure on the plumbing system by creating a buffer or a place for water to expand into as water expands with thermal expansion. Installation of an expansion device or pressure tank is modern installation practice and will be required if a pressure reducing valve has been installed on a public water supply or if the plumbing system is closed for any reason. Open systems do not require a thermal expansion device though they can still be an excellent way to help prevent build-up of pressures in the piping system.

Water Heater 2

Energy Source: Gas

System Type: Tank

Tank

Manufacturer: Bradford-White

Size: 50 gal

Age: 2020

Full-way Valve: Yes

Yes

Mixing Valve: No

No

Supply Lines / Nipples: Corrosion free

Corrosion free

Straps : Present

Drip Pan: None Noted - Recommended

Expansion Tank: None Noted - Recommended

TPRV: Present - Not Tested

TPRV NOTE

All water heaters need a temperature and pressure relief valve (TPRV) to manage excess pressure, with a discharge pipe directing water to a safe location. New installations should direct the pipe to the building exterior or an approved indoor drain. It’s advisable to test the valve annually and have it inspected every three years. The provided image shows a typical TPRV, which may be mounted on the side of the heater in some models. I don’t test these valves due to the risk of leaks, so any malfunctioning TPRV should be replaced by a licensed plumber. For installation specifics, follow the manufacturer’s instructions, which generally recommend a discharge termination 6 inches above the floor.

Bollard: None Required

🔥Gas Water Heater🔥: Sediment Trap Issue

Combustion Air: Appeared sufficient

Min. 18" Platform: Yes

Service Disconnect: No

No

NO DRAIN PAN FOR WATER HEATER

No drain pan has been installed below the water heater here. A drain pan is recommended under water heaters that are located in finished spaces or where a leak could damage finishes. Where a pan does not already exist, the tricky part is providing a drain to the outside. A pan without a drain is often of limited benefit / protection. For improved protection from accidental water heater leaks, and where a drain is difficult to install, consider a pan with a moisture alarm and a flood-safe device such as this: Watts Water Heater Leak Prevention.

GAS SEDIMENT TRAP ISSUE

Sediment traps, often called "dirt legs," are designed to capture sediment and water in gas lines before it reaches an appliance. The assembly includes a tee, a nipple, and a cap, with careful attention to orientation. The purpose is to force a 90° shift in gas flow, which helps keep sediment from bypassing the trap. Typically, the nipple is at least 3 inches long, allowing it to effectively trap any water or debris in the gas, ensuring a clean and unobstructed flow into the appliance.

THERMAL EXPANSION DEVICE ADVISED

An expansion tank is recommended for the water heater. Expansion tanks help reduce pressure on the plumbing system by creating a buffer or a place for water to expand into as water expands with thermal expansion. Installation of an expansion device or pressure tank is modern installation practice and will be required if a pressure reducing valve has been installed on a public water supply or if the plumbing system is closed for any reason. Open systems do not require a thermal expansion device though they can still be an excellent way to help prevent build-up of pressures in the piping system.

🔥❄️ Heating, Cooling, Fireplaces and Ventilation

Heating System 1

Natural gas

Natural gas High-efficiency

High-efficiency

This house has a gas forced air furnace. A critical component to all combustion heating equipment is the heat exchanger. This is the welded metal assembly inside the furnace that contains the products of combustion so that moisture, carbon monoxide and other products of combustion do not mix with interior air and get safely vented to the exterior. Heat exchangers on modern furnaces have an average life expectancy of 15-20 years. Unfortunately, heat exchangers are concealed inside the heating equipment; they are not visible and specifically excluded from a home inspection. Cracks in heat exchangers may be concealed and can pose a potential safety hazard.

HIGH-EFFICIENCY FURNACE NOTE

A High-Efficiency (HE) furnace extracts more heat from combustion gases than standard models, achieving an Annual Fuel Utilization Efficiency (AFUE) of 90% or higher with a secondary heat exchanger that captures additional heat from exhaust gases, causing them to cool significantly. Condensation of water vapor into acidic liquid due to combustion byproducts occurs as these gases cool below their dew point. High-efficiency furnaces manage this condensate with a drainage system that safely directs acidic water away to prevent damage and maintain efficiency. Venting systems vary: while some use PVC or CPVC plastic pipes, others use stainless steel or aluminum based on furnace design, local codes, and installation needs, ensuring safe and efficient removal of gases and condensate per manufacturer and regulatory standards.

Disconnecting Means: Plug

Plug

✅: Heat system functional

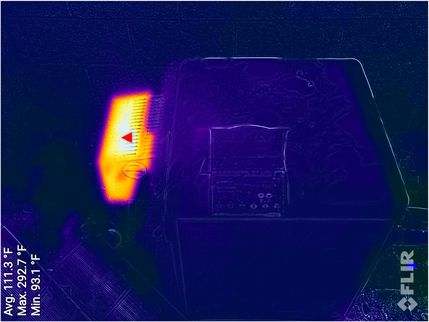

HEAT SYSTEM FUNCTIONAL

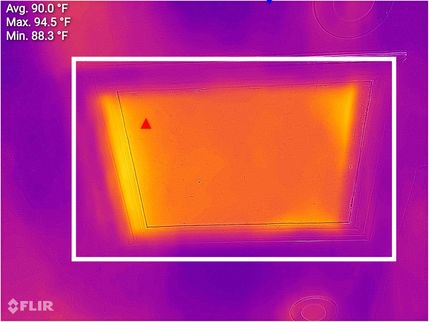

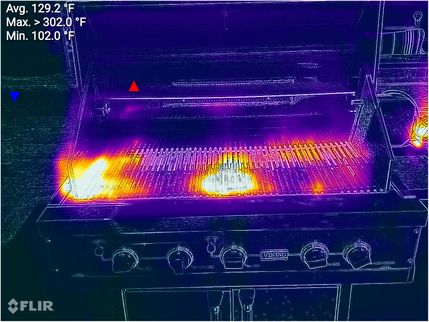

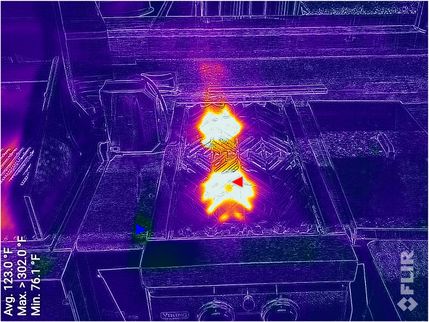

This primary heat source for the structure was reviewed utilizing normal operating controls. Adequacy, efficiency or even distribution of the system is outside the scope of this inspection. Airflow at all supply registers was captured using infrared thermography.

FURNACE & FORCED AIR UNIT ACCESSIBILITY

I inspected the primary heating and cooling systems, and confirmed the presence of permanent heating and cooling sources in habitable rooms. Using normal operating controls, heating/cooling equipment, automatic safety controls, flues and vents were examined within visible limits. All readily accessible cover panels were removed from furnaces or forced-air units located outside confined spaces, such as attics or crawl spaces.

Heating System 2

Natural gas

Natural gas

This house has a gas forced air furnace. A critical component to all combustion heating equipment is the heat exchanger. This is the welded metal assembly inside the furnace that contains the products of combustion so that moisture, carbon monoxide and other products of combustion do not mix with interior air and get safely vented to the exterior. Heat exchangers on modern furnaces have an average life expectancy of 15-20 years. Unfortunately, heat exchangers are concealed inside the heating equipment; they are not visible and specifically excluded from a home inspection. Cracks in heat exchangers may be concealed and can pose a potential safety hazard.

Disconnecting Means: Plug

Plug

✅: Heat system functional

HEAT SYSTEM FUNCTIONAL

This primary heat source for the structure was reviewed utilizing normal operating controls. Adequacy, efficiency or even distribution of the system is outside the scope of this inspection. Airflow at all supply registers was captured using infrared thermography.

FURNACE & FORCED AIR UNIT ACCESSIBILITY

I inspected the primary heating and cooling systems, and confirmed the presence of permanent heating and cooling sources in habitable rooms. Using normal operating controls, heating/cooling equipment, automatic safety controls, flues and vents were examined within visible limits. All readily accessible cover panels were removed from furnaces or forced-air units located outside confined spaces, such as attics or crawl spaces.

Heating System 3

Natural gas

Natural gas

This house has a gas forced air furnace. A critical component to all combustion heating equipment is the heat exchanger. This is the welded metal assembly inside the furnace that contains the products of combustion so that moisture, carbon monoxide and other products of combustion do not mix with interior air and get safely vented to the exterior. Heat exchangers on modern furnaces have an average life expectancy of 15-20 years. Unfortunately, heat exchangers are concealed inside the heating equipment; they are not visible and specifically excluded from a home inspection. Cracks in heat exchangers may be concealed and can pose a potential safety hazard.

Disconnecting Means: Plug

Plug

✅: Heat system functional

HEAT SYSTEM FUNCTIONAL

This primary heat source for the structure was reviewed utilizing normal operating controls. Adequacy, efficiency or even distribution of the system is outside the scope of this inspection. Airflow at all supply registers was captured using infrared thermography.

FURNACE & FORCED AIR UNIT ACCESSIBILITY

I inspected the primary heating and cooling systems, and confirmed the presence of permanent heating and cooling sources in habitable rooms. Using normal operating controls, heating/cooling equipment, automatic safety controls, flues and vents were examined within visible limits. All readily accessible cover panels were removed from furnaces or forced-air units located outside confined spaces, such as attics or crawl spaces.

Heating System 4

Natural gas

Natural gas

This house has a gas forced air furnace. A critical component to all combustion heating equipment is the heat exchanger. This is the welded metal assembly inside the furnace that contains the products of combustion so that moisture, carbon monoxide and other products of combustion do not mix with interior air and get safely vented to the exterior. Heat exchangers on modern furnaces have an average life expectancy of 15-20 years. Unfortunately, heat exchangers are concealed inside the heating equipment; they are not visible and specifically excluded from a home inspection. Cracks in heat exchangers may be concealed and can pose a potential safety hazard.

Disconnecting Means: Plug

Plug

✅: Heat system functional

HEAT SYSTEM FUNCTIONAL

This primary heat source for the structure was reviewed utilizing normal operating controls. Adequacy, efficiency or even distribution of the system is outside the scope of this inspection. Airflow at all supply registers was captured using infrared thermography.

FURNACE & FORCED AIR UNIT ACCESSIBILITY

I inspected the primary heating and cooling systems, and confirmed the presence of permanent heating and cooling sources in habitable rooms. Using normal operating controls, heating/cooling equipment, automatic safety controls, flues and vents were examined within visible limits. All readily accessible cover panels were removed from furnaces or forced-air units located outside confined spaces, such as attics or crawl spaces.

Heating System 5

Natural gas

Natural gas

This house has a gas forced air furnace. A critical component to all combustion heating equipment is the heat exchanger. This is the welded metal assembly inside the furnace that contains the products of combustion so that moisture, carbon monoxide and other products of combustion do not mix with interior air and get safely vented to the exterior. Heat exchangers on modern furnaces have an average life expectancy of 15-20 years. Unfortunately, heat exchangers are concealed inside the heating equipment; they are not visible and specifically excluded from a home inspection. Cracks in heat exchangers may be concealed and can pose a potential safety hazard.

Disconnecting Means: Plug

Plug

HVAC SYSTEM DISTRIBUTION LIMITATIONS

I was unable to fully test the heating distribution during inspection today. This is for the heating servicing the 2nd floor bedrooms. Because the cooling system is not operational this zone was 93º and the heating set point maxed out at 90º. This limited the scope of this inspection.

FURNACE & FORCED AIR UNIT ACCESSIBILITY

I inspected the primary heating and cooling systems, and confirmed the presence of permanent heating and cooling sources in habitable rooms. Using normal operating controls, heating/cooling equipment, automatic safety controls, flues and vents were examined within visible limits. All readily accessible cover panels were removed from furnaces or forced-air units located outside confined spaces, such as attics or crawl spaces.

Vents and Flues

📝: Present, Natural draft, Power vent

Air Filters

Filtration Systems: Electronic

The heating and cooling system has an electrostatic air filter installed. This are specialty filtration systems that can be cleaned. Be sure to clean the filter at least quarterly to ensure reliable air flow. Most of these filters have 4 pieces: 2 pre-filters and 2 main filters. Be sure to disconnect the power to the unit prior to cleaning.

A/C 1

Electric cooling

Electric cooling

Manufacturer: York

Type: Split system

Split system

System: Air Conditioning

Air Conditioning

HVAC SERVICING CHECKLIST

The following list is a minimum set of requirements to be expected of heat pump or air conditioning servicing. I provide this as a courtesy to show the types of check-ups that should be expected from a professional servicing, which should be done annually at minimum.

- Check compressor efficiency

- Check refrigerant level

- Clean the condenser coil

- Change or clean air filters

- Inspect contactors and wiring

- Inspect drive-sheaves, pulleys and belts

- Check and adjust for proper air flow

- Clean the blower motor as needed

- Lubricate all motors and shaft bearings

- Check, calibrate and program the thermostats and be sure the thermostat has adequate batteries as needed

- Check unit smoke detector, clean filter if applicable

- Check safety disconnect, laser-temp -- check across contacts

HVAC SYSTEM NOTE

My assessment of the air conditioning system is based on visual examination and operational testing at the time of inspection. We do not verify if the system components are matched. This evaluation does not guarantee future performance or uncover hidden defects. For a complete understanding of the system's condition and longevity, we recommend regular maintenance and additional evaluation by a licensed HVAC professional.

Source: Air

Air

Age: 2015

Nominal Capacity: 5 Tons

Refrigerant Type: R-410A

R-410A

R-410A is currently one of the most commonly used refrigerants in air conditioning systems. It gained popularity as a replacement for ozone-depleting refrigerants like R-22 due to its ozone-friendly properties. However, R-410A has a high global warming potential (GWP), leading to increasing scrutiny and calls for its phase-down or replacement with lower-GWP alternatives, such as R-454B. Starting as soon as January 1, 2025, restrictions will take effect on the use of higher-GWP HFCs in new 1) aerosols, 2) foams, and 3) refrigeration, air conditioning, and heat pump equipment. As regulations evolve and R-407C, and R-410A becomes less common, maintaining and servicing systems that use this refrigerant may become more challenging. Depending on future regulations and market trends, retrofitting existing systems or transitioning to alternative refrigerants may become necessary.

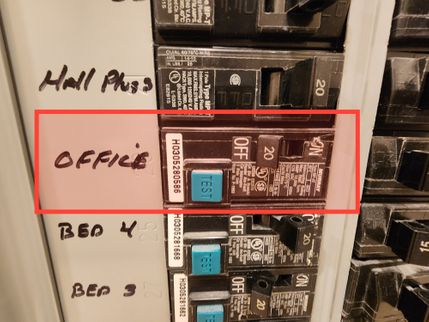

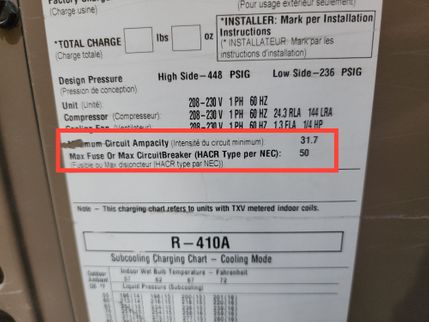

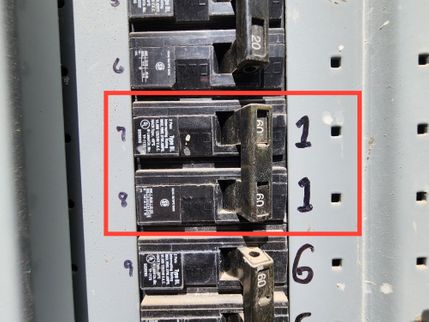

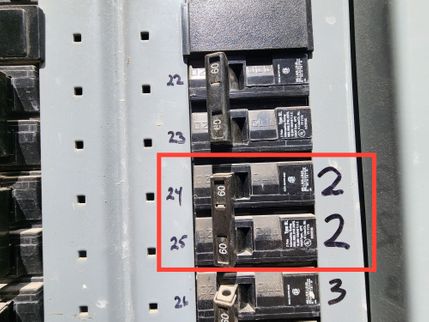

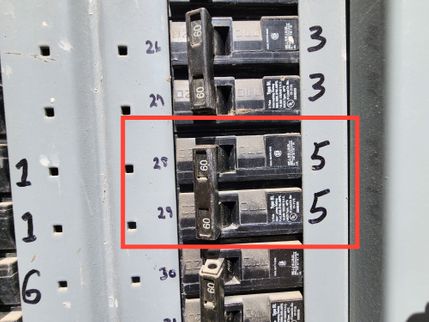

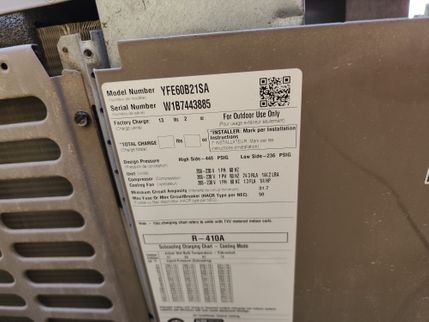

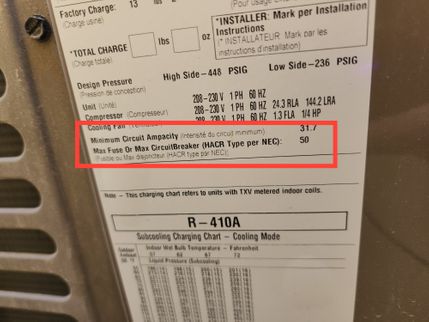

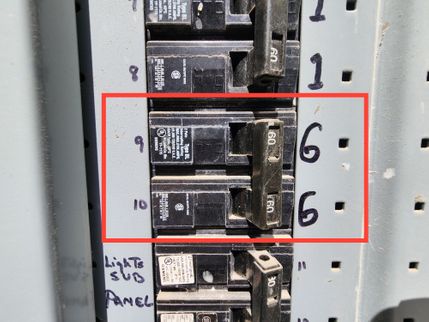

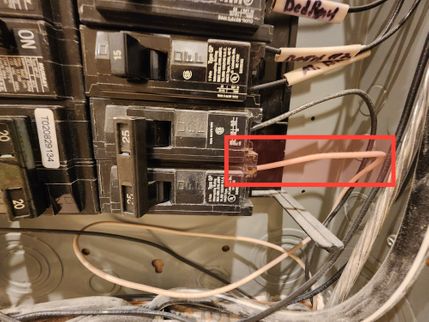

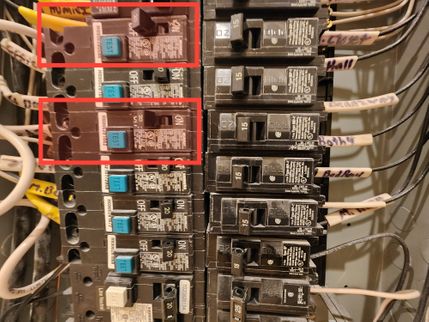

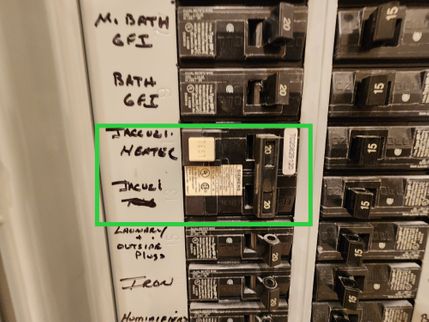

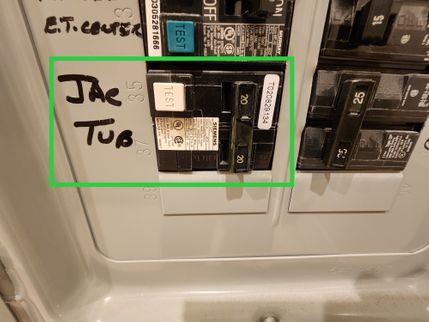

Breaker Sizing: Improper

Improper

Disconnecting Means: Blade

IMPROPERLY SIZED CONDENSER UNIT BREAKER

The AC condenser unit unit breaker was noted to be improperly sized. The manufacturer requires a minimum breaker size of 31.7 amps and a maximum breaker size of 50 amps However, a 60 amp breaker was noted in the Main panel panel. The nameplate data on the condenser nit specifies the minimum and maximum sized breaker allowed to be installed. If the installed breaker does not conform to manufacturer requirements, it may void any relevant manufacturer warranty that would have otherwise been honored. Additionally, improperly sized breakers provide home warranty companies with reasoning to not honor a claim.

A/C 2

Electric cooling

Electric cooling

Manufacturer: Trane

Type: Split system

Split system

System: Air Conditioning

Air Conditioning

HVAC SERVICING CHECKLIST

The following list is a minimum set of requirements to be expected of heat pump or air conditioning servicing. I provide this as a courtesy to show the types of check-ups that should be expected from a professional servicing, which should be done annually at minimum.

- Check compressor efficiency

- Check refrigerant level

- Clean the condenser coil

- Change or clean air filters

- Inspect contactors and wiring

- Inspect drive-sheaves, pulleys and belts

- Check and adjust for proper air flow

- Clean the blower motor as needed

- Lubricate all motors and shaft bearings

- Check, calibrate and program the thermostats and be sure the thermostat has adequate batteries as needed

- Check unit smoke detector, clean filter if applicable

- Check safety disconnect, laser-temp -- check across contacts

HVAC SYSTEM NOTE

My assessment of the air conditioning system is based on visual examination and operational testing at the time of inspection. We do not verify if the system components are matched. This evaluation does not guarantee future performance or uncover hidden defects. For a complete understanding of the system's condition and longevity, we recommend regular maintenance and additional evaluation by a licensed HVAC professional.

Source: Air

Air

Age: 2014

Nominal Capacity: 5 Tons

Refrigerant Type: R-410A

R-410A

R-410A is currently one of the most commonly used refrigerants in air conditioning systems. It gained popularity as a replacement for ozone-depleting refrigerants like R-22 due to its ozone-friendly properties. However, R-410A has a high global warming potential (GWP), leading to increasing scrutiny and calls for its phase-down or replacement with lower-GWP alternatives, such as R-454B. Starting as soon as January 1, 2025, restrictions will take effect on the use of higher-GWP HFCs in new 1) aerosols, 2) foams, and 3) refrigeration, air conditioning, and heat pump equipment. As regulations evolve and R-407C, and R-410A becomes less common, maintaining and servicing systems that use this refrigerant may become more challenging. Depending on future regulations and market trends, retrofitting existing systems or transitioning to alternative refrigerants may become necessary.

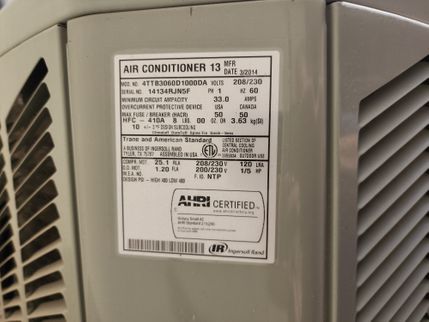

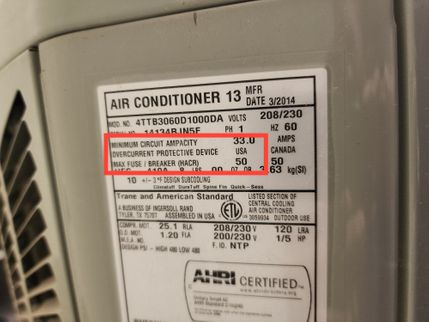

Breaker Sizing: Improper

Improper

Disconnecting Means: Blade

IMPROPERLY SIZED CONDENSER UNIT BREAKER

The AC condenser unit unit breaker was noted to be improperly sized. The manufacturer requires a minimum breaker size of 33 amps and a maximum breaker size of 50 amps However, a 60 amp breaker was noted in the Main panel panel. The nameplate data on the condenser unit specifies the minimum and maximum sized breaker allowed to be installed. If the installed breaker does not conform to manufacturer requirements, it may void any relevant manufacturer warranty that would have otherwise been honored. Additionally, improperly sized breakers provide home warranty companies with reasoning to not honor a claim.

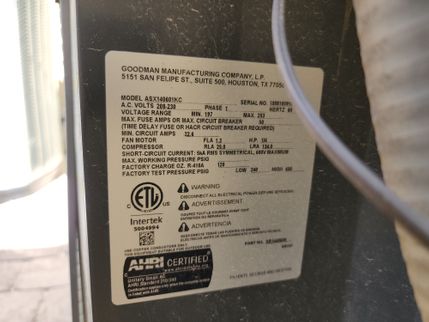

A/C 3

Electric cooling

Electric cooling

Manufacturer: Air Temp

Type: Split system

Split system

System: Air Conditioning

Air Conditioning

HVAC SERVICING CHECKLIST

The following list is a minimum set of requirements to be expected of heat pump or air conditioning servicing. I provide this as a courtesy to show the types of check-ups that should be expected from a professional servicing, which should be done annually at minimum.

- Check compressor efficiency

- Check refrigerant level

- Clean the condenser coil

- Change or clean air filters

- Inspect contactors and wiring

- Inspect drive-sheaves, pulleys and belts

- Check and adjust for proper air flow

- Clean the blower motor as needed

- Lubricate all motors and shaft bearings

- Check, calibrate and program the thermostats and be sure the thermostat has adequate batteries as needed

- Check unit smoke detector, clean filter if applicable

- Check safety disconnect, laser-temp -- check across contacts

HVAC SYSTEM NOTE

My assessment of the air conditioning system is based on visual examination and operational testing at the time of inspection. We do not verify if the system components are matched. This evaluation does not guarantee future performance or uncover hidden defects. For a complete understanding of the system's condition and longevity, we recommend regular maintenance and additional evaluation by a licensed HVAC professional.

Source: Air

Air

Age: 2021

Nominal Capacity: 5 Tons

Refrigerant Type: R-410A

R-410A

R-410A is currently one of the most commonly used refrigerants in air conditioning systems. It gained popularity as a replacement for ozone-depleting refrigerants like R-22 due to its ozone-friendly properties. However, R-410A has a high global warming potential (GWP), leading to increasing scrutiny and calls for its phase-down or replacement with lower-GWP alternatives, such as R-454B. Starting as soon as January 1, 2025, restrictions will take effect on the use of higher-GWP HFCs in new 1) aerosols, 2) foams, and 3) refrigeration, air conditioning, and heat pump equipment. As regulations evolve and R-407C, and R-410A becomes less common, maintaining and servicing systems that use this refrigerant may become more challenging. Depending on future regulations and market trends, retrofitting existing systems or transitioning to alternative refrigerants may become necessary.

Breaker Sizing: Compliant

Compliant

Disconnecting Means: Fuse

OVERCURRENT PROTECTION PROPERLY SIZED

I verified that the labeled breakers and fuses for the installed unit did not exceed the manufacturer’s requirements. In the Las Vegas Valley, it's common to find homes with improperly sized circuit breakers for central air conditioner condenser units that exceed the maximum size specified by the HVAC manufacturer. This issue often arises from poor communication between the HVAC and electrical contractors during construction and is prevalent in both custom and production homes, especially when an original condenser or compressor has been replaced. Such conditions can void the manufacturer's warranty and may affect aftermarket home warranties.

A/C 4

Electric cooling

Electric cooling

Data Plate: No data plate noted

Manufacturer: Unknown

Type: Cooling only

Cooling only

System: Air Conditioning

Air Conditioning

HVAC SERVICING CHECKLIST

The following list is a minimum set of requirements to be expected of heat pump or air conditioning servicing. I provide this as a courtesy to show the types of check-ups that should be expected from a professional servicing, which should be done annually at minimum.

- Check compressor efficiency

- Check refrigerant level

- Clean the condenser coil

- Change or clean air filters

- Inspect contactors and wiring

- Inspect drive-sheaves, pulleys and belts

- Check and adjust for proper air flow

- Clean the blower motor as needed

- Lubricate all motors and shaft bearings

- Check, calibrate and program the thermostats and be sure the thermostat has adequate batteries as needed

- Check unit smoke detector, clean filter if applicable

- Check safety disconnect, laser-temp -- check across contacts

HVAC SYSTEM NOTE

My assessment of the air conditioning system is based on visual examination and operational testing at the time of inspection. We do not verify if the system components are matched. This evaluation does not guarantee future performance or uncover hidden defects. For a complete understanding of the system's condition and longevity, we recommend regular maintenance and additional evaluation by a licensed HVAC professional.

Source: Air

Air

Age: Unknown

Nominal Capacity: Unknown

Refrigerant Type: Unknown

Unknown

Breaker Sizing: Unknown

Unknown

Disconnecting Means: Blade

INOPERATIVE AIR CONDITIONER

The outdoor air conditioner compressor appears to be inoperative; it did not respond to testing using normal thermostat controls. Have this appliance serviced and repaired or replaced as recommended.

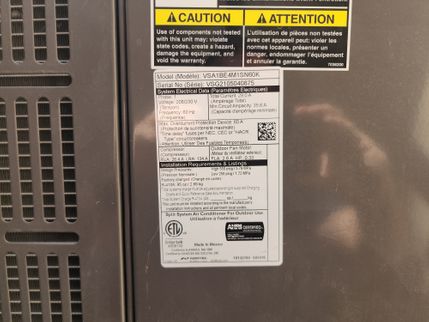

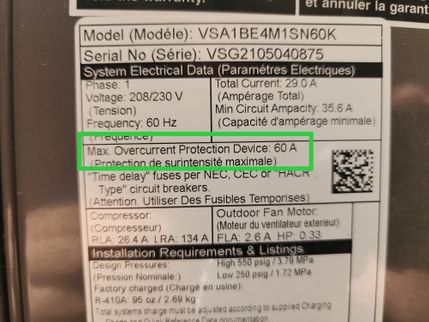

A/C 5

Electric cooling

Electric cooling

Manufacturer: Amana (Daikin)

Type: Split system

Split system

System: Air Conditioning

Air Conditioning

HVAC SERVICING CHECKLIST

The following list is a minimum set of requirements to be expected of heat pump or air conditioning servicing. I provide this as a courtesy to show the types of check-ups that should be expected from a professional servicing, which should be done annually at minimum.

- Check compressor efficiency

- Check refrigerant level

- Clean the condenser coil

- Change or clean air filters

- Inspect contactors and wiring

- Inspect drive-sheaves, pulleys and belts

- Check and adjust for proper air flow

- Clean the blower motor as needed

- Lubricate all motors and shaft bearings

- Check, calibrate and program the thermostats and be sure the thermostat has adequate batteries as needed

- Check unit smoke detector, clean filter if applicable

- Check safety disconnect, laser-temp -- check across contacts

HVAC SYSTEM NOTE

My assessment of the air conditioning system is based on visual examination and operational testing at the time of inspection. We do not verify if the system components are matched. This evaluation does not guarantee future performance or uncover hidden defects. For a complete understanding of the system's condition and longevity, we recommend regular maintenance and additional evaluation by a licensed HVAC professional.

Source: Air

Air

Age: 2018

Nominal Capacity: 5 Tons

Refrigerant Type: R-410A

R-410A

R-410A is currently one of the most commonly used refrigerants in air conditioning systems. It gained popularity as a replacement for ozone-depleting refrigerants like R-22 due to its ozone-friendly properties. However, R-410A has a high global warming potential (GWP), leading to increasing scrutiny and calls for its phase-down or replacement with lower-GWP alternatives, such as R-454B. Starting as soon as January 1, 2025, restrictions will take effect on the use of higher-GWP HFCs in new 1) aerosols, 2) foams, and 3) refrigeration, air conditioning, and heat pump equipment. As regulations evolve and R-407C, and R-410A becomes less common, maintaining and servicing systems that use this refrigerant may become more challenging. Depending on future regulations and market trends, retrofitting existing systems or transitioning to alternative refrigerants may become necessary.

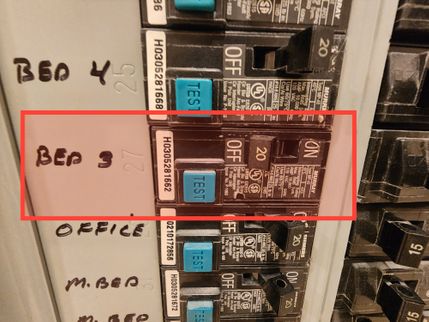

Breaker Sizing: Improper

Improper

Disconnecting Means: Blade

IMPROPERLY SIZED CONDENSER UNIT BREAKER

The AC condenser unit unit breaker was noted to be improperly sized. The manufacturer requires a minimum breaker size of 32.6 amps and a maximum breaker size of 50 amps However, a 60 amp breaker was noted in the Main panel panel. The nameplate data on the condenser unit specifies the minimum and maximum sized breaker allowed to be installed. If the installed breaker does not conform to manufacturer requirements, it may void any relevant manufacturer warranty that would have otherwise been honored. Additionally, improperly sized breakers provide home warranty companies with reasoning to not honor a claim.

A/C 6

Electric cooling

Electric cooling

Manufacturer: York

Type: Split system

Split system

System: Air Conditioning

Air Conditioning

HVAC SERVICING CHECKLIST

The following list is a minimum set of requirements to be expected of heat pump or air conditioning servicing. I provide this as a courtesy to show the types of check-ups that should be expected from a professional servicing, which should be done annually at minimum.

- Check compressor efficiency

- Check refrigerant level

- Clean the condenser coil

- Change or clean air filters

- Inspect contactors and wiring

- Inspect drive-sheaves, pulleys and belts

- Check and adjust for proper air flow

- Clean the blower motor as needed

- Lubricate all motors and shaft bearings

- Check, calibrate and program the thermostats and be sure the thermostat has adequate batteries as needed

- Check unit smoke detector, clean filter if applicable

- Check safety disconnect, laser-temp -- check across contacts

HVAC SYSTEM NOTE

My assessment of the air conditioning system is based on visual examination and operational testing at the time of inspection. We do not verify if the system components are matched. This evaluation does not guarantee future performance or uncover hidden defects. For a complete understanding of the system's condition and longevity, we recommend regular maintenance and additional evaluation by a licensed HVAC professional.

Source: Air

Air

Age: 2017

Nominal Capacity: 5 Tons

Refrigerant Type: R-410A

R-410A

R-410A is currently one of the most commonly used refrigerants in air conditioning systems. It gained popularity as a replacement for ozone-depleting refrigerants like R-22 due to its ozone-friendly properties. However, R-410A has a high global warming potential (GWP), leading to increasing scrutiny and calls for its phase-down or replacement with lower-GWP alternatives, such as R-454B. Starting as soon as January 1, 2025, restrictions will take effect on the use of higher-GWP HFCs in new 1) aerosols, 2) foams, and 3) refrigeration, air conditioning, and heat pump equipment. As regulations evolve and R-407C, and R-410A becomes less common, maintaining and servicing systems that use this refrigerant may become more challenging. Depending on future regulations and market trends, retrofitting existing systems or transitioning to alternative refrigerants may become necessary.

Breaker Sizing: Improper

Improper

Disconnecting Means: Blade

IMPROPERLY SIZED CONDENSER UNIT BREAKER

The AC condenser unit unit breaker was noted to be improperly sized. The manufacturer requires a minimum breaker size of 32.6 amps and a maximum breaker size of 50 amps However, a 60 amp breaker was noted in the Main panel panel. The nameplate data on the condenser unit specifies the minimum and maximum sized breaker allowed to be installed. If the installed breaker does not conform to manufacturer requirements, it may void any relevant manufacturer warranty that would have otherwise been honored. Additionally, improperly sized breakers provide home warranty companies with reasoning to not honor a claim.

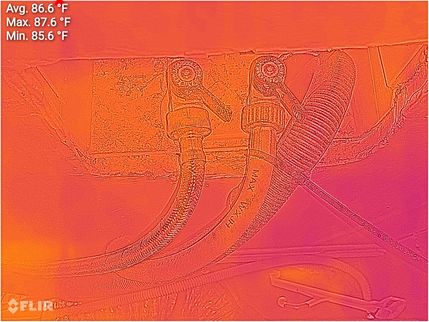

AC Refrigerant Lines

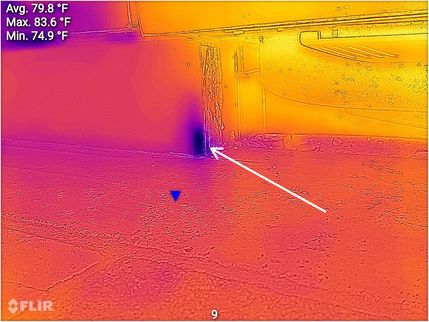

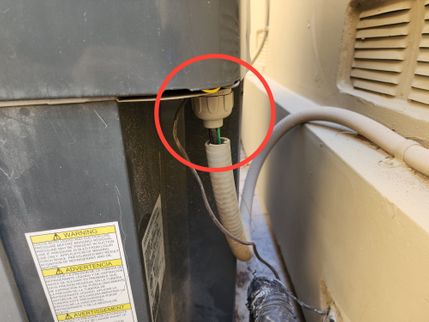

SUCTION LINE INSULATION SUBSTANDARD

One of more sections of foam pipe insulation were noted to be missing and gapped on the low-pressure refrigerant line in the attic. This may result in a measurable efficiency degradation. Condensation can form on the exposed copper portion of the low pressure refrigerant line and drip onto finishes below. If located in the attic, this may eventually cause staining of the interior ceiling surface.

- This condition was observed to varying degrees at all FAU's in the attic. All insulation should be corrected to avoid possible water damage.

Condensate Drains

Condensate Lines: Primary

Primary Un-trapped

Un-trapped

CONDENSATE DRAIN TRAP MISSING

When the unit operates without a trap, or with an un-primed trap, it sucks in outside air, dirt, bugs, etc. through the condensate line and blows that stuff into conditioned air space. This is because the condensate line is typically located on the negative pressure side of the blower. Most traps need roughly 3" lift to work properly and allow for static pressure fluctuations. Also, most manufacturers recommend installation of a trap, and missing, or improperly installed traps may void any existing warranty. Discretion advised. The significance of the situation, problem or defect is uncertain.

▲T (Delta T)

ΔT: Below 16 °F

Below 16 °F 16 - 22 °F

16 - 22 °F

ΔT (Delta T) Temperature Differential LOW

The ΔT of an HVAC system in cool mode is a comparative test, measuring the temperature of the air entering the unit (return air) against the temperature of the "conditioned" air exiting the unit (supply air). I use a laser thermometer to get my comparative readings at the return air grill and the closest supply register to the coil, whereas an HVAC contractor would insert probe thermometers into the evaporator plenum on each side of the evaporator coil to provide a true differential. A properly operating unit will provide at least 16°F difference in temperature and no greater than 22°F difference in temperature. The differential temperature observed for the unit in this home was less than 16°F. A low differential temperature can be the result of insufficient or excessive refrigerant; air or non-condensables in the oil; poor insulation coverage on the refrigerant line; or a myriad of other reasons. The unit will provide cold air to the home but the amount of electricity needed to bring the home to the desired setpoint will be significantly higher than the amount of electricity required for a properly operating system. This issue can have a very significant impact on the electrical utility costs for the home.

Systems with low temperature splits.

- Servicing dining and SW bed - Return air temp

- Servicing dining and SW bed - Supply air temp

- Servicing 2nd floor beds - Return air temp

- Servicing 2nd floor beds - Supply air temp

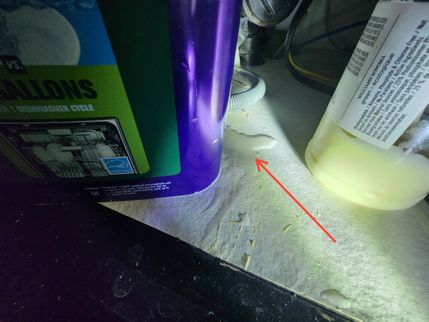

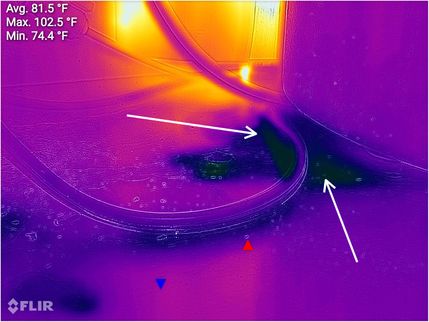

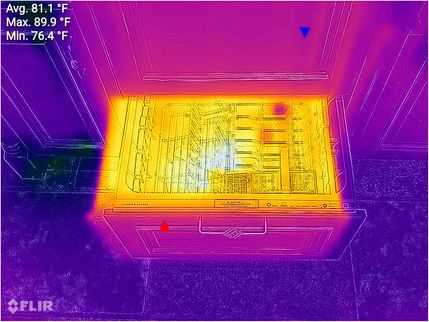

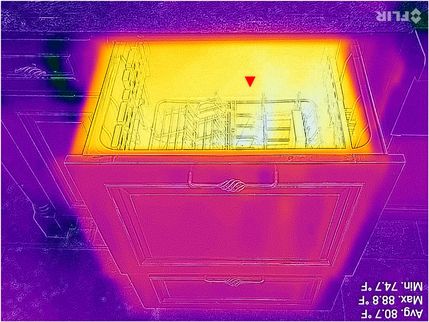

ΔT (Delta T) OK