The Scope and Purpose

Purchasing a property involves risk

💲The purpose of a home inspection is to help reduce the risk associated with the purchase of a structure by providing a professional opinion about the overall condition of the structure. A home inspection is a limited visual inspection and it cannot eliminate this risk. Some homes present more risks than others. We cannot control this, but we try to help educate you about what we don’t know during the inspection process. This is more difficult to convey in a report and one of many reasons why we recommend that you attend the inspection.

These reports are typically created with time constraints. While I do my best to proof them and send them out without errors, some typographical errors and other errors and omissions will occur. I apologize in advance, and if any of these errors result in the report being unclear, confusing or incomplete, please contact me immediately for clarification/correction.

A home inspection is not an insurance policy

This report does not substitute for or serve as a warranty or guarantee of any kind. Home warranties can be purchased separately from insuring firms that provide this service.

A home inspection is visual and not destructive

The descriptions and observations in this report are based on a visual inspection of the structure. We inspect the aspects of the structure that can be viewed without dismantling, damaging or disfiguring the structure and without moving furniture and interior furnishings. Areas that are concealed, hidden or inaccessible to view are not covered by this inspection. Some systems cannot be tested during this inspection as testing risks damaging the building. For example, overflow drains on bathtubs are generally not tested because if they were found to be leaking, they could damage the finishes below. Our procedures involve non-invasive investigation and non-destructive testing which will limit the scope of the inspection.

☢️Environmental/Mold Exclusions

The reported or actual health effects of many potentially harmful, toxic or environmentally hazardous elements that may be found in building materials or in the air, soil, water in and/or around any house are varied, and, in some cases controversial. A home inspection does not include the detection, identification or analysis of any such elements or related concerns such as, but not limited to, mold, allergens, legal/illegal drugs and other biological contaminants, radon, , bed bugs, cockroaches, fleas, lice, formaldehyde, asbestos, lead, electromagnetic fields, carbon monoxide, insecticides, Chinese drywall, refrigerants and fuel oils. Furthermore, no evaluations are performed to determine the effectiveness or appropriateness of any method or system (e.g., water filter, radon mitigation, etc.), designed to prevent or remove any hazardous or unwanted materials or elements. An environmental health specialist should be contacted for evaluation of any potential health or environmental concerns. The noting of the presence of materials commonly considered to contain asbestos, formaldehyde, lead, mold etc in the inspection report, should not be construed to mean the inspector is inspecting for these things but instead should be seen as a "heads-up" regarding these materials and further evaluation by qualified professionals may be warranted.

This is just my opinion and just for you

The contents of this report are for the sole use of the client named above and no other person or party may rely on this report for any reason or purpose whatsoever without the prior written consent of the inspector who authored the report. Any person or party who chooses to rely on this report for any reason or purpose whatsoever without my express written consent does so at their own risk and by doing so waives any claim of error or deficiency in this report.

Construction techniques and standards vary. There is no one way to build a house or install a system in a house. The observations in this report are my opinions based on my training and experience. Other inspectors and contractors are likely to have differing opinions. You are welcome to seek opinions from other professionals in the context of doing your due diligence.

When the definitions of terms used in this report are not obvious through context, refer to the legal definitions used in the modern building standards and/or manufacturer instructions.

The scope of this inspection

The inspection and report are intended to provide Super Client with information regarding the condition of the systems and components of the property as observed at the time of the inspection. I examine the readily accessible systems and components using normal operating controls. The inspection is not technically exhaustive and will not identify concealed conditions or latent defects. Any comments offered by me that could be construed as over or beyond the standards of practice or the language of this contract, are offered as a professional courtesy. Refer to the Washington State, Standards of Practice and/or Pre-Inspection Agreement for additional information regarding the scope and limitations of the inspection. The Standards of Practice are linked below and describe the "minimum" standards a Licensed Washington State Home Inspector must adhere to: Standards of Practice

All homes are likely to have some faults which may range from cosmetic defects to major safety hazards. Not all defects will be found. While some minor deficiencies may be mentioned, the emphasis of this report is to inform the buyer of the property condition by detecting deficiencies or circumstances that may affect the structural integrity of the building and its components and its safe use as a residence.

You are encouraged to obtain competitive estimates for major repair needs. Safety and health issues should be addressed promptly. It is recommended that all corrective work, other than routine maintenance activities, be performed by qualified licensed contractors.

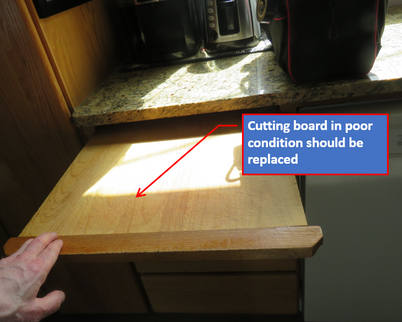

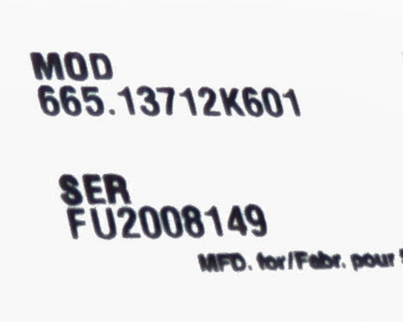

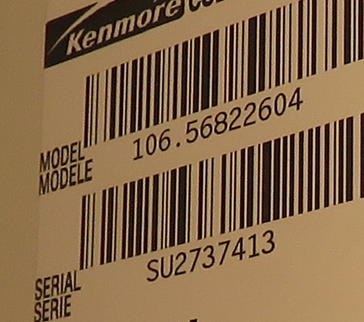

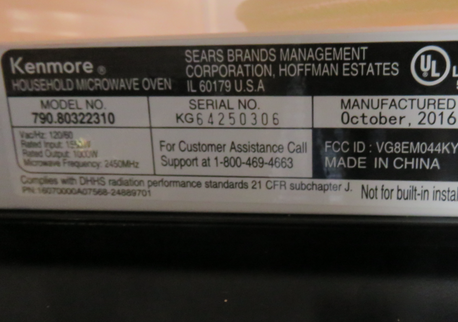

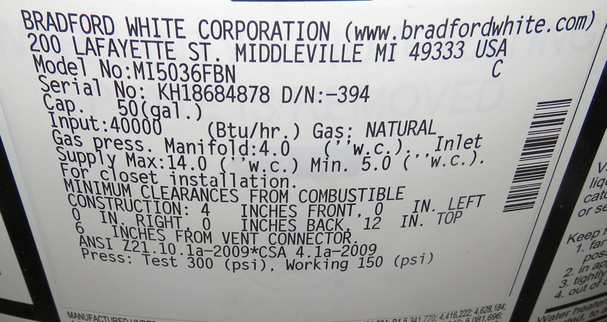

It is beyond the scope of the Standard Home Inspection to identify components within the home that may have been part of a "manufacturer's recall". Mention of specific recalls within this report must not be construed to mean that all such recalls have been identified, or that such identification is part of a Standard Home Inspection. When possible, appliance Model Numbers and Serial Numbers are included in the report and can be used to check for recall related issues. If you have any question about specific appliances, information can be found at the CPSC (Consumer Products Safety Commission) website or contact the manufacturer directly.

I recommend you obtain as much history as is available concerning this property. This historical information may include copies of any seller's disclosures, previous inspection or engineering reports, reports performed for or by relocation companies, municipal inspection departments, lenders, insurers and appraisers. You should attempt to determine whether repairs, renovation, remodeling, additions or other such activities have taken place at this property, and this report will attempt to identify such items when possible.

Ranges, Dish Washers, and Refrigerators, Microwaves (and the like) are typically tested for basic function (Do they turn on). No assertions are made as to how well they function. Clothes washers/dryers are typically not operated.

Throughout this report, comments will be made as to the presence or absence of components or parts of components. This must not be construed to mean that these components or parts of components exist (or don't exist) in concealed areas or behind finished surfaces. For example: if foundation bolting was seen in one area, it does not mean that the bolting exists (or doesn't exist) in areas that are concealed. Also if an item was noted as "not being visible," that should not be construed to mean that none of whatever was "not visible" does not exist on the premises---it just means none was noted at the time of inspection and should be seen as a "heads-up" that the concern or condition might be present but hidden, or that the conditions that would allow its presence to be known was not replicated at the time of inspection.

Many of the non-narrative observations/documentation detailed in the report that are related to more "cosmetic" issues should not be construed as "all inclusive" but should instead be seen as "suggestive" or a "guideline" of conditions that may exist elsewhere in the home. It is not the focus of the report to comment extensively on cosmetic issues, but I do make note of them at times to help complete the "snap-shot" of the home at the time of inspection. For example, "nail-pops" seen in one room are likely to be seen (and should be anticipated) in other rooms even though I may not have noted them in the report.

Throughout the report I may make recommendations as to possible repairs. These recommendations are not intended to be substitutes or construed to be more appropriate than the recommendations of the professionals making the repairs. Conflicts in recommendations should be resolved prior to repairs being made.

Who should make repairs and what should their qualifications be?

Worker qualifications: In the text of the report, in some instances, I recommend that work be done by a "qualified" persons or "qualified" parties. I consider qualified parties, in licensed trades, to be those individuals who hold the necessary licenses to legally work in their profession -- licensed electricians, licensed pest control applicators, licensed plumbers, licensed HVAC professionals, licensed engineers, licensed general contractors, etc. In instances where a task may not, typically, need to be done by a person with a professional license, my recommendation is to hire an individual to do the work who is, based on past training, experience or expertise, qualified to further evaluate the condition or problem listed in the report and to then make appropriate repairs.

For additional fees, I can perform invasive inspection of concealed areas if desired. Please contact me for more information regarding this service.

💧Moisture meters used

Throughout the report, reference may be made to moisture conditions and percentages of moisture content. These moisture readings are obtained by the use of a Protimeter, Surveymaster Moisture Meter or the Extech MO55 or the Tramex MEP. Generally moisture meters are used "qualitatively" as opposed to "quantitatively." This means that actual percentages shown by meter are meant to be indicative of moisture as compared to likely dryer areas. False positives are not always possible to eliminate entirely, but moisture meters can give good guidance.

🌈Infrared

I routinely use infrared cameras when helpful but typically only qualitatively, so specific temperatures captured by the camera should not be seen as a quantitative analysis of surfaces but only used as a guide to thermal differences that would then be verified visually, by moisture meter or more invasive investigation.

Your participation is requested

Your presence is requested during this consultation. A written report will not substitute for all the possible information that can be conveyed verbally by a shared visual observation of the conditions of the property. If you were not present, you are urged to contact me for a verbal consultation. I am happy to do a zoom meetup to go through areas of concern in the report. If you choose not to be present or contact me after, I cannot be responsible for misinterpretation of the report.

How to Read This Report

Getting the Information to You

This report is designed to deliver important and technical information in a way that is easy for anyone to access and understand. If you are in a hurry, you can take a quick look at our "Summary Page” and quickly get critical information for important decision making. However, we strongly recommend that you take the time to read the full Report, which includes digital photographs, captions, diagrams, descriptions, videos and hot links to additional information.

The best way to get the layers of information that are presented in this report is to read your report online, which will allow you to expand your learning about your house. You will notice some words or series of words highlighted in blue and underlined – clicking on these will provide you with a link to additional information.

For the most reliable viewing experience, I recommend viewing the report on as large a screen as practical, as much detail can be lost on small devices like smart phones. For similar reasons, reports should only be printed in color to retain as much detail as possible and minimize misinterpretation.

This report can also be printed on paper or to a PDF document.

Chapters and Sections

This report is divided into chapters that parcel the home into logical inspection components. Each chapter is broken into sections that relate to a specific system or component of the home. You can navigate between chapters with the click of a button on the left side margin.

Most sections will contain some descriptive information done in black font. Observation narratives, done in colored boxes, will be included if a system or component is found to be significantly deficient in some way or if we wish to provide helpful additional information about the system or the scope of our inspection. If a system or component of the home was deemed to no noteworthy defects or was in some way operational, there may be no narrative comments in that section and it may simply describe the components.

Observation Labels

All narrative observations are colored, numbered and labeled to help you find, refer to, and understand the severity of the observation.

Pest Inspection

All items with the bug emoji (🐞) are part of a structural pest inspection. If your inspector included a structural pest inspection as a part of the scope of your home inspection, you can distinguish pest inspection items by this emoji. You can also go to the pest inspection summary page to see a summary of the items that are part of a pest inspection.

Summary Page of Findings

The inspection findings are summarized below. They are listed by importance with substantial safety hazard at the top in red or orange. These can be life safety hazards or issues that could result in a major short-term expense to correct or possible significant expense in the future if not addressed. This summary is not a complete listing of the findings in the report and reflects the opinion of the inspector. It should be considered highly likely there will be other issues you would like in the summary, and you should add these as desired. Please review all of the report pages. All repairs must be done by the applicable qualified, licensed & bonded trades or professionals. I recommend obtaining receipts and warranties for the work done (including copies of any necessary permits).

Many of these Narrative comments in the Summary have pictures and web links that better clarify the issues. Please refer to their place in the report body for additional clarification/information. Lack of information under any given component only means that, in my opinion, there was nothing in the body of the report that warranted posting it to the Summary. There will certainly be valuable information under each applicable component in the body of the report.

SUMMARY

Major Concerns

📌 Not ApplicableSignificant Repair/Safety Items

- ND1-1 North Deck/Entryway:

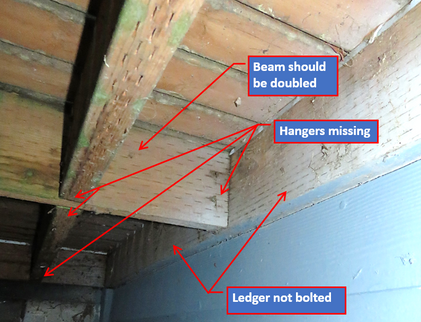

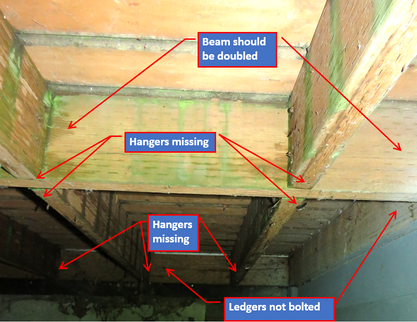

NORTH DECK/ENTRYWAY:

The deck structure had numerous issues and no attempt to document all these issues will be made in this report. The bulleted lists and narratives related to the information and pictures below should be seen as more representative as opposed to all inclusive and other concerns should be anticipated. Concerns were noted in relation to:

GENERAL INFORMATION:

- There were issues with:

- 🔹the structure

- 🔹the walking surface

- 🔹the stairs

STAIRS:

- Conditions:

- 🔹paint failure

TREADS:

- 🔹thickness of stair treads is less than the required 1-1/2"

HANDRAILS:

- Conditions:

- 🔹not present

FLOOR STRUCTURE:

- Construction:

LEDGERS:

- 🔹not bolted or not adequately bolted

- 🔹ledger attached on top of siding

JOISTS:

- Metal hangers/brackets:

- 🔹missing at some locations

STAINED/TREATED SURFACE:

- Conditions:

- 🔹weathering/deterioration

- 🔹inadequate clearances between siding and deck surface. the siding is too close to the deck surface and moisture damage can occur over time. Proper clearances should be created and/or vigilantly maintained.

PAINTED:

- 🔹failed paint

POSTS/COLUMNS:

- 🔹improper/insufficient attachment noted

BEAMS:

- 🔹improperly supported beams

Notes, and maintenance documentation/details about the deck, will be detailed in the pertinent sections below this narrative.

The following pictures with descriptions are meant to convey the necessity for evaluation/repair of the structure by a qualified deck installation/repair contractor as deemed necessary. The recommended minimum standards can be found in the American Wood Council's Prescriptive Wood Residential Deck Construction Guide. This guide is also known as "DCA-6." Another great reference, even though a little ahead of requirements in most jurisdictions and not free, Deck Construction Based on the 2021 IRC. I recommend evaluation, repairs and improvements by a qualified deck construction contractor.

🛑 Safety 🔨Repair 🔧 Maintenance 👁🗨 Monitor annually 🐞 WDO’s ➕ Upgrade 🔍 Due Diligence

- PLUMBING5-3 🚿PLUMBING:

BUILDING DRAINAGE SYSTEMS:

There were issues documented below in bulleted lists, narratives, and pictures related to the drainage system of the home: I recommend evaluation, repairs and maintenance as deemed necessary by a licensed plumber (or in some cases by other qualified parties).

PUBLIC SEWER:

- 🚩Sewer scoping is recommended. Proper function of the building drain to the city sewer is beyond the scope of this inspection. I recommend that proper function be both determined and maintained. The best method to verify function is to have them inspected with a remote camera device. I recommend the drains associated with this property be professionally scoped by a qualified drainage scoping company (preferably one not associated with, or part of, a plumbing repair company).

- 🔹the long run of the drain

- 🔹the age

ABS DRAINS:

- Installation concerns:

- 🔹less than professional installation noted

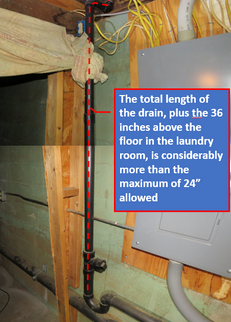

- 🔹the drain from the laundry drops more that 8 feet to the trap and the maximum drop is closer to 24". This whole configuration of drain should be repaired in the context of fixing the venting discussed below.

FLOOR DRAINS:

- 🔹function not determined

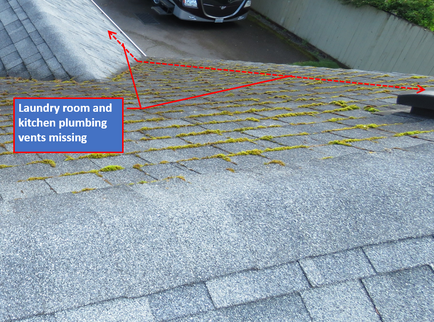

VENTING:

- 🔹don't run above roof line

- No vent was found terminated above the roof. There was no plumbing vents through the roof as required. I recommend a full evaluation of all of the vent plumbing by a licensed plumber. It is possible it terminates in the attic space and was never extended through the roof when the roof/addition was installed. Currently the only vent is provided by an improperly installed air admittance valve. At least one vent is required to go through the roof. The laundry and kitchen could be accomplished with air admittance valves but the bathroom should vent through the roof.

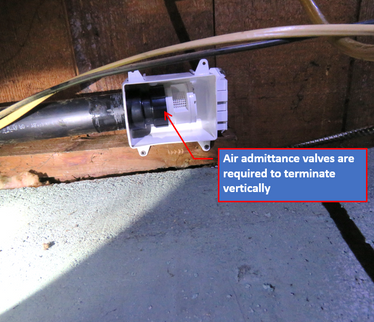

AIR ADMITTANCE VALVES (AAV):

- 🔹🚩AAV's This installation is not done to manufacturer's specifications and could cause the unit to fail. Have this further evaluated and repaired by a licensed plumber. From one brand of AAV: The Sure-Vent® AAV must be located a minimum of 4 inches above the horizontal branch drain and 6 inches above any insulation material and within 15 degrees of vertical.

- 🔹not installed within 15° of vertical

- 🔹installed in a horizontal orientation

🛑 Safety 🔧 Maintenance (as needed) 👁🗨 Monitor annually 🔍 Due Diligence

- E2-12 ⚡ELECTRICAL:

☠️CARBON MONOXIDE CONCERNS:

The CO Detectors of the home had the following concerns. The pictures and bulleted list below document some of those concerns, but not likely all of them. I recommend evaluation/repairs by the licensed electrical contractor or other qualified parties following manufacturer's instructions.

CO DETECTORS:

- 🚩None seen post 2011. I recommend that homeowner/handy-person install carbon monoxide alarm/detector according to the manufacturers specifications wherever missing. These alarm/detectors are currently required in all homes. They are currently required on each floor level of the home and outside each sleeping area of the home. A plug-in type detector with digital readout is preferred. They are required to be maintained to the manufacturer's instructions by the tenant of the home. Sometimes there are combination smoke/carbon monoxide alarm/detectors in the home (verify with builder). Carbon monoxide alarm/detectors had the following issues and/or were missing outside the sleeping room areas:

- 🔹sleeping rooms at main floor level

🛑 SAFETY 🔧 Maintenance 👁🗨 Monitor monthly ➕ Upgrade 🔍 Due Diligence

- E2-13 ⚡ELECTRICAL:

SMOKE ALARM CONCERNS:

There were issues documented below in bulleted lists, narratives, and pictures related to the smoke alarms in the home and proper evaluation/repairs by a licensed electrical contractor or other qualified party should be made.

SMOKE ALARM/DETECTOR:

- 🔹smoke alarms should be installed

- 🔹🚩past expected life. The smoke alarms are likely past their expected life at the basement. I recommend replacement of all of the alarms unless it can be shown they are less than 10 years old. If the alarms are more than 10 years old they should all be replaced by a qualified party throughout the home with photo-electric type alarms.

- 🔹🚩smoke Alarms not verified. The presence of smoke alarms was not verified at main floor level. I recommend evaluation/repairs/verification by a qualified party and that all alarms be placed where recommended by current regulations and manufacturer instructions. If the alarms are more than 10 years old they should all be replaced by a qualified party throughout the home with photo-electric type alarms. Information from NFPA

- 🚩None seen. I recommend installation of smoke alarms for improved safety. Smoke alarms were not found in the sleeping rooms or other rooms that could be sleeping areas or at other required locations around the home at the:

- 🔹basement level

- 🔹main floor level

- 🔹inside of main floor bedrooms

- 🔹main floor within 21 feet of bedrooms

🛑 SAFETY 🔧 Maintenance 👁🗨 Monitor monthly ➕ Upgrade 🔍 Due Diligence

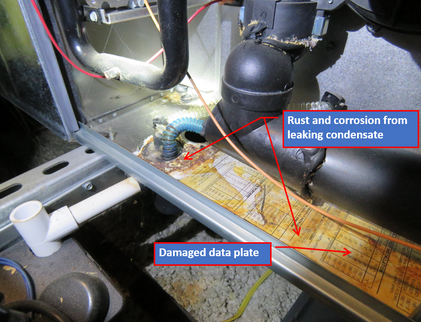

- HC-2 🔥HEATING / ❄️COOLING:

HIGH-EFFICIENCY GAS FURNACE CONDITIONS:

There were issues documented below in bulleted lists, narratives and pictures related to the High-Efficiency Gas furnace that should be further evaluated, repaired and maintained as deemed necessary by the licensed HVAC contractor.

FUNCTION:

- 🔹not operated at time of inspection and proper operation should be verified

SECONDARY PAN:

- 🔹secondary pan is missing.

CONDITIONS/ACCESS:

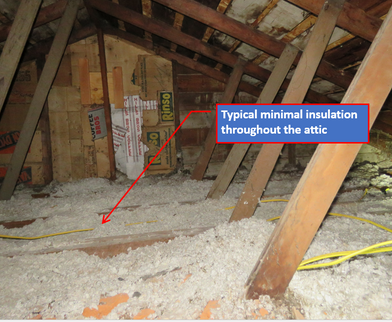

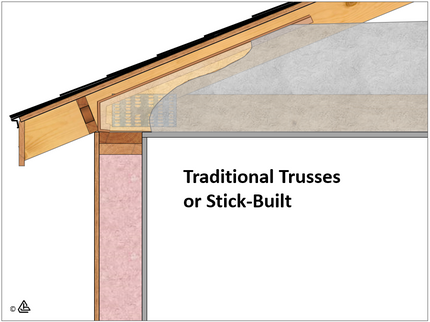

- 🔹poor access. The location of the furnace in the attic is so difficult that I recommend it be relocated to the attic where the unit and all ductwork could be inside the conditioned space. This could not only improve access, but make the unit more efficient and allow the attic to be better insulated and no proper walkway would need to be installed to the unit.

- 🔹inspection limited

COMPARTMENT:

- 🔹rusting

CONDENSATE DISPOSAL:

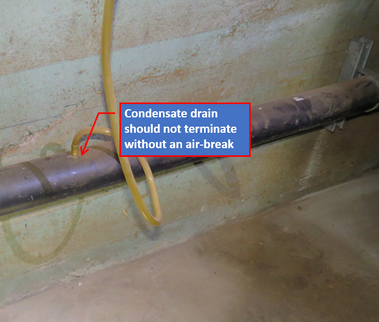

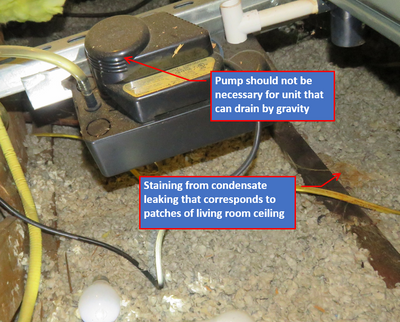

- 🔹pump not necessary as condensate can drain by gravity

- 🔹drain improperly terminates in plumbing drain with out an air break

- 🔹condensate leaking into insulation

COMBUSTION/DILUTION AIR:

- 🔹adequacy of Combustion Air not determined. It is not always possible to assess at the time of inspection whether there is adequate combustion air provided. It is my intent to report on conditions indicative of the lack of combustion air. A combustion type water heater must have an adequate source of combustion air for the fuel to burn properly. An inadequate air supply may cause incomplete combustion and can produce carbon monoxide. This installation does not appear to have enough combustion air for proper/safe function.

VENTING:

- 🔹non-cellular core type pipe NOT verified

🛑 Safety 🔧 Maintenance (as needed) 👁🗨 Monitor annually 🌲 Efficiency / IAQ 🔍 Due Diligence

Repair Items

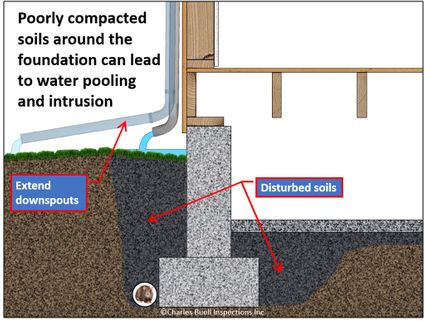

- G3-1 ⛺GROUNDS:

CONDITIONS RELATED TO THE GROUNDS AROUND THE BUILDING:

There were issues documented below in bulleted lists, narratives and pictures related to the grounds that should be evaluated and repaired as deemed necessary by the appropriate qualified parties.

GRADING CONCERNS RELATED TO:

- Reverse grade. Improving grading around the home to minimize the flow of surface water toward the foundation is recommended. This is primarily a concern at the north side of the home where the overall slant of the grade is toward the home. Improvements to the grading by a licensed landscaping contractor is recommended. Grade should slope away from the home for at least 10 feet or to whatever distance can be created due to close proximity to adjacent properties or have proper drainage to accommodate surface water that can impact the building:

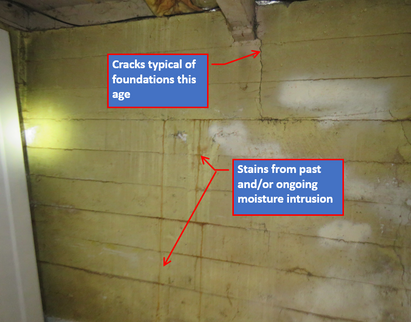

- 🔹crawl space/basement involved. This water can impact the foundation and find its way into the crawl space and basement contributing to the overall moisture burden of the home.

- 🔹at west side of the home

🛑 Safety 🔨Repair 🔧 Maintenance 👁🗨 Monitor annually 🐞 WDO’s ➕ Upgrade 🔍 Due Diligence

- G3-2 ⛺GROUNDS:

PROPERTY DRAINAGE SYSTEMS:

There were issues documented below in bulleted lists, narratives and pictures related to the Drainage around the building. Drainage systems around the property warrant ongoing vigilant maintenance/cleaning. Conditions of such drainage mostly cannot be determined in the context of an inspection. The following conditions were noted and evaluation and repairs should be made by a qualified party as deemed necessary.

ROOF WATER DRAINS:

- Conditions:

- 🔹debris filled pipes evident

🛑 Safety 🔨Repair 🔧 Maintenance 👁🗨 Monitor monthly 🐞 WDO’s ➕ Upgrade 🔍 Due Diligence

- G3-6 ⛺GROUNDS:

FENCES AROUND THE PROPERTY:

There were issues documented below in bulleted lists, narratives and pictures related to the Fences. While fences around the home are generally not inspected except as to how they impact the home, as a courtesy, I still report safety concerns and general conditions when warranted. All fences should be maintained and inspected periodically. Sometimes maintenance and replacement involves the neighbors and I make no determination as to ownership of fences on the borders of the property. Your due diligence is advised.

GENERAL FENCE CONCERNS:

- 🔹fences in poor condition and should be replaced if desired

- 🔹repairs will likely involve neighbors

🛑 Safety 🔨Repair 🔧 Maintenance 👁🗨 Monitor annually 🐞 WDO’s ➕ Upgrade 🔍 Due Diligence

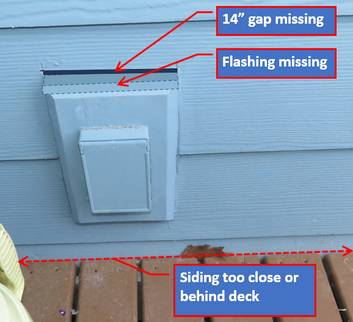

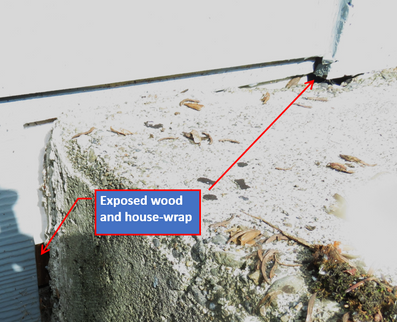

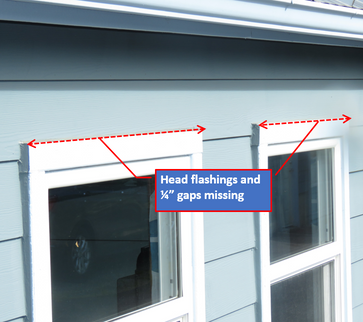

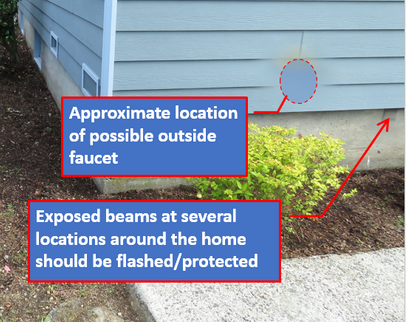

- BES-2 🏡BUILDING EXTERIOR & STRUCTURE:

FIBER CEMENT SIDING:

There were issues documented below in bulleted lists, narratives and pictures related to the Fiber Cement Cladding. Siding protects the home from the elements and requires ongoing maintenance. Sometimes there are enough issues that entire replacement is warranted. The following issues were noted:

CONCERNS:

- Siding clearance conditions:

- 🔹too close to deck/porch/balcony surfaces

- 🔹behind deck structures

- 🔹siding behind/in-contact-with concrete structures

- 🔹not installed per manufacturers instructions/recommendations. Issues were noted that may impact the reliability, longevity or warranty of the product but may be difficult or cost-prohibitive to correct. Repairs to these items are often put off until such time as larger repairs become needed or damage becomes obvious.

- 🔹evidence of patching/repairs

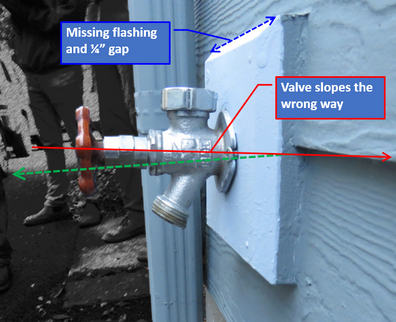

FLASHINGS:

- 🔹1/4 inch gaps missing at horizontal flashings

- Penetrations. With cement board siding there are specific requirements related to penetrations of the siding. This includes pipes. There are numerous issues that do not meet modern requirements. Location (under overhangs for example) will dictate how important repairs will be. Sometimes maintenance is all that is necessary. I recommend evaluation/repairs by a qualified party experienced with cement board siding installation requirements at the following locations: outside faucets, etc. There are also other siding details that do not meet cement board installation related to penetrations:

- 🔹missing flashings

I recommend a full evaluation by a qualified siding contractor to determine what repairs are necessary and to make proper repairs including, where appropriate, evaluation/repairs of hidden damage. Some amount of hidden damage should be anticipated..

🛑 Safety 🔨Repair 🔧 Maintenance 👁🗨 Monitor annually 🐞 WDO’s ➕ Upgrade 🔍 Due Diligence

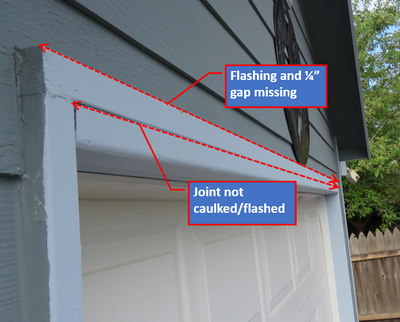

- BES-4 🏡BUILDING EXTERIOR & STRUCTURE:

EXTERIOR TRIM:

There were issues documented below in bulleted lists, narratives and pictures related to the trim of the home. There are conditions that should be evaluated and repaired as deemed necessary by a qualified party. Any damaged materials should be replaced, repaired and maintained as deemed necessary.

WOOD TRIM:

- Conditions:

- 🔹gaps not caulked

- 🔹horizontal flashings improperly caulked

- Too close to:

- 🔹ground

🛑 Safety 🔨Repair 🔧 Maintenance 👁🗨 Monitor annually 🐞 WDO’s ➕ Upgrade 🔍 Due Diligence

- G-1 🚘GARAGE:

GARAGE INTERIORS:

There were issues documented below in bulleted lists, narratives and pictures related to the garage floor that should be evaluated and repaired as deemed necessary by a qualified party and monitored annually. The pictures and notes below detail some of these concerns, but should not be construed to be a complete accounting of the issues.

INTERIORS:

- 🔹Wall between house and basement. Having the exposed wood, between the garage and basement interior spaces covered with drywall to improve fire safety is recommended. Fire-resistant materials on the walls and ceilings between the house and the garage have been required by building standards for a long time. Consult with drywall installation company regarding installation. Taping of all drywall seams is recommended.

- 🔹exposed, kraft-faced insulation

🛑 Safety 🔨Repair 🔧 Maintenance 👁🗨 Monitor annually 🐞 WDO’s ➕ Upgrade 🔍 Due Diligence

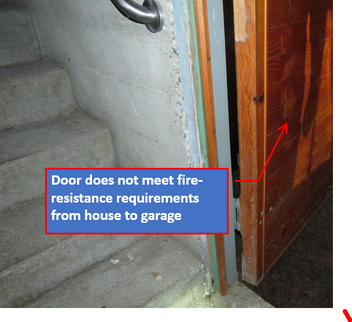

- G-2 🚘GARAGE:

GARAGE/HOUSE DOOR:

There were issues documented below in bulleted lists, narratives and pictures related to the door between the house and the garage that should be evaluated and repaired as deemed necessary by a qualified party. Some of the conditions will be documented below but should not be considered all inclusive.

GENERAL DOOR CONCERNS:

- Conditions:

- 🔹shows "distress" consistent with age

🔥FIRE RESISTANCE:

- 🔹the garage/house door does not meet current standards. The door should be a solid wood door not less than 1-3/8 inches thick, a solid or honeycomb-core steel door not less than 1-3/8 inches thick, or 20-minute fire-rated door. All doors between the house and the garage are required to have a self-closure device. It should also be weather-stripped at threshold, sides and top. Improper doors can allow fumes from the garage to enter the home.

- 🔹door should be replaced in conjunction with upgrading garage for fire safety.

- 🔹automatic closer device is not present

THRESHOLD/WEATHER-STRIPPING:

- Bottom of door weather-stripping:

- 🔹not installed

- Threshold weather-stripping:

- 🔹none Present

LOCKING MECHANISMS:

- 🔹Site-built slide lock

🛑 Safety 🔧 Maintenance (as needed) 👁🗨 Monitor annually 🌲 Efficiency / IAQ 🔍 Due Diligence

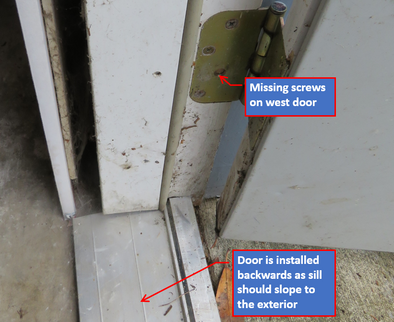

- G-3 🚘GARAGE:

WEST GARAGE EXTERIOR DOOR CONDITIONS:

There were issues documented below in bulleted lists, narratives and pictures related to the exterior doors of the home. All should be evaluated, repaired and maintained as deemed necessary by a qualified door installation contractor or other qualified party. Concerns will be documented in the pictures below but should not be construed to be all inclusive but instead more representative:

OUT SWING:

- Not security type hinges for out-swing type door. For improved security the hinges on this out-swing type door should be replaced with security-pin type hinges. This prevents removal of the pins from the exterior when the door is closed.

- Installed backwards--threshold slopes to the interior

HINGES:

- Hinge conditions:

- 🔹not security type hinges

LOCKSET & SECURITY:

- 🔹🚩Security pin enters strike plate. It is common in homes for the lock-set security pin to enter the strike plate hole. When this happens the door can be unlocked from the outside with a credit card (in-swing type) and from the outside with a knife (out-swing type). The strike plates should be adjusted toward the weather stripping to make the door more secure. Adjustments should be made so that the pin does not enter the strike plate when closed.

- 🔹latch can be "knifed" to gain entry. The door is not secure because latch can be "knifed" to gain entry, a dead-bolt would make a good improvement..

DEAD-BOLT:

- 🔹none present

🛑 Safety 🔨Repair 🔧 Maintenance 👁🗨 Monitor annually ➕ Upgrade 🌲 Efficiency / IAQ 🔍 Due Diligence

- G-4 🚘GARAGE:

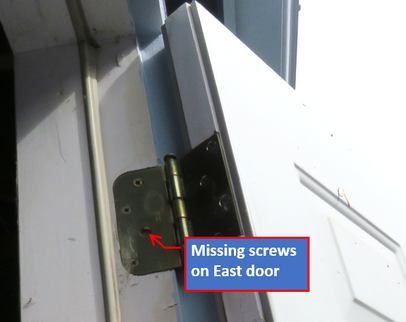

EAST GARAGE EXTERIOR DOOR CONDITIONS:

There were issues documented below in bulleted lists, narratives and pictures related to the exterior doors of the home. All should be evaluated, repaired and maintained as deemed necessary by a qualified door installation contractor or other qualified party. Concerns will be documented in the pictures below but should not be construed to be all inclusive but instead more representative:

OUT SWING:

- Not security type hinges for out-swing type door. For improved security the hinges on this out-swing type door should be replaced with security-pin type hinges. This prevents removal of the pins from the exterior when the door is closed.

STRUCTURE/SURFACE:

- 🔹Shows distress consistent with age. The door could benefit from upgrading for energy efficiency and safety. They had cosmetic as well as defects related to age and use. Replacement of the doors can improve overall energy efficiency of the home as well as improve security of the home. Until these doors can be replaced, maintain the door well painted and sealed to protect the home from damage from the elements.

- 🔹distress consistent with weathering/exposure

- 🔹some rot/decay in door

- 🔹steel clad type doors with bottom wood edges not sealed

- Steel clad type doors with bottom wood edges not sealed. Steel clad insulated doors have a wood frame behind the metal. This wood must be kept well sealed maintained especially along the bottom of the door to prevent damage from water that can splash against the jamb and weather-stripping and wick around the metal cladding and into the wood. This condition is exacerbated by draft-stop materials installed in the area that the edge of the door closes against. This is particularly problematic on doors exposed to the weather side of the home. Preventing this kind of damage on this type of door can be difficult. Other types of flashings and weather-stripping are available to minimize the chances of damage but keeping the area well painted and sealed should be considered the first line of defense. Once decay has begun it is likely the entire door will need to be replaced.

BOTTOM OF DOOR WEATHER-STRIPPING:

- 🔹weather-Stripping in poor condition

- 🔹loose/Not properly attached

THRESHOLD WEATHER-STRIPPING:

- 🔹none Present

HINGES:

- 🔹missing screws

LOCKSET & SECURITY:

- 🔹🚩Security pin enters strike plate. It is common in homes for the lock-set security pin to enter the strike plate hole. When this happens the door can be unlocked from the outside with a credit card (in-swing type) and from the outside with a knife (out-swing type). The strike plates should be adjusted toward the weather stripping to make the door more secure. Adjustments should be made so that the pin does not enter the strike plate when closed.

- 🔹latch can be "knifed" to gain entry. The door is not secure because latch can be "knifed" to gain entry, and installation of a dead-bolt is recommended..

DEAD-BOLT:

- 🔹none present

🛑 Safety 🔨Repair 🔧 Maintenance 👁🗨 Monitor annually ➕ Upgrade 🌲 Efficiency / IAQ 🔍 Due Diligence

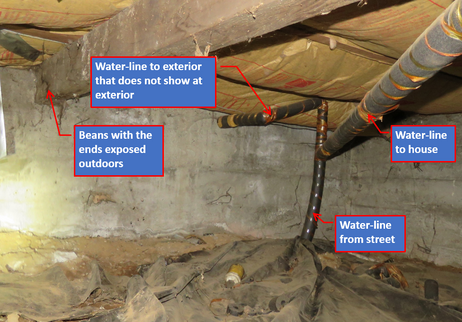

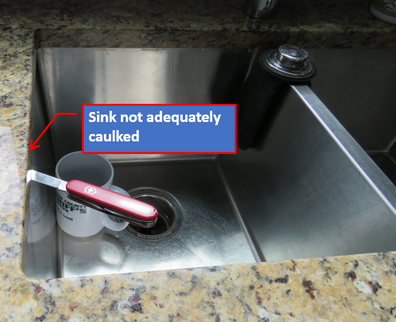

- PLUMBING5-2 🚿PLUMBING:

FROST-FREE/ANTI-SIPHON OUTSIDE FAUCET:

There were issues documented below in bulleted lists, narratives, and pictures related to the outside faucet that should be evaluated and repaired as deemed necessary by a licensed plumber.

FROST-FREE ANTI-SIPHON:

- 🔹🚩Valve stem did NOT drain when test gauge removed indicative of improper slope and/or that the valve is not frost-free type. The frost-free type faucet at the north side of the home does not slope so that it can drain. I recommend evaluation/repairs by the licensed plumber or other qualified party to allow for proper function of the device (otherwise it is not frost-free). There are plastic shims available to create the proper slope.

🛑 Safety 🔧 Maintenance (as needed) 👁🗨 Monitor during use 🔍 Due Diligence

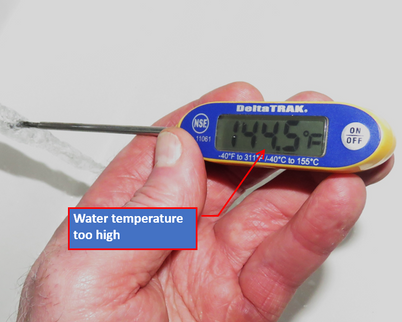

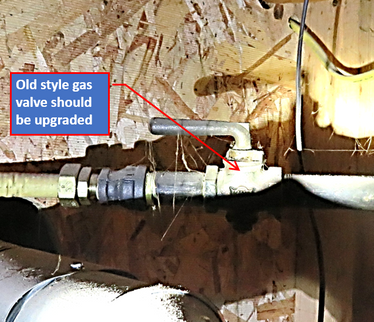

- PLUMBING5-4 🚿PLUMBING:

GAS WATER HEATER:

There were issues documented below in bulleted lists, narratives, and pictures related to the water heater that should be further evaluated, repaired and maintained as deemed necessary by a licensed plumber (or in some cases, repairs can be made by other qualified parties):

WATER HEATER CONDITIONS:

- ❌Approaching its expected life. The water heater at more than 10 years old is approaching the end of its useful life. I recommend factoring replacement of the heater by a licensed plumber in the near future.

GAS SHUT-OFF:

- 🔹older type of valve should be replaced in the context of the next water heater replacement

DRIP LEGS/SEDIMENT TRAPS:

- 🔹none present. Many appliances require sediment traps located as close to the appliance as practical. None is present on this appliance and I recommend evaluation/repairs as deemed necessary by a licensed plumber in the context of other plumbing repairs at the home.

B-VENT CHIMNEY:

- 🚩Missing insulation baffle in attic. The water heater vent has inadequate clearance to insulation in the attic. While this insulation might not be considered combustible, the concern is that it might reduce the ability of the vent to cool itself and conduct that heat through the insulation to materials that are combustible. A proper insulation baffle should be installed to provide the required 1" clearance to materials required for B-vent.

WATER TEMPERATURE:

- 🔹🚩Water temperature too hot likely inadequate supply. Given the number of bathrooms and other points of use of hot water, it is possible that the water heater will not be sufficient to provide an uninterrupted supply of hot water (this can vary widely depending on use and life-style). I recommend improving amounts of supply if, under daily use, there proves to be insufficient supply. Consult with a licensed plumber about possible options.

🛑 Safety 🔧 Maintenance (as needed) 👁🗨 Monitor annually 🔍 Due Diligence

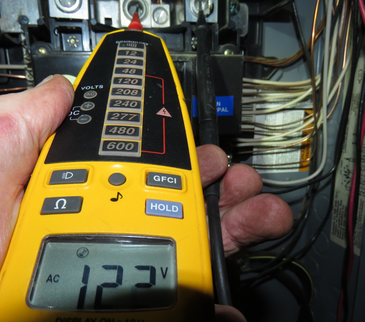

- E2-1 ⚡ELECTRICAL:

ELECTRICAL SERVICE TO PROPERTY:

There were issues documented below in bulleted lists, narratives and pictures related to the Electrical Service to the property that should be evaluated and repaired as deemed necessary by a licensed electrical contractor. Additional issues should be anticipated and uncovered during repairs.

LOW VOLTAGE UTILITY WIRES:

- 🔹improperly connected to electrical mast---should be removed

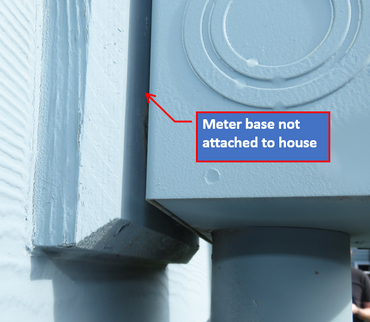

METER CONDITION:

- 🔹meter base not attached to house. The electric meter base is not well-secured to the house. Have this further investigated by the utility or an electrician and repaired as recommended to insure water does not get trapped behind the meter and to insure the meter base is well-secured.

🛑 Safety 🔧 Maintenance (as needed) 👁🗨 Monitor annually 🔍 Due Diligence

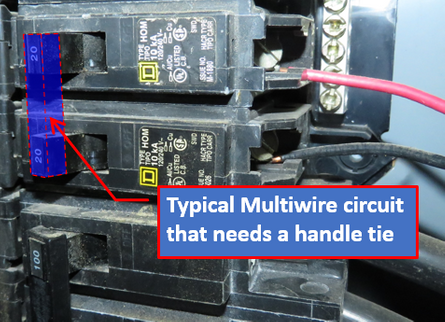

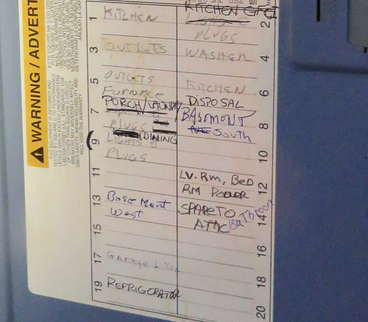

- E2-2 ⚡ELECTRICAL:

ELECTRICAL SERVICE EQUIPMENT:

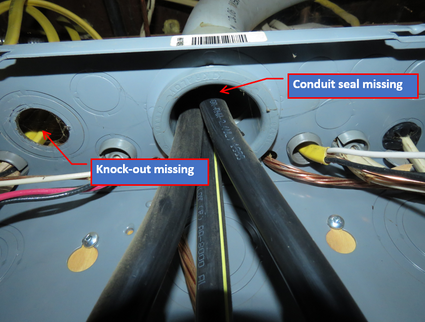

There were issues documented below in bulleted lists, narratives, and pictures related to the electrical service equipment that should be evaluated and repaired as deemed necessary by the licensed electrical contractor.

PANEL CONDITION:

- 🔹missing knock-outs--exposed energized components

- 🔹vermin activity in panel

- 🔹conduit from meter base not sealed

🛑 Safety 🔧 Maintenance (as needed) 👁🗨 Monitor annually 🔍 Due Diligence

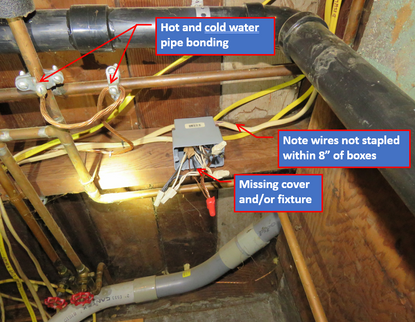

- E2-3 ⚡ELECTRICAL:

ELECTRICAL SYSTEM BONDING:

There were issues documented below in bulleted lists, narratives, and pictures related to the bonding of metallic systems of a building. Bonding is important for electrical safety to keep grounded metal components at the same potential. I recommend all aspects of required bonding be evaluated and repaired as deemed necessary by the licensed electrical contractor. The items below, should be seen as a guide and not necessarily all inclusive but more representative.

YELLOW CSST:

- 🔹🚩not bonded with #6 copper minimum

🛑 Safety 🔧 Maintenance (as needed) 👁🗨 Monitor annually 🔍 Due Diligence

- E2-4 ⚡ELECTRICAL:

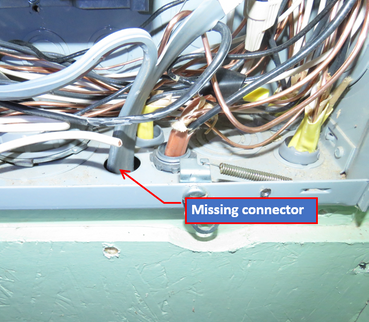

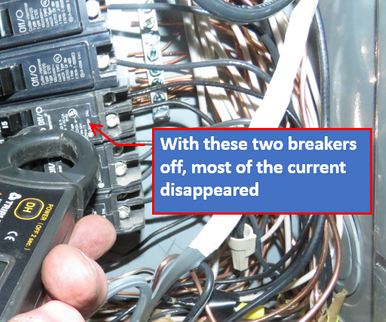

DETACHED BUILDING SUB-PANEL CONDITIONS:

There were issues documented below in bulleted lists, narratives, and pictures related to the Sub-Panel that should be evaluated and repaired as deemed necessary by a licensed electrical contractor. They should not be construed to be all concerns that need to be addressed but more representative.

PANEL CONDITION:

- 🔹connector issues

- 🔹amperage on grounding conductor. This should be further evaluated by the licensed electrical contractor to both determine the cause and make necessary repairs.

🛑 SAFETY 🔧 Maintenance (as needed) 🔍 Due Diligence

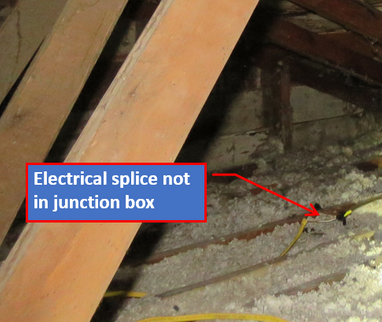

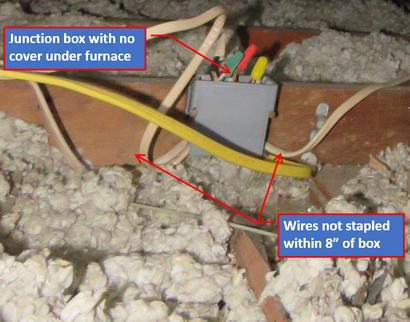

- E2-6 ⚡ELECTRICAL:

DISTRIBUTION WIRING CONCERNS:

There were issues documented below in bulleted lists and narratives related to the distribution wiring in the home that should be evaluated and repaired as deemed necessary by the licensed electrical contractor.

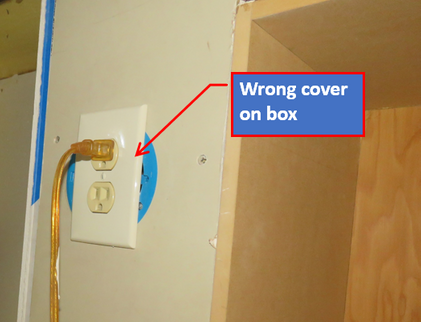

GENERAL CONCERNS:

- Junction Boxes.

- 🔹missing covers

- 🔹missing knockouts

🛑 Safety 🔧 Maintenance (as needed) 👁🗨 Monitor annually ➕ Upgrade 🔍 Due Diligence

- E2-7 ⚡ELECTRICAL:

WIRING SUPPORT/PROTECTION:

There were issues documented below in bulleted lists and narratives related to the wiring in the home that should be evaluated and repaired as deemed necessary by a licensed electrical contractor. It should be seen as representative of the concerns and not all inclusive.

ATTIC WIRING:

- 🔹wiring not properly supported in Attic

- 🔹Improper use and installation of din rail

BASEMENT WIRING:

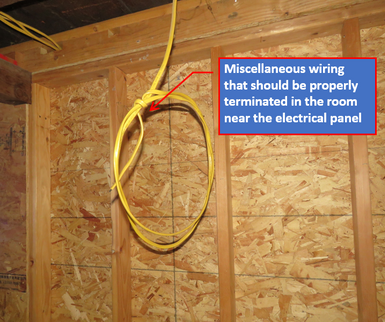

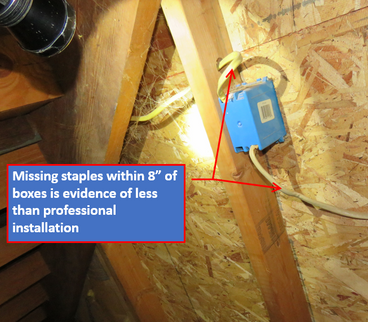

- 🔹not secured within 8" of plastic junction boxes is indicative of less than professional work

- 🔹abandoned wiring that should be removed and/or properly terminated

🛑 Safety 🔧 Maintenance (as needed) ➕ Upgrade 🔍 Due Diligence

- E2-8 ⚡ELECTRICAL:

RECEPTACLE OUTLET CONDITIONS:

There were issues documented below in bulleted lists and narratives related to the receptacles in the home:

RECEPTACLES GENERAL:

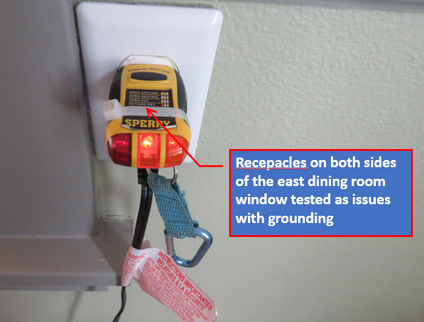

- 🔹some three prong receptacles tested as "ungrounded"

GFCI Receptacles

- 🔹some garage receptacles not GFCI protected (south end in removed stove location)

- 🔹missing at west side of garage

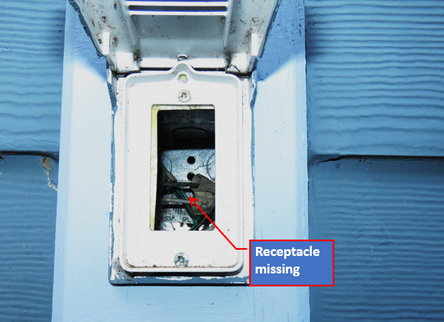

MISING RECEPTACLES/COVERS:

- 🔹at numerous locations, covers should be installed wherever found to be missing

- 🔹furniture often conceal missing covers

TAMPER RESISTANT RECEPTACLES:

- Tamper resistant receptacles missing. No tamper-resistant receptacles were noted in the home. Electrical permits drawn after June 6, 2009 would likely require this type of receptacle throughout the home.

WEATHER RESISTANT RECEPTACLES:

- Weather resistant receptacles missing. No tamper-resistant receptacles were noted in the home. Electrical permits drawn after June 6, 2009 would likely require this type of receptacle throughout the home.

I recommend evaluation and repairs by a licensed electrical contractor. Other similar conditions should be anticipated.

🛑 Safety 🔨Repair 🔧 Maintenance 👁🗨 Monitor annually ➕ Upgrade 🔍 Due Diligence

- E2-9 ⚡ELECTRICAL:

LIGHTING OUTLET CONDITIONS:

There were issues documented below in bulleted lists, narratives, and pictures related to the lighting components in the home including:

FIXTURES:

- 🔹cotton pull chains

- 🔹missing fixtures

PORCELAIN BULB HOLDERS:

- 🔹several basement locations

SWITCHES:

- 🔹missing cover plates

- 🔹other missing covers should be anticipated and installed wherever found missing

EXTERIOR LIGHTS:

- 🔹broken fixtures

- 🔹missing fixtures

- Missing at exterior at:

- 🔹doors at east side of garage which can be a safety hazard approaching or leaving the garage in the dark. All doors with access to grade are required to be illuminated at the exterior. Proper lighting should be installed

- Function not determined at:

- 🔹some locations

While the pictures below document some of these concerns, I recommend all lighting locations be evaluated and repaired as deemed necessary by a licensed electrical contractor.

🛑 Safety 🔧 Maintenance (as needed) 👁🗨 Monitor during use ➕ Upgrade 🌲 Efficiency / IAQ 🔍 Due Diligence

- ED4-1 🚪EXTERIOR DOORS:

FRONT ENTRYWAY DOOR CONDITIONS:

There were issues documented below in bulleted lists, narratives and pictures related to the exterior doors of the home. All should be evaluated and repaired as deemed necessary by a qualified door installation contractor or other qualified party.

LOCKSET & SECURITY:

- 🔹🚩security pin enters strike plate. It is common in homes for the lock-set security pin to enter the strike plate hole. When this happens the door can be unlocked from the outside with a credit card (in-swing type) and from the outside with a knife (out-swing type). The strike plates should be adjusted toward the weather stripping to make the door more secure. Adjustments should be made so that the pin does not enter the strike plate when closed.

- 🔹latch can be "credit carded" because it is type of latch with no security pin. The door is not secure because latch can be "credit-carded" to gain entry if dead-bolt is not used.

Concerns will be documented in the pictures below but should not be construed to be all inclusive but instead more representative:

🛑 Safety 🔨Repair 🔧 Maintenance 👁🗨 Monitor annually ➕ Upgrade 🌲 Efficiency / IAQ 🔍 Due Diligence🌲 Efficiency / IAQ 🔍 Due Diligence

- ED4-2 🚪EXTERIOR DOORS:

NORTH ENTRYWAY DOOR CONDITIONS:

There were issues documented below in bulleted lists, narratives and pictures related to the exterior doors of the home. All should be evaluated and repaired as deemed necessary by a qualified door installation contractor or other qualified party.

OUT SWING:

- 🔹🚩not security type hinges for out-swing type door. For improved security the hinges on this out-swing type door should be replaced with security-pin type hinges. This prevents removal of the pins from the exterior when the door is closed.

HINGES:

- 🔹not security type hinges

- 🔹missing screws

LOCKSET & SECURITY:

- 🔹🚩security pin enters strike plate. It is common in homes for the lock-set security pin to enter the strike plate hole. When this happens the door can be unlocked from the outside with a credit card (in-swing type) and from the outside with a knife (out-swing type). The strike plates should be adjusted toward the weather stripping to make the door more secure. Adjustments should be made so that the pin does not enter the strike plate when closed.

- 🔹latch can be "knifed" to gain entry if dead-bolt is not used. The door is not secure because latch can be "knifed" to gain entry if dead-bolt is not used..

Concerns will be documented in the pictures below but should not be construed to be all inclusive but instead more representative:

🛑 Safety 🔨Repair 🔧 Maintenance 👁🗨 Monitor annually ➕ Upgrade 🌲 Efficiency / IAQ 🔍 Due Diligence🌲 Efficiency / IAQ 🔍 Due Diligence

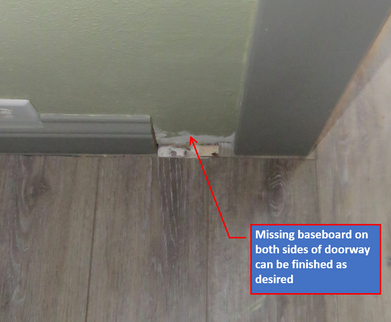

- I9-1 🖼️INTERIORS:

BUILDING INTERIORS:

Concerns noted below related to the interior spaces of the home should be evaluated and repaired and repaired as deemed necessary by the appropriate qualified party.

GENERAL INFORMATION:

- 🌳Building Performance Professional recommended. This building could greatly benefit from a full evaluation by a qualified Building Performance Professional, to determine how best to address air quality issues as well as improvements for overall energy efficiency.

- 🔹some baseboard not complete, finish as desired

- 🔹🚩Evidence of heavy smoking. Throughout the interior smells of heavy use of tobacco were noted. Toxic residues from smoking can permeate walls and building materials and heating system ductwork and can be extremely difficult to seal/clean--sometimes requiring removal/replacement of affected materials. Consult with qualified painting contractor as to best options--including proper clean-up/removal.

HABITABILITY/EGRESS:

- 🔹ceiling height less than 6'-8" in basement non-habitable areas

- 🔹non conforming basement spaces. None of the basement spaces are included in this report as "habitable spaces" but some aspects have been reported on throughout the report. It is strongly recommended that if any of these spaces, including the kitchen area, bathroom area and defined rooms are to used for anything more than storage spaces that they be improved to meet the requirements of those spaces. Insufficient headroom is likely the biggest obstacle to use of the basement space for many uses.

ESCAPE & RESCUE:

- 🔹no second means of egress or escape and rescue from basement space

INTERIOR MOISTURE CONCERNS:

- 🔹walls, previous condition that should be monitored

🛑 Safety 🔧 Maintenance (as needed) 👁🗨 Monitor (ongoing) 🔍 Due Diligence 📝 Informational note

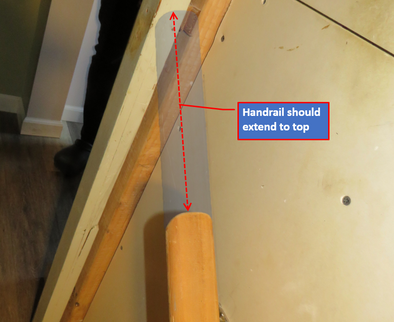

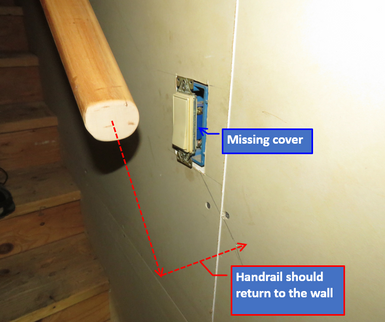

- S5-1 Stairs:

BASEMENT STAIR CONDITIONS:

There were issues documented below in bulleted lists, narratives and pictures related to the stairs that indicate the need for evaluation and repairs by a qualified stair installation contractor. I recommend such work prior to use of the stairs.

STAIR GENERAL INFORMATION:

- 🔹Poor basement stairs. It is common for stairs to the basement to be of lower quality than stairs in finished areas of the home. Improper side barriers, handrails, tread spacings, head room etc. Changes to these stairs for safety may be warranted but often times adjustments are difficult and/or expensive.

HANDRAILS:

- 🚩Handrail does not conform to current safety standards. Proper handrails on stairs can promote safe use of the stairs and prevent falls that can result in serious injury or even death. Handrails are required to meet specific guidelines on all stairs with 4 risers or more. In some cases they are prudent on stairs with fewer risers. The handrail is required to be graspable as defined in the building codes. The following concerns should be addressed by a qualified party:

- 🔹does not return to wall at top and bottom of railing

- 🔹does not extend all the way from top riser to bottom riser. Handrails are required to run the full length of the stairs from a point vertical above the top riser and bottom riser.

🛑 Safety 🔨Repair 🔧 Maintenance 🔍 Due Diligence

- F7-1 🔥Fireplaces:

FREE-STANDING STOVE CONDITIONS:

There were issues documented below in bulleted lists, narratives and pictures related to the free-standing stove that should be evaluated as deemed necessary by a qualified fireplace installation contractor. Information about the chimney it is connected to can be found in the chimney section of the roofing chapter.

FREE-STANDING STOVE:

- Function not determined and it should not be used until inspected and verified as safe

- Installation not complete---verify proper completion of installation

VENTING:

- Not installed, unit must not be operated

- 🔹abandoned vent for removed gas fireplace in the bedroom can be removed as desired, and roof patched as necessary.

🛑 Safety 🔨Repair 🔧 Maintenance 👁🗨 Monitor annually ➕ Upgrade 🌲 Efficiency / IAQ 🔍 Due Diligence

- K3-3 🥧Kitchen:

RANGE/COOKTOP:

There were issues documented below in bulleted lists, narratives, and pictures related to the cooktop:

CONCERNS:

- Anti-Tipping Device:

- 🔹NOT Installed/Is necessary

INSTALLATION/TESTING:

- No re-ignition feature. Many modern gas ranges have auto-relight functions for the burners. In the event that a gust of wind were to blow out the flame--especially when adjusted to low--the re-light function allows the burner to re-light itself for safety. This particular unit does not appear to have that function and no determination is made as to whether it can be added or not. Upgrade/modify as desired.

- 🔹did not re-light with flame blown out

I recommend evaluation and repair by a qualified party.

🛑 Safety 🔧 Maintenance 👁🗨 Monitor 🔍 Due Diligence

- K3-4 🥧Kitchen:

MICROWAVE/HOOD:

There were issues documented below in bulleted lists, narratives, and pictures related to the Microwave and exhaust fan:

DUCTWORK:

- 🔹NOT insulated

VENT TERMINATION:

- 🔹missing. There is no screen installed as required on the cooktop exhaust fan/hood at the east exterior of the home. I do not like screens on this location but they are required. If one is going to be installed it would be better to install it on the outside of the damper. They are prone to clogging with lint/grease over time. Maintenance is necessary regardless.

- Damper:

- 🔹does not close tight

- 🔹mechanical damage to cap

I recommend evaluation and repair as deemed necessary by a qualified party.

🛑 Safety 🔧 Maintenance 👁🗨 Monitor 🌲 Efficiency / IAQ 🔍 Due Diligence

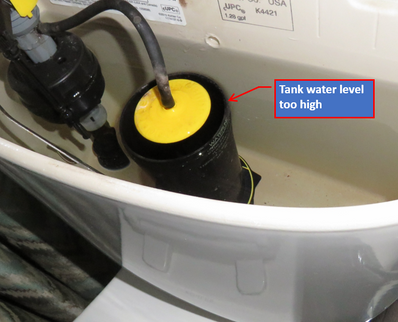

- MB-1 🛀Main Bathroom:

TOILET CONDITIONS:

There were issues documented below in bulleted lists and narratives related to the toilet in the main bathroom that should be evaluated and repaired as deemed necessary by a licensed plumber or other qualified party.

TANK:

- 🔹water level too high. The toilet tank water level in the main bathroom is too high allowing the water to run continuously. This can waste considerable water.

🛑 Safety 🔨Repair 🔧 Maintenance 👁🗨 Monitor annually 🐞 WDO’s 🔍 Due Diligence

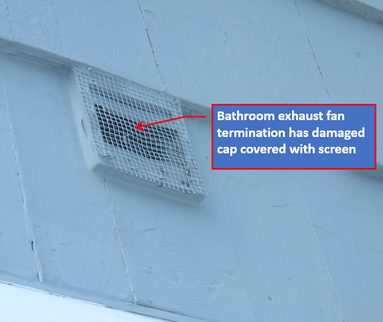

- MB-2 🛀Main Bathroom:

EXHAUST FANS:

There were issues documented below in bulleted lists and narratives related to the laundry exhaust fan:

COMPONENTS/CONDITION/FUNCTION:

- 🚩Insulation baffle missing. When the insulation baffle is not present it should be verified that units with heating components are rated to be in contact with insulation and if not, a proper separation should be installed or the fan should be upgraded for improved safety and energy efficiency. Before the additional insulation is added to the attic it should be verified a proper baffle is installed or that the unit is rated for insulation contact.

VENT TERMINATION:

- Exhaust improperly terminated:

- 🔹damper missing--all exhaust vent caps require a damper for energy efficiency. Without a damper, the damper in the unit will open when the house is under negative pressure, resulting in air bypassing the damper.

I recommend evaluation and repairs as deemed necessary by a qualified party.

🛑 Safety 🔨Repair 🔧 Maintenance 👁🗨 Monitor annually 🐞 WDO’s ➕ Upgrade 🌲 Efficiency / IAQ 🔍 Due Diligence

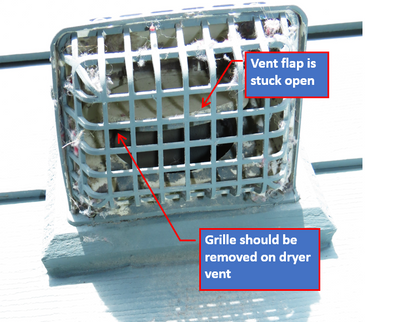

- L1-1 🧺Laundry:

DRYER CONDITIONS:

There were issues documented below in bulleted lists, narratives, and pictures related to the dryer that should be addressed by a qualified party.

TRANSITION DUCT:

- 🔹🚩Foil flexible duct. Most flexible metal foil type dryer transition duct is considered less desirable and not allowed by most manufacturers, even if it meets UL 2158A, Class 0, requirements. If your dryer is connected with this type of vent pipe I recommend replacement of the pipe with smooth wall metal type pipe or approved flexible metal type pipe. This foil type pipe is considered a fire hazard.

VENT TERMINATION:

- 🚩"Cage" type vent cap. The vent cap for the dryer has a cage type cover. These cages tend to plug with lint. I recommend removal of the cage to allow for better flow of air out of the vent. Maintaining these vents free of lint should be done on a monthly basis until the necessity for less frequent cleaning can be determined. Clogged dryer vents, besides being a fire hazard, can result in longer drying times.

- 🔹single flap type cap (with "cage" type cover)

- 🔹cap stuck in open position. The dryer vent cap is stuck in the open position. This can allow vermin entry into the vent and allows allows cold air to be drawn into the vent when the house is under negative pressure. Oftentimes, when one opens the dryer in the winter and it is VERY cold inside the dryer, this can be an indication the vent is stuck open. The cap should be inspected monthly to verify it is functioning properly and maintained properly.

🛑 Safety 🔨Repair 🔧 Maintenance 👁🗨 Monitor monthly ➕ Upgrade 🌲 Efficiency / IAQ 🔍 Due Diligence

Repair and/or Maintenance Items

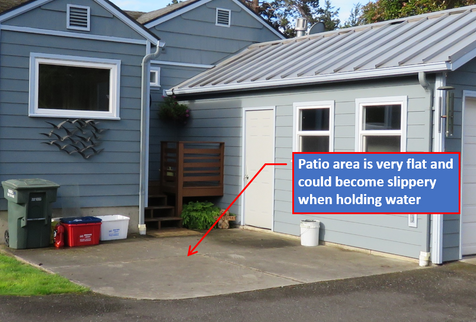

- G3-4 ⛺GROUNDS:

PATIO CONDITIONS:

There were issues documented below in bulleted lists, narratives and pictures related to the patio.

CONCRETE PATIO:

- 🔹very flat

DRAINAGE:

- 🔹ability of patio to drain away water not determined

- 🔹poorly drained--very flat

- 🔹ponding should be anticipated

I recommend evaluation by a qualified party as deemed necessary.

🛑 Safety 🔨Repair 🔧 Maintenance 👁🗨 Monitor annually 🐞 WDO’s ➕ Upgrade 🔍 Due Diligence

- G3-5 ⛺GROUNDS:

PROPERTY WALKWAYS:

There were issues documented below in bulleted lists, narratives and pictures related to the Property Walkways. There were numerous conditions with the concrete property walkways that should be evaluated, repaired and maintained by a qualified party. Some areas merely need monitoring and maintenance typical of any walkway. Maintenance of these walkways is typically the responsibility of the property owner and defects such as trip hazards and the presence of snow/ice can lead to increased liability if persons are injured. The following conditions were noted to the walkway:

PROPERTY CONCRETE WALKWAYS:

- Surface Conditions:

- 🔹settlement

- 🔹displacement

- 🔹cracks

🛑 Safety 🔨Repair 🔧 Maintenance 👁🗨 Monitor annually 🐞 WDO’s ➕ Upgrade 🔍 Due Diligence

- BES-1 🏡BUILDING EXTERIOR & STRUCTURE:

THE BUILDING EXTERIOR HAS THE FOLLOWING CONCERNS:

There were issues documented below in bulleted lists, narratives and pictures related to the Building's Exterior. The following concerns should be evaluated, repaired, replaced and improved by a qualified party as deemed necessary. Hidden damage in exterior cladding is common and should be anticipated.

EXTERIOR CONDITION:

- 🔹inadequate clearances to finish grade

- 🔹mechanical damage

- 🔹missing components

🛑 Safety 🔧 Maintenance (annual) 👁🗨 Monitor annually 🐞 WDO’s 🔍 Due Diligence

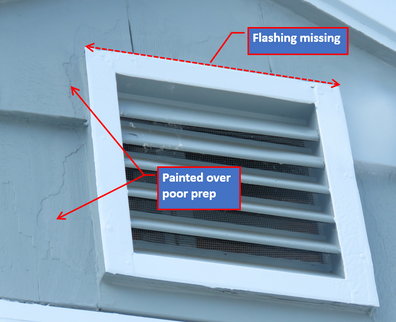

- BES-3 🏡BUILDING EXTERIOR & STRUCTURE:

CEDAR SHINGLE SIDING:

There were issues documented below in bulleted lists, narratives and pictures related to the Cedar Shingle Siding. Siding protects the home from the elements and requires ongoing maintenance. Sometimes there are enough issues that entire replacement is warranted. The following issues were noted:

CONCERNS:

- Siding installation conditions:

- 🔹much over-painting and poor prep--replace as desired

I recommend evaluation by a qualified siding contractor to determine what repairs are necessary and to make proper repairs including, where appropriate, evaluation/repairs of hidden damage

🛑 Safety 🔨Repair 🔧 Maintenance 👁🗨 Monitor annually ➕ Upgrade 🔍 Due Diligence

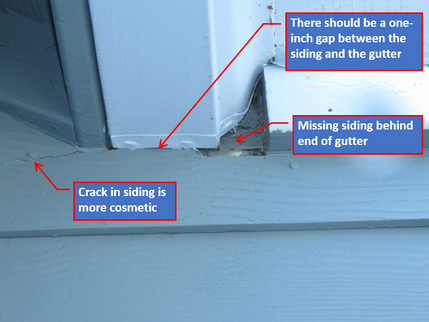

- BES-5 🏡BUILDING EXTERIOR & STRUCTURE:

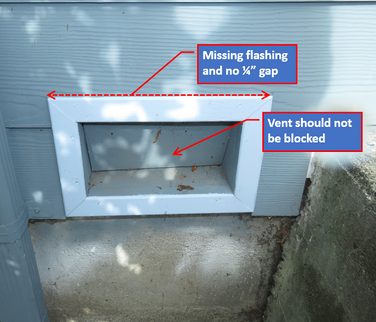

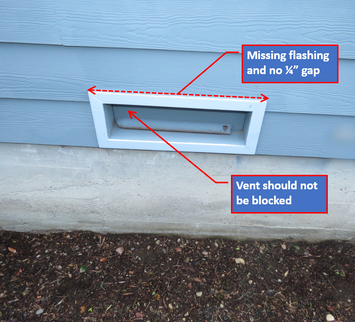

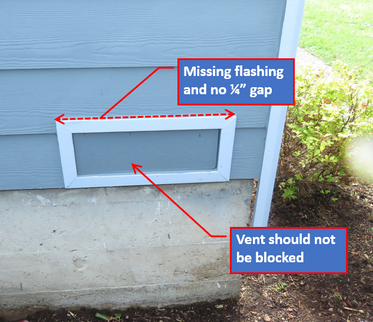

FLASHINGS RELATED TO EXTERIOR CLADDING:

There were issues documented below in bulleted lists, narratives and pictures related to the Exterior Cladding. Proper flashings of exterior cladding is critical to keep moisture out of the structure. The following conditions were noted and should be evaluated and repaired as deemed necessary by a qualified party. Hidden damage should be anticipated.

FLASHINGS:

- 🔹Missing/Inadequate. This can lead to water penetration behind the siding and can lead to water penetration of the house sheathing at these locations. Repairs would likely prove difficult but repairs may become necessary in time--this is especially true in areas that are not well protected by overhangs on the South and West sides of the home. Hidden damage is common, with at least the trim boards. I recommend monitoring and repairs later when it becomes necessary or that proper flashings be installed now by a qualified siding contractor to avoid perhaps more costly repairs later. In the context of repainting the home you might want to consider having proper flashings installed. If flashings are not installed it will be necessary to be vigilant about keeping the connections well caulked and sealed to prevent water intrusion. The big drawback to caulking these connections as opposed to proper flashings is that water that finds its way behind the trim where it becomes trapped and promotes hidden decay/rot. These flashings are obviously less critical in areas well protected by overhangs. While a common installation practice with cement board siding it is still not best practice.

- Missing locations:

- 🔹head flashings

- 🔹crawl space vents

- 🔹These flashings are obviously less critical in areas well protected by overhangs.

🔨Repair 🔧 Maintenance 👁🗨 Monitor annually 🐞 WDO’s ➕ Upgrade 🔍 Due Diligence

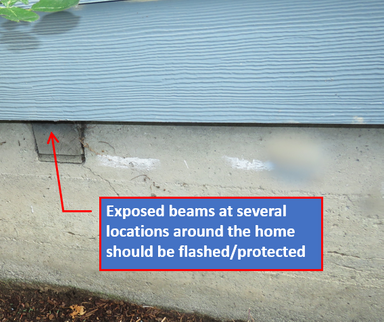

- SE-1 SE Entryway:

FRONT ENTRYWAY STOOP:

The deck structure had numerous issues and no attempt to document all these issues will be made in this report. The bulleted lists and narratives related to the information and pictures below should be seen as more representative as opposed to all inclusive and other concerns should be anticipated. Concerns were noted in relation to:

GENERAL INFORMATION:

- There were issues with:

- 🔹the structure

HANDRAILS:

- 🔹not present

MASONRY:

- 🔹🚩concrete covers untreated wood structures (rim joist). This is very common in older construction and hidden damage is common and should be anticipated. This is one of those things where repairs/improvements might be better left until obvious damage becomes apparent. Frequent monitoring is advised and any water intrusion/staining noted in adjacent finished areas would warrant immediate invasive evaluation.

- 🔹settlement. It may be possible to have the stoop slab-jacked (lifted) into place by a qualified jacking company.

- 🔹Inadequate clearances between siding and walking surface. Moisture damage can occur over time. Proper clearances should be created and/or vigilantly maintained. Proper flashings behind the siding to the stoop surface should be installed

SURFACE DRAINAGE:

- 🔹slopes toward home

- 🔹more than 1/4" per foot for landing

- 🔹improper drainage

Notes, and maintenance documentation/details about the deck, will be detailed in the pertinent sections below this narrative.

The following pictures with descriptions are meant to convey the necessity for a full evaluation/repair or possibly even replacement of the structure by a qualified deck installation/repair contractor as deemed necessary. The recommended minimum standards can be found in the American Wood Council's Prescriptive Wood Residential Deck Construction Guide. This guide is also known as "DCA-6." Another great reference, even though a little ahead of requirements in most jurisdictions and not free, Deck Construction Based on the 2021 IRC. I recommend evaluation, repairs and replacement by a qualified deck construction contractor.

🛑 Safety 🔨Repair 🔧 Maintenance 👁🗨 Monitor annually 🐞 WDO’s ➕ Upgrade 🔍 Due Diligence

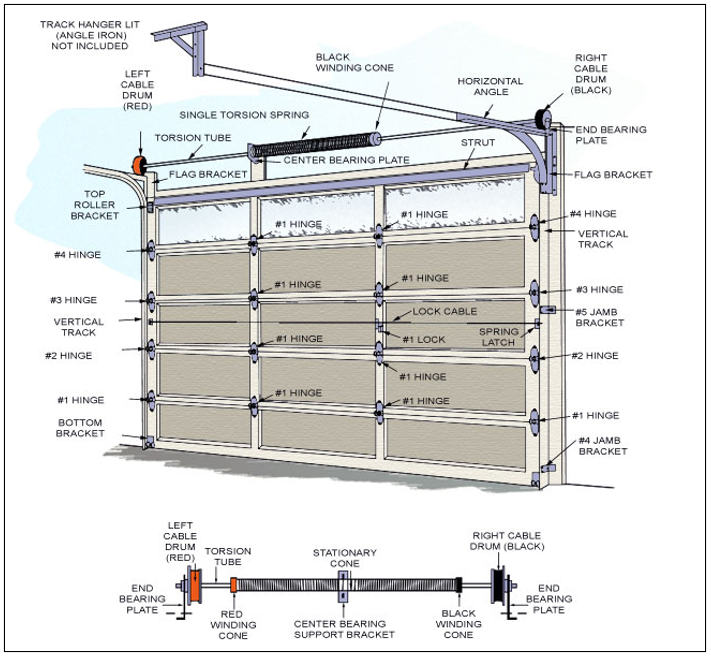

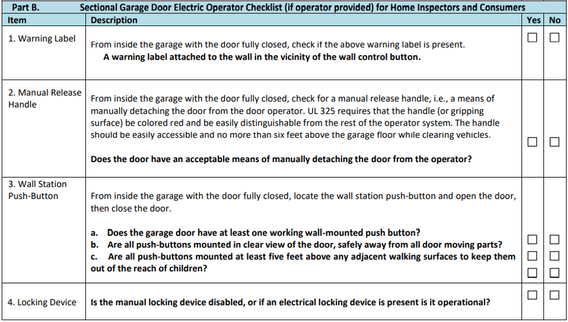

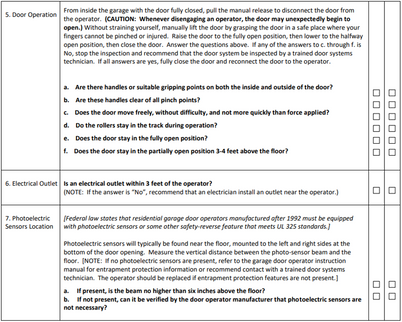

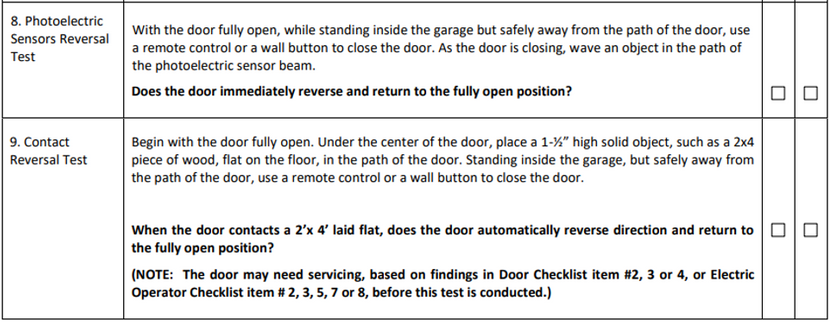

- G-5 🚘GARAGE:

GARAGE OVERHEAD DOOR:

There were issues documented below in bulleted lists, narratives and pictures related to the door installation:

TESTING:

- Not tested

MANUAL OPERATION/DOOR BALANCE:

- Not opened

DASMA TESTING:

- Stopping points:

- 🔹due to vehicles in garage. When there are automobiles in the garage at the time of inspection the auto-reversing functions of the door are not tested because of possible damage to the vehicles if testing were to result in collapse of the door. I recommend that all reversing functions be properly tested---see testing instructions in the Notes and Information portion of the report---and the testing procedures attached to

A qualified overhead door installation contractor should evaluate and repair the door as deemed necessary and then the opener device should be fully tested per DASMA protocols.

🛑 Safety 🔨Repair 🔧 Maintenance 👁🗨 Monitor annually ➕ Upgrade 🌲 Efficiency / IAQ 🔍 Due Diligence 📝 Informational note

- G-6 🚘GARAGE:

GARAGE OVERHEAD DOOR AUTOMATIC OPENER:

There were issues documented below in bulleted lists, narratives and pictures related to the automatic opener that should be addressed.

CONDITIONS:

- 🚩Automatic Opener Prior to 1982. Due to the age of this overhead door automatic opener may not be equipped with an auto-reversing mechanism. Auto-reversing mechanisms were not required prior to 1982 (although some manufacturers started installing them in the early 1970's). Automatic door openers that do not have reversing functions or where it cannot be determined at the time of inspection that it has reversing function, are not tested. Upgrading non-reversing type door openers or openers without sensor beams is recommended.

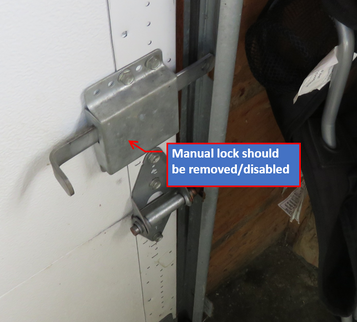

MANUAL LOCKING MECHANISM:

- Manual lock still functional. When garage doors have automatic opening devices, the Manual Lock Mechanism should be disabled/removed. This represents a serious safety issue as the opener can tear away from its attachments or force the door out of its tracks causing injury and damage to persons and property. I recommend that a qualified garage door company be contacted to remove/disable this mechanism as required.

TESTING:

- Not tested

WARNING LABELS:

- Warning label at opener button:

- 🔹label missing

- 🔹NOT Present consistent with age of opener (pre-1990)

REMOTE CONTROL:

- None seen--I recommend asking seller

PHOTO-SENSOR REVERSAL:

- 🔹not present--consistent with age of opener

2x4 REVERSAL:

- Not tested:

- 🔹vehicles in garage. When there are vehicles in the garage at the time of inspection the auto-reversing functions of the door are not tested because of possible damage to the vehicle if testing were to result in collapse of the door. I recommend that all reversing functions be properly tested--see testing instructions in the Notes and Information portion of the report

I recommend evaluation, repairs and maintenance by a qualified overhead door installation company or other qualified party.

🛑 Safety 🔨Repair 🔧 Maintenance 👁🗨 Monitor annually 🐞 WDO’s ➕ Upgrade 🔍 Due Diligence

- R5-2 ROOF:

DIMENSIONAL SHINGLE CONDITIONS:

There were issues documented below in bulleted lists, narratives, and pictures related to the roof surface that should be evaluated, repaired and maintained by a qualified roofing contractor as deemed necessary. The pictures below document some of the concerns related to this roof and should not be construed to mean there are no other conditions that need to be addressed. Hidden damage is common with roofs. I recommend factoring replacement of the roof within 3 years.

GENERAL CONDITIONS:

- Conditions:

- 🔹considerable failure of seal-down strips

UNDERLAYMENT:

- 🔹visible at eaves

🛑 Safety 🔨Repair 🔧 Maintenance ➕ Upgrade 👁🗨 Monitor annually 🔍 Due Diligence 🐞 WDO’s

- R5-3 ROOF:

METAL ROOF CONDITIONS:

There were issues documented below in bulleted lists, narratives, and pictures related to the roof surface that should be evaluated, repaired and maintained by a qualified roofing contractor as deemed necessary. The pictures below document some of the concerns related to this roof and should not be construed to mean there are no other conditions that need to be addressed. Hidden damage is common with roofs. I recommend factoring replacement of the roof within 3 years.

METAL ROOF CONCERNS:

- 🔹at ridge there is a gap of unknown purpose. This should be evaluated as to whether it is adequate to keep wind driven rain out of the structure.

🛑 Safety 🔨Repair 🔧 Maintenance ➕ Upgrade 👁🗨 Monitor annually 🔍 Due Diligence 🐞 WDO’s

- R5-4 ROOF:

FLASHINGS RELATED TO THE ROOF:

There were issues documented below in bulleted lists, narratives, and pictures related to the roof flashings.

EAVE FLASHINGS:

- 🔹eave flashings NOT present/roofing materials overhanging gutters--consistent with age of roof. Modern roof installations (installed after July 1st 2014) are required to have metal flashings installed along the eaves of the roof. They are not present on this roof consistent with installation prior to that date. Damage to the edge of the sheathing is common and some amount of repairs should be anticipated when the roof is replaced. It likely would not be considered practical to install these flashings prior to roof replacement.

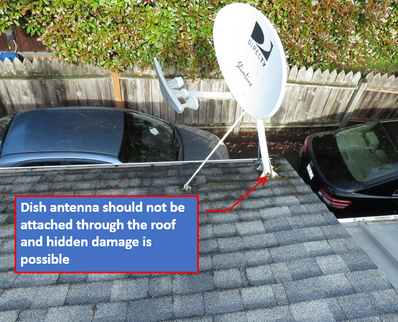

DISH ANTENNA:

- 🔹attached to roof through surface of shingles. The satellite dish is mounted directly over the roof shingles. No determination could be made as to how of if sealing of this attachment was done. Improper sealing of these attachments can lead to damage to the roof structure. Maintaining seals on these connections is I recommended. Relocation to a type of bracket that doesn't penetrate the roof covering is a better solution.

- 🔹will need routine maintenance of seals to keep water out of roof

- 🔹hidden damage with these installations is common--relocating to side wall is recommended

The pictures below document some of the issues and a full evaluation and repairs of these conditions by a qualified roofing contractor is recommended.

🚩CAUTIONS:

- These repairs should be done as soon as possible to prevent water damage to underlying structures.

- Hidden damage should be anticipated.

- Repairs to any of these flashing details should always include evaluation and repair of any covered structures.

🔨Repair 🔧 Maintenance 👁🗨 Monitor annually 🐞 WDO’s ➕ Upgrade 🔍 Due Diligence

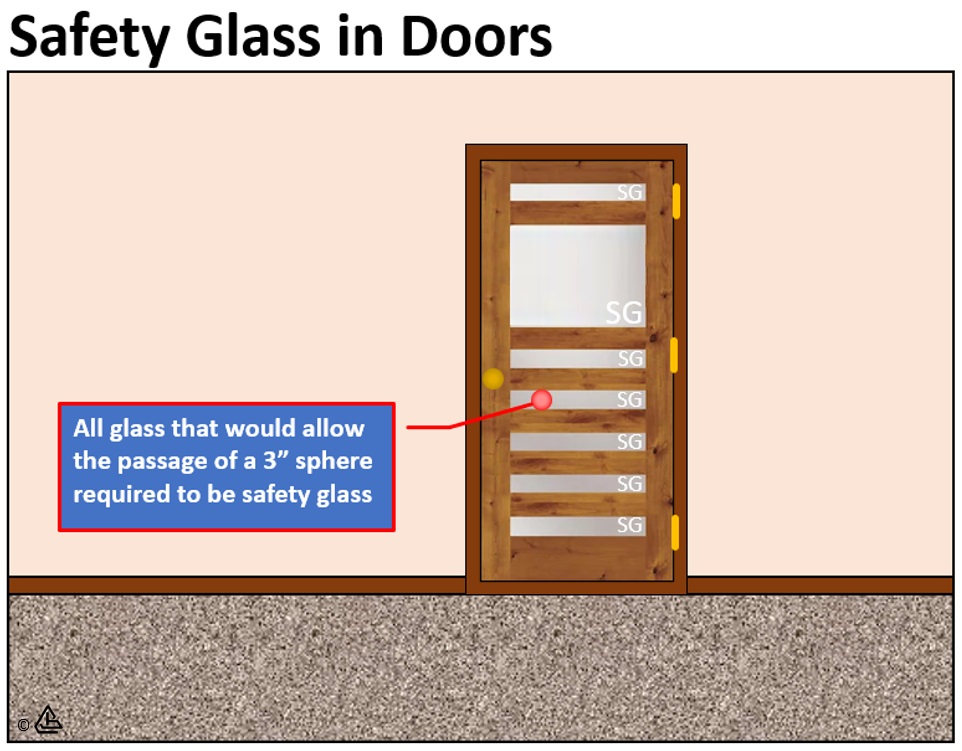

- W-1 🪟 WINDOWS:

WINDOW CONDITIONS:

There were issues documented below in bulleted lists, narratives and pictures related to the windows of the home. I recommend further evaluation, repairs and improvements of these conditions by a qualified window installation/repair contractor.

RECENT REPLACEMENT:

- 🔹recent installation--methods of installation not determined. The windows have been replaced relatively recently. It is not possible to determine methods or appropriateness of some replacement installations and problems with improper flashing details are common---especially on windows with more exposure to the elements. Areas around the interiors of the windows should be monitored for staining and/or water intrusion and further evaluation may be necessary if these conditions are noted. Usually installations where there is actually wood trim wrapping around the window on the exterior are less problematic.

EXTERIOR WINDOW SILLS:

- 🔹painted-over deterioration/weathering typical of windows in homes this age

VINYL WINDOWS:

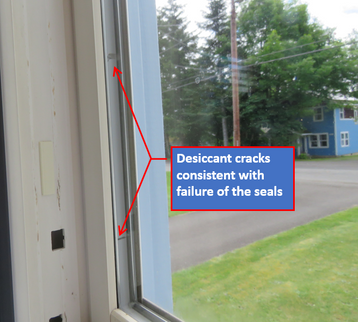

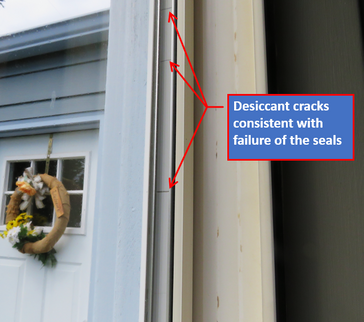

- 🔹failed thermal seals

- 🔹failing desiccant

WOOD SINGLE PANE:

- The windows in the home are older style (original) single pane wood windows. The following conditions below were noted. I recommend factoring replacement of all of the windows in the home by a qualified window installation company. All of these windows should be properly maintained until they can be replaced. Window replacement should include evaluation/repair/replacement of trim/sills and related components as well.

- 🔹broken sash components

- 🔹painted shut,

- 🔹poor/missing glazing

- 🔹cracked glass,

Some of the issues will be documented in the pictures below but should not be construed to be all inclusive but instead more representative.

🛑 Safety 🔧 Maintenance 🔨Repair 👁🗨 Monitor annually 🐞 WDO’s ➕ Upgrade 🌲 Efficiency / IAQ 🔍 Due Diligence

- K3-2 🥧Kitchen:

DISHWASHER:

There were issues documented below in bulleted lists, narratives, and pictures related to the dishwasher that should be addressed by a qualified appliance installation company, plumber, or other qualified party.

AIR GAP:

- 🔹Air-Gap device missing / but "High Loop" is present

🛑 Safety 🔨Repair 🔧 Maintenance 👁🗨 Monitor monthly ➕ Upgrade 🌲 Efficiency / IAQ 🔍 Due Diligence

Maintenance Items

- G3-3 ⛺GROUNDS:

VEGETATION IMPACTING BUILDING/PROPERTY:

There was vegetation at the south side of the home that was too close to the home. All vegetation should be maintained away from the home at least 12 inches. Vegetation too close to the home can create a pathway to the home for moisture, insects and vermin. Inspection of some components of the home was limited by the proximity of vegetation to the home and further evaluation may be warranted when the vegetation is cleared away and some amount of damage should be anticipated. I recommend evaluation and maintenance by a qualified party.

NOTED CONDITIONS:

- 🔹vegetation too close to the building at front entryway stoop

🛑 Safety, 🔨Repair, 🔧 Maintenance, 👁🗨 Monitor annually, 🐞 WDO’s, ➕ Upgrade and 🔍 Due Diligence

- R5-1 ROOF:

ROOF GENERAL CONDITIONS:

There were issues documented below in bulleted lists, narratives, and pictures related to the roof. I recommend evaluation, repairs and maintenance of the roof by a qualified roofing contractor. Conditions related to specific types of roof coverings will be discussed below. The conditions should not be construed to be all inclusive but instead more representative:

MOSS/LICHEN/ALGAE:

- 🔹Moss growth, preventing evaluation

- 🔹Enough moss growth to limit inspection of surface in areas. The roof has enough growth to limit inspection of the surface. I recommend the roof be professionally cleaned by a qualified party. Air or Water pressure washing is not recommended. After cleaning I recommend I be called back to evaluate the condition of the roof.

🛑 Safety 🔨Repair 🔧 Maintenance 👁🗨 Monitor annually 🐞 WDO’s ➕ Upgrade 🔍 Due Diligence

- HC-3 🔥HEATING / ❄️COOLING:

HIGH EFFICIENCY GAS FURNACE SERVICING:

I recommend servicing of the furnace prior to the next heating season. Servicing should include cleaning of the interior of the furnace compartment, inspecting the furnace venting system, and evaluation for carbon monoxide, in conjunction with all other normal servicing aspects performed by the qualified heating contractor., conditions not noted at the time of inspection should be anticipated, especially with older units, furnaces this age should be serviced annually and It is my opinion that this furnace should be replaced due to age and inefficiency.

List of the "minimum" inspection items to be expected of furnace servicing:

1. Inspect heat exchanger.

2. Inspect and operate heating controls, and calibrate thermostat as deemed necessary.

3. Check ignitor & clean pilot orifice, adjust flame.

4. Check and adjust main burners for proper combustion

5. Inspect and operate furnace safety devices.

6. Check draft and vent or motor assembly.

7. Inspect drive-sheaves, pulleys, and belts. Adjust tension.

8. Lubricate all motors and shaft bearings.

9. Change and/or clean filters.

10. Clean interiors of all heating equipment interior compartments.

11. Inspect all of the venting system, including sections in attic spaces and above the roof.

12. Check and adjust air-flow, and temperature differential

13. Check unit smoke detector, clean filter--if applicable

14. Inspect piping and valves for gas leaks.

This list is meant to be "suggestive" of necessary repairs and not a "prescriptive" list of how to do it. Many appliances have other necessary maintenance requirements and protocols. This list also includes items that may not be applicable with this heating system. It is intended to inform all parties as to why professional evaluation/inspection is necessary.

🛑 Safety 🔧 Maintenance (as needed) 👁🗨 Monitor annually 🌲 Efficiency / IAQ 🔍 Due Diligence

Efficiency & IAQ Items

- HC-4 🔥HEATING / ❄️COOLING:

WHOLE BUILDING AIR CHANGE SYSTEM:

Modern homes require a means of changing the air in the home in a controlled manor since 1991. The following conditions related to these requirements were noted and repairs and improvements should be made by a qualified party.

AIR CHANGE SYSTEM:

- 🔹missing in Remodeled homes. At the time the home was remodeled (unless prior to 1991), some method of whole house ventilation would have been required. Lack of installation may be an oversight or be an indication of work being done without permits. I recommend further evaluation as desired. Sometimes these are incorporated on timers installed on bathroom or laundry room exhaust fans. It is possible I missed the timer location or it was hidden. Whole-house air exchangers for cool climates helps reduce excess moisture problems -- like condensation on windows -- that contribute to Mold/Fungal Growth. This is especially true of HRV's that also filter the air as well. It’s the same principle as using your bathroom exhaust fan to remove moisture created by running the shower.