The Scope and Purpose of a Building Inspection

Purchasing property involves risk

The purpose of a building inspection is to help reduce the risk associated with the purchase of a structure by providing a professional opinion about the overall condition of the structure. A building inspection is a limited visual inspection and it cannot eliminate this risk. Some buildings present more risks than others. We cannot control this, but we try to help educate you about areas of uncertainty and risk as part of our inspection.

A building inspection is not an insurance policy

This report does not substitute for or serve as a warranty or guarantee of any kind. Warranties can be purchased separately from insuring firms that provide this service.

A building inspection is visual and not destructive

The descriptions and observations in this report are based on a visual inspection of the structure. We inspect the aspects of the structure that can be viewed without dismantling, damaging or disfiguring the structure and without moving furniture and interior furnishings. Areas that are concealed, hidden or inaccessible to view are not covered by this inspection. Some systems cannot be tested during this inspection as testing risks damaging the building. For example, overflow drains on bathtubs are generally not tested because if they were found to be leaking they could damage the finishes below. Our procedures involve non-invasive investigation and non-destructive testing which will limit the scope of the inspection.

This is not an inspection for code compliance

This inspection and report are not intended for city / local code compliance. During the construction process structures are inspected for code compliance by municipal inspectors. Framing is open at this time and conditions can be fully viewed. Framing is not open during inspections of finished buildings, and this limits the inspection. All buildings fall out of code compliance shortly after they are built, as the codes continually change. National codes are augmented at least every three years for all of the varying disciplines. Municipalities can choose to adopt and phase in sections of the codes on their own timetables. There are generally no requirements to bring older buildings into compliance unless substantial renovation is being done.

This is just our opinion

Construction techniques and standards vary. There is no one way to construct a building. The observations in this report are the opinions of the inspector. Other inspectors and contractors are likely to have some differing opinions. You are welcome to seek opinions from other professionals.

The scope of this inspection

This inspection will include the following systems: exterior, roof, structure, drainage, foundation, attic, interior, plumbing, electrical and heating. The evaluation will be based on limited observations that are primarily visual and non-invasive. This inspection and report are not intended to be technically exhaustive.

Your expectations

The overall goal of this inspection is to help ensure that your expectations are appropriate with the building you are proposing to buy, sell or lease. To this end we assist with discovery by showing and documenting observations during the building inspection. This should not be mistaken for a technically exhaustive inspection designed to uncover every defect with a building. Such inspections are available but they are generally cost-prohibitive and time-prohibitive.

Your participation is requested

Your presence is requested during this inspection. A written report will not substitute for all the possible information that can be conveyed verbally by a shared visual observation of the conditions of the property.

How to Read This Report

Getting the Information to You

This report is designed to deliver important and technical information in a way that is easy for anyone to access and understand. If you are in a hurry, you can take a quick look at our "Summary Page” and quickly get critical information for important decision making. However, we strongly recommend that you take the time to read the full Report, which includes digital photographs, captions, diagrams, descriptions, videos and hot links to additional information.

The best way to get the layers of information that are presented in this report is to read your report online (the HTML version), which will allow you to expand your learning about your building. You will notice some words or series of words highlighted in blue and underlined – clicking on these will provide you with a link to additional information. The HTML version of this report also contains streaming videos. Short video clips often contain important information and critical context and sounds that can be difficult to capture in words and still pictures.

For the most reliable viewing experience, I recommend viewing the report on as large a screen as practical, as much detail can be lost on small devices like smart phones. For similar reasons, reports should only be printed in color to retain as much detail as possible and minimize misinterpretation of photographs.

This report can also be printed on paper or to a PDF document.

Chapters and Sections

This report is divided into chapters that parcel the building into logical inspection components. Each chapter is broken into sections that relate to a specific system or component of the building. You can navigate between chapters with the click of a button on the left side margin.

Most sections will contain some descriptive information done in black font. Observation narrative, done in colored boxes, will be included if a system or component is found to be significantly deficient in some way or if we wish to provide helpful additional information about the system or the scope of our inspection. If a system or component of the building was deemed to be in satisfactory or serviceable condition, there may be no narrative observation comments in that section and it may simply say “tested,” or “inspected.”

Observation Labels

All narrative observations are colored, numbered and labeled to help you find, refer to, and understand the severity of the observation. Observation colors and labels used in this report are:

- MAJOR CONCERNS:Repair items that may cost significant money to correct now or in the near future, or items that require immediate attention to prevent additional damage or eliminate safety hazards.

- REPAIR NEEDED:Repair and maintenance items noted during inspection. Please note that some repair items can be expensive to correct such as re-finishing hardwood floors, but are considered simply repair items due to their cosmetic nature.

- IMPROVE/UPGRADE:Observations that are not necessarily defects, but which could be improved for safety, efficiency, or reliability reasons.

- DEFERRED MAINTENANCE:These are repair items that should be considered "routine building ownership items," such as servicing the furnace, cleaning the gutters or changing the air filters in the furnace.

- Disclaimer:Detailed description of various aspects of the property noted during the inspection.

- REFER TO SPECIALIST:Observation such as a buried oil tank that may require further investigation to determine the severity and / or urgency of repair.

- NOTES:Refers to aside information and /or any comments elaborating on descriptions of systems in the building or limitations to the building inspection.

Pest Inspection

All items with the bug logo () are part of a structural pest inspection. If your inspector included a structural pest inspection as a part of the scope of your building inspection, you can distinguish pest inspection items by this logo. You can also go to the pest inspection summary page to see a summary of the items that are part of a pest inspection.

Summary Page

The Summary Page is designed as a bulleted overview of all the observations noted during inspection. This helpful overview is not a substitution for reading the entire inspection report. The entire report must be read to get a complete understanding of this inspection report as the Summary Page does not include photographs or photo captions.

Moisture Meter Testing

Where moisture meter testing is indicated in this report a Protimiter Survey Master Dual Function was used.

Summary

Major Concerns

- RG-1 Roof and Gutters - Roofing Materials:

Upon the roof inspection, here are my observations:

- The roof currently has a silver coating, which indicates that the underlying original roofing material is no longer in good condition. The coating is showing signs of blistering in several areas, which suggests deterioration and I’m recommending reapplication if a full roof replacement is not planned at this time. However, it may be more effective and cost-efficient in the long run to replace the entire roof instead of adding another layer of coating.

- There is significant water ponding observed in multiple areas of the roof, indicating poor drainage design or inadequate slope. This standing water can accelerate deterioration of the roofing materials and is likely to lead to leaks or structural damage over time if not addressed.

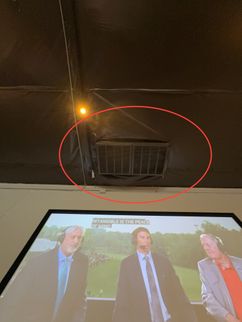

- Evidence of a past leak was observed inside the brewery ceiling, and while repairs have been made, this suggests ongoing vulnerability until the roof is fully upgraded or repaired. The persistent issue could recur, especially if drainage and roofing conditions are not improved, so further evaluation or comprehensive roofing repairs may be necessary to prevent recurrent leaks.

Consult with a qualified contractor for repair and update as needed.

- ES-4 Electric Service - Electric Service Equipment:

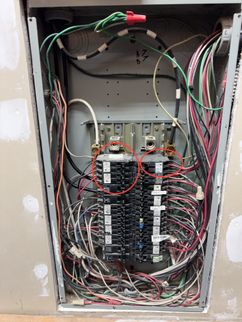

During the inspection of the bar's electrical panel, a buzzing sound was observed along with elevated heat readings. It is strongly recommended to consult with a qualified electrician to assess the panel's condition, identify any potential issues, and perform necessary repairs or upgrades to ensure safe and reliable operation.

Safety/Health

- G-3 Grounds - Exterior Paving:

Front walk shows cracks with the potential for trip hazards. This is a safety concern. We suggest consulting with a qualified paving contractor for possible repair or re-paving options to improve safety.

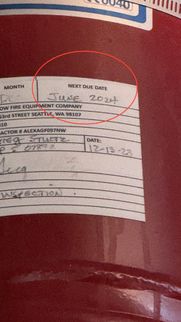

- P-2 Plumbing - Fire Suppression:

The fire hydrant has an expired tag. It is recommended to conduct a further evaluation of the hydrant’s condition and arrange for the renewal or replacement of the expired tag to ensure compliance with local fire safety regulations.

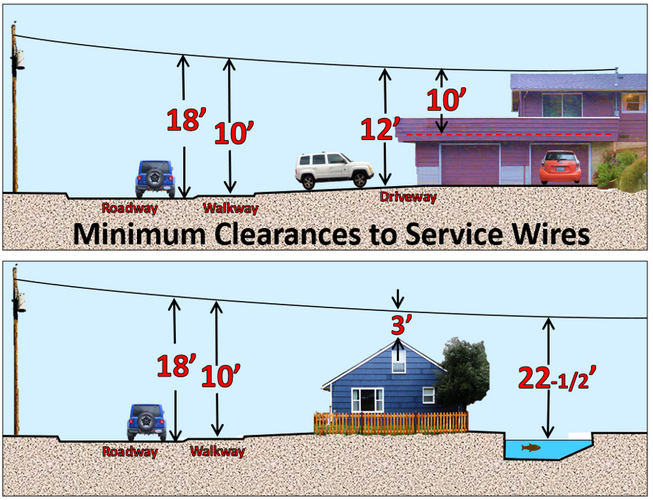

- ES-1 Electric Service - Incoming Electric Service:

The electric service conductors are too close to the roof. This is a safety hazard. Conductors should generally be 3 feet above a sloped roof and 8 feet above a low-slope roof. Consult with a licensed electrician and/or your utility provider to further evaluate and repair this condition. This could necessitate raising the electric service.

- ES-3 Electric Service - Electric Service Equipment:

An inadequate working clearance was noted for the electric load center. A 30 inch wide and 36 inch deep unobstructed working clearance is recommended for improved safety. This limits our inspection of this area. Consult with a licensed electrician or general contractor to further evaluate this condition and improve access as needed.

- ES-5 Electric Service - Electric Service Equipment:

The dead front cover is missing some of the screws needed to adequately secure the cover. Install missing screws as needed for improved safety and please note that screws with sharp ends are not recommended.

Repair Needed

- HC-5 Heating, Cooling - Ducting/Distribution:

The metal ducting shows signs of corrosion and water retention in some areas. This can accelerate deterioration and impact performance. Repairs, including cleaning, sealing, and treating the affected areas, are recommended to prevent further damage and extend the ductwork’s lifespan. Addressing these issues promptly will help avoid more costly repairs later.

- HC-8 Heating, Cooling - Fresh Air Circulation:

During our inspection, we noted that the up-blast exhaust system on the roof is excessively vibrating during operation. This could affect system performance and safety. We recommend consulting a professional HVAC technician for further diagnosis and necessary repairs or replacement of components like fan blades, bearings, or mounts. Regular maintenance is also advised to prevent future issues.

- HC-9 Heating, Cooling - Fresh Air Circulation:

The upblast exhaust system is near the end of its estimated service life, which is typically 15-20 years. Replacement or upgrade should be budgeted accordingly. It is recommended to consult with a qualified HVAC contractor to assess the system’s condition and determine the appropriate course of action.

- HC-10 Heating, Cooling - Fresh Air Circulation:

At the time of inspection, an upblast exhaust system was not operational. It is recommended to have a qualified HVAC technician evaluate the system to identify and address any issues to ensure proper functionality and compliance. Repair or replacement may be necessary.

- ES-6 Electric Service - Electric Service Equipment:

Overheated breaker/wiring was noted in the main panel. Consult with a qualified electrician for further review and repair as needed. This often indicates loose connections or defective breaker/wiring inside the panel.

- ES-7 Electric Service - Appliance Disconnects:

Rust noted at the exterior electrical disconnect. Repair and treatment are recommended to prevent further corrosion and ensure safety.

- BWF-1 Branch Wiring/Electrical Fixtures - Branch Wiring:

The open electrical junction box needs to be covered for improved safety - see roof top. This is as simple as installing a cover plate over the box to protect the wiring. Sometimes, an extension ring is needed if finishes are covering the box. Repair as needed for improved safety.

- BWF-2 Branch Wiring/Electrical Fixtures - Branch Wiring:

Damaged and scorched wiring was noted at the up-blast exhaust system. It is recommended to consult with a qualified electrician for assessment and necessary repairs to ensure safety and proper operation.

- BWF-3 Branch Wiring/Electrical Fixtures - Branch Wiring:

Extension cords have been used to supply power on roof top. This is non-standard and a safety hazard. An electric receptacle should be provided for all appliances and extension cords should be eliminated for all permanent fixtures.

- BWF-4 Branch Wiring/Electrical Fixtures - Branch Wiring:

The loose electrical junction box in the bar needs to be secured for improved safety.

- B-1 Bathrooms - Toilets:

The loose toilet in the bathroom need to be reset and the wax ring and flange should be replaced to prevent hidden plumbing leaks. Hire a licensed plumber to further evaluate and repair.

Improve/Upgrade

- RG-4 Roof and Gutters - Gutter/Downspout Systems:

Downspouts discharge near the foundation due to missing extensions or splash blocks. Install extensions to ensure water discharges at least 6 feet away from the foundation to prevent damages to the foundation.

- G-1 Grounds - Lot Description:

Voids/Depressions adjacent to the structure were noted at the left side. This can result in saturate soils, erosion and/or water migration through the foundation. We suggest adding dirt/backfill or regrading, as needed, to any low lying areas near the foundation to correct the grade and ensure proper drainage away from the structure. Recommended grade should have a 6-inch drop over the first 10 feet from the foundation.

- F-1 Foundation/Substructure - Foundation Type:

Minor crack(s) noted at the visible foundation walls. This type of cracking is fairly common and in many instances does not relate to serious foundation issues. We suggest sealing the exterior cracks to prevent water intrusion and monitor the affected area for signs of expansion or movement. If concerned, or if expansion is noted, we suggest consulting with a qualified, licensed contractor for further assessment.

- ED-3 Exteriors and Decks - Exterior Electrical/Faucets:

Exterior faucets are not frost-proof or equipped with anti-siphon valves. Frost-proof faucets protect the faucet and plumbing from possible freeze damage. An anti-siphon valve prevents backflow of water into the plumbing system. These features were not required at the time of construction, however, upgrades are recommended.

- HC-1 Heating, Cooling - Chiller:

The chiller on the roof has worn out insulation. It is recommended to add insulation to improve efficiency and prevent energy loss.

- HC-2 Heating, Cooling - Heat Pump/Air Conditioning:

This heat pump unit is close to the end of its useful design life. The average service life of heat pump units is 15-20 years. Funds should be reserved to replace this AC system at any time. Older AC units like this are also less reliable and subject to the need for constant repairs.

- HC-4 Heating, Cooling - Heat Pump/Air Conditioning:

Some of the rooftop HVAC units are reaching the end of their service life and should be budgeted for replacement within the next 2 to 3 years.

- HC-7 Heating, Cooling - Fresh Air Circulation:

A filter is missing at the fresh air system. It is recommended to install a filter to ensure proper air quality and system performance.

- WH-1 Water Heaters - Water Heater ( Bar ):

No expansion tank installed. An expansion tank may be recommended for the water heater; these are required if the structure has a closed plumbing system (a backflow preventer - normally installed at the water meter). A thermal expansion tank helps reduce pressure on the water heater caused by expansion of water when heated. Consult with a licensed plumber to determine if a thermal expansion tank should be installed on this unit.

- P-1 Plumbing - Distribution Pipe:

The supply pipe insulation is incomplete in the basement. Be sure all supply lines in unheated spaces have been adequately insulated to protect from freezing conditions that could damage the pipes and to prevent heat loss.

- B-2 Bathrooms - Sinks/Cabinets:

The sinks in the main floor bathroom are loose and needs to be secured to prevent accidental damage to the sink or plumbing.

- I-2 Interior - Interior Electrical Conditions:

Some light fixture(s) were inoperable at the time of the inspection, possibly due to a missing/failed bulb. Replace the bulb(s) and check the function. If the fixture remains inoperative, consult with a licensed electrician for review and repair.

Deferred Maintenance Items

- RG-2 Roof and Gutters - Roofing Materials:

Organic debris (branches, leaves, moss) present on the roof surface. Removal recommended to ensure proper drainage and prevent premature deterioration of the roofing materials.

- RG-3 Roof and Gutters - Gutter/Downspout Systems:

The gutters are clogged with organic debris and require cleaning to ensure proper control of roof runoff. Clean the gutters and ensure they are unobstructed, leak free and properly sloped to drain. This is routine property maintenance; I would expect the need to clean gutters and downspouts regularly.

- G-2 Grounds - Exterior Paving:

Common cracks noted at the driveway and walkway. Cleaning and sealing cracks in concrete can help reduce settling from sub-surface erosion.

- G-4 Grounds - Vegetation/Trees:

A minimum clearance of 6 feet should be maintained between trees and structures to prevent damage and/or premature wear of materials and to reduce access by rodents and wood destroying insect. Big trees can cause foundation and roof related issues. Trees can also hide defects during a building inspection. Contact a landscape maintenance professional for improvements.

- ED-1 Exteriors and Decks - Siding and Trim:

Exterior caulking is cracked/separated in some areas. We suggest checking all siding joints and penetrations and re-caulking as needed to ensure a watertight seal is provided.

- FSD-1 Fuel Storage and Distribution - Natural Gas - Meter/Supply:

Majority of gas line on the roof shows significant signs of corrosion. It is recommended to paint or apply a protective coating to prevent further deterioration and ensure safety.

- HC-3 Heating, Cooling - Heat Pump/Air Conditioning:

Heating and cooling contractors recommend annual servicing to ensure safe and reliable performance and to prolong the useful life of heating and cooling equipment. No recent service records were noted for all the heat pumps. I recommend having this system serviced and further evaluated by a qualified heating contractor if it has not been done in the last year.

Conditions

- ED-2 Exteriors and Decks - Siding and Trim:

A tight alley was noted on the right side of the property, which was inaccessible due to limited space and fencing. This restriction limited our ability to inspect that side of the building thoroughly. Further assessment may be needed if access becomes available.

- HC-6 Heating, Cooling - Additional Heat/Cooling Sources:

The heating in the men's bathroom was not operable during the inspection due to the control box being sealed. It is recommended to have a qualified technician evaluate the control box and heating system to determine the cause and ensure proper operation.

Due Diligences

- ES-2 Electric Service - Electric Service Equipment:

The brewery is equipped with a phase converter to operate specialized brewing equipment, which converts single-phase power to three-phase power as required for the operation of such industrial systems. During the inspection, the location of the electrical setup and permit documentation could not be verified. It is recommended to consult with a qualified licensed electrician to confirm that the phase converter and associated electrical components were installed properly and in compliance with local electrical codes and regulations.

- I-1 Interior - Flooring:

Minor to moderate floor settlement was noted in the building. Inquire with the seller for any history of repairs or movement. No signs of recent movement were visible at the time of inspection. Consult with a structural engineer for further evaluation.

Full report

Exteriors and Decks

Porches

Siding and Trim

Eaves/Soffits

Exterior Doors

Exterior Windows

Exterior Electrical/Faucets

Heating, Cooling

Chiller

Heat Pump/Air Conditioning

Thermostat(s)

Ducting/Distribution

Additional Heat/Cooling Sources

Fresh Air Circulation

Plumbing

Water Service

Distribution Pipe

Waste System

Fire Suppression

Exterior Hose Bibs

Interior Water Features

Electric Service

Incoming Electric Service

Electric Service Equipment

Electrical Grounding System

Electrical Bonding System

Appliance Disconnects

Kitchen

General Kitchen Comments

Ranges, Ovens, Cooktops

Refrigerators

Ventilation Method

Kitchen Electrical

Sinks and Faucets

Cabinets and Countertops

General Comments

Building Characteristics, Conditions and Limitations

Type of Inspection: Commercial Inspection

Photo Comments: Photos included in this report are representative of conditions and may not show all affected areas or materials noted in the various report sections. If areas, locations or components are not specifically identified, you should assume that conditions noted are present in multiple areas. If we recommended further review, maintenance or repairs, all related/similar areas, locations or components should be assessed by an appropriate and qualified professional. (Example: Separated Caulking - photos may show one or more areas, but all exterior caulk should be checked and repaired to prevent water intrusion and associated deterioration.)

Attending the Inspection: Client's agent

Inspector/State License Number: Anh Le, #22014482

Anh Le, #22014482

Approximate Square Footage: 8000 square feet approx

Occupancy: Occupied - Tenant

Animals Present: None

Weather Conditions: Clear

Approximate temperature: 70 degrees

Ground/Soil surface conditions: Dry

Orientation of Report: Facing structure from the street

Occupied Dwelling: The dwelling was occupied at the time of the inspection. Due to this condition, some areas, materials, or components may not have been visible or accessible for inspection. We do our best during the inspection to work around items, however, we do not move personal belongings, furniture or appliances. In some buildings, this may limit our inspection.

In 1984 the National Electrical Code increased heat rating of residential wiring to 90 degrees Celsius, older wiring was rated for 60 degrees Celsius. The primary reason for the change was due to increased heat produced by some modern ceiling light and fan fixtures. Connecting these fixtures to older wiring can pose a fire hazard. To avoid this hazard, certain wiring practices are required.

It is beyond the scope of this inspection to determine if any fixtures installed in this building pose a fire hazard or if the wiring has been upgraded to accommodate the increased heat. Buyers are advised to consult with a licensed electrician for further review.

Note regarding possible Asbestos and Lead applications in residential construction:

Asbestos: Asbestos is a known source of lung disease and cancer. Asbestos materials were commonly used for fire protection, thermal insulation and sound-proofing in residential construction from the early 1940's through 1982.

Lead: Lead is a known to affect the brain and nervous systems. Lead was a common ingredient in paints as far back as Colonial times. Since the Puget Sound area was not settled until the mid-1800's, this means that all buildings in this area constructed before 1978 may contain lead-based paint.

In 1978, federal laws were passed to prohibit future use of lead and asbestos in residential building materials. However, to prevent creating a hardship on the construction industry, contractors were allowed a 4-year grace period in which to use asbestos products already on hand. As a result, asbestos-containing materials may be present in residential structures built through 1982. Identification and testing for lead and asbestos and other environmental testing is beyond the scope of our inspections and should be performed by an approved testing facility. For further information on lead or asbestos in the building, consult the EPA website at: https://www.epa.gov

This building has 2 business : the brewery and the bar . Both businesses were operational at the time of inspection, with guests, staff, including chefs and waiters, present. The inspection was conducted while the establishments were actively in use, providing a snapshot of current conditions but not disrupting ongoing activities.

Roof and Gutters

Roofing Materials

Method of Inspection: Mounted, viewed from the surface

Roof Style: Flat

Roofing Type: Rubber , Coated

Age of Roofing (if known): Over 20 Years

Flashings: Appear intact

Multiple Layers?: No

Upon the roof inspection, here are my observations:

- The roof currently has a silver coating, which indicates that the underlying original roofing material is no longer in good condition. The coating is showing signs of blistering in several areas, which suggests deterioration and I’m recommending reapplication if a full roof replacement is not planned at this time. However, it may be more effective and cost-efficient in the long run to replace the entire roof instead of adding another layer of coating.

- There is significant water ponding observed in multiple areas of the roof, indicating poor drainage design or inadequate slope. This standing water can accelerate deterioration of the roofing materials and is likely to lead to leaks or structural damage over time if not addressed.

- Evidence of a past leak was observed inside the brewery ceiling, and while repairs have been made, this suggests ongoing vulnerability until the roof is fully upgraded or repaired. The persistent issue could recur, especially if drainage and roofing conditions are not improved, so further evaluation or comprehensive roofing repairs may be necessary to prevent recurrent leaks.

Consult with a qualified contractor for repair and update as needed.

Gutter/Downspout Systems

Gutter and Downspout Materials: Metal gutters and downspouts

Downspout Discharge: Discharge into underground drains, Discharge above ground

The gutters are clogged with organic debris and require cleaning to ensure proper control of roof runoff. Clean the gutters and ensure they are unobstructed, leak free and properly sloped to drain. This is routine property maintenance; I would expect the need to clean gutters and downspouts regularly.

Grounds

Lot Description

Lot/Site Description: Sloped lot

Grade at Foundation: Slopes towards structure

Property Drainage: Appears adequate

Voids/Depressions adjacent to the structure were noted at the left side. This can result in saturate soils, erosion and/or water migration through the foundation. We suggest adding dirt/backfill or regrading, as needed, to any low lying areas near the foundation to correct the grade and ensure proper drainage away from the structure. Recommended grade should have a 6-inch drop over the first 10 feet from the foundation.

Fencing/Gates

Fencing/Type(s): Excluded from inspection ( If present )

Exterior Paving

Driveway: Permeable concrete

Walkways: Concrete

Patio(s): Concrete

Vegetation/Trees

Trees/Vegetation: Vegetation contact with structure

A minimum clearance of 6 feet should be maintained between trees and structures to prevent damage and/or premature wear of materials and to reduce access by rodents and wood destroying insect. Big trees can cause foundation and roof related issues. Trees can also hide defects during a building inspection. Contact a landscape maintenance professional for improvements.

Foundation/Substructure

Foundation Type

Foundation - Perimeter: Raised - Poured concrete

Foundation Configuration: Partial basement

% of Foundation Not Visible: 70%

Minor crack(s) noted at the visible foundation walls. This type of cracking is fairly common and in many instances does not relate to serious foundation issues. We suggest sealing the exterior cracks to prevent water intrusion and monitor the affected area for signs of expansion or movement. If concerned, or if expansion is noted, we suggest consulting with a qualified, licensed contractor for further assessment.

Exteriors and Decks

Porches

Porches: Left side

Posts, Beams and Footings: Inspected

Support Structure: Pressure-treated lumber

Ledger Board: Not applicable

Porch Cover: Full Cover

Siding and Trim

Siding Material: Concrete w/stucco, Concrete block

Eaves/Soffits

Eave Style/Materials: No overhang - typical for style

Exterior Doors

Exterior Door Type: Tested

Exterior Windows

Windows/Frames: Metal frames

Exterior Electrical/Faucets

Exterior Electrical Components: Grounded outlets

Exterior Faucets: Older faucet(s) - not frost-proof

Exterior faucets are not frost-proof or equipped with anti-siphon valves. Frost-proof faucets protect the faucet and plumbing from possible freeze damage. An anti-siphon valve prevents backflow of water into the plumbing system. These features were not required at the time of construction, however, upgrades are recommended.

Fuel Storage and Distribution

Natural Gas - Meter/Supply

Present

Gas Meter Location: Front of structure, Rear of structure

Gas Pipe Materials: Steel and flex piping

Gas Shut-off Locations: At all gas appliances

Parking Type/Conditions

Garage/Carport General

Parking Type: No Covered Parking

Heating, Cooling

Chiller

The chiller on the roof has worn out insulation. It is recommended to add insulation to improve efficiency and prevent energy loss.

Heat Pump/Air Conditioning

Type of System: Package unit

Manufacturer: Carrier

Manufacture Date/Age: 2007, 2012

Exterior Equipment Location(s): Roof

Energy Source: Gas

This heat pump unit is close to the end of its useful design life. The average service life of heat pump units is 15-20 years. Funds should be reserved to replace this AC system at any time. Older AC units like this are also less reliable and subject to the need for constant repairs.

Heating and cooling contractors recommend annual servicing to ensure safe and reliable performance and to prolong the useful life of heating and cooling equipment. No recent service records were noted for all the heat pumps. I recommend having this system serviced and further evaluated by a qualified heating contractor if it has not been done in the last year.

Some of the rooftop HVAC units are reaching the end of their service life and should be budgeted for replacement within the next 2 to 3 years.

Thermostat(s)

Thermostat Type: Manual

Ducting/Distribution

Heat Source in Each Room: Present

Distribution Materials: Metal ducting

The metal ducting shows signs of corrosion and water retention in some areas. This can accelerate deterioration and impact performance. Repairs, including cleaning, sealing, and treating the affected areas, are recommended to prevent further damage and extend the ductwork’s lifespan. Addressing these issues promptly will help avoid more costly repairs later.

Additional Heat/Cooling Sources

Description: Wall-mounted forced air electric heaters

The heating in the men's bathroom was not operable during the inspection due to the control box being sealed. It is recommended to have a qualified technician evaluate the control box and heating system to determine the cause and ensure proper operation.

Fresh Air Circulation

During our inspection, we noted that the up-blast exhaust system on the roof is excessively vibrating during operation. This could affect system performance and safety. We recommend consulting a professional HVAC technician for further diagnosis and necessary repairs or replacement of components like fan blades, bearings, or mounts. Regular maintenance is also advised to prevent future issues.

The upblast exhaust system is near the end of its estimated service life, which is typically 15-20 years. Replacement or upgrade should be budgeted accordingly. It is recommended to consult with a qualified HVAC contractor to assess the system’s condition and determine the appropriate course of action.

At the time of inspection, an upblast exhaust system was not operational. It is recommended to have a qualified HVAC technician evaluate the system to identify and address any issues to ensure proper functionality and compliance. Repair or replacement may be necessary.

Water Heaters

Water Heater ( Brewery )

Water Heater Type: Tank Style

Energy Source: Electric

Manufacturer: Bradford-White

Capacity: 79

Manufacture Date/Age: 2021

Water Heater Location: Kitchen

Pressure Relief Valve: Installed

Seismic Restraints: Installed

Expansion Tank: Installed

Typical life expectancy is 10 to 15 years. Visible materials and components at the water heater appeared to be intact and functional. No evidence of current or recent leaks or damage noted at the time of the inspection.

Hot water was noted at all tested plumbing fixtures indicating the water heater was functioning properly at time of the inspection, unless noted elsewhere in this report. Gas burners are not visible and, electric heating elements are not visible for inspection, therefore, our inspection is limited. As with all appliances, gas burners and/or electric elements can fail at any time without warning. If a change in performance is noted, consult with a licensed plumber for review.

Water Heater ( Bar )

Water Heater Type: Tank Style

Energy Source: Natural Gas

Manufacturer: Rheem

Capacity: 75 gal

Manufacture Date/Age: 2020

Water Heater Location: Pantry

Pressure Relief Valve: Installed

Seismic Restraints: Installed

Expansion Tank: None - may be required

No expansion tank installed. An expansion tank may be recommended for the water heater; these are required if the structure has a closed plumbing system (a backflow preventer - normally installed at the water meter). A thermal expansion tank helps reduce pressure on the water heater caused by expansion of water when heated. Consult with a licensed plumber to determine if a thermal expansion tank should be installed on this unit.

Water Heater Exhaust

Exhaust Duct: Metal, single wall, Metal, double-wall 'B'-vent

Plumbing

Water Service

Water Service/Source: Public Water Utility

Main Supply Pipe: Main supply pipe not confirmed

Water Pressure: 60-70 PSI

Water pressure was tested at the exterior hose faucet. This is within the recommended range of 40 to 80 psi for municipal water supply systems.

Distribution Pipe

Supply Pipe Materials: Copper, PEX Tubing (cross-linked polyethylene)

Functional Flow: Adequate

Pipe Insulation: Missing in unfinished basement

Circulation Pump: Present

The supply pipe insulation is incomplete in the basement. Be sure all supply lines in unheated spaces have been adequately insulated to protect from freezing conditions that could damage the pipes and to prevent heat loss.

Waste System

Waste System: Public Sewer System

Waste and Vent Pipe Materials: ABS plastic

Fire Suppression

The fire hydrant has an expired tag. It is recommended to conduct a further evaluation of the hydrant’s condition and arrange for the renewal or replacement of the expired tag to ensure compliance with local fire safety regulations.

Exterior Hose Bibs

Operating

Interior Water Features

This building contains brewing machinery and boiler equipment specialized for brewing purposes. Inspection of these systems is beyond the scope of this inspection. It is recommended to consult with a qualified contractor or specialist to review and assess these systems if there are any concerns.

Electric Service

Incoming Electric Service

Service Entrance: Overhead

Meter Base Amperage: Unable to Confirm

Service Voltage: Voltage assessed visually

Overhead incoming electrical service. Visible service equipment appeared intact.

The electric service conductors are too close to the roof. This is a safety hazard. Conductors should generally be 3 feet above a sloped roof and 8 feet above a low-slope roof. Consult with a licensed electrician and/or your utility provider to further evaluate and repair this condition. This could necessitate raising the electric service.

Electric Service Equipment

The brewery is equipped with a phase converter to operate specialized brewing equipment, which converts single-phase power to three-phase power as required for the operation of such industrial systems. During the inspection, the location of the electrical setup and permit documentation could not be verified. It is recommended to consult with a qualified licensed electrician to confirm that the phase converter and associated electrical components were installed properly and in compliance with local electrical codes and regulations.

An inadequate working clearance was noted for the electric load center. A 30 inch wide and 36 inch deep unobstructed working clearance is recommended for improved safety. This limits our inspection of this area. Consult with a licensed electrician or general contractor to further evaluate this condition and improve access as needed.

During the inspection of the bar's electrical panel, a buzzing sound was observed along with elevated heat readings. It is strongly recommended to consult with a qualified electrician to assess the panel's condition, identify any potential issues, and perform necessary repairs or upgrades to ensure safe and reliable operation.

Overheated breaker/wiring was noted in the main panel. Consult with a qualified electrician for further review and repair as needed. This often indicates loose connections or defective breaker/wiring inside the panel.

Electrical Grounding System

Electrical Grounding: Grounding System Not Confirmed

During a visual inspection, every effort is made to inspect the visible components of the electrical system grounding. The grounding system is critical for safely discharging electrical surges, especially in the case of lightning strikes. There is no way in the context of a building inspection to verify the "effectiveness" of the grounding system as much of the system is not visible and there are not practical tests one can perform in the way we can test a furnace or a plumbing fixture. However, there are many things that can lead me to recommend further evaluation of the grounding system by a licensed electrical contractor and they will be documented in the observations below if discovered.

Electrical Bonding System

Electrical Bonding: Bonding Connections Not Located

Bonding connections were not visible at the time of the inspection. This is a common condition as bonding connections are often hidden within wall or floor cavities or behind finished surfaces. Due to this condition electrical bonding could not be confirmed.

Electrical bonding is an important system intended to control stray voltage which can affect metal systems in the building. If confirmation of electrical bonding is desired, consult with a licensed electrician.

Branch Wiring/Electrical Fixtures

Branch Wiring

The open electrical junction box needs to be covered for improved safety - see roof top. This is as simple as installing a cover plate over the box to protect the wiring. Sometimes, an extension ring is needed if finishes are covering the box. Repair as needed for improved safety.

Extension cords have been used to supply power on roof top. This is non-standard and a safety hazard. An electric receptacle should be provided for all appliances and extension cords should be eliminated for all permanent fixtures.

Receptacles and Fixtures

Inspection Method: Random Testing

Receptacle Type(s): Grounded 3-wire receptacles

In most buildings, we operate all accessible wall switches (lights, fans) and approximately 25% of the outlets (minimum 2 per room). If any anomalies are noted we will test additional receptacles and attempt to identify the issue.

Tested devices and fixtures appeared functional and intact, unless noted elsewhere in this report.

During inspection I test all Ground Fault Circuit Interrupter (GFCI) devices that are readily accessible. GFCI's are those electric receptacles with re-set buttons that you commonly see in bathrooms, kitchens and at the exterior of the building. GFCI's are important safety devices that limit the duration of electrical shocks and have demonstrably saved lives. I recommend being aware of where re-set buttons are located in the building as GFCI's can trip and disable a circuit which can not be re-energized without re-setting the button. I avoid testing to determine if a receptacle or circuit is GFCI protected if it is not clear where the re-set button can be found. This is because re-set buttons can be concealed behind stored items, so such a test risks disabling a circuit in the building. Occasionally, during testing of GFCI's one can fail. This is a statistical reality that some of these devices will fail under testing and require replacement after testing.

An inoperative receptacle was noted. This may be on a switched or GFCI protected circuit, but no switch or GFCI was found during inspection. Have the receptacle further evaluated and repaired by a licensed electrician.

Kitchen

General Kitchen Comments

The bar areas in both restaurants were in operation during the inspection and appeared to be functional. Continued regular maintenance is recommended to ensure ongoing proper performance.

Ranges, Ovens, Cooktops

Range/ Oven /Cook-tops: Tested/Inspected

The Type 1 hood is equipped with a suppression system, and the material appeared to be intact during the inspection. Regular inspection and testing of the suppression system are recommended to ensure it remains fully operational and compliant with safety regulations.

Refrigerators

Refrigerator: Tested/Inspected

Ventilation Method

Kitchen Exhaust: Tested

The kitchen is equipped with a Type 1 hood designed to exhaust grease, steam, and heat from the kitchen and bar area. During the inspection, these systems were operational. Regular cleaning and maintenance of the hood and exhaust filters are necessary to ensure proper performance, prevent grease buildup, and comply with fire safety standards.

Kitchen Electrical

Tested

Sinks and Faucets

Tested/Inspected

Cabinets and Countertops

Cabinet Material: Wood/Plywood

Countertop Material: Intact

Bathrooms

Toilets

Tested/Inspected

Sinks/Cabinets

Sinks/Faucets: Tested/Inspected

Cabinets/Counters: Appeared intact

Bathroom Electrical

Tested

Bathroom Ventilation

Ventilation Type: Ceiling fan(s)

Interior

General Interior Conditions

Flooring

Floor Materials: Inspected

Floor Settlement: Minor

Minor to moderate floor settlement was noted in the building. Inquire with the seller for any history of repairs or movement. No signs of recent movement were visible at the time of inspection. Consult with a structural engineer for further evaluation.

Walls, Ceilings, Trim and Closets

Wall and Ceiling Materials: Gypsum board/Drywall

Windows / Glass doors

Window: Tested

Please be advised that during the building inspection, any windows that are blocked by personal items such as couches, bed frames, or other large furniture may not be accessible for testing. In such cases, the inspector will be unable to verify the operation, condition, or functionality of those windows. We recommend that all windows be made accessible prior to the inspection to ensure a comprehensive evaluation.

Interior Electrical Conditions

Some light fixture(s) were inoperable at the time of the inspection, possibly due to a missing/failed bulb. Replace the bulb(s) and check the function. If the fixture remains inoperative, consult with a licensed electrician for review and repair.

Checking Out Procedure

Check Out List

Oven: Off

Off

Lights: Off

Off

Heating and Cooling: Restored to Pre-inspection temperatures

Restored to Pre-inspection temperatures

Appliances: Off / finishing cycle

Off / finishing cycle

Receipt -- Full report

8650 Greenwood Ave N seattle, WA 98103

| Inspection Fee | $4,300.00 |

| $4,300.00 | |

| PAID |

LAT Inspection

32238 11TH AVE SW

FEDERAL WAY, WA 98023

206-202-7522

.jpg)

.jpg)

(1) (1).png)