McCall Home Inspections - Matthew Merlino, License #ASHI Certified Inspector #244711

The Scope and Purpose of a Home Inspection

Purchasing property involves risk

The purpose of a home inspection is to help reduce the risk associated with the purchase of a structure by providing a professional opinion about the overall condition of the structure. A home inspection is a limited visual inspection and it cannot eliminate this risk. Some homes present more risks than others. We cannot control this, but we try to help educate you about what we don’t know during the inspection process. This is more difficult to convey in a report and one of many reasons why we recommend that you attend the inspection.

A home inspection is not an insurance policy

This report does not substitute for or serve as a warranty or guarantee of any kind. Home warranties can be purchased separately from insuring firms that provide this service.

A home inspection is visual and not destructive

The descriptions and observations in this report are based on a visual inspection of the structure. We inspect the aspects of the structure that can be viewed without dismantling, damaging or disfiguring the structure and without moving furniture and interior furnishings. Areas that are concealed, hidden or inaccessible to view are not covered by this inspection. Some systems cannot be tested during this inspection as testing risks damaging the building. For example, overflow drains on bathtubs are generally not tested because if they were found to be leaking they could damage the finishes below. Our procedures involve non-invasive investigation and non-destructive testing which will limit the scope of the inspection.

This is not an inspection for code compliance

This inspection and report are not intended for city / local code compliance. During the construction process structures are inspected for code compliance by municipal inspectors. Framing is open at this time and conditions can be fully viewed. Framing is not open during inspections of finished homes, and this limits the inspection. All houses fall out of code compliance shortly after they are built, as the codes continually change. National codes are augmented at least every three years for all of the varying disciplines. Municipalities can choose to adopt and phase in sections of the codes on their own timetables. There are generally no requirements to bring older homes into compliance unless substantial renovation is being done.

This is just our opinion

Construction techniques and standards vary. There is no one way to build a house or install a system in a house. The observations in this report are the opinions of the home inspector. Other inspectors and contractors are likely to have some differing opinions. You are welcome to seek opinions from other professionals.

The scope of this inspection

This inspection will include the following systems: exterior, roof, structure, drainage, foundation, attic, interior, plumbing, electrical and heating. The evaluation will be based on limited observations that are primarily visual and non-invasive. This inspection and report are not intended to be technically exhaustive.

Your expectations

The overall goal of a home inspection is to help ensure that your expectations are appropriate with the house you are proposing to buy. To this end we assist with discovery by showing and documenting observations during the home inspection. This should not be mistaken for a technically exhaustive inspection designed to uncover every defect with a building. Such inspections are available but they are generally cost-prohibitive to most homebuyers.

Your participation is requested

Your presence is requested during this inspection. A written report will not substitute for all the possible information that can be conveyed verbally by a shared visual observation of the conditions of the property.

How to Read This Report

Getting the Information to You

This report is designed to deliver important and technical information in a way that is easy for anyone to access and understand. If you are in a hurry, you can take a quick look at our "Summary Page” and quickly get critical information for important decision making. However, we strongly recommend that you take the time to read the full Report, which includes digital photographs, captions, diagrams, descriptions, videos and hot links to additional information.

The best way to get the layers of information that are presented in this report is to read your report online (the HTML version), which will allow you to expand your learning about your house. You will notice some words or series of words highlighted in blue and underlined – clicking on these will provide you with a link to additional information. The HTML version of this report also contains streaming videos. Short video clips often contain important information and critical context and sounds that can be difficult to capture in words and still pictures.

For the most reliable viewing experience, I recommend viewing the report on as large a screen as practical, as much detail can be lost on small devices like smart phones. For similar reasons, reports should only be printed in color to retain as much detail as possible and minimize misinterpretation of photographs.

This report can also be printed on paper or to a PDF document.

Chapters and Sections

This report is divided into chapters that parcel the home into logical inspection components. Each chapter is broken into sections that relate to a specific system or component of the home. You can navigate between chapters with the click of a button on the left side margin.

Most sections will contain some descriptive information done in black font. Observation narrative, done in colored boxes, will be included if a system or component is found to be significantly deficient in some way or if we wish to provide helpful additional information about the system or the scope of our inspection. If a system or component of the home was deemed to be in satisfactory or serviceable condition, there may be no narrative observation comments in that section and it may simply say “tested,” or “inspected.”

Observation Labels

All narrative observations are colored, numbered and labeled to help you find, refer to, and understand the severity of the observation. Observation colors and labels used in this report are:

- Safety Concern:These are repairs or improvements that need correction for improved occupant safety, or may be mentioned for the purpose of raising awareness

- Recommended Repair:Repair and maintenance items noted during inspection. Please note that some repair items can be expensive to correct such as re-finishing hardwood floors, but are considered simply repair items due to their cosmetic nature.

- Recommended Maintenance:These are more routine repair items that would typically be considered minor deferred maintenance or routine home-ownership items, such as servicing the furnace, routine caulking, paint maintenance cleaning the gutters or changing the air filters in the furnace

- Monitor:Items that should be watched or checked periodically to see if correction may be needed in the future

- Suggested Due Diligence:Observation such as a septic system needing routine pumping and inspection by a specialist or other items that may require further investigation to determine if repairs may be needed. Another example might be inquiring with a seller for more information regarding improvements or additions

- Note:Refers to aside information and /or any comments elaborating on descriptions of systems in the home or limitations to the home inspection

- Description:Descriptions and various aspects of the property or system noted during the inspection

Pest Inspection

All items with the bug logo () are part of a structural pest inspection. If your inspector included a structural pest inspection as a part of the scope of your home inspection, you can distinguish pest inspection items by this logo. You can also go to the pest inspection summary page to see a summary of the items that are part of a pest inspection.

Summary Page

The Summary Page is designed as a bulleted overview of all the observations noted during inspection. This helpful overview is not a substitution for reading the entire inspection report. The entire report must be read to get a complete understanding of this inspection report as the Summary Page does not include photographs or photo captions.

Moisture Meter Testing

Where moisture meter testing is indicated in this report a Protimiter Survey Master Dual Function was used.

Summary

Safety Concerns

- EDFW-5 Electric Distribution & Finish Wiring:

I don't recall seeing any carbon monoxide (CO) alarms. CO alarms were not required until the 2012 code cycle. The installation of carbon monoxide alarms is recommended for all homes that have fuel burning appliances such as gas or oil furnaces, gas water heaters, gas ovens and cook-tops, gas fireplaces and wood stoves. Modern standards in many states now recommend one CO alarm outside of all bedrooms and at least one per floor of the house.

Recommended Repairs

- RG-3 Roof & Gutters:

The rubber gasket in the plumbing vent boot is degraded. The potential for water entry is present. Recommend replacement by a qualified roofing contractor.

- ARCV-3 Attic & Roof Cavity Ventilation:

The screens that protect the gable vent openings above the shop are damaged and require repair to exclude birds, bats and insects. Use 1/4 inch wire mesh to seal-up openings from rodents and birds. Refrain from using tight-mesh window screen as this can accumulate dust which will obstruct air flow.

- HCFV-9 Heating, Cooling, Fireplaces & Venilation:

Rust stains noted on top of wood stove. I noticed the chimney cap appeared to partially collapsed leaving the chimney open to weather, which I suspect would leak some during heavy rains and during snow melt. Regardless, I recommend further evaluation of this older wood stove and chimney by a certified chimney sweep to make repair(s) as deemed necessary. Heartland Chimney Sweeps is local and reputable and does this type of work. http://www.heartlandchimneysweepsid.com/

- I-4 Interior:

Adjustment/repair needed: The basement door to the unfinished storage room was hitting on the frame and wouldn't close properly.

- B1-1 Bathroom 1:

Shower head bracket in the second floor master bath was cracked and needs replacement.

Recommended Maintenance Items

- E-1 Exterior:

Some areas more exposed to sun and weather seem to indicate an exterior stain job hasn't been done in recent years. This is routine maintenance and should probably be done withing a couple of years. How often you need to re-stain wood siding depends on climate and exposure to sun and other factors. Generally, you should expect to re-stain every five to seven years.

- G1-3 Garage:

The self-closing hinges do not self-latch the fire separation door between the garage and living space as required. Many garage to living area entry doors have hinge springs have been purposely disengaged. Recommend re-tensioning the springs in the self-closing hinges https://www.youtube.com/watch?v=3qzP0ge3U_s

- HCFV-3 Heating, Cooling, Fireplaces & Venilation:

It should be noted that this furnace is nearing the end of its industry standard suggested design life. The average service life of natural gas and propane forced air furnaces is about 20 years. The risk of running a gas forced air furnace past its suggested design life is that the furnace could continue to operate with a cracked heat exchanger. Recommend having this furnace serviced and the heat exchanger inspected by a qualified heating contractor. Keep the furnace on a regular service schedule and budget to update at any time and install carbon monoxide alarms in the home.

- HCFV-8 Heating, Cooling, Fireplaces & Venilation:

Recommended annual maintenance: The readily visible portions of the fireplace appeared to be in good working condition. The National Fire Protection Association recommends scheduling a professional chimney sweep at least once a year to ensure the safe operation of fireplaces, wood stoves and chimneys. For a thorough job, call a chimney sweep who is certified by the Chimney Safety Institute of America. Heartland Chimney Sweeps is local and reputable and does this type of work. http://www.heartlandchimneysweepsid.com/

- I-1 Interior:

The hardwood floors are scratched in some of the traffic areas. This appears to be just normal/typical wear. You may wish to hire a wood floor specialist to refinish the floors. The best time to refinish floors is when the home is vacant prior to moving your furniture in.

Items to Monitor

- EDFW-9 Electric Distribution & Finish Wiring:

Smoke alarms were found and noted during inspection. Be sure to check smoke and carbon monoxide alarms regularly and change backup batteries and replace alarms regularly as recommended by the manufacturer (most manufacturers recommend replacement every 7 - 10 years).

Suggested Due Diligence Items

- E-2 Exterior:

Maintenance Reminder: There were a few rodent bait stations noted at the exterior of the building. This is common best practice for rodent control in the area. I recommend continued vigilance going forward. Inquire with the seller regarding regarding any contracts for ongoing pest control.

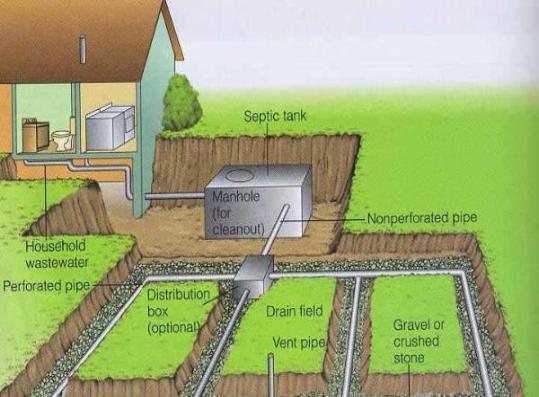

- P-6 Plumbing:

Based on visible components, this property appears to have a private on-site septic system. These are specialty systems and are excluded from this inspection. Generally, septic tanks should be pumped and inspected about every 3 - 5 years but this can vary depending on the number of occupants and usage. Depending on the type of system and municipal regulations, inspection and maintenance may be required more frequently. I recommend:

- Investigating any information about this system's maintenance and repair history

- Have the system pumped and tank inspected by a septic pumping company.

- Reviewing any documentation available for this system

- Learning inspection and maintenance requirements for this system

- Link to EPA guide.

Notes

- EDFW-10 Electric Distribution & Finish Wiring:

This building may have some low voltage wiring installed. Evaluation of alarm systems, phone and internet wiring is beyond the scope of this inspection.

- HCFV-4 Heating, Cooling, Fireplaces & Venilation:

The heating system has a clean disposable air filter installed. This should be changed regularly to ensure proper air flow at the furnace.

- I-6 Interior:

The unfinished storage room in the basement had a bed set up in it. This room does not have adequate egress. All bedrooms must have a second means of egress in case of emergency. This is typically provided through a window of legal fire egress size (Maximum of 44 inches off the floor and openings no smaller than 5.7 square feet).

The Full Report

Exterior

Siding & Trim

Fascia & Eves

Window Types

Exterior Doors

Other Observations

Decks, Porches, Balconies & Guardrails

General Exterior Photos

Roof & Gutters

Roof Type & Inspection Method

Roof Covering

Flashings

Chimneys

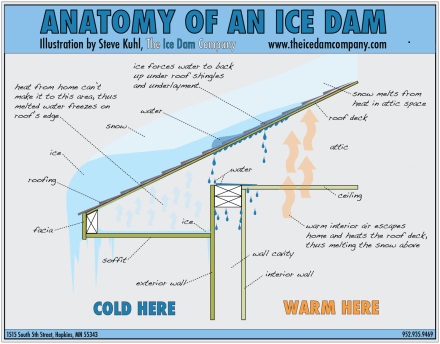

Evidence of Ice Dams?

General Roof Photos

Attic & Roof Cavity Ventilation

Attic Access

Roof Structure

Sheathing

Insulation

Ventilation

General Attic Photos

Garage

General Information

Descriptions

Overhead Vehicle Doors

Garage Occupant Door

General Garage/Shop Photos

Shop

Descriptions

Overhead Vehicle Doors

Garage Occupant Door

Other General Observations

General Garage/Shop Photos

Electric Service & Distribution

State / Municipal Permits

Service Equipment & Meter Base

General Service Equipment Photos

Distribution Panel

Distribution Panel Photos

Distribution Panel 2

Distribution Panel 2 Photos

Grounding & Bonding

Electric Distribution & Finish Wiring

Branch Wiring

Receptacles & Fixtures

Ceiling Fans

Smoke & Carbon Monoxide Alarms

Low Voltage Systems

Heating, Cooling, Fireplaces & Venilation

Heating System

Vents & Flues

Air Filters

Cooling System

Heating & Cooling Distribution Systems

Mechanical Ventilation Systems

Solid Fuel Fireplace

Wood Stove - Shop

Plumbing

State / Municipal Permits

Water Service & Supply

Distribution Pipe

Fuel Distribution Pipe

Waste Pipe & Discharge

Water Heater

Water Temperature

Interior

Floors & Floor Materials

Walls, Ceilings, Trim & Closets

Wall Insulation Air Bypass

Stairs & Railings

Interior Doors

Windows

Other Observations

General Interior Photos

Bathroom 1

Location & Type

Sinks, Faucet, Drains

Vanity Cabinets

Toilet

Bathtubs / Showers

Ventilation

General Bathroom Photos

Bathroom 2

Location & Type

Sinks, Faucet, Drains

Vanity Cabinets

Toilet

Bathtubs / Showers

Ventilation

General Bathroom Photos

Bathroom 3

Location & Type

Sinks, Faucet, Drains

Vanity Cabinets

Toilet

Bathtubs / Showers

Ventilation

General Bathroom Photos

Kitchen

Sinks, Faucets & Drains

Disposers

Cabinets & Countertops

Kitchen Floor

Ventilation Method

Appliance Disclaimer

Ranges, Ovens & Cooktops

Refrigerators

Dishwasher

Other Appliances

General Kitchen Photos

Building Site & Other General Information

Weather: Clear, Recent isolated thunderstorms

Soil Conditions: Mostly dry

Approximate Outside Temperature: 60 - 70

Building Orientation: For the purposes of this report, the front entry door faces approximately north

Approximate Year Built: 2002

Building Type: Single family Residential, Wood Frame

Stories: 2 - Story

Space Below Grade: Basement

Utility Services: Private Well, Private Septic

Utility Status: All utilities on

Occupancy Status: Vacation home, Occupancy varies

Attendance: Selling Agent

Grounds

Grade & Site Drainage

Ideally, the ground should drop one inch for every one foot that you move away from the house for the first 5-to-10 feet around your house. While this is not always possible, the ground should never be sloping upwards as you move away from your house foundation.

Grade: No red flags

Site Drainage: No concerns observed

Driveways, Walkways & Landscape

Driveway: Gravel

A note regarding concrete: Concrete driveways, patio slabs and walkways are prone to cracking due to several reasons. The reasons for cracking of concrete are as follows:

- Temperature and plastic shrinkage

- Thermal variation

- Drying shrinkage

- Chemical reaction

- Weathering

- Poor construction practices

Many existing concrete on existing residential homes has at least some cracking. More severe cracking is common when one or more of the above listed variables were/are present. Existing concrete driveways and walkways in cold climates with more extreme temperature fluctuations will usually show signs of *surface spalling/deterioration and is prone to cracking due to frost heaving. Asphalt will typically perform better in cold climates as the material has some elasticity and is more resistant to surface spalling. In general, we look for and report on raised or uneven walking surfaces that may pose a trip hazard which is a safety concern. Otherwise, cracked or spalling concrete will just be categorized as cosmetic and may not be mentioned in the report.

*Spalling is the flaking or peeling away of small particles of cement paste from the near-surface portion of the finished slab. In most instances, the defect does not affect the slab's service life if untreated. Freezing and thawing cycles are the most common cause for concrete to spall.

Walkways: Brick, Pavers

Landscape: General appearance good, Well manicured

Snow Removal: Food For Thought

General Awareness: Just as a reminder and food for thought: Snow removal in winter months is a necessity for ease of access with most properties in this area. Consideration should be given to ways and means of snow removal. Some opt to do it themselves, while others hire a snow removal contractor. Each property will have different requirements for snow removal.

Patio

Type: Brick / Pavers

Condition / Observations: Appearance good

Fences & Gates

Type: None

Exterior

Siding & Trim

Type(s): Wood Siding (Horizontal Lap)

Condition: Appearance and condition good, Installation practices appear standard

Some areas more exposed to sun and weather seem to indicate an exterior stain job hasn't been done in recent years. This is routine maintenance and should probably be done withing a couple of years. How often you need to re-stain wood siding depends on climate and exposure to sun and other factors. Generally, you should expect to re-stain every five to seven years.

Fascia & Eves

Fascias: Wood

Soffits/Eves: Plywood

Condition: Appearance and condition good, Installation practices appear standard

Window Types

Frames: Vinyl

Glazing: Double Pane

Insect Screens: Present

Condition / Observations: Overall appearance good

Exterior Doors

Types: Standard exterior rated doors, Sliding, Glass paneled

Condition / Observations: Appearance and function good

Other Observations

Maintenance Reminder: There were a few rodent bait stations noted at the exterior of the building. This is common best practice for rodent control in the area. I recommend continued vigilance going forward. Inquire with the seller regarding regarding any contracts for ongoing pest control.

Decks, Porches, Balconies & Guardrails

Modern Deck Standards:

To see a prescriptive guide for residential wood deck construction click this link: Most existing decks do not meet the standards set forth in this guide, but these standards do help guide our deck inspections.

Type: Wood Structure, Composite Decking

Condition: Newer - Appearance good, Structure and building practices good

Fuel Sources

Fuel Type

Meter / Fuel Storage

Propane Tank: Above ground, General appearance good, Tank Size (1000 gallons), Gauge Reading (80%)

Roof & Gutters

Roof Type & Inspection Method

Style: Gable

Roof Covering: Corrugated Metal Roof Panels

Inspection Method: Viewed From Ground, Aerial Photography

Metal roofs offer many benefits, including longevity. Metal roofs can last 40-70 years, depending on the material. Screws tend to be the best way for you to hold the roof panels in place. When a screw looks compromised, arrange to get it replaced. Regularly inspect the roof and tighten any screws that may have worked loose due to temperature fluctuations and expansion/contraction cycles.

Roof Covering

Condition: Appearance good, Installation practices appear standard

Flashings

Roof flashings are used to keep a roofing system water proof where the roofing material starts, stops, changes direction or is penetrated. During inspection, we look for standard flashing techniques that could be considered normal or standard in our region. Damaged, incomplete or non-standard flashings can be a sign of an older or less reliable roofing system and may require repair. Any non-standard flashings noted during inspection will be reported on below if found.

Type: Metal, Rubber Vent Boots

Condition: Overall appearance good, Installation practices appeared standard

Chimneys

Chimney Materials: Stone, Masonry

Flue Material: Metal

Condition / Observations: Condition good as visible

Evidence of Ice Dams?

Ice dams are common in colder climates due to weather conditions and temperature swings between freezing overnight and thawing during the day. The main problem with ice dams is the roof can't drain properly and water can back up beneath the shingles and enter the structure and the ice can cause damage to the roof covering. Ice dams form when snow is melted on the roof and then freezes again at the eaves. Ice dams are exacerbated by air bypasses and stack effect. A “cold roof” is the only proven method of completely stopping ice dams. This is achieved by sealing ALL penetrations in the ceiling and any heating or return ducts in the attic in conjunction with proper roof ventilation and a dense insulation product such as cellulose or spray foam. Air-sealing keeps conditioned air from rising up and warming the roof deck. Proper ventilation and insulation keeps the roof deck cold..

Attic & Roof Cavity Ventilation

Attic Access

Attic spaces can present challenges and limitations. We try to access and view the entire space whenever possible. Most attics will have limitations due to: Low headroom, limited accessibility where framing and ductwork are installed, lack of ramps or walk-boards. Crawling or walking through insulation can damage ceiling finishes, thermal barriers, unseen wiring/fixtures/ducts, etc.

Attic Access Locations: Garage ceiling, Shop ceiling

Inspection Method: Walked/Traversed, Viewed From Readily Accessible Areas, Some or All Vaulted Ceilings

Note that the house has vaulted ceilings - there is no attic space and no access to inspect roof framing, thermal barriers or fans exhaust ductwork in the vaulted parts of the house.

Roof Structure

Type: Trusses, 2 x 6 w/2x4 bracing

Condition: Readily visible portions of roof framing appeared good

Sheathing

Type: Plywood

Condition: Readily visible portions appeared good

Insulation

Type: Fiberglass Batting, Fiberglass Blown

Condition: Appears adequate

Ventilation

Method: Gable vents, Continuous ridge vent, Soffit vents

Vent Screens: Damaged

Adequacy: Attic ventilation method appears adequate

The screens that protect the gable vent openings above the shop are damaged and require repair to exclude birds, bats and insects. Use 1/4 inch wire mesh to seal-up openings from rodents and birds. Refrain from using tight-mesh window screen as this can accumulate dust which will obstruct air flow.

Garage

General Information

Fire Separation General Information:

Some general rules for fire separation between garage and living areas:

- Opening Protection; Openings from a private garage directly into a room used for sleeping purposes shall not be permitted. Other openings between the garage and residence shall be equipped with solid wood doors not less than 13/8 inches (35 mm) in thickness, solid or honeycomb core steel doors not less than 13/8 inches (35 mm) thick, or 20-minute fire-rated doors.

- The garage shall be separated from the residence and its attic area by not less than 1/2-inch (12.7 mm) gypsum board applied to the garage side. Garages beneath habitable rooms shall be separated from all habitable rooms above by not less than 5/8-inch (15.9 mm) Type X gypsum board or equivalent.

- Where the separation is a floor-ceiling assembly, the structure supporting the separation shall also be protected by not less than 1/2-inch (12.7 mm) gypsum board or equivalent.

- Garages located less than 3 feet (914 mm) from a dwelling unit on the same lot shall be protected with not less than 1/2-inch (12.7 mm) gypsum board applied to the interior side of exterior walls that are within this area.

Descriptions

Type: Attached garage, Double car

Roof: Same as house

Siding: Same as house

Construction Method: Wood frame, Same as house

Floors: Poured concrete

Foundation: Poured concrete

Attic Insulated: Yes

Overhead Vehicle Doors

Type: Metal

You should have your garage door serviced periodically if no other issues arise. Service technicians prolong the life of your garage door with preventative maintenance: Lubricating moving parts of the door, tightening bolts and screws, adjusting spring tension, etc.

Automatic Door Openers: Present, Normal operation

Garage Occupant Door

Type: Wood, Fire separtion door

Condition / Observations: Appearance and function good, Adjust self-closing hinges

The self-closing hinges do not self-latch the fire separation door between the garage and living space as required. Many garage to living area entry doors have hinge springs have been purposely disengaged. Recommend re-tensioning the springs in the self-closing hinges https://www.youtube.com/watch?v=3qzP0ge3U_s

Shop

Descriptions

Type: Detached shop

Roof: Corrugated metal roof panels

Siding: Same as house

Construction Method: Wood frame, Same as house

Floors: Poured concrete

Foundation: Poured concrete

Attic Insulated: Yes

Overhead Vehicle Doors

Type: Metal

Maintenance Recommendation: You should have these garage doors serviced periodically. Service technicians prolong the life of your garage door with preventative maintenance: Lubricating moving parts of the door, tightening bolts and screws, adjusting spring tension, etc.

Automatic Door Openers: Present, Normal operation

Garage Occupant Door

Type: Standard, Exterior rated

Condition / Observations: Appearance and function good

Other General Observations

Electric Service & Distribution

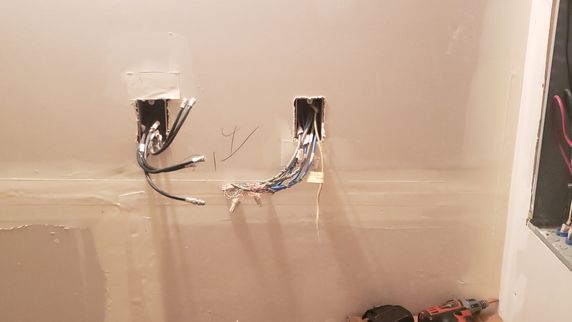

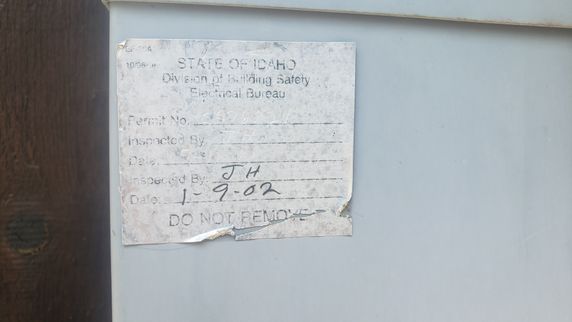

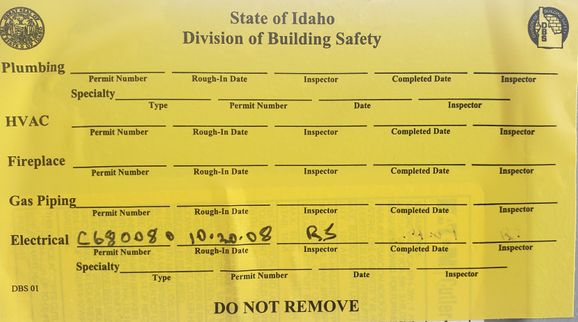

State / Municipal Permits

Permit Tags Observed: Yes

Location: Meter box, Distribution panel

Service Equipment & Meter Base

Supply Voltage: 120/240

Type: Below ground, Service lateral

Meter Base Manufacturer & Rating: Milbank, 200 amps

Main Disconnect Breaker: 200 amps

Observations: No problems observed

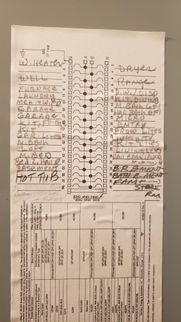

Distribution Panel

Panel Type & Location: Sub distribution panel, Basement

Panel Manufacturer & Rating: Siemans, 200 amps

Incoming Wire Type & Size: Stranded Aluminum, 4/0, Appropriately sized

Observations: No problems observed

Distribution Panel 2

Panel Type & Location: Sub distribution panel, Shop

Panel Manufacturer & Rating: Cutler Hammer, 100 amps

Grounding & Bonding

Grounding - General Note:

During a home or property inspection, every effort is made to inspect the visible components of the electrical system grounding. The grounding system is critical for safely discharging electrical surges, especially in the case of lightning strikes. There is no way in the context of a home inspection to verify the "effectiveness" of the grounding system as much of the system is not visible and there are not practical tests one can perform in the way we can test a furnace or a plumbing fixture. General info about grounding systems:

- Modern homes (2008 and newer) generally use UFER grounds (foundation rebar) and no longer need ground rods.

- Older houses (1963 and earlier) used metal water pipes for grounding instead of ground rods and these older ground conductors may be disabled if the old metal pipes have been updated with plastic pipes.

- In between, (very roughly 1963-1990) ground rods have been used for grounding. Typically two ground rods are required (to try and achieve the recommended 25 ohms or less) unless there is also an older metal water piping system that can be grounded, then often 1 ground rod will suffice.

Observations: Electric grounding conductor (EGC) observed, No concerns observed

Bonding - General Note:

All metallic systems in the building are required to be "bonded" (connected) to the the building's electrical grounding system. Bonding creates a pathway to shunt static charges (that would otherwise build up on the system) to earth, and to provide a pathway to trip a breaker in the event that these bonded metallic components became energized. During the inspection, I attempt to visually document electrical system bonding. There is no way in the context of a home inspection to verify the "effectiveness" of system bonding.

Electric Distribution & Finish Wiring

Branch Wiring

Electrical Permits Present: Yes

Wire Types Observed: Copper, Stranded Copper, NM Cable (a.k.a. Romex)

Wiring Methods Observed: Non Metallic Sheathed Cable

Installation & Workmanship: Standard as visible

Receptacles & Fixtures

Testing Method: Random testing - Representative sample

During inspection I make an effort to test and inspect all accessible electric receptacles and switches. In general, the scope of testing is directly related to access; where personal belonging and furniture obstruct access to receptacles and fixtures, fewer of them can be reasonably tested during inspection. Any defects found during inspection today will be listed in this report.

During inspection I test all Ground Fault Circuit Interrupter (GFCI) devices that are readily accessible. GFCI's are those electric receptacles with re-set buttons that you commonly see in bathrooms, kitchens and at the exterior of the home. GFCI's are important safety devices that limit the duration of electrical shocks and have demonstrably saved lives. I recommend being aware of where re-set buttons are located in the house as GFCI's can trip and disable a circuit which can not be re-energized without re-setting the button. I avoid testing to determine if a receptacle or circuit is GFCI protected if it is not clear where the re-set button can be found. This is because re-set buttons can be concealed behind stored items, so such a test risks disabling a circuit in the home. Occasionally, during testing of GFCI's one can fail. This is a statistical reality that some of these devices will fail under testing and require replacement after testing.

Electrical Receptacles: Three wire receptacles

Condition & Functionality: Appearance and function good

Ceiling Fans

Ceiling Fans: Present and tested

Ceiling fan(s) were tested and were operating normally during inspection.

Smoke & Carbon Monoxide Alarms

Smoke Alarms: Smoke alarms present

The link below includes important information about smoke alarms that could save lives in the event of a fire. There are two basic types of smoke alarms: ionization, which are better at detecting flaming fires and photoelectric, which are better at detecting smoldering fires. Standards in the building industry are moving toward recommending BOTH types of alarms in the home. It is nearly impossible to accurately test smoke alarms during a home inspection. I recommend learning more about these important life saving devices and consider installing both types of smoke detectors in your home. http://getscribeware.com/blog/wp-content/uploads/2016/04/Ionization-vs-photoelectric.pdf

During the home inspection, I try and test a representative sample of the smoke alarms by using the test button on the alarms. This is NOT an accurate test of the sensor just a test to see if the unit is powered. For reliability, fire marshals recommended updating smoke alarms every 10 years and changing batteries bi-annually. The latest data indicate that we should be using photoelectric technology in our smoke alarms for improved fire detection and to reduce problems with false alarms which can lead to disabling of this important safety system. Unfortunately, the alarms have to be removed to determine if they are photo-electric or ionization types. It is surprisingly complex to accurately test a smoke alarm system and determine the reliability, age, and type of sensor technology used, especially as many homes can have half a dozen or more alarms throughout the house. A complete evaluation of smoke alarms is beyond the scope of this inspection. For optimal fire safety, I recommend taking control of these important safety devices and learning about how to service and maintain your smoke alarm system to keep the building occupants safe. For more information, please read this link. For more information, please read this link.

The installation of carbon monoxide alarms is recommended for all homes that have fuel burning appliances such as gas or oil furnaces, gas water heaters, gas ovens and cook-tops, gas fireplaces and wood stoves. Best practices are to have these alarms hardwired with a battery back-up - though requirements are for the installation to meet manufacturer's specifications. Carbon monoxide is a colorless, odorless gas that can cause sickness, nausea and even death. Alarms have a useful service life of roughly 6 years, so changing them more frequently than smoke alarms is recommended.

Carbon Monoxide Alarms: None found

I don't recall seeing any carbon monoxide (CO) alarms. CO alarms were not required until the 2012 code cycle. The installation of carbon monoxide alarms is recommended for all homes that have fuel burning appliances such as gas or oil furnaces, gas water heaters, gas ovens and cook-tops, gas fireplaces and wood stoves. Modern standards in many states now recommend one CO alarm outside of all bedrooms and at least one per floor of the house.

Smoke alarms were found and noted during inspection. Be sure to check smoke and carbon monoxide alarms regularly and change backup batteries and replace alarms regularly as recommended by the manufacturer (most manufacturers recommend replacement every 7 - 10 years).

Heating, Cooling, Fireplaces & Venilation

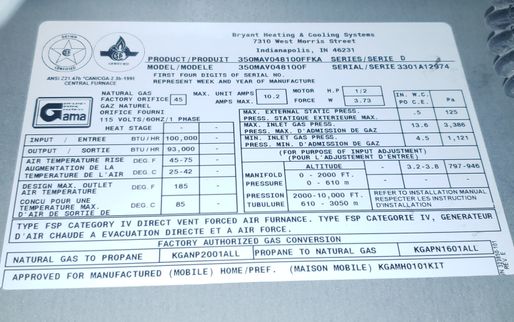

Heating System

Location: Basement, Mechanical Room

Energy Source: Propane Gas

Heating Method: Forced air gas furnace

This house has a gas forced air furnace. A critical component to all combustion equipment is the heat exchanger. This is the welded clam-shell piece of metal inside the furnace that contains the products of combustion so that moisture, carbon monoxide and other products of combustion do not mix with interior air and get safely vented to the exterior. Heat exchangers on modern furnaces have an average life expectancy of 15-20 years. Unfortunately, heat exchangers are concealed inside of heating equipment; they are not visible and specifically excluded from a home inspection.

Manufacturer: Bryant

Capacity: 100,000 btu's, Appropriately sized

Age: At or nearing end of expected design life (2001)

Recent Service Records: Unknown

Appearance & Function: Appears older with typical wear, Normal operation

It should be noted that this furnace is nearing the end of its industry standard suggested design life. The average service life of natural gas and propane forced air furnaces is about 20 years. The risk of running a gas forced air furnace past its suggested design life is that the furnace could continue to operate with a cracked heat exchanger. Recommend having this furnace serviced and the heat exchanger inspected by a qualified heating contractor. Keep the furnace on a regular service schedule and budget to update at any time and install carbon monoxide alarms in the home.

Vents & Flues

Type: PVC

Condition: Good, Visually Standard

Air Filters

Filtration Systems: Disposable

Condition: Clean

Cooling System

System Type: No air conditioning system

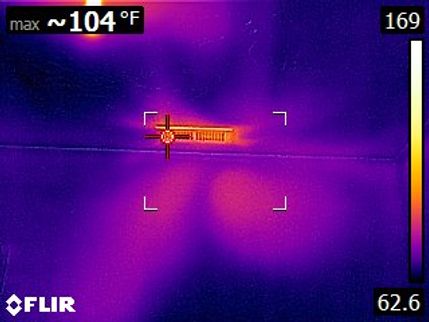

Heating & Cooling Distribution Systems

Heat Source All Rooms?: Present

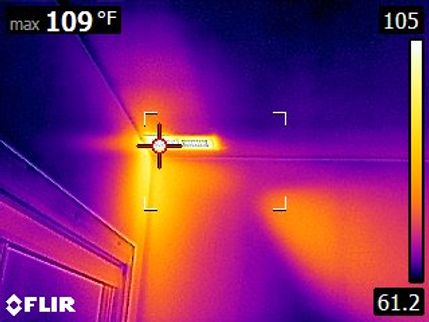

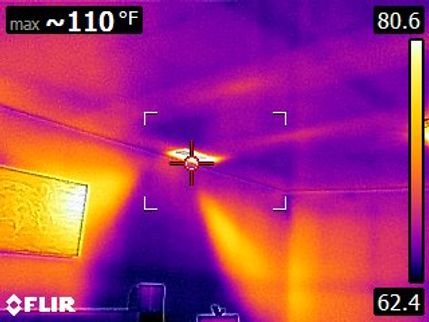

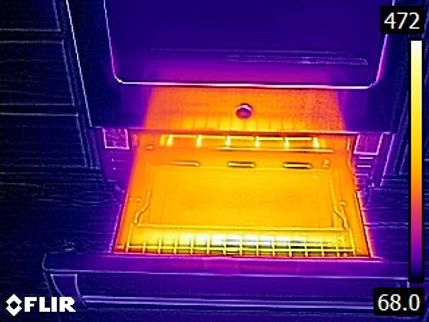

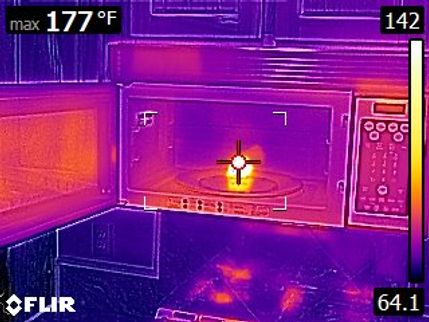

Distribution Method: Forced air / ducts, Thermal images - ducts

Mechanical Ventilation Systems

Bath Fans & Exhaust: Appeared to be properly ducted to the exterior

Kitchen Fan & Exhaust: Microwave Fan, Vents to Room

Determining proper ventilation to the exterior from kitchen, bath and laundry fans can be tricky as exhaust fan ductwork is often concealed beneath insulation, behind finishes and fan terminations can be all over the house from the roof to the foundation, presenting difficulties for systematically checking every fan termination. During inspection, every effort is made to verify proper terminations of fan vents to the exterior, but it is possible to miss something here that is latent or concealed.

Solid Fuel Fireplace

Location: Main floor, Living room

Fireplace Type: Masonry firebox

Appearance & Observations: Overall appearance good, Damper operating normally

Recommended annual maintenance: The readily visible portions of the fireplace appeared to be in good working condition. The National Fire Protection Association recommends scheduling a professional chimney sweep at least once a year to ensure the safe operation of fireplaces, wood stoves and chimneys. For a thorough job, call a chimney sweep who is certified by the Chimney Safety Institute of America. Heartland Chimney Sweeps is local and reputable and does this type of work. http://www.heartlandchimneysweepsid.com/

Wood Stove - Shop

Location: Shop

Fireplace Type: Free standing wood stove

Appearance & Observations: Rust stains. Leaking chimney suspected

Rust stains noted on top of wood stove. I noticed the chimney cap appeared to partially collapsed leaving the chimney open to weather, which I suspect would leak some during heavy rains and during snow melt. Regardless, I recommend further evaluation of this older wood stove and chimney by a certified chimney sweep to make repair(s) as deemed necessary. Heartland Chimney Sweeps is local and reputable and does this type of work. http://www.heartlandchimneysweepsid.com/

Plumbing

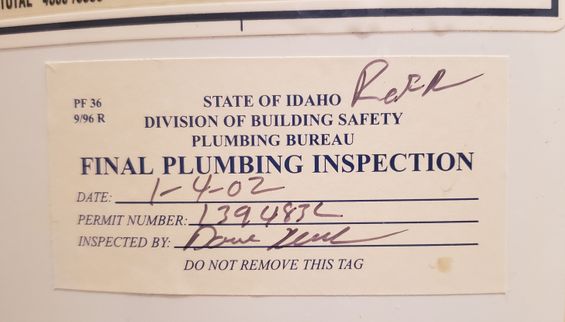

State / Municipal Permits

Plumbing Permit Observed: Yes

Location: Water heater

Water Service & Supply

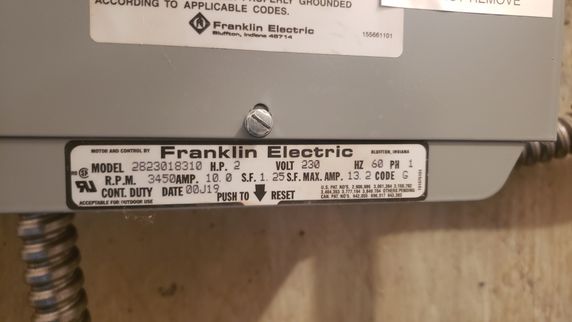

Water Supply: Private well

Water Meter: N/A

Main Water Shutoff: Location

Pipe Material: Copper

Water Pressure: Water pressure tested, Water pressure (45 psi)

This shows the water pressure tested during inspection. Generally, "normal water pressure," should be between 30-80 PSI, though pressures near or below 30 can result in poor functional flow to fixtures. Water pressures in excess of 80 PSI risk damaging supply piping components and should be controlled with a pressure reducing valve.

Water for this home is supplied by a well system. The readily visible pumping equipment appeared good and performance was normal. Installed by Dales Pump Works.. a reputable local well specialist.

Please Note - Home Inspectors are not well drillers or pump specialists. Per ASHI Standards of Practice we check only for adequate and sustained water flow and pressure at all fixtures. A well driller or pump specialist will be recommended to perform further evaluation only if the system is found to be under performing or where component deterioration and or advanced aging is viewed. Unless there is detailed information available , you may wish to hire a well specialist to further evaluate the well for more in-depth knowledge of this system. Pumps and captive storage tanks have limited service lives and often require updating on a 20-year schedule. There are other elements of a well system that you may wish to be evaluated such as the well depth, flow and refresh rates and well production, often tested in a draw down test.

Distribution Pipe

Supply Pipe Material: Copper

Comments/Observations: Functional flow, Normal

Hose Faucets: Operating normally

Yard Hydrant(s): Operating normally

Fuel Distribution Pipe

Pipe Material: Black steel, CSST

Observations: Visually standard

Waste Pipe & Discharge

Sinks are flood tested and waste assemblies are checked for leaks or minor drips. Homeowners should check the waste plumbing connections beneath the sinks periodically to avoid water damage from unseen drips that can occur. Wastebaskets and other storage coming in contact with waste assemblies beneath sinks can sometimes loosen connections and can cause drips to develop. We also often find that sink stopper assemblies in the drain assemble work loose and drip.

Discharge Type: Private Septic

Waste & Vent Pipe Materials: ABS plastic

P-Traps / Waste Assemblies: PVC Plastic

Drainage Performance: Normal at all fixtures

Based on visible components, this property appears to have a private on-site septic system. These are specialty systems and are excluded from this inspection. Generally, septic tanks should be pumped and inspected about every 3 - 5 years but this can vary depending on the number of occupants and usage. Depending on the type of system and municipal regulations, inspection and maintenance may be required more frequently. I recommend:

- Investigating any information about this system's maintenance and repair history

- Have the system pumped and tank inspected by a septic pumping company.

- Reviewing any documentation available for this system

- Learning inspection and maintenance requirements for this system

- Link to EPA guide.

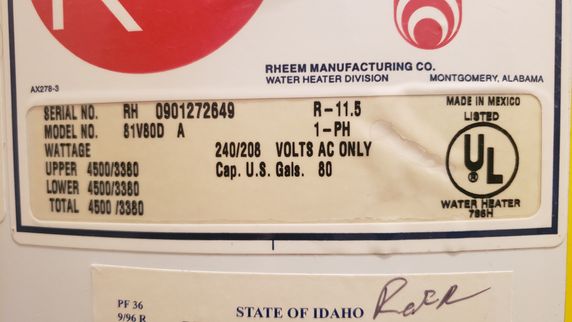

Water Heater

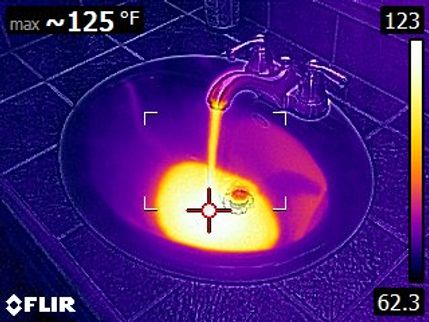

Water Temperature

Water temperature measured at inspection: 125 Degrees F

The water temperature was tested multiple times during inspection. It is common for water temperatures to fluctuate throughout the house depending on the distance from the water heater, the water heater settings, the type of water heater and any thermostatic controls used in the plumbing fixtures and mixing valves. For reporting, the median temperature is used.

Interior

Floors & Floor Materials

Floor Coverings: Carpet, Tile, Wood

Floor Settlement: None noted

General Condition: Installation practices appear standard, Overall appearance good, Refinishing wood flooring may be desired

The hardwood floors are scratched in some of the traffic areas. This appears to be just normal/typical wear. You may wish to hire a wood floor specialist to refinish the floors. The best time to refinish floors is when the home is vacant prior to moving your furniture in.

Walls, Ceilings, Trim & Closets

Wall & Ceiling Materials: Textured drywall

Appearance & Condition: Appearance good

Wall Insulation Air Bypass

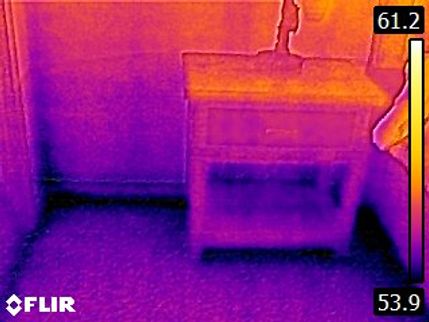

Wall Insulation: Not Visible, R-factor undetermined, Thermal imaging note

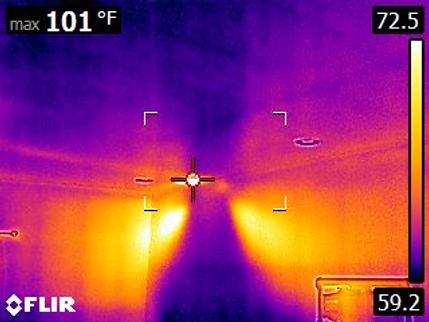

During the inspection today, I used an infrared camera inside the house scanning walls and ceilings. I use this tool for system verification, to make sure heat ducts and ovens and such are working. I also use it to look for "thermal anomalies" which could indicate concealed moisture problems or damaged or incomplete thermal or air barriers. No significant thermal anomalies were noted. These are representative photos:

Stairs & Railings

Condition / Observations: Good condition, Handrailing(s) installed

Interior Doors

We make every effort to visually inspect and operate every single interior door. All interior doors may be tested on smaller homes - where a representative sample of interior doors are tested on larger homes. Occasionally we find doors be locked or blocked by stored items or otherwise inaccessible.

Types: Standard interior rated doors, Wood

Condition: Appearance and function good

Adjustment/repair needed: The basement door to the unfinished storage room was hitting on the frame and wouldn't close properly.

Windows

Type: Double pane, Vinyl frame

Condition / Observations: Good overall, Representative sample

Several readily accessible windows were viewed and operated. I found these windows to be in good condition with regard to age.

Note: In accordance with industry standards, we may not test every window in the house, and particularly if the house is furnished. We do test every unobstructed window in every bedroom to ensure that at least one facilitates an emergency exit.

Other Observations

The unfinished storage room in the basement had a bed set up in it. This room does not have adequate egress. All bedrooms must have a second means of egress in case of emergency. This is typically provided through a window of legal fire egress size (Maximum of 44 inches off the floor and openings no smaller than 5.7 square feet).

Bathroom 1

Location & Type

Bathroom Location & Type: Second floor master bedroom, Full bathroom

Sinks, Faucet, Drains

Comments / Observations: Tested, Appearance and function good

Vanity Cabinets

Comments / Observations: Appearance and function good

Toilet

Comments / Observations: Tested, Appearance and function good, Toilet tight to floor

Bathtubs / Showers

Comments / Observations: Tested, Appearance and function good

Ventilation

Standard ceiling exhaust fan

Bathroom 2

Location & Type

Bathroom Location & Type: Main floor, Hallway, Full bathroom

Sinks, Faucet, Drains

Comments / Observations: Tested, Appearance and function good

Vanity Cabinets

Comments / Observations: Appearance and function good

Toilet

Comments / Observations: Tested, Appearance and function good, Toilet tight to floor

Bathtubs / Showers

Comments / Observations: Tested, Appearance and function good

Ventilation

Standard ceiling exhaust fan

Bathroom 3

Location & Type

Bathroom Location & Type: Basement, 3/4 bath

Sinks, Faucet, Drains

Comments / Observations: Tested, Appearance and function good

Vanity Cabinets

Comments / Observations: Appearance and function good

Toilet

Comments / Observations: Tested, Appearance and function good, Toilet tight to floor

Bathtubs / Showers

Comments / Observations: Tested, Appearance and function good

Ventilation

Standard ceiling exhaust fan

Kitchen

Sinks, Faucets & Drains

Condition / Observations: Tested, Appearance and function good

Disposers

Condition / Observations: Tested, Appearance and function good

Cabinets & Countertops

Countertop Material: Appeared to be granite tiles

Cabinet Material: Wood

Condition / Observations: Appearance and function good

Kitchen Floor

Type: Wood

Condition / Observations: Overall appearance good

Ventilation Method

Microwave fan, ducted to room

Appliance Disclaimer

Kitchen appliances were tested during inspection today. The typical design life of appliances can range from 4-20 years. Some appliances such as an older electric range are simple and tend to last longer than more complex appliances such as dishwashers and refrigerators or modern appliances with circuit boards. It is impossible to predict the useful remaining life of an appliance. I ran appliances during inspection. Any defects noted will be listed in this report. There are companies that offer warranties for appliances such as AHS Home Shield. While I do not endorse or recommend any specific warranty. I know that some home owners have been very happy with this insurance. For your convenience, I have attached a link to a web site of one such warranty product. LINK

Ranges, Ovens & Cooktops

Comments / Observations: Tested, Operated (see thermal images), Appearance and function good

Refrigerators

Condition / Observations: Tested, Operative (see thermal images), Appearance and function good

Dishwasher

Dishwasher: Appearance and function good, Operated (Thermal images)

Other Appliances

Built-in Microwave: Tested, Operated normally (thermal image), Appearance and function good

Laundry Facilities

Laundry - General Info

Washer Present? : Yes

Yes

Dryer Present?: Yes

Yes

Laundry Hookups Visible?: Yes

Yes

General Appearance: Laundry Appliances Appear Newer

Laundry Appliances Appear Newer

Washer

Comments / Observations: Laundry hookups appear standard, Not tested

Dryer & Exhaust Duct

Comments / Observations: Visually standard, Normal operation

Monitor dryer duct: Inspect and clean dryer duct regularly as needed

Homeowners should inspect their dryer and transition ducts regularly and have them cleaned as needed to remove lint and debris to prevent the potential for a dryer fire. Every year, dryer duct fires cause $35 million in damages, hundreds of injuries and even deaths. If you ever notice a burning stench in your laundry room, this is another indication you should get cleaning sooner rather than later. If you don't want to do it yourself - hire a duct cleaning professional to take care of dryer vent cleaning.

7 Signs You Need to Clean Your Dryer Vent:

- Clothes take longer than normal to dry

- Clothes are unusually hot to the touch

- The room is warmer than normal when the dryer is running

- You've noticed burning smells

- The lint flap isn't opening

- The dryer tells you there's a problem

- The dryer stops working

Crawl Space

Accessibility

Crawlspace Access - Location & Method:

During inspection of the crawl space, every effort is made to inspect the entire space. Visual inspection of crawlspaces can present challenges and limitations as access to some areas is often restricted by pipes, ducts and sub-floor insulation as well as limited clearances.

Basement

Accessibility & Type

Basement Access: Interior stairs, Patio door

Basement Type: Full, Finished

Foundation & Structure

Building Configuration: Basement

Foundation & Structure: Poured concrete walls, Poured concrete slab

% of Foundation Not Visible: 70%

Floor, Wall & Ceiling Framing

Wall Framing: Not visible

Wall Sheathing: Not visible

Floor Framing: Partly visible

Sub-Floor Material: Partly visible

Ceiling Framing: Partly visible

Basement Moisture Conditions

Comments / Observations: No water or signs of moisture observed at time of inspection

Visually inspected, utilized a moisture meter and thermal imaging camera along basement perimeter walls and carpet. I found no evidence of current or past moisture.

Wrap-Up Check List

Lights: Off

Off Left as found

Left as found

Thermostat: Returned to setting as found

Returned to setting as found

Doors & Windows: Closed

Closed Locked

Locked Left as found

Left as found

Dishwasher: Cycle Complete

Cycle Complete Finishing Cycle

Finishing Cycle

Agent/Owner: Agent still Present

Agent still Present Homeowner onsite

Homeowner onsite Inspector only

Inspector only

Receipt -- The Full Report

23456 Anywhere Place Somewhere, Idaho 83456

| Home Inspection | $625.00 |

| Detached Shop | $75.00 |

| $700.00 | |

| PAID |