The Scope and Purpose of a Sewer Line Inspection

Video pipeline inspections are performed using specific camera equipment designed to evaluate the condition of below-ground piping systems. These inspections are designed to evaluate the condition of subsurface pipes and identify any areas in need of maintenance or repair or any materials that are deficient or sub-standard. The scope of this report is only what is shown here and includes only the parts of the pipe that were accessible to camera inspection.

How to Read This Report

Getting the Information to You

The best way to get the information that is presented in this report is to read your report online (the HTML version), which will allow you to stream the pipeline video as well as read narrative comments and see any still photos that have been presented as part of this inspection.

For the most reliable viewing experience, I recommend viewing the report on as large a screen as practical, as much detail can be lost on small devices like smartphones. For similar reasons, reports should only be printed in color to retain as much detail as possible and minimize misinterpretation of photographs.

This report can also be printed on paper or to a PDF document.

Observation Labels

All narrative observations are colored, numbered and labeled to help you find, refer to, and understand the severity of the observation. Observation colors and labels used in this report are:

Inspection Information

All comments and observations made by the inspector should be considered and actions taken prior to the close of escrow. This includes any recommendation to employ a professional plumber to further evaluate any anomalous findings noted during this inspection. All recommendations for repair, replacement, remediation of limitations and any follow-up re-inspection should be considered and actions taken prior to the close of escrow. Your best interests are your inspector's primary concern however, your inspector is not a licensed plumber. A qualified professional plumber can provide options, insights and cost estimates that are unknown to your inspector. All costs associated with further inspection fees, and the repair or replacement of any component should be considered prior to the close of escrow. The inspection, and this inspection report, do not constitute a warranty or guarantee of any kind, expressed or implied.

Sewer Line Inspection Report

Access Point 1

Access Point: Clean Out

Clean Out

SIDE SEWER ACCESSED THROUGH CLEAN OUT

I accessed the sewer line through a 3 inch, PVC clean out. Location: Basement.

Access Point 2

Grey Water Access Point

Grey Water Discharge

The home features two discharge pipes exiting the rear foundation wall toward the back yard: the main waste line (black water- fed by the bathrooms and additional plumbing on the upper levels) as well as a separate grey water line. Grey water is a term used to refer to wastewater that does not contain urine or excrement. In homes that were originally constructed with septic systems, it was common practice to take the wastewater from the kitchen, the slop sink, and the washing machine and discharge it separately of the main waste line that would feed the septic system. Grey water plumbing was commonly discharged into a drywell: a pit that would allow for the liquid to seep into the earth.

The 2 inch (galvanized steel into cast iron) drain line for the washing machine and the slop sink in the basement was inspected with a fiber optic camera. The cast iron line travels approximately 38 feet across the backyard and discharges into what appears the be a concrete tank. The concrete structure is most likely a drywell/seepage pit or an old septic tank. The tank is over 6 feet in interior depth. The tank was located and flagged in the back yard. The tank appears to be approximately 3-4 feet below grade based on the camera's locating sonde.

The grey water plumbing should not be discharging separately of the main sewer line when a connection the public sewer system is present. The grey water tank found in the backyard will need to be excavated and inspected to determine if there are any other connections present in the tank. If the tank is determined to be strictly for the grey water discharge, then the tank will need to be properly abandoned and the grey water plumbing will need to be rerouted into the main waste line that discharges to the public sewer system. I recommend further evaluation by a qualified licensed sewer plumbing contractor and correction as required. This work should be completed prior to the close of escrow.

Side Sewer Type (Public/On-Site)

Side Sewer Type: Public Sewer System

Public Sewer System

PUBLIC SEWER SYSTEM

The main waste line serving this property is connected to a public sewer system. The connection to the public sewer was noted at approximately 158 feet from Access Point 1.

Scope Findings

PIPE MATERIAL(S): PIPE MATERIAL(S)

PIPE MATERIAL(S) Cast Iron

Cast Iron Plastic

Plastic Transite

Transite

PIPE MATERIAL(S)

I noted the presence of the following type(s) of pipe material(s): The materials are listed below in the order that I encountered them, moving from the point of access toward the main sewer line.

- PVC: Access Point 1.

- Cast Iron: Access Point 1 to 139 feet.

- Transite: 139 feet to Sewer Main Connection (158 feet).

APPROXIMATE DEPTH:

APPROXIMATE DEPTH TO MAIN TIE-IN

The side sewer's tie-in to the main is over 7 feet below grade. Please note: this depth is based on the camera's locating sonde, and may not be accurate depending on the material of the pipe the signal was transmitted through.

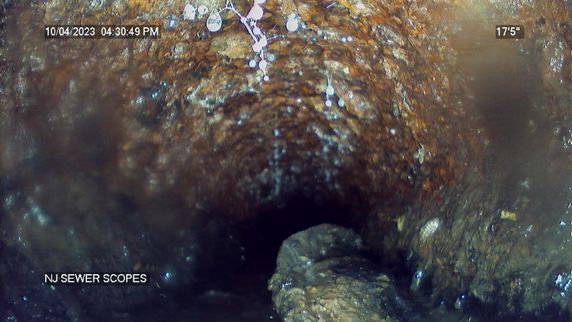

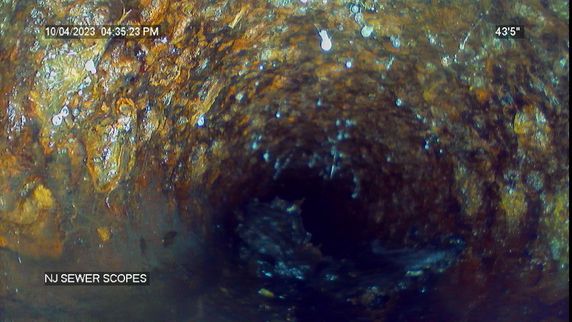

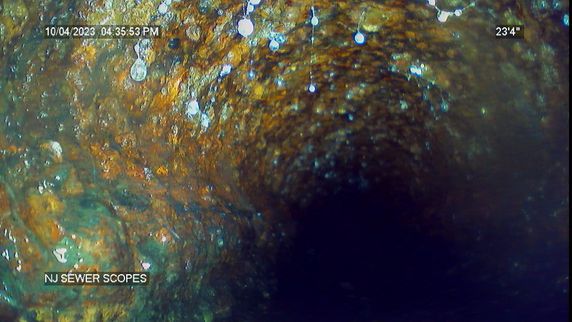

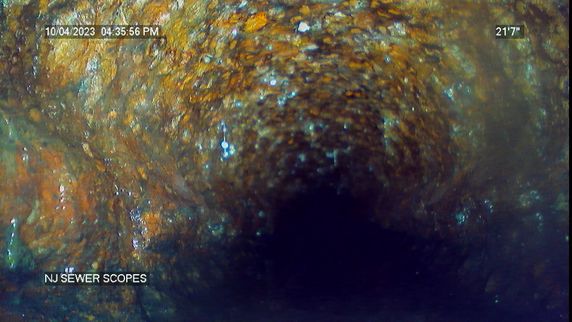

DEBRIS/BUILDUP: Moderate

Moderate

SCALING: Moderate

Moderate

MODERATE DEBRIS/BUILDUP

The debris/buildup seen during your sewer scope inspection is MODERATE and it is located at various points throughout the cast iron sewer pipe. Debris accumulation is considered moderate if it occludes the sewer pipe by 25 percent to 50 percent of the pipe diameter at any point. For pipes that have debris buildup with no structural defects, the pipes may be cleaned to remove the buildup. I recommend further evaluation by a qualified licensed sewer plumbing contractor and maintenance as required. This work should be completed prior to the close of escrow.

Debris can build up in a side sewer if there are structural defects or obstructions in the pipe (such as sags, roots or offset joints) that obstruct the flow of the sewer and if inappropriate items are flushed or poured down the drains. Or, if pipes are constructed at slopes less than the recommended ¼-inch drop per foot of pipe, the liquids won’t be moving fast enough to carry away the solids in the pipe. If debris build up is severe enough, it can eventually fill a pipe and cause backups or slow-draining side sewers.

Examples of items that do not degrade like toilet paper and should not be flushed down a drain (even though they may be advertised as flushable) include baby wipes, disinfectant wipes, paper towels, egg shells, coffee grounds, dental floss, toilet bowl scrub pads, feminine hygiene products and grease. Even very hot grease cools quickly once it reaches an underground pipe and sticks to the walls of the side sewer. Over time, grease can cause a side sewer to either drain very slowly or cause a complete blockage of the side sewer. Grease is one of the more common causes of backups and slow-draining side sewers.

MODERATE SCALING

The scaling seen during your sewer scope inspection is MODERATE and is located at various points throughout the cast iron sewer pipe. Scaling is considered moderate if 25 to 50 percent of the pipe diameter is obstructed at any point. Moderate scale may have an impact on the function of the side sewer. Scaling in a cast iron pipe causes buildup inside the pipe that may eventually lead to a slow draining side sewer or blockages. Descaling of the pipe by a professional licensed plumber is strongly recommended to ensure the best functionality in your side sewer. I recommend further evaluation by a qualified licensed sewer plumbing contractor and maintenance as required.

Scaling is a common issue within side sewers, especially older cast iron side sewers. Scaling occurs when hard deposits begin to form on the inside walls of a pipe. These hard deposits are the by-product of chemical reactions within metallic pipes. The resulting buildup that occurs over time reduces the diameter of the pipe. Eventually this buildup can disrupt the flow of solid and liquid waste through the pipe. Cast iron pipes tend to have more severe scaling because their interior surfaces become coated with iron oxide. When scaling is severe enough, debris can end up getting caught in the pipe which can potentially lead to blockages.

Video(s)

VIDEO: Video

SEWER SCOPE VIDEO LINK

Here are the videos recorded during your sewer scope inspection. Please contact me if you have any questions or need assistance viewing the videos.

NJ Sewer Scopes, LLC

201-546-2873

NJSewerScopes@gmail.com

Receipt --

10 Elm Street Park Ridge, NJ 07656

| Sewer Line Inspection | $300.00 |

| 300.00 | |

| PAID |

NJ Sewer Scopes, LLC

C/O Joe Ragusa

3 Roetman Court

Midland Park, New Jersey 07432

201-546-2873