The Scope and Purpose of a Home Inspection

Purchasing property involves risk

The purpose of a home inspection is to help reduce the risk associated with the purchase of a structure by providing a professional opinion about the overall condition of the structure. A home inspection is a limited visual inspection, and it cannot eliminate this risk. Some homes present more risks than others. We cannot control this, but we try to help educate you about what we don’t know during the inspection process. This is more difficult to convey in a report and one of many reasons why we recommend you attend the inspection.

A home inspection is not an insurance policy.

This report does not substitute for or serve as a warranty or guarantee. Home warranties can be purchased separately from insuring firms that provide this service.

A home inspection is visual and not destructive.

The descriptions and observations in this report are based on a visual inspection of the structure. We inspect the aspects of the structure that can be viewed without dismantling, damaging, or disfiguring the structure and without moving furniture and interior furnishings. Areas that are concealed, hidden, or inaccessible to view are not covered by this inspection. Some systems cannot be tested during this inspection as testing risks damaging the building. For example, overflow drains on bathtubs are generally not tested because if they were found to be leaking, they could damage the finishes below. Our procedures involve non-invasive investigation and non-destructive testing, which will limit the scope of the inspection.

This is not an inspection for code compliance.

This inspection and report are not intended for city / local code compliance. During the construction, process structures are inspected for code compliance by municipal inspectors. Framing is open at this time, and conditions can be fully viewed. Framing is not open during inspections of finished homes, limiting the inspection. All houses fall out of code compliance shortly after they are built, as the codes continually change. National codes are augmented at least every three years for all disciplines. Municipalities can adopt and phase in sections of the codes on their timetables. There are generally no requirements to bring older homes into compliance unless substantial renovation is being done.

This is just our opinion.

Construction techniques and standards vary. There is no one way to build a house or install a system in a house. The observations in this report are the opinions of the home inspector. Other inspectors and contractors are likely to have some differing opinions. You are welcome to seek opinions from other professionals.

The scope of this inspection

This inspection will include the following systems: exterior, roof, structure, drainage, foundation, attic, interior, plumbing, electrical, and heating. The evaluation will be based on limited observations that are primarily visual and non-invasive. This inspection and report are not intended to be technically exhaustive.

Your expectations

The overall goal of a home inspection is to help ensure that your expectations are appropriate for the house you are proposing to buy. To this end, we assist with the discovery by showing and documenting observations during the home inspection. This should not be mistaken for a technically exhaustive inspection designed to uncover every defect in a building. Such inspections are available, but they are generally cost-prohibitive to most homebuyers.

Your participation is requested.

Your presence is requested during this inspection. A written report will not substitute for all the possible information that can be conveyed verbally by a shared visual observation of the conditions of the property.

How to Read This Report

Getting the Information to You

This report is designed to deliver important and technical information in a way that is easy for anyone to access and understand. If you are in a hurry, you can take a quick look at our "Summary Page” and quickly get the critical information for important decision-making. However, we strongly recommend that you take the time to read the full Report, which includes digital photographs, captions, diagrams, descriptions, videos, and hot links to additional information.

The best way to get the layers of information presented in this report is to read your report online, which will allow you to expand your learning about your house. You will notice some words or series of words highlighted in blue and underlined – clicking on these will provide you with additional information.

This report can also be printed to a PDF file and printed on paper as desired.

Chapters and Sections

This report is divided into chapters that parcel the home into logical inspection components. Each chapter is broken into sections that relate to a specific system or component of the home. You can navigate between chapters with the click of a button on the left-side margin.

Most sections will contain some descriptive information in black font. Observation narrative, done in colored boxes, will be included if a system or component is found to be significantly deficient in some way or if we wish to provide helpful additional information about the system or the scope of our inspection. If a system or component of the home was deemed to be in satisfactory or serviceable condition, there might be no narrative observation comments in that section, and it may simply say “tested” or “inspected.”

Observation Labels

All narrative observations are colored, numbered, and labeled to help you find, refer to, and understand the severity of the observation. Observation colors and labels used in this report are:

- Major Concern:Repair items that may cost significant money to correct now or in the near future, or items that require immediate attention to prevent additional damage or eliminate safety hazards.

- Repair:Repair and maintenance items noted during inspection. Please note that some repair items can be expensive to correct such as re-finishing hardwood floors, but are considered simply repair items due to their cosmetic nature.

- Recommended Maintenance:These are repair items that should be considered "routine home ownership items," such as servicing the furnace, cleaning the gutters or changing the air filters in the furnace.

- Recommended Disclosure Items:These are observations for which we recommend that sellers disclose more information to buyers so that buyers can better understand recent servicing, repairs or maintenance or even construction history or building and site design.

- Monitor:Items that should be watched to see if correction may be needed in the future.

- Improve or Upgrade:Observations that are not necessarily defects, but which could be improved for safety, efficiency, or reliability reasons. These are often items which reflect changes in building codes or standards.

- Efficiency:Denotes observations that are needed to make the home more energy efficient as well as to bring the home up to modern insulation standards. This category typically includes windows and insulation. Other items, such as lighting and appliances, are not inspected for their energy status.

- Inspection Notes:Aside information and /or comments elaborating on descriptions of systems in the home that the inspector might find useful to purchase decisions or home ownership. .

- Limitations:Conditions present at the time of inspection which limited the scope of this visual inspection

Summary Page

The Summary Page is designed as a bulleted overview of all the observations noted during the inspection. This helpful overview is not a substitute for reading the entire inspection report. The entire report must be read to get a complete understanding of this inspection report, as the Summary Page does not include photographs or photo captions.

Moisture Meter Testing

Where moisture meter testing is indicated in this report, a Protimiter Survey Master Dual Function was used.

Summary

Major Concerns

No major concerns were noted during this visual inspection.Repairs

- E-3 Exterior:

LOST SEAL IN DOOR GLASS

A failed insulated glass unit (IGU) was noted in one of the exterior doors - exterior basement door. This is when the glass has a cloudy appearance from condensation between the panes of glass. This cannot be cleaned, so the IGU needs to be replaced. This is a cosmetic defect that does not significantly impact the performance of the glass just the appearance. Hire a glass replacement company to further evaluate this glass and replace as needed.

- DPB-1 Decks, Porches and Balconies:

TUNE-UP DECK REPAIRS / MAINTENANCE NEEDED

Tune-up repairs are needed to the decks. This building has two decks on the back side of the building. The decks seems to have had some updates since the original build. Examples of specific observations noted during the inspection include:

Repairs

- The posts for the small deck are in soil contact and vulnerable to wood decay. Updating these posts will eventually be needed. The south post had some minor decay that I could access.

Improvements

- The 4x4 deck railing posts are notched - this weakens the railing system and is not recommended. This is common in older deck guard systems.

- The graspable handrail for the deck stairs is not the correct profile - an improved graspable handrail is recommended for the back deck stairs.

Notes

- The large deck has a better footing system than the small deck.

- Several decking boards seem to be recently updated

Recommendation

Hire a qualified contractor to further evaluate and implement repairs and improvements as recommended to ensure safe and reliable performance and to prolong the useful life of the decking systems here.

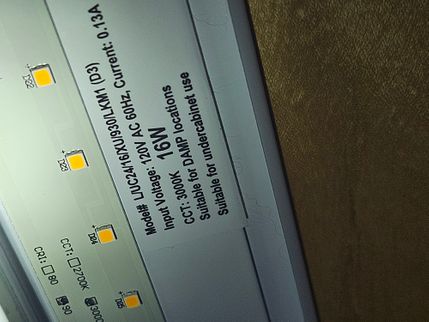

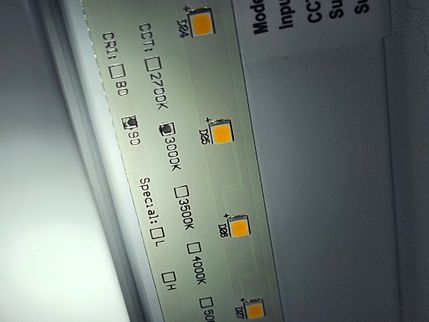

- EDF-1 Electric Distribution and Finish:

REPAIR UNDERCABINET LIGHTS

One of the under cabinet lights is out. Repair / replace the inoperative light as needed.

- EDF-2 Electric Distribution and Finish:

REPLACE MISSING RECEPTACLE COVER

Replace the missing electric receptacle cover on the exterior.

- EDF-3 Electric Distribution and Finish:

REPAIR THE LAUNDRY ROOM LIGHT

The laundry room light is out. This may be the ballast of a fluorescent light. Repair as needed.

- EDF-4 Electric Distribution and Finish:

NO CARBON MONOXIDE ALARMS FOUND

The installation of carbon monoxide alarms is recommended for all homes that have fuel-burning appliances such as gas or oil furnaces, gas water heaters, gas ovens and cook-tops, gas fireplaces, and wood stoves. Carbon monoxide is a colorless, odorless gas that can cause sickness, nausea, and even death. For more information, consult the Consumer Product Safety Commission at 1-800-638-2772 (C.P.S.C.) Modern standards in many states now recommend one CO alarm outside of all bedrooms and at least 1 per floor of the house.

- MB-2 Main Bathroom:

BROKEN FAUCET HANDLE - MAIN BATH

The porcelain faucet handle is broken and requires replacement.

- MB-3 Main Bathroom:

LEAKING SHOWER HEAD - MAIN BATH SHOWER

The shower head in the main bath tub is leaking and requires repair. Leaky shower heads are common and not a significant concern. Adjust as needed to prevent leakage at the shower head.

- A-2 Attic:

INACCESSIBLE ATTIC AREA

Part of the attic was not accessible - see the 2nd floor. Additional attic accesses are recommended so that all of the attic spaces can be accessed and inspected. Install additional access hatches as needed and re-inspect the inaccessible areas of the attic. Standards recommend an access opening of 30 inches x 22 inches when there is greater than 30 sq/ft of attic space.

✒️ - I looked several times in the closets and could not find an access for the 2nd floor.

Recommended Maintenance

- G1-1 Grounds:

TREE AND VEGETATION PRUNING

Pruning trees, branches and vegetation away from the building is recommended. Where trees, branches and large shrubs can provide rodent access to the roof, a minimum 6-foot clearance is recommended as many rodents can jump 6-feet. All vegetation, including smaller landscaping such as grasses, flowers and shrubs should be kept 1-foot off the house to eliminate contact which could trap moisture against the building.

- E-1 Exterior:

JOINT FLASHING DETAILS

The end joints between pieces of siding are missing joint flashings. These are recommended behind the end joints in the siding for a weather-proof detail. In the absence of these flashings, keep end joints sealed with caulking. Caulking is an approved method for sealing these joints, but is higher maintenance, less reliable and more unsightly. Attached are some photos and diagrams showing how butt joint flashings can be retrofit.

- E-2 Exterior:

LOCALIZED PAINT TOUCH UP NEEDED

The exterior of the building seems to have been recently panted. A few touch up areas are needed:

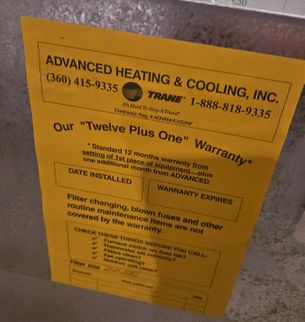

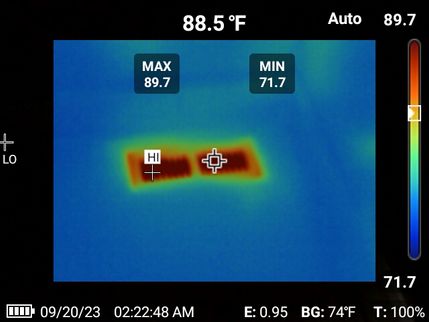

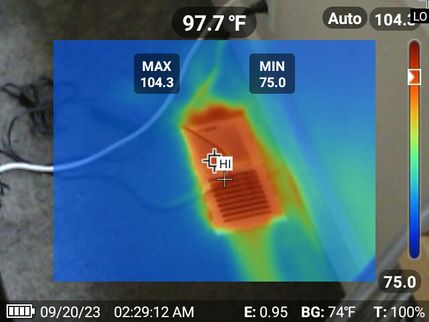

- HCFV-2 Heating, Cooling, Fireplaces and Ventilation:

DUCTED HEAT PUMP SERVICING RECOMMENDED

Heating and cooling contractors recommend annual servicing of heat pump systems to maximize the useful life and efficiency of heating and cooling equipment. No recent service records were noted on this system. I recommend having this system serviced and further evaluated by a qualified heating contractor if it has not been done in the last year. The system was tested in heating mode during the inspection and responded well to normal operating controls. Examples of testing procedures and observations noted during the inspection include:

- The compressor was operative at the time of inspection

- Repair the damaged insulation on the heat pump refrigerant lines.

- The air handler was nice and clean at the time of the inspection

- HCFV-5 Heating, Cooling, Fireplaces and Ventilation:

SCREEN RECOMMENDED FOR FIREPLACES

For improved child safety, consider installing a metal screen in front of the gas log fireplace glass. These screens are required on newer gas logs. The glass panels on gas fireplaces and even materials around the fireplace can become very hot and pose a burn hazard. Use caution when using these fireplaces when small children are present.

- HCFV-6 Heating, Cooling, Fireplaces and Ventilation:

GAS LOG FIREPLACES ARE SHUT DOWN

The gas log fireplace has been shut down and was not responding to normal operating controls. I recommend making this unit operational prior to listing the house.

✒️

- The fireplaces may have just been shut down for the summer time.

- RPWDO-2 Rodents, Pests and Wood Destroying Organisms:

REMOVE CELLULOSE DEBRIS FROM THE CRAWL SPACE

Wood and cellulose debris was noted in the crawl space. This can encourage wood-destroying organisms such as subterranean termites. Removal of all cellulose debris from the crawl space is recommended to eliminate conditions conducive to wood-destroying organisms. This should include the removal of all wood storage.

Recommended Disclosure Items

- RCG-1 Roof, Chimney and Gutters:

NEW ROOF NOTED

The roofing material on this building is a recently installed architectural grade shingle. These are often rated as 30-40 year shingles. In practice, as a roof assembly, I find these last closer to 18-23 years, depending on the quality of the installation, the steepness of the roof, and the amount of exposure. The installation appears neat and professional. Many professional roofing companies will offer limited workmanship warranties. Please note that roofs are not a shingle, they are an assembly, and they require regular cleaning and maintenance to keep them performing reliably. Examples of observations noted during the inspection include:

- No drip edge flashings have been installed at roof terminations. These are now required. I would install during the next re-roof.

- Quality externally baffled ridge vents noted

- Nice straight rows, no buckling noted

- Metal valleys noted

Recommendation

Disclose any warranty and/or installer information for this new roof installation.

- P-1 Plumbing:

SEWER SCOPE RECOMMNEDED

An evaluation of the sewer line below the ground is beyond the scope of this inspection. Due to the age and location of the building, a sewer scope is recommended to further evaluate the sewer line and the below ground connections between the house and the municipal sewer line. Sewer scopes are done using video cameras and can reveal the materials, condition and reliability of the sewer line. If that has been done recently, I recommend disclosing available information. If this has not been done recently, this would be valuable information to disclose to a buyer.

- AP-1 Additional Plumbing:

ABANDONED IRRIGATION SYSTEM

This site has an old irrigation system that appears to be disabled. Disclose any additional information about this system. I am guessing that this piping can just be removed as this system no longer looks functional.

Items for Monitoring

- SB-1 Structure and Basement:

A FEW WATER STAINS ON THE BASEMENT FOUNDATION WALLS

The basement was dry at the time of inspection. A few signs of seepage were noted on the basement walls. This is unfinished space so it likely does not matter much if some seasonal seepage occurs.

- One water stain was noted below the main water pipe inlet. Ideally the pipe here is sleeved and the hole sealed for moisture control.

- A small crack was noted on the north side. This may require some seal up. Monitor during wet weather.

Recommendation

Monitor during wet weather and seal up as needed.

- RPWDO-1 Rodents, Pests and Wood Destroying Organisms:

SIGNS OF RODENTS

Evidence of rodent entry into the attic was discovered. It appeared to be old, but this is difficult to verify during a one-time inspection. I recommend disclosing any history of rodent problems and/or treatment.

Recommendation

A trapping and baiting program should be implemented to determine if these conditions are old. In general, rodent control should be considered an ongoing part of home ownership in this region. If rodents are trapped, additional exclusion and prevention work is needed. Basic rodent proofing recommendations include:

- Prune trees off the house and keep vegetative cover away from the building to reduce nearby habitat

- Seal all openings to the exterior - use copper wool for small holes.

- Implement a trapping plan to target entry points and rodent-proof as needed.

- Regular baiting can help, but this does distribute poison into the nearby food chain.

Examples of observations noted during the inspection include:

- Rodent feces noted in the attic - these look older

- Rodent bait stations noted around the exterior

Improve Or Upgrade Items

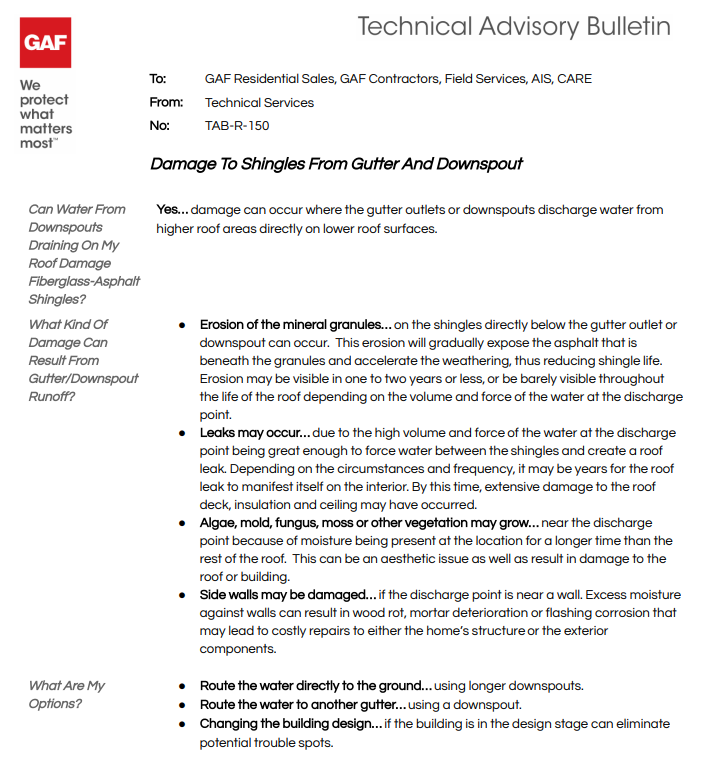

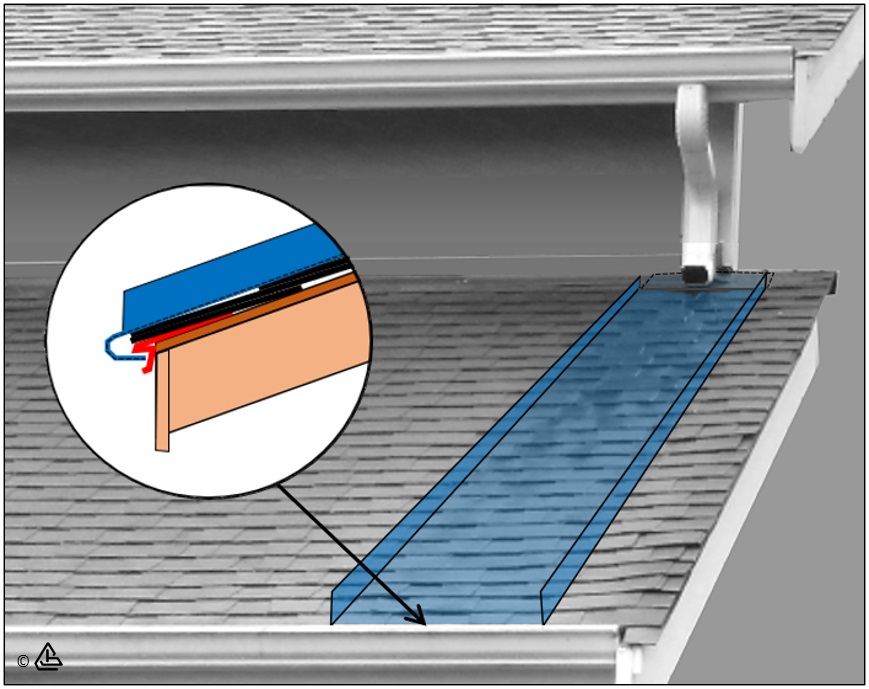

- RCG-2 Roof, Chimney and Gutters:

UPPER DOWNSPOUTS DRAIN ONTO LOWER ROOF

Several of the downspouts on the upper gutter system are terminating onto the lower roof. This is industry standard practice but it will prematurely deteriorate the roofing shingles in these locations and it is not recommended by many shingle manufacturers. I recommend extending the downspouts into lower gutters to better protect the roof.

- ES-2 Electric Service:

NO SURGE PROTECTION FOUND

No surge protection was noted at the electrical equipment today. The 2020 edition of the National Electric Code requires type I or type 2 surge protection on new or renovated homes. Though not adopted yet this code change reflects the growing complexity of electric appliances in our houses and the growing risk of damage to electrical equipment due to internal or external electrical surges. This short video explains more about electrical surges and surge protection. I recommend upgrading and adding surge protection for improved protection of the electrical appliances in this building. I would do this in the context of other electrical repairs or upgrades.

- ES-3 Electric Service:

IMPROVED CONDUCTOR IDENTIFICATION RECOMMENDED

The white conductors inside the electric panel at the breakers are not correctly identified as hot or ungrounded conductors - these should be painted in black or red ink for correct identification and improved safety. I would do this in the context of other electrical repairs or upgrades.

- EDF-5 Electric Distribution and Finish:

OLDER SMOKE ALARMS NOTED

There appear to be some old smoke alarms. Fire marshals recommended updating smoke alarms every 10 years to ensure reliable performance. Systematic updating of smoke and CO alarms is recommended.

- LF-2 Laundry Facilities:

MOISTURE ALARM RECOMMENDED

A moisture alarm with water shut-off features is recommended under the washing machine to protect against accidental leaks in the supply hoses. Pans can be effective when there is a drain, but even these will not protect against a burst supply connector. A moisture alarm with automatic shut-off will. Watts is a brand I have seen installed: Link.

Efficiency Items

- CS-3 Crawl Space:

SAGGING SUBFLOOR INSULATION NOTED

The under-floor insulation in the crawl space is sagging and not touching the sub-floor, as such, it is not performing as intended. Use inset string to support the sub-floor insulation up against the sub-floor. The insulation must be in substantial contact with the surface it is insulating to perform as intended.

📸 The Complete Report

Grounds

Drainage and Site

Window and Stairwells

Driveways/Walkways/Flatwork

Grounds, Trees and Vegetation

Exterior Stairs

Retaining Walls

Fences

Outbuildings, Trellises, Storage Sheds, Barns

Decks, Porches and Balconies

Wood Decks Porches and Balconies

Concrete Decks, Stoops, Landings and Porches

Water-Resistant Decks and Balconies

Electric Service

Electric Service Voltage Tested

Electric Service

Electric Service Equipment

Generator Equipment

Appliance Disconnects

Electrical Grounding System

Electrical Bonding System

Electric Distribution and Finish

Branch Wiring

Receptacles and Fixtures

Smoke and Carbon Monoxide Alarm Systems

Heating, Cooling, Fireplaces and Ventilation

Heating Systems

Air Filters

Cooling Systems and Heat Pumps

Heating and Cooling Distribution Systems

Mechanical Ventilation Systems

Gas Fireplaces

Solid Fuel Fireplaces

Plumbing

Water Service Supply

Distribution Pipe

Waste Pipe and Discharge

Exterior Hose Bibs

Additional Sinks

Sump Pumps and Drains

Sewage Ejector Pumps

Interior

Floors and Floor Materials

Walls, Ceilings, Trim, Hallways and Closets

Wall Insulation and Air Bypass

Stairs and Railings

Interior Doors

Windows

Kitchen

General Kitchen Photos

Sinks and Faucets

Cabinets and Countertops

Disposers

Dishwasher

Ventilation Method

Ranges, Ovens and Cooktops

Refrigerators

General Kitchen Condition

Powder Bathroom

General Bathroom Photos

Sinks and Cabinets

Toilet

Bathtub / Shower

Bathroom Ventilation

General Bath

Main Bathroom

General Bathroom Photos

Sinks and Cabinets

Toilet

Bathtub / Shower

Bathroom Ventilation

General Bath

Guest Bathroom

General Bathroom Photos

Sinks and Cabinets

Toilet

Bathtub / Shower

Bathroom Ventilation

General Bath

Attic

Attic Access

Roof Framing and Sheathing

Fire Separation and Fire Blocking

Attic Insulation

Attic and Roof Cavity Ventilation

General Comments

Building Characteristics, Conditions and Limitations

Type of Building : Single Family (2-story)

Approximate Square Footage: 2627

Approximate Year of Original Construction: 2001

Attending the Inspection: Owner

Occupancy: Occupied

Animals Present: No

Weather during the inspection: Cloudy, Light Rain

Approximate temperature during the inspection: Below 65[F]

Ground/Soil surface conditions: Dry

For the Purposes of This Report, the Front Door Faces: South

This home was occupied at the time of the inspection. Inspection of occupied homes presents some challenges as occupant belongings can obstruct visual inspection of and access to parts of the building. We do our best during inspection to work around belongings to discover as much as possible about the house without moving or damaging personal property, however, the presence of personal items does limit the inspection.

Grounds

Drainage and Site

Clearance to Grade: Standard

Downspout Discharge: Below grade

Site Description: Moderate slope

Window and Stairwells

None Noted

Driveways/Walkways/Flatwork

Driveway: Concrete, Pavers

Walkways: Concrete

Patios: Concrete

Grounds, Trees and Vegetation

Trees/Vegetation too near building: Yes - Prune Vegetation off House

TREE AND VEGETATION PRUNING

Pruning trees, branches and vegetation away from the building is recommended. Where trees, branches and large shrubs can provide rodent access to the roof, a minimum 6-foot clearance is recommended as many rodents can jump 6-feet. All vegetation, including smaller landscaping such as grasses, flowers and shrubs should be kept 1-foot off the house to eliminate contact which could trap moisture against the building.

Exterior Stairs

Exterior Stairs: Standard

Retaining Walls

Retaining Wall Material: None Noted

Fences

Exterior Fencing: None noted

Outbuildings, Trellises, Storage Sheds, Barns

None noted

Exterior

Siding and Trim

Trim Material: Wood

Siding Material: Cedar shingles, Fiber-cement

Manufacturers of fiber cement siding have done a poor job helping inspectors and consumers distinguish their products after installation; these products have few if any distinguishing characteristics. This report will site James Hardie manufacturers installation requirements for reference because they are the most common manufacturer of fiber cement siding and the various manufactures seem to share similar installation guidelines. Here is a link to the HZ-10 Best Practices Guide. However, reference of these guidelines in this report does not ensure that the fiber cement siding here is a James Hardie product.

JOINT FLASHING DETAILS

The end joints between pieces of siding are missing joint flashings. These are recommended behind the end joints in the siding for a weather-proof detail. In the absence of these flashings, keep end joints sealed with caulking. Caulking is an approved method for sealing these joints, but is higher maintenance, less reliable and more unsightly. Attached are some photos and diagrams showing how butt joint flashings can be retrofit.

LOCALIZED PAINT TOUCH UP NEEDED

The exterior of the building seems to have been recently panted. A few touch up areas are needed:

Eaves

Open rafters

Exterior Doors

Exterior Door Styles: Glass panel doors, Solid core

LOST SEAL IN DOOR GLASS

A failed insulated glass unit (IGU) was noted in one of the exterior doors - exterior basement door. This is when the glass has a cloudy appearance from condensation between the panes of glass. This cannot be cleaned, so the IGU needs to be replaced. This is a cosmetic defect that does not significantly impact the performance of the glass just the appearance. Hire a glass replacement company to further evaluate this glass and replace as needed.

Exterior Window Frames

Window Frames: Vinyl

Decks, Porches and Balconies

Wood Decks Porches and Balconies

Present

To see a prescriptive guide for residential wood deck construction click this link:

Structure: Ground contact treated lumber

Ledger Board: Standard

Guardrail: Standard

Decking Material: Softwood

This house has cedar softwood decking installed. The recommended maintenance of this type of decking is annual cleaning and staining with transparent or semi-transparent deck stain. It is common to use decking paints when the decking is older and in the last phase of its useful life, however, painting is not recommended as this can trap moisture in the wood, facilitate wood decay and lead to higher maintenance costs when prepping peeling paint. Annual cleaning and sealing is important to prevent the deck from becoming slippery and unsafe, especially as pollen organic growth accumulate on the decking.

Posts, Beams and Footings: Inspected

TUNE-UP DECK REPAIRS / MAINTENANCE NEEDED

Tune-up repairs are needed to the decks. This building has two decks on the back side of the building. The decks seems to have had some updates since the original build. Examples of specific observations noted during the inspection include:

Repairs

- The posts for the small deck are in soil contact and vulnerable to wood decay. Updating these posts will eventually be needed. The south post had some minor decay that I could access.

Improvements

- The 4x4 deck railing posts are notched - this weakens the railing system and is not recommended. This is common in older deck guard systems.

- The graspable handrail for the deck stairs is not the correct profile - an improved graspable handrail is recommended for the back deck stairs.

Notes

- The large deck has a better footing system than the small deck.

- Several decking boards seem to be recently updated

Recommendation

Hire a qualified contractor to further evaluate and implement repairs and improvements as recommended to ensure safe and reliable performance and to prolong the useful life of the decking systems here.

Concrete Decks, Stoops, Landings and Porches

Concrete Structure: Concrete entry

Water-Resistant Decks and Balconies

Water Proof Surfaces: None Noted

Garage

Garage General

Garage Type: Attached

Garage Doors and Automatic Openers

Overhead Garage Door Type: Metal

Automatic Garage Opener: Present

Garage Occupant Door: Solid Wood

Garage Floor

Garage Slab: Concrete

Garage Stairs

Garage Stairs: Standard

Vehicle Chargers

None noted

Roof, Chimney and Gutters

Roof Materials

Method of Roof Inspection: Walked on roof

Roof Style: Gable

Flashings, Valleys and Penetrations: Present and Visually Standard

Roof flashings are used to keep a roofing system waterproof where the roofing material starts, stops, changes direction, or is penetrated. During the inspection, we look for standard flashing techniques that could be considered normal or standard in our region. Damaged, incomplete or non-standard flashings can be a sign of an older or less reliable roofing system and may require repair. Any non-standard flashings noted during the inspection will be reported below if found.

Roof Covering Materials: Architectural grade composition shingle

Approximate Age of Roof Covering: New

Overlay Roof: No

Shingle Fastening Accessible For Inspection : Yes - New Installation - Fastening Looked Standard

This building has a very new composition roof installed. The shingles are not bonded together yet, so I was able to check the fastening pattern. Fastening looked correct where I spot-checked. Proper fastening of roofing shingles is critical to ensure reliable long-term performance. Fasteners should be specifically located in the correct area of the shingle and not high or low-nailed. Fasteners should also be driven straight and flush with the shingle. Over time, the shingles should start to bond and fastening will no longer be visible without prying the shingles apart, which we avoid doing during visual home inspections.

NEW ROOF NOTED

The roofing material on this building is a recently installed architectural grade shingle. These are often rated as 30-40 year shingles. In practice, as a roof assembly, I find these last closer to 18-23 years, depending on the quality of the installation, the steepness of the roof, and the amount of exposure. The installation appears neat and professional. Many professional roofing companies will offer limited workmanship warranties. Please note that roofs are not a shingle, they are an assembly, and they require regular cleaning and maintenance to keep them performing reliably. Examples of observations noted during the inspection include:

- No drip edge flashings have been installed at roof terminations. These are now required. I would install during the next re-roof.

- Quality externally baffled ridge vents noted

- Nice straight rows, no buckling noted

- Metal valleys noted

Recommendation

Disclose any warranty and/or installer information for this new roof installation.

Chimneys

Present

Chimney Material: Metal below siding

Chimney Flue Liners: Present

Skylights

None noted

Gutters and Downspouts

Gutter and Downspout Materials: Seamless Aluminum

UPPER DOWNSPOUTS DRAIN ONTO LOWER ROOF

Several of the downspouts on the upper gutter system are terminating onto the lower roof. This is industry standard practice but it will prematurely deteriorate the roofing shingles in these locations and it is not recommended by many shingle manufacturers. I recommend extending the downspouts into lower gutters to better protect the roof.

Fuel Storage and Distribution

Oil Storage

None noted

Propane Storage

Present, Leased Tank Sticker Noted

Storage Type: Above ground tank

Propane Tank Size: 120 gallons

Propane Tank Location: West side of building

Gas Meter

None noted

Gas, Propane and Oil Piping

Gas Piping Materials Noted: Steel, Copper

Electric Service

Electric Service Voltage Tested

Electric Service

Service Entrance: Below Ground

Meter Base Amperage: 200

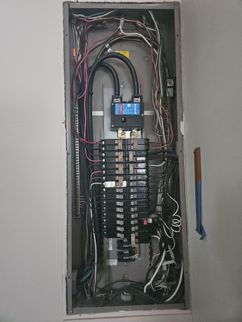

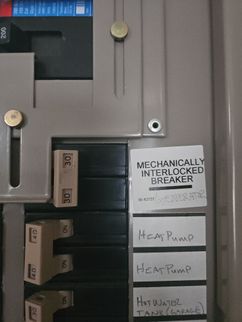

Electric Service Equipment

Service Entrance (SE) conductor Size: Aluminum, 4/0, 200 amps

Main Panel Amperage: 200 amps

Electric Service Amperage: 200 amps

Main Electric Panel Location: Garage

Panel Manufacturer: Cutler Hammer

NO SURGE PROTECTION FOUND

No surge protection was noted at the electrical equipment today. The 2020 edition of the National Electric Code requires type I or type 2 surge protection on new or renovated homes. Though not adopted yet this code change reflects the growing complexity of electric appliances in our houses and the growing risk of damage to electrical equipment due to internal or external electrical surges. This short video explains more about electrical surges and surge protection. I recommend upgrading and adding surge protection for improved protection of the electrical appliances in this building. I would do this in the context of other electrical repairs or upgrades.

IMPROVED CONDUCTOR IDENTIFICATION RECOMMENDED

The white conductors inside the electric panel at the breakers are not correctly identified as hot or ungrounded conductors - these should be painted in black or red ink for correct identification and improved safety. I would do this in the context of other electrical repairs or upgrades.

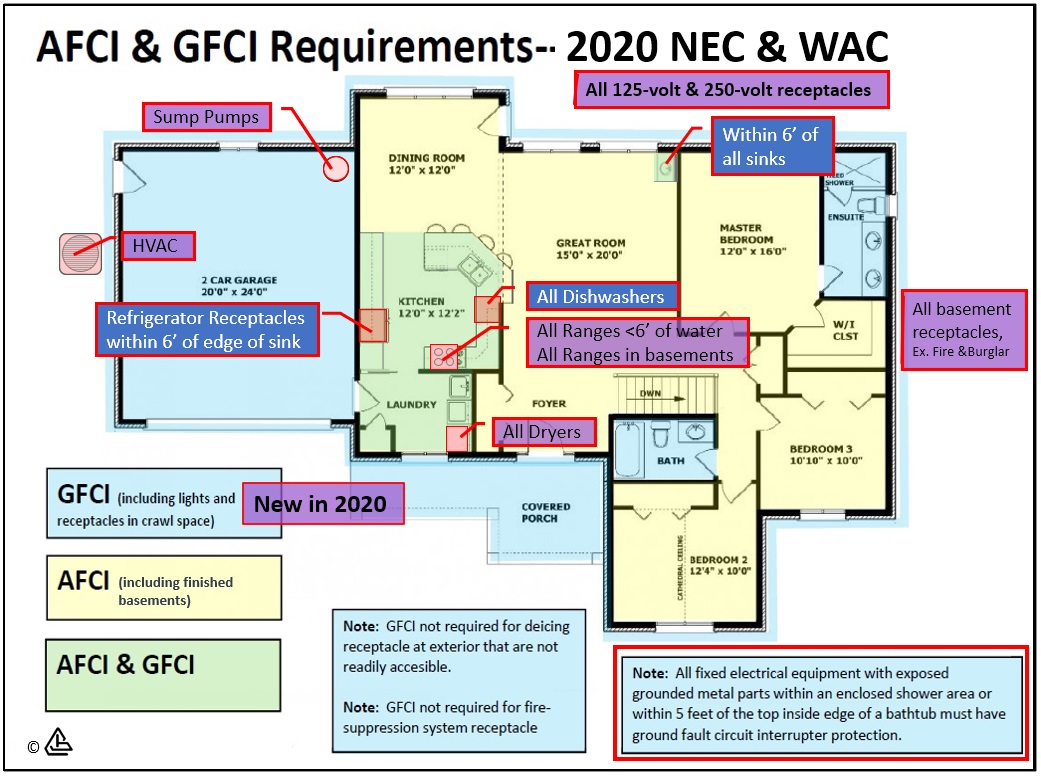

MODERN AFCI PROTECTION IS A SAFETY IMPROVEMENT

AFCI (arc fault protection) is now required on all branch circuits supplying outlets or devices installed in residential dwelling unit kitchens, family rooms, dining rooms, living rooms, parlors, libraries, dens, bedrooms, sunrooms, recreation rooms, closets, hallways, laundry areas, and similar rooms and areas. The goal of this protection is to reduce risks of electrical fires. Consult with a licensed electrician about improving circuit protection as desired. I would consider this improvement in the context of other electrical repairs or upgrades. Please note that if you add or replace receptacle outlets to the existing system, they should comply with modern AFCI standards.

Generator Equipment

Portable generator

MANUAL TRANSFER SWITCH FOR A GENERATOR

This building has a transfer switch for a generator for backup electric power supply - see the manual transfer switch on the exterior of the building to back-feed the panel. Generator systems are beyond the scope of this inspection. I recommend disclosing more information regarding the operation and maintenance of this system. Generators need to be run and serviced regularly to ensure reliable operation.

✒️

- Is there a generator included in the sale?

Appliance Disconnects

Disconnects Noted: Heat Pump

Electrical Grounding System

Present - Could Not Confirm

During a home or property inspection, every effort is made to inspect the visible components of the electrical system grounding. The grounding system is critical for safely discharging electrical surges, especially in the case of lightning strikes. There is no way in the context of a home inspection to verify the "effectiveness" of the grounding system as much of the system is not visible, and there are no practical tests one can perform in the way we can test a furnace or a plumbing fixture. However, many things can lead me to recommend further evaluation of the grounding system by a licensed electrical contractor, and they will be documented in the observations below if discovered.

Electrical Bonding System

Present - Could Not Confirm

During the inspection, I attempt to visually document electrical system bonding. There is no way in the context of a home inspection to verify the "effectiveness" of system bonding. All metallic systems in the building are required to be "bonded" (connected) to the the building's electrical grounding system. Bonding creates a pathway to shunt static charges (that would otherwise build up on the system) to earth, and to provide a pathway to trip a breaker in the event that these bonded metallic components became energized. There are many things that can lead me to recommend further evaluation of this system by a licensed electrical contractor and they will be documented as repair items in the observations below if discovered.

Electric Distribution and Finish

Branch Wiring

Wire Material: Copper, Multi-strand Aluminum

Wiring Method: Non-metallic sheathed cable

Receptacles and Fixtures

Inspection Method: Tested All Accessible

During inspection I make an effort to test and inspect all accessible electric receptacles and switches. In general, the scope of testing is directly related to access; where personal belonging and furniture obstruct access to receptacles and fixtures, fewer of them can be reasonably tested during inspection. All defects found during inspection today will be listed in this report. Inspection/testing of the electrical system can be challenging. It should be anticipated that not all defects will be discovered and that some issues found may actually not be defects at all. Tools used to verify proper wiring and function can vary wildly in reliability/consistency. The kinds of tools that could be used to confidently analyze the system and its function cannot typically be done in the context of a Standard Home Inspection. I look for indications of issues, based on the age of the home, types of wiring systems used etc, as well as personal experience and by testing with a variety of common tools. Issues identified, will be further discussed with recommendations in the electrical section below.

Electric Receptacles: Three wire receptacles

REPAIR THE LAUNDRY ROOM LIGHT

The laundry room light is out. This may be the ballast of a fluorescent light. Repair as needed.

Smoke and Carbon Monoxide Alarm Systems

CO Alarms: None Noted

The installation of carbon monoxide alarms is recommended for all homes that have fuel burning appliances such as gas or oil furnaces, gas water heaters, gas ovens and cooktops, gas fireplaces and wood stoves. In addition, Washington State law (WAC 51-51-0315) now requires UL 2034 approved carbon monoxide alarms in ALL homes and condominiums being sold in Washington State. The location should be: at least one alarm outside of all sleeping areas and one on each floor of the house. Best practices are to have these alarms hardwired with a battery back-up - though requirements are for the installation to meet manufacturer's specifications. Carbon monoxide is a colorless, odorless gas that can cause sickness, nausea and even death. Alarms have a useful service life of roughly 6 years, so changing them more frequently than smoke alarms is recommended.

Smoke Alarms Noted: On Main Floor

On Main Floor On 2nd Floor

On 2nd Floor In All Bedrooms

In All Bedrooms

Smoke Alarms: Present, Old, Updating Recommended

During the home inspection, I try and test a representative sample of the smoke alarms by using the test button on the alarms. This is NOT an accurate test of the sensor, just a test to see if the unit is powered. For reliability, fire marshals recommended updating smoke alarms every ten years and changing batteries bi-annually. The latest data indicate that we should be using photoelectric technology in our smoke alarms for improved fire detection and reducing problems with false alarms, which can lead to disabling of this critical safety system. Unfortunately, the alarms must be removed to determine if they are photo-electric or ionization types. It is surprisingly complex to accurately test a smoke alarm system and determine the reliability, age, and type of sensor technology used, especially as many homes can have half a dozen or more alarms throughout the house. A complete evaluation of smoke alarms is beyond the scope of this inspection. For optimal fire safety, I recommend taking control of these critical safety devices and learning about how to service and maintain your smoke alarm system to keep the building occupants safe. For more information, please read this link. For more information, please read this link.

NO CARBON MONOXIDE ALARMS FOUND

The installation of carbon monoxide alarms is recommended for all homes that have fuel-burning appliances such as gas or oil furnaces, gas water heaters, gas ovens and cook-tops, gas fireplaces, and wood stoves. Carbon monoxide is a colorless, odorless gas that can cause sickness, nausea, and even death. For more information, consult the Consumer Product Safety Commission at 1-800-638-2772 (C.P.S.C.) Modern standards in many states now recommend one CO alarm outside of all bedrooms and at least 1 per floor of the house.

Heating, Cooling, Fireplaces and Ventilation

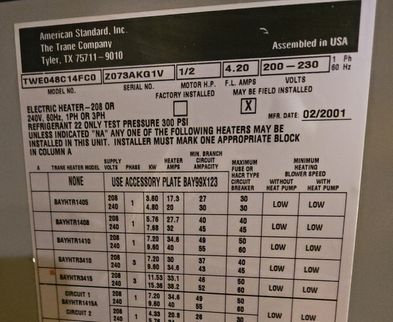

Heating Systems

Energy Source: Electricity

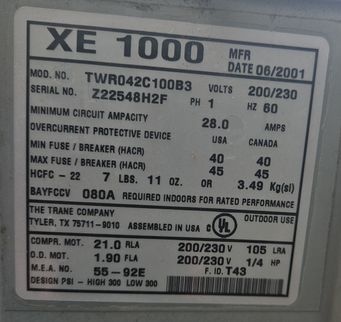

Heating Method: Electric forced air furnace, Heat pump

Manufacturer: Trane

Age: 2001

Air Filters

Filtration Systems: Disposable

Cooling Systems and Heat Pumps

Heat Pump Present

The following list is a minimum set of requirements to be expected of heat pump or air conditioning servicing. I provide these as a courtesy to show they types of check-ups that should be expected from a professional servicing.

- Check compressor efficiency

- Check refrigerant level

- Clean the condenser coil

- Change or clean air filters

- Inspect contactors and wiring

- Inspect drive-sheaves, pulleys and belts

- Check and adjust for proper air flow

- Clean the blower motor as needed

- Lubricate all motors and shaft bearings

- Check, calibrate and program the thermostats and be sure the thermostat has adequate batteries as needed

- Check unit smoke detector, clean filter if applicable

- Check safety disconnect, laser-temp -- check across contacts

Manufacturer: Trane

System Type: Air Source

Listed Nominal Capacity: 3.5 Tons

Energy Source: Electric

Age: 2001

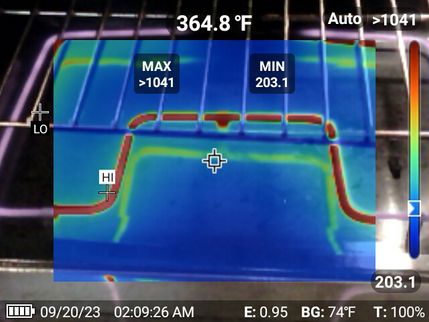

DUCTED HEAT PUMP SERVICING RECOMMENDED

Heating and cooling contractors recommend annual servicing of heat pump systems to maximize the useful life and efficiency of heating and cooling equipment. No recent service records were noted on this system. I recommend having this system serviced and further evaluated by a qualified heating contractor if it has not been done in the last year. The system was tested in heating mode during the inspection and responded well to normal operating controls. Examples of testing procedures and observations noted during the inspection include:

- The compressor was operative at the time of inspection

- Repair the damaged insulation on the heat pump refrigerant lines.

- The air handler was nice and clean at the time of the inspection

OLD R-22 REFRIGERENT NOTED

The heat pump compressor system currently uses the R-22 type of refrigerant. On January 1, 2010, the Environmental Protection Agency placed a ban on the manufacture of new HVAC systems using R-22 refrigerant. General phase out of R-22 refrigerant is estimated to be complete by the year 2020. New, more efficient systems will utilize non-ozone-depleting refrigerants such as 410-A. Unfortunately, 410-A cannot be utilized in some older systems which previously used R-22 without making substantial and costly changes to the equipment. A loophole in current regulations allowed the manufacturer of units after 2010 that were delivered with no refrigerant. These units were designed for R-22 refrigerant to be installed in the field. Maintenance of this unit could pose unexpected challenges due to the growing scarcity of R-22 refrigerant and replacement of the unit may become necessary prior to the end of its expected life.

Heating and Cooling Distribution Systems

Heat Source in Each Room: Present

Distribution Method: Forced Air / Ducts

Mechanical Ventilation Systems

Whole House Fans, Ventilation and HRVs: Duro Dyne (Noted)

Bath Fan Ducting: Ducted to exterior

Kitchen Fan Ducting: Ductwork not visible

Determining proper ventilation to the exterior from kitchen, bath, and laundry fans can be tricky as exhaust fan ductwork is often concealed behind finishes and fan terminations can be all over the house from the roof to the foundation, presenting difficulties for systematically checking every fan termination. During inspection, every effort is made to verify proper terminations of fan vents to the exterior, but it is possible to miss something here that is latent or concealed.

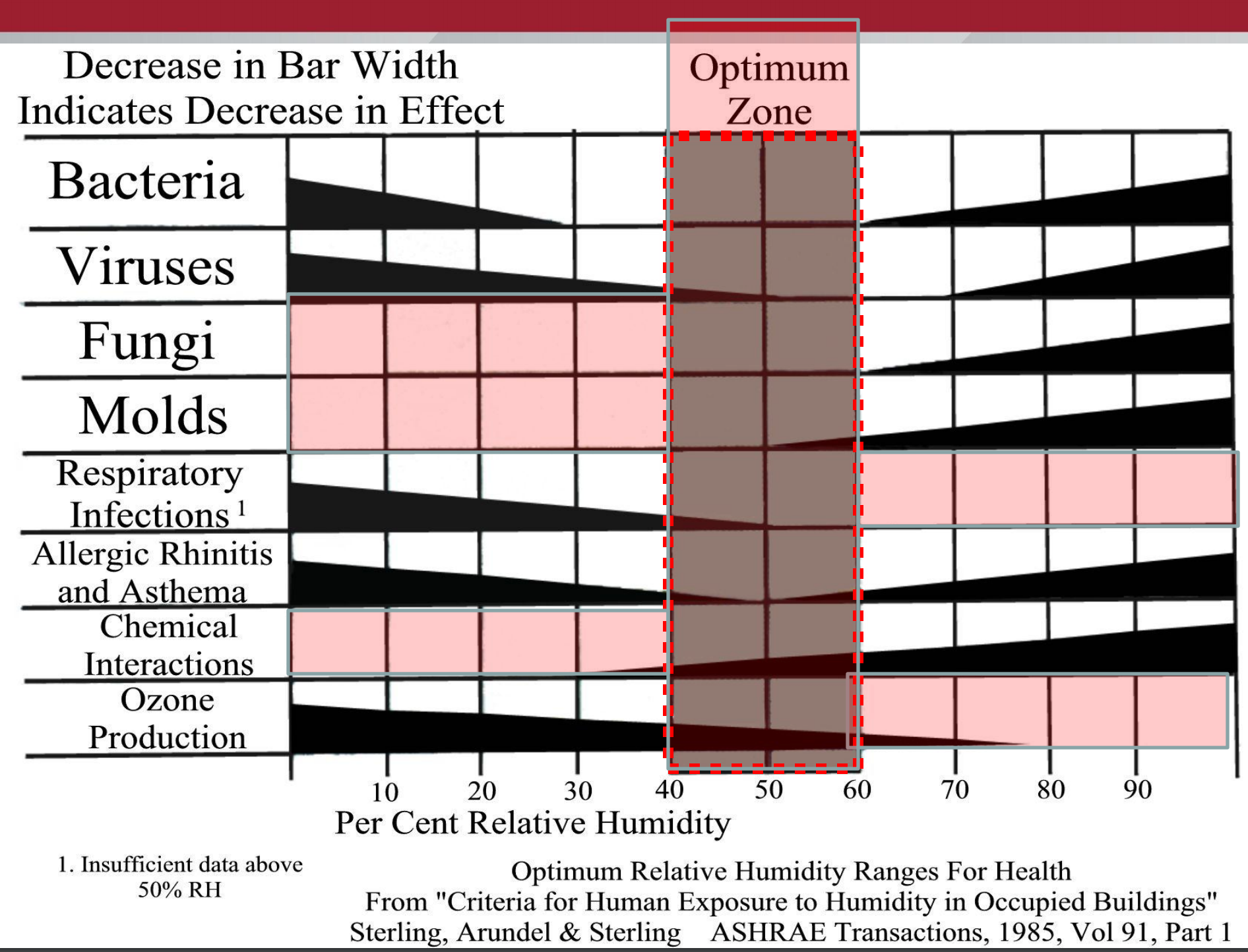

MECHANICAL VENTILATION NOTED

The Duro Dyne mechanical ventilation timer was set at the time of inspection - this appeared to be operating when tested. The goal of this fan is to provide fresh air for the house and to control relative humidity. During winter months, try and keep relative humidity around 50%.

Gas Fireplaces

Fireplace Types: Direct vent gas log fireplace

Fan Present: Yes

Gas Rating Sticker Noted: LP

Screen Covering For Direct Vent: No

System Responded to Testing: No - System Shut Down - Make Operable Prior to Listing

SCREEN RECOMMENDED FOR FIREPLACES

For improved child safety, consider installing a metal screen in front of the gas log fireplace glass. These screens are required on newer gas logs. The glass panels on gas fireplaces and even materials around the fireplace can become very hot and pose a burn hazard. Use caution when using these fireplaces when small children are present.

Solid Fuel Fireplaces

Fireplace Types: No wood burning fireplaces or appliances noted

Plumbing

Water Service Supply

Pipe Material: Copper

Water Supply: Public water

Water Pressure: Water Pressure Tested, 80 PSI

This shows the water pressure tested during the inspection. Generally, "normal water pressure" should be between 30-80 PSI, though pressures near or below 30 can result in poor functional flow to fixtures. Water pressures in excess of 80 PSI risk damaging supply piping components and should be controlled with a pressure-reducing valve.

Pressure Reducing Valve: None noted

Distribution Pipe

Pipe Insulation: Present, Only partly visible

The visible portions of the supply piping appear to be insulated. However, prior to freezing weather it is always a good idea to check pipes and hose bibs for adequate insulation and freeze protection to protect pipes from cold weather and freezing conditions. Hose bibs can often be winterized prior to cold weather.

Supply Pipe Materials: Copper

Copper water supply pipes were installed. Copper pipes installed prior to the late 1980's may be joined with solder that contains lead, which is a known health hazard especially for children. Laws were passed in 1985 prohibiting the use of lead in solder, but prior to that solder normally contained approximately 50% lead. Note that testing for toxic materials such as lead, is beyond the scope of this inspection. Consider having a qualified lab test for lead, and if necessary take steps to reduce or remove lead from the water supply. Various solutions include:

- Flush water taps or faucets. Do not drink water that has been sitting in the plumbing lines for more than 6 hours

- Install appropriate filters at points of use

- Use only cold water for cooking and drinking, as hot water dissolves lead more quickly than cold water

- Treat well water to make it less corrosive

- Have a qualified plumber replace supply pipes and/or plumbing components as necessary

Functional Flow: Average

Circulation Pump: None Noted

Waste Pipe and Discharge

Discharge Type: Public Sewer - Seller

Waste and Vent Pipe Materials: ABS plastic

SEWER SCOPE RECOMMNEDED

An evaluation of the sewer line below the ground is beyond the scope of this inspection. Due to the age and location of the building, a sewer scope is recommended to further evaluate the sewer line and the below ground connections between the house and the municipal sewer line. Sewer scopes are done using video cameras and can reveal the materials, condition and reliability of the sewer line. If that has been done recently, I recommend disclosing available information. If this has not been done recently, this would be valuable information to disclose to a buyer.

Exterior Hose Bibs

Operating

Additional Sinks

None noted

Sump Pumps and Drains

Floor Drain: Basement Floor Drain Present

Sump Pumps: None noted

A floor drain was noted in the basement. I do not test floor drains, but I do recommend they be tested for function by the homeowner or a handy person by running a hose in them for a prolonged time or having them professionally scoped by a qualified plumber. The traps in these drains sometimes dry out allowing sewer gases and vermin into the home. As a part of routine maintenance, I recommend making sure the drain trap has water in it and is properly covered.

✒️

- In this case, I believe the drains are run to a yard drain and are not connected to a sewer line

Sewage Ejector Pumps

Sewage Ejector Pump: None noted

Water Heaters

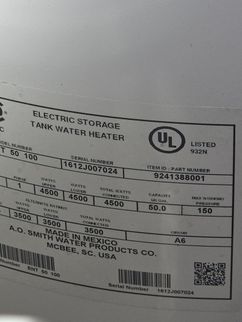

Water Heater - Garage

System Type: Tank

Manufacturer: A.O.Smith

Size: 50 gal

Age: 2012

Energy Source: Electricity

Straps : Present

Pad: Present

Drain Pan: Not Needed

Expansion Tank: Present

Relief Valve: Present - Not Tested

A temperature and pressure relief valve (TPRV) is required on all water heaters to discharge any excessive pressure within the tank. A discharge pipe should be attached to the valve and directed to a safe location away from body contact. Newer installations must be directed to the building exterior or to an approved indoor drain receptor. Most manufacturers suggest that homeowners test these valves at least once a year by lifting the lever to ensure the valve discharges properly and also recommend inspection of these safety devices every three years. The picture here shows a typical TPRV. They may also be found on the side of the heater on some models. I do not test these valves due to the possibility that they may leak after testing. A leaking or inoperative TPRV should be replaced immediately by a licensed plumber.

Due to inconsistencies between both UPC and IPC Plumbing codes, and water heater manufacturer's instructions, and TPRV manufacturer instructions, it is not actually possible to install the drain from the Water Heater TPRV "properly." There are conflicts with distance of termination to the floor/ground, types of pipes approved, and diameters of pipes approved. Additional confusion is added when jurisdictional inspectors approve installations/materials specifically not allowed by both codes and manufacturers. My recommendations will vary depending on the installation and will be included in the applicable narratives below.

Most codes defer to manufacturer instructions and I favor those recommendations. The yellow tag on the valve states clearly the termination should be 6" above the floor which is more consistent with the UPC code requirements.

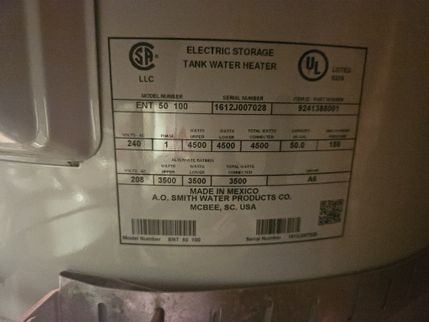

Water Heater - Basement

System Type: Tank

Manufacturer: A.O.Smith

Size: 50 gal

Age: 2012

Energy Source: Electricity

Straps : Present

Pad: Present

Drain Pan: Not Needed

Expansion Tank: Present

Relief Valve: Present - Not Tested

A temperature and pressure relief valve (TPRV) is required on all water heaters to discharge any excessive pressure within the tank. A discharge pipe should be attached to the valve and directed to a safe location away from body contact. Newer installations must be directed to the building exterior or to an approved indoor drain receptor. Most manufacturers suggest that homeowners test these valves at least once a year by lifting the lever to ensure the valve discharges properly and also recommend inspection of these safety devices every three years. The picture here shows a typical TPRV. They may also be found on the side of the heater on some models. I do not test these valves due to the possibility that they may leak after testing. A leaking or inoperative TPRV should be replaced immediately by a licensed plumber.

Due to inconsistencies between both UPC and IPC Plumbing codes, and water heater manufacturer's instructions, and TPRV manufacturer instructions, it is not actually possible to install the drain from the Water Heater TPRV "properly." There are conflicts with distance of termination to the floor/ground, types of pipes approved, and diameters of pipes approved. Additional confusion is added when jurisdictional inspectors approve installations/materials specifically not allowed by both codes and manufacturers. My recommendations will vary depending on the installation and will be included in the applicable narratives below.

Most codes defer to manufacturer instructions and I favor those recommendations. The yellow tag on the valve states clearly the termination should be 6" above the floor which is more consistent with the UPC code requirements.

Water Temperature

Water Temperature Measured During Inspection: Testing Note, 118 Degrees F

The water temperature was tested multiple times during inspection. It is common for water temperatures to fluctuate throughout the house depending on the distance from the water heater, the water heater settings, the type of water heater and any thermostatic controls used in the plumbing fixtures and mixing valves. For reporting, the median temperature is used.

Additional Plumbing

Irrigation

Old Abandoned System - Inquire / Disclose

ABANDONED IRRIGATION SYSTEM

This site has an old irrigation system that appears to be disabled. Disclose any additional information about this system. I am guessing that this piping can just be removed as this system no longer looks functional.

Interior

Floors and Floor Materials

Floor Materials: Hardwood

Floor Settlement: None noted

Walls, Ceilings, Trim, Hallways and Closets

Wall and Ceiling Materials: Drywall

Wall Insulation and Air Bypass

Wall Insulation: Not Visible

Stairs and Railings

Standard

Interior Doors

Interior Doors: Solid Core

Windows

Window Glazing: Double pane

Interior Window Frame: Vinyl

Window Styles: Sliding, Fixed pane

Window Brands Noted: Milgard

Kitchen

Sinks and Faucets

Tested, Under-mount

The kitchen sink here is done as an under-mount style sink. The proper mounting of the sink is considered during inspection but this is difficult to verify. Ideally the sink is both sealed to the countertop and employs additional physical attachment such as clips or supporting plywood. Any indications of a loose or poorly mounted sink will be noted. Use caution when stacking dishes in an under-mount sink and the weight of the dishes can cause the sink to pull free of the countertop.

Cabinets and Countertops

Countertop Material: Slab Surface

Cabinet Material: Wood, Wood laminate

Disposers

Disposer: Operated

Dishwasher

Dishwasher: Operated

Dishwasher Air Gap: Just a high loop

HIGH LOOP NOTED

No air gap was noted for the dishwasher waste line, but they did run a high loop. This is not done to general standards but is generally satisfactory, and many jurisdictions in the state allow for simply a "high loop" installation.

Ventilation Method

Fan Ducted to Exterior

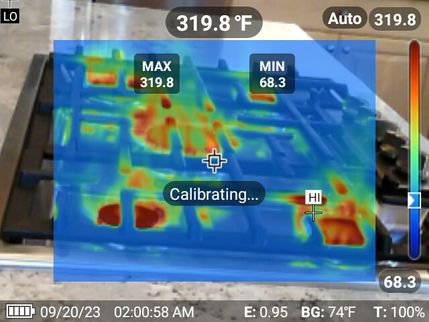

Ranges, Ovens and Cooktops

Range/ Oven /Cook-tops: Gas and electric

The oven and cooktop were tested during the inspection and were operable. Ovens are tested in bake mode only. Appliances are generally beyond the scope of a home inspection but are tested for basic function as a courtesy. This does not include testing to see if the thermostat is accurate, for example.

Refrigerators

Refrigerator: Operating

General Kitchen Condition

Standard

Laundry Facilities

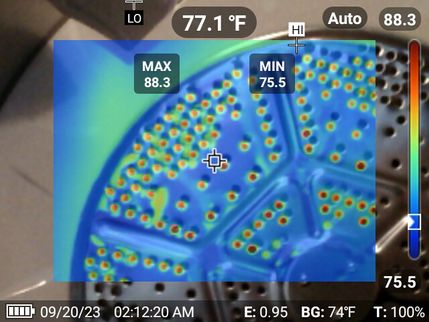

Washer

Tested

During inspection, I try and run the clothes washing machine. This is mostly so that I can push water down the drain to test the waste piping system. Running the clothes washer during an inspection is not a reliable test of the appliance. I am not actually doing a load of laundry, so please note the limitations of this test.

MOISTURE ALARM RECOMMENDED

A moisture alarm with water shut-off features is recommended under the washing machine to protect against accidental leaks in the supply hoses. Pans can be effective when there is a drain, but even these will not protect against a burst supply connector. A moisture alarm with automatic shut-off will. Watts is a brand I have seen installed: Link.

Dryer

Tested

Proper dryer exhaust venting is critical for safe and reliable performance from the dryer. Here are some basic rules of thumb for dryer exhaust duct installation: Unless a vent-free appliance is being used, the dryer exhaust vent must terminate outdoors. It should be no more than 25 feet long and for every 90 degree turn subtract 5 feet and for every 45 degree bend subtract 2.5 feet. Use only smooth-wall metal vent pipe @ 4 inch pipe diameter. Do not use plastic pipe and plastic flex pipe. If a flexible connector is needed behind the dryer use a short amount of corrugated metal pipe. If the exhaust duct is getting pinched behind dryer, consider use of a dryer vent box, pictured here. Flex and corrugated pipes should never be used in concealed spaces such as through walls or in attic or crawl spaces. Insulate dryer exhaust duct where it passes through unconditioned spaces to prevent condensation that could hasten lint build-up inside the pipe. Do not use screws to connect pipe as these can trap lint. Secure duct with foil tape as needed. Be sure duct is sleeved properly so that it will not trap lint and clean the vent regularly, especially if it is a long exhaust run.

Power Source: Electric

Exhaust Duct: Ducted to Exterior

Laundry Sinks

Tested

Laundry Ventilation

Type: Laundry fan

Powder Bathroom

Sinks and Cabinets

Tested

Toilet

Tested

Bathtub / Shower

None noted

Bathroom Ventilation

Type: Bath fan

General Bath

Standard

BATHROOM TESTING PROCEEDURES

During inspection today I operated all plumbing fixtures in bathrooms. I ran a moisture meter around toilets and tile shower enclosures to check for concealed leaks and sounded for loose tile and finishes in shower and tub enclosures. I do not test bathtub overflow drains as this risks damaging finishes around the tub. Monitor tubs while filling and avoid pushing water into the overflow. Even well-installed overflow drains can leak as the gaskets that seal the overflow will dry out over time and may no longer provide a watertight seal. Monitor plumbing after moving into a new home as testing during inspection presents less stress on plumbing than daily use. Please note that vacant homes present additional risk as it can be difficult to distinguish how the plumbing system will respond to daily use. Any defects uncovered during inspection are listed in this report.

Main Bathroom

Sinks and Cabinets

Tested

Toilet

Tested

Bathtub / Shower

Tested

Shower Type: Tile

Tub Type: Acrylic/Fiberglass

Bathroom Ventilation

Type: Bath fan

General Bath

Standard

Guest Bathroom

Sinks and Cabinets

Tested

Toilet

Tested

Bathtub / Shower

Tested

Shower Type: Acrylic/Fiberglass

Tub Type: Acrylic/Fiberglass

Bathroom Ventilation

Type: Fan and window

General Bath

Standard

Attic

Attic Access

Viewed at access

INACCESSIBLE ATTIC AREA

Part of the attic was not accessible - see the 2nd floor. Additional attic accesses are recommended so that all of the attic spaces can be accessed and inspected. Install additional access hatches as needed and re-inspect the inaccessible areas of the attic. Standards recommend an access opening of 30 inches x 22 inches when there is greater than 30 sq/ft of attic space.

✒️ - I looked several times in the closets and could not find an access for the 2nd floor.

Roof Framing and Sheathing

Rafters: Truss, 2x12

Sheathing: OSB

I inspected the attic space today and no red flags were noted regarding prior moisture build-up or relative humidity. Venting appeared unrestricted where visible. Wood has a nice bright color indicating no prior moisture problems with relative humidity or heat migration into the attic.

Fire Separation and Fire Blocking

Fire Blocking and Fire Separation in Attic: Not Visible

Attic Insulation

Insulation Type: Fiberglass

Approximate Insulation R-Value on Attic Floor: 38

Attic and Roof Cavity Ventilation

Attic Ventilation Method: Soffit vents, Ridge vents

Attic and roof cavity ventilation is a frequently misunderstood element of residential construction. All roof cavities are required to have ventilation. The general default standard is 1 to 150 of the attic area and ideally, this comes from at least 60% lower roof cavity ventilation and 40% upper, but this is an over-simplifications of the subject. As a good guiding principle the most important elements for healthy attic spaces, which are traditionally insulated and ventilated are:

- Make sure the ceiling between the living space and the attic is airtight

- Ventilate consistently across the whole lower part of the roof cavity with low, intake soffit venting

- Upper roof cavity venting is less important and if over-installed can exacerbate air migration into the attic from the living space.

- Avoid power ventilators which can depressurize the attic and exacerbate air migration from the house into the attic.

For more information, please see: Link

Crawl Space

General Crawl Space

Crawl Space: Present

Crawl Space Access

Method of Inspection: Crawled

During inspection of the crawl space, every effort is made to inspect the entire space. Visual inspection of crawl spaces is difficult and limited as access is often restricted by pipes, ducts and sub-floor insulation as well as limited clearances.

Crawl Space Access Hatch Location: Interior access hatch

Vapor Barrier

Vapor Barrier Material: Plastic on earth

Crawl Space Ventilation

Ventilation Method: Exterior wall vents

BLOCKED OFF CRAWL SPACE VENTS

These vents on the entry side of the building are blocked off. This is now basement space so there is no need for them.

Posts and Footings

Standard

Insulation

Insulation Type: Fiberglass

Approximate R-Value: R-19

SAGGING SUBFLOOR INSULATION NOTED

The under-floor insulation in the crawl space is sagging and not touching the sub-floor, as such, it is not performing as intended. Use inset string to support the sub-floor insulation up against the sub-floor. The insulation must be in substantial contact with the surface it is insulating to perform as intended.

Moisture Conditions

No water was visible or present at the time of inspection

Structure and Basement

Foundation

% of Foundation Not Visible: 30%

Evidence of Seismic Protection: Present

Building Configuration: Crawl space, Basement, Slab on grade (garage slab)

Foundation Description: Poured concrete

Floor, Wall and Ceiling Framing

Wall Framing: Partly visible, 2x6

Wall Sheathing: Partly visible, OSB

Floor Framing: Partly visible, Wood I-Joists

Sub-Floor Material: Not visible

Ceiling Framing: Not visible

Basement

Partial

Basement Moisture

None noted

A FEW WATER STAINS ON THE BASEMENT FOUNDATION WALLS

The basement was dry at the time of inspection. A few signs of seepage were noted on the basement walls. This is unfinished space so it likely does not matter much if some seasonal seepage occurs.

- One water stain was noted below the main water pipe inlet. Ideally the pipe here is sleeved and the hole sealed for moisture control.

- A small crack was noted on the north side. This may require some seal up. Monitor during wet weather.

Recommendation

Monitor during wet weather and seal up as needed.

Rodents, Pests and Wood Destroying Organisms

Rodents

Some signs

SIGNS OF RODENTS

Evidence of rodent entry into the attic was discovered. It appeared to be old, but this is difficult to verify during a one-time inspection. I recommend disclosing any history of rodent problems and/or treatment.

Recommendation

A trapping and baiting program should be implemented to determine if these conditions are old. In general, rodent control should be considered an ongoing part of home ownership in this region. If rodents are trapped, additional exclusion and prevention work is needed. Basic rodent proofing recommendations include:

- Prune trees off the house and keep vegetative cover away from the building to reduce nearby habitat

- Seal all openings to the exterior - use copper wool for small holes.

- Implement a trapping plan to target entry points and rodent-proof as needed.

- Regular baiting can help, but this does distribute poison into the nearby food chain.

Examples of observations noted during the inspection include:

- Rodent feces noted in the attic - these look older

- Rodent bait stations noted around the exterior

Other Pests

None noted

Wood Destroying Organisms

Visible Evidence of Active Wood Destroying Insects: None noted

Visible Evidence of Inactive Wood Destroying Insects: None noted

Visible Evidence of Damage from Wood Destroying Insects: None noted

Visible Evidence of Active Wood Decay and Fungi: None noted

Visible Evidence of Conditions Conducive to Wood Destroying Organisms: Present, See WDO observations in this report

REMOVE CELLULOSE DEBRIS FROM THE CRAWL SPACE

Wood and cellulose debris was noted in the crawl space. This can encourage wood-destroying organisms such as subterranean termites. Removal of all cellulose debris from the crawl space is recommended to eliminate conditions conducive to wood-destroying organisms. This should include the removal of all wood storage.

Wind Mitigation Form

Wind Mitigation Photos

Roof Deck Attachment (#RDA)

Invoice -- 📸 The Complete Report

Well Maintained House Seattle, WA

| Single-Family Home (Home Maintenance Inspection) | $845.00 |

| 845.00 | |

| DUE |

Orca Inspection Services LLC

C/O Dylan Chalk

5761 NE Tolo Rd

Bainbridge Island, WA 98110

206-713-5715

.png)

.jpg)

.gif)

.gif)

.jpg)

.png)

.jpg)

.jpg)

.jpg)

(1) (1).jpg)

.jpg)

.jpg)

.png)

.png)

.jpg)