Kirt Fourman, OH State License # OHI.2023003019 / Commercial Applicator ID# 163866 / Pesticide Business ID# 113650 / Radon Tester Lic# RT2078 / FAA UAS Pilot 4840875 / InterNACHI CPI #23022402

The Scope and Purpose of a Home Inspection

Purchasing property involves risk

The purpose of a home inspection is to help reduce the risk associated with the purchase of a structure by providing a professional opinion about the overall condition of the structure. A home inspection is not all encompassing, but rather a limited visual, non invasive inspection and it cannot evaluate all risk. Some homes present more risks than others. We cannot control this, but we try to help you make an informed decision on the purchase of your home.

A home inspection is not an insurance policy

This report does not substitute for or serve as a warranty or guarantee of any kind. Home warranties can be purchased separately from insuring firms that provide this service.

A home inspection is visual and not destructive

The descriptions and observations in this report are based on a visual inspection of the structure. We inspect the aspects of the structure that can be viewed without dismantling, damaging or disfiguring the structure and without moving furniture and interior furnishings. Areas that are concealed, hidden or inaccessible to view are not covered by this inspection. Some systems cannot be tested during this inspection as testing risks damaging the building. Our procedures involve non-invasive investigation and non-destructive testing which will limit the scope of the inspection. For a complete listing of what will, or will not be in the report, view the Ohio standards of practice at the following link. https://codes.ohio.gov/ohio-administrative-code/rule-1301:17-1-17

The scope of this inspection

The INSPECTOR agrees to provide professional home inspection services to the CLIENT in conformance with the standards, limitations, exceptions, and exclusions as contained in division (C) of section 4764.01 of the Revised Code, ORC Ann. 4764.01, et seq., OAC Ann. 1301:17-1-01, et seq. (“OH Standards”), and this Agreement. Although the INSPECTOR agrees to follow the OH Standards, CLIENT understands that these Standards contain limitations, exceptions, and exclusions. The inspection is non-invasive. Inspectors who perform home inspections are not required to identify or disclose a property’s concealed conditions, latent defects or cosmetic deficiencies that do not significantly affect a property’s system or part of a system’s performance for the system’s intended purpose. The inspection is limited to a visual and not a technically exhaustive examination of readily accessible components and systems as of the specific date and time that the inspection occurred.

This is not an inspection for code compliance

This inspection and report are not intended for city / local code compliance. During the construction process structures are inspected for code compliance by municipal inspectors. Framing is open at this time and conditions can be fully viewed. Framing is typically not open during inspections of finished homes, and this limits the inspection. Some houses fall out of code compliance shortly after they are built, as the codes continually change. National codes are augmented typically every three years for all of the varying disciplines. Municipalities can choose to adopt and phase in sections of the codes on their own timetables. There are generally no requirements to bring older homes into compliance unless substantial renovation is being done or safety hazards exist.

This is just our opinion

Construction techniques and standards vary. There is no one way to build a house or install a system in a house. The observations in this report are the opinions of the home inspector at the date and time of the inspection. Other inspectors and contractors may have some differing opinions. You are welcome to seek opinions from other professionals.

Your expectations

The overall goal of a home inspection is to help ensure that your expectations are appropriate with the house you are proposing to buy. To this end we assist with discovery by showing and documenting observations during the home inspection. This should not be mistaken for a technically exhaustive inspection designed to uncover every defect with a building. Such inspections are available but they are generally cost-prohibitive to most homebuyers.

Your participation is requested

Your presence is requested during this inspection. A written report will not substitute for all the possible information that can be conveyed verbally by a shared visual observation of the conditions of the property.

How to Read This Report

Getting the Information to You

This report is designed to deliver important and technical information in a way that is easy for anyone to access and understand. If you are in a hurry, you can take a quick look at our "Summary" page and quickly get critical information for important decision making. However, we strongly recommend that you take the time to read the "Full Report", which may include digital photographs, captions, diagrams, descriptions, videos and hot links to additional information.

The best way to get the layers of information that are presented in this report is to read your report online (the HTML version), which will allow you to expand your learning about your house. You may notice some words or series of words highlighted in blue and underlined – clicking on these will provide you with a link to additional information. The HTML version of this report may also contains streaming videos. Short video clips often contain important information and critical context and sounds that can be difficult to capture in words and still pictures.

This report can also be printed on paper or to a PDF document.

Chapters and Sections

This report is divided into chapters that parcel the home into logical inspection components. Each chapter is broken into sections that relate to a specific system or component of the home. You can navigate between chapters with the click of a button on the left side margin.

Most sections will contain some descriptive information done in black font. Observation narrative, done in colored boxes, will be included if a system or component is found to be significantly deficient in some way or if we wish to provide helpful additional information about the system or the scope of our inspection. If a system or component of the home was deemed to be in satisfactory or serviceable condition, there may be no narrative observation comments in that section and it may simply say “tested,” or “inspected.”

Observation Labels

All narrative observations are colored, and labeled to help you find, refer to, and understand the type of observation.

Summary Page

The Summary Page is designed as a bulleted overview of all the observations noted during inspection. This helpful overview is not a substitution for reading the entire inspection report. The entire report must be read to get a complete understanding of this inspection report as the Summary Page does not include photographs or photo captions.

Moisture & IR Testing

Where moisture meter testing is indicated in this report a Tramex ME5 was used. If and when thermal imaging is required to aid in the inspection report an Hikmicro B20 thermal imaging camera was used.

Summary

Attic Observations

- A-1 Attic:

Attic and roof cavity ventilation is a frequently misunderstood element of residential construction. All roof cavities are required to have ventilation. The general default standard is 1 to 150 of the attic area and ideally, this comes from at least 60% lower roof cavity ventilation and 40% upper, but this is a wild over-simplifications of the subject. As a good guiding principle the most important elements for healthy attic spaces, which are traditionally insulated and ventilated are:

- Make sure the ceiling between the living space and the attic is airtight

- Ventilate consistently across the whole lower part of the roof cavity with low, intake soffit venting

- Upper roof cavity venting is less important and if over-installed can exacerbate air migration into the attic from the living space.

- Avoid power ventilators which can depressurize the attic and exacerbate air migration from the house into the attic.

For more information, please see: Link

Kitchen Appliances Observations

- K-2 Kitchen:

No air gap noted for the dishwasher waste line but they did run a high loop. This is generally satisfactory and many jurisdictions in the state allow for simply a "high loop" installation. Contact a qualified plumber or your local jurisdiction housing enforcement for further compliance requirements and repair as necessary. (Plumber)

- K-3 Kitchen:

A Range hood/microwave ductless exhaust fan was noted for the cook-top. Installation of a fan that ducts to the exterior is recommended to remove moist air and odors to the exterior. Please note that if you switch to a gas range or cooktop in the future, a fan that vents to the exterior is still not required, as long as there is some ventilation in the kitchen, but is more strongly recommended. Gas ovens produce carbon monoxide while running and should really have an exhaust vent to the exterior.

✒

- In modern construction, all kitchens require some form of mechanical ventilation but modern buildings are generally much tighter and have more precise requirements for mechanical ventilation. It was common for older kitchens to have fans that do not vent to the exterior.

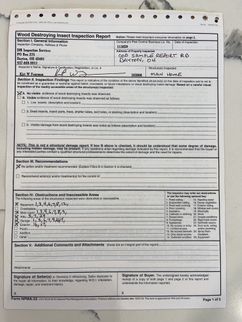

Wdi Wood Destroying Insects

- RPWDO-1 Rodents, Pests and Wood Destroying Organisms:

A WDI Diagnostic inspection was conducted in conjunction with the home inspection. Signs of wood destroying insects were not present the day of the home inspection. A copy of the NPMA-33 form may be obtained when required upon request.

Applicator Kirt Fourman Lic# 163866

DM Inspection Services Lic# 113650

PO Box 275 Dayton, OH 45401

dminspserv@gmail.com

Insulation Ventilation Observations

- I-1 Interior:

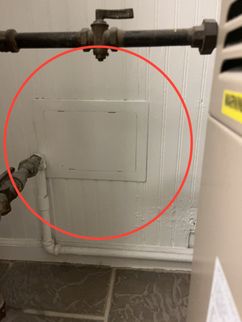

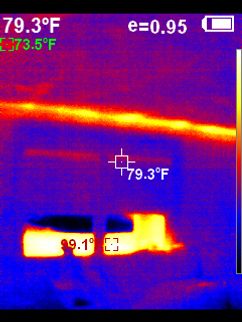

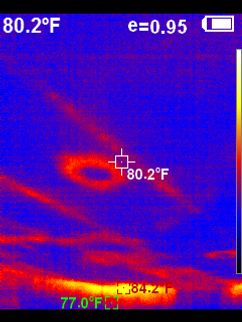

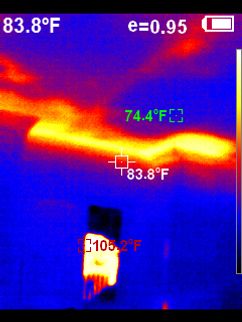

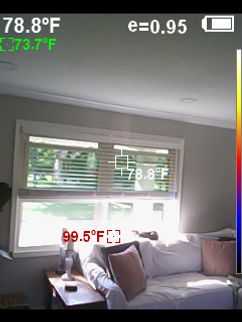

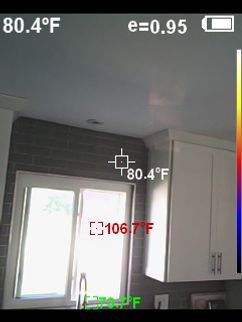

During this inspection, a thermal imaging camera was used to check walls, ceilings and appliances for thermal anomalies. Thermal imaging cameras use the infrared light spectrum to build a picture based on temperature differentials. Experienced thermogrophers look for clues in these thermal images that could lead us to otherwise-concealed moisture control problems or missing air or thermal barriers. We can also use them for appliance verification. We do not use infrared for electrical inspections. In older homes, incomplete air and thermal barriers are so common, we will only report on items that look significantly deficient and which seem worthy of correction.

This service is included with our home inspection; it is limited and is not a complete thermal mapping of the house. The use of an infrared camera is well beyond the minimum standards for a home inspection. We offer this service because we know it is valuable and can help us help our clients by improving our inspection services.

Please note that this tool has limitations when done in conjunction with a home inspection. Environmental conditions at the time of inspection present limitations to the information that can be gathered during the course of a home inspection. For example, occupant behavior, the time of day, time of year and weather conditions can all impact the usefulness of the data that can be gathered.

Relevant thermal images will be included in this report. A few examples photos are provided here.

- I-2 Interior:

The eaves are lacking insulation in localized areas of the home. This will create heat transfer and reduced HVAC control of your home. Improve as desired. (Qualified Insulation Contractor)

- I-3 Interior:

Can lights are a common area for loss of conditioned air. This decreases comfort levels in the home, increases utility bills and could lead to attic moisture issues. Improve as desired. (Homeowner/Handyman)

Interior Systems Observations

- G-1 Garage:

The door between the garage and the house does not appear to be compliant per modern fire prevention standards. According to modern building practices a door between the garage and living space must be a solid wood door at least 1 3/8 inches thick, a solid or honeycomb-core steel door of the same thickness, or a 20-minute fire-rated door with a self-closing mechanism. Rated doors are important fire safety protection to slow a fire from spreading from the garage into the house. (Handyman/General Contractor)

- EDFW-2 Electric Distribution and Finish Wiring:

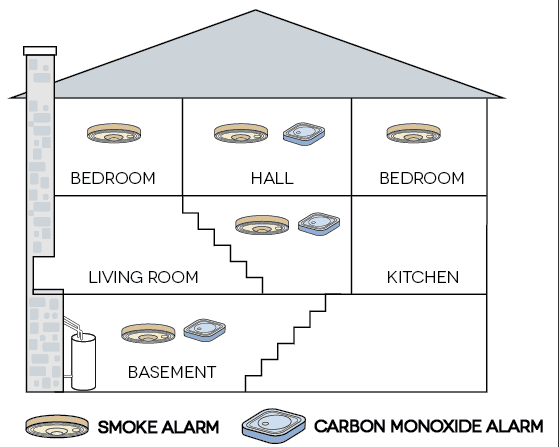

Carbon monoxide alarms were found during the inspection. Be sure to check these regularly. The general standard is 1/ floor and 1 outside all sleeping areas.

- EDFW-3 Electric Distribution and Finish Wiring:

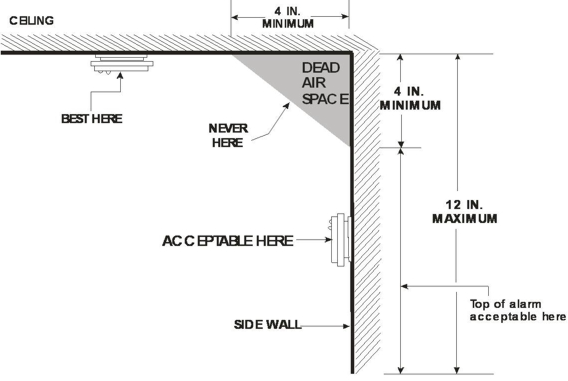

- Modern Building practices have smoke and carbon monoxide detectors, (CO) generally located in the same areas. Smoke and CO combined use detectors are suggested for improved safety in all required locations. Smoke/CO detectors are usually installed on the ceiling or high on the wall, as smoke rises and they need to detect it as early as possible. (Install smoke/CO per manufactures recommendations)

- They are commonly placed in all bedrooms, outside of all bedrooms in the hallways, and on each level of the home, including the basement.

- Best practice is to have all smoke/CO detectors interconnected so that if one detects smoke/CO, all alarms throughout the home will sound.

Smoke detectors where not found in all of the required locations and/or were improperly positioned. This creates a health and safety issue in the event of a fire. Evaluate and improve as required. (Homeowner/Handyman)

- I-4 Interior:

The ends of the handrail should return to the wall to prevent clothing or accessories from catching on the end of the railing and creating a fall hazard. (Qualified Contractor)

- LF-3 Laundry Facilities:

Present and functional

Hvac Cooling Observations

- HCFV-4 Heating, Cooling, Fireplaces and Ventilation:

Plant growth near the condenser unit should be cut back. This limits air flow resulting in poor performance and possibly reduced equipment life. (Homeowner/Landscaper)

- HCFV-5 Heating, Cooling, Fireplaces and Ventilation:

This shows the data plate from the exterior compressor. 📸The industry average service design life for most forced air furnaces is 15-20 years, and the industry average service design life for most air conditioning condensing units is 10-15 years. The average service design life of boilers can vary from as little as 10 years to as many as 50 years depending on the type and quality of materials used in their manufacture. Routine upkeep/maintenance, regional weather/climate, and location/placement of the mechanical systems will all play critical roles in the longevity of these systems.

Hvac Heating Observations

- HCFV-2 Heating, Cooling, Fireplaces and Ventilation:

This gas forced air furnace is close to the end of its useful design life. The average service life of natural gas and propane forced air furnaces is 15-20 years. Proper maintenance and care may extend the life significantly. Annual inspections of a older furnace are recommended to continue peak performance. Budgeting for future replacement is recommended as a preventative measure. (HVAC Technician)

- HCFV-3 Heating, Cooling, Fireplaces and Ventilation:

The heating and cooling system has disposable air filters installed. These should be changed quarterly or more to ensure proper airflow at the furnace. Be sure to install the filters with the arrows pointing in the same direction as the airflow in the furnace. (Homeowner)

Structural Observations

- SB-1 Structure and Basement:

The basement is a finished space and eliminates the possibility to inspect framing, insulation, moisture barriers and other systems. No areas of concern noted the day of the inspection.

Exterior Systems Observations

- G1-4 Grounds:

Trimming vegetation away from a house helps prevent damage and maintenance issues. Branches rubbing against siding or roofing can cause wear or leaks, and roots may impact foundations or underground piping. Overgrown plants also create pathways for pests such as ants, rodents, and termites to access the home. Clearing plants from around windows and vents also improves airflow and natural light, reducing moisture buildup and supporting a healthier indoor environment.

Tree branches should be kept about 10 feet from the home, and general landscaping should be maintained at least 12 inches away from exterior cladding.(Homeowner/Landscaper)

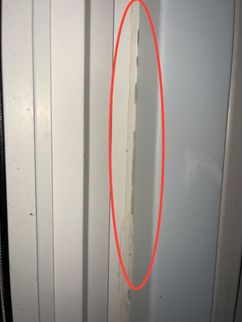

- ESDW-1 Exterior Siding, Doors and Windows:

Window caulk requires improvement in localized areas. Failure to properly seal windows may allow water and/or pest intrusion. (Homeowner/Handyman)

- DPB-1 Decks, Porches and Balconies:

The stair system does not have a graspable hand rail according to modern building practices. This creates a safety fall hazard, and must be corrected. (Handyman/Contractor)

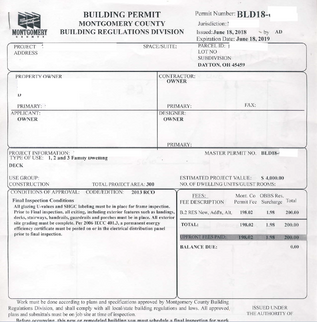

- DPB-2 Decks, Porches and Balconies:

The deck was built and a permit pulled thru the county in 2018. The home owner provided drawings and inspection approvals by the county verifying compliance with code at the time of construction. Other than the previously mentioned hand rail note, no other issues where found.

- DPB-3 Decks, Porches and Balconies:

The main egress stoop has settled. This creates a riser height inconsistent with modern building practices and could present a trip hazard. (Qualified Concrete Contractor)

- RCG-2 Roof, Chimney and Gutters:

The downspout on the north east corner has damage and is slightly crushed. This will restrict rain water potentially overflowing the gutter system in heavy rain storms. Overflowing gutters may lead to soil erosion around the foundation of the building. Over time this may lead to destabilizing the footings and premature foundation settlement. (Roofing/Gutter Contractor)

Roof System Observations

- RCG-1 Roof, Chimney and Gutters:

Excessive granular loss was noted in the roof system. Localized areas had fiberglass fibers exposed. A older patch was done around the B-vent and electrical service mast. Nails on the ridge cap are exposed and require sealant to prevent moisture intrusion in the roofing system. The roof has some good life left but, I recommend budgeting for future replacement. (Qualified Roofing Contractor)

Electrical Observations

- ES-1 Electric Service:

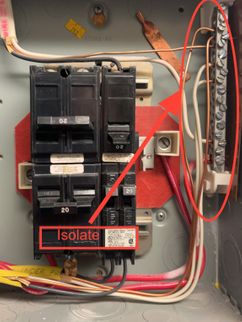

The circled breaker in the picture is the main disconnect for the homes 110V branch circuit wiring.

- ES-2 Electric Service:

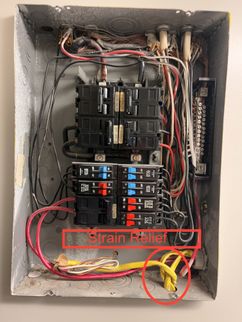

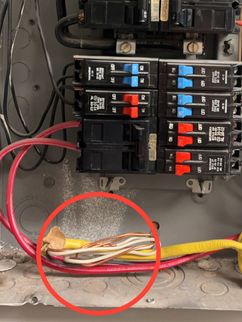

Overall, numerous problems were noted in the wiring system indicating older, incomplete and unreliable wiring practices. I recommend correction of these items or upgrading for improved safety.

- Elimination of double lugged circuits in the electric panel

- Correction of open and running splices not contained inside electrical junction boxes.

- Correct all open grounds

- Supporting all loose wiring

- Protecting all wiring subject to physical damage

- Correcting all receptacles with reverse polarity

- Non compliant strain reliefs.

- Sub panel neutral and grounds not isolated.

These and other findings could cause electrical hazards and require improvements to meet modern building standards. (Qualified Electrician)

- ES-3 Electric Service:

Inadequate labeling of the electric panel circuit breakers was noted during inspection. This should be corrected for improved safety. (Electrician)

- ES-4 Electric Service:

This shows the location of the air conditioner disconnect.

- ES-5 Electric Service:

During a home or property inspection, every effort is made to inspect the visible components of the electrical system grounding. The grounding system is critical for safely discharging electrical surges, especially in the case of lightning strikes. A driven ground rod was located on the east side of the home. There is no way in the context of a home inspection to verify the "effectiveness" of the grounding system as much of the system is not visible, and there are no practical tests one can perform in the way we can test a furnace or a plumbing fixture.

- ES-6 Electric Service:

Bonding connections were noted on the water pipes. Typically the bonding connection should be made within the first 5 feet of the water supply pipe. In this case the clamp was not properly located. Using water pipes for grounding purposes beyond 5 feet from the pipe entrance point could compromise safety, lead to violations, and cause issues like improper grounding, corrosion, or the risk of electrical faults. For safety and compliance, the bonding wire should be installed in accordance with modern building practices and local regulations, ensuring that it is properly connected and within the first 5 feet of the service pipe being connected to. (Qualified Electrician)

- EDFW-1 Electric Distribution and Finish Wiring:

A representative number of receptacles and switches were tested during inspection. Any defects found during inspection are noted in this report. Only visible and accessible receptacles and switches were tested during inspection and personal items and furnishings are not moved to access any receptacles or fixtures. Inspection/testing of the electrical system can be challenging. It should be anticipated that not all defects will be discovered and that some issues found may actually not be defects at all. Tools used to verify proper wiring and function can vary wildly in reliability/consistency. The kinds of tools that could be used to confidently analyze the system and its function cannot typically be done in the context of a Standard Home Inspection. I look for indications of issues, based on the age of the home, types of wiring systems used etc, as well as personal experience and by testing with a variety of common tools. Issues identified, will be further discussed with recommendations in the electrical section below.

Plumbing Observations

- FSD-1 Fuel Storage and Distribution:

This shows the location of the gas meter and the main service shutoff south east side of the house.

- P-1 Plumbing:

This shows the location of the water meter at the front of the house.

- P-2 Plumbing:

This shows the location of the main water shut off located in the laundry room.

- P-3 Plumbing:

This shows the location of the sewer cleanout found during inspection - garage. 📸

- P-4 Plumbing:

No drain pan has been installed below the water heater here. A drain pan is recommended under water heaters that are located in finished spaces or where a leak could damage finishes. Where a pan does not already exist, the tricky part is providing a drain to the outside. A pan without a drain is often of limited benefit / protection. For improved protection from accidental water heater leaks, and where a drain is difficult to install, consider a pan with a moisture alarm and a flood-safe device such as this: Watts Water Heater Leak Prevention. Watts Water Heater Leak Prevention.

- P-5 Plumbing:

A temperature and pressure relief valve (TPRV) is required on all water heaters to discharge any excessive pressure within the tank. A discharge pipe should be attached to the valve and directed to a safe location away from body contact. Newer installations must be directed to the building exterior or to an approved indoor drain receptor. Most manufacturers suggest that homeowners test these valves at least once a year by lifting the lever to ensure the valve discharges properly and also recommend inspection of these safety devices every three years. The picture here shows a typical TPRV. They may also be found on the side of the heater on some models. I do not test these valves due to the possibility that they may leak after testing. A leaking or inoperative TPRV should be replaced immediately by a licensed plumber.

- P-7 Plumbing:

Testing of the plumbing system today, the water tested as too hot - 134 degrees F. This is a scald hazard. To prevent scalding, standards recommend indoor hot water temperatures do not exceed 120 degrees. There is some evidence that hot water temperatures should be greater than 130 degrees to prevent Legionnaires' disease from developing in the water heater. If this is a concern, you can heat the water in the tank to 140 degrees F and have a tempering valve installed at the hot water tank. Have this further evaluated and repaired by a licensed plumber or simply turn down the temperature as desired to eliminate a scald hazard. Please note that during inspection it is difficult to accurately test the water temperature as it can vary between fixtures. Testing is done in multiple locations during inspection and a median temperature is taken.

- AP-1 Additional Plumbing:

This building has a sump pump installed. Sump pumps are generally installed as a means of collecting and discharging groundwater that is entering a building's crawl space or basement. These are difficult systems to inspect during a one-time inspection as much depends on how critical the sump system is for keeping the space dry. Some systems are installed as prophylactic measures to provide a backup in case of other drainage failures. Other systems can be critical to keeping a space dry. It is important when buying or selling a home to learn more about or provide more information about sump systems so owners can plan accordingly. During the inspection, we make an effort to see if the pump is working and evaluate the overall quality of the installation - some comments may be noted below. If it is determined that a sump pump is critical for keeping a space dry, I would consider installing additional backup measures such as: (Plumber)

- This system already has a battery back-up

- Have a backup pump in case of pump failure

- Install a high water alarm to warn occupants of a failing sump system

Site Condition Observations

- G1-2 Grounds:

Discharge for the downspouts is located in the front yard. Care should be given to monitor and verify flow over time. Drain pipes are prone to clogging with tree debris transferred from the gutters. (Homeowner)

- G1-3 Grounds:

OSHA defines any change greater than 1/4 inch as a trip hazard. Although no standard is in place for home inspections, it is generally accepted that vertical displacement of 3/4 inch or greater is considered a trip hazard and may cause personal injury. The driveway and sidewalk have notable displacement. (Concrete Contractor)

General Inspector Observations

- RT-1 Report Tools:

View the complete list of the Ohio Standards Of Practice for home inspections to better understand what your report will, and will not cover.

Clients and Realtors, after completely reviewing the report please note the " Create Request List" at the top of your report. This is a powerful tool to help generate your repair request, adding comments to your inspectors notes, and redemption values if applicable.

- RT-2 Report Tools:

All Observations in this report refer to the property or item listed as inspected at the time of the inspection. Any pictures used in this report were for the purpose of providing examples of problems and do not necessarily indicate the whole problem or all of the problems. Further evaluation and repair of all defect observations is highly recommended to determine the extent of defect, and defect estimated repair cost. Each defect observation will indicate in parenthesis what type qualified contractor to contact for further evaluation and repairs as required. The report represents a snapshot in time when the inspection was done and does not represent the condition of the home or its components before or any time after the inspection.

- GC-1 General Comments:

In 1978, federal laws were passed to prohibit use of lead and asbestos in building materials. Manufacturers of building materials were allowed to sell existing stocks of materials that were manufactured with lead and asbestos, so even buildings constructed as late as the mid-1980's could possibly contain lead or asbestos. Identification and testing for lead and asbestos and other environmental testing is beyond the scope of this home inspection. If you wish to seek additional information, I recommend contacting an environmental lab or industrial hygienist.

- GC-2 General Comments:

Solid conductor aluminum wiring was used in residential construction for 15 and 20-amp circuits in the 1960's through the 1970's. This wiring has proven to be problematic and a fire hazard, primarily due to problems with loose connections and metal fatigue. I looked hard to find any signs of solid conductor aluminum. There is always a chance that solid conductor aluminum wiring exists and is concealed from view. If this wiring is ever uncovered during subsequent renovation work, I recommend removal and replacement.

- GC-3 General Comments:

This home was occupied at the time of the inspection. Inspection of occupied homes presents some challenges as occupant belongings can obstruct visual inspection of and access to parts of the building. We do our best during inspection to work around belongings to discover as much as possible about the house without moving or damaging personal property, however, the presence of personal items does limit the inspection.

- G1-5 Grounds:

Please note that the storage shed was locked and inaccessible for interior inspection. Inquire with the sellers agent for access if desired.

- LF-2 Laundry Facilities:

During inspection, I try and run the clothes washing machine. This is mostly so that I can push water down the drain to test the waste piping system. Running the clothes washer during an inspection is not a reliable test of the appliance. I am not actually doing a load of laundry, so please note the limitations of this test.

📃 The Complete Inspection Report

Grounds

Drainage and Site

Driveways/Walkways/Flatwork

Window and Stairwells

Grounds, Trees and Vegetation

Exterior Stairs

Retaining Walls

Fences

Outbuildings, Trellises, Storage Sheds, Barns

Exterior Siding, Doors and Windows

Siding and Trim

Exterior Vent and Exhaust Terminations

Eaves

Exterior Doors

Exterior Window Frames

Decks, Porches and Balconies

Wood Decks Porches and Balconies

Concrete Decks, Stoops, Landings and Porches

Water-Resistant Decks and Balconies

Electric Service

Electrical System Safety Overview

Electric Service

Electric Service Equipment

Sub Panel

Generator Equipment

Appliance Disconnects

Electrical Grounding System

Electrical Bonding System

Electric Distribution and Finish Wiring

Branch Wiring

Receptacles and Fixtures

Ceiling Fans

Smoke and Carbon Monoxide Alarm Systems

Heating, Cooling, Fireplaces and Ventilation

Heating Systems

Vents and Flues

Air Filters

Cooling Systems and Heat Pumps

Heating and Cooling Distribution Systems

Mechanical Ventilation Systems

Additional Heat Sources

Gas Fireplaces

Solid Fuel Fireplaces

Plumbing

Water Meter

Water Service Supply

Distribution Pipe

Waste Pipe and Discharge

Water Heater

Water Temperature

Exterior Hose Bibs

Additional Sinks

Interior

Floors and Floor Materials

Walls, Ceilings, Trim, Hallways and Closets

Wall Insulation and Air Bypass

Stairs and Railings

Interior Doors

Windows

Report Tools

View the complete list of the Ohio Standards Of Practice for home inspections to better understand what your report will, and will not cover.

Clients and Realtors, after completely reviewing the report please note the " Create Request List" at the top of your report. This is a powerful tool to help generate your repair request, adding comments to your inspectors notes, and redemption values if applicable.

All Observations in this report refer to the property or item listed as inspected at the time of the inspection. Any pictures used in this report were for the purpose of providing examples of problems and do not necessarily indicate the whole problem or all of the problems. Further evaluation and repair of all defect observations is highly recommended to determine the extent of defect, and defect estimated repair cost. Each defect observation will indicate in parenthesis what type qualified contractor to contact for further evaluation and repairs as required. The report represents a snapshot in time when the inspection was done and does not represent the condition of the home or its components before or any time after the inspection.

General Comments

Building Characteristics, Conditions and Limitations

Style of Home: Bi-Level

Type of Building : Single Family (1 story with Basement)

Approximate Square Footage: 1750

Approximate Year of Original Construction: 1970

Attending the Inspection: Listing Agent

Occupancy: Occupied

Animals Present: Yes

Weather during the inspection: Dry, Partly sunny

Approximate temperature during the inspection: 79

Ground/Soil surface conditions: Dry

For the Purposes of This Report, the Front Door Faces: West

In 1978, federal laws were passed to prohibit use of lead and asbestos in building materials. Manufacturers of building materials were allowed to sell existing stocks of materials that were manufactured with lead and asbestos, so even buildings constructed as late as the mid-1980's could possibly contain lead or asbestos. Identification and testing for lead and asbestos and other environmental testing is beyond the scope of this home inspection. If you wish to seek additional information, I recommend contacting an environmental lab or industrial hygienist.

Solid conductor aluminum wiring was used in residential construction for 15 and 20-amp circuits in the 1960's through the 1970's. This wiring has proven to be problematic and a fire hazard, primarily due to problems with loose connections and metal fatigue. I looked hard to find any signs of solid conductor aluminum. There is always a chance that solid conductor aluminum wiring exists and is concealed from view. If this wiring is ever uncovered during subsequent renovation work, I recommend removal and replacement.

This home was occupied at the time of the inspection. Inspection of occupied homes presents some challenges as occupant belongings can obstruct visual inspection of and access to parts of the building. We do our best during inspection to work around belongings to discover as much as possible about the house without moving or damaging personal property, however, the presence of personal items does limit the inspection.

Grounds

Drainage and Site

Clearance to Grade: Standard

Downspout Discharge: Below grade

Site Description: Moderate slope

Driveways/Walkways/Flatwork

Driveway: Concrete

Walkways: Concrete

Patios: None noted

OSHA defines any change greater than 1/4 inch as a trip hazard. Although no standard is in place for home inspections, it is generally accepted that vertical displacement of 3/4 inch or greater is considered a trip hazard and may cause personal injury. The driveway and sidewalk have notable displacement. (Concrete Contractor)

Window and Stairwells

None Noted

Grounds, Trees and Vegetation

Trees/Vegetation too near building: Yes - Prune Vegetation off House

Trimming vegetation away from a house helps prevent damage and maintenance issues. Branches rubbing against siding or roofing can cause wear or leaks, and roots may impact foundations or underground piping. Overgrown plants also create pathways for pests such as ants, rodents, and termites to access the home. Clearing plants from around windows and vents also improves airflow and natural light, reducing moisture buildup and supporting a healthier indoor environment.

Tree branches should be kept about 10 feet from the home, and general landscaping should be maintained at least 12 inches away from exterior cladding.(Homeowner/Landscaper)

Exterior Stairs

Exterior Stairs: See decks section of this report

Retaining Walls

Retaining Wall Material: None Noted

Fences

Exterior Fencing: Stain Or Paint The Fence - Recommended

Exterior Siding, Doors and Windows

Siding and Trim

Trim Material: Metal

Siding Material: Vinyl

Exterior Vent and Exhaust Terminations

Present

Eaves

Vinyl

Exterior Doors

Exterior Door Styles: Hollow core, Sliding glass

Decks, Porches and Balconies

Wood Decks Porches and Balconies

Present

Structure: Ground contact treated lumber

Ledger Board: Standard

Guardrail: Standard

Decking Material: Treated wood

Posts, Beams and Footings: Not Fully Visible

The deck was built and a permit pulled thru the county in 2018. The home owner provided drawings and inspection approvals by the county verifying compliance with code at the time of construction. Other than the previously mentioned hand rail note, no other issues where found.

Concrete Decks, Stoops, Landings and Porches

Concrete Structure: Concrete entry

Water-Resistant Decks and Balconies

Water Proof Surfaces: None Noted

Garage

Garage General

Garage Type: Attached

Garage Doors and Automatic Openers

Overhead Garage Door Type: Metal

Automatic Garage Opener: Present

Garage Occupant Door: Hinges Missing, Not Fire Rated

The door between the garage and the house does not appear to be compliant per modern fire prevention standards. According to modern building practices a door between the garage and living space must be a solid wood door at least 1 3/8 inches thick, a solid or honeycomb-core steel door of the same thickness, or a 20-minute fire-rated door with a self-closing mechanism. Rated doors are important fire safety protection to slow a fire from spreading from the garage into the house. (Handyman/General Contractor)

Garage Floor

Garage Slab: Concrete

Garage Stairs

Garage Stairs: None noted

Roof, Chimney and Gutters

Roof Materials

Method of Roof Inspection: Walked on roof & Drone

Roof Style: Gable

Flashings, Valleys and Penetrations: Present and Visually Standard

Roof Covering Materials: Architectural grade composition shingle

Overlay Roof: No

Excessive granular loss was noted in the roof system. Localized areas had fiberglass fibers exposed. A older patch was done around the B-vent and electrical service mast. Nails on the ridge cap are exposed and require sealant to prevent moisture intrusion in the roofing system. The roof has some good life left but, I recommend budgeting for future replacement. (Qualified Roofing Contractor)

Chimneys

None noted

Skylights

None noted

Gutters and Downspouts

Gutter and Downspout Materials: Seamless Aluminum

The downspout on the north east corner has damage and is slightly crushed. This will restrict rain water potentially overflowing the gutter system in heavy rain storms. Overflowing gutters may lead to soil erosion around the foundation of the building. Over time this may lead to destabilizing the footings and premature foundation settlement. (Roofing/Gutter Contractor)

Fuel Storage and Distribution

Oil Storage

None noted

Propane Storage

None noted

Gas Meter

Present

Gas, Propane and Oil Piping

Gas Piping Materials Noted: Steel

Electric Service

Electrical System Safety Overview

Overall, numerous problems were noted in the wiring system indicating older, incomplete and unreliable wiring practices. I recommend correction of these items or upgrading for improved safety.

- Elimination of double lugged circuits in the electric panel

- Correction of open and running splices not contained inside electrical junction boxes.

- Correct all open grounds

- Supporting all loose wiring

- Protecting all wiring subject to physical damage

- Correcting all receptacles with reverse polarity

- Non compliant strain reliefs.

- Sub panel neutral and grounds not isolated.

These and other findings could cause electrical hazards and require improvements to meet modern building standards. (Qualified Electrician)

Electric Service

Service Entrance: Above Ground

Meter Base Amperage: 150

Electric Service Equipment

Service Entrance (SE) conductor Size: Aluminum, 2/0, 150 amps

Main Panel Amperage: 100 amps

Electric Service Amperage: 100 amps

Main Electric Panel Location: Utility room

Panel Manufacturer: Murray

Sub Panel

Sub Panel: Present

Service Conductor Size: Copper, #4, 60 amps

Sub Panel Amperage: 40 amps

Sub Panel Location: Utility room

Sub Panel Manufacturer: Murray

Generator Equipment

None noted

Appliance Disconnects

Disconnects Noted: Air Conditioner

Electrical Grounding System

Present - Could Not Confirm

During a home or property inspection, every effort is made to inspect the visible components of the electrical system grounding. The grounding system is critical for safely discharging electrical surges, especially in the case of lightning strikes. A driven ground rod was located on the east side of the home. There is no way in the context of a home inspection to verify the "effectiveness" of the grounding system as much of the system is not visible, and there are no practical tests one can perform in the way we can test a furnace or a plumbing fixture.

Electrical Bonding System

Bonding Noted on Water Pipes

Bonding connections were noted on the water pipes. Typically the bonding connection should be made within the first 5 feet of the water supply pipe. In this case the clamp was not properly located. Using water pipes for grounding purposes beyond 5 feet from the pipe entrance point could compromise safety, lead to violations, and cause issues like improper grounding, corrosion, or the risk of electrical faults. For safety and compliance, the bonding wire should be installed in accordance with modern building practices and local regulations, ensuring that it is properly connected and within the first 5 feet of the service pipe being connected to. (Qualified Electrician)

Electric Distribution and Finish Wiring

Branch Wiring

Wire Material: Copper

Wiring Method: Non-metallic sheathed cable

Receptacles and Fixtures

Inspection Method: Representative Testing

Electric Receptacles: Three wire receptacles

A representative number of receptacles and switches were tested during inspection. Any defects found during inspection are noted in this report. Only visible and accessible receptacles and switches were tested during inspection and personal items and furnishings are not moved to access any receptacles or fixtures. Inspection/testing of the electrical system can be challenging. It should be anticipated that not all defects will be discovered and that some issues found may actually not be defects at all. Tools used to verify proper wiring and function can vary wildly in reliability/consistency. The kinds of tools that could be used to confidently analyze the system and its function cannot typically be done in the context of a Standard Home Inspection. I look for indications of issues, based on the age of the home, types of wiring systems used etc, as well as personal experience and by testing with a variety of common tools. Issues identified, will be further discussed with recommendations in the electrical section below.

Ceiling Fans

Ceiling Fans: None Noted

Smoke and Carbon Monoxide Alarm Systems

CO Alarms: Present

Smoke Alarms: None In Bedrooms

- Modern Building practices have smoke and carbon monoxide detectors, (CO) generally located in the same areas. Smoke and CO combined use detectors are suggested for improved safety in all required locations. Smoke/CO detectors are usually installed on the ceiling or high on the wall, as smoke rises and they need to detect it as early as possible. (Install smoke/CO per manufactures recommendations)

- They are commonly placed in all bedrooms, outside of all bedrooms in the hallways, and on each level of the home, including the basement.

- Best practice is to have all smoke/CO detectors interconnected so that if one detects smoke/CO, all alarms throughout the home will sound.

Smoke detectors where not found in all of the required locations and/or were improperly positioned. This creates a health and safety issue in the event of a fire. Evaluate and improve as required. (Homeowner/Handyman)

Heating, Cooling, Fireplaces and Ventilation

Heating Systems

Energy Source: Natural gas

Heating Method: Gas forced air furnace

Manufacturer: Amana

Data Plate: 📸

Age: 1999

This gas forced air furnace is close to the end of its useful design life. The average service life of natural gas and propane forced air furnaces is 15-20 years. Proper maintenance and care may extend the life significantly. Annual inspections of a older furnace are recommended to continue peak performance. Budgeting for future replacement is recommended as a preventative measure. (HVAC Technician)

Vents and Flues

Present

Air Filters

Filtration Systems: Disposable

The heating and cooling system has disposable air filters installed. These should be changed quarterly or more to ensure proper airflow at the furnace. Be sure to install the filters with the arrows pointing in the same direction as the airflow in the furnace. (Homeowner)

Cooling Systems and Heat Pumps

Air Conditioning Present

Manufacturer: Haier

Data Plate: shown below

System Type: Air Source

Energy Source: Electric

Age: 2006

This shows the data plate from the exterior compressor. 📸The industry average service design life for most forced air furnaces is 15-20 years, and the industry average service design life for most air conditioning condensing units is 10-15 years. The average service design life of boilers can vary from as little as 10 years to as many as 50 years depending on the type and quality of materials used in their manufacture. Routine upkeep/maintenance, regional weather/climate, and location/placement of the mechanical systems will all play critical roles in the longevity of these systems.

Heating and Cooling Distribution Systems

Heat Source in Each Room: Present

Distribution Method: Forced Air / Ducts

Mechanical Ventilation Systems

Whole House Fans, Ventilation and HRVs: No Mechanical Ventilation Found

Bath Fan Ducting: Ducted to exterior

Kitchen Fan Ducting: Range Hood/Microwave Non-vented Recirculating Air Filtration

Additional Heat Sources

Description: None Noted

Gas Fireplaces

Fireplace Types: No gas fireplaces or woodstoves noted

Solid Fuel Fireplaces

Fireplace Types: No wood burning fireplaces or appliances noted

Plumbing

Water Meter

Location of Water Meter Note

Water Service Supply

Pipe Material: Plastic, Copper

Pressure Reducing Valve: None noted

Main Water Shut-off Location: Utility room

Distribution Pipe

Pipe Insulation: Not visible

Supply Pipe Materials: Copper

Functional Flow: Average

Circulation Pump: None Noted

Waste Pipe and Discharge

Waste and Vent Pipe Materials: Cast Iron, PVC

Location of Sewer Cleanout: Garage

Water Heater

System Type: Tank

Manufacturer: GE

Data Plate: Shown Here

Size: 40 gal

Age: 2011

Energy Source: Gas

Straps : None Found

Pad: None Needed

Drain Pan: None Noted - Recommended

Expansion Tank: None Noted

Relief Valve: Present - Not Tested

No drain pan has been installed below the water heater here. A drain pan is recommended under water heaters that are located in finished spaces or where a leak could damage finishes. Where a pan does not already exist, the tricky part is providing a drain to the outside. A pan without a drain is often of limited benefit / protection. For improved protection from accidental water heater leaks, and where a drain is difficult to install, consider a pan with a moisture alarm and a flood-safe device such as this: Watts Water Heater Leak Prevention. Watts Water Heater Leak Prevention.

A temperature and pressure relief valve (TPRV) is required on all water heaters to discharge any excessive pressure within the tank. A discharge pipe should be attached to the valve and directed to a safe location away from body contact. Newer installations must be directed to the building exterior or to an approved indoor drain receptor. Most manufacturers suggest that homeowners test these valves at least once a year by lifting the lever to ensure the valve discharges properly and also recommend inspection of these safety devices every three years. The picture here shows a typical TPRV. They may also be found on the side of the heater on some models. I do not test these valves due to the possibility that they may leak after testing. A leaking or inoperative TPRV should be replaced immediately by a licensed plumber.

Water Temperature

Water Temperature Measured During Inspection: 125 Degrees F

Testing of the plumbing system today, the water tested as too hot - 134 degrees F. This is a scald hazard. To prevent scalding, standards recommend indoor hot water temperatures do not exceed 120 degrees. There is some evidence that hot water temperatures should be greater than 130 degrees to prevent Legionnaires' disease from developing in the water heater. If this is a concern, you can heat the water in the tank to 140 degrees F and have a tempering valve installed at the hot water tank. Have this further evaluated and repaired by a licensed plumber or simply turn down the temperature as desired to eliminate a scald hazard. Please note that during inspection it is difficult to accurately test the water temperature as it can vary between fixtures. Testing is done in multiple locations during inspection and a median temperature is taken.

Exterior Hose Bibs

Operating

Additional Sinks

None noted

Additional Plumbing

Sump Pumps and Drains

Floor Drain: None noted

Sump Pumps: Present

This building has a sump pump installed. Sump pumps are generally installed as a means of collecting and discharging groundwater that is entering a building's crawl space or basement. These are difficult systems to inspect during a one-time inspection as much depends on how critical the sump system is for keeping the space dry. Some systems are installed as prophylactic measures to provide a backup in case of other drainage failures. Other systems can be critical to keeping a space dry. It is important when buying or selling a home to learn more about or provide more information about sump systems so owners can plan accordingly. During the inspection, we make an effort to see if the pump is working and evaluate the overall quality of the installation - some comments may be noted below. If it is determined that a sump pump is critical for keeping a space dry, I would consider installing additional backup measures such as: (Plumber)

- This system already has a battery back-up

- Have a backup pump in case of pump failure

- Install a high water alarm to warn occupants of a failing sump system

Interior

Floors and Floor Materials

Floor Materials: Hardwood, Tile, (LVP) Luxury Vinal Planks

Floor Settlement: None noted

Walls, Ceilings, Trim, Hallways and Closets

Wall and Ceiling Materials: Drywall

During this inspection, a thermal imaging camera was used to check walls, ceilings and appliances for thermal anomalies. Thermal imaging cameras use the infrared light spectrum to build a picture based on temperature differentials. Experienced thermogrophers look for clues in these thermal images that could lead us to otherwise-concealed moisture control problems or missing air or thermal barriers. We can also use them for appliance verification. We do not use infrared for electrical inspections. In older homes, incomplete air and thermal barriers are so common, we will only report on items that look significantly deficient and which seem worthy of correction.

This service is included with our home inspection; it is limited and is not a complete thermal mapping of the house. The use of an infrared camera is well beyond the minimum standards for a home inspection. We offer this service because we know it is valuable and can help us help our clients by improving our inspection services.

Please note that this tool has limitations when done in conjunction with a home inspection. Environmental conditions at the time of inspection present limitations to the information that can be gathered during the course of a home inspection. For example, occupant behavior, the time of day, time of year and weather conditions can all impact the usefulness of the data that can be gathered.

Relevant thermal images will be included in this report. A few examples photos are provided here.

Wall Insulation and Air Bypass

Wall Insulation: Not Visible

Stairs and Railings

Standard, Guardrail, Handrail (No Wall Returns)

Interior Doors

Interior Doors: Solid Core, Hollow Core Closet

Windows

Window Glazing: Triple pane

Interior Window Frame: Vinyl

Window Styles: Double hung

Kitchen

Sinks and Faucets

Tested

Cabinets and Countertops

Countertop Material: Quartz

Cabinet Material: Wood

Disposers

Disposer: Operated

Dishwasher

Dishwasher: Operated

Dishwasher Air Gap: Just a high loop

No air gap noted for the dishwasher waste line but they did run a high loop. This is generally satisfactory and many jurisdictions in the state allow for simply a "high loop" installation. Contact a qualified plumber or your local jurisdiction housing enforcement for further compliance requirements and repair as necessary. (Plumber)

Ventilation Method

Ductless Fan - Electric

A Range hood/microwave ductless exhaust fan was noted for the cook-top. Installation of a fan that ducts to the exterior is recommended to remove moist air and odors to the exterior. Please note that if you switch to a gas range or cooktop in the future, a fan that vents to the exterior is still not required, as long as there is some ventilation in the kitchen, but is more strongly recommended. Gas ovens produce carbon monoxide while running and should really have an exhaust vent to the exterior.

✒

- In modern construction, all kitchens require some form of mechanical ventilation but modern buildings are generally much tighter and have more precise requirements for mechanical ventilation. It was common for older kitchens to have fans that do not vent to the exterior.

Ranges, Ovens and Cooktops

Range/ Oven /Cook-tops: Electric

Refrigerators

Refrigerator: Operating

General Kitchen Condition

Recently renovated

Laundry Facilities

Washer

Tested

During inspection, I try and run the clothes washing machine. This is mostly so that I can push water down the drain to test the waste piping system. Running the clothes washer during an inspection is not a reliable test of the appliance. I am not actually doing a load of laundry, so please note the limitations of this test.

Dryer

Tested

Power Source: Electric

Exhaust Duct: Ducted to Exterior

Laundry Sinks

None noted

Laundry Ventilation

Type: None noted

Attic

Attic Access

Walked

Roof Framing and Sheathing

Rafters: 2x4, Truss

Sheathing: Plywood

Attic Insulation

Insulation Type: Fiberglass

Attic and Roof Cavity Ventilation

Attic Ventilation Method: Soffit vents, Ridge vents

Attic and roof cavity ventilation is a frequently misunderstood element of residential construction. All roof cavities are required to have ventilation. The general default standard is 1 to 150 of the attic area and ideally, this comes from at least 60% lower roof cavity ventilation and 40% upper, but this is a wild over-simplifications of the subject. As a good guiding principle the most important elements for healthy attic spaces, which are traditionally insulated and ventilated are:

- Make sure the ceiling between the living space and the attic is airtight

- Ventilate consistently across the whole lower part of the roof cavity with low, intake soffit venting

- Upper roof cavity venting is less important and if over-installed can exacerbate air migration into the attic from the living space.

- Avoid power ventilators which can depressurize the attic and exacerbate air migration from the house into the attic.

For more information, please see: Link

Structure and Basement

Foundation

% of Foundation Not Visible: 95

Building Configuration: Basement

Foundation Description: Poured concrete

Floor, Wall and Ceiling Framing

Wall Framing: Not visible

Wall Sheathing: Not visible

Floor Framing: Not visible

Sub-Floor Material: Not visible

Ceiling Framing: Not visible

Basement

Partial, Finished

Basement Moisture

None noted

Rodents, Pests and Wood Destroying Organisms

Rodents

None noted

Other Pests

None noted

NPMA-33

A WDI Diagnostic inspection was conducted in conjunction with the home inspection. Signs of wood destroying insects were not present the day of the home inspection. A copy of the NPMA-33 form may be obtained when required upon request.

Applicator Kirt Fourman Lic# 163866

DM Inspection Services Lic# 113650

PO Box 275 Dayton, OH 45401

dminspserv@gmail.com

Checking Out Procedure

Check Out List

Oven: Off

Off

Lights: Off

Off Owner Still in House

Owner Still in House

Heating and Cooling: Restored to Pre-inspection temperatures

Restored to Pre-inspection temperatures

Appliances: Off / finishing cycle

Off / finishing cycle

Receipt -- 📃 The Complete Inspection Report

Dayton, Ohio

| Inspection Fee | $0.00 |

| $0.00 | |

| PAID |

DM Inspection Services

PO Box 275

Dayton, Ohio 45401

937-609-9911

(1).jpg)

.jpg)

.jpg)