The Scope and Purpose of a Home Inspection

Purchasing property involves risk

The purpose of a home inspection is to help reduce the risk associated with the purchase of a structure by providing a professional opinion about the overall condition of the structure. A home inspection is a limited visual inspection and it cannot eliminate this risk. Some homes present more risks than others. We cannot control this, but we try to help educate you about what we don’t know during the inspection process. This is more difficult to convey in a report and one of many reasons why we recommend that you attend the inspection.

A home inspection is not an insurance policy

This report does not substitute for or serve as a warranty or guarantee of any kind. Home warranties can be purchased separately from insuring firms that provide this service.

A home inspection is visual and not destructive

The descriptions and observations in this report are based on a visual inspection of the structure. We inspect the aspects of the structure that can be viewed without dismantling, damaging or disfiguring the structure and without moving furniture and interior furnishings. Areas that are concealed, hidden or inaccessible to view are not covered by this inspection. Some systems cannot be tested during this inspection as testing risks damaging the building. For example, overflow drains on bathtubs are generally not tested because if they were found to be leaking they could damage the finishes below. Our procedures involve non-invasive investigation and non-destructive testing which will limit the scope of the inspection.

This is not an inspection for code compliance

This inspection and report are not intended for city / local code compliance. During the construction process structures are inspected for code compliance by municipal inspectors. Framing is open at this time and conditions can be fully viewed. Framing is not open during inspections of finished homes, and this limits the inspection. All houses fall out of code compliance shortly after they are built, as the codes continually change. National codes are augmented at least every three years for all of the varying disciplines. Municipalities can choose to adopt and phase in sections of the codes on their own timetables. There are generally no requirements to bring older homes into compliance unless substantial renovation is being done.

Environmental/Mold Exclusions

The reported or actual health effects of many potentially harmful, toxic or environmentally hazardous elements that may be found in building materials or in the air, soil, water in and/or around any house are varied, and, in some cases controversial. A home inspection does not include the detection, identification or analysis of any such elements or related concerns such as, but not limited to, mold, allergens, legal/illegal drugs and other biological contaminants, radon, , bed bugs, cockroaches, fleas, lice, formaldehyde, asbestos, lead, electromagnetic fields, carbon monoxide, insecticides, Chinese drywall, refrigerants and fuel oils. Furthermore, no evaluations are performed to determine the effectiveness or appropriateness of any method or system (e.g., water filter, radon mitigation, etc.), designed to prevent or remove any hazardous or unwanted materials or elements. An environmental health specialist should be contacted for evaluation of any potential health or environmental concerns. The noting of the presence of materials commonly considered to contain asbestos, formaldehyde, lead, mold etc in the inspection report, should not be construed to mean the inspector is inspecting for these things but instead should be seen as a "heads-up" regarding these materials and further evaluation by qualified professional may be warranted.

This is just our opinion and just for you

The contents of this report are for the sole use of the client named above and no other person or party may rely on this report for any reason or purpose whatsoever without the prior written consent of the inspector who authored the report. Any person or party who chooses to rely on this report for any reason or purpose whatsoever without the express written consent of the inspector does so at their own risk and by doing so without the prior written consent of the inspector waives any claim of error or deficiency in this report.

Construction techniques and standards vary. There is no one way to build a house or install a system in a house. The observations in this report are the opinions of the home inspector. Other inspectors and contractors are likely to have some differing opinions. You are welcome to seek opinions from other professionals.

The scope of this inspection

The inspection and report are intended to provide the client with information regarding the condition of the systems and components of the property as observed at the time of the inspection. The inspector examines the readily accessible systems and components using normal operating controls. The inspection is not technically exhaustive and will not identify concealed conditions or latent defects. Any comments offered by the INSPECTOR that could be construed as over or beyond the standards of practice or the language of this contract, are offered as a professional courtesy. Refer to the Washington State, Standards of Practice and/or Pre-Inspection Agreement for additional information regarding the scope and limitations of the inspection. The Standards of Practice are linked below and describe the "minimum" standards a Licensed Washington State Home Inspector must adhere to: http://app.leg.wa.gov/RCW/default.aspx?cite=18.280.030.

All homes are likely to have some faults which may range from cosmetic defects to major safety hazards. Not all defects will be found. While some minor deficiencies may be mentioned, the emphasis of this report is to inform the buyer of the property condition by detecting deficiencies or circumstances that may affect the structural integrity of the building and its components and its safe use as a residence.

You are encouraged to obtain competitive estimates for major repair needs. Safety and health issues should be addressed promptly. It is recommended that all corrective work, other than routine maintenance activities, be performed by qualified licensed contractors.

It is beyond the scope of the Standard Home Inspection to identify components within the home that may have been part of a "manufacturer's recall". Mention of specific recalls within this report must not be construed to mean that all such items have been identified, or that such identification is part of a Standard Home Inspection. When possible, appliance Model Numbers and Serial Numbers are included in the report and can be used to check for recall related issues. If you have any question about specific appliances, information can be found at the CPSC (Consumer Products Safety Commission) website: https://www.cpsc.gov, or contact the manufacturer directly.

It is recommended that you obtain as much history as is available concerning this property. This historical information may include copies of any seller's disclosures, previous inspection or engineering reports, reports performed for or by relocation companies, municipal inspection departments, lenders, insurers and appraisers. You should attempt to determine whether repairs, renovation, remodeling, additions or other such activities have taken place at this property, and this report will attempt to identify such items when possible.

Ranges, Dish Washers, and Refrigerators (and the like) are typically tested for basic function (Do they turn on). No assertions are made as to how well they function. Microwave ovens, clothes washers/dryers are not operated.

Throughout this report, comments will be made as to the presence or absence of components or parts of components. This must not be construed to mean that these components or parts of components exist (or don't exist) in concealed areas or behind finished surfaces. For example: if foundation bolting was seen in one area, it does not mean that the bolting exists (or doesn't exist) in areas that are concealed. Also if an item was noted as "not being visible," that should not be construed to mean that none of whatever was "not visible" does not exist on the premises---it just means none was noted at the time of inspection and should be seen as a "heads-up" that the concern or condition might be present but hidden, or that the conditions that would allow its presence to be known was not replicated at the time of inspection.

Many of the non-narrative observations/documentation detailed in the report that are related to more "cosmetic" issues should not be construed as "all inclusive" but should instead be seen in as "suggestive" or a "guideline" of conditions that may exist elsewhere in the home. It is not the focus of the report to comment extensively on cosmetic issues, but I do make note of them at times to help complete the "snap-shot" of the home at the time of inspection. For example, "nail-pops" seen in one room are likely to be seen (and should be anticipated) in other rooms even though I may not have noted them in the report.

Throughout the report I may make recommendations as to possible repairs. These recommendations are not intended to be substitutes or construed to be more appropriate than the recommendations of the professionals making the repairs. Conflicts in recommendations should be resolved prior to repairs being made.

Who should make repairs and what should their qualifications be?

Contractor qualifications: In the text of the report, in some instances, I recommend that work be done by a "qualified" person or "qualified" parties. I consider qualified parties, in licensed trades, to be those individuals who hold the necessary licenses to legally work in their profession -- licensed electricians, licensed pest control applicators, licensed plumbers, licensed HVAC professionals, licensed engineers, licensed general contractors, etc. In instances where a task may not, typically, need to be done by a person with a license, my recommendation is to hire an individual to do the work who is, based on past training, experience or expertise, qualified to further evaluate the condition or problem listed in the report and to then make appropriate repairs.

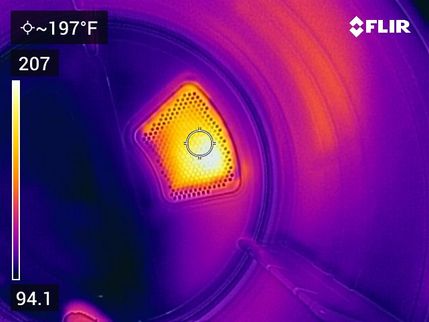

Photography/Infrared and Moisture meters used

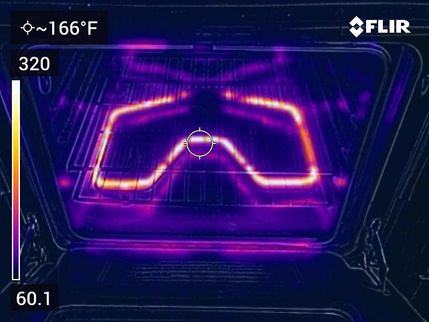

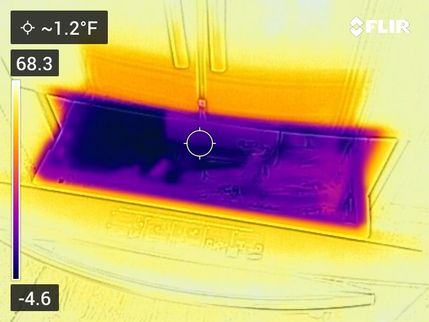

Digital photographs, thermographs and illustrations may be included in this report. If included, their purpose is to better illustrate an observation or recommendation. No degree of importance should be inferred by the presence or absence of photos and illustrations. Some pictures will undergo lightening, darkening, cropping and have callouts and other "overlays" present, but the image itself will not be altered unless specifically noted on the picture. The use of infrared thermography (IR) must not be construed to mean that a full thermal survey of the structure was done. The use of IR is primarily for recording thermal differences to show the function or lack of function of heating and cooling of HVAC equipment; and, anomalies associated with temperature differences sometimes produced by water leaks, air infiltration etc. IR during a home inspection is mainly a qualitative evaluation and, in most cases, "thermal tuning" will not have been performed and therefor temperatures present on any thermal images in the report should not be seen as an absolute temperature but only "relative temperature."

Throughout the report, reference may be made to moisture conditions and percentages of moisture content. These moisture readings are obtained by the use of a Protimeter Surveymaster Moisture Meter.

Your participation is requested

Your presence is requested during this inspection. A written report will not substitute for all the possible information that can be conveyed verbally by a shared visual observation of the conditions of the property. If you were not present during the inspection, you are urged to contact the inspector for a verbal consultation. I am happy to speak on the phone or a similar method to go through areas of concern in the report. If you choose not to consult with the inspector, West Inspect LLC cannot be responsible for misinterpretation of the report.

How to Read This Report

Getting the Information to You

This report is designed to deliver important and technical information in a way that is easy for anyone to access and understand. If you are in a hurry, you can take a quick look at our "Summary Page” and quickly get critical information for important decision making. However, we strongly recommend that you take the time to read the full Report, which includes digital photographs, captions, diagrams, descriptions, videos and hot links to additional information.

The best way to get the layers of information that are presented in this report is to read your report online, which will allow you to expand your learning about your house. You will notice some words or series of words highlighted in blue and underlined – clicking on these will provide you with a link to additional information.

This report can also be printed on paper or to a PDF document.

Chapters and Sections

This report is divided into chapters that parcel the home into logical inspection components. Each chapter is broken into sections that relate to a specific system or component of the home. You can navigate between chapters with the click of a button on the left side margin.

Most sections will contain some descriptive information done in black font. Observation narrative, done in colored boxes, will be included if a system or component is found to be significantly deficient in some way or if we wish to provide helpful additional information about the system or the scope of our inspection. If a system or component of the home was deemed to be in satisfactory or serviceable condition, there may be no narrative observation comments in that section and it may simply say “tested,” or “inspected.”

Observation Labels

All narrative observations are colored, numbered and labeled to help you find, refer to, and understand the severity of the observation. Observation colors and labels used in this report are:

- Repair/Replace:Repair and maintenance items noted during inspection. Please note that some repair items can be expensive to correct such as re-finishing hardwood floors, but are considered simply repair items due to their cosmetic nature.

- Recommended Maintenance:These are repair items that should be considered "routine home ownership items," such as servicing the furnace, cleaning the gutters or changing the air filters in the furnace.

- Improvements & Upgrades:Observations that are not necessarily defects, but which could be improved for safety, efficiency, or reliability reasons.

- Monitor:Items that should be watched to see if correction may be needed in the future.

- Due Diligence:Observation such as a buried oil tank that may require further investigation to determine the severity and / or urgency of repair.

- Future Project:A repair that may be deferred for some time but should be on the radar for repair or replacement in the near future.

- Efficiency:Denotes observations that are needed to make the home more energy efficient as well as to bring the home up to modern insulation standards. This category typically includes windows and insulation. Other items, such as lighting and appliances, are not inspected for their energy status.

- Inspection Notes & Limitations:Refers to aside information and /or any comments elaborating on descriptions of systems in the home or limitations to the home inspection.

- Description:Detailed description of various aspects of the property noted during the inspection.

Summary Page

The Summary Page is designed as a bulleted overview of all the observations noted during inspection. This helpful overview is not a substitution for reading the entire inspection report. The entire report must be read to get a complete understanding of this inspection report as the Summary Page does not include photographs or photo captions.

Moisture Meter Testing

Where moisture meter testing is indicated in this report a Protimeter Surveymaster Dual Function was used.

Summary

Repairs

- E-2 Exteriors:

The backdraft damper was missing at the vent termination - see dryer vent at the rear side. This can allow pest entry into the vent and possibly into the dwelling. I recommend the missing vent damper be replaced.

- DPB-1 Decks, Porches and Balconies:

A few items were noted with the deck installation needing modifications - see list below. Hire a licensed decking contractor to repair these items as needed.

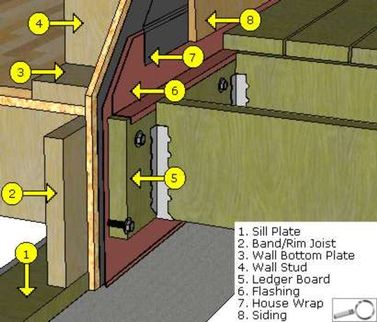

- No flashing were noted between the deck ledger board and the home connection. The ledger board connection was also lacking lag screws at the connection to the home as needed. This can be a difficult retrofit once the deck is constructed. No water damage was visible, but this could cause long term moisture control problems at the deck.

- Some areas of the deck support were common concrete masonry units (CMU) blocks installed on their sides. I recommend the installation of properly sized support posts with piers to support the deck materials.

- FSD-1 Fuel Storage and Distribution:

The threaded steel gas pipe will need improved support - see crawl space. General standards are to support vertical runs every 10 feet for 3/4" pipe and 12 feet for 12" pipe. Vertical runs should be supported every 15 feet.

- G2-1 Garage:

A support post for the garage covered walkway was wood decayed and no longer providing adequate support. I could put my screw driver directly through the bottom of the materials indicating post replacement may be needed. Hire a licensed general contractor to repair this condition.

- ES1-1 Electric Service:

Overall a few repairs are needed in the left side service equipment. I recommend an additional inspection and repairs by a licensed electrical contractor as additional repairs could be needed that are latent or concealed. Examples of observations and defects found during inspection are included below:

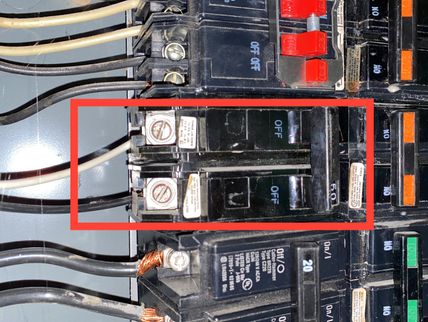

- Circuit breakers were of a brand different from the panel manufacture. Because circuit breakers made by different manufacturers vary in design, panel manufacturers typically require that breakers manufactured by their company be used in their panels. Breakers from one manufacturer used in the panel of another manufacturer may result in poor connections which can create a potential fire or shock/electrocution hazard.

- A few circuit breakers in the panel had corrosion noted on the materials. This can be due to foreign chemical entering the areas or related to water entry.

- Water was noted leaking inside the electric panel at a previous time and I observed corrosion in the panel.

- A knock out did not fit correctly at the enclosure cover and will need to be replaced

- The front cover was from a Squared D panel and was not originally designed for this application.

- ES1-2 Electric Service:

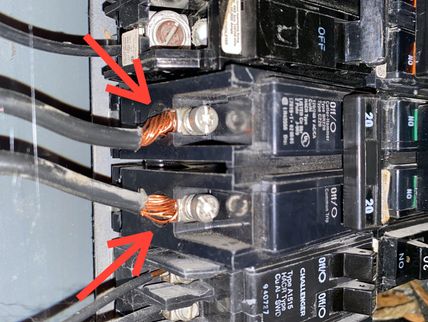

Overall several conditions were noted in the right side service equipment. I recommend an additional inspection and repairs by a licensed electrical contractor as additional repairs could be needed that are latent or concealed. Examples of observations and defects found during inspection are included below:

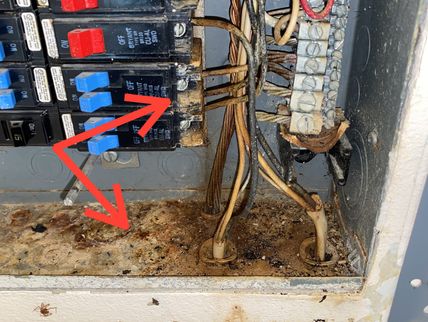

- Water was noted leaking inside the electric panel at a previous time and I observed corrosion in the panel.

- Grommets or bushings are needed to protect the non-metallic sheathed cable where the wiring enters the electrical panel and provide strain relief.

- Abandoned wiring was noted in the panel that was not terminated correctly

- Repair the over-fused circuit in the load center. Over-fusing risks overheating the conductor and poses greater risk for electrical fires. These #14 should be on a 15 amp breaker not a 50 amp breaker.

- The wiring gauge was too large for an installed circuit breaker and did not fit correctly -see photo below.

- The front cover was from a Squared D panel and was not originally designed for this application.

- EDFW1-2 Electric Distribution and Finish Wiring:

Overall several conditions were noted in the wiring system - see list below. I recommend additional inspection and repair of the wiring system by a licensed electrical contractor as additional repairs could be needed that are latent or concealed. Examples of observations and defects found during inspection are included here:

- There is an electric receptacle at the exterior that does not appear rated from exterior use - see front side below the deck. Replace with a proper exterior rated receptacle with an in-use cover and be sure this is GFCI protected.

- The open electrical splices in the attic needs to be contained inside of a listed junction box - see entryway attic access. It is not recommended to splice into wiring without use of a listed junction box.

- Abandoned wiring was noted in the attic near the entryway access hatch. This should be eliminated or properly terminated inside a listed junction box. It is often not feasible to determine if wire is still connected to a power source. I can test these with a voltage sensor, but they could be shut off by a switch or temporarily disconnected. For safety, all abandoned wires should be eliminated.

- Reverse polarity was noted at the electrical receptacle. This is when the hot and the neutral have been wired backwards.

- A homemade extension cord with common Romax wiring was noted at the front side of the home. This is not an exterior rated material for this application.

- Circuit testing was showing open grounds at some of the electric receptacles today - Entry suite bedroom, primary bedroom, and so on. An open ground is often a case of never connecting a ground to the receptacle or forgetting to reconnect the ground if they had occasion to disrupt it. I did see grounding conductors in the electric panel and this house has three-wire system where I tested. Have this further investigated and repaired as recommended by a qualified electrical contractor.

- The missing cover plates to electric receptacles, switches and junction boxes should be installed to cover all access to wiring at switches and receptacles.

- Several mystery switches were found in the home as well that had no obvious usage.

- P-3 Plumbing:

The Polybutylene (PB, gray plastic) supply hoses and angle stops noted below several sinks are an unreliable plumbing product with a reputation for failing fittings. Updating to copper or braided steel supply hoses and new angle stops is recommended. These are common to find in 1990's era buildings. Consult with a licensed plumber to further evaluate and repair.

- WH2-1 Water Heater:

Corrosion was noted on the supply connectors on top of the water heater. Have this connection repaired by a licensed plumbing contractor to ensure reliable performance.

- WH2-2 Water Heater:

Overall, several conditions were noted with the water heater installation. Due to the age of the unit, performing these repairs may not be cost effective and replacement is recommended instead due to age. Examples of my observations and defects found during inspection are included below:

- This is a very old water heater. Replacement is recommended for improved reliability as this unit could fail at any point. The average life of these water heaters is 8-16 years. The service life of a water heater will depend on a variety of factors such as water quality and regular scheduled maintenance such as flushing the tank and replacing sacrificial anodes.

- Install listed seismic straps to restrain the water heater in the event of an earthquake; none were noted during inspection. Two straps should be located on the water heater: one on upper 1/3rd of tank and one at the lower 1/3rd.

- The discharge tube for the water heater temperature and pressure relief valve (TPRV) is not correctly installed - see attached link. The piping terminated horizontally at the exterior of the home and had an improper connection near the TPRV itself. This is a potential safety hazard.

- LAP-2 Laundry and Additional Plumbing:

Several conditions were noted with the installation of the dryer venting systems. Hire a general contractor to repair and upgrades the system to ensure safe functionality. My observations include:

- The dryer exhaust ductwork should be insulated where run outside of the thermal envelope of the building; this is to prevent condensation forming inside the duct that could trap lint. Accumulation of dryer lint can be a fire hazard. Insulate this exhaust duct for improved safety and performance - see crawl space

- The dryer vent is currently partially disconnected in the crawl space.

- The dryer vent should be cleaned annually for safety purposes and proper functionality. If this service had not been done in the last year I recommend it be cleaned prior to first use. Inquire with the seller to see if they have had the dryer exhaust duct recently cleaned.

- HB5-1 Hallway Bathroom:

The fiberglass / acrylic bathtub was noted to have chips in the acrylic finish. Hire a specialist to repair the chip to prevent leaks and to make a satisfactory cosmetic repair. This can be done with a gel coat repair kit from the hardware store though without having a specialist do the work it can be difficult to match the color.

- HB5-2 Hallway Bathroom:

The bathroom shower diverter, which diverts water from the tub fill spigot to the shower head, is leaky and will need repair to prevent wasting water and to improve flow to the shower head.

- A-3 Attic:

Several conditions were noted with the venting systems for the bathrooms fans - see list below. Have a licensed general contractor repair these conditions. My observations include:

- The ductwork for the bathroom fans is uninsulated in the attic space. This can cause condensation during cold weather and is less energy efficient. Replace these with insulated exhaust ducts or insulate to R-8 or better.

- The materials were connected with improper tape at the joints.

- CS3-2 Crawl Space:

The crawl space access hatch was not rodent proof. Rebuilding is recommended to eliminate a rodent entry point. A nice way to seal the opening is to build a frame of pressure treated wood that fits snugly into the opening in the foundation and then cover this with 1/4 wire mesh.

- CS3-3 Crawl Space:

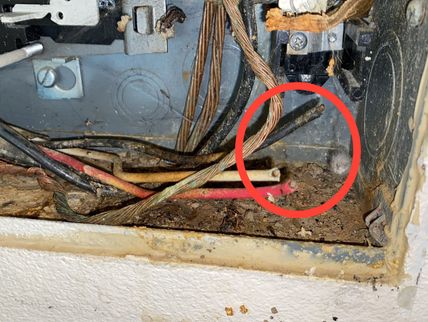

Rodent contamination was noted in the crawl space below the house. Hire a rodent control specialist or crawl space clean-up company to eliminate and seal all openings and set and monitor traps. Once all rodents have been sealed out all contaminated insulation and construction materials should be removed and replaced. On-going baiting and trapping as well as control of vegetation and elimination of food sources on the exterior of the home are often needed to prevent rodent problems / infestations. Keeping all trees pruned 6 feet off the house is recommended.

- CS3-4 Crawl Space:

The plastic vapor barrier in the crawl space is incomplete. Use 6 mil black plastic to cover all exposed earth. This helps to reduce humidity and eliminate conducive pest conditions in the crawl space. Adjust the current vapor barrier or add more plastic as needed.

Recommended Maintenance Items

- E-1 Exteriors:

Overall the siding materials were is good condition with a few localized maintenance items needed - see list below. I noted areas of missing caulking and some areas of the paint starting to show its age. I recommend caulking all penetrations around the home and touching up the paint where needed unit a full re-paint of the home is warranted.

- The paint was starting to crack and show its age at some locations - right side.

- The hose bib connection was not fully caulked and secured as needed - left side

- Areas of cable entry were missing caulking - several sides

- Caulk around the kitchen vent penetration - front side

- HCFV-3 Heating, Cooling, Fireplaces and Ventilation:

The heat pump system was tested in the heating mode only during the inspection due to exterior temperatures. This is an older unit and the design life of a heat pump system is 15-20 years. I recommend having the system serviced/inspected by a licensed HVAC contractor and to have the refrigerant charge checked to ensure proper performance. Proper refrigerant change is important for the system to perform as intended and this is not visible or within the scope of a home inspection. Observations and noted made during inspection include:

- HCFV-5 Heating, Cooling, Fireplaces and Ventilation:

Annual servicing of the gas log fireplaces is recommended to ensure safe and reliable performance. No recent service records were noted on or around the unit. Have these appliances cleaned and serviced by a qualified gas appliance specialist if it has not been in the last year.

Improve & Upgrade

- ES1-3 Electric Service:

Current regulations require an “Inter-system Bonding Terminal” to be installed as a place for the low voltage utilities to run their ground wires to. It will be attached to a #6 minimum copper ground wire run to the location from the service equipment. Such a terminal was not found during inspection. Have this further evaluated and repaired by a licensed electrician.

- EDFW1-1 Electric Distribution and Finish Wiring:

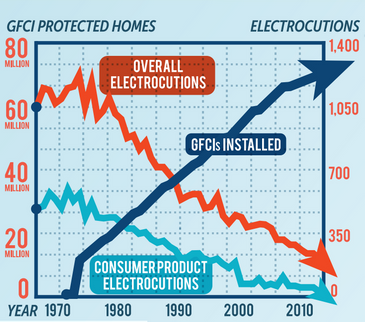

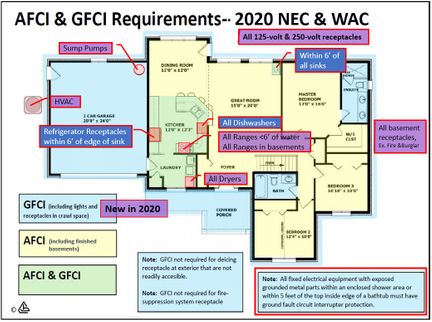

The use of GFCI (Ground Fault Circuit Interruption) protection is inconsistent with modern minimum standards for safety - see kitchen countertops and living room bar. GFCI protection is recommended for the electrical receptacles in the following locations: the two dedicated kitchen appliance circuits, all receptacles within 6 feet of a sink, bathrooms, exterior, garage, unfinished basements, laundry and all wet and damp locations. GFCI's protect against electrocution by limiting the duration of an electrical shock. These are an important modern safety feature that have proven to save lives. Hire a licensed electrician to further evaluate and update GFCI protection for improved safety.

- P-5 Plumbing:

Corrugated waste pipe was used to drain this entryway sink. This is not a listed plumbing product and tends to indicate plumbing work that has not been done by a licensed plumber. Use smooth wall pipe only. Hire a licensed plumber to further evaluate and repair as needed.

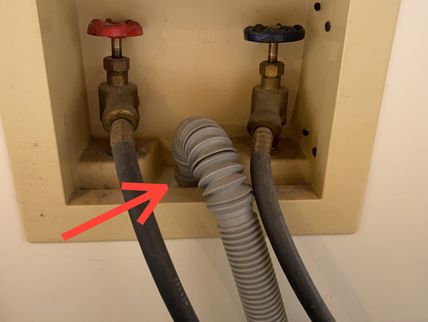

- LAP-1 Laundry and Additional Plumbing:

A few upgrades could be performed at the washer installation - see list below.

- The drain piping for the washing machine was not secured as needed. As the washer drains, the piping will pulsate and can back out over time. I recommend the piping be mechanically fastened to the nearby water piping and/or similar.

- For improved reliability, update the old water supply connectors to the washing machine. These are old and should be regularly swapped out to prevent accidental leaks from bursting hoses. Consider improving the reliability of this water supply by installing a flood safe hose system.

- LAP-3 Laundry and Additional Plumbing:

The laundry room did not have a ventilation system as needed to remove humid air. Consult with a general contractor for costs and options to have a fan installed in your laundry room.

- HCFV-6 Heating, Cooling, Fireplaces and Ventilation:

Both gas fireplaces terminated in the masonry chimney very close to each other. I recommend extending the termination point of one of the vents higher than the other to ensure proper exhausting of the gas fireplaces.

- I-3 Interior:

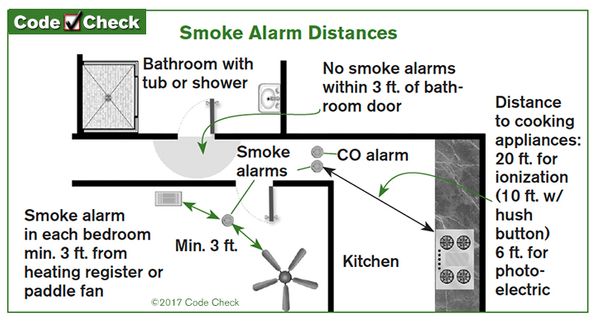

The installed smoke alarms were older units that were beginning to fade in color. Fire marshals recommended updating smoke alarms every 10 years to ensure reliable performance. I recommend updating to photoelectric style smoke alarms in all currently required areas of the home.

- K-1 Kitchen:

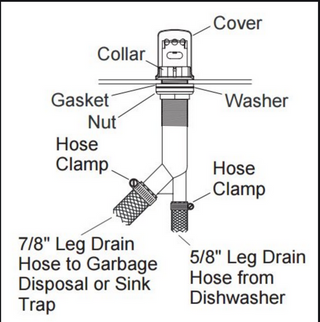

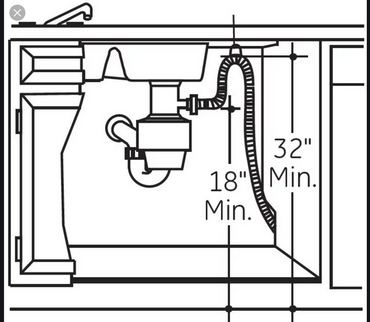

An air gap is recommended to protect the dishwasher from accidental contamination if the sewer line were to back up. If an air gap cannot be installed, at least run the drain line above the level of the sink drain to create a high loop. This was an older way of protecting the dishwasher. Hire a licensed plumber to install an air gap.

- PBB2-2 Primary Bedroom Bathroom:

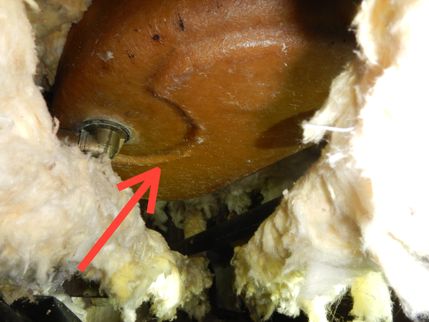

The bathtub did not appear to be adequately supported below in the crawl space. I recommend adding additional support as needed.

- PBB2-3 Primary Bedroom Bathroom:

The main bathroom in this home has carpeting for flooring. Updating this flooring is recommended as this is bad for indoor air quality and conducive to microbial growth. It can also create some sanitary health hazards.

- HB5-3 Hallway Bathroom:

The laundry room fan is loud during operation. Based on the age and visible condition of the fans, I recommend updating this fan.

- CS3-6 Crawl Space:

No positive connections were noted connecting the posts to the footings in the floor frame of the house. This is a standard practice in older construction, but makes the home more susceptible to seismic damage. Positive connections are recommended. Hire a general contractor to further evaluate and repair.

Monitors

- G-1 Grounds:

Inadequate clearance between the siding and the soils was noted. This is conducive to wood destroying organisms as it can trap water against the siding. Where possible, a gap should be provided to allow the wood to keep dry. Generally, a 6-inch clearance is recommended between siding and soils. Please note that this is a fairly common installation, and inadequate clearances can often be kept maintained by being diligent about keeping new soils, mulch and leaves from accumulating.

- RCG2-1 Roof, Chimney and Gutters:

The roofing material on this home is done in an architectural grade composition shingle. These shingles are often rated as 30 years shingles, though I find in practice 18-22 years is more realistic depending on the quality of the installation, the amount of exposure and the pitch of the roof. The roof looks to be done as an overlay, meaning there is another layer of shingles below the existing layer. In general, overlays are not recommended as they have less predictable service lives. They often suffer from non-standard installation techniques such as inadequate fastening and inadequate flashings which can lead to premature leaks, nail pops and failure. They tend to break down more quickly as well, due to heat build-up. During inspection, no red flags were found, however, I would monitor the roof for nail pops as it is difficult to predict how an installation such as this will perform.

- RCG2-4 Roof, Chimney and Gutters:

Gutters that were accessible to inspection were clean. Given this wooded setting, I would plan on regular gutter cleaning.

- K-2 Kitchen:

The appliances and finishes in the kitchen are generally old. They were in working order at the time of the inspection, but failure and breakdown should be expected at any time due to the age and visible condition of the appliances. For reliable performance, budget to update in the future.

Due Diligences

- FSD-2 Fuel Storage and Distribution:

The propane tank might be a leased tank. Inquire with the seller for more information.

- P-1 Plumbing:

Water for this home appears to be supplied by a well system. Inspection of the well, water supply and water quality is beyond the scope of this inspection. I recommend hiring a well specialist to inspect and evaluate the well and well water. Well equipment: the pump and captive storage tank have limited service lives and often require updating on a 20-year schedule. There are other elements of a well system that should be evaluated as well, such as the well production, often tested in a draw down test, water quality and well depth.

- P-2 Plumbing:

No main water shut off was found inside the house. There is typically a shut off at the meter in the street, but this can be a time-consuming and difficult shut-off to access in an emergency. Inquire with the seller for the location of the main water shut as it may be concealed behind finishes or stored items. If no readily accessible shut off exists, hire a licensed plumber to further evaluate and install.

- P-4 Plumbing:

Based on visible components, this property appears to have a private on-site septic system - see this LINK for more information. These are specialty systems and are excluded from this inspection. Comments in this report related to this system are made as a courtesy only and are not meant to be a substitute for a full evaluation by a qualified specialist. Generally, septic tanks should be pumped and inspected every 3 years. Depending on the type of system and municipal regulations, inspection and maintenance may be required more frequently, often annually. I recommend:

- Investigating any information about this system's maintenance and repair history

- Reviewing any documentation available for this system

- Learning inspection and maintenance requirements for this system

- Hire a qualified specialist evaluate, perform maintenance and make repairs as needed

Future Projects

- A-1 Attic:

Areas of damaged sheathing were noted from the previous roof installation. I tested the areas with my moisture and confirmed the materials to be dry. When re-roofing in the future, I recommend replacing all areas as needed.

Efficiencies

- A-2 Attic:

The attic insulation could be improved to modern standards, which recommend R-49 on the floor and R-21 on walls. R-value is the measure of resistance to heat loss; the higher the R-value the better the insulation. During insulation repairs it is best practices to implement any air seal-up repairs to seal air leakage. Also, be sure you have completed any wiring or other projects that are needed in the attic. Then, hire an insulation contractor to improve thermal barriers.

- CS3-5 Crawl Space:

Crawl space vents are currently blocked by organic debris in places. Remove leaves and soils from the crawl space vents and ensure the vents remain unobstructed to allow proper ventilation of the crawl space.

- CS3-7 Crawl Space:

The sub-floor insulation in the crawl space could be improved to modern standards. Insulating the sub-floor to R-30 or better is recommended for improved energy efficiency. If you do improve insulation, check for any air leakage points in the sub-floor. These are common around plumbing, wiring and HVAC penetrations and can lead to heat loss.

Inspection Notes Limitations

- GC-1 General Comments:

This inspection report has been procured by the seller and is provided for informational and disclosure purposes only. It is not intended to constituent a warranty, both expressed or implied about the condition of the property. Every effort is made on pre-listing inspections to provide the same comprehensive inspection and report as for a buyer's inspection. If you are a buyer and you are reading this report, I am happy to provide a complementary phone consult about this report once I have permission from my client to discuss the report. If repairs have been made, and re-inspection services are requested, I recommend contacting me directly about scheduling a re-inspection of the property. Please note that if you are under contract to purchase the house, Washington state requires that I provide a complete home inspection and report; I am not allowed to provide a verbal consultation.

- GC-2 General Comments:

This home was occupied at the time of the inspection. Inspection of the occupied homes presents some challenges as occupant belongings can obstruct a visual inspection of and access to parts of the home. We do out best during the inspection to work around belonging to discover as much as possible about the house without moving or damaging personal property, however, the presence of personal items does limit the inspection.

- RCG2-3 Roof, Chimney and Gutters:

A plumbing vent was too short by current industry standards. 6 inches or more is needed for anticipated snow loads. Extend the plumbing vent as feasible.

- HCFV-1 Heating, Cooling, Fireplaces and Ventilation:

Dissimilar wiring materials were in contact with each other inside of the furnace enclosure. This may allow for corrosion over time due to the reactions of the dissimilar materials. Have a licensed electrical contractor repair this condition as needed.

- HCFV-2 Heating, Cooling, Fireplaces and Ventilation:

The furnace filter access is leaking air - see photo. Adjust the installation as needed to ensure an air tight seal.

- HCFV-4 Heating, Cooling, Fireplaces and Ventilation:

The heat pump compressor system currently uses the R-22 type of refrigerant. On January 1, 2010, the Environmental Protection Agency placed a ban on the manufacture of new HVAC systems using R-22 refrigerant. General phase out of R-22 refrigerant is estimated to be complete by the year 2020. New, more efficient systems will utilize non-ozone-depleting refrigerants such as 410-A. Unfortunately, 410-A cannot be utilized in some older systems which previously used R-22 without making substantial and costly changes to the equipment. A loophole in current regulations allowed the manufacturer of units after 2010 that were delivered with no refrigerant. These units were designed for R-22 refrigerant to be installed in the field. Maintenance of this unit could pose unexpected challenges due to the growing scarcity of R-22 refrigerant and replacement of the unit may become necessary prior to the end of its expected life.

- I-1 Interior:

Doors throughout the home were in need of adjustments and general maintenance. I noted doors rubbing on their frames, doors not latching correctly and so on. I recommend a handy person adjust and repair all doors as needed.

- I-2 Interior:

A lost seal was noted in the glazing - at least 1 but more may be present when exterior conditions change. This has resulted in fogging between the panes of glass that cannot be cleaned without glazing repair or replacement. Hire a glazing specialist to further evaluate and repair or replace all glazing with lost seals.

- PBB2-1 Primary Bedroom Bathroom:

The drain stop did not function when tested. Adjust/repair the unit.

- CS3-1 Crawl Space:

The inspection of the crawl space was limited by fallen insulation and very low clearances blocking access from much of the area. Please note that this condition risks additional concealed damage that was not visible today. When the insulation had been repaired and access has been provided, I recommend an additional inspection of the areas as deemed feasible.

The Full Report

General Comments

Building Characteristics, Conditions and Limitations

Type of Building : Residential Single Family (1 story)

Approximate Square Footage: 2700

Approximate Year of Original Construction: 1980

This building likely has wiring that predates the late 1980's. Branch circuit wiring installed in buildings built prior to the late 1980s is typically rated for a maximum temperature of only 60 degrees Celsius. This includes non-metallic sheathed (Romex) wiring, and both BX and AC metal-clad flexible wiring. Knob and tube wiring, typically installed in homes built prior to 1950, may be rated for even lower maximum temperatures. Newer electric fixtures including lighting and fans typically require wiring rated for 90 degrees Celsius. Connecting newer fixtures to older, 60-degree-rated wiring is a potential fire hazard. Repairs for such conditions may involve replacing the last few feet of wiring to newer fixtures with new 90-degree-rated wire, and installing a junction box to join the old and new wiring. It is beyond the scope of this inspection to determine if any such incompatible components are installed. Based on the age of this building, be aware that such components may be present.

In 1978, federal laws were past to prohibit use of lead and asbestos in building materials. Manufacturers of building materials were allowed to sell existing stocks of materials that were manufactured with lead and asbestos, so even buildings constructed as late as the mid-1980's could possibly contain lead or asbestos. Identification and testing for lead and asbestos and other environmental testing is beyond the scope of this home inspection. If you wish to seek additional information, I recommend contacting an environmental lab or industrial hygienist.

Attending the Inspection: Seller and Listing Agent

Occupancy: Occupied

Animals Present: No

Weather during the inspection: Heavy Rain

Approximate temperature during the inspection: Below 65[F]

Ground/Soil surface conditions: Wet

For the Purposes of This Report, the Front Door Faces: Away from the driveway (Front Side)

This inspection report has been procured by the seller and is provided for informational and disclosure purposes only. It is not intended to constituent a warranty, both expressed or implied about the condition of the property. Every effort is made on pre-listing inspections to provide the same comprehensive inspection and report as for a buyer's inspection. If you are a buyer and you are reading this report, I am happy to provide a complementary phone consult about this report once I have permission from my client to discuss the report. If repairs have been made, and re-inspection services are requested, I recommend contacting me directly about scheduling a re-inspection of the property. Please note that if you are under contract to purchase the house, Washington state requires that I provide a complete home inspection and report; I am not allowed to provide a verbal consultation.

This home was occupied at the time of the inspection. Inspection of the occupied homes presents some challenges as occupant belongings can obstruct a visual inspection of and access to parts of the home. We do out best during the inspection to work around belonging to discover as much as possible about the house without moving or damaging personal property, however, the presence of personal items does limit the inspection.

Grounds

Drainage and Site Information

Clearance to Grade: Non-standard, Siding Too Close to Soils - Monitor

Downspout Discharge: Below grade

Site Description: Flat

Inadequate clearance between the siding and the soils was noted. This is conducive to wood destroying organisms as it can trap water against the siding. Where possible, a gap should be provided to allow the wood to keep dry. Generally, a 6-inch clearance is recommended between siding and soils. Please note that this is a fairly common installation, and inadequate clearances can often be kept maintained by being diligent about keeping new soils, mulch and leaves from accumulating.

Driveways/Walkways/Flatwork

Driveway: Gravel

Walkways: Gravel, Flagstone

Exteriors

Siding and Trim

Trim Material: Wood

Siding Material: Wood clapboard

Overall the siding materials were is good condition with a few localized maintenance items needed - see list below. I noted areas of missing caulking and some areas of the paint starting to show its age. I recommend caulking all penetrations around the home and touching up the paint where needed unit a full re-paint of the home is warranted.

- The paint was starting to crack and show its age at some locations - right side.

- The hose bib connection was not fully caulked and secured as needed - left side

- Areas of cable entry were missing caulking - several sides

- Caulk around the kitchen vent penetration - front side

Exterior Vent and Exhaust Terminations

Eaves

Type: Enclosed System

Exterior Doors

Type: Sliding glass, Glass panel doors, Solid core

Exterior Hose Bibs

Observations: Operating

Decks, Porches and Balconies

Decks, Porches and Balconies

General Information: Present

Structure: Ground contact treated lumber

Ledger Board & Hardware: Defects Noted (Flashings, Missing)

Guardrail: None needed

Decking Material: Plastic - Synthetic material

Posts, Beams and Footings: Too low to view areas

A few items were noted with the deck installation needing modifications - see list below. Hire a licensed decking contractor to repair these items as needed.

- No flashing were noted between the deck ledger board and the home connection. The ledger board connection was also lacking lag screws at the connection to the home as needed. This can be a difficult retrofit once the deck is constructed. No water damage was visible, but this could cause long term moisture control problems at the deck.

- Some areas of the deck support were common concrete masonry units (CMU) blocks installed on their sides. I recommend the installation of properly sized support posts with piers to support the deck materials.

Fuel Storage and Distribution

Gas, Propane and Oil Piping

Gas Piping Materials Noted: Steel

The threaded steel gas pipe will need improved support - see crawl space. General standards are to support vertical runs every 10 feet for 3/4" pipe and 12 feet for 12" pipe. Vertical runs should be supported every 15 feet.

Propane Storage

Present

Storage Type: Above ground tank

Propane Tank Size: 120 gallons

Propane Tank Location: Left side of the home

Propane Shutoff Location: At tank, At secondary pressure regulator

This shows a propane shutoff at the secondary pressure regulator - south side of house.

The propane tank might be a leased tank. Inquire with the seller for more information.

Roof, Chimney and Gutters

Roof Materials

Method of Roof Inspection: Walked on roof

Roof Style: Gable, Hip

Flashings: Present and Visually Standard

Roof Covering Materials: Architectural grade composition shingle

Approximate Age of Roof Covering: New

Overlay Roof: Yes - New and Hard to Predict Life

The roofing material on this home is done in an architectural grade composition shingle. These shingles are often rated as 30 years shingles, though I find in practice 18-22 years is more realistic depending on the quality of the installation, the amount of exposure and the pitch of the roof. The roof looks to be done as an overlay, meaning there is another layer of shingles below the existing layer. In general, overlays are not recommended as they have less predictable service lives. They often suffer from non-standard installation techniques such as inadequate fastening and inadequate flashings which can lead to premature leaks, nail pops and failure. They tend to break down more quickly as well, due to heat build-up. During inspection, no red flags were found, however, I would monitor the roof for nail pops as it is difficult to predict how an installation such as this will perform.

From the 2015 IRC

R908.3.1 Roof Re-Cover

The installation of a new roof covering over an existing roof covering shall be permitted where any of the following conditions occur:

1. Where the new roof covering is installed in accordance with the roof covering manufacturer's approved instructions

2. Complete and separate roofing systems, such as standing-seam metal roof systems, that are designed to transmit the roof loads directly to the building's structural system and do not rely on existing roofs and roof coverings for support, shall not require the removal of existing roof coverings.

3. Metal panel, metal shingle and concrete and clay tile roof coverings shall be permitted to be installed over existing wood shake roofs where applied in accordance with Section R908.4.

4. The application of a new protective coating over an existing spray polyurethane foam roofing system shall be permitted without tear-off of existing roof coverings.

R908.3.1.1 Roof Re-Cover Not Allowed

A roof recover shall not be permitted where any of the following conditions occur:

1. Where the existing roof or roof covering is water soaked or has deteriorated to the point that the existing roof or roof covering is not adequate as a base for additional roofing.

2. Where the existing roof covering is slate, clay, cement or asbestos-cement tile.

3. Where the existing roof has two or more applications of any type of roof covering.

Chimneys

Present

Chimney Material: Masonry

Chimney Flue Liners: Present

Roof Penetrations and Flashing

Roof Ventilation

Type: Soffit & Ridge Vents

Gutters and Downspouts

Gutter and Downspout Materials: Metal

Gutters that were accessible to inspection were clean. Given this wooded setting, I would plan on regular gutter cleaning.

Garage

Garage General

Garage Type: Detached

A support post for the garage covered walkway was wood decayed and no longer providing adequate support. I could put my screw driver directly through the bottom of the materials indicating post replacement may be needed. Hire a licensed general contractor to repair this condition.

Garage Doors and Automatic Openers

Overhead Garage Door Type: Wood

Automatic Garage Opener: Present

MOST COMMON: Ok - SEV

The garage doors were tested and found to be functional. Ongoing maintenance in the form of minor adjustments, greasing of the track and rollers, visual inspections of the weather stripping, and so on will be needed.

Garage Floor

Garage Slab: Not Visible

Electric Service

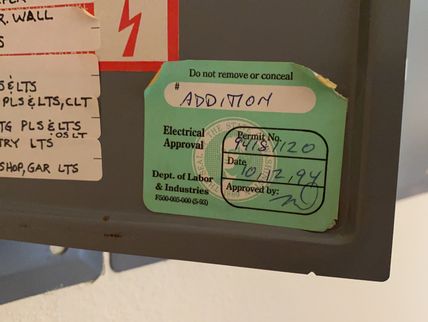

Electric Service Permits Found

Electric Service Voltage Tested

Service Voltage: 120/240

Testing Note: Testing Note

I tested the voltage at the electric panel today. It tested in a normal range of 235-245 volts. Most residential construction is listed as 120/240 volts and it is normal for some slight fluctuation.

Electric Service

Service Entrance: Above Ground

Meter Base Amperage: 150

Electric Service Equipment - Left Side

Service Entrance (SE) conductor Size: Aluminum, 4/0, 200 amps

Main Panel Amperage: 200 amps

Electric Service Amperage: 200 amps

Main Electric Panel Location: Entry Bedroom

Panel Manufacturer: Square D

Overall a few repairs are needed in the left side service equipment. I recommend an additional inspection and repairs by a licensed electrical contractor as additional repairs could be needed that are latent or concealed. Examples of observations and defects found during inspection are included below:

- Circuit breakers were of a brand different from the panel manufacture. Because circuit breakers made by different manufacturers vary in design, panel manufacturers typically require that breakers manufactured by their company be used in their panels. Breakers from one manufacturer used in the panel of another manufacturer may result in poor connections which can create a potential fire or shock/electrocution hazard.

- A few circuit breakers in the panel had corrosion noted on the materials. This can be due to foreign chemical entering the areas or related to water entry.

- Water was noted leaking inside the electric panel at a previous time and I observed corrosion in the panel.

- A knock out did not fit correctly at the enclosure cover and will need to be replaced

- The front cover was from a Squared D panel and was not originally designed for this application.

Electric Service Equipment - Right Side

Service Entrance (SE) conductor Size: Aluminum, 4/0, 200 amps

Main Panel Amperage: 200 amps

Electric Service Amperage: 200 amps

Main Electric Panel Location: Entry Bedroom

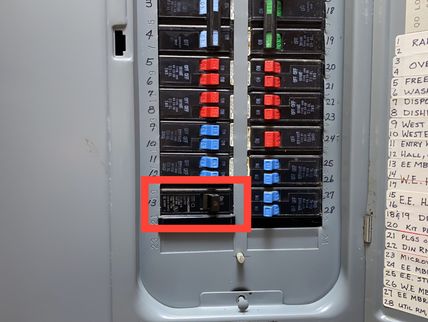

Overall several conditions were noted in the right side service equipment. I recommend an additional inspection and repairs by a licensed electrical contractor as additional repairs could be needed that are latent or concealed. Examples of observations and defects found during inspection are included below:

- Water was noted leaking inside the electric panel at a previous time and I observed corrosion in the panel.

- Grommets or bushings are needed to protect the non-metallic sheathed cable where the wiring enters the electrical panel and provide strain relief.

- Abandoned wiring was noted in the panel that was not terminated correctly

- Repair the over-fused circuit in the load center. Over-fusing risks overheating the conductor and poses greater risk for electrical fires. These #14 should be on a 15 amp breaker not a 50 amp breaker.

- The wiring gauge was too large for an installed circuit breaker and did not fit correctly -see photo below.

- The front cover was from a Squared D panel and was not originally designed for this application.

Electrical Grounding System

Information: Grounding Rod Noted

Electrical Bonding System

Information: Inter-bonding Terminal Noted

Current regulations require an “Inter-system Bonding Terminal” to be installed as a place for the low voltage utilities to run their ground wires to. It will be attached to a #6 minimum copper ground wire run to the location from the service equipment. Such a terminal was not found during inspection. Have this further evaluated and repaired by a licensed electrician.

Electric Distribution and Finish Wiring

Branch Wiring

Wire Material: Copper

Wiring Method: Non-metallic sheathed cable

Receptacles and Fixtures

Inspection Method: Random Testing, Interior Belongings Obstructing Access

The current occupant's belongings are restricting access to some of the electric receptacles. This is inhibiting access to and testing of some of the electric receptacles.

Electric Receptacles: Three wire receptacles

COMMON GFCI COMMENTS: Inconsistent With Modern Standard, GFCI - Testing Procedure Note

During inspection I test all Ground Fault Circuit Interrupter (GFCI) devices that are readily accessible. GFCI's are those receptacles with re-set buttons that you commonly see in bathrooms, kitchens and at the exterior of the home. GFCI's are important safety devices that limit the duration of electrical shocks and have demonstrably saved lives. I recommend being aware of where re-set buttons are located in the house as GFCI's can trip and disable a circuit which can not be re-energized without re-setting the button. I avoid testing to determine if a receptacle or circuit is GFCI protected if it is not clear where the re-set button can be found. This is because re-set buttons can be concealed behind stored items, so such a test risks disabling a circuit in the home. occasionally, during testing of GFCI's one can fail. This is a statistical reality that some of these devices will fail under testing and require replacement after testing.

The use of GFCI (Ground Fault Circuit Interruption) protection is inconsistent with modern minimum standards for safety - see kitchen countertops and living room bar. GFCI protection is recommended for the electrical receptacles in the following locations: the two dedicated kitchen appliance circuits, all receptacles within 6 feet of a sink, bathrooms, exterior, garage, unfinished basements, laundry and all wet and damp locations. GFCI's protect against electrocution by limiting the duration of an electrical shock. These are an important modern safety feature that have proven to save lives. Hire a licensed electrician to further evaluate and update GFCI protection for improved safety.

Overall several conditions were noted in the wiring system - see list below. I recommend additional inspection and repair of the wiring system by a licensed electrical contractor as additional repairs could be needed that are latent or concealed. Examples of observations and defects found during inspection are included here:

- There is an electric receptacle at the exterior that does not appear rated from exterior use - see front side below the deck. Replace with a proper exterior rated receptacle with an in-use cover and be sure this is GFCI protected.

- The open electrical splices in the attic needs to be contained inside of a listed junction box - see entryway attic access. It is not recommended to splice into wiring without use of a listed junction box.

- Abandoned wiring was noted in the attic near the entryway access hatch. This should be eliminated or properly terminated inside a listed junction box. It is often not feasible to determine if wire is still connected to a power source. I can test these with a voltage sensor, but they could be shut off by a switch or temporarily disconnected. For safety, all abandoned wires should be eliminated.

- Reverse polarity was noted at the electrical receptacle. This is when the hot and the neutral have been wired backwards.

- A homemade extension cord with common Romax wiring was noted at the front side of the home. This is not an exterior rated material for this application.

- Circuit testing was showing open grounds at some of the electric receptacles today - Entry suite bedroom, primary bedroom, and so on. An open ground is often a case of never connecting a ground to the receptacle or forgetting to reconnect the ground if they had occasion to disrupt it. I did see grounding conductors in the electric panel and this house has three-wire system where I tested. Have this further investigated and repaired as recommended by a qualified electrical contractor.

- The missing cover plates to electric receptacles, switches and junction boxes should be installed to cover all access to wiring at switches and receptacles.

- Several mystery switches were found in the home as well that had no obvious usage.

Ceiling Fans

Ceiling Fans: Present and Tested

Low Voltage Wiring

Information: Limitations

- Low voltage wiring systems, including timers and sensors, are not part of this inspection.

- Security and alarm systems are not within the scope of this inspection.

- Evaluation of auxiliary, low voltage, electric or electronic equipment (e.g., TV, doorbell, computer, cable, lightning protection, surge protection, low voltage lighting, intercoms, site lighting, etc.,) is not performed as part of a standard home inspection.

- Unless otherwise noted no determination is made as to whether any electrical component has the proper UL Listing. Permanently installed light fixtures made in other countries sometimes do not have the proper UL Listing indicated on them.

Plumbing

Water Service Supply

Pipe Material: Unknown

Water Supply: Shared well

Water Pressure: Water Pressure Tested, 50 PSI

This shows the water pressure tested during inspection. Generally, "normal water pressure," should be between 30-80 PSI, though pressures near or below 30 can result in poor functional flow to fixtures. Water pressures in excess of 80 PSI risk damaging supply piping components and should be controlled with a pressure reducing valve.

Pressure Reducing Valve: None noted

Main Water Shut-off Location: Not Found - House

Water for this home appears to be supplied by a well system. Inspection of the well, water supply and water quality is beyond the scope of this inspection. I recommend hiring a well specialist to inspect and evaluate the well and well water. Well equipment: the pump and captive storage tank have limited service lives and often require updating on a 20-year schedule. There are other elements of a well system that should be evaluated as well, such as the well production, often tested in a draw down test, water quality and well depth.

No main water shut off was found inside the house. There is typically a shut off at the meter in the street, but this can be a time-consuming and difficult shut-off to access in an emergency. Inquire with the seller for the location of the main water shut as it may be concealed behind finishes or stored items. If no readily accessible shut off exists, hire a licensed plumber to further evaluate and install.

Distribution Pipe

Pipe Insulation: Present

Supply Pipe Materials: Copper

Functional Flow: Excellent

Circulation Pump: None Noted

Angle Stop Testing Note

Angle stops are the shut offs located below plumbing fixture such as sinks and toilets. These are designed so that water can be shut off locally to a fixture without shutting off the water to the entire house so that localized fixtures can be serviced and repaired or replaced. Home inspectors do NOT test angle stops during inspection as there is a risk of leakage.

The Polybutylene (PB, gray plastic) supply hoses and angle stops noted below several sinks are an unreliable plumbing product with a reputation for failing fittings. Updating to copper or braided steel supply hoses and new angle stops is recommended. These are common to find in 1990's era buildings. Consult with a licensed plumber to further evaluate and repair.

Waste Pipe and Discharge

Discharge Type: Septic system

Please note that when the sewage discharge type is listed here, it is listed based on public records and disclosure. It is always possible that the system is not as it is listed; for example, a property could be listed as a public sewer system when in fact it is on a private septic system. This is unlikely, but is another reason why we recommend further evaluation of all sewage discharge systems.

Waste and Vent Pipe Materials: ABS plastic

Based on visible components, this property appears to have a private on-site septic system - see this LINK for more information. These are specialty systems and are excluded from this inspection. Comments in this report related to this system are made as a courtesy only and are not meant to be a substitute for a full evaluation by a qualified specialist. Generally, septic tanks should be pumped and inspected every 3 years. Depending on the type of system and municipal regulations, inspection and maintenance may be required more frequently, often annually. I recommend:

- Investigating any information about this system's maintenance and repair history

- Reviewing any documentation available for this system

- Learning inspection and maintenance requirements for this system

- Hire a qualified specialist evaluate, perform maintenance and make repairs as needed

Additional Sinks

Observations: Tested

Corrugated waste pipe was used to drain this entryway sink. This is not a listed plumbing product and tends to indicate plumbing work that has not been done by a licensed plumber. Use smooth wall pipe only. Hire a licensed plumber to further evaluate and repair as needed.

Water Heater

Water Heater - Entry Suite Bathroom

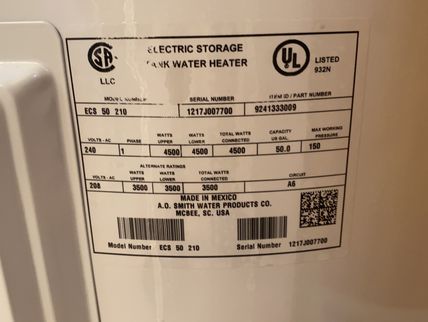

Manufacturer: A.O.Smith

System Type: Tank

Size: 50 gal

Age: 2012

Energy Source: Electricity

Straps : Present

Pad: Present

Drain Pan: None Noted - Recommended

Expansion Tank: Present

Temperature Pressure Relief Value: Present - Not Tested

The temperature and pressure relief valve is arguably one of the most important safety devices in your house. Should the thermostats fail inside your water heater, this allows excess pressure to "blow off," which will prevent catastrophic build up of temperature and pressure which can make water heaters explosive. I do not test the "blow off valve" during inspection as there is a risk it could stick open and testing could cause the need for a repair. It is recommended that these be inspected annually; I would at least ask for a plumber to test the device every time I had a plumber out for any other job.

Water Heater - Primary Bedroom Closet

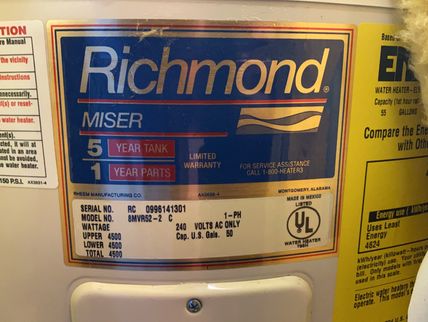

Manufacturer: Richmond

System Type: Tank

Size: 50 gal

Age: 1996

Energy Source: Electricity

Straps : None Found

Expansion Tank: None Noted - Recommended

Temperature Pressure Relief Value: Present - Not Tested, Terminates Horizontal

The temperature and pressure relief valve is arguably one of the most important safety devices in your house. Should the thermostats fail inside your water heater, this allows excess pressure to "blow off," which will prevent catastrophic build up of temperature and pressure which can make water heaters explosive. I do not test the "blow off valve" during inspection as there is a risk it could stick open and testing could cause the need for a repair. It is recommended that these be inspected annually; I would at least ask for a plumber to test the device every time I had a plumber out for any other job.

Overall, several conditions were noted with the water heater installation. Due to the age of the unit, performing these repairs may not be cost effective and replacement is recommended instead due to age. Examples of my observations and defects found during inspection are included below:

- This is a very old water heater. Replacement is recommended for improved reliability as this unit could fail at any point. The average life of these water heaters is 8-16 years. The service life of a water heater will depend on a variety of factors such as water quality and regular scheduled maintenance such as flushing the tank and replacing sacrificial anodes.

- Install listed seismic straps to restrain the water heater in the event of an earthquake; none were noted during inspection. Two straps should be located on the water heater: one on upper 1/3rd of tank and one at the lower 1/3rd.

- The discharge tube for the water heater temperature and pressure relief valve (TPRV) is not correctly installed - see attached link. The piping terminated horizontally at the exterior of the home and had an improper connection near the TPRV itself. This is a potential safety hazard.

Water Temperature

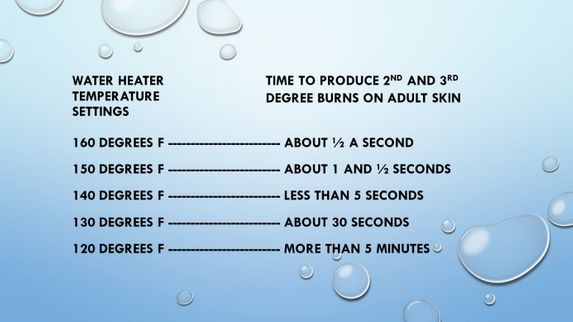

Water Temperature Measured During Inspection: Acceptable

This shows the water temperature measured during inspection. The range of 120-125 degrees F is the generally recommended temperature.

Laundry and Additional Plumbing

Washer

Observations : Tested

The washing machine was tested through a cycle and found to be functional. My testing is not exhaustive and I cannot comment on the ability to clean clothing items.

Here is a link to washing machine maintenance tips: LINK

Common Conditions: Not Secured To Drain, Update Hoses

A few upgrades could be performed at the washer installation - see list below.

- The drain piping for the washing machine was not secured as needed. As the washer drains, the piping will pulsate and can back out over time. I recommend the piping be mechanically fastened to the nearby water piping and/or similar.

- For improved reliability, update the old water supply connectors to the washing machine. These are old and should be regularly swapped out to prevent accidental leaks from bursting hoses. Consider improving the reliability of this water supply by installing a flood safe hose system.

Dryer

Observations: Tested

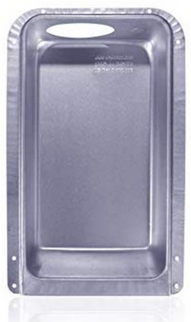

Proper dryer exhaust venting is critical for safe and reliable performance from the dryer. Here are some basic rules of thumb for dryer exhaust duct installation: Unless a vent-free appliance is being used, the dryer exhaust vent must terminate outdoors. It should be no more than 25 feet long and for every 90 degree turn subtract 5 feet and for every 45 degree bend subtract 2.5 feet. Use only smooth-wall metal vent pipe @ 4 inch pipe diameter. Do not use plastic pipe and plastic flex pipe. If a flexible connector is needed behind the dryer use a short amount of corrugated metal pipe. If the exhaust duct is getting pinched behind dryer, consider use of a dryer vent box, pictured here. Flex and corrugated pipes should never be used in concealed spaces such as through walls or in attic or crawl spaces. Insulate dryer exhaust duct where it passes through unconditioned spaces to prevent condensation that could hasten lint build-up inside the pipe. Do not use screws to connect pipe as these can trap lint. Secure duct with foil tape as needed. Be sure duct is sleeved properly so that it will not trap lint and clean the vent regularly, especially if it is a long exhaust run.

Power Source: Electric

Exhaust Duct: Ducted to Exterior

Several conditions were noted with the installation of the dryer venting systems. Hire a general contractor to repair and upgrades the system to ensure safe functionality. My observations include:

- The dryer exhaust ductwork should be insulated where run outside of the thermal envelope of the building; this is to prevent condensation forming inside the duct that could trap lint. Accumulation of dryer lint can be a fire hazard. Insulate this exhaust duct for improved safety and performance - see crawl space

- The dryer vent is currently partially disconnected in the crawl space.

- The dryer vent should be cleaned annually for safety purposes and proper functionality. If this service had not been done in the last year I recommend it be cleaned prior to first use. Inquire with the seller to see if they have had the dryer exhaust duct recently cleaned.

Ventilation and Fans

Observations : Missing

The laundry room did not have a ventilation system as needed to remove humid air. Consult with a general contractor for costs and options to have a fan installed in your laundry room.

Heating, Cooling, Fireplaces and Ventilation

Heating System

Energy Source: Electricity

Heating Method: Electric forced air furnace, Electric baseboard heaters

The heating system was tested and found to be functional with heat sources in each room. An electric furnace uses a blower fan and motor to send air through the heating elements and then into the ventilation system. In most central systems, this same blower fan works with the AC (if equipped), and so it undergoes a great deal of stress during the year. Maintenance checks the blower fan and motor to see they aren’t damaged or wearing down. Lubricating and cleaning the motor are important parts of maintenance.

Checking the heating elements—the parts of the furnace that heat up with electric current in order to transfer heat to the air—is also a key part of maintaining the furnace. The elements may need cleaning, their connections tightened, or broken ones replaced.

The heating elements also known as heat strips typically have multiple “sets” of strip heating controlled by relays and sequencers. It’s not uncommon for one or two sets of strip heat to fail while others still work. This issue often goes undetected and causes the heat to run much longer than necessary to warm your home, costing you money and comfort. There are many other crucial steps, such as checking the thermostat calibration and changing the air filter that can all be down during annual maintenance of the heating system by a licensed HVAC contractor.

Electric/hydronic baseboard heaters are zonal heaters controlled by thermostats located within each room. Baseboard heaters contain electric heating elements encased in metal pipes. The pipes, surrounded by aluminum fins to aid heat transfer, run the length of the baseboard heater's housing, or cabinet. As air within the heater is warmed, it rises into the room, and cooler air is drawn into the bottom of the heater. Some heat is also radiated from the pipe, fins, and housing.

Baseboard heaters are usually installed underneath windows. There, the heater's rising warm air counteracts falling cool air from the cold window glass. Baseboard heaters are seldom located on interior walls because standard heating practice is to supply heat at the home's perimeter, where the greatest heat loss occurs.

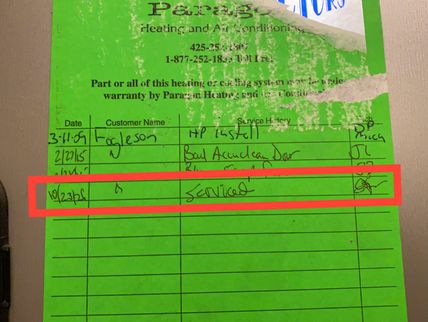

Manufacturer: Payne

Capacity: Unknown

Age: 2008

Data Plate: Shown Here

Last Service Record: Service Records and Listing Plate Pics

These photos show the most recent service records on the furnace as well as the listing plate.

Dissimilar wiring materials were in contact with each other inside of the furnace enclosure. This may allow for corrosion over time due to the reactions of the dissimilar materials. Have a licensed electrical contractor repair this condition as needed.

Air Filters

Filtration Systems: Electronic

The heating system has an electrostatic air filter installed. This are above-average filtration systems that can be cleaned rather than a paper disposable filter. Be sure to clean the filter at least quarterly to ensure reliable air flow. Most of these filters have 4 pieces: 2 pre-filters and 2 main filters. Be sure to disconnect the power to the unit prior to cleaning.

The furnace filter access is leaking air - see photo. Adjust the installation as needed to ensure an air tight seal.

Cooling Systems and Heat Pumps

Air Conditioning / Heat Pump: Heat Pump Present

Manufacturer: Payne

System Type: Air Source

Energy Source: Electric

Age: 2007

The heat pump system was tested in the heating mode only during the inspection due to exterior temperatures. This is an older unit and the design life of a heat pump system is 15-20 years. I recommend having the system serviced/inspected by a licensed HVAC contractor and to have the refrigerant charge checked to ensure proper performance. Proper refrigerant change is important for the system to perform as intended and this is not visible or within the scope of a home inspection. Observations and noted made during inspection include:

The heat pump compressor system currently uses the R-22 type of refrigerant. On January 1, 2010, the Environmental Protection Agency placed a ban on the manufacture of new HVAC systems using R-22 refrigerant. General phase out of R-22 refrigerant is estimated to be complete by the year 2020. New, more efficient systems will utilize non-ozone-depleting refrigerants such as 410-A. Unfortunately, 410-A cannot be utilized in some older systems which previously used R-22 without making substantial and costly changes to the equipment. A loophole in current regulations allowed the manufacturer of units after 2010 that were delivered with no refrigerant. These units were designed for R-22 refrigerant to be installed in the field. Maintenance of this unit could pose unexpected challenges due to the growing scarcity of R-22 refrigerant and replacement of the unit may become necessary prior to the end of its expected life.

Heating and Cooling Distribution Systems

Gas Fireplaces

Fan Present: Yes

System Responded to Testing: Yes