How to Read This Report

This digital report or a printed version of this report should only be viewed in full color where the photos are discernible and on a device where the report page width is no less than 8.5" wide. Please note, Right and Left of the building are determined as facing the front of building shown on the report cover. The client has the duty and obligation to read the entire report. Feel free to reach out to the inspector should you have any questions or concerns.

This report is designed to inform the client of obvious major structural deficiencies, inoperative conditions and the presence of noticeable, detrimental moisture issues for areas inspected. Additionally, the inspection report may advise regarding notable safety concerns and appropriate upgrades recommended by the inspector that you should consider and act on when appropriate. Please note, undesirable conditions pertaining to this inspection may be present and unreported for concealed areas and areas with limited or blocked access.

Photos

Photos included in this report are intended to help describe a reported item or area only. The photos, while representative, may not encompass the full scope of work required to correct the item or area listed. Repairs should be based on actual condition of property and not solely on the photos included in this report. Note, when viewing photos in the online report, clicking on a photo will zoom in and enlarge the photo. Clicking on a photo a second time will enlarge and zoom in on the photo one more time.

Repairs

Repairs or corrections needed at the inspected property should be completed by competent qualified professions familiar with the type of work being performed. Obtain competitive bids as needed. Obtain further evaluation when needed.

Getting the Information to You

This report is designed to deliver important and technical information in a way that is easy to access and understand. The best way to get the layers of information that are presented in this report is to read your report online in the HTML format, which will allow you to expand your learning about the inspected property. You will notice some words or series of words highlighted in blue and underlined – clicking on these will provide you with a link to additional information, if desired. Other text colors, if present, have no real meaning. Please read all written text.

This report can also be printed on paper or to a PDF document.

Chapters and Sections

This report is divided into chapters that parcel the home into logical inspection components. Each chapter is broken into sections that relate to a specific system or component of the home. You can navigate between chapters with the click of a button on the left side margin when viewing the report online.

Observation Labels

Narrative observation labels are defined here. Some of the following observation labels may not appear in all reports. Hazardous, Key Concerns and Further Evaluation observation label types, if used, will appear in the report and in the summary. All other observation labels, when used, appear only in the report and will not appear in the summary. All narrative observation label types are labeled, and numbered to help differentiate each reported narrative observation. When narrative observation labels are given a color, the specific color used has no meaning. Some observation labels are given a specific icon to group the observation types. The specific icon used also has no meaning.

Observation labels and colors used for reporting are:

- Key Concerns:Observations listed as key concerns will typically include inoperative equipment, common and significant corrections needed for plumbing, electrical, heating/cooling, structure, interior and exterior areas including the roof covering. When used, this observation will appear in the report and in the summary.

- Further Evaluation:Observations listed as further evaluation need a more extensive or technically exhaustive evaluation. For areas where corrections may not be straight forward or where a proper plan should be developed to implement corrections, then further evaluation is recommended. To obtain further evaluation is to hire a specialist that is highly experienced in the repair or correction of a specific item or area. Some observations listed under other labels that also require further evaluation will appear under the other label only. When used, this observation will appear in the report and in the summary.

- Periodic Maintenance Needed:Observations listed as periodic maintenance needed are items or areas that are expected to have maintenance performed at some interval. Maintenance neglect may be from lack of maintenance knowledge or lack of adequate funding for periodic maintenance. Some irregular or substandard installations may need more frequent maintenance until properly replaced. Start dates and intervals for periodic maintenance are a matter of personal judgment. When used, this observation will appear only in the report.

- Safety Concerns:Observations listed as safety concerns are items or areas listed to help reduce the risk of personal injury. Safety standards and expectations change. Consideration should be given to evaluate and act upon your risk exposure to help reduce the risk of personal injury. Some observations listed under other labels that are also safety concerns will appear under the other label only, such as electrical repairs, which almost always pose some safety risk. Some safety concerns may also be considered improvements but will fall under the safety concerns label if deemed more appropriate. When used, this observation will appear only in the report.

- Routine Correction Needed:Observations listed as routine correction are not unusual for the type and age property inspected. These routine items are typically not recurring and once properly corrected should not require repetitive correction. When used, this observation will appear only in the report.

- Monitor:Observations listed as monitor are typically items or areas that need subsequent observations and should be monitored over time to obtain historical data. These items may or may not require correction in the future based upon their performance over time. If you are unable to do the monitoring, the inspector recommends you appropriately schedule monitoring by a qualified competent contractor. Some observations listed under other labels that also may require monitoring will appear under the other label only. When used, this observation will appear only in the report.

- Improve:Observations listed as improve are items or areas that were ready for improvement or upgrade. This label is used for predictable expected opportunities to better the property condition or installation deficiencies that may or may not affect equipment function. Some observations listed under other labels that also may be considered improvements will appear under the other label only. When used, this observation will appear only in the report.

- Note:Notes are general remarks or comments elaborating on descriptions of systems, limitations, restrictions, or other similar conditions present during the inspection. Notes do not appear in the summary.

- Inspector Informational Note:Inspector informational note regarding inspection process.

- Description:Descriptive information for various aspects of the property, equipment, items, or areas noted during the inspection. Descriptions do not appear in the summary.

- Deck Description:Description of observed deck conditions and issues.

Summary Page

For convenience, the report contains a summary. The inspector uses the Summary to list non Periodic Maintenance issues that, in his opinion, he would expect to be completed before marketing the home for sale. Be advised, the summary contains only text from the observations listed as Key Concerns, Further Evaluation Needed, Hazardous and when applicable, New Construction Builder Punch List Items. The summary does not show any photos or photo captions that may be listed with an observation. The summary provides the least information for the observations listed.

The report body contains the most information and includes full descriptions, digital photographs, captions, and when applicable, diagrams, videos and hot links to additional information. Refer to the report body when making actual corrections, upgrade or repairs. Please understand that you have a duty and obligation to read the full report.

Summary

Key Concerns

- K-1 KITCHEN:

Kitchen Beneath Sink - Horizontal Plumbing Waste Piping Stays Flooded

Irregular plumbing waste drain installation observed leaves horizontal piping before the water seal trap (P Trap) flooded rather than leaving water only at the water seal trap. Proper correction is recommended as unnecessary clogging may occur.

- K-2 KITCHEN:

Dishwasher ────

Dishwasher drain line appeared to discharge after the water seal trap at the kitchen sink waste drain. The dishwasher drain line should be properly relocated to an area before the water trap at the kitchen sink waste drain to eliminate any chance of sewer gases from entering the dishwasher.

- K-3 KITCHEN:

Ducted Exhaust ────

Kitchen exhaust fan appeared to discharge to the attic area as it was aimed towards a roof deck vent but did not properly exhaust directly to an exterior area. For safety this unit should properly exhaust directly to the exterior or be properly converted to a ductless or recirculating exhaust. Refer to the installation instructions. Properly correct or replace kitchen exhaust as needed for function and safety. Correct any affected areas, if needed.

- B-2 BATHROOM:

Location 1/2 Bathroom Upstairs Front ──── ────

Area: Sink Faucet

The Hot and Cold faucet outlets appeared to be reversed and should be properly changed for safety to help prevent scalding.

- P-1 PLUMBING:

Water Heater ──── ────

Questionable Installation

Water heater did not appear to meet manufacturer installation standards for proper installation when inspected. Refer to installation instructions and have a competent contractor correct as needed for function and safety.

- CS-1 CENTRAL SYSTEM:

Cooling System ──── ────

Condensate leak pan was expected and not present. Cooling system evaporator coils installed at, adjacent to, or above a finished living space should have a properly installed condensate overflow leak pan to help minimize damage to finished areas when the system malfunctions. A properly installed float switch should be present at the overflow pan to switch off the condensing unit when the condensate drain becomes clogged or a separate drain should be present for the overflow pan that drains directly to an exterior area. Consider having a qualified competent heat/cool contractor properly correct area to control unnecessary preventable damage.

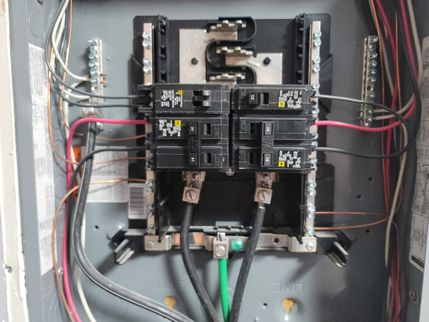

- E-1 ELECTRICAL:

Main Breaker Panel Basement ────

Multiple corrections were needed at electrical distribution panel. A competent electrical contractor should further evaluate this area. Make proper corrections as needed for safety and function now. Refer to the full report for additional information and photos regarding obvious corrections recommended for this electrical panel.

- E-2 ELECTRICAL:

Sub Breaker Panel Basement ────

Multiple corrections were needed at electrical distribution panel. A competent electrical contractor should further evaluate this area. Make proper corrections as needed for safety and function now. Refer to the full report for additional information and photos regarding obvious corrections recommended for this electrical panel.

- E-3 ELECTRICAL:

Sub Breaker Panel Garage Detached ────

Multiple corrections were needed at electrical distribution panel. A competent electrical contractor should further evaluate this area. Make proper corrections as needed for safety and function now. Refer to the full report for additional information and photos regarding obvious corrections recommended for this electrical panel.

- E-4 ELECTRICAL:

Branch Wiring

Multiple corrections were needed to improve the safety of the electrical branch wiring. These corrections are usually non-recurring once properly completed. A competent electrical contractor should review the installed branch wiring making proper corrections where needed for both safety and function.

- Representative Photos Provided

- E-5 ELECTRICAL:

Electrical Receptacle Outlet Hot/Neutral Reversed ────

One or more electrical receptacles tested as having hot/neutral reversed. Reversed wiring can damage sensitive equipment such as computers and poses safety concerns. Properly correct reversed hot/neutral wiring conditions where needed for function and safety.

- Electrical receptacle at enclosed deck area tested hot/neutral reversed.

- E-6 ELECTRICAL:

Lighting

Some lighting was inoperative when inspected. Some light fixtures were improperly installed. Check all lighting/fans making functional and safe where needed.

Representative Photos Provided

- AL-1 ATTIC LADDER:

Attic ladder was observed ready for corrections now and before use to improve the function and safety aspects of the attic ladder. Refer to the full report for additional information and photos regarding obvious corrections recommended now for the attic ladder area. A competent qualified contractor capable of reading and following the manufacturer installation instructions should check all attic ladder areas. Make attic ladder functional, safe and structurally sound where needed.

- R1-1 ROOF:

Roofing covering was ready for corrections now.

A competent roofing contractor should check entire roof system and associated flashings. Properly repair or replace roof covering system as needed.

Roof Covering was Ready for Correction

- Representative Photos Provided

- Some roof shingles observed improperly installed. Refer to installation instructions properly correcting where needed. Dimensional shingles at roof valleys typically should not be woven.

- Temporary repairs observed. Execute permanent corrections where needed. Flashing was expected at chimney where sealant was present at chimney perimeter. Properly install roof flashing where omitted.

- Remove vegetation debris from roofing where needed.

- D-1 DECK:

Deck areas were observed ready for corrections now and before use to improve the structure of the deck and to improve the safety aspects for the fall prevention measures installed at deck areas. Refer to the full report for additional information and photos regarding obvious corrections recommended now for any deck areas. A competent deck contractor should check all deck areas. Make deck areas functional, safe and structurally sound where needed.

- Representative Photos Provided

Further Evaluations

- CS-2 CENTRAL SYSTEM:

Inspection performed does not determine system adequacy. Capacity of central heat/cool unit appeared undersized for reported (square footage) area served. A competent heat/cool contractor should further evaluate system and perform load/distribution analysis properly correcting system as needed.

- 4 ton heat pump appeared insufficient to serve reported 4124 sqft home.

- SH-1 Space Heating:

Instructions for wood burning stoves must be closely adhered to and these instructions often vary by manufacturer. Wood burning stoves are not fully evaluated when inspected. The inspector recommends further evaluation by a chimney specialist and a revue of installation and maintenance instructions before use.

- SH-2 Space Heating:

Wood stove chimneys should be evaluated when having the wood stove evaluated. Properly correct if needed for function and safety before use.

- LG-1 LOTS and GROUNDS:

Properly maintain storm water drainage to protect building and driveway.

- Storm water drainage piping beneath driveway appeared smaller than expected. Consider having further evaluation to determine adequacy for piping beneath the driveway to serve storm water drainage. Inspection or evaluation of such drainage systems is beyond the scope of the inspection performed.

The Full Report

About the Inspection Process

Home Inspection: Scope and Purpose of a Home Inspection

The Scope and Purpose of a Home Inspection

Purchasing property involves risk

The purpose of a home inspection is to help reduce the risk associated with the purchase of a structure by providing a professional opinion about the overall condition of the structure. A home inspection is a limited visual inspection and it cannot eliminate this risk. Some homes present more risks than others. We cannot control this, but we try to help educate you about what we don’t know during the inspection process. This is more difficult to convey in a report and one of many reasons why we recommend that you attend the inspection.

A home inspection is not an insurance policy

This report does not substitute for or serve as a warranty or guarantee of any kind. Home warranties can be purchased separately from insuring firms that provide this service.

A home inspection is visual and not destructive.

The descriptions and observations in this report are based on a visual inspection of the structure. We inspect the aspects of the structure that can be viewed without dismantling, damaging or disfiguring the structure and without moving furniture and interior furnishings. Areas that are concealed, hidden or inaccessible to view are not covered by this inspection. Some systems cannot be tested during this inspection as testing risks damaging the building. For example, overflow drains on bathtubs are generally not tested because if they were found to be leaking they could damage the finishes below. Our procedures involve non-invasive investigation and non-destructive testing which will limit the scope of the inspection.

This is not an inspection for code compliance

This inspection and report are not intended for city / local code compliance. During the construction process structures are inspected for code compliance by municipal inspectors. Framing is open at this time and conditions can be fully viewed. Framing is not open during inspections of finished homes, and this limits the inspection. All houses fall out of code compliance shortly after they are built, as the codes continually change. National codes are augmented at least every three years for all of the varying disciplines. Municipalities can choose to adopt and phase in sections of the codes on their own timetables. There are generally no requirements to bring older homes into compliance unless substantial renovation is being done.

This is just our opinion

Construction techniques and standards vary. There is no one way to build a house or install a system in a house. The observations in this report are the opinions of the home inspector. Other inspectors and contractors are likely to have some differing opinions. You are welcome to seek opinions from other professionals.

The scope of this inspection

This inspection will include the following systems: exterior, roof, structure, drainage, foundation, attic, interior, plumbing, electrical and heating. The evaluation will be based on limited observations that are primarily visual and non-invasive. This inspection and report are not intended to be technically exhaustive.

Your expectations

The overall goal of a home inspection is to help ensure that your expectations are appropriate with the house you are proposing to buy. To this end we assist with discovery by showing and documenting observations during the home inspection. This should not be mistaken for a technically exhaustive inspection designed to uncover every defect with a building. Such inspections are available but they are generally cost-prohibitive to most home buyers.

Home Inspection Agreement

Inspection Agreement

Major Structural and Electromechanical Inspection

HomePro Inspection, Inc. agrees to conduct an inspection for the purpose of informing the CLIENT of major deficiencies in the condition of the property in accordance with the Standards as set forth by the American Society of Home Inspectors (ASHI) and the State of Tennessee. The inspection and written report are performed and prepared for the sole, confidential and exclusive use and possession of the CLIENT; the report is nontransferable.

The written report will include the following only:

- general exterior, including roof, siding, windows, chimney, drainage and grading

- structural condition of foundation & frame

- electrical, plumbing, hot water heater, heating and air conditioning

- general interior, including ceilings, walls, floors, windows, insulation and ventilation

Maintenance and other items may be discussed but they are not a part of the inspection. The report is not a compliance inspection or certification for past or present governmental codes or regulations of any kind and is only based on the inspector’s opinions.

It is understood and agreed that the inspection will be of readily accessible areas of the building and is limited to visual observations of apparent conditions existing at the time of the inspection only. Latent and concealed defects and deficiencies are excluded from the inspection; equipment, items and systems will not be moved or dismantled. When the inspection is for only one or a limited number of systems or components, the inspection is limited to only those systems or components that were inspected. Detached structures are not included. HomePro Inspection, Inc. will be under no obligation under any circumstances for any further follow-up inspection.

ENVIRONMENTAL HAZARDS including Asbestos, Mold, Fungus, Lead, Radon, Cockroaches, Rodents, Pesticides, Treated Lumber, Mercury, Carbon Monoxide, Urea Formaldehyde, Toxic Wastes, Polluted Water, Contaminants and all Pollutants and Hazardous Materials or other similar environmental hazards are not part of this Home Inspection. In addition, no inspection for household insects or unwanted animals will be done.

This report does not address Subterranean Systems or system components for Sewage Disposal, Water Supply, or Fuel Storage or Delivery. Auxiliary systems such as Alarm, Security, Intercom, other low voltage wiring, Generator, Private Water, Sprinkler, Elevator, Central Vacuum, Refrigerators, Laundry Equipment, Solar, Swimming Pools, Hot Tubs, Saunas, Space Heaters, Window Air Conditioners and or any system not considered a part of the major building systems are not a part of the inspection process.

The parties agree that the HomePro Inspection, Inc., and its employees and agents, assume no liability or responsibility for the cost of repairing or replacing any unreported defects or deficiencies, either current or arising in the future, or for any property damage, consequential damage or bodily injury of any nature. THE INSPECTION AND REPORT ARE NOT INTENDED AS A GUARANTEE OR WARRANTY, EXPRESSED OR IMPLIED INCLUDING REGARDING THE ADEQUACY, OR PERFORMANCE OF ANY INSPECTED STRUCTURE, ITEM OR SYSTEM. THE HOMEPRO INSPECTION, INC. IS NOT AN INSURER OF ANY INSPECTED CONDITIONS.

It is understood and agreed that should HomePro Inspection, Inc. and/or its agents or employees be found liable for any loss or damages resulting from a failure to perform any of its obligations, including but not limited to negligence, breach of contract or otherwise, then the liability of HomePro Inspection, Inc. and/or its agents or employees, shall be limited to a sum equal to the amount of the fee paid by the CLIENT for the Inspection and Report.

The parties agree that the faxed or digital copy of the agreement is to be relied upon in lieu of the original.

Acceptance and understanding of this agreement are hereby acknowledged:

General Comments

Building Characteristics, Conditions and Limitations

Type of Building : Single Family Home

Site Built

Approximate Square Footage: 4142

Approximate Year of Original Construction: 1969

Weather during the inspection: Partly Cloudy

Approximate Low Temperature During Inspection: 60[F]

Approximate High Temperature During Inspection: 65[F]

Ground/Soil surface conditions: Damp

INTERIOR

Access

Furniture, Property, Rugs

Access and visibility was limited at interior areas as furnishings, personal property and area rugs were present.

Walls

Wall Materials: Drywall, Paneling

Some wear noted. Recondition as desired.

Ceilings

Ceiling Materials: Drywall

Serviceable, fulfilling its function.

Flooring

Floor Covering Materials: Engineered Flooring, Tile

Some wear noted. Recondition as desired.

Doors at Interior

Doors at Interior: Some door operation could be improved

Doors to Exterior

Door Condition: Hinge Screws

────

Screws were missing at hinges that are designed to connect the door frame to the structure. Refer to installation instructions properly completing door installation where needed.

- Hinge Screws to Structure Were Missing Right Door

- Hinge Screws to Structure Were Missing Left Door

Glazing/Glass

Insulated glass was present.

Windows

Metal framed windows were present.

Vinyl framed windows were present.

Wood framed windows were present.

Screens

Window screens are not required on homes with central cooling system air conditioning. Install window screens where missing, if desired.

Serviceable

A representative number of accessible windows were operated and were found generally serviceable within the parameters of their given service life.

Refurbish Before Painting

Refurbish before painting windows. A quality paint or stain job will include washing/cleaning all areas to be painted, repair/replacement of damaged areas, seal all gaps, prime all unpainted areas and sufficient paint coverage to achieve desired color without bleed through.

Stairs/Railings Interior

Diagram: Older Railing & Stairs

Railings and Stairs, as expected, appeared older and did not meet current safety standards. Railings and stairs were ready for modernization for improved safety. Evaluate your risk exposure. Consider proper repair or replacement of stairs and railings where needed now for safety and function.

GARAGE

DETACHED GARAGE

GARAGE TYPE: Detached

Garage Location: Left

Garage Restrictions: Excess Stored Items

Garage Floor: Floor Cracks Multiple

________________________________________________________________________________________________________________________________________________________________

DETACHED GARAGE OVERHEAD DOOR: Two Installed

Overhead Door Material: Metal

Overhead Door Insulation: Partially Insulated

Detached Garage Overhead Door Operation: Tested Using Operator

________________________________________________________________________________________________________________________________________________________________

DETACHED GARAGE OVERHEAD DOOR OPERATOR: Testing Garage Overhead Door Operators

Testing Garage Overhead Door Operators

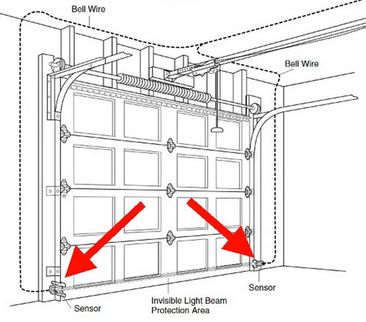

Garage overhead door operators require periodic maintenance to maintain safe operation. Electric overhead operators are checked for function and safety during the inspection. Modern garage overhead door operators have two safety reversal means, Contact Reversal and Non Contact Reversal. Contact Reversal is when the garage overhead door hits an obstruction and the operator should reverse for safety. Non Contact Reversal is when the electronic eye detects an obstruction without the garage overhead door hitting an object and the operator should reverse for safety.

The Contact Reversal of the garage door operator is tested using a 1.5 inch obstruction on the floor at the center point of the door. If the Contact Reversal requires correction this is typically accomplished by a simple adjustment on the operator but other corrections could also be necessary. See operator owners manual for additional details.

The Non Contact Reversal is tested by obstructing the electronic eyes, if installed properly, while the electric operator is closing the garage overhead door. The installed height of the electronic eyes varies slightly by manufacture but most typically advise installing the electronic eyes no more than six inches above the floor. If the electronic eyes require adjustment this is typically accomplished by remounting or correcting the aim of the eyes but other corrections could also be necessary. See overhead door operator owners manual for additional details. If the electronic eyes are out of alignment the operator will not close the garage overhead door without pushing and holding the wired push button until the garage overhead door is fully closed.

Overhead Door Operator: Two Installed

Electronic Eyes / Non Contact Reversal: Eyes Functional

Attached Garage Both Overhead Door Operators

Overhead door operator, non contact reversal means, electronic eyes, tested functional.

Contact Reversal: Contact Failed

Attached Garage Both Overhead Door Operators

Overhead door operator contact reversal means failed pinning an obstruction. It is not uncommon for the garage overhead door operators to require minor adjustment periodically. See overhead door operator owners manual for how to adjust the operator force for correct function. Correct as needed now for improved safety.

KITCHEN

Inspection Process

Kitchen Inspection Process

Kitchen Inspection Process

Kitchen inspection was of the readily accessible and visible portions of the kitchen. The kitchen inspection includes the countertops and a representative number of cabinets. Kitchen faucets, when functional, are run for longer than one minute checking for observable leaks and hot/cold orientation.

The following builtin kitchen appliances, where installed, were inspected and on/off operated testing the main function of each appliance using the normal operating controls:

- Cooktop / Oven / Range (cook surface with integral oven)

- Microwave

- Garbage Disposal

- Trash Compactor

Installed dishwashers are run through a normal cycle. Obvious functional issues and leaks observed around the dishwasher are reported, if present.

Ventilation equipment, such as range hoods, are inspected, on/off operated and are reported as ductless, ducted or recirculating. It is beyond the scope of this inspection to determine the effectiveness of the kitchen exhaust fan, such as to verify air flow quantity or discharge location.

Appliance inspection does not cover clocks, timers, self cleaning function, calibration, automatic functions or optional equipment on appliances. Refrigerators are considered personal property and are not evaluated. Refrigerator presence or absence is noted.

Equipment that appears to be shut down, inoperable or intentionally taken out of service is noted but will not be operated by the inspector. Shut down equipment may be unplugged, breaker off, water off, gas off or otherwise taken out of service.

Installation conditions and functional issues for this area requiring correction should be performed by a competent qualified contractor.

Kitchen

Kitchen Area: Upstairs

Kitchen ────

Countertop: Granite

Serviceable fulfilling its function

Cabinets: Wood painted

Wear noted recondition as desired

Floor Covering: Engineered Flooring

Serviceable fulfilling its function

────

Sink: Single Bowl ────

No leaks were viewed at faucet or visible supply lines or waste drain just beneath the sink.

Excess personal property beneath sink greatly restricted view of area.

Disposal: Not Present

Dishwasher: Present and ran through a normal cycle without incident

Range: Range (Electric Top/Oven)

Present and On/Off Tested functional

Microwave: Present and On/Off Tested functional

Kitchen Exhaust: Questionable installation observed, see Summary of report

Refrigerator: Present but not evaluated

Trash Compactor: Not Present

Kitchen Beneath Sink - Horizontal Plumbing Waste Piping Stays Flooded

Irregular plumbing waste drain installation observed leaves horizontal piping before the water seal trap (P Trap) flooded rather than leaving water only at the water seal trap. Proper correction is recommended as unnecessary clogging may occur.

Dishwasher ────

Dishwasher drain line appeared to discharge after the water seal trap at the kitchen sink waste drain. The dishwasher drain line should be properly relocated to an area before the water trap at the kitchen sink waste drain to eliminate any chance of sewer gases from entering the dishwasher.

Ducted Exhaust ────

Kitchen exhaust fan appeared to discharge to the attic area as it was aimed towards a roof deck vent but did not properly exhaust directly to an exterior area. For safety this unit should properly exhaust directly to the exterior or be properly converted to a ductless or recirculating exhaust. Refer to the installation instructions. Properly correct or replace kitchen exhaust as needed for function and safety. Correct any affected areas, if needed.

Extra Photos

LAUNDRY

Laundry Connections

Laundry: Appliances Present, Connections Available

Laundry appliances were present during inspection at basement 1/2 bathroom. ────

Laundry appliances restricted view of laundry connections. Laundry appliances typically do not convey with property. Laundry appliances are not evaluated during inspection. Laundry faucets are not operated when appliances are connected to faucets. Verify your clothes dryer exhaust is functional, safe and properly installed to meet the requirements of clothes dryer manufacturer in use.

Clothes washer and dryer connections were available at basement full bathroom. ────

Laundry appliances were not present during inspection. Laundry faucets are not operated when the basin beneath the faucets is inadequate to contain the faucet flow without a hose being connected to the faucets. Verify your clothes dryer exhaust is functional, safe and properly installed to meet the requirements of clothes dryer manufacturer when installed.

BATHROOM

Inspection Process

Testing Limitations

Bathroom Inspection Process

The following opinion was based on an inspection of the readily accessible and visible portions of bathroom areas.

Hand washing faucets, when functional, are run for longer than one minute checking for observable leaks at the faucet and beneath the sink as well as checking Hot/Cold orientation.

Bathing area faucets, when functional, are run for longer than five minutes checking for observable leaks and Hot/Cold orientation.

Toilets, when functional, are flushed no less than two times. Inspector checks for leaks around toilet, checks that toilet fills and shuts off, and checks to see if toilet appears securely mounted.

Effectiveness and discharge locations for mechanical bathroom exhaust vents are not confirmed during inspection.

Installation conditions and functional issues for this area requiring correction should be performed by a competent, qualified contractor.

Bathroom 1

Full Bathroom

Location Full Bathroom Upstairs Rear Master ────

Bathing Area: Combination tub and shower

Tile work appeared older. Budget upgrade to help prevent leaks.

────

────

Hand Washing: Two basins in vanity ────

No leaks were observed around faucet visible supply lines or waste drain just beneath the sink.

Personal property beneath sink restricted view of area.

────

Toilet: Water tank type ────

No Leaks were observed around toilet and it appeared secured in place.

Ventilation: Window present to ventilate bathroom.

Fan on/off tested operative. Consider exhausting to exterior if needed.

Floor Covering: Tile

Wear noted. Properly recondition to meet your needs.

────

Location Full Bathroom Upstairs Rear Master

Stop was missing at cold water side of left sink faucet. Proper correction is recommended.

Bathroom 2

Full Bathroom

Location Full Bathroom Upstairs at Hall ──── ────

Bathing Area: Combination tub and shower

No leaks were observed around faucet and the water containment area appeared serviceable.

Properly maintain tile work to meet your needs.

────

Hand Washing: Vanity with basin ────

No leaks were observed around faucet visible supply lines or waste drain just beneath the sink.

────

────

Toilet: Water tank type ────

No Leaks were observed around toilet and it appeared secured in place.

Ventilation: ────

Fan on/off tested operative. Consider exhausting to exterior if needed.

Floor Covering: Tile

Some wear noted. Recondition as desired.

────

Bathroom 3

Half Bathroom

Location 1/2 Bathroom Upstairs Front ──── ────

Hand Washing: Vanity with basin ────

No leaks were observed around faucet visible supply lines or waste drain just beneath the sink.

────

────

Toilet: Water tank type ────

No Leaks were observed around toilet and it appeared secured in place.

Ventilation: ────

Window present to ventilate bathroom.

Floor Covering: Tile

Some wear noted. Recondition as desired.

────

Location 1/2 Bathroom Upstairs Front ──── ────

Area: Sink Faucet

The Hot and Cold faucet outlets appeared to be reversed and should be properly changed for safety to help prevent scalding.

Bathroom 4

Full Bathroom

Location Full Bathroom Basement ──── ──── ────

Bathing Area: Shower

No leaks were observed around faucet and the water containment area appeared serviceable.

────

────

Hand Washing: Vanity with basin ────

No leaks were observed around faucet visible supply lines or waste drain just beneath the sink.

────

────

Toilet: Water tank type ────

No Leaks were observed around toilet and it appeared secured in place.

Ventilation: ────

Fan on/off tested. The sound heard appeared to be appropriate for the fan.

Floor Covering: Engineered Flooring

Some wear noted. Recondition as desired.

────

Bathroom 5

Half Bathroom

Location 1/2 Bathroom Basement ──── ──── ────

Hand Washing: Vanity with basin ────

No leaks were observed around faucet visible supply lines or waste drain just beneath the sink.

Signs of past leakage observed. Maintain area to meet your needs.

────

Toilet: Water tank type ────

No Leaks were observed around toilet and it appeared secured in place.

Ventilation: ────

None. Bath ventilation recommended. Consider adding.

Floor Covering: Engineered Flooring

Serviceable. Fulfilling its function.

────

PLUMBING

Main Shut Of Valve

Plumbing Supply Piping - Main Water Shut Off Valve - Apparent Location - Note Such Valves are Not Operated: ________________________________________________________________________________________________________________________________________________________________

Water Heater

Water Heater

Discharge Piping: Missing

Water Heater ──── ────

Water heater relief valve did not appear to have a discharge extension pipe. This pipe should extend to within 6" above floor level for safety. The pipe should be rated for hot water and the diameter of the pipe should match that of the valve. Properly add discharge line for safety.

Leak Mitigation: Installed at Interior

Water Heater ──── ────

It is recommended that water heaters installed at or adjacent to interior type areas have contingency measures installed to mitigate expected leakage or rupture of water heater. Such measures would collect and drain unwanted water to exterior to avoid damaging interior finishes. Consider upgrading water heater installation to help reduce unnecessary damage when the water heater fails.

Water Heater ──── ────

Questionable Installation

Water heater did not appear to meet manufacturer installation standards for proper installation when inspected. Refer to installation instructions and have a competent contractor correct as needed for function and safety.

Supply Piping

Supply Piping: Copper, CPVC, PEX

Some Galvanized Fittings Observed

Water Flow at Supply Piping: Adequate

Adequate functional supply water flow was observed during inspection for water outlets operated.

Waste Piping

Waste Piping: Plastic, Metal

Functional waste water flow observed during inspection for water outlets operated.

Apparent Vent Piping

Plastic, Metal - No Adverse

Material: Plastic and Metal

No adverse conditions were observed, maintain to meet your needs.

Exterior Hose Faucets

Consider Adding at Cooling Unit

Exterior Hose Faucet

Consider adding exterior hose faucet near cooling system condensing unit to facilitate cleaning condensing coils.

Performance: Leaked at Handle, Functional

Exterior Hose Faucet at Front

Water viewed leaking from hose faucet handle when faucet was on. Repair faucet for proper operation.

Exterior Hose Faucet at Rear

Exterior hose faucet was turned on and off briefly and appeared to function normally.

Equipment Observed

Plumbing Equipment Observed Present But Not Tested or Evaluated: ________________________________________________________________________________________________________________________________________________________________

Thermal Expansion: About Thermal Expansion

Regarding Plumbing System Thermal Expansion:

Thermal expansion occurs when a tanked water heater operates without any plumbing valves open for a period of time. If the property water meter has a check or backflow preventer valve installed it will prevent the expanding contained water from flowing backwards through the water meter. This expansion causes the water heater pressure relief valve to open briefly releasing a small amount of water if an expansion control device is not present or not working properly. If the pressure relief valve on the water heater opens and does not seal closed properly then active leaks and subsequent damage may occur.

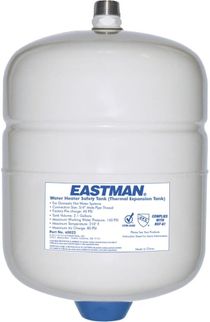

Tank Missing

A plumbing thermal expansion tank was not observed near the water heater. ────

Monitor this area for leaks adding an expansion tank if needed.

________________________________________________________________________________________________________________________________________________________________

Pressure Reducer: About Pressure Reducing Valves

Regarding Plumbing System Pressure Reducing Valves:

The pressure reducer or pressure regulator in a plumbing system is designed to reduce the water pressure to a reasonable level in an effort to help prevent damage to the plumbing system. For most areas if the utility water pressure is greater than 80 PSI (pounds per square inch) a pressure reducer is needed. For some areas with extremely high utility pressure multiple pressure reducers may be needed installed in series. Pressure reducers are typically factory set for 50 PSI and property water pressure is expected to be between 30 PSI and 80 PSI. Inspector notes presence of pressure reducer when observed. Pressure readings for plumbing system are not part of the inspection performed.

Pressure Reducer Location: Unknown

A plumbing system pressure reducer was not located. Verify location of installed pressure reducer or add as needed, if needed.

CENTRAL SYSTEM

Central Heat/Cool

Split System - Heat Pump

Central Heating/Cooling

Split Heat Pump System served: System served entire home ────

Brand Furnace: Tempstar / Location: Equipment Closet, not for storage / Fuel: Electric Heat Pump

Size: 4 ton / Year of Manufacture: 2016

Heat pumps typically have a service life of 12-18 years when properly maintained

Filter Type: Disposable / Thermostat Type: Digital

Cooling Brand: Tempstar / Location: Exterior / Fuel: Electric

Year of Manufacture: 2015

Heat pumps typically have a service life of 12-18 years when properly maintained

Condensate disposal method: Gravity drain piping - service annually

────

Refrigerant Piping: Some Insulation Missing

Cooling system refrigerant piping needed additional insulation. Sections of the insulation on the compressor refrigerant lines appeared to be missing. These lines should be suitably insulated to prevent sweating lines from dripping moisture to finished areas and to improve efficiency of the cooling system.

Cooling System ──── ────

Condensate leak pan was expected and not present. Cooling system evaporator coils installed at, adjacent to, or above a finished living space should have a properly installed condensate overflow leak pan to help minimize damage to finished areas when the system malfunctions. A properly installed float switch should be present at the overflow pan to switch off the condensing unit when the condensate drain becomes clogged or a separate drain should be present for the overflow pan that drains directly to an exterior area. Consider having a qualified competent heat/cool contractor properly correct area to control unnecessary preventable damage.

Inspection performed does not determine system adequacy. Capacity of central heat/cool unit appeared undersized for reported (square footage) area served. A competent heat/cool contractor should further evaluate system and perform load/distribution analysis properly correcting system as needed.

- 4 ton heat pump appeared insufficient to serve reported 4124 sqft home.

Central Heat/Cool

________________________________________________________________________________________________________________________________________________________________

Cooling Function: Functional

Cooling System Functional

Inspector adjusted thermostat. Cooling system engaged and was found to be functional.

________________________________________________________________________________________________________________________________________________________________

Heat Pump Single Fuel: Warm Day Backup Functional

Electric Heat Pump System - Backup heating was operated on a warm day.

For heating function, the electric single fuel heat pump system was operated only in the back up heating mode due to warmer outdoor ambient air temperature. Backup heating was briefly operated on heat pump. System engaged and was found to be functional.

Central Ductwork

Distribution Ductwork

Ductwork Information: About your central heating and cooling ductwork

Regarding calculating the load of a central system:

Several factors are considered when performing a load evaluation for central heating and cooling systems to determine the appropriate size system for the area served. Factors such as installed ductwork, insulation, ceiling height, basement area served, if present, shade, climate zone along with size, number and placement of windows have to be taken into account before sizing a system. The inspector does not calculate the load of a central heating and cooling system during the performed inspection. The inspector also does not confirm that the installed ductwork is appropriately sized to serve the the installed central heating and cooling equipment. Properly maintain the ductwork system to meet your comfort needs and to allow system to operate properly.

Ductwork: Duct Vents Installed at Interior Walls, Return at One Level, Single Unit Serving Multiple Floors, Foam Panel Ductwork Present

Ductwork ──── ────

Some rooms have supply vents discharging closer to an interior wall rather than near an exterior wall. Monitor and evaluate your comfort level upgrading or replacing existing ductwork if needed.

Ductwork ──── ────

The central heat/cool system served multiple floor levels with an air return installed only at one of those levels. Monitor your comfort level properly correcting if needed.

Ductwork ──── ────

A single central heat/cool system was installed serving multiple floor levels. When one central system serves multiple floor levels expect some temperature disparity between floor levels. Seasonal adjustment of vent diffusers may help. A heating contractor may also be hired to modify the system. Monitor your comfort level and correct as desired to meet your needs.

Foam panel ductwork was observed. Monitor this ductwork as it punctures easily correcting as necessary.

Space Heating

Fireplace

Fireplace Use Nonessential

Regarding Fireplace Use:

Fireplace use was nonessential. The installed fireplace was not the sole heating system for the inspected property and does not have to function if you do not desire to use the fireplace area. Typically, deficient fireplaces are not listed in the summary of the report. Properly repair fireplace area for function and safety if use is desired.

Type: Masonry Fireplace

Location: Living Room

Firebox: Sooted

Damper: Operated

The fireplace damper was opened and closed and functioned normally.

Gas Log Set Heater: Not Present

Chimney Type: Masonry Chimney

Fireplace

Fireplace Use Nonessential

Regarding Fireplace Use:

Fireplace use was nonessential. The installed fireplace was not the sole heating system for the inspected property and does not have to function if you do not desire to use the fireplace area. Typically, deficient fireplaces are not listed in the summary of the report. Properly repair fireplace area for function and safety if use is desired.

Location: Basement Den

Solid Fuel Stove

Wood Stove Observed but not evaluated

Wood Stove Chimney

Instructions for wood burning stoves must be closely adhered to and these instructions often vary by manufacturer. Wood burning stoves are not fully evaluated when inspected. The inspector recommends further evaluation by a chimney specialist and a revue of installation and maintenance instructions before use.

ELECTRICAL

Electrical Inspection

Electrical System Inspection

What is an electrical system?

The electrical system consists of an electrical service, distribution equipment and branch wiring. The electric metering equipment is usually at the electrical service. Distribution equipment is most often one or more installed breaker panels and the branch wiring runs to all equipment, receptacles, lighting outlets and devices such as the light switches. The inspection report focuses on wiring operating between 100-250 Volts. Most low voltage wiring is excluded from the performed inspection. Low voltage items such as a heating and cooling thermostat are operated in order to determine the function of such equipment.

There are now a wide variety of lighting bulbs or lamps that will fit into lighting fixtures. Some choices may not be appropriate for some lighting fixtures. It is beyond the scope of this inspection to verify each lamp or bulb is appropriate for the installed lighting fixture. The inspector recommends that you review the bulb or lamp installations for each fixture correcting as needed for safety and function. Common errors include 100 watt bulbs installed in fixtures rated for 60 watt max bulbs and interior rated bulbs installed at exterior or damp locations. Other types of errors also exist.

The following opinion was based on an inspection of the readily accessible and visible portions of the electrical system. The Inspector is responsible for checking a representative number of installed lighting fixtures, switches, and receptacles. Electrical installation conditions and functional issues requiring correction should be performed by a competent licensed electrical contractor. Most, if not all, electrical corrections should be considered a safety concern.

System Amps / Volts

System Amperage: 200 Amps

System Voltage: 120/240 Volts

ELECTRICAL SERVICE

Electrical Service Type: Overhead

Routine Correction: Service Conduit Strap Routine

MAIN PANEL

Location

Main Breaker Panel Basement ────

- ────

Service Entrance Conductors: Copper, Stranded

Index: Index

Properly index or label each electrical panel circuit as needed for clarity and safety.

Access: Working Access

Observed electrical equipment panel should have unobstructed dedicated safe service access area of no less than 30" in width and 36" depth as measured out from the inspected electrical panel. This clear area is needed for safe access to this type of equipment. Consider relocating equipment or obstruction as needed to provide minimum safe working access to the electrical panel.

Enclosure: Panel Cover Not Installed

Wiring: Remark White 240V Breaker

Upgrade: Distribution Equipment Upgrade Recommended

In the inspector's opinion, now is the time to consider an electrical upgrade for the distribution electrical equipment. Updating this older equipment properly will improve safety and convenience.

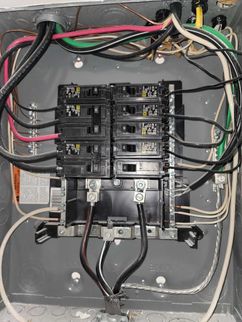

Main Breaker Panel Basement ────

Multiple corrections were needed at electrical distribution panel. A competent electrical contractor should further evaluate this area. Make proper corrections as needed for safety and function now. Refer to the full report for additional information and photos regarding obvious corrections recommended for this electrical panel.

SUB PANEL

Location

Sub Breaker Panel Basement ────

- ────

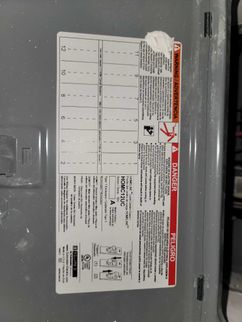

Index: Index

Enclosure: Panel Cover INNER Not Installed

Upgrade: Distribution Equipment Upgrade Recommended

In the inspector's opinion, now is the time to consider an electrical upgrade for the distribution electrical equipment. Updating this older equipment properly will improve safety and convenience.

Sub Breaker Panel Basement ────

Multiple corrections were needed at electrical distribution panel. A competent electrical contractor should further evaluate this area. Make proper corrections as needed for safety and function now. Refer to the full report for additional information and photos regarding obvious corrections recommended for this electrical panel.

SUB PANEL

Location

Index: Index

Access: Area Not For Storage

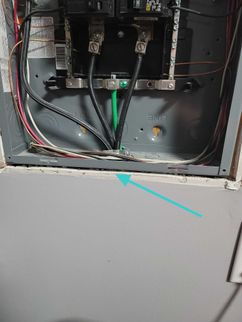

Wiring Sub Panel: 4 Isolate

Sub Breaker Panel Garage Detached ────

Multiple corrections were needed at electrical distribution panel. A competent electrical contractor should further evaluate this area. Make proper corrections as needed for safety and function now. Refer to the full report for additional information and photos regarding obvious corrections recommended for this electrical panel.

Branch Wiring

Material: Copper

Wiring Method: Non Metallic Sheathed Cable

Service Disconnect Missing

Electrical service disconnect was not observed near water heater at Basement. An electrical service disconnect within view of the permanently installed appliance is an important safety device for personnel servicing equipment. A competent electrical contractor should properly install an electrical service disconnect where missing for safety.

Branch Wiring

Multiple corrections were needed to improve the safety of the electrical branch wiring. These corrections are usually non-recurring once properly completed. A competent electrical contractor should review the installed branch wiring making proper corrections where needed for both safety and function.

- Representative Photos Provided

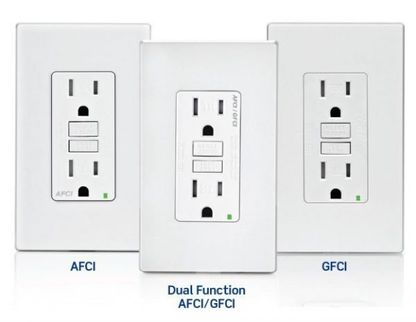

AFCI

AFCI Residential

What is Arc Fault Circuit Interrupter (AFCI) Protection?

AFCI protection is designed to help reduce the chance of fire when a specific type of malfunction occurs at installed electrical outlets. This protection detects unintended electrical arcs and disconnects the power before the arc starts a fire.

Most, but not all, homes will have a need for additional AFCI protection based on varied municipal enforcement and the numerous changes for which areas require AFCI protection. Evaluate your risk exposure. Consider adding AFCI protection where needed for improved safety, particularly where construction was completed 2002 or later.

Modern Locations Where AFCI Protection is Known to Improve Safety for 15 and 20 Amp Electrical Circuits:

For all 15 and 20 ampere single phase residential electrical circuits serving outlets and devices in Kitchens, Family Rooms, Dining Rooms, Living Rooms, Parlors, Libraries, Dens, Bedrooms, Sunrooms, Recreation Rooms, Closets, Hallways, Laundry Areas, or similar rooms or areas.

Testing AFCI Function

The inspector uses push button at AFCI breakers, where installed, to confirm AFCI protection trips. Once tripped, the inspector checks indexed electrical circuits to determine where AFCI protection is present or missing.

Obvious locations lacking AFCI protection are listed in the body of the report.

Obvious broken, non working and improperly wired AFCI receptacles or breakers are listed in the summary of the report. Evaluate your risk exposure.

No AFCI Built Before 2002

Areas That Did Not Appear AFCI Protected

No AFCI protection was observed at inspected property. AFCI protection is not expected for homes built before 2002. If installation of AFCI protection is desired, consult a competent electrical contractor.

GFCI

GFCI Residential

What is Ground Fault Circuit Interrupter (GFCI) Protection?

GFCI protection is designed to help reduce the risk of being shocked when using electricity in certain areas.

Most, but not all, buildings will have a need for additional GFCI protection based on varied municipal enforcement and the numerous changes for which areas require this type of protection. Evaluate your risk exposure. Consider adding GFCI protection for 15 and 20 ampere electrical circuits where needed for improved safety.

Modern Locations Where GFCI Protection is Known to Improve Safety for 15 and 20 Amp Electrical Circuits:

- all electrical receptacles at Bathrooms, Crawl Spaces, Exterior Areas, Garages, Unfinished Basements

- all electrical receptacles serving Kitchen Counter Surfaces

- all electrical circuits for Dishwashers

- all electrical circuits for Hydro Massage Tubs

- all 120 V electrical receptacles at Laundry Areas

- all electrical receptacles near Showers or plumbing Sinks (within 6 feet/arms reach)

- all 3 wire electrical receptacles installed on 2 wire circuits (such as at older homes)

- all electrical receptacles at accessory buildings (OUTBUILDINGS) that have a floor located at or below grade level not intended as habitable rooms

Testing GFCI Function

The inspector uses an electrical tester at receptacles that simulates a remote ground fault current to confirm which areas lack proper GFCI protection at electrical receptacles.

Obvious locations lacking GFCI protection are listed in the body of the report.

Obvious broken, non working and improperly wired GFCI receptacles or breakers are listed in the summary of the report.

GFCI Some, GFCI Older Home

Some GFCI protection was present. Multiple areas would benefit from adding further GFCI protection. Consider modernizing electrical installation adding this shock protection, where missing, for all electrical areas where GFCI protection is known to improve safety.

GFCI protection was ready for upgrade at older inspected property. Consider modernizing electrical installation adding this shock protection for all electrical areas where GFCI protection is known to improve safety.

Receptacle Outlets

Receptacle Appeared Missing: Cooling Unit

Electrical Receptacle Outlet ──── ────

An electrical receptacle was not observed near the cooling condensing unit at exterior. Equipment requiring periodic servicing should have a permanent electrical receptacle installed close by. Consider properly adding an electrical receptacle at exterior ground level within 25 feet of cooling condensing unit to service this equipment.

Electrical Receptacle Outlet Hot/Neutral Reversed ────

One or more electrical receptacles tested as having hot/neutral reversed. Reversed wiring can damage sensitive equipment such as computers and poses safety concerns. Properly correct reversed hot/neutral wiring conditions where needed for function and safety.

- Electrical receptacle at enclosed deck area tested hot/neutral reversed.

Lighting/Ceiling Fans

Photo Cell, Exposed Closet

Photo cell was installed at some exterior light fixtures. Fixtures with photo cells are designed to operate after dark. Verify such lighting fixtures operate properly or correct as needed for function and safety.

Lighting

Exposed incandescent type light fixture was observed at closet. Stored items should be kept away from surface mounted incandescent closet lights to reduce the risk of fire. Use caution with this type fixture. Install low wattage LED light bulbs or fixture with a globe to help reduce heat transfer risk.

Representative Photos

Inoperative/Improper

Lighting

Some lighting was inoperative when inspected. Some light fixtures were improperly installed. Check all lighting/fans making functional and safe where needed.

Representative Photos Provided

Switches

Switch Reads NO at Lettering

Switches

Correction was needed for electrical switch installation.

The lettering on the switch should read 'ON' when up rather than reading 'NO' when the switch is down but in the 'on' position.

Smoke Alarms

Modernize, Test After Installation, Not Tested Occupants

Smoke Alarms - Consider Upgrade Modernizing Smoke Alarm Installation:

Consider modernizing smoke alarm installation to improve safety. Modern smoke alarm systems typically are hardwired to the electrical system and will have battery backup so that they will function when the power is off to the building. Modern smoke alarm systems typically have all smoke alarms interconnected so that when one alarm sounds then all smoke alarms will sound simultaneously. This is useful for heavy sleepers and in larger homes.

Modern smoke alarm systems typically have smoke alarms installed at the following locations:

- Outside sleeping areas

- Inside sleeping areas

- At least one per floor level including basements

- Near stairs

- In garages

- In unfinished basements

- (some installations will require additional smoke alarms)

It is important to note that a single smoke alarm can satisfy multiple areas if carefully placed.

It is common to have a single smoke alarm near the top of the stairs and just outside multiple sleeping areas.

Evaluate your risk exposure. Upgrade smoke alarms to meet your needs.

Read and follow the smoke alarm manufacturer installation and operating instructions.

Contact your local Fire Marshal if need be.

Regarding Testing Smoke Alarms:

After installing smoke alarms, test weekly and replace batteries when needed. Properly replace smoke alarms when not functioning correctly and at least every ten years. Smoke alarms should be at least the photoelectric type and dual sensor photoelectric and ionization smoke alarms are available, and preferred. Refer to installation and care instructions for proper locations and periodic maintenance.

Smoke alarms were not tested as to not disturb occupants. Home was occupied and occupants were present. Test smoke alarms weekly correcting if needed.

ATTIC LADDER

Installation / Condition

Overall Condition: Attic Ladder Correct Before Use

Box Frame Connection To Structure: Excess Gap Box Frame to Structure, Nails Missing All Brackets

The gap observed between the structural framing and the pull down attic ladder stairway box frame appeared greater than expected. Proper correction is needed to help prevent collapse of stairway.

- Gap between structure and attic ladder box frame was much greater than 1/4".

Attic ladder was observed ready for corrections now and before use to improve the function and safety aspects of the attic ladder. Refer to the full report for additional information and photos regarding obvious corrections recommended now for the attic ladder area. A competent qualified contractor capable of reading and following the manufacturer installation instructions should check all attic ladder areas. Make attic ladder functional, safe and structurally sound where needed.

STRUCTURE

Attic Access

Roof Framing

Framing: Rafters, Wooden

Sheathing: Plywood

Roof Framing: Older Typical

Framing, where visible, was observed typical for age of structure and may not meet current building standards. Monitor area periodically and make corrections if condition changes.

Ceiling Framing

Framing Access: Finished and Insulated Restricted

Finished areas restricted view of structural components. Visibility was limited due to installed insulation in this area. Some areas were not observed by inspector.

Wall Framing

Framing Access: Finished Prevented

Finished areas prevented view of structural components. Structural areas were not observed by inspector.

Underfloor Access

Basement: Finished

Finished areas prevented view of structural components. Structural components were not observed by inspector at such areas.

Underfloor Description

Attributes: Basement

Underfloor Area

Access:

Basement walked

────

Construction Type:

Basement - Finished ────

────

Foundation:

Concrete Block ────

────

Columns or Piers:

Load Bearing Wall ────

Floor Structure:

Floor Framing - Not Observed ────

Beam - Not Observed ────

Subfloor - Wood ────

────

MOISTURE

Basement

Basement: Basement Dry But Older

Basement appeared dry when inspected but structure was older. Monitor area and properly maintain basement to meet your needs.

INSULATION

Above Ceiling Insulation

Recommended Insulation

Recommended attic insulation depth above living spaces for this area of the country is R-38 to R-60 to help lower utility costs. This recommendation comes from the US Department of Energy. Evaluate your comfort level and utility costs correcting insulation depth if needed.

Insulation Type: Blown In

Observed Insulation Approximate Depth: R - 30, R - 19

Consider Improving Insulation: Missing, Energy Audit Recommended

Insulation was missing at some areas. Inspector recommends insulation be properly installed where missing to lower utility costs.

Consider obtaining evaluation by an energy auditor for property to improve energy efficiency and comfort.

Wall Insulation

Insulation: Wall Insulation Not Observed, Undetermined

VENTILATION

Attic Ventilation

Attic Exhaust Vents: Ridge Roof Vent, Roof Deck Vent

Attic Intake Vents: Soffit Vents Where Installed

ROOF

Roof Covering

Method of Roof Inspection: Walked on portions of roof

Roof Style: Gable

Approximate Age of Roof Covering: 2-4 Years

Roofing covering was ready for corrections now.

A competent roofing contractor should check entire roof system and associated flashings. Properly repair or replace roof covering system as needed.

Roof Covering was Ready for Correction

- Representative Photos Provided

- Some roof shingles observed improperly installed. Refer to installation instructions properly correcting where needed. Dimensional shingles at roof valleys typically should not be woven.

- Temporary repairs observed. Execute permanent corrections where needed. Flashing was expected at chimney where sealant was present at chimney perimeter. Properly install roof flashing where omitted.

- Remove vegetation debris from roofing where needed.

Gutters and Downspouts

Gutter and Downspout Materials: Metal

Observation: Screens

While gutter screens help keep gutters clean they do not completely eliminate the need for periodic cleaning of gutters.

Downspout: Near, Under

One or more gutter downspouts were discharging close to the foundation.

It is recommended that all downspouts be extended to allow storm water to flow quickly away from and around the structure. Correct as needed to meet your needs.

One or more gutter downspouts were discharging into a below grade drainage system. The drainage system was subterranean and inaccessible and was therefore not inspected.

Gutters: Maintain

Properly maintain rain gutters to meet your needs.

SIDING and TRIM

Brick

Brick Veneer Painted

Brickwork: Serviceable

Brickwork

The exterior readily visible areas of the brickwork were inspected and appeared to be in overall serviceable condition, fulfilling its function. All siding requires maintenance. Properly maintain siding condition correcting when needed.

Siding - Vinyl

Vinyl Siding

Siding: Serviceable

Vinyl Siding -

The exterior readily visible areas of the siding were inspected and appeared to be in overall serviceable condition, fulfilling its function. All siding requires maintenance. Properly maintain siding condition correcting when needed.

DECK

Deck or Wooden Porch Areas Overall Condition Statement

Correct Deck and Fall Areas Before Use

Inspecting decks which are also known as wooden porches.

Decks and their attached steps are inspected for structural integrity, fall prevention and possible entrapment openings. Concealed areas such as deck footers are not included in the inspection. Most inspected decks will be ready for some correction or upgrade due to age, wear or improper construction. For any areas ready for upgrade, you should evaluate your risk exposure properly correcting as needed for improved structural integrity and improved safety.

Any deck needing correction should be further reviewed and corrections performed by a Competent Qualified Deck Contractor as the deck inspection performed in this report is not meant to discover every possible correction that a deck might need.

Each deck should be properly stained to prolong deck life. A solid deck stain is preferred as it will also protect the deck from sun light damage.

Two useful sources for deck information may be found at the following websites:

https://knoxcounty.org/codes/pdfs/construction_info/DeckInformation.pdf

Deck areas were observed ready for corrections now and before use to improve the structure of the deck and to improve the safety aspects for the fall prevention measures installed at deck areas. Refer to the full report for additional information and photos regarding obvious corrections recommended now for any deck areas. A competent deck contractor should check all deck areas. Make deck areas functional, safe and structurally sound where needed.

- Representative Photos Provided

Deck or Wooden Porch Location, Attributes and Restrictions

Deck Location: Left, Rear

Deck Roof Area: Deck Was Partially Enclosed

Restrictions: Grade Partial, Finished Areas

Deck was partially at or close to exterior grade or ground level restricting visual access to some components.

Finished areas restricted view of structural components.

Deck or Wooden Porch Structure

Attachment: Brick Veneer

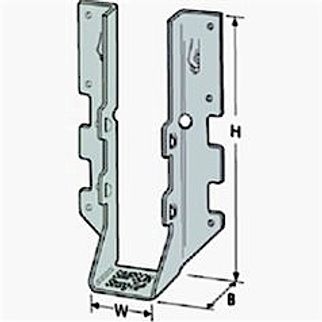

Girder or Beam: Undersized, Not Properly Supported

Observed girder or beam appeared undersized for the span between columns. Properly correct girder or beam as needed for structural integrity.

Joist Hangers: Not Installed Correctly

Deck or Wooden Porch Railings and Stairs

Diagram: Correction Needed Railing

LOTS and GROUNDS

Patio

Walkway

Driveway

Concrete, Gravel

Vegetation

Dead Tree, Vegetation Maintenance

Properly maintain vegetation to meet your needs. Vegetation should not touch building exterior or overhang roof. Vegetation should not interfere with access or servicing of electrical, gas or heating/cooling equipment.

Site

Properly maintain storm water drainage to protect building and driveway.

- Storm water drainage piping beneath driveway appeared smaller than expected. Consider having further evaluation to determine adequacy for piping beneath the driveway to serve storm water drainage. Inspection or evaluation of such drainage systems is beyond the scope of the inspection performed.

.jpg)

.jpg)

.png)

p20(5)p20(2).png)

.jpg)

.jpg)

.jpg)