The Scope and Purpose of a Home Inspection

Purchasing property involves risk

Buying a home—whether for yourself, your family, or as an investment—is a major decision. It’s not just about money; it’s about where and how you’ll live. My role is to support you in this process by offering a clear, honest, and detailed look at the condition of the property on the day of the inspection.

This home inspection is a limited, visual review of the building. It’s designed to help you better understand what you’re buying, not to give you a guarantee or make the decision for you. Old homes, new builds, quirky spaces, and fixer-uppers all come with their own stories and surprises—and that’s okay. My job is to help you see the parts that are visible and raise awareness about what may be hidden, uncertain, or outside the inspection’s scope.

I believe that good decisions come from good information. You won’t hear “don’t worry” from me—I’ll give you what I see, what I know, and what I don’t. That includes moments where I simply don’t have full access or where something needs a specialist’s opinion. Whenever possible, I encourage you to attend the inspection. Being there gives you a richer, real-time understanding of the property that’s hard to capture fully in a written report.

Whether you’re buying your first home or your fifth, in Lisbon or Leiria, the goal is the same: make informed, confident decisions about where you’ll live, grow, or invest.

This report is prepared in accordance with the terms of your inspection agreement with SEGUNDOS AFAMADOS - LDA and reflects the conditions observed on the date of inspection.

A home inspection is not an insurance policy

A home inspection is not a warranty or insurance policy. It won’t protect you from future problems or guarantee that nothing will go wrong with the house. Think of it instead as a snapshot of the property’s condition on a specific day, taken by someone who knows what to look for.

A home inspection is visual and not destructive

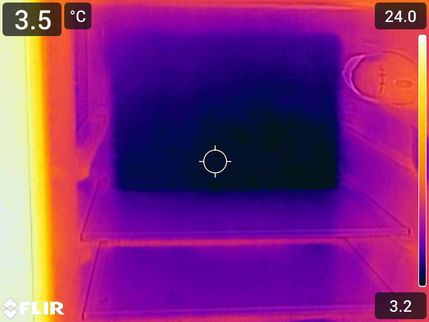

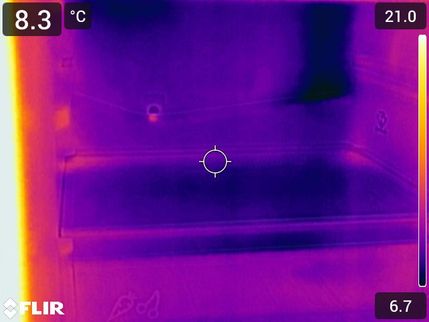

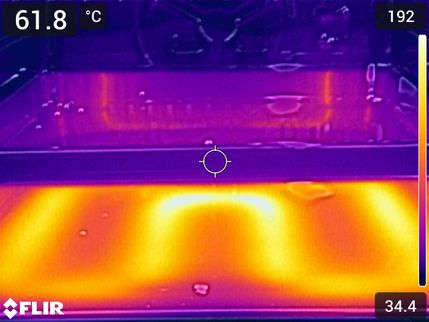

The inspection is visual and non-invasive. That means I don’t move furniture, open walls, dismantle equipment, or disturb finishes. I inspect only what’s accessible and visible without causing damage. Some systems—like overflow drains or waterproofing—can’t be tested without risk to the structure and are therefore excluded from direct testing. Tools such as thermal cameras or moisture meters may be used to support these observations. These tools provide visual context only and are not calibrated instruments for diagnostic or certified measurements.

This is not an inspection for code compliance

In Portugal, like many countries, there is no single national standard for home inspections, and we don’t check for compliance with municipal building codes. Code compliance is something typically reviewed by licensed architects or municipal officials during the construction phase, not after the home is finished. Building codes also evolve frequently, and older homes are not required to meet the latest standards unless major renovations are done.

In short: this inspection won’t catch everything, and it’s not meant to. But it will give you grounded, expert feedback on what’s visible and noteworthy—and that can make a world of difference in your planning and decision-making.

This is just our opinion

Every house is a little different—each with its own quirks, history, and construction choices. There’s no single “correct” way to build or repair everything, and that’s part of what makes homes so unique.

This report reflects my professional opinion, based on 20+ years of experience restoring and evaluating properties. But it’s still just that—an informed opinion. Other inspectors or contractors might see things differently, and that’s okay. You’re always welcome to get second opinions, especially on complex systems or repairs.

What I offer is context and perspective. I don’t just note problems; I explain them. And when something’s uncertain, I’ll say so. That might mean recommending further evaluation by a specialist, or simply highlighting something that’s outside the scope of this inspection.

In the end, this report isn’t a checklist—it’s a conversation starter. It gives you the groundwork to make your next steps with clarity and confidence.

The scope of this inspection

This inspection includes a visual evaluation of the exterior, roof, structure, foundation, attic, interior spaces, plumbing, electrical, and heating systems. I also assess conditions related to indoor air quality and the potential for mold growth where relevant. In some cases, I use tools such as a moisture meter, thermal camera or other handheld testers to gather additional visual context. These tools assist in visual evaluation but are not used to deliver technical measurements, official diagnostics, or precise readings. Any findings based on these tools will be included in the report where applicable.

Only areas that are accessible and safe on the day of the inspection will be included. When more detailed analysis is necessary, I’ll note it and recommend appropriate follow-up.

For clients who request it, I offer floor plans as an additional service. These are for reference only and are not intended for permitting, renovation planning, or any official use.

Your expectations

The goal of this inspection is to help align your expectations with the home you’re planning to buy. No home is perfect—every property has a history, and part of my job is to give you a clear picture of what that looks like on the day of the inspection.

I aim to highlight what’s working, what might need attention, and what’s unknown. This isn’t about finding every flaw—it’s about helping you make an informed decision. If you’re expecting a checklist of every minor issue, this report won’t provide that. But if you’re looking for guidance grounded in experience and transparency, that’s exactly what this offers.

This process is about discovery. It’s about seeing the home with informed eyes so you can decide how it fits into your plans.

How to Read This Report

Getting the Information to You

This report is designed to be clear and approachable, even if you’re not familiar with construction terms. If you’re short on time, you can start with the Summary Page to quickly see the most important findings. Just keep in mind—it’s not a replacement for reading the full report.

The full report includes photos, captions, descriptions, and links to more information to help you understand what you’re seeing. Some words or phrases may be highlighted and underlined—clicking on these will take you to additional resources or definitions.

You’ll also notice the use of emojis throughout the report. These are visual markers meant to draw your attention to specific items—they are not used to indicate the severity of an issue. The true meaning of each observation is described in the associated text and clearly labeled with a severity modifier.

For the best experience, I recommend reading the report online. It’s interactive, easy to navigate, and allows you to dive deeper into any areas that matter most to you. You can also download it as a PDF, and if needed, I can provide a high-quality translation to Portuguese.

Chapters and Sections

This report is organized into chapters, each covering a major part of the home. Within each chapter, you’ll find sections that focus on specific systems or components—like the roof, plumbing, or electrical. This structure makes it easy to navigate and understand the findings.

You’ll see most sections begin with a brief description in standard text. If I’ve observed something notable—whether it’s a concern or just something worth explaining more—you’ll find a colored box with a narrative. These narratives are meant to help you understand not just what was seen, but what it might mean in context.

Observation Labels used for Lisbon

Observations are numbered, colored, and labeled for clarity. The labels follow a standard set of observation modifiers, which define the nature and severity of each observation. If something is functioning as expected, the report may simply note “tested” or “inspected,” and no further comment will be needed.

Detailed description of various aspects of the property noted during the inspection.

Summary Page

The Summary Page at the front of the report gives you a quick overview of the key findings. It’s a helpful tool for fast reference, but it’s not a substitute for reading the full report. The summary doesn’t include photo captions or detailed context, so for a full understanding, be sure to explore the full report.

Summary

Critical Issues

- RACG-1 Roof, Attics, Chimney and Gutters:

ROOF CONSTRUCTION CONDITIONS:

There were issues documented below in bulleted lists, narratives, and/or pictures related to the roof. Concerns related to the vaulted roof installation should be evaluated, replaced, and repaired as deemed necessary by a qualified party or parties.

Cracks in the ceiling near the dormers appear to have developed after recent painting was completed, which suggests that movement may be ongoing; I strongly recommend that a qualified professional evaluate the area to determine whether any structural concerns exist, regardless of any previous cosmetic repairs.

ROOF CONSTRUCTION:

- SAGGING TILE ROW – Green reference line illustrates expected straight alignment; actual roofing tiles are visibly sagging below this line, indicating possible structural deflection.

- VARIATION IN DORMER CONSTRUCTION – Differences in dormer materials indicate they were likely installed after the original construction.

- Converted into living space — Vaulted roof areas that have been converted to living space must meet structural, insulation, and ventilation requirements. Such conversions may not be compliant unless formally permitted and reviewed.

RAFTERS:

- Much sagging of rafters noted – excessive deflection observed, likely requiring evaluation by a structural professional

- Poorly supported – rafters lacking sufficient structural connections or bearing points

- Unsupported – rafter span observed without intermediate or end support as needed

🛑 SAFETY 🛑 IMMEDIATE REPAIRS 👁🗨 Monitor during use 🔨Repair

- RACG-2 Roof, Attics, Chimney and Gutters:

ROOF AREA CONDITIONS: There were issues documented below in bulleted lists, narratives, and/or pictures related to the roof area components that should be evaluated and repaired as deemed necessary by a qualified party.

When the attic is not traversed or only partially traversed there will be much that cannot be determined, such as:, roof leaks, broken/missing framing, missing fire-blocking, air-bypasses, roof sheathing concerns, missing/compromised insulation, chimney issues, vermin activity, mold and/or wood decay, and none of this should be implied as being all inclusive

INSULATION:

- Missing – insulation not present where expected in roof or ceiling cavities, which compromises thermal resistance

NOT INSULATED:

- Vaulted ceiling areas

- Connection with upper living area

PRESENT MOISTURE IN ATTIC/ROOF SPACE:

- Signs of water intrusion around roof penetrations – Staining or discoloration near chimneys, vents, or skylights may indicate flashing failures or past leaks.

- Low clearance impeding inspection – Access to attic space was restricted due to limited height, which prevents full visual inspection. Undetected issues should be assumed where obstructions exist.

- over moisture meter measureable limit

PAST LEAKS:

- Active leak into roof structure – Moisture was actively entering through visible openings or damaged waterproofing; source should have been identified and sealed by a qualified roofing professional.

- Leaks at roof valleys – Stains and material lifting indicated water accumulation and entry along valleys where tiles or membranes were insufficiently sealed or degraded.

🔧 Maintenance (as needed) 👁🗨 Monitor 🛑 SAFETY 🛑 IMMEDIATE REPAIRS

- RACG-3 Roof, Attics, Chimney and Gutters:

ROOF PAST EXPECTED LIFE:

There were issues documented below in bulleted lists, narratives, and/or pictures related to the roof that was in very poor condition. I recommend replacement of the roof by a qualified roofing contractor. A full evaluation and repair of underlying surfaces is recommended and proper repairs made as deemed necessary. Some amount of hidden damage should be anticipated. The following conditions were noted but should not be construed to be all inclusive.

ROOF GENERAL CONCERNS:

- Cracked or chipped tiles – Damage from impacts or thermal stress compromising tile integrity.

- Improper flashing – Faulty sealing around roof penetrations allowing water ingress.

- Algae or moss growth – Organic accumulation retaining moisture and accelerating wear.

- Sagging roof sections – Structural issues causing depressions or uneven surfaces.

- Mechanical damage – Impact from debris or foot traffic causing cracks or dislodged tiles.

- Cracked or broken tiles – Tiles exhibiting fractures, potentially leading to leaks.

- Extensive use of Butly repair tape – widespread use of Butyl tape which has failed

Flashings:

- Failed

- Failed at chimney

- Failed at pipes

- Failed valleys

Ponding:

- Past/ongoing ponding – Recurrent signs of water accumulation noted; condition appears to persist over time and may require correction to avoid material degradation or leaks.

- RACG-4 Roof, Attics, Chimney and Gutters:

ROOF GENERAL CONDITIONS:

There were issues documented below in bulleted lists, narratives, and/or pictures related to the roof. I recommend evaluation, repairs and maintenance of the roof by a qualified roofing contractor. Conditions related to specific types of roof coverings will be discussed below. The conditions should not be construed to be all inclusive but instead more representative:

ROOF INSPECTION:

- Cracked or broken tiles – Individual clay tiles exhibiting cracks or breaks can allow water infiltration, compromising the roofing system.

- Mortar deterioration at ridge caps – Degraded mortar can lead to ridge cap instability, posing risks of tile displacement and leaks.

- Algae or moss growth – Organic growth retains moisture against tiles, potentially leading to accelerated wear and structural concerns.

- Improper lapping of roofing material over gutters – Roofing materials not extending adequately over gutters can result in water damage to fascia and soffits.

MOSS/LICHEN/ALGAE:

- Lichen colonization – Lichen formations noted on tile surfaces, which can penetrate and deteriorate the tile material over time.

- Moss growth on clay tiles – Thick moss layers observed, retaining moisture and potentially leading to tile displacement and water infiltration.

- Vegetation growth between tiles – Plants or weeds growing in gaps between tiles, indicating prolonged moisture retention and potential structural issues.

- Root intrusion under tiles – Roots from vegetation penetrating beneath tiles, possibly lifting them and compromising the roof’s integrity.

- Blocked drainage paths – Organic growth obstructing water flow, leading to water pooling and increased load on the roof structure.

- Discoloration and staining – Visible staining from biological growth, which may signify underlying moisture problems.

LEAKING INTO THE ROOF STRUCTURE WAS NOTED AT:

- Leaking into roof structure – moisture entry visible or suspected at multiple roof areas

- Soffits – water entry at eaves due to slope or flashing issues

- Missing shingles – exposed areas increasing risk of infiltration

- Valleys – improper slope or mortar failures

- RACG-6 Roof, Attics, Chimney and Gutters:

CLAY TILE CONDITIONS

There were issues documented below in bulleted lists, narratives, and/or pictures related to the roof surface that should be evaluated and replaced by a qualified roofing contractor. The pictures below document some of the concerns related to this roof and should not be construed to mean there are no other conditions that need to be addressed. Hidden damage is common with roofs.

CLAY TILE CONCERNS:Roof covering past expected life – Tiles show signs of aging, brittleness, or wear; underlying surfaces may require evaluation and repair.

- Excessive organic growth – Moss, algae, or lichen present; can retain moisture and degrade tiles over time.

- Vegetation growing on roof surface – Plants or weeds rooted between tiles; may disrupt tile alignment and integrity.

- Evidence of less than professional installation – Misaligned tiles, inconsistent spacing, or other signs of substandard workmanship.

- Roof covering past expected life – Tiles show signs of aging, brittleness, or wear; underlying surfaces may require evaluation and repair.

STRUCTURE ADEQUACY:

- Structure not likely adequate for weight of tiles – structural design may not support the combined dead load of heavy clay or concrete tiles and underlayment

- Roof elements show signs of sagging – visible downward deflection of beams or rafters observed, possibly due to excessive load or insufficient design

- Unsupported or insufficiently reinforced spans – large roof spans lack adequate mid-span support or reinforcement

- Recommendations: A full structural evaluation by a licensed engineer is advised when heavy tile materials are used, especially on older buildings or where no documentation of design load calculations is available.

GENERAL CONDITIONS:

- Mechanical damage – physical damage to roofing materials

- Evidence of repairs/patching – visible signs of previous repairs

- Evidence of less than professional repairs – substandard repair work observed

- Sagging of rafters – rafters exhibit downward curvature

- IC-1 Indoor Climate:

INTERIOR MOISTURE:

Moisture-related conditions were evaluated using thermal imaging, non-invasive moisture meter readings, and visual inspection. Depending on environmental conditions and observed building features, signs of potential or active moisture intrusion were identified. These issues may be seasonal in nature or ongoing and are influenced by both environmental humidity and building design or maintenance. Where elevated readings, staining, or mold-like material is present, or if conditions suggest hidden or structural moisture, further evaluation by a qualified moisture remediation contractor to determine the source and appropriate corrective measures.

0% moisture content is an ideal level for interiors, 1-2% is typically what is seen. Moisture content levels as low as 6% can create paint failure issues and wide spread internal wall damage should be expected when moisture content exceeds 20%.

OBSERVED MOISTURE:

- Suspected water infiltration from failing repair tape in roof gutters at parapet walls - moisture measurement was elevated across the entire ceiling line on the south side of the building.

- Light signs of surface condensation were present -

- Significant moisture accumulation was detected -

- • Readings ranged from 16% to 20% or more in localized areas

- • Slight paint bubbling, uneven wall sheen, or minor texture distortion observed

- Evidence suggests a developing or repeat moisture issue needing ventilation, insulation, or heating improvements.

AREAS AFFECTED:

- Elevated moisture levels found in rooms across the south wall on both levels:

MOISTURE SOURCES:

- Building design and construction materials –

- The structure and material composition of the building contribute to moisture retention and condensation.

- Roof or façade infiltration –

- Water entering the structure through worn or damaged exterior surfaces contributes to recurring interior dampness.

- • Defective or poorly sealed flashing, tiles, or façade joints allow rainwater to enter

- • Moisture may accumulate in ceiling voids or behind wall finishes before becoming visible

- • Staining patterns on walls or ceilings near junctions or chimneys suggest water intrusion

- • Flat roofs or terraces with poor drainage design are frequent problem zones

CORRECTIONS AND RECOMMENDATIONS:

- Moisture intrusion may be present –

- Stains, high meter readings, or visible material damage suggest potential leaks or water entry.

- • A qualified roofer, façade repair technician, or waterproofing contractor should assess exterior envelope elements (roof, windows, masonry, etc.)

- • Further invasive investigation may be necessary to confirm hidden moisture sources behind walls, ceilings, or finishes

- F-1 Foundation:

FOUNDATION CONCERNS:

There were issues documented below in bulleted lists, narratives and/or pictures related to the Basement. I recommend that a qualified contractor be consulted to determine the necessity for repairs, to estimate costs and perform evaluated, repaired, and replaced as deemed necessary. A structural engineer may need to be involved.

FOOTINGS:

- Not visible – Footings not accessible or covered

- Significant settlement/uplift/movement – More advanced signs of structural displacement requiring professional assessment

- Cracks that warrant monitoring – Should be periodically reassessed to detect progression

- Settlement – Visible sinking or sloping in sections of the foundation

NOT TRAVERSED:

- 🚩The crawl space was NOT adequately inspected. I recommend that a qualified party improve clearances throughout the crawl space so that there is a minimum of 18" between the floor joists and the ground and 12" minimum between the ground and wood beams. In the context of proper access being made, further evaluation of all of the wood structures can be made. There does not appear to be any lateral bracing in the few areas checked. I recommend a full evaluation by a qualified foundation contractor that utilizes the services of a licensed structural engineer that could design any changes deemed necessary. After repairs are made, and before the structure is re-insulated I recommend that I be called back for further evaluation/recommendations.

- NOT traversed

WALLS ABOVE FOUNDATION:

WOOD BUILDING WALL STRUCTURE:

- Walls leaning – Wall misalignment from vertical indicates possible structural movement

- Failure of wall framing apparent – Structural integrity of the wall framing is compromised

- Headers not supported – Beam or opening headers lack proper bearing or framing support

- Walls bowing – Vertical wall deformation observed

-------

-------

FLOOR FRAMING:

- Generally floor joists undersized by current standards. Improvements may be warranted.

SUPPORT BEAMS:

- Sagging beams present – Visible deflection in beams suggests overloading or inadequate support

- Improperly supported beams – Beams lack sufficient bearing or support structure

FLOOR TRUSSES:

- Past repairs noted

- Less than professional repairs made

WALL CAVITY INSULATION:

- None present

EXTERIOR/INTERIOR WALL SURFACE INSULATION:

- None

The pictures below should be considered representative of the issues and is not meant to be all inclusive. Other issues should be anticipated.

Safety or Major Repairs

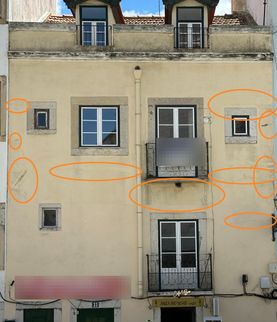

- ED-2 Exteriors and Decks:

BUILDING EXTERIOR:

There were issues documented below in bulleted lists, narratives and/or pictures related to the Building's Exterior. The following concerns should be evaluated and repaired by a qualified party as deemed necessary. Hidden damage in exterior cladding is common and should be anticipated.

BUILDING STRUCTURE:

- Walls appear unreinforced — no visible signs of embedded steel or modern reinforcement; this is common in older homes and may limit seismic resilience.

- Wall separation or misalignment — leaning or offset planes may indicate past movement, soil shifting, or inadequate bracing.

- Decay or rot in decorative corbels — common in older or ornate facades

- Cracks in masonry walls — may suggest aging, movement, or limited seismic reinforcement in older structures; structural evaluation is advised if concerns arise.

- Bulging or displaced masonry walls — visible outward movement of brick, stone, or blockwork may signal hidden structural issues; further review recommended.

EXTERIOR CONDITION:

- General exterior surface failure — widespread signs of wear, aging, or damage

- Failed cladding materials — deformation, cracking, or separation from wall structure

MOISTURE PROTECTION:

- Missing or inadequate flashing — missing or improperly installed flashing at transitions and penetrations

- Signs of historic water penetration — staining or material degradation visible at wall bases

- Visible moisture staining — evidence of past or ongoing water infiltration

- Inadequate waterproofing at wall penetrations — insufficient sealing around pipes, vents, or other penetrations

MASONORY STONE OR TILE ISSUES:

- Plaster deterioration or bubbling — suggests trapped moisture behind the exterior surface

- Exterior wall bowing or displacement — outward bulging or shifting indicating structural movement

IDENTIFICATION CONCERNS:

- Building identification number missing or not visible — all buildings must display a clearly visible "número de polícia" affixed to the façade for emergency and visitor access

- Missing numbers — no street numbers present at entry or façade

🔨Repair 🛑 IMMEDIATE REPAIRS 🛑 SAFETY

- ED-5 Exteriors and Decks:

DECK:

The deck structure had numerous issues and no attempt to document all these issues will be made in this report. The bulleted lists, narratives and/or pictures related to the information below should be seen as more representative as opposed to all inclusive and other concerns should be anticipated. Concerns were noted in relation to:

FLOOR STRUCTURE:

- Paint or coating failure on framing components — protective barrier deteriorated; increased moisture risk

- Signs of settlement or sagging — minor deflection in deck surface may indicate shifting supports or framing fatigue

- Sloping towards building — signs of moisture entering the building apparent

MASONRY:

- Settlement visible — masonry or concrete has shifted or sunken; may indicate subsurface instability

- Cracks observed in masonry or tile — minor structural movement or thermal stress likely

- Repairs noted — prior patching or modifications visible; condition should be monitored

- Spalling or surface deterioration — concrete flaking or erosion evident; durability may be compromised

🛑 Safety 👁🗨 Monitor

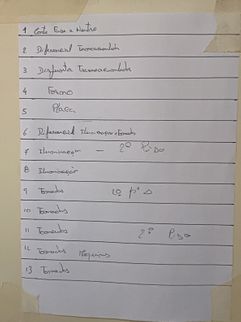

- ES-2 Electric Service:

ELECTRICAL SERVICE EQUIPMENT:

There were issues documented below in bulleted lists, narratives and/or pictures related to the electrical service equipment that should be evaluated or repaired as deemed necessary by a licensed electrical contractor.

PANEL CONDITION:

- Possible Neutral Sharing Issue – 10 circuits were found protected, but only 7 neutral conductors were visible which suggests potential neutral sharing

- Potential Missing Ground Connections – 10 circuits were identified, but only 5 grounding conductors were visible. This raises concern that some circuits may lack proper earth grounding, which is critical for safety and electronics protection

- Bonding issues – improper or missing connections that ensure conductive parts are at same electrical potential

- Grounding issues – improper or missing grounding components or conductors

- Connector issues – loose, improper, or missing conductor connectors

LEGEND DATA PLATE:

- Improper Breaker Labeling – Temporary or handwritten label used; replace with permanent, legible marker

MULTIPLE LUGS:

- Improper Hot Terminal Connections – Multiple wires connected to a single terminal; though common, using dedicated junction terminals is safer and more compliant

- Improper Hot Terminal Connections –Wire and busbar connected to a single terminal; though common, using dedicated junction terminals is safer and more compliant

🔨Repair ➕ Upgrade 🛑 Safety

- EDFW-2 Electric Distribution and Finish Wiring:

RECEPTACLE OUTLET CONDITIONS:

There were issues documented below in bulleted lists, narratives and/or pictures related to the receptacles in the home:

RECEPTACLES GENERAL:

- Painted – A few surfaces covered in paint, obscuring condition or labeling

UNGROUNDED 3-PRONG RECEPTACLES:

- Other ungrounded receptacles should be expected – Similar conditions likely in untested areas; professional review advised

- Most 3-prong receptacles tested ungrounded – Indicates widespread absence of proper grounding conductors throughout circuits

REPLACEMENT OF RECEPTACLES:

- 🚩Three-prong ungrounded receptacles present – Receptacles in this building have been replaced with three-prong types despite the absence of a proper equipment ground. These configurations are common in older buildings but do not provide a safe grounding path. Such a path is important to allow overcurrent protection devices to trip properly in the event of a fault.

- ◽Receptacles installed without equipment grounding – Can lead to an increased risk of electric shock and are incompatible with many grounded appliances.

- ◽Recommend professional evaluation – Upgrading these receptacles should involve one of the following by a qualified electrician:

- Rewire affected circuits to include a proper protective earth

- Evaluate and label receptacles appropriately if grounding cannot be achieved

I recommend evaluation and repairs by a licensed electrical contractor. Other similar conditions should be anticipated.

- EDFW-3 Electric Distribution and Finish Wiring:

LIGHTING OUTLET CONDITIONS:

There were issues documented below in bulleted lists, narratives and/or pictures related to the lighting components in the home including:

FIXTURES:

- Cotton pull chains – outdated, possibly deteriorating components noted

CLOSET LIGHTING:

- 🚩Exposed bulbs: Exposed bulbs pose a risk of fire from stored items and are subject to mechanical damage.

While the pictures below document some of these concerns, I recommend all lighting locations be evaluated and maintained as deemed necessary by a licensed electrical contractor.

- EDFW-4 Electric Distribution and Finish Wiring:

RCD INFORMATION:

There were issues related to the receptacle RCD's. These bulleted lists, narratives and/or pictures document some of those concerns, but not likely all of them. I recommend evaluation, upgrade, and repairs by the licensed electrical contractor. Observations/recommendations/issues include:

RCD'S CONCERNS:

- Receptacle failed High.During RCD testing, failure is indicated by a red screen. The receptacle failed to trip at the standard 30 mA threshold, indicating either an excessively high tripping value or a complete lack of proper RCD functionality. This malfunction suggests that the protective device is not operating within its specified limits, which compromises electrical safety. Immediate evaluation and corrective action by a qualified electrician are recommended to ensure proper operation and compliance with safety standards.

PROTECTION NOT FOUND AT:

- Bathroom

- Kitchen countertop

- Within 2 meters of sinks, bathtubs, or shower

RELATED TO TIME OF CONSTRUCTION:

- Missing RCD protection suggests unpermitted work – When required RCD protection is not observed in recently modified electrical systems, it may indicate the work was completed without proper permits or inspections. I recommend evaluation by a licensed electrical contractor to ensure all safety provisions are met.

🛑 Safety ➕ Upgrade

- P-1 Plumbing:

CONDITIONS RELATED TO THE WATER SUPPLY:

There were issues documented below in bulleted lists, narratives and/or pictures related to the the water supply system. Maintaining the meter accessible and clear of debris both inside the compartment and outside the compartment is important for proper access in an emergency. The below conditions related to the house water supply should be evaluated, repaired and maintained as deemed necessary by a licensed plumber.

MAIN WATER SHUT-OFF:

- Rusting noted – corrosion observed, may impair operation

- At meter only – no internal shut-off found; water only shut off externally at meter

- House vacant long term – extended vacancy limits reliability of plumbing inspection

- ◽Recommend post-occupancy testing and visual monitoring for leaks

GALVANIZED PIPE:

- Galvanized pipe confirmed – The main water supply line is galvanized steel. Replacement is advised due to risk of restricted flow and leaks from internal corrosion.

- Long run to street complicates replacement – Consider pipe upgrade during any renovation or excavation projects.

- BIDS-1 Building Interiors, Doors and Stairs:

BUILDING INTERIORS:

Concerns noted below in bulleted lists, narratives and/or pictures related to the interior spaces of the home should be evaluated, repaired and maintained and repaired as deemed necessary by the appropriate qualified party.

GENERAL INFORMATION:

- General Poor Floor Condition. Generally, throughout the building (including bathrooms, kitchen, laundry etc) the floors have considerable mechanical damage and wear consistent with age and use and some sloping of floors was noted.

- General Poor Wall/Ceiling Condition. Generally, throughout the building (including bathrooms, kitchen, laundry etc) the walls and ceilings have considerable mechanical damage, extensive settlement/shrinkage cracks typical of plaster installations of this age and degree of maintenance.

HABITABILITY/EGRESS:

- ◽Ceiling height less than 2.5 meters – For habitable rooms, the minimum required ceiling height is 2.5 meters. In circulation areas or non-habitable rooms (such as storage), reduced heights may be acceptable down to 2.2 meters.

- BIDS-2 Building Interiors, Doors and Stairs:

FLOORS:

There were issues documented below in bulleted lists, narratives and/or pictures related to the floors:

WOOD FLOORING:

- Gaps between floorboards noted – spacing may be seasonal movement, installation tolerance, or substrate issue

- Mechanical damage observed – scratches, gouges, or dents in flooring consistent with impact or dragging

- Exposed nail heads observed – presents safety hazard; proper setting and patching recommended

- Patching or repairs noted – inlay or fill consistent with past damage or alteration

- Patching associated with remodeling – floor modifications likely due to wall removal, layout change, or fixture relocation

- Staining observed – localized discoloration may relate to moisture, sunlight, or usage

- Stains and wear consistent with age of floor – finish thinning and dulling typical of long-term use

CONSTRUCTION:

- Damage consistent with structural movement – flooring defects align with framing settlement or shifting; further evaluation may be required

- Sloped floor sections observed – uneven floor plane may relate to framing deflection or prior settlement

- Flooring installation appears less than professional – visible seams, misalignments, or surface inconsistencies noted

See Foundation section below for more information on floor settling.

TILE FLOOR:

- Built up area – elevated floor structure over existing floor could indicate previous extensive damage. Assume damage under this subfloor

- Cracked tiles present – breaks in rigid vinyl or composite tile; potential for sharp edges

Wood Destroying Insects:

- Evidence of past damage from

- Powderpost Beetles — larvae bore through dry seasoned wood; leave powdery frass

- Woodworm — general term for beetle larvae boring into wood, causing widespread tunneling

I recommend evaluation, repairs and maintenance by a qualified party as desired.

- BIDS-3 Building Interiors, Doors and Stairs:

WALLS AND CEILINGS:

There were issues documented below in bulleted lists, narratives and/or pictures related to the ceilings:

WALL/CEILING CONCERNS;

- Unevenness in wall or ceiling finish – surface not flush; may relate to previous damage, settling, or poor finishing

- Mechanical damage present – punctures, scrapes, or dents to wall or ceiling finishes

- Drywall joints and seams visible – may need refinishing or improved taping

- Shrinkage or settlement cracks observed – minor cracking consistent with seasonal or material movement

- Evidence of prior repairs – patches, color mismatch, or retexturing visible

- Damage below or around window corners – localized issues, possibly condensation-related

- Baseboard trim missing – common at transitions or during remodeling

- Signs of past or active water damage – discoloration, swelling, or bubbling of surface

- Moisture confirmed by meter reading – elevated levels support need for further assessment

- Ceiling height below required minimum of 2.40 m (habitable space) – lower ceiling observed in the converted attic. Discuss with local municipal office if exceptions were permitted during construction or renovation

CLOSETS:

- Modular storage unit present. In the context of a home inspection it is not typically possible to determine how adequately closet shelving is installed and whether the installation will support weight or how much weight. The following comments and recommendations apply to any closets in the home that have built-in shelving. Manufacturers have different requirements for installation but most have specific requirements for installation on drywall, on wall studs and/or on concrete.

CLOSET CONCERNS:

- Hanger bar damaged – bending, splitting, or cracking noted; may not support typical loads

- Hanger bar or shelf brackets loose or improperly attached – hardware not securely fastened; stability compromised

- Shelf support brackets loose or improperly secured – mounting not flush or stable; risk of collapse

- Brackets not visibly attached to framing – may be fastened only to drywall or thin paneling; insufficient for load-bearing

- Visible damage to storage system components – includes cracked plastic, warped wood, or rusted hardware

I recommend evaluation, replacement, and improvements by a qualified party as desired.

- K-1 Kitchen:

FLOORS/WALLS/CEILINGS/CLOSETS:

There were issues documented below in bulleted lists, narratives and/or pictures related to the floors/walls and ceilings:

CONSTRUCTION:

- Elevated moisture detected with moisture meter – localized reading suggests possible leak, past water intrusion, or condensation issue

STONE/TILE FLOOR:

- Tiles:

- ◽Staining

- ◽Cracked grout joints noted

- ◽Unevenness

CONSTRUCTION:

- Flooring installation appears less than professional – visible seams, misalignments, or surface inconsistencies noted

WALL/CEILING CONCERNS;

- Unevenness in wall or ceiling finish – surface not flush; may relate to framing, settling, or poor finishing

- Mechanical damage present – punctures, scrapes, or dents to wall or ceiling finishes

- Shrinkage or settlement cracks observed – minor cracking consistent with seasonal or material movement

- Evidence of prior repairs – patches, color mismatch, or retexturing visible

- Paint touch-ups or discoloration visible – sheen or tone differences suggest incomplete refinishing

- Painted tile peeling and shrinking noted – painted tile frequently fails, monitor for loose paint

I recommend improvements by a qualified party as desired.

Repair or Replace

- ED-1 Exteriors and Decks:

EXTERIOR TRIM:

There were issues documented below in bulleted lists, narratives and/or pictures related to the exterior trim of the home. All should be evaluated, repaired and maintained as deemed necessary by a qualified door installation contractor or other qualified party.

WOOD TRIM:

- Failed Paint- Areas of failed paint coating on surfaces.

- Failed caulk — deterioration of sealant observed

- Cracks and weathering — indicative of low-quality or aged trim materials

- Mechanical damage evident — dents, breaks, or deformation observed

- Trim behind roof structures — may restrict proper flashing or water control

MECHANICAL DAMAGE:

- Mechanical damage noted — dents, bends, or deformation observed on trim surfaces

- Patching and repairs noted — prior attempts to fix damaged areas identified

CLEARANCE CONCERNS:

- Trim in contact with roof surfaces — limits proper water runoff and may accelerate decay

STONE TRIM:

- Mechanical damage evident — dents, breaks, or deformation observed

- Mortar joint deterioration evident — cracking or erosion may allow water intrusion

- Cracks present — visible splits or fractures noted

MECHANICAL DAMAGE:

- Patching and repairs noted — prior attempts to fix damaged areas identified

- Mechanical damage noted — dents, bends, or deformation observed on trim surfaces

🔨Repair 👁🗨 Monitor annually

- ED-3 Exteriors and Decks:

WINDOW CONDITIONS:

There were issues documented below in bulleted lists, narratives and/or pictures related to the windows of the home. I recommend further evaluation, repairs and improvements of these conditions by a qualified window installation/repair contractor.

GENERAL CONDITIONS:

- Single-pane windows — less energy-efficient; consider upgrading

RECENT REPLACEMENT:

- Recent installation — methods not determined — installation appears recent; unable to fully verify methods or flashing; monitor for future issues

- Caulking missing at some locations — localized deficiencies observed

EXTERIOR WINDOW SILLS:

- Much deterioration/decay in exterior wood sills — significant conditions noted on multiple windows

INTERIOR WINDOW SILLS:

- Staining noted — moisture exposure or general wear observed

- Decay present — moisture damage affecting material integrity

INTERIOR WINDOW COVERINGS/BLINDS:

- Some blinds function with difficulty — sticking, catching, or misalignment noted

- Damaged blinds noted — slats bent, broken, or warped

- Functioned with difficulty — repeated trouble operating smoothly

WOOD SINGLE PANE:

- I recommend factoring the replacement of all remaining older windows in the home by a qualified window installation company. All existing windows should be properly maintained until they can be replaced.

- Window replacement should include evaluation, repair, or replacement of trim, sills, and related components as well.

Some of the issues will be documented in the pictures below but should not be construed to be all inclusive but instead more representative.

👁🗨 Monitor ➕ Upgrade 🔨Repair

- RACG-5 Roof, Attics, Chimney and Gutters:

GUTTER CONDITIONS: There were issues at the home, documented below in bulleted lists, narratives, and/or pictures related to the roof drainage system. I recommend evaluation and repairs by a qualified gutter installation contractor or other qualified party is recommended. Failed gutters can cause damage to the home and not direct water properly away from the home.

Care should be taken related to maintenance of gutters as they represent a safety hazard for falls and other injuries.

ROOF DRAINAGE SYSTEM ISSUES:

- Gutters need to be cleaned. Most of the gutters need cleaning. I recommend professional cleaning/maintenance by a qualified gutter cleaning company experienced in all the safety concerns. This cleaning should include downspouts and verification of proper function.

GUTTERS:

- Debris noted in drains

DOWNSPOUTS:

- Discharging on to roof of another unit – observed water discharge onto roof of another building unit

ROOF DRAIN TERMINATION:

- Pipes Clogged or Non-Functional – blockage or failure of drainage pipes noted

👁🗨 Monitor 🔨Repair

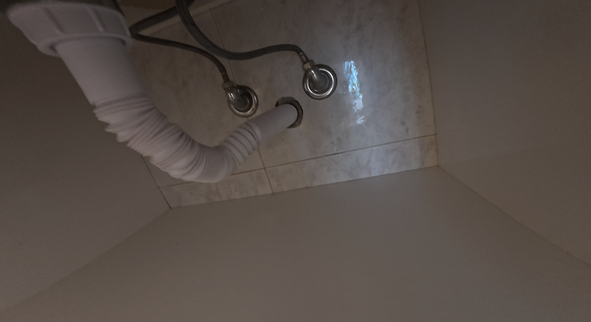

- DP-1 Drainage Plumbing:

BUILDING DRAINAGE SYSTEMS:

There were issues documented below in bulleted lists, narratives, and/or pictures related to the drainage system of the home: I recommend evaluation, repairs and maintenance as deemed necessary by a licensed plumber (or in some cases by other qualified parties).

PUBLIC SEWER:

- Older homes are even more prone to damage and elevates the importance of having a sewer scope done.

- Sewer scoping is recommended. Proper function of the building drain to the city sewer is beyond the scope of this inspection. I recommend that proper function be both determined and maintained. The best method to verify function is to have them inspected with a remote camera device. I recommend the drains associated with this property be professionally scoped by a qualified drainage scoping company (preferably one not associated with, or part of, a plumbing repair company).

EXTERIOR CLEAN-OUT:

- Older building – exterior clean-out may not have been required – retrofitting recommended only during broader plumbing updates

- Main clean-out not located – may be hidden or absent; recommended to confirm location with owner or during plumbing work

S-TRAPS:

- ◽Kitchen sink, more information in kitchen section

- S-Traps are installed on kitchen sink and may affect drainage. They can be prone to siphoning.

VENTING:

- Vent does not extend above roof line – termination through exterior wall noted; this is a common practice in Portugal, but clearance from openings must still be respected

- Vent termination located less than 1 meter above exterior door – insufficient clearance for safe air dispersion

PVC VENTS:

- Patches present on pipe – evidence of repair work; functionality and sealing should be confirmed

- HCFV-1 Heating, Cooling, Fireplaces and Ventilation:

HEAT:

- Only source of heat found in the home. I did not test and do not recommend turning this on. Consider the whole home to be unheated.

- BIDS-4 Building Interiors, Doors and Stairs:

INTERIOR DOORS:

Many of the interior doors show evidence of wear-and-tear associated with the age and use of the home. Adjustments/repairs/maintenance should be anticipated as normal for all doors. I recommend repairs by a qualified party as warranted. The bulleted lists, narratives and/or pictures below document some of these conditions:

INTERIOR DOORS:

- Broken – Door is visibly broken or structurally compromised.

- Damaged – General surface or edge damage noted.

- Not functional – Door cannot be opened, closed, or latched properly.

- Doors that don’t latch noted at – Latching issues prevent secure closure.

- Door not aligned properly in jamb – Frame or hinge misalignment affecting function.

TRIM/JAMBS:

- Mechanical damage – Latch, knob, or lock shows physical wear or damage

HAND-SET/LATCHING:

- Not functional – Door latch or lock does not operate as intended

- Not functional typical of age – Latch hardware non-functional due to age; repair or replacement recommended

- K-2 Kitchen:

KITCHEN SINKS/COUNTERTOPS/CABINETS:

There were issues documented below in bulleted lists, narratives and/or pictures related to the Kitchen sink, cabinets, and countertops:

SINK CONCERNS:

- SINK NOT PROPERLY CAULKED AT CONNECTION WITH COUNTERTOP – hygiene concern due to unsealed edges

DRAINAGE:

- TRAP/COMPONENTS NOT PROFESSIONALLY INSTALLED – trap shape, seal, and arm must be to standard with listed components and proper venting

- NOT TESTED – water not turned on at the time of inspection

- DRAIN RESULTS IN S-TRAP – prone to siphoning; not compliant

CABINET CONCERNS:

- Mechanical Damage – Cabinet surfaces or hinges are visibly damaged.

ATTACHMENT CONCERNS:

- Cabinets With Inadequate Attachment – Improperly secured cabinets pose a risk of collapse. Full evaluation of all units by a qualified carpenter or cabinet installer is recommended, with repairs undertaken where needed.

I recommend evaluation and repair by a qualified party.

- B-5 Bathrooms:

EXHAUST FANS:

There were issues documented below in bulleted lists, narratives and/or pictures related to the bathroom exhaust fan:

COMPONENTS/CONDITION:

- No exterior ducting – Vent fan appears to vent internally or is disconnected

I recommend evaluation, repairs and maintenance as deemed necessary by a qualified party.

Recommended Improvements

- ED-4 Exteriors and Decks:

EXTERIOR DOOR CONDITIONS:

There were issues documented below in bulleted lists, narratives and/or pictures related to the exterior doors of the home. All should be evaluated, repaired and maintained as deemed necessary by a qualified door installation contractor or other qualified party.

MECHANICAL DAMAGE:

- Some mechanical damage to door noted — cosmetic or minor functional impacts observed

JAMB/OPENING:

- Mechanical damage to trim/jamb — combined damage to both components

- Weathering or damage to trim/jamb — from sun, rain, or age-related exposure

- Decay/rot in door trim — wood deterioration noted

HINGES:

- Rusting hinges — may weaken structural support over time

LOCKSET & SECURITY:

- Less than professional installation — recent lock replacement was performed with less than professional quality of work. Permanent damage to door was caused.

DEAD-BOLT:

- Deadbolt not installed properly — visible misalignment, tilt, or improper hardware

Concerns will be documented in the pictures below but should not be construed to be all inclusive but instead more representative:

🛑 Safety 🔨Repair

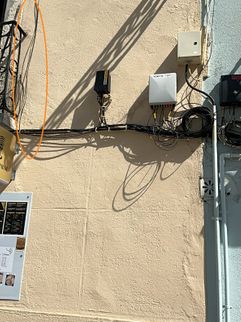

- ES-1 Electric Service:

ELECTRICAL SERVICE TO PROPERTY:

There were issues documented below in bulleted lists, narratives and pictures related to the Electrical Service to the property that should be evaluated and maintained as deemed necessary by the appropriate qualified parties. Additional issues should be anticipated and uncovered during repairs.

LOW VOLTAGE UTILITY WIRES:

- Inadequately attached to side of house — insecure mounting may result in sagging or disconnection

- EDFW-1 Electric Distribution and Finish Wiring:

ELECTRICAL SYSTEM WIRING TYPES:

There were issues documented below in bulleted lists, narratives, and/or pictures related to the wiring in the home that should be evaluated and repaired as deemed necessary by a licensed electrical contractor. It should be seen as representative of the concerns and not all inclusive.

ELECTRICAL NON-METALLIC TUBING (ENT):

- Not connected properly – connections are loose, misaligned, or insecure

- Improper connector – wrong type or size of connector used for the application

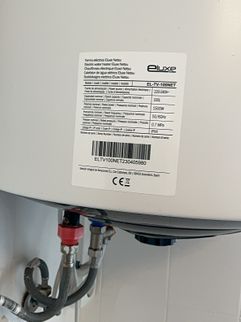

- P-2 Plumbing:

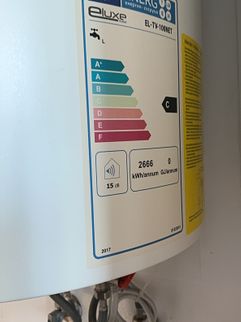

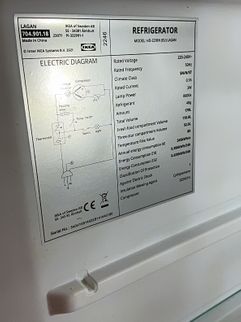

ELECTRIC WATER HEATER:

There were issues documented below in bulleted lists, narratives, and/or pictures related to the water heater had the conditions discussed below that should be further evaluated, repaired and maintained as deemed necessary by a licensed plumber (or in some cases, repairs can be made by other qualified parties):

DRAIN:

- Not a proper place of termination – termination location does not meet best practice or safety guidance

- BIDS-5 Building Interiors, Doors and Stairs:

STAIR CONDITIONS:

There were issues documented below in bulleted lists, narratives and/or pictures related to the stairs that indicate the need for evaluation, repairs and maintenance by a qualified stair installation contractor. I recommend such work prior to use of the stairs.

STAIR GENERAL INFORMATION:

- 🚶♂️ Use caution navigating stairways until defects are evaluated and repaired

STAIR RISERS:

- ⚠️ Inconsistent riser heights noted — uneven first step height presents a trip/fall hazard

HANDRAILS:

- Handrail missing — not installed on one or more sides where expected

🛑 Safety 🔨Repair

- B-1 Bathrooms:

FLOORS/WALLS/CEILINGS/CLOSETS:

There were issues documented below in bulleted lists, narratives and/or pictures related to the ceilings:

STONE/TILE FLOOR:

- ◽Staining

- Tiles:

- ◽Mechanical damage

- ◽Staining of grout

WALL/CEILING CONCERNS;

- Shrinkage or settlement cracks observed – minor cracking consistent with seasonal or material movement

- Evidence of prior repairs – patches, color mismatch, or retexturing visible

- ◽Some areas have headroom below 2.40 m – typically seen in attic conversions or unpermitted spaces

- Wood ceiling materials used in close contact to the shower – wood is very prone to heavy moisture damage and rot. Monitor regularly

I recommend evaluation, repairs and maintenance by a qualified party as desired.

- B-2 Bathrooms:

BATHROOM SINKS/COUNTERTOPS/CABINETS:

There were issues documented below in bulleted lists, narratives and/or pictures related to the sink, cabinets and countertops:

FAUCET:

- Water Shut-Offs Not Tested – Local shut-off valves beneath the sink found but not turned

DRAINAGE:

- TRAP/COMPONENTS NOT PROFESSIONALLY INSTALLED – trap shape, seal, and arm must be to standard with listed components and proper venting

- DRAIN RESULTS IN S-TRAP – prone to siphoning; not compliant

- CORRUGATED TRAP/DRAIN COMPONENTS PRESENT – not compliant; prone to clogging and poor flow

- NOT TESTED – water not turned on at the time of inspection

TOWEL BARS/HOOKS/TP:

- TP holder:

- ◽Damage noted to toilet paper holder

I recommend evaluation and improvements by a licensed plumber.

- B-3 Bathrooms:

BATHTUB CONDITIONS:

There were issues documented below in bulleted lists, narratives and/or photos related to the tub in the second floor bathroom:

WATER FLOW AND TEMP:

- Not tested—water not turned on – Functionality not verified due to water supply being off

SHOWER HEAD:

- Damaged – Physical or mechanical defects noted

TUB DRAINAGE:

- Drainage not tested – Functionality not confirmed during inspection

WALLS AROUND TUB:

- Evidence of tiles having been painted over – Tiles show signs of being painted rather than replaced

- Bathtub surround does not drain into tub – Damage from water escaping due slope issues

I recommend evaluation and repairs as deemed necessary by a licensed plumber.

- B-4 Bathrooms:

SHOWER CONCERNS:

There were issues documented below in bulleted lists, narratives and/or pictures related to the tub in the main bathroom:

SHOWER:

- Wall finish not waterproof to 1.5m height – May not meet hygiene standards

FAUCET COMPONENT:

- Damaged handle – Handle is present but cracked or broken

WATER FLOW:

- Not tested--water not turned on

SHOWER DRAINAGE:

- Drainage not tested – Functionality not confirmed during inspection

- Some fraying on shower hose

- Shower pan modified to allow clearance for cleanout

I recommend evaluation and maintenance as deemed necessary by a licensed plumber or other qualified party.

🛑 Safety 🔨Repair 🔧 Maintenance ➕ Upgrade 🔍 Due Diligence

The Full Report

Electric Service

Electric Service Main Panel

Main Panel Photo Bucket

Main Panel Observations

Electrical Grounding/Bonding

Electrical Grounding and Bonding Observations

Electric Distribution and Finish Wiring

Branch Wiring

Wiring Photo Bucket

Electrical Distribution and Finish Wiring Observations

Plumbing

Supply Plumbing

Supply Plumbing Photo Bucket

Plumbing Observations

Water Heater

Water Heater Photo Bucket

Water Heater Observations

General Comments

Building Characteristics, Conditions and Limitations

Style of Home: Pombaline (Pombalino 🇵🇹)

Type of Building : Row House/Townhouse (Moradia em Banda 🇵🇹), Duplex

Approximate Year of Original Construction: Estado Novo Era:, 1951

Reported Area: 159m2

Reported Energy Class: F

Reported Bedrooms: T4

Reported Bathrooms: 2

Attending the Inspection: Listing Agent

Personal Belongings Present: No

Occupancy: Unoccupied

Animals Present: No

Weather during the inspection: Sunny

Approximate temperature during the inspection: 20°C to 25°C

Last Measurable Rain : 1 to 2 days

Ground/Soil surface conditions: Dry

Front Façade Orientation: Northwest (Noroeste 🇵🇹)

Pre-2004 Structures: Lead

Homes constructed prior to 1962 in Portugal likely contain lead-based paints, both interior and exterior. While lead in paints was significantly restricted starting in 1962, materials already in use remained in place, and some exposure risk may still exist, particularly where paints are deteriorating or disturbed. Lead is not considered hazardous when it is intact and not friable (i.e., not chipping or airborne), but deteriorating surfaces can pose health concerns.

Lead was common in paints, lead supply piping, glazes of old bathtubs, brass fixtures, galvanized pipes (zinc has small amounts of lead) and numerous other building materials. The acidity of the water is an important factor in how much lead is leached from plumbing fixtures and pipes.

As Portugal aligned with European Union directives in the 1980s and 1990s, including those on drinking water quality and construction products, the use of lead was further restricted. Notably, the REACH Regulation and the Drinking Water Directive set limits on the allowable levels of lead in plumbing and consumer materials, effectively eliminating its use in modern construction.

It is advisable to maintain painted surfaces in good condition and avoid sanding or stripping old paint unless proper lead-safe practices are followed. When remodeling or removing old materials, professional evaluation and handling are recommended to minimize lead exposure risks.

Regardless the date, there is no guarantee houses after this date do not have lead.

Pre-1999 Structures: Abestos

Homes constructed prior to 2005 in Portugal may contain asbestos in various building materials, including roofing panels, insulation, floor tiles, pipe insulation, and certain textured wall or ceiling coatings. Asbestos is not considered a health risk when intact and undisturbed, but it becomes hazardous if the material is damaged or deteriorates, releasing fibers into the air. Inhalation of asbestos fibers can cause serious health problems, including asbestosis, mesothelioma, and lung cancer. It is strongly recommended not to disturb suspected asbestos-containing materials. If renovations or repairs are planned, especially in older homes, a licensed professional should evaluate the materials and, if necessary, conduct testing and removal in accordance with applicable safety regulations. For safety, materials suspected of containing asbestos should be left intact and encapsulated unless professional removal is required.

Grounds

Grounds Information

Clearance to Grade: Standard Clearances

Walkway Composition: Calçada

Calçada is a traditional style of Portuguese paving made from natural stone arranged in intricate, decorative patterns. Commonly seen in historic city centers, sidewalks, and public plazas, calçada is celebrated for its aesthetic appeal and cultural significance. However, maintaining calçada requires regular attention. Over time, weather conditions can cause the stones to shift or become uneven, and the joints between stones may deteriorate, leading to gaps or weed growth. Periodic cleaning is necessary to remove dirt, moss, and algae that can accumulate, while occasional re-leveling and repointing are recommended to restore its original appearance and ensure the durability of the pavement.

Exteriors and Decks

Info for Exteriors and Decks

Trim Material: Masonry, Granite

Siding Material: Stucco

Eaves: Parapet wall

Exterior Doors: Tilt and Turn, Timber (Wood) Door

Exterior of Windows: Thermally Broken Aluminum, Wood

Window opening types: Tilt and Turn, Fixed, Casement

Deck, Porches, Balconies: Juliet Balcony

Guardrail: Metal

Decking materials: Elastomeric Over Concrete

Limitations/Exclusions Related to Exteriors: Present

The following limitations and exclusions were noted related to the exterior of the home;

EXTERIORS LIMITATIONS:

- Most of exterior difficult to assess due to proximity to adjacent buildings

- Some components not included in this inspection

Exterior and Deck Observations

EXTERIOR TRIM:

There were issues documented below in bulleted lists, narratives and/or pictures related to the exterior trim of the home. All should be evaluated, repaired and maintained as deemed necessary by a qualified door installation contractor or other qualified party.

WOOD TRIM:

- Failed Paint- Areas of failed paint coating on surfaces.

- Failed caulk — deterioration of sealant observed

- Cracks and weathering — indicative of low-quality or aged trim materials

- Mechanical damage evident — dents, breaks, or deformation observed

- Trim behind roof structures — may restrict proper flashing or water control

MECHANICAL DAMAGE:

- Mechanical damage noted — dents, bends, or deformation observed on trim surfaces

- Patching and repairs noted — prior attempts to fix damaged areas identified

CLEARANCE CONCERNS:

- Trim in contact with roof surfaces — limits proper water runoff and may accelerate decay

STONE TRIM:

- Mechanical damage evident — dents, breaks, or deformation observed

- Mortar joint deterioration evident — cracking or erosion may allow water intrusion

- Cracks present — visible splits or fractures noted

MECHANICAL DAMAGE:

- Patching and repairs noted — prior attempts to fix damaged areas identified

- Mechanical damage noted — dents, bends, or deformation observed on trim surfaces

🔨Repair 👁🗨 Monitor annually

BUILDING EXTERIOR:

There were issues documented below in bulleted lists, narratives and/or pictures related to the Building's Exterior. The following concerns should be evaluated and repaired by a qualified party as deemed necessary. Hidden damage in exterior cladding is common and should be anticipated.

BUILDING STRUCTURE:

- Walls appear unreinforced — no visible signs of embedded steel or modern reinforcement; this is common in older homes and may limit seismic resilience.

- Wall separation or misalignment — leaning or offset planes may indicate past movement, soil shifting, or inadequate bracing.

- Decay or rot in decorative corbels — common in older or ornate facades

- Cracks in masonry walls — may suggest aging, movement, or limited seismic reinforcement in older structures; structural evaluation is advised if concerns arise.

- Bulging or displaced masonry walls — visible outward movement of brick, stone, or blockwork may signal hidden structural issues; further review recommended.

EXTERIOR CONDITION:

- General exterior surface failure — widespread signs of wear, aging, or damage

- Failed cladding materials — deformation, cracking, or separation from wall structure

MOISTURE PROTECTION:

- Missing or inadequate flashing — missing or improperly installed flashing at transitions and penetrations

- Signs of historic water penetration — staining or material degradation visible at wall bases

- Visible moisture staining — evidence of past or ongoing water infiltration

- Inadequate waterproofing at wall penetrations — insufficient sealing around pipes, vents, or other penetrations

MASONORY STONE OR TILE ISSUES:

- Plaster deterioration or bubbling — suggests trapped moisture behind the exterior surface

- Exterior wall bowing or displacement — outward bulging or shifting indicating structural movement

IDENTIFICATION CONCERNS:

- Building identification number missing or not visible — all buildings must display a clearly visible "número de polícia" affixed to the façade for emergency and visitor access

- Missing numbers — no street numbers present at entry or façade

🔨Repair 🛑 IMMEDIATE REPAIRS 🛑 SAFETY

WINDOW CONDITIONS:

There were issues documented below in bulleted lists, narratives and/or pictures related to the windows of the home. I recommend further evaluation, repairs and improvements of these conditions by a qualified window installation/repair contractor.

GENERAL CONDITIONS:

- Single-pane windows — less energy-efficient; consider upgrading

RECENT REPLACEMENT:

- Recent installation — methods not determined — installation appears recent; unable to fully verify methods or flashing; monitor for future issues

- Caulking missing at some locations — localized deficiencies observed

EXTERIOR WINDOW SILLS:

- Much deterioration/decay in exterior wood sills — significant conditions noted on multiple windows

INTERIOR WINDOW SILLS:

- Staining noted — moisture exposure or general wear observed

- Decay present — moisture damage affecting material integrity

INTERIOR WINDOW COVERINGS/BLINDS:

- Some blinds function with difficulty — sticking, catching, or misalignment noted

- Damaged blinds noted — slats bent, broken, or warped

- Functioned with difficulty — repeated trouble operating smoothly

WOOD SINGLE PANE:

- I recommend factoring the replacement of all remaining older windows in the home by a qualified window installation company. All existing windows should be properly maintained until they can be replaced.

- Window replacement should include evaluation, repair, or replacement of trim, sills, and related components as well.

Some of the issues will be documented in the pictures below but should not be construed to be all inclusive but instead more representative.

👁🗨 Monitor ➕ Upgrade 🔨Repair

EXTERIOR DOOR CONDITIONS:

There were issues documented below in bulleted lists, narratives and/or pictures related to the exterior doors of the home. All should be evaluated, repaired and maintained as deemed necessary by a qualified door installation contractor or other qualified party.

MECHANICAL DAMAGE:

- Some mechanical damage to door noted — cosmetic or minor functional impacts observed

JAMB/OPENING:

- Mechanical damage to trim/jamb — combined damage to both components

- Weathering or damage to trim/jamb — from sun, rain, or age-related exposure

- Decay/rot in door trim — wood deterioration noted

HINGES:

- Rusting hinges — may weaken structural support over time

LOCKSET & SECURITY:

- Less than professional installation — recent lock replacement was performed with less than professional quality of work. Permanent damage to door was caused.

DEAD-BOLT:

- Deadbolt not installed properly — visible misalignment, tilt, or improper hardware

Concerns will be documented in the pictures below but should not be construed to be all inclusive but instead more representative:

🛑 Safety 🔨Repair

DECK:

The deck structure had numerous issues and no attempt to document all these issues will be made in this report. The bulleted lists, narratives and/or pictures related to the information below should be seen as more representative as opposed to all inclusive and other concerns should be anticipated. Concerns were noted in relation to:

FLOOR STRUCTURE:

- Paint or coating failure on framing components — protective barrier deteriorated; increased moisture risk

- Signs of settlement or sagging — minor deflection in deck surface may indicate shifting supports or framing fatigue

- Sloping towards building — signs of moisture entering the building apparent

MASONRY:

- Settlement visible — masonry or concrete has shifted or sunken; may indicate subsurface instability

- Cracks observed in masonry or tile — minor structural movement or thermal stress likely

- Repairs noted — prior patching or modifications visible; condition should be monitored

- Spalling or surface deterioration — concrete flaking or erosion evident; durability may be compromised

🛑 Safety 👁🗨 Monitor

Roof, Attics, Chimney and Gutters

Roof info

Method of Roof Inspection: Viewed with drone

Roof Style: Hip

Roof Structure: Timber

Roof Covering Materials: Marseilles Tiles (flat)

Flashings: Mortar Flashing

Approximate Age of Roof Covering: Original to house

Chimney: Masonry

Gutters and Downspouts: Plastic

Roof Inspection Limitations / Exclusions: Includes attic spaces

This report provides an opinion of the general condition of the roof system based on a visual inspection of representative areas. The inspector does not offer an opinion or warranty as to whether the roof leaks or is subject to future leakage.

- Water stains on ceilings, walls, and soffits that tested dry at the time of inspection may test elevated for moisture under other conditions or at another time.

- Specific notation of leakage or stains does not preclude additional areas of leakage and/or hidden damage. Monitor attic for any changes; ongoing or questionable situations should be assessed and corrected. Leakage can lead to Mold or Mold-like/Fungal Growth.

LIMITATIONS TO INSPECTION OF ROOF/STRUCTURES:

- Not walked on

- Height

- Fragile Roofing

- Roof covering at end of expected life

- Vegetative debris on roof

- Moss covering

- Lichen growth in some areas

ABOVE CEILING SPACES:

- No access to any above ceiling spaces found

ROOF DRAINAGE:

- Vegetative debris on roof

- Scuppers blocked preventing proper drainage

CHIMNEYS:

- Present but sealed

Roof, Attic, Chimney and Gutter Observations

ROOF CONSTRUCTION CONDITIONS:

There were issues documented below in bulleted lists, narratives, and/or pictures related to the roof. Concerns related to the vaulted roof installation should be evaluated, replaced, and repaired as deemed necessary by a qualified party or parties.

Cracks in the ceiling near the dormers appear to have developed after recent painting was completed, which suggests that movement may be ongoing; I strongly recommend that a qualified professional evaluate the area to determine whether any structural concerns exist, regardless of any previous cosmetic repairs.

ROOF CONSTRUCTION:

- SAGGING TILE ROW – Green reference line illustrates expected straight alignment; actual roofing tiles are visibly sagging below this line, indicating possible structural deflection.

- VARIATION IN DORMER CONSTRUCTION – Differences in dormer materials indicate they were likely installed after the original construction.

- Converted into living space — Vaulted roof areas that have been converted to living space must meet structural, insulation, and ventilation requirements. Such conversions may not be compliant unless formally permitted and reviewed.

RAFTERS:

- Much sagging of rafters noted – excessive deflection observed, likely requiring evaluation by a structural professional

- Poorly supported – rafters lacking sufficient structural connections or bearing points

- Unsupported – rafter span observed without intermediate or end support as needed

🛑 SAFETY 🛑 IMMEDIATE REPAIRS 👁🗨 Monitor during use 🔨Repair

CHIMNEYS:

There were issues documented below in bulleted lists, narratives, and/or pictures related to the chimney at the West side of the home that was in unknown condition and will need to undergo maintenance.

CONDITIONS RELATED TO THE CHIMNEY:

- Capped/Abandoned – chimney is no longer in use and has been sealed; ensure cap is weather-tight and monitor for future leaks

I recommend evaluation of the above conditions by a qualified chimney repair contractor, experienced with this type of chimney.

🔍 Due Diligence

ROOF AREA CONDITIONS: There were issues documented below in bulleted lists, narratives, and/or pictures related to the roof area components that should be evaluated and repaired as deemed necessary by a qualified party.

When the attic is not traversed or only partially traversed there will be much that cannot be determined, such as:, roof leaks, broken/missing framing, missing fire-blocking, air-bypasses, roof sheathing concerns, missing/compromised insulation, chimney issues, vermin activity, mold and/or wood decay, and none of this should be implied as being all inclusive

INSULATION:

- Missing – insulation not present where expected in roof or ceiling cavities, which compromises thermal resistance

NOT INSULATED:

- Vaulted ceiling areas

- Connection with upper living area

PRESENT MOISTURE IN ATTIC/ROOF SPACE:

- Signs of water intrusion around roof penetrations – Staining or discoloration near chimneys, vents, or skylights may indicate flashing failures or past leaks.

- Low clearance impeding inspection – Access to attic space was restricted due to limited height, which prevents full visual inspection. Undetected issues should be assumed where obstructions exist.

- over moisture meter measureable limit

PAST LEAKS:

- Active leak into roof structure – Moisture was actively entering through visible openings or damaged waterproofing; source should have been identified and sealed by a qualified roofing professional.

- Leaks at roof valleys – Stains and material lifting indicated water accumulation and entry along valleys where tiles or membranes were insufficiently sealed or degraded.

🔧 Maintenance (as needed) 👁🗨 Monitor 🛑 SAFETY 🛑 IMMEDIATE REPAIRS

ROOF PAST EXPECTED LIFE:

There were issues documented below in bulleted lists, narratives, and/or pictures related to the roof that was in very poor condition. I recommend replacement of the roof by a qualified roofing contractor. A full evaluation and repair of underlying surfaces is recommended and proper repairs made as deemed necessary. Some amount of hidden damage should be anticipated. The following conditions were noted but should not be construed to be all inclusive.

ROOF GENERAL CONCERNS:

- Cracked or chipped tiles – Damage from impacts or thermal stress compromising tile integrity.

- Improper flashing – Faulty sealing around roof penetrations allowing water ingress.

- Algae or moss growth – Organic accumulation retaining moisture and accelerating wear.

- Sagging roof sections – Structural issues causing depressions or uneven surfaces.

- Mechanical damage – Impact from debris or foot traffic causing cracks or dislodged tiles.

- Cracked or broken tiles – Tiles exhibiting fractures, potentially leading to leaks.

- Extensive use of Butly repair tape – widespread use of Butyl tape which has failed

Flashings:

- Failed

- Failed at chimney

- Failed at pipes

- Failed valleys

Ponding:

- Past/ongoing ponding – Recurrent signs of water accumulation noted; condition appears to persist over time and may require correction to avoid material degradation or leaks.

ROOF GENERAL CONDITIONS:

There were issues documented below in bulleted lists, narratives, and/or pictures related to the roof. I recommend evaluation, repairs and maintenance of the roof by a qualified roofing contractor. Conditions related to specific types of roof coverings will be discussed below. The conditions should not be construed to be all inclusive but instead more representative:

ROOF INSPECTION:

- Cracked or broken tiles – Individual clay tiles exhibiting cracks or breaks can allow water infiltration, compromising the roofing system.

- Mortar deterioration at ridge caps – Degraded mortar can lead to ridge cap instability, posing risks of tile displacement and leaks.

- Algae or moss growth – Organic growth retains moisture against tiles, potentially leading to accelerated wear and structural concerns.

- Improper lapping of roofing material over gutters – Roofing materials not extending adequately over gutters can result in water damage to fascia and soffits.

MOSS/LICHEN/ALGAE:

- Lichen colonization – Lichen formations noted on tile surfaces, which can penetrate and deteriorate the tile material over time.

- Moss growth on clay tiles – Thick moss layers observed, retaining moisture and potentially leading to tile displacement and water infiltration.

- Vegetation growth between tiles – Plants or weeds growing in gaps between tiles, indicating prolonged moisture retention and potential structural issues.

- Root intrusion under tiles – Roots from vegetation penetrating beneath tiles, possibly lifting them and compromising the roof’s integrity.

- Blocked drainage paths – Organic growth obstructing water flow, leading to water pooling and increased load on the roof structure.

- Discoloration and staining – Visible staining from biological growth, which may signify underlying moisture problems.

LEAKING INTO THE ROOF STRUCTURE WAS NOTED AT:

- Leaking into roof structure – moisture entry visible or suspected at multiple roof areas

- Soffits – water entry at eaves due to slope or flashing issues

- Missing shingles – exposed areas increasing risk of infiltration

- Valleys – improper slope or mortar failures

GUTTER CONDITIONS: There were issues at the home, documented below in bulleted lists, narratives, and/or pictures related to the roof drainage system. I recommend evaluation and repairs by a qualified gutter installation contractor or other qualified party is recommended. Failed gutters can cause damage to the home and not direct water properly away from the home.

Care should be taken related to maintenance of gutters as they represent a safety hazard for falls and other injuries.

ROOF DRAINAGE SYSTEM ISSUES: