The inspection was performed in accordance with the current Standards of Practice and Code of Ethics of ASHI (American Society of Home Inspectors). The standards contain certain and very important limitations, expectations, and exclusions to the inspection. A copy is available prior to, during, and after the inspection and it is part of the report.

Who should make repairs and what should their qualifications be?

Worker qualifications: In the text of the report, in some instances, I recommend that work be done by a "qualified" persons or "qualified" parties. I consider qualified parties, in licensed trades, to be those individuals who hold the necessary licenses to legally work in their profession -- licensed electricians, licensed pest control applicators, licensed plumbers, licensed HVAC professionals, licensed engineers, licensed general contractors, etc. In instances where a task may not, typically, need to be done by a person with a professional license, my recommendation is to hire an individual to do the work who is, based on past training, experience or expertise, qualified to further evaluate the condition or problem listed in the report and to then make appropriate repairs.

The Full Report

EXTERIOR/GROUNDS

Siding and Trim

Soffits/Fascia

Exterior Doors

Flatwork

Grading

Downspouts

Vegetation

Deck

Radon Mitigation System

BATHROOM(S)

PHOTOS

BATHROOMS

Sinks, Faucets and Drains

Toilet

Bathtub / Shower[Faucets, Drains and Surround]

Bathroom Ventilation

ELECTRICAL

Ground

Electrical Service

Panel

Panel 2

Branch Wiring

Receptacles and Fixtures

Smoke and CO Alarm Systems

PLUMBING

Main Water Shut-Off

Water Pressure

Exterior Hose Bibs

Pressure Regulator

Distribution Pipe

Drain Waste Vent

Expansion Tank

Water Heater

Sump Pump

Floor Drains (1)

GENERAL COMMENTS

Disclaimers

PROPERTY VACANT/OCCUPIED: Occupied

This house was occupied at the time of the inspection. Inspection of occupied houses presents some challenges as occupant belongings can obstruct visual inspection of and access to parts of the building. We do our best during inspection to work around belongings to discover as much as possible about the house without moving or damaging personal property; however, the presence of personal items does limit the inspection. All floor surfaces, wall surfaces, countertop surfaces, windows, and electrical receptacles could not be inspected or tested.

PERSONS PRESENT DURING THE INSPECTION: Client, Realtor Professional

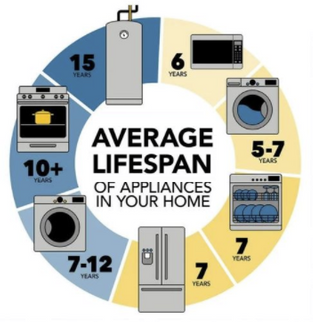

COMPONENT LIFE EXPECTANCY-: YES

Components may be listed as having no deficiencies at the time of inspection, but may fail at any time due to their age or lack of maintenance, that couldn't be determined by the inspector. A life expectancy chart can be viewed by visiting http://prohitn.com/component-life-expectancies/

Building Characteristics / Conditions

📸: Elevation Photos

Elevation Photos

APPROXIMATE YEAR OF CONSTRUCTION-Per the MLS listing or the DCPVA-: 2005

WEATHER DURING INSPECTION-: 🔹WEATHER

🔹WEATHER Clear

Clear 🔹GROUND SURFACE CONDITIONS

🔹GROUND SURFACE CONDITIONS Dry

Dry

TEMP. AT START OF THE INSPECTION: 80 degrees

80 degrees

ROOFING SYSTEM

Roofing Materials & Flashings

ROOF MATERIALS: Asphalt Shingles

Asphalt Shingles

METHOD OF ROOF INSPECTION: Drone

Drone

PERCENTAGE VIEWABLE: 90%

APPROX AGE: 15-20 years

Gutters

Plumbing Vent

Plumbing Vent: No concerns

No concerns

B-Vent

B-Vent: Not Present

Not Present

EXTERIOR/GROUNDS

Siding and Trim

SIDING and TRIM: Vinyl

Vinyl

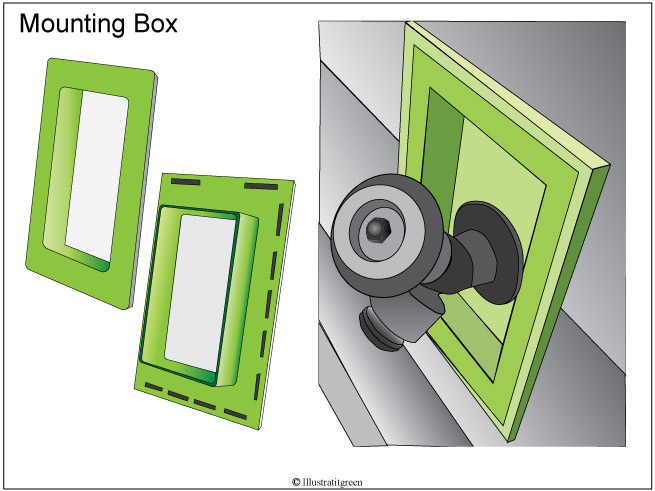

One or more penetrations through the siding (e.g., hose bibs, electrical meters, exhaust vents) were missing mounting blocks, had improperly installed mounting blocks, or had damaged mounting blocks. Properly installed mounting blocks are recommended at siding penetrations to help prevent water intrusion and related damage. Recommend evaluation and repairs by a qualified contractor.

Soffits/Fascia

CONDITION: No Concerns

No Concerns

Exterior Doors

CONDITION: No Concerns

No Concerns

Flatwork

Driveway: Concrete

Concrete

Walks: Concrete

Concrete

Patio: Concrete

Concrete

Porch: Concrete

Concrete

Grading

CONDITION: No Concerns

No Concerns

Downspouts

CONDITION: No Concerns

No Concerns

Vegetation

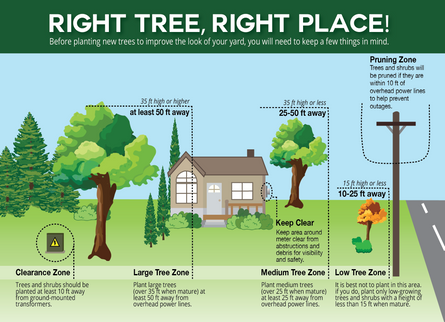

One or more trees are too close to or overhanging the roof. This can increase the risk of damage to the home, promote moisture issues, and provide pathways for rodents. Recommend evaluation by a qualified arborist for pruning or removal as needed to maintain safety and proper clearance.

Deck

Location: Back

Back

Settlement was observed at one or more deck support posts, with at least one post leaning. This condition may indicate inadequate footing support or soil movement and can compromise the deck’s stability. Further evaluation and repairs by a qualified contractor are recommended.

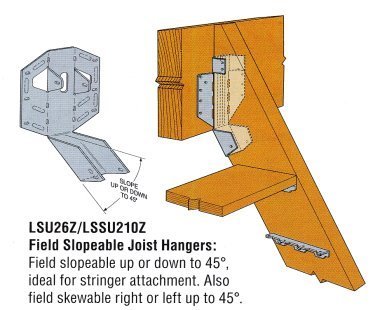

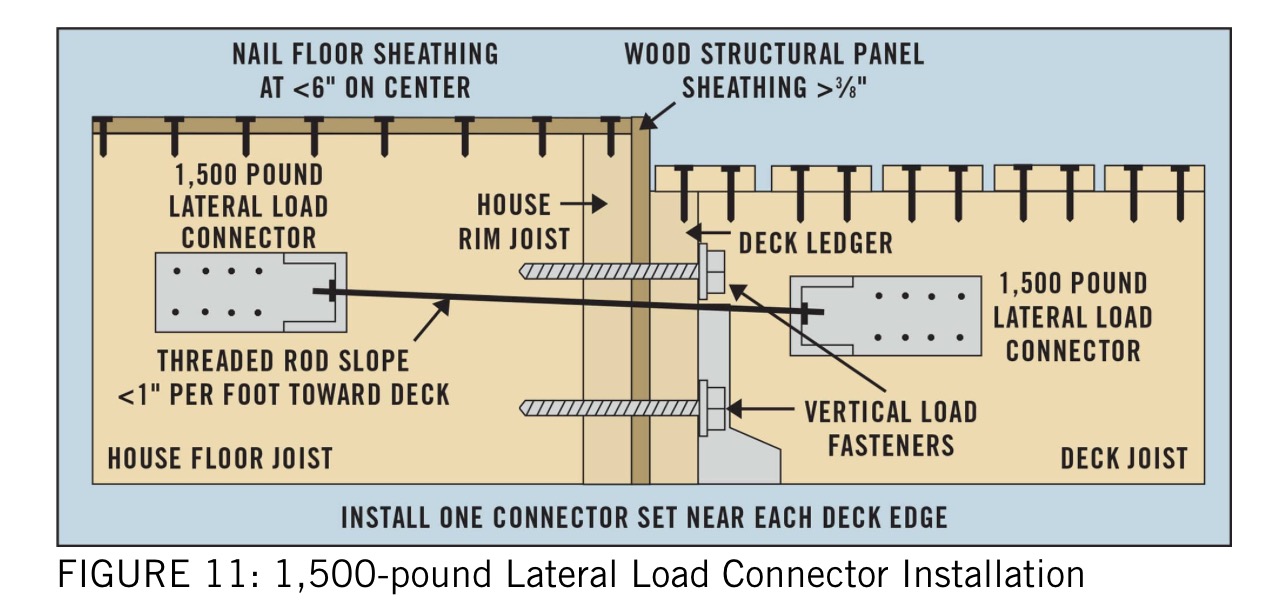

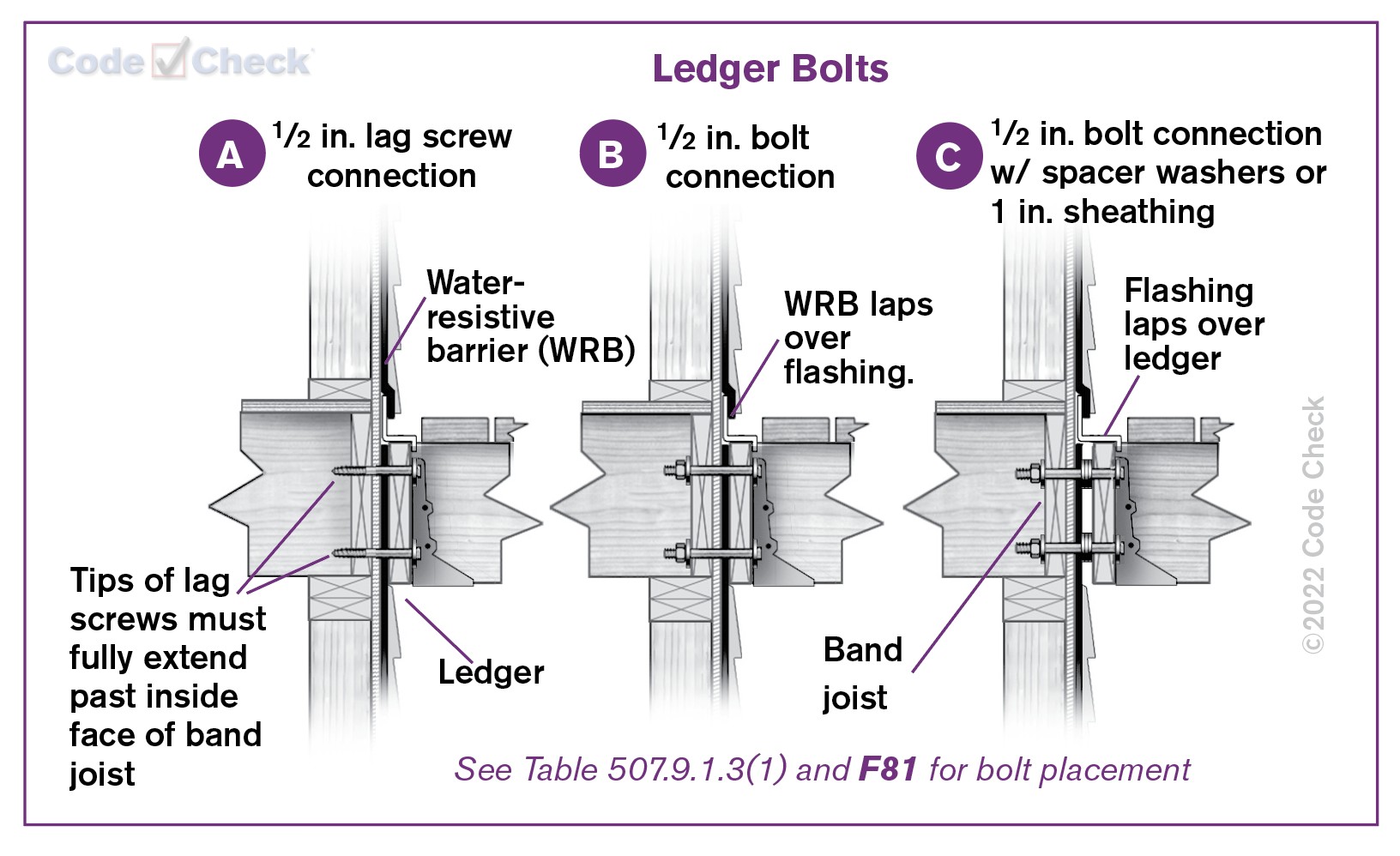

There were no lateral load connectors observed at the deck connection to the home. The lateral load connectors help with the deck load that is pulling away from the home. The lag bolts/screws handle more of the vertical load. Recommend corrections be made by a qualified deck contractor.

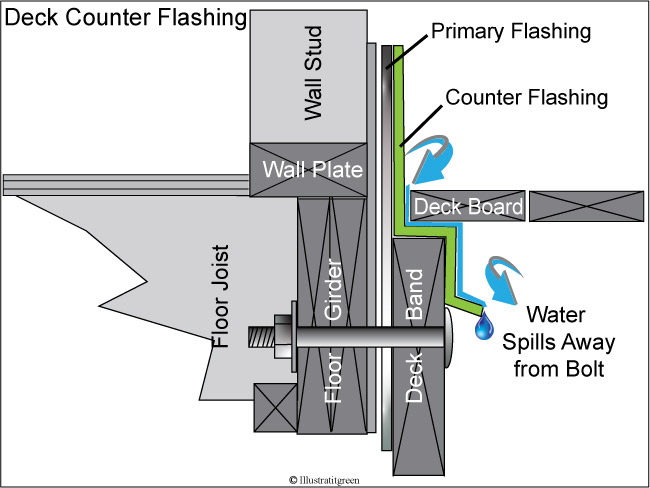

- No flashings were

noted between the deck ledger board and the home. This could allow water to get trapped between the deck and the house, causing rot and a conducive pest condition. This can be a difficult retrofit once the deck is constructed. Recommend repairs by a qualified contractor.

- Right side deck

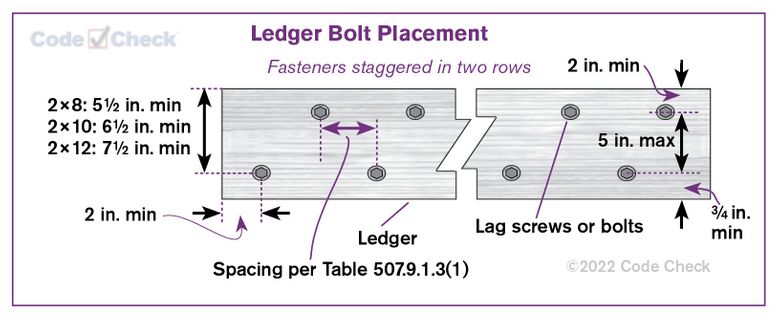

The deck ledger board was attached to the home with fasteners that are not rated for this type of installation. Using the wrong fasteners makes the deck more prone to failure. The required fasteners for this attachment are 1/2" lag bolts and or 1/2" lag screws. Recommend repairs be made by a qualified deck contractor.

- Right side deck

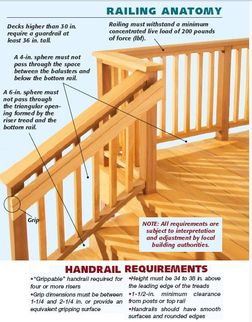

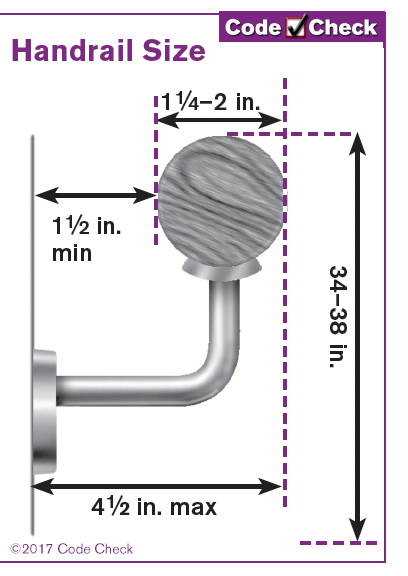

The stairs are missing a graspable handrail for safety. This should be a round railing 1 1/4" - 2" in diameter. If the railing is not round it must have a finger groove that is 3/4" down from the tallest point of the rail. The graspable handrail should also be 1.5" from the wall. 2x material is not considered a graspable handrail. Have a qualified contractor build suitable railings to reduce the potential for falls.

Radon Mitigation System

CONDITION: Not Present

Not Present

GARAGE/CARPORTS

Garage/Carport/Detached Building

TYPE OF STRUCTURE: Attached Garage

Attached Garage

SERVICE DOOR: No Concerns

No Concerns

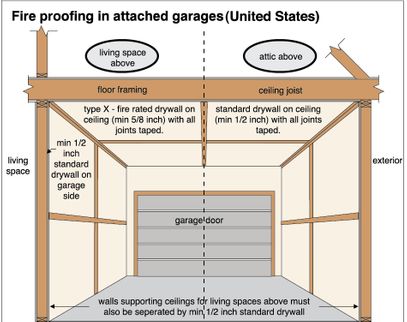

An unprotected opening[s] was found in the garage fire separation between the garage and living space. This should be repaired to complete the fire separation between the house and the garage. Large holes should be repaired with the proper sheetrock materials. Small holes and openings should be sealed with mud or high temperature of "fire stop" caulking. Recommend repairs be made by a qualified contractor.

During the inspection, physical damage was observed on the garage door, that may include dents and scratches. Despite the visible damage, the door operates as intended, opening and closing smoothly without any issues. No immediate functional concerns were noted. Recommend monitoring and make repairs as necessary.

KITCHEN

Sinks, Faucets and Drains

Cabinets and Countertops

CONDITION: No Concerns

No Concerns

Kitchen Appliances

REGRIGERATOR CONDITION: No Concerns

No Concerns

DISHWASHER CONDITION: No Concerns

No Concerns

MICROWAVE CONDITIONS: No Concerns

No Concerns

EXHAUST FAN: Vents to Exterior

Vents to Exterior

RANGE/OVEN CONDITIONS: No Concerns

No Concerns

DISPOSAL CONDITIONS: No Concerns

No Concerns

LAUNDRY AREA

Laundry Room/Area

WASHER & DRYER: Present but not tested

Present but not tested

DRYER ENERGY SOURCE: Electric

Electric

WASHER DRAIN: No Concerns

No Concerns

LAUNDRY TUB: Not Present

Not Present

WASHER BIBS AND HOSES: No concerns

No concerns

BATHROOM(S)

BATHROOMS

BATHROOM LOCATION: Main Floor

Main Floor Basement

Basement

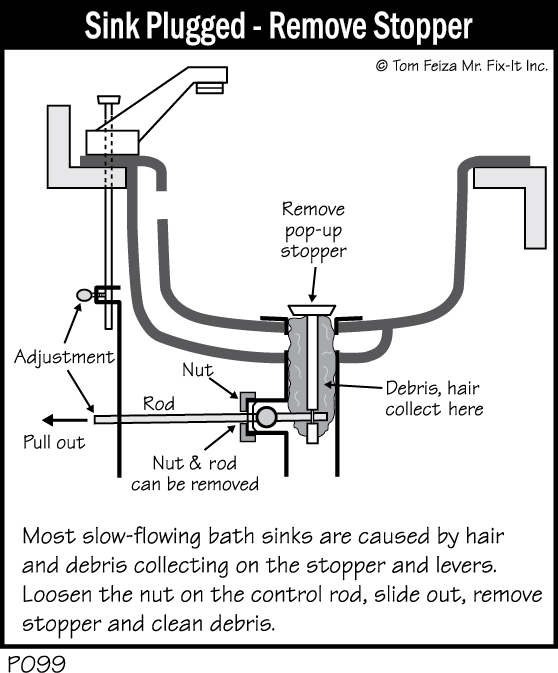

Sinks, Faucets and Drains

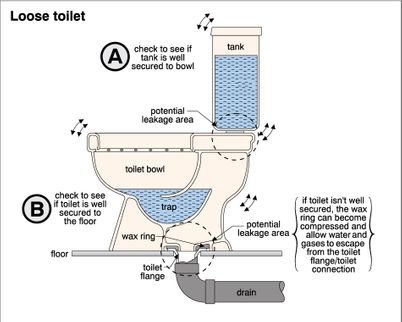

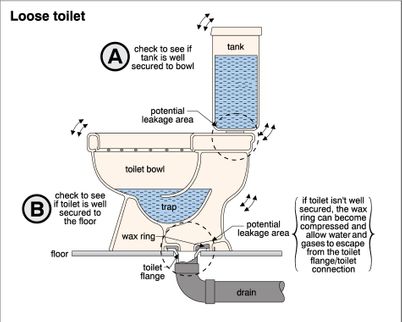

Toilet

One or more bathroom toilets were found to be loose at the base. This may indicate loose mounting bolts, a damaged flange, or subfloor deterioration, and could lead to a compromised wax seal and potential leaks. Recommend repairs be made by a qualified plumbing contractor.

- Master

- Basement

Bathtub / Shower[Faucets, Drains and Surround]

Shower/Tub : No Concerns

No Concerns

Bathroom Ventilation

OPERATION: No Concerns

No Concerns

FIREPLACE/WOOD STOVE

FIREPLACE TYPE

FIREPLACE TYPES: Ventless, Gas

Ventless, Gas

FIREPLACE

FIREBOX: Steel

Steel

The pilot light for the gas fireplace was not turned on. The ASHI standards of practice prevents me from lighting and operating fireplaces when the pilot light is not lit. It is recommended that the pilot be lit and the fireplace operation be verified with the current owner. Recommend any repairs necessary be made by a qualified HVAC contractor.

Chimney Scan

CHIMNEY SCAN VIDEO AND PICTURES:

CHIMNEY SCAN VIDEO LINK

Here is the video and audio recorded during your chimney scan inspection. Please contact me if you have any questions or need assistance viewing the video.

FIREPLACE/WOOD STOVE Basement

FIREPLACE TYPE

FIREPLACE TYPES: Prefabricated, Wood Burning

Prefabricated, Wood Burning

FIREPLACE

HEARTH EXTENSION AND FACE WALL: No Concern

No Concern

FIREBOX: Refectory Panels

Refectory Panels

GLASS DOOR AND SPARK SCREEN : Functional

Functional

LOG GRATE: Unknown Rated

Unknown Rated

DAMPER: Functional

Functional

COMBUSTION AIR: Exterior Vent

Exterior Vent

The fireplace blower fan was not plugged in and could not be tested. Recommend connecting and testing for proper operation.

The fireplace grate in the prefab unit could not be confirmed as rated or approved for use with this specific model. Use of an incompatible grate may lead to overheating or damage. Recommend verifying compatibility with manufacturer specifications.

Chimney

FLUE TYPE: Metal

Metal

CHASE: Wood

Wood

CAP/SHROUD: Present

Present

CHASE COVER: Metal

Metal

FLASHING: Present

Present

Creosote buildup was observed inside the flue, which can reduce draft efficiency, limit visibility during camera inspection, and increase the risk of chimney fires. Recommend professional cleaning and evaluation before use.

INTERIOR

PHOTOS

Floors

CONDITION: No Concerns

No Concerns

Walls and Ceilings

CONDITION: No Concerns

No Concerns

Windows

CONDITION: No Concerns

No Concerns

Stairs and Railings

STAIRWELL: No Concerns

No Concerns

ELECTRICAL

Ground

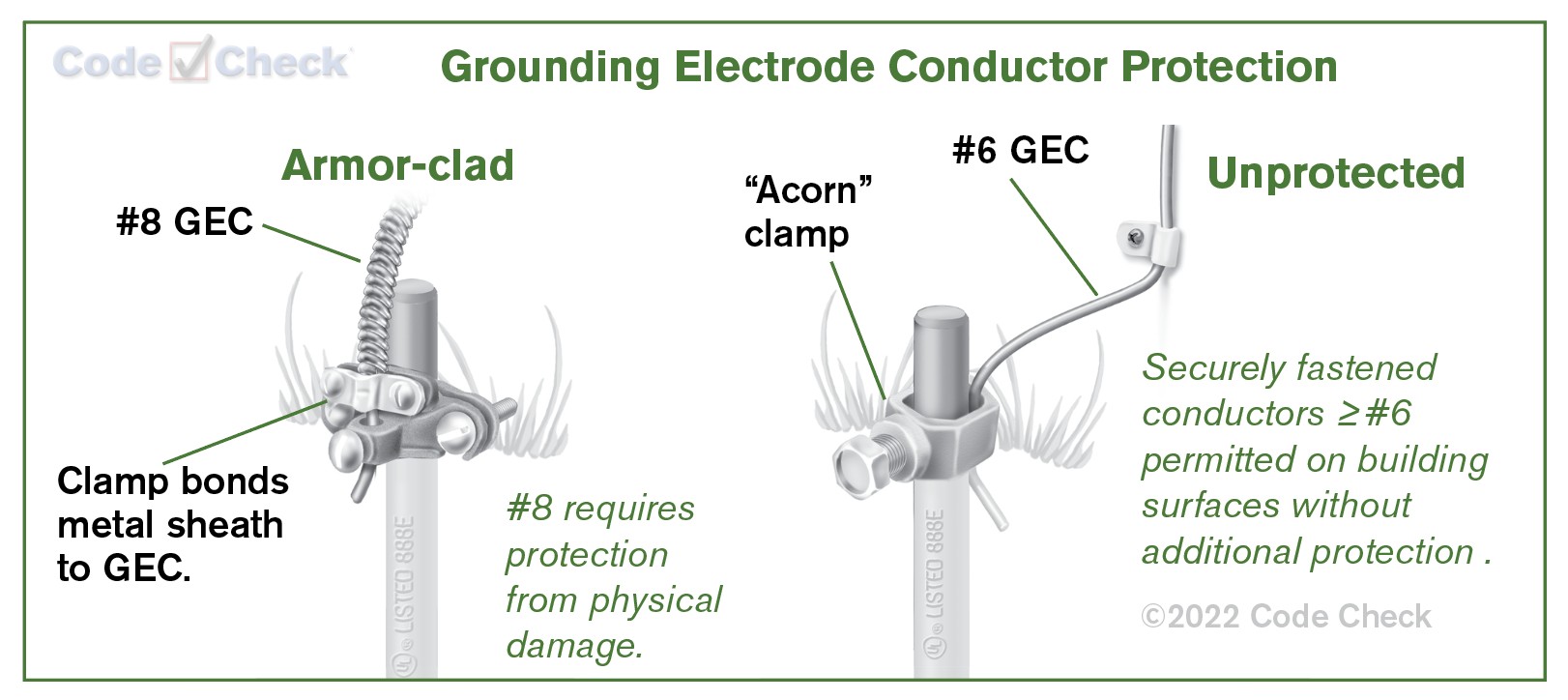

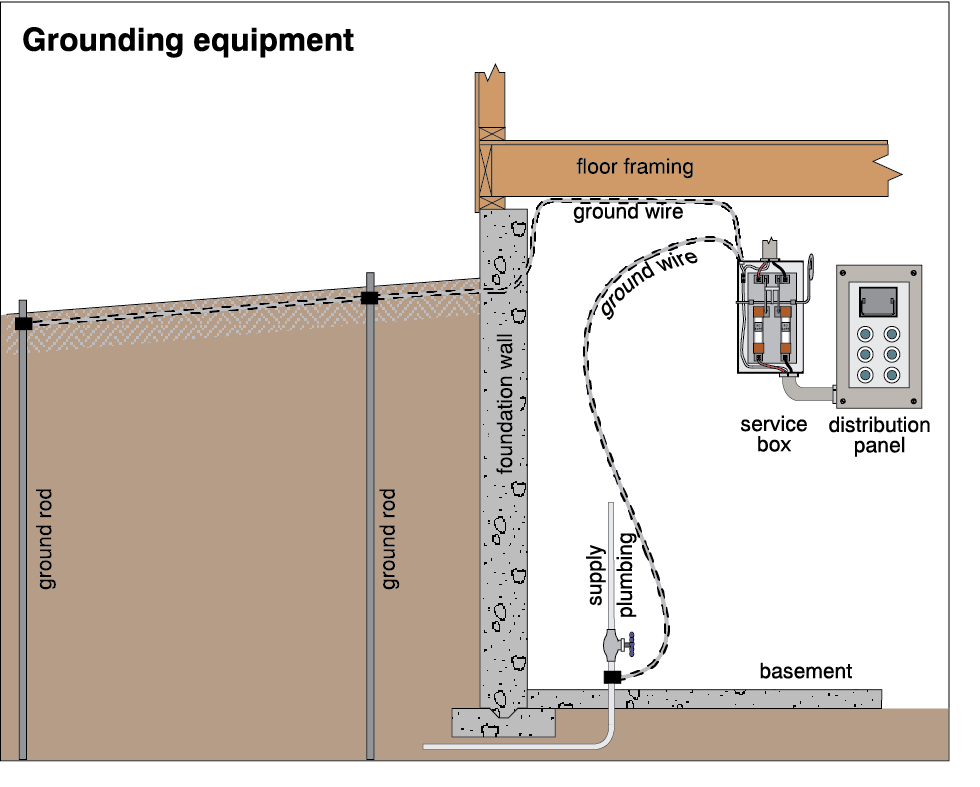

GROUNDING METHODS: Ground Rod

Ground Rod Plumbing Ground

Plumbing Ground Ufer Ground

Ufer Ground

The water supply line was not properly grounded and or bonded. Water pipes should be grounded within 5' from where they enter the home. Grounding and bounding help protect against electrical surges and against electrocution. Recommend repairs be made by a qualified electrical contractor.

Electrical Service

SERVICE TYPE : 🔹SERVICE ENTRANCE (Undereground)

SERVICE LOCATION: Left

Left

SERVICE AMPS: 400 amps

400 amps

Main Disconnect location: In the electrical panel

In the electrical panel

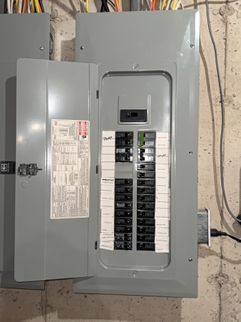

Panel

SERVICE PANEL MANUFACTURER: 🔹MANUFACTURER

🔹MANUFACTURER Cutler Hammer

Cutler Hammer

ELECTRIC PANEL LOCATION: 🔹LOCATION

🔹LOCATION Basement

Basement

PANEL AMPERAGE: 200 amps

200 amps

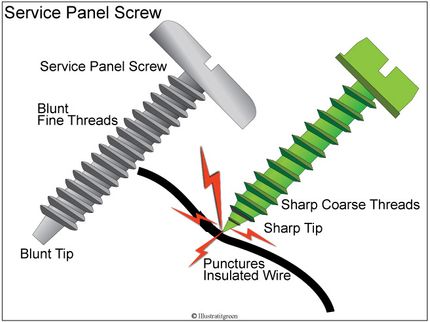

Screws with sharp ends, like wood screws, are not recommended to secure the dead-front cover to the electric panel as these can puncture wiring insulation. This condition can result in energizing the metal enclosure, which is a shock/electrocution hazard. Replace the current sharp screws with the correct blunt screws only.

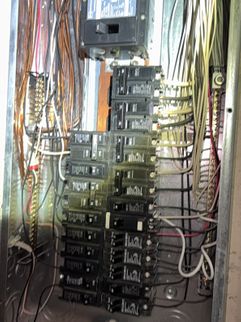

Panel 2

SERVICE PANEL MANUFACTURER: 🔹MANUFACTURER

🔹MANUFACTURER Cutler Hammer

Cutler Hammer

ELECTRIC PANEL LOCATION: 🔹LOCATION

🔹LOCATION Basement

Basement

PANEL AMPERAGE: 200 amps

200 amps

Branch Wiring

TYPE OF WIRE: Non Metallic Sheathed Cable

Non Metallic Sheathed Cable Aluminum 1960's to 1970's

Aluminum 1960's to 1970's Rag/Cloth Wiring

Rag/Cloth Wiring Knob & Tube

Knob & Tube

Receptacles and Fixtures

GFCI PROTECTION: No-Recommend update-[see observation]

No-Recommend update-[see observation]

AFCI PROTECTION: No-Recommended update-[see observation]

No-Recommended update-[see observation]

One or more outlets showed an open neutral, meaning the return path for electricity is disconnected. This can cause outlets or devices to stop working and may pose a shock or fire risk. Recommend evaluation and repair by a licensed electrician to ensure safe operation.

- Front yard

- Garage, multiple noted

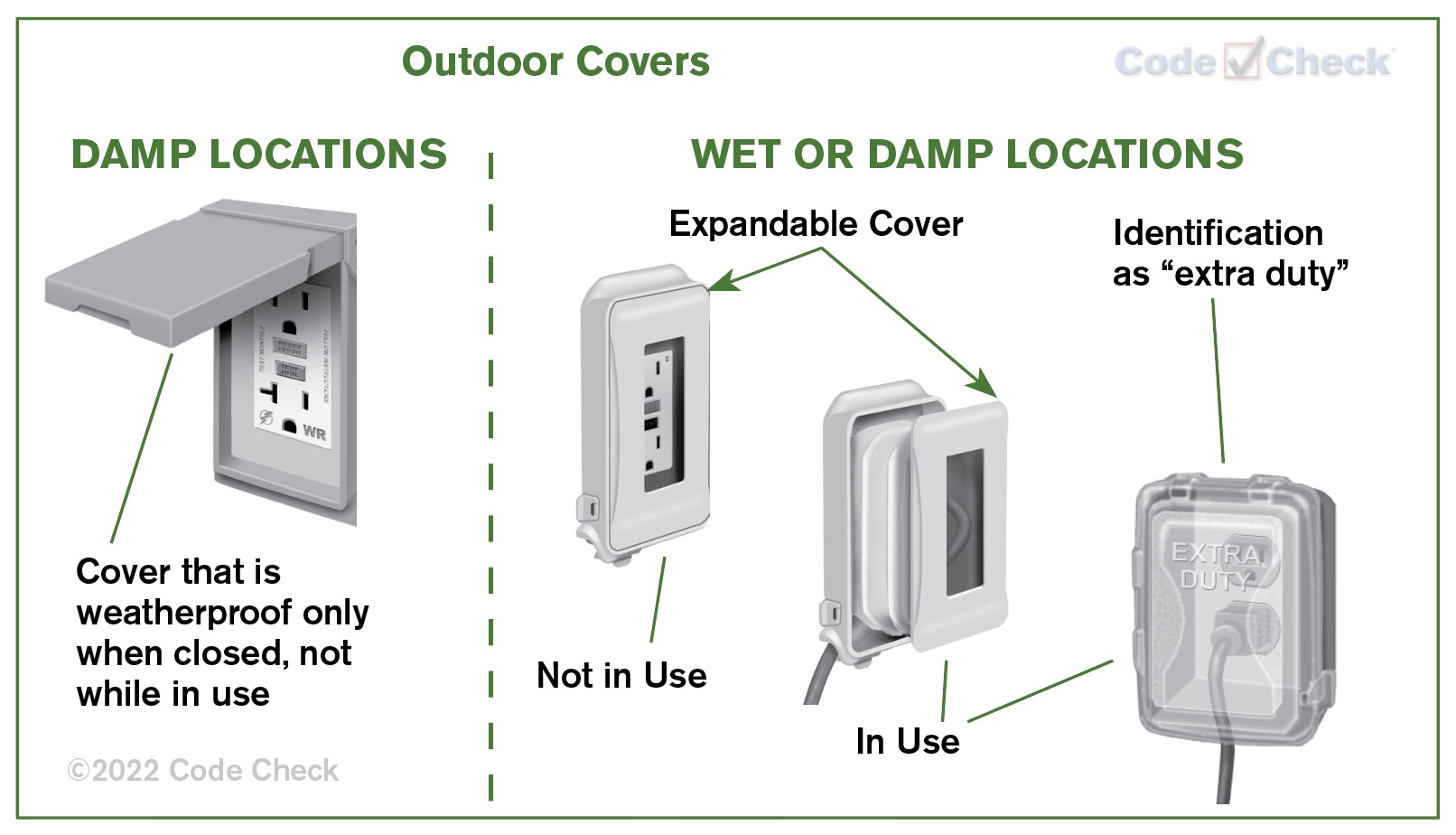

The exterior receptacle in wet and or damp locations lack proper covers. Receptacle covers rated for wet locations should allow for receptacle to be sealed while in-use. Recommend upgrades be made by a qualified electrical contractor.

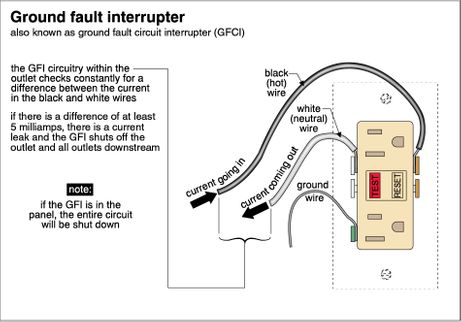

The use of GFCI (Ground Fault Circuit Interruption) protection is inconsistent with modern minimum standards for safety. GFCI's protect against electrocution by limiting the duration of an electrical shock. Hire a licensed electrician to further evaluate and update this home's system for improved safety.

- Garage

- Laundry room

- Under kitchen sink

- Master bathroom

- Basement bar

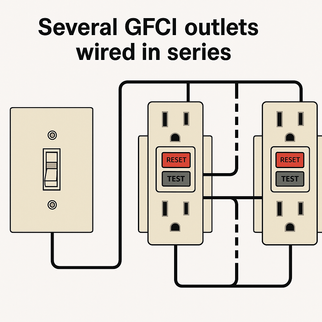

- Several GFCI outlets were found wired in series. While not a safety hazard, this is a non-standard installation and can cause confusion when resetting, as one outlet may not reset until another is cleared. Recommend having a licensed electrician evaluate and correct if desired.

- in the garage

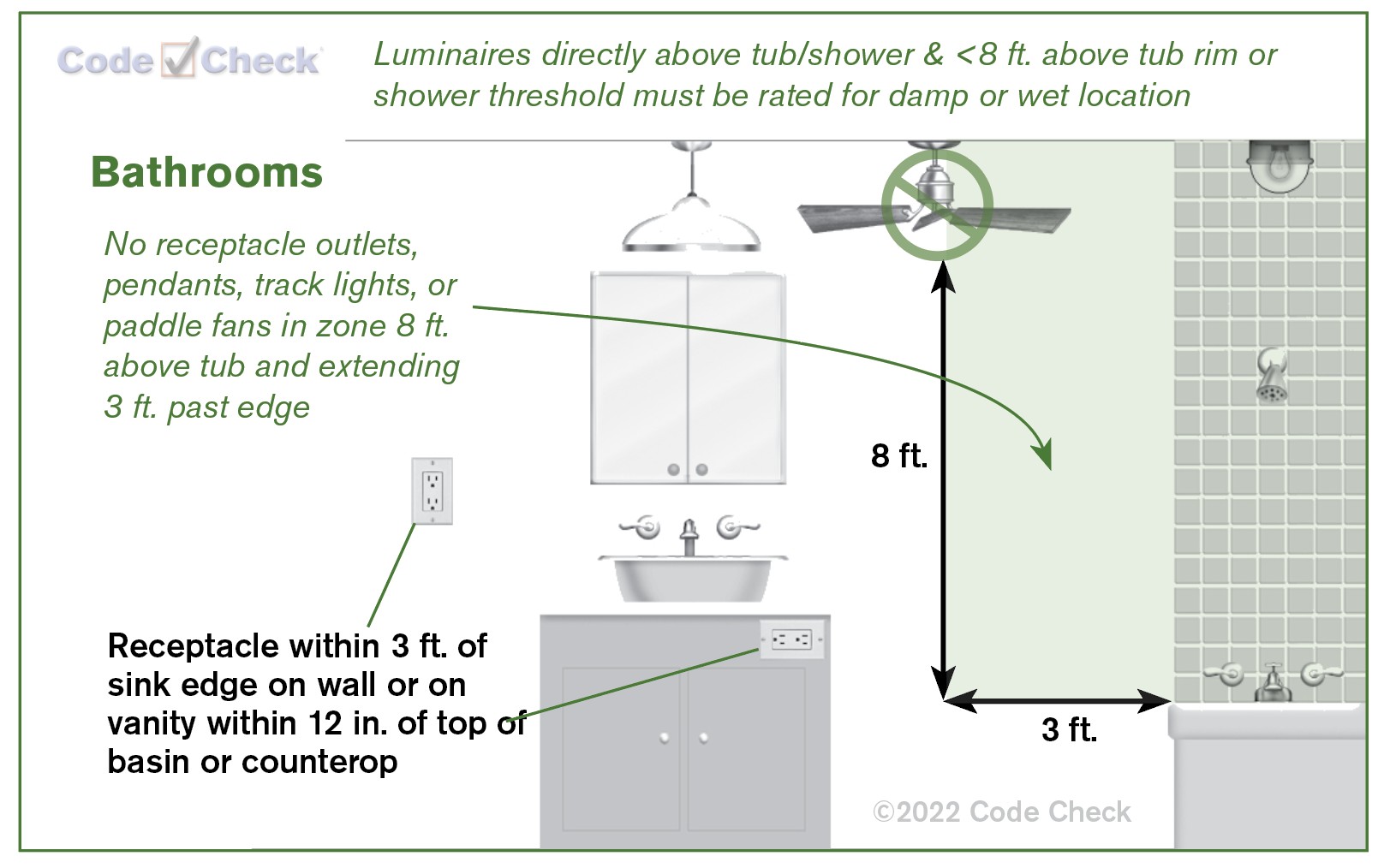

The ceiling fan in the bathroom does not appear to be damp rated. Damp rated fans are designed for areas with high humidity but no direct exposure to moisture. If a ceiling fan that is only rated for dry locations is installed in a bathroom the fan may degrade prematurely and there is the potential for electrical shorts. Recommend repairs be made by a qualified electrical contractor.

The ceiling fan is wobbling during operation. This can indicate the fan blades are not properly balanced. There is also a risk that the fan may be poorly mounted. Ceiling fans are heavy and need adequate support to the house framing. This is not visible to inspection. I recommend having the fan serviced and repaired as recommended by a qualified contractor.

- Bedroom 1

- Basement

- Basement bedroom

The loose outlet/s should be secured to prevent accidental damage to the wiring connections. Securing loose outlets can often be done by just tightening some set screws between the receptacle and the junction box, though sometimes it can get more complex if the box itself is loose. Recommend repairs be made by a qualified electrical contractor.

- Bedroom 1

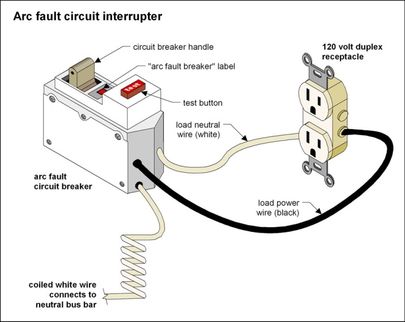

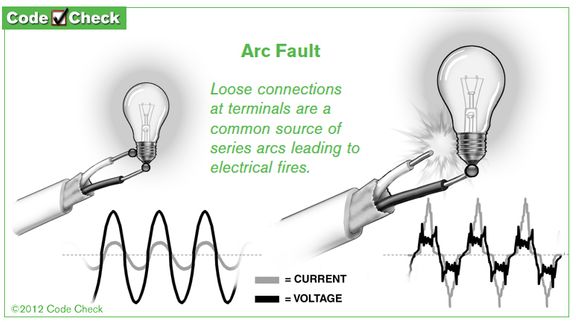

AFCI (arc fault protection) is now required on all branch circuits supplying outlets or devices installed in residential dwelling unit kitchens, family rooms, dining rooms, living rooms, parlors, libraries, dens, bedrooms, sunrooms, recreation rooms, closets, hallways, laundry areas, and similar rooms and areas. The goal of this protection is to reduce risks of electrical fires. Consult with a licensed electrician about improving circuit protection as desired.

Smoke and CO Alarm Systems

SMOKE ALARMS : Present

Present

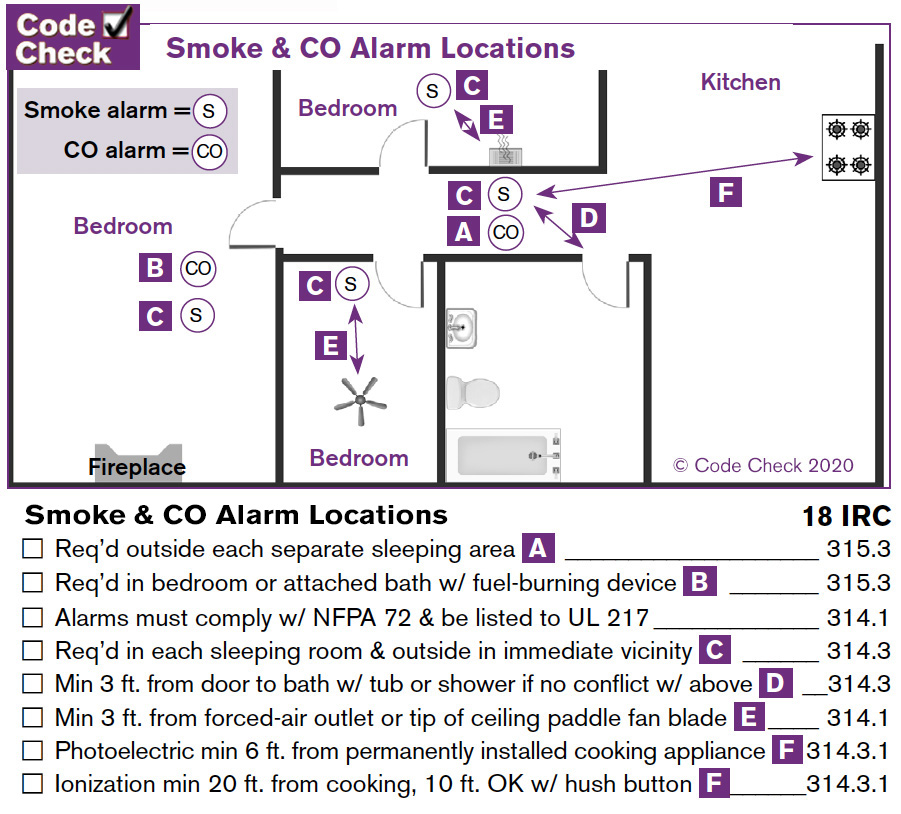

CO alarms were missing in one or more locations. CO alarms are an important safety feature and are recommended outside of all sleeping areas. It is also recommended that there be at least one CO alarm on each floor of the house. [ recommend having CO alarms installed to meet modern safety standards.

PLUMBING

Exterior Hose Bibs

OPERATION: Functional

Functional

Distribution Pipe

SUPPLY PIPE MATERIALS : Copper

Copper

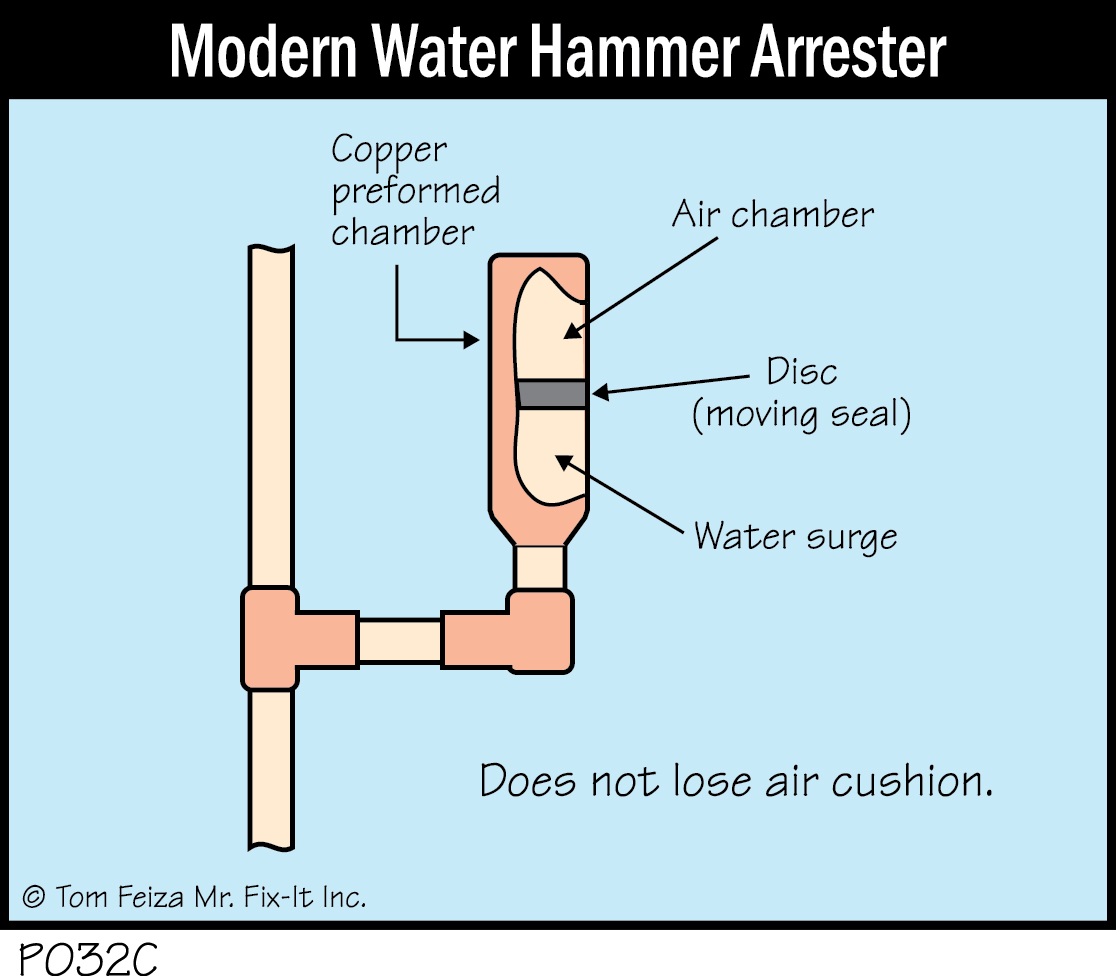

Hammer arresters were missing at one or more locations. These are required by current building standards for all quick closing valves such as washing machines, dishwashers and ice makers. Hammer arresters are used to absorb the shock when water suddenly stops. Recommend upgrades be made by a qualified plumbing contractor.

Drain Waste Vent

WASTE/DISCHARGE TYPE: Public sewer

Public sewer

PIPE MATERIALS: PVC

PVC

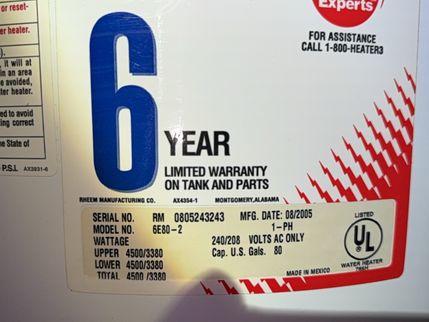

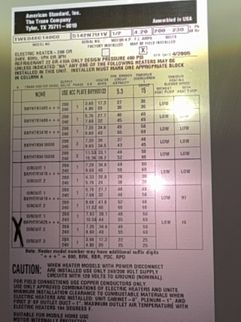

Water Heater

SYSTEM TYPE & MANUFACTURER: 🔹SYSTEM TYPE

🔹SYSTEM TYPE Tank

Tank 🔹ENERGY SOURCE

🔹ENERGY SOURCE Electric

Electric

TEMPERATURE PRESSURE RELIEF VALVE: Present - Not Tested

Present - Not Tested

AREA SERVED: Whole House

Whole House

AGE: 2005

CAPACITY: 80 Gallons

80 Gallons

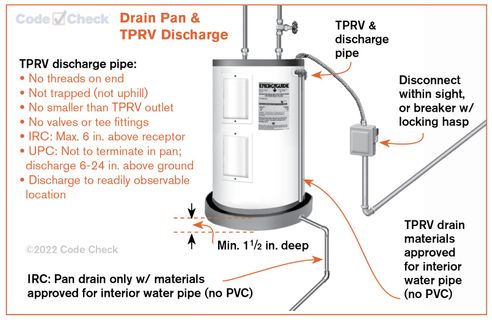

The discharge pipe of the water heater temperature/pressure relief (TPR) valve was terminated more than 6" above the floor. This condition could result in scalding if the pressure relief valve were activated while a person was nearby. The Inspector recommends correction by a qualified plumbing or HVAC contractor.

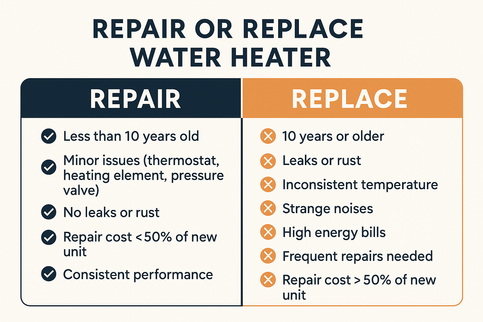

FYI - The water heater was nearing or past its typical service life. Major repairs or replacement should be anticipated in the future due to its age alone. Depending on prior maintenance and other factors the unit could last anywhere from months to years, the remaining life is undetermined. A typical life expectancy for a gas water heater is 8-12 years and an electric is 10-15 years.

Floor Drains (1)

FLOOR DRAIN: No Concerns

No Concerns

FUEL & DISTRIBUTION

Propane Storage

STORAGE TYPE: Above ground tank

PROPANE TANK SIZE & LOCATION: 🔹SIZE

🔹SIZE 150 gal

150 gal 🔹LOCATION

🔹LOCATION Side of structure

Side of structure 🔹SHUTOFF LOCATION

🔹SHUTOFF LOCATION At Tank

At Tank

COOLING SYSTEMS

Cooling System

COOLING SYSTEM TYPE: Central Air

Central Air

AREA SERVED: Whole House

Whole House

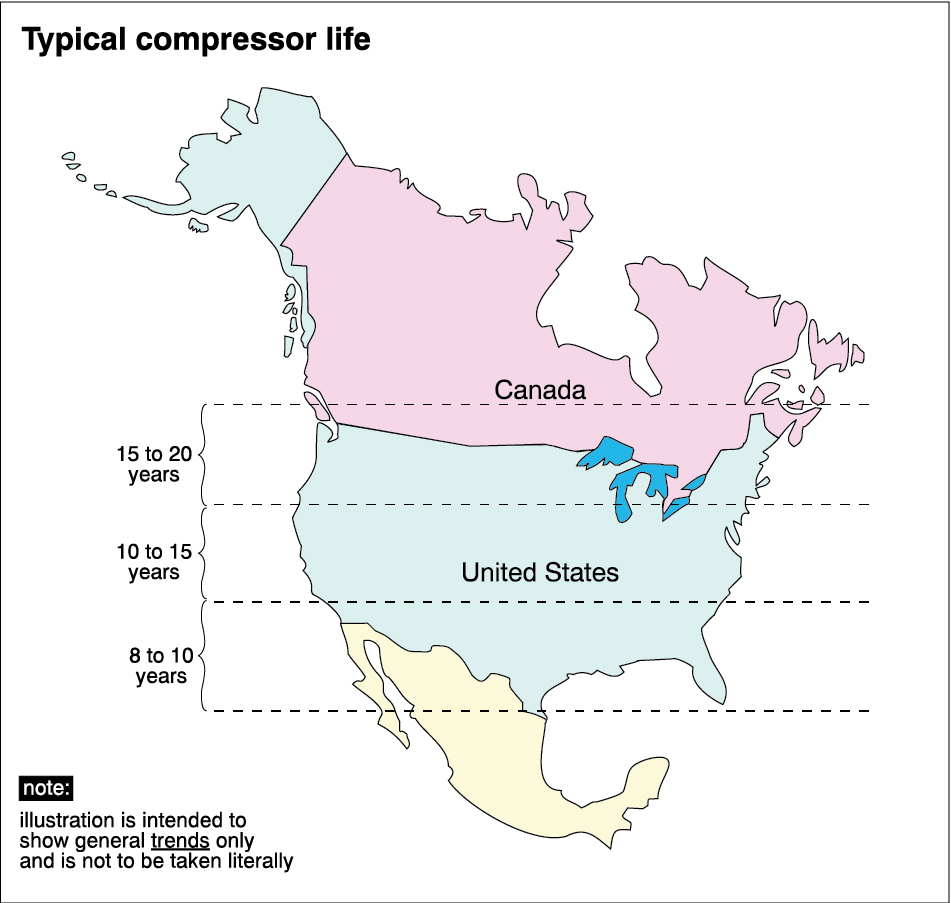

AGE: 2004

2004

CAPACITY: 4 ton

4 ton

The AC disconnects are mounted too high for proper access. Electrical code generally requires that disconnects be readily accessible, with the center of the operating handle not more than 6 feet 7 inches (79 inches) above the ground or working platform. Recommend adjustment by a qualified electrician to ensure compliance and safe operation.

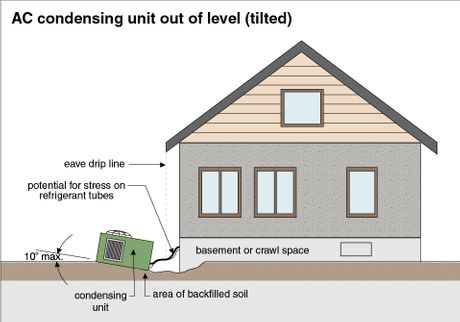

Equipment Not Installed Level : The outdoor condensing unit pad is not level. Mechanical requirements call for ground-supported equipment to be level and firmly supported on a concrete slab or other approved material at least 3 inches above grade, per manufacturer instructions. Recommend evaluation and correction by a qualified HVAC contractor.

The air conditioner uses R-22 refrigerant, which was phased out by 2020 due to environmental concerns. R-22 is now expensive and hard to find, and retrofitting is often not practical. Repairs may be difficult, and early replacement may be necessary. Recommend consulting an HVAC professional for options.

HEATING SYSTEMS

Heating System

HEATING SYSTEM: 🔹HEATING METHOD

🔹HEATING METHOD Forced air furnace

Forced air furnace 🔹ENERGY SOURCE

🔹ENERGY SOURCE Electricity

Electricity

AREA SERVED: Whole House

Whole House

THERMOSTAT LOCATION: Main Floor

Main Floor

Age: 2005

FILTRATION SYSTEM: Disposable

Disposable

Be sure to change your air filters for the furnace every 90 days or so.

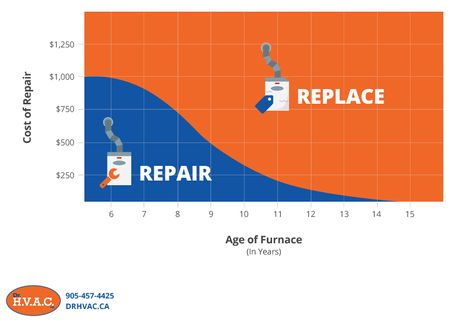

This furnace is old and past its useful design life. The average service life of forced air furnaces is 15-20 years. I recommend having this furnace serviced and the heat exchanger inspected by a qualified heating contractor. If this furnace is kept in service, budget to update at anytime.

HVAC Distribution System

SUPPLY: Metal Ducts

Metal Ducts

RETURN: Central

Central

STRUCTURE/BASEMENT

Foundation

FOUNDATION TYPE: Basement

Basement Poured

Poured

% OF FOUNDATION NOT VISIBLE: 40%

Structure

STURCTURE TYPE: Wood Frame

Wood Frame

ATTIC

Attic Access

CONDITION: No Concerns

No Concerns

% OF ATTIC VISIBLE: 75%

75%

Roof Framing & Sheathing

TRUSS/RAFTER TYPE: Truss

Attic Insulation

INSULATION TYPE: 🔹INSULATION TYPE (Cellulose)

Ventilation

ATTIC VENTILATION METHOD: Soffit vents

Soffit vents Ridge vents

Ridge vents

Attic Wiring/Lighting

CONDITION: No Concerns

No Concerns

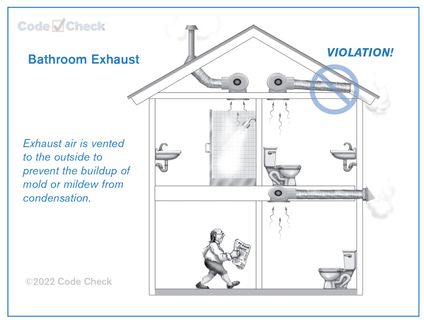

Bathroom Fan Termination

A bathroom exhaust vent terminates in the attic instead of at the home exterior. This condition can raise moisture vapor levels in the attic to the point at which home materials are damaged or unhealthy conditions related to bio growth develop. The inspector recommends correction by a qualified person.

Sewer Inspection Report

Access Point

Access Point: Cleanout

Cleanout

Sewer (Public/Septic)

Sewer System Type: Public

Public

Inspections Findings

LIMITATIONS: GRINDER PUMP SCOPE LIMITATION

GRINDER PUMP SCOPE LIMITATION

PIPE MATERIAL(S): PVC

PVC

GRINDER PUMP SCOPE LIMITATION

The sewer lateral inspection was limited to the section of pipe from the access point to the grinder pump, known as the drain inlet gravity service line (typically 3–4 inches in diameter). This section can usually be inspected in full unless blocked. The pipe beyond the grinder pump, called the ground sewage outlet line, is approximately 1-1/4 inches in diameter and cannot accommodate the inspection camera.

Videos

VIDEO: Video

SEWER SCOPE VIDEO LINK

Here is the video and audio recorded during your sewer scope inspection. Please contact me if you have any questions or need assistance viewing the video.

Pest

PEST

MOLD

Possible Mold: No Concerns Observed

No Concerns Observed

YOUR REVIEW IS IMPORTANT!

Review Submittals

Please Consider Leaving Us A Review!: Please Leave Us A Review

Please Leave Us A Review

Summary

Safety Upgrades

- G-2 GARAGE/CARPORTS:

An unprotected opening[s] was found in the garage fire separation between the garage and living space. This should be repaired to complete the fire separation between the house and the garage. Large holes should be repaired with the proper sheetrock materials. Small holes and openings should be sealed with mud or high temperature of "fire stop" caulking. Recommend repairs be made by a qualified contractor.

- E-8 ELECTRICAL:

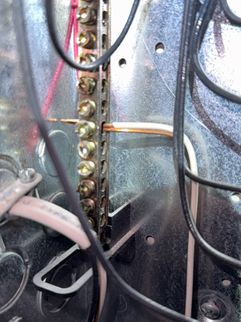

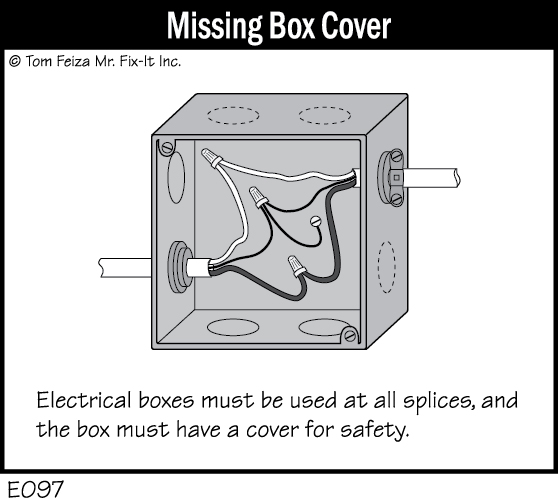

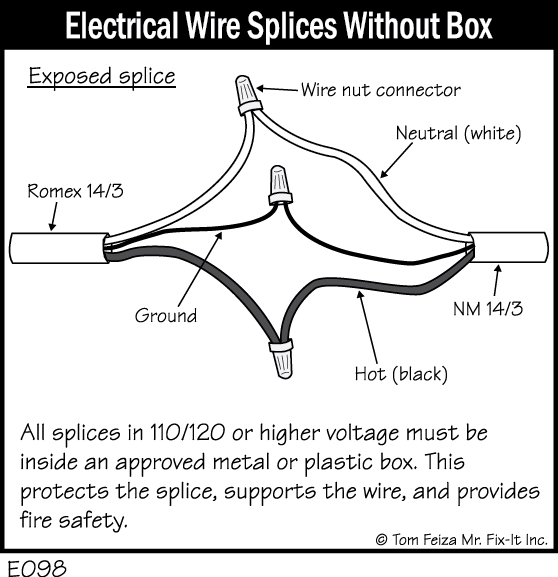

Open/exposed electrical splice/s were noted. All electrical connections must be terminated inside a junction box with a cover plate or within the fixture. Recommend consulting an Electrical Contractor for evaluation and repairs concerning this issue.

- Basement

- E-12 ELECTRICAL:

The use of GFCI (Ground Fault Circuit Interruption) protection is inconsistent with modern minimum standards for safety. GFCI's protect against electrocution by limiting the duration of an electrical shock. Hire a licensed electrician to further evaluate and update this home's system for improved safety.

- Garage

- Laundry room

- Under kitchen sink

- Master bathroom

- Basement bar

- E-20 ELECTRICAL:

AFCI (arc fault protection) is now required on all branch circuits supplying outlets or devices installed in residential dwelling unit kitchens, family rooms, dining rooms, living rooms, parlors, libraries, dens, bedrooms, sunrooms, recreation rooms, closets, hallways, laundry areas, and similar rooms and areas. The goal of this protection is to reduce risks of electrical fires. Consult with a licensed electrician about improving circuit protection as desired.

- E-21 ELECTRICAL:

CO alarms were missing in one or more locations. CO alarms are an important safety feature and are recommended outside of all sleeping areas. It is also recommended that there be at least one CO alarm on each floor of the house. [ recommend having CO alarms installed to meet modern safety standards.

- P-7 PLUMBING:

The discharge pipe of the water heater temperature/pressure relief (TPR) valve was terminated more than 6" above the floor. This condition could result in scalding if the pressure relief valve were activated while a person was nearby. The Inspector recommends correction by a qualified plumbing or HVAC contractor.

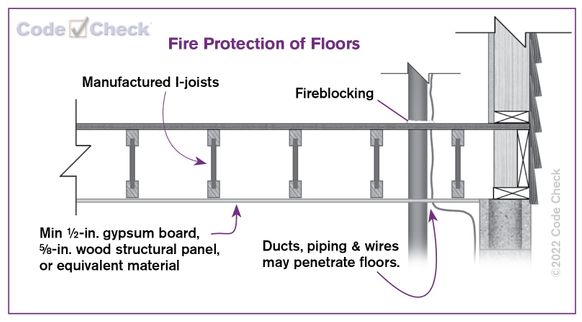

- S-1 STRUCTURE/BASEMENT:

The floor joist are missing a fire protection assembly. Current building standards now require some means of fire protection to the underside of I-joist. This is to slow the spread of fire to the living space of the home. Recommend adding fire protection to increase safety.

- S-2 STRUCTURE/BASEMENT:

Missing fire blocking at the subfloor in one or more locations. Fire blocking is meant to slow the spread of fire from one floor to the next. Recommend repairs be made by a qualified contractor.

Upgrade Improves

- E1-1 EXTERIOR/GROUNDS:

One or more penetrations through the siding (e.g., hose bibs, electrical meters, exhaust vents) were missing mounting blocks, had improperly installed mounting blocks, or had damaged mounting blocks. Properly installed mounting blocks are recommended at siding penetrations to help prevent water intrusion and related damage. Recommend evaluation and repairs by a qualified contractor.

- E1-11 EXTERIOR/GROUNDS:

There were no lateral load connectors observed at the deck connection to the home. The lateral load connectors help with the deck load that is pulling away from the home. The lag bolts/screws handle more of the vertical load. Recommend corrections be made by a qualified deck contractor.

- LA-2 LAUNDRY AREA:

The dryer power cord lacks a visible strain relief clamp where it enters the rear panel. This can lead to wire damage or loosening over time. Recommend installation of a proper strain relief connector by a qualified person for safety.

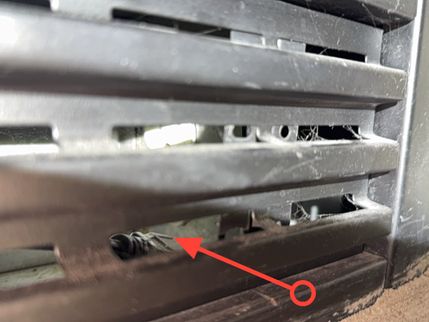

- E-1 ELECTRICAL:

The ground wire is subject to damage. The ground wire should be protected in metal conduit or the wire should be secured and run along the surface of the building. Recommend corrections be made by a qualified electrical contractor.

- E-7 ELECTRICAL:

The lug/s at the electric panel has double tapped neutrals. These lugs are not approved for more than one neutral conductor. This can create a loose connection. Have this further evaluated and corrected by a licensed electrician.

- E-10 ELECTRICAL:

The exterior receptacle in wet and or damp locations lack proper covers. Receptacle covers rated for wet locations should allow for receptacle to be sealed while in-use. Recommend upgrades be made by a qualified electrical contractor.

- E-13 ELECTRICAL:

- Several GFCI outlets were found wired in series. While not a safety hazard, this is a non-standard installation and can cause confusion when resetting, as one outlet may not reset until another is cleared. Recommend having a licensed electrician evaluate and correct if desired.

- in the garage

- P-4 PLUMBING:

Hammer arresters were missing at one or more locations. These are required by current building standards for all quick closing valves such as washing machines, dishwashers and ice makers. Hammer arresters are used to absorb the shock when water suddenly stops. Recommend upgrades be made by a qualified plumbing contractor.

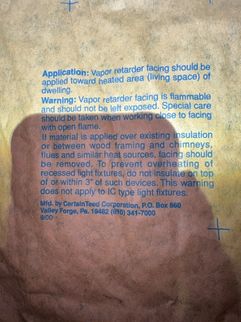

- S-3 STRUCTURE/BASEMENT:

The paper face of the insulation in the basement rim joist is exposed. This is a flammable material and should be covered by sheetrock. Repair as needed: you can remove the paper face of insulate with un-faced batts.

- A-3 ATTIC:

A bathroom exhaust vent terminates in the attic instead of at the home exterior. This condition can raise moisture vapor levels in the attic to the point at which home materials are damaged or unhealthy conditions related to bio growth develop. The inspector recommends correction by a qualified person.

- P1-1 Pest:

Wood forms were not removed after concrete was poured. This is not standard practice, as left-in-place forms can retain moisture and promote wood rot or pest activity. Recommend removal by a qualified contractor.

Repairs

- RS-2 ROOFING SYSTEM:

One or more shingles were found to be damaged. This can lead to water intrusion, further roof deterioration, and possible structural damage if not addressed. Recommend repair or replacement by a qualified roofing contractor to maintain proper protection.

- RS-3 ROOFING SYSTEM:

The gutters show signs of physical damage, including dents, cracks, and misalignment. These issues could hinder proper water drainage. Repair or replacement is recommended to prevent further damage.

- E1-2 EXTERIOR/GROUNDS:

Physical damage was noted to the siding in one or more locations. Physical damage usually consist of cracks, holes, and dents. Damaged siding should be repaired or replaced to prevent water damage to the home. Recommend repairs be made by a qualified siding contractor.

- E1-3 EXTERIOR/GROUNDS:

Cracks, damage and or deficiencies were observed in the flatwork. Deficiencies in flatwork may be an indication of material defects, lack of maintenance, movement, settlement or age. Recommend repairs be made as necessary by a qualified contractor.

- Damage, driveway

- E1-7 EXTERIOR/GROUNDS:

One or more joist are not properly secured to the ledger board and or beam. Proper attachment is important to help prevent joist movement. Recommend repairs be made by a qualified deck contractor.

- Missing hangers at landing and right side

- E1-8 EXTERIOR/GROUNDS:

The beam is not properly secured to the post. Current standards require the post to be notched and secured with bolts or the beam can be mounted on top with post cap. Recommend repairs be made by a qualified deck contractor.

- E1-10 EXTERIOR/GROUNDS:

The ledger board fasteners were not staggered as required. Staggering the fasteners will help minimized the chance of the ledger board splitting. Recommend corrections be made by a qualified deck contractor.

- E1-12 EXTERIOR/GROUNDS:

Wood rot was noted at one or more locations in the decking system. Wood rot is caused by moisture and mildew. Recommend having all boards repaired or replaced by a qualified deck contractor.

- Post

- Joist

- Beam

- Stairs

- E1-13 EXTERIOR/GROUNDS:

- No flashings were

noted between the deck ledger board and the home. This could allow water to get trapped between the deck and the house, causing rot and a conducive pest condition. This can be a difficult retrofit once the deck is constructed. Recommend repairs by a qualified contractor.

- Right side deck

- E1-14 EXTERIOR/GROUNDS:

The deck ledger board was attached to the home with fasteners that are not rated for this type of installation. Using the wrong fasteners makes the deck more prone to failure. The required fasteners for this attachment are 1/2" lag bolts and or 1/2" lag screws. Recommend repairs be made by a qualified deck contractor.

- Right side deck

- E1-15 EXTERIOR/GROUNDS:

Deck stairs were observed to shake when walked on, which may indicate loose connections, inadequate bracing, or insufficient fastening of the stringers or landing. This can pose a safety hazard. Recommend repairs be made as necessary by a qualified deck contractor.

- K-1 KITCHEN:

The loose faucet for the kitchen sink should be secured to prevent leaks. Repair may be performed by a qualified plumber.

- B-3 BATHROOM(S):

One or more bathroom toilets were found to be loose at the base. This may indicate loose mounting bolts, a damaged flange, or subfloor deterioration, and could lead to a compromised wax seal and potential leaks. Recommend repairs be made by a qualified plumbing contractor.

- Master

- Basement

- FSB-4 FIREPLACE/WOOD STOVE Basement :

Rusted chimney chase cover observed, likely due to prolonged weather exposure. Recommend replacement by a qualified contractor to prevent water intrusion and further deterioration.

- I-2 INTERIOR:

One or more doors are rubbing or hitting the frame and are difficult to open and shut. The reason for the door being difficult to open and shut should be determined and repairs made by a qualified contractor.

- E-2 ELECTRICAL:

The water supply line was not properly grounded and or bonded. Water pipes should be grounded within 5' from where they enter the home. Grounding and bounding help protect against electrical surges and against electrocution. Recommend repairs be made by a qualified electrical contractor.

- E-9 ELECTRICAL:

One or more outlets showed an open neutral, meaning the return path for electricity is disconnected. This can cause outlets or devices to stop working and may pose a shock or fire risk. Recommend evaluation and repair by a licensed electrician to ensure safe operation.

- Front yard

- Garage, multiple noted

- E-11 ELECTRICAL:

One or more of the electric receptacles have been painted. This is non-standard and can inhibit proper electrical connections. I recommend replacing all outlets that have been painted over to ensure reliable performance.

- Garage, multiple noted

- E-14 ELECTRICAL:

One or more lights were not functional at the time of the inspection. No sign of power was found when the switch was turned on. Have this further investigated a repaired as needed. If a new bulb does not correct the problem, consult with a licensed electrical contractor.

- Garage

- E-17 ELECTRICAL:

There was a fixture and or outlet in the wet zone above and or around the shower/tub area in the bathroom. This is a safety hazard and corrections are recommended by a qualified contractor.

- Master bathroom

- Basement bathroom

- CS1-3 COOLING SYSTEMS:

The AC disconnects are mounted too high for proper access. Electrical code generally requires that disconnects be readily accessible, with the center of the operating handle not more than 6 feet 7 inches (79 inches) above the ground or working platform. Recommend adjustment by a qualified electrician to ensure compliance and safe operation.

- CS1-4 COOLING SYSTEMS:

Equipment Not Installed Level : The outdoor condensing unit pad is not level. Mechanical requirements call for ground-supported equipment to be level and firmly supported on a concrete slab or other approved material at least 3 inches above grade, per manufacturer instructions. Recommend evaluation and correction by a qualified HVAC contractor.

Further Evaluations

- E1-4 EXTERIOR/GROUNDS:

One or more trees are too close to or overhanging the roof. This can increase the risk of damage to the home, promote moisture issues, and provide pathways for rodents. Recommend evaluation by a qualified arborist for pruning or removal as needed to maintain safety and proper clearance.

- E1-5 EXTERIOR/GROUNDS:

Settlement was observed at one or more deck support posts, with at least one post leaning. This condition may indicate inadequate footing support or soil movement and can compromise the deck’s stability. Further evaluation and repairs by a qualified contractor are recommended.

- FS-2 FIREPLACE/WOOD STOVE:

The pilot light for the gas fireplace was not turned on. The ASHI standards of practice prevents me from lighting and operating fireplaces when the pilot light is not lit. It is recommended that the pilot be lit and the fireplace operation be verified with the current owner. Recommend any repairs necessary be made by a qualified HVAC contractor.

- A-2 ATTIC:

Minor damage observed to one or more trusses that does not appear to affect performance. Recommend monitoring or obtaining a second opinion and repairing if advised

Future Projects

- RS-1 ROOFING SYSTEM:

The asphalt shingles appear to be nearing the end of their expected service life. While no active leaks were noted, aging may reduce effectiveness and increase the risk of water intrusion. Recommend monitoring the roof and budgeting for replacement within the next 5 years.

- P-9 PLUMBING:

FYI - The water heater was nearing or past its typical service life. Major repairs or replacement should be anticipated in the future due to its age alone. Depending on prior maintenance and other factors the unit could last anywhere from months to years, the remaining life is undetermined. A typical life expectancy for a gas water heater is 8-12 years and an electric is 10-15 years.

- CS1-5 COOLING SYSTEMS:

The air conditioner uses R-22 refrigerant, which was phased out by 2020 due to environmental concerns. R-22 is now expensive and hard to find, and retrofitting is often not practical. Repairs may be difficult, and early replacement may be necessary. Recommend consulting an HVAC professional for options.

- CS1-6 COOLING SYSTEMS:

The air conditioning is past its expected service life. The average life expectancy for an AC system is around 15 years. I recommend budgeting for a replacement in the near future.

- HS-3 HEATING SYSTEMS:

This furnace is old and past its useful design life. The average service life of forced air furnaces is 15-20 years. I recommend having this furnace serviced and the heat exchanger inspected by a qualified heating contractor. If this furnace is kept in service, budget to update at anytime.

Efficiencies

- LA-4 LAUNDRY AREA:

Lint was observed inside the living area, likely from a poor dryer vent connection. This can reduce efficiency, degrade indoor air quality, and pose a fire hazard. Recommend repairing the vent connection and cleaning the area.

- CS1-2 COOLING SYSTEMS:

Insulation is damaged or missing from a portion/s of the refrigerant lines at the exterior. We recommend all missing insulation be replaced to increase energy efficiency.

.jpg)

.jpg)

.jpg)

-59843.jpg)