The Scope and Purpose of a Home Inspection

PROVIEW Professional Home Inspections is proud to include our SAFE HOME BOOK as part of your home inspection report. This publication is a compilation of well-researched articles, especially for homeowners. They include valuable information and tips for helping keep families safe and their homes in top condition. Please enjoy it with our compliments.

This inspection was performed in accordance with the current Standards of Practice and Code of Ethics of InterNACHI (International Association of Certified Home Inspectors). The Standards contain certain and very important limitations, expectations, and exclusions to the inspection. A copy is available prior to, during and after the inspection and it is part of the report.

©2013 International Association of Certified Home Inspectors & Master Inspector Certification Board.

💲Purchasing property involves risk

The purpose of a home inspection is to help reduce the risk associated with the purchase of a structure by providing a professional opinion about the overall condition of the structure. A home inspection is a limited visual inspection and it cannot eliminate this risk. Some homes present more risks than others. We cannot control this, but we try to help educate you about what we don’t know during the inspection process. This is more difficult to convey in a report and one of many reasons why we recommend that you attend the inspection.

Occasional typographical errors and other minor errors and omissions will occur in the report. I apologize in advance for these. If any of these typos make the report unclear, confusing or incomplete, please contact me immediately for clarification/correction.

A home inspection is not an insurance policy

This report does not substitute for or serve as a warranty or guarantee of any kind. Home warranties can be purchased separately from insuring firms that provide this service.

A home inspection is visual and not destructive

The descriptions and observations in this report are based on a visual inspection of the structure. We inspect the aspects of the structure that can be viewed without dismantling, damaging or disfiguring the structure and without moving furniture and interior furnishings. Areas that are concealed, hidden or inaccessible to view are not covered by this inspection. Some systems cannot be tested during this inspection as testing risks damaging the building. For example, overflow drains on bathtubs are generally not tested because if they were found to be leaking they could damage the finishes below. Our procedures involve non-invasive investigation and non-destructive testing which will limit the scope of the inspection.

☠️Environmental/Suspected bio-growth Exclusions

The reported or actual health effects of many potentially harmful, toxic or environmentally hazardous elements that may be found in building materials or in the air, soil, water in and/or around any house are varied, and, in some cases controversial. A home inspection does not include the detection, identification or analysis of any such elements or related concerns such as, but not limited to, suspected bio-growth, allergens, legal/illegal drugs and other biological contaminants, radon, , bed bugs, cockroaches, fleas, lice, formaldehyde, asbestos, lead, electromagnetic fields, carbon monoxide, insecticides, Chinese drywall, refrigerants and fuel oils. Furthermore, no evaluations are performed to determine the effectiveness or appropriateness of any method or system (e.g., water filter, radon mitigation, etc.), designed to prevent or remove any hazardous or unwanted materials or elements. An environmental health specialist should be contacted for evaluation of any potential health or environmental concerns. The noting of the presence of materials commonly considered to contain asbestos, formaldehyde, lead, suspected bio-growth etc in the inspection report, should not be construed to mean the inspector is inspecting for these things but instead should be seen as a "heads-up" regarding these materials and further evaluation by qualified professionals may be warranted.

This is not an inspection for code compliance

This inspection and report are not intended for city / local code compliance. During the construction process structures are inspected for code compliance by municipal inspectors. Framing is open at this time and conditions can be fully viewed. Framing is not open during inspections of finished homes, and this limits the inspection. All houses fall out of code compliance shortly after they are built, as the codes continually change. National codes are augmented at least every three years for all of the varying disciplines. Municipalities can choose to adopt and phase in sections of the codes on their own timetables. There are generally no requirements to bring older homes into compliance unless substantial renovation is being done.

This is just my opinion and just for you

The contents of this report are for the sole use of the client named above and no other person or party may rely on this report for any reason or purpose whatsoever without the prior written consent of the inspector who authored the report. Any person or party who chooses to rely on this report for any reason or purpose whatsoever without my express written consent does so at their own risk and by doing so waives any claim of error or deficiency in this report.

Construction techniques and standards vary. There is no one way to build a house or install a system in a house. The observations in this report are my opinions based on my training and experience. Other inspectors and contractors are likely to have differing opinions. You are welcome to seek opinions from other professionals in the context of doing your due diligence.

The scope of this inspection

This inspection will include the following systems: exterior, roof, structure, drainage, foundation, attic, interior, plumbing, electrical and heating. The evaluation will be based on limited observations that are primarily visual and non-invasive. This inspection and report are not intended to be technically exhaustive.

All homes are likely to have some faults which may range from cosmetic defects to major safety hazards. Not all defects will be found. While some minor deficiencies may be mentioned, the emphasis of this report is to inform the buyer of the property condition by detecting deficiencies or circumstances that may affect the structural integrity of the building and its components and its safe use as a residence.

You are encouraged to obtain competitive estimates for major repair needs. Safety and health issues should be addressed promptly. It is recommended that all corrective work, other than routine maintenance activities, be performed by qualified licensed contractors.

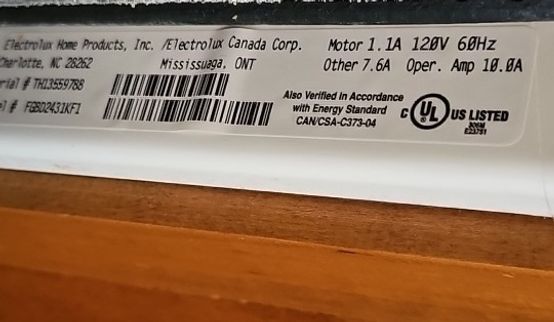

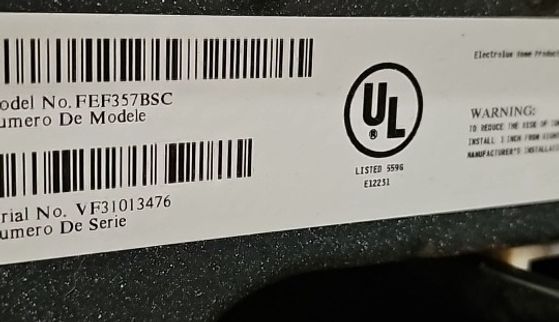

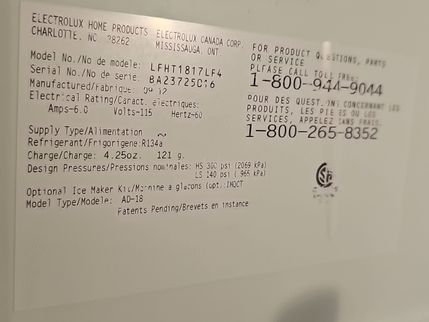

It is beyond the scope of the Standard Home Inspection to identify components within the home that may have been part of a "manufacturer's recall". Mention of specific recalls within this report must not be construed to mean that all such items have been identified, or that such identification is part of a Standard Home Inspection. When possible, appliance Model Numbers and Serial Numbers are included in the report and can be used to check for recall related issues. If you have any question about specific appliances, information can be found at the CPSC (Consumer Products Safety Commission) website or contact the manufacturer directly.

I recommend you obtain as much history as is available concerning this property. This historical information may include copies of any seller's disclosures, previous inspection or engineering reports, reports performed for or by relocation companies, municipal inspection departments, lenders, insurers and appraisers. You should attempt to determine whether repairs, renovation, remodeling, additions or other such activities have taken place at this property, and this report will attempt to identify such items when possible.

Ranges, Dish Washers, and Refrigerators, Microwaves (and the like) are typically tested for basic function (Do they turn on). No assertions are made as to how well they function. Clothes washers/dryers are typically not operated.

Throughout this report, comments will be made as to the presence or absence of components or parts of components. This must not be construed to mean that these components or parts of components exist (or don't exist) in concealed areas or behind finished surfaces. For example: if foundation bolting was seen in one area, it does not mean that the bolting exists (or doesn't exist) in areas that are concealed. Also if an item was noted as "not being visible," that should not be construed to mean that none of whatever was "not visible" does not exist on the premises---it just means none was noted at the time of inspection and should be seen as a "heads-up" that the concern or condition might be present but hidden, or that the conditions that would allow its presence to be known was not replicated at the time of inspection.

Many of the non-narrative observations/documentation detailed in the report that are related to more "cosmetic" issues should not be construed as "all inclusive" but should instead be seen in as "suggestive" or a "guideline" of conditions that may exist elsewhere in the home. It is not the focus of the report to comment extensively on cosmetic issues, but I do make note of them at times to help complete the "snap-shot" of the home at the time of inspection. For example, "nail-pops" seen in one room are likely to be seen (and should be anticipated) in other rooms even though I may not have noted them in the report.

Throughout the report I may make recommendations as to possible repairs. These recommendations are not intended to be substitutes or construed to be more appropriate than the recommendations of the professionals making the repairs. Conflicts in recommendations should be resolved prior to repairs being made.

Your expectations

The overall goal of a home inspection is to help ensure that your expectations are appropriate with the house you are proposing to buy. To this end we assist with discovery by showing and documenting observations during the home inspection. This should not be mistaken for a technically exhaustive inspection designed to uncover every defect with a building. Such inspections are available but they are generally cost-prohibitive to most home-buyers.

Who should make repairs and what should their qualifications be?

Worker qualifications: In the text of the report, in some instances, I recommend that work be done by a "qualified" persons or "qualified" parties. I consider qualified parties, in licensed trades, to be those individuals who hold the necessary licenses to legally work in their profession -- licensed electricians, licensed pest control applicators, licensed plumbers, licensed HVAC professionals, licensed engineers, licensed general contractors, etc. In instances where a task may not, typically, need to be done by a person with a professional license, my recommendation is to hire an individual to do the work who is, based on past training, experience or expertise, qualified to further evaluate the condition or problem listed in the report and to then make appropriate repairs.

For additional fees, I can perform invasive inspection of concealed areas if desired. Please contact me for more information regarding this service.

Your participation is requested

Your presence is requested during this inspection. A written report will not substitute for all the possible information that can be conveyed verbally by a shared visual observation of the conditions of the property.

How to Read This Report

Getting the Information to You

This report is designed to deliver important and technical information in a way that is easy for anyone to access and understand. If you are in a hurry, you can take a quick look at our "Summary Page” and quickly get critical information for important decision making. However, we strongly recommend that you take the time to read the full Report, which includes digital photographs, captions, diagrams, descriptions, videos and hot links to additional information.

The best way to get the layers of information that are presented in this report is to read your report online, which will allow you to expand your learning about your house. You will notice some words or series of words highlighted in blue and underlined – clicking on these will provide you with a link to additional information.

This report can also be printed on paper or to a PDF document.

Chapters and Sections

This report is divided into chapters that parcel the home into logical inspection components. Each chapter is broken into sections that relate to a specific system or component of the home. You can navigate between chapters with the click of a button on the left side margin.

Most sections will contain some descriptive information done in black font. Observation narrative, done in colored boxes, will be included if a system or component is found to be significantly deficient in some way or if we wish to provide helpful additional information about the system or the scope of our inspection. If a system or component of the home was deemed to be in satisfactory or serviceable condition, there may be no narrative observation comments in that section and it may simply say “tested,” or “inspected.”

Observation Labels

All narrative observations are colored, numbered and labeled to help you find, refer to, and understand the severity of the observation. Observation colors and labels used in this report are:

These are repair items that should be considered "routine home ownership items," such as servicing the furnace, cleaning the gutters or changing the air filters in the furnace.

Summary Page

The Summary Page is designed as a bulleted overview of all the observations noted during inspection. This helpful overview is not a substitution for reading the entire inspection report. The entire report must be read to get a complete understanding of this inspection report as the Summary Page does not include photographs or photo captions.

Summary

Major Concerns

- EG-7 EXTERIOR / GARAGE:

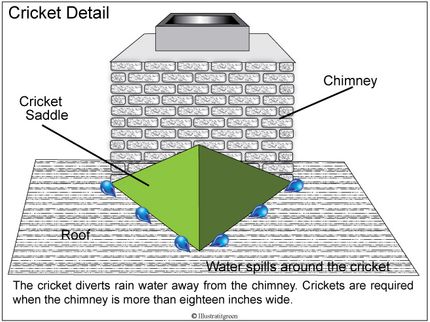

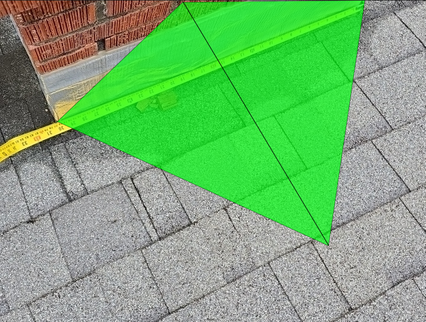

I recommend having a cricket and flashing installed for this chimney to divert water around the chimney. The current installation is vulnerable to leaks as the entire roof drains toward the chimney. Please note that modern standards require chimney cricket flashings when the chimney is at the bottom of a roof and more than 30 inches wide.

- P-5 PLUMBING:

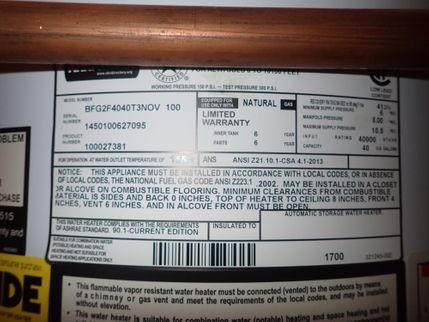

Numerous red flags were noted for the water heater. Due to the number of issues found, total replacement is the best option. It may be beneficial to replace instead of repair. Recommend hiring a licensed plumber to evaluate and make proper repairs or replacement. Here is a list of the following observations that were found during the inspection:

THERMAL EXPANSION DEVICE

- 🛠️Missing Thermal Expansion Relief Device--A Thermal Expansion Relief Valve can replace a water heater expansion tank because it functions similarly. Both products absorb the excess pressure in the plumbing system created by thermal expansion. As plumbers know, the expansion tank equalizes pressure throughout the plumbing system by providing a space for hot water to flow into. I recommend that you have this evaluated by a licensed plumber and make correction as needed.

FLUE/DRAFT ISSUES

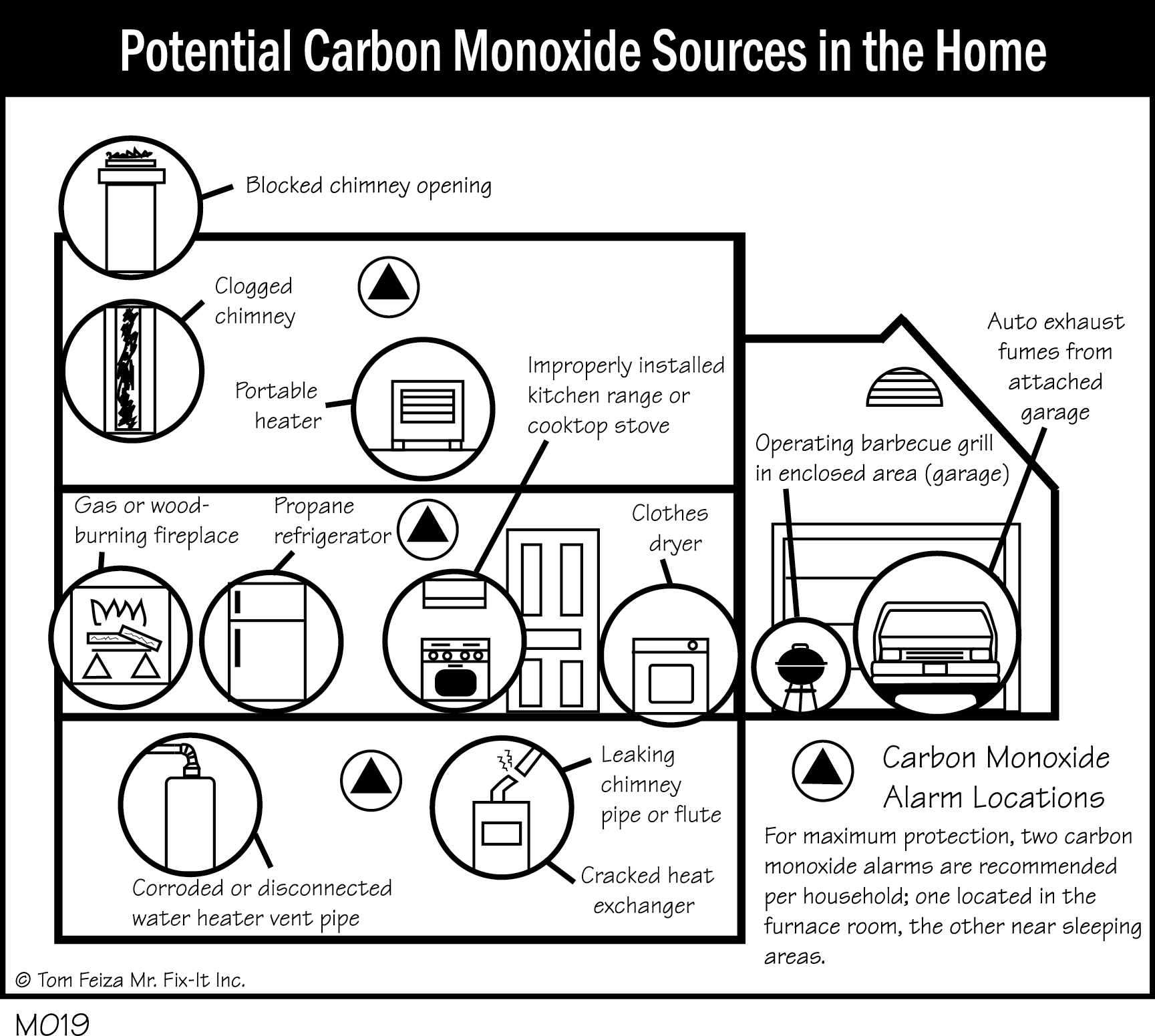

- 🛠️Backdraft--The plastic grommets on the top of the water heater around the cold water inlet and hot water outlet is melted. This indicates the water heater has been back drafting on start-up. This can be a safety hazard for the water heater backdrafts for too long. At the time of inspection, I saw no evidence of flame roll-out at the burner assembly. I recommend installing a carbon monoxide detector in this closet to monitor this appliance if no rollout occurred. If the detector goes off, have the water heat evaluated and repaired by a licensed plumber.

- 🛠️Loose Draft Hood--The draft diverter of this gas-fired water heater was inadequately fastened at the time of the inspection. The draft diverter is part of the system designed to help exhaust the invisible, odorless, tasteless, toxic products of combustion to the home exterior.

SUPPLY CONNECTORS

- 🛠️Corroded Connectors, Old Tank--Corrosion was noted on the supply connectors on top of the house water heater. This is an old water heater. Consider updating the water heater soon as it may not be worth correcting these older corroded connectors and keeping this old tank.

TANK

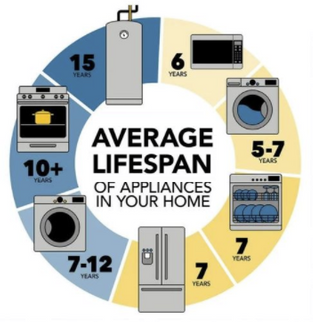

- 🛠️Aged Unit--FYI - The unit was at or past its typical service life. Major repairs or replacement should be anticipated in the future due to its age alone. Depending on prior maintenance and other factors the unit could last anywhere from months to years, the remaining life is undetermined. A typical life expectancy chart can be found here: component-life-expectancies

- 🛠️Larger Than Old--In 2015, the federal government updated minimum standards for the energy efficiency of water heaters. Because of this update the same size of water heater [that is gallons] will require a larger space. This article will help you understand how this could impact your next water heater purchase. https://getscribeware.com/blog/federal-government-changed-next-water-heater/

ELECTRICAL CONNECTION

- 🛠️Missing Disconnect--All water heaters require that there be a disconnect within sight or have provisions to install a lock on the switch or circuit breaker. If the panel with the branch circuit is not within sight then it then a disconnect should be installed by a Licensed Electrical contractor.

DETAILED LOCATION OF PHOTOS AND ILLUSTRATIONS:

Repairs

- RA-1 ROOF / ATTIC:

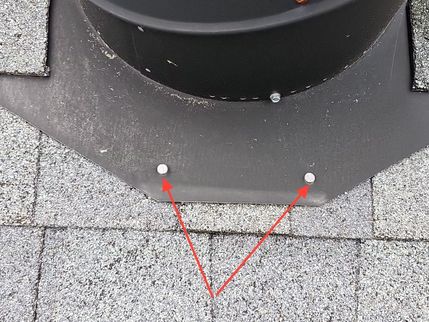

All exposed fasteners or "shiners" on the roof should be sealed with mastic. The photos provided may only show a representation of occurrences. I recommend having a professional roofing contractor inspect and repair the issues mentioned. Many roof problems get worse over time if not appropriately addressed. A good contractor will know how to make repairs correctly using the best products. For example, silicone should never be used; roof mastic or high-quality sealants like GEOCEL work much better for roof repairs. I'd advise getting the repairs done according to the contractor's recommendations to ensure the problems are fully resolved, and your roof will be safe and leak-free for years.

✒️

- 💦 At roof penetrations. Pipes, exhaust vents, and other objects that penetrate the roof often have exposed fasteners holding flashing or collars in place. Make sure all fasteners are secure with no corrosion.

- RA-2 ROOF / ATTIC:

The plumbing boot flashing/s is not properly secured and should be corrected. This situation may cause moisture intrusion due to strong winds or heavy rains. I recommend that you have a qualified person make sure all flashings are properly secured and sealed where secured.

- RA-3 ROOF / ATTIC:

Damaged boot flashing or damaged flashing at electric service mast which should be repaired to prevent moisture intrusion. Sealant may eventually crack and allow damage to the area around the mast. Recommend consulting a Contractor for evaluation and repairs concerning this issue.

- RA-4 ROOF / ATTIC:

Leaks were noted in the gutters that need to be repaired to control roof runoff. Seal up all leaking areas and tune up to insure gutters are adequately sloped to drain. Repair may be performed by a qualified person.

- RA-5 ROOF / ATTIC:

The gutters are no longer properly supported in locations. Gutters that are not properly supported can cause drainage concerns and additional damage to the framing behind them. Correction of this defect is important to prevent moisture-related issues in the future. Recommend consulting a for evaluation and repairs concerning this issue.

✒️

- This drainage system for supporting the gutters is using spikes. These spikes may become loose due to damage to the wood fascia becoming soft due to moisture.

- RA-6 ROOF / ATTIC:

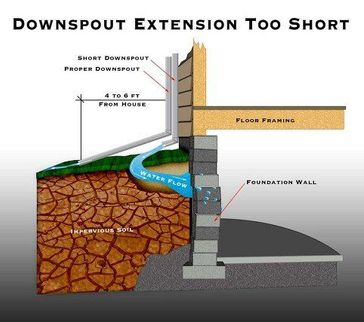

Some of the downspouts discharged roof drainage next to the foundation. This condition can affect the ability of the soil to support the weight of the structure above and can cause damage related to soil/foundation movement. The Inspector recommends the installation of downspout extensions to discharge roof drainage a minimum of 6 feet from the foundation.

- RA-7 ROOF / ATTIC:

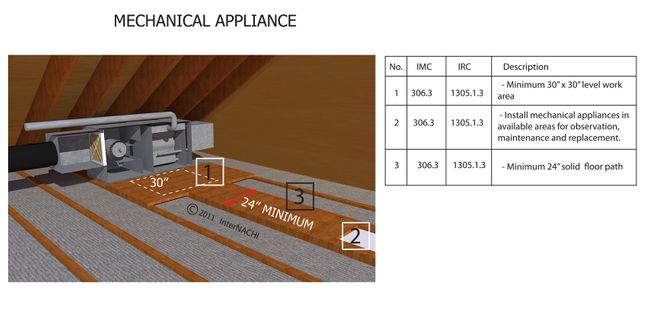

The attic access is one place that is often neglected and, if not properly constructed or located, can become a dangerous place to enter. Access may be scuttle access, dropdown stairs, privacy door, or attic doors. The following observations here may indicate improvements that are needed. Updates required or defective conditions that require repairs. Repairs or improvements may range from simple to complex and may require qualified persons to make such repairs. For evaluation and repairs concerning this issue, always practice safety when making repairs.

PULLDOWN STAIRWAY

- 🛠️The attic stair pulldown was noted to be broken/damaged or weak and may cause injury.. This unit should be repaired or replaced for safety reasons. Repair may be performed by a qualified person.

ACCESS - HEAT MIGRATION

- 🛠️ An attic stair pulldown has been installed in the heated part of the home. This will result in heat loss in the home as this entire hatch is now uninsulated and poorly air sealed. Use rigid foam to construct a box that fits over this access or such a device can be bought pre-assembled. Also, use weather strip to seal the door closed.

- G-1 GROUNDS:

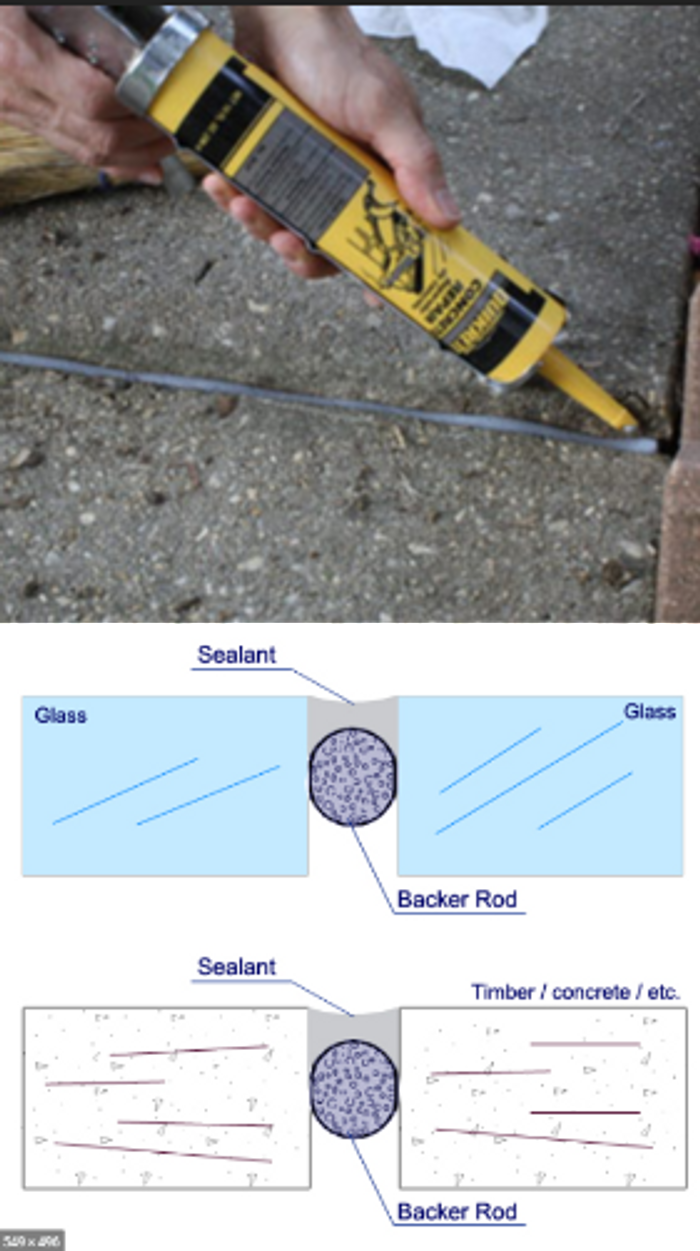

Large crack/s at the concrete driveway flatwork should be filled to stop moisture intrusion. When moisture freezes, it will continue to expand the crack.

✒️

- Recommend that a qualified person install the proper size backer rod and then apply concrete self-leveling filler to protect the concrete. Make sure you remove any debris in the crack before applying the concrete filler product.

- G-2 GROUNDS:

An examination of the grounds revealed standing water being an issue, at least during the inspection. The water does not appear to be directly affecting the structure; however, it may indicate poor drainage or the possibility of other concerns such as plumbing underground leakage. Therefore, it is a concern that should be evaluated due to its effect on the soils and structure. I recommend consulting with a Qualified Person for evaluation and repairs concerning this issue. Current conditions will require a more invasive means to determine the needs found.

LOCATIONS WITH PONDING WATER

- Elevation Concerns

- 🛠️ The surface water, if not properly controlled, can accumulate around the foundation or can pond on the lawn or over the entry path, foundation vents or crawlspace entries. If the house is inspected when it is not raining, you might not see any problems. However, based on the slope and overall grading of the land around the house, you can at least determine the potential for a problem. Surface water can run directly to the foundation, seep down along the foundation walls, and accumulate at the lower section. This usually results in water seepage into the basement or crawl space. A rule of thumb for grading this area is a drop of about 1 inch per foot. The lawn should slope away from the house for at least 10 feet and should be pitched so that there is approximately a 10-inch drop over that distance.

- G-3 GROUNDS:

Localized damage was noted in the retaining wall material -Loose brick, missing mortar, or missing brick should be properly repaired by a mason contractor.

- EG-1 EXTERIOR / GARAGE:

The exterior paint job requires localized touch-up due to peeling paint and bare wood exposed. This is typical on older homes. Be prepared to make repairs such as wood putty to fill in areas that need it. Have the exterior paint job touched up and completed by the painter. During inspection today, I noted:

- EG-3 EXTERIOR / GARAGE:

Seal wall penetration/s. The hole/s in the exterior wall-covering cut to allow penetration of air-conditioning lines/gas lines or electrical lines should be sealed with an appropriate sealant to prevent moisture and insect entry in some cases mortar should be used if the hole is large.

- EG-6 EXTERIOR / GARAGE:

The dead bolt/s for the exterior door/s are opened with a key rather than a thumb-toggle. This can inhibit easy fire egress. Keep the key for these deadbolts nearby and easily accessible or better - switch this deadbolt with a thumb-toggle dead bolt for improved safety.

- Front and rear entry

- EG-9 EXTERIOR / GARAGE:

Overall the garage as a whole has numerous defects that could be a potential safety hazard if the issues observed are not addressed accordingly. The items listed below require repair or replacement to ensure proper safety and performance. I recommend consulting with a licensed contractor or garage door specialist to evaluate and repair as needed.

OVERHEAD DOOR

- 🔹Automatic Opener

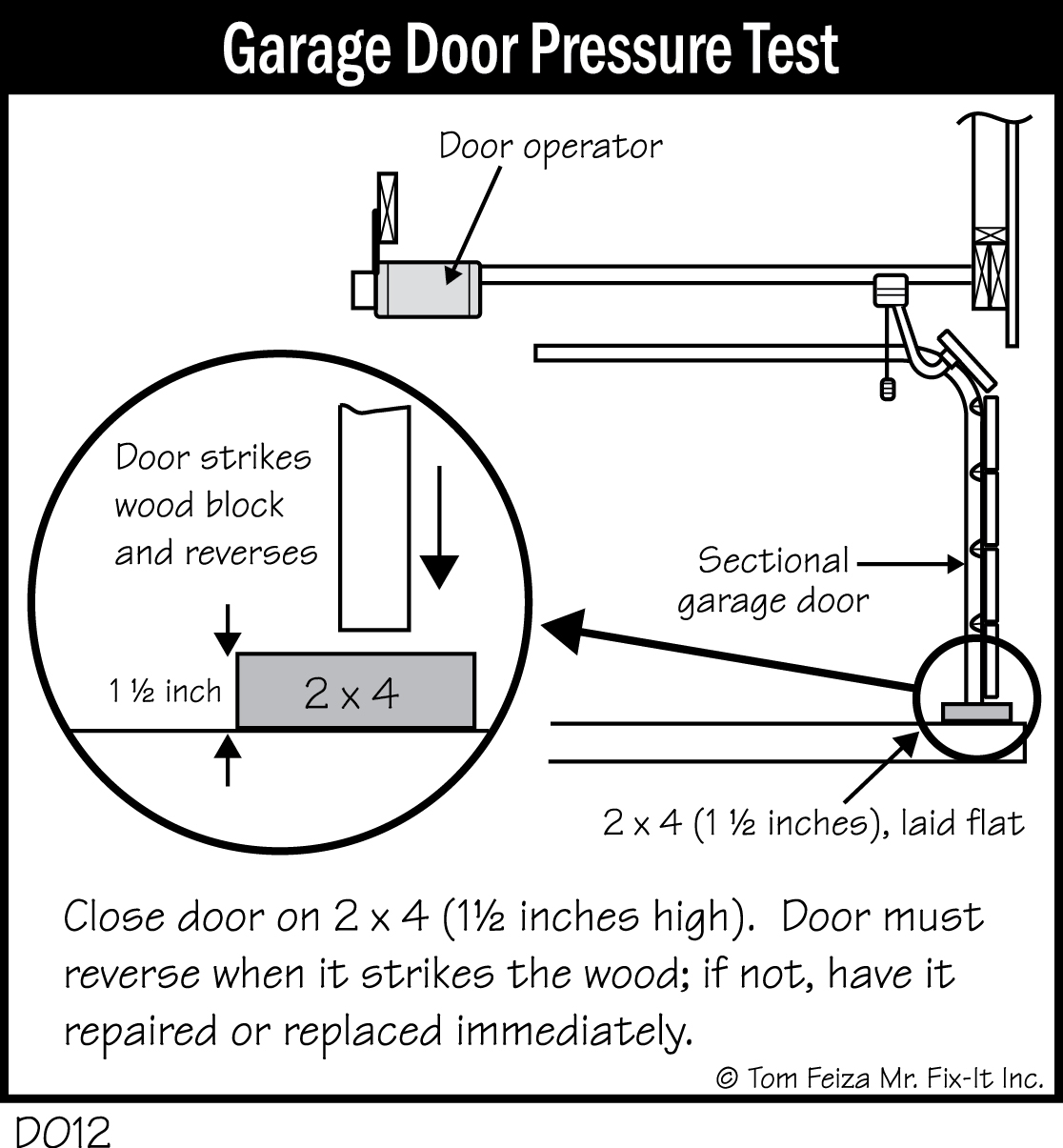

- 🛠️Adjust Sensitivity (One Door)--The overhead garage door does not reverse under resistance to closing. Adjustment of the sensitivity is recommended for improved safety. This typically involves adjusting a small plastic screw on the opener.

- 🔹Laser Eyes

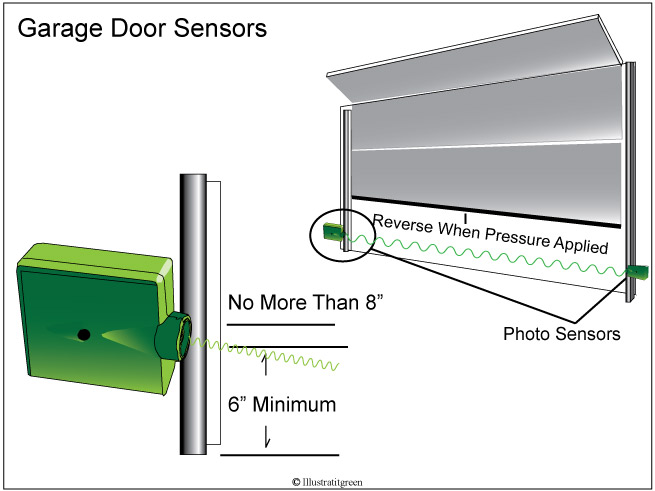

- 🛠️Set Too High--The laser eye safety mechanism for the overhead garage door has been set too high - this sensor should be 5-6 inches off of the floor to perform as intended and prevent entrapment.

- 🔹Overhead Door

- 🛠️Damaged Weather-stripping--Repair the damaged weather stripping on the garage door. This is important to prevent water and rodent entry.

- 🛠️Damaged Gasket--Repair the damaged bottom panel gasket on the garage door. This is important to prevent water and rodent entry.

- FSD-1 FUEL STORAGE and DISTRIBUTION:

The gas piping in the crawlspace is corroding and appears to have inadequate protection from rust-inhibitive paint and the metal is showing some advanced stages of corrosion. I recommend additional inspection and repair of this gas piping by a qualified plumbing contractor.

- FSD-2 FUEL STORAGE and DISTRIBUTION:

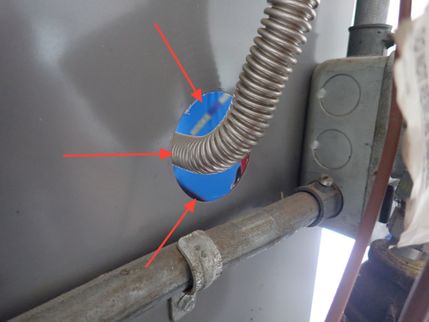

Flexible gas connectors should not run through walls, floors or disappear into a concealed location or the walls of appliances such as a furnace. It has been determined that the vibrations of the housing and the sharp edges around the point of entry of the flexible tubing can cut the gas line. The flexible gas line is only 2-3 sheets of typing paper thick. The flex line must now attach to a black pipe outside of the housing to avoid being a safety hazard. A plumber can do this job for you... but do not let them tell you to just wrap a piece of foam rubber around it. If the vibrations can cut metal, foam rubber provides little, if any, protection. Use rigid steel pipe only. Have this further evaluated and repaired by a qualified plumber or gas appliance technician.

- FSD-3 FUEL STORAGE and DISTRIBUTION:

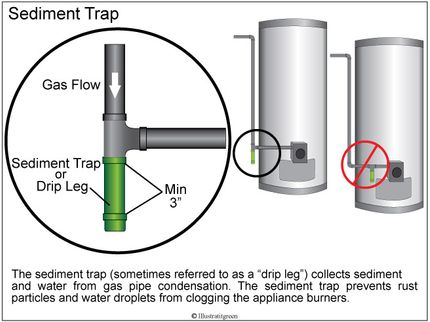

I did not see a sediment trap for the gas pipe at the furnace and water heater. Have this further evaluated and repaired as recommended by a qualified plumber. A sediment trap is recommended to trap sediment in the pipe and prevent fouling of gas equipment.

✒️

- Due to the age or condition of the unit/s, it may be the most cost-effective to correct these issues at the time of replacement.

- HCF-2 HEATING, COOLING and FIREPLACES:

The combustion vent pipe system appears to be nearing the end of its lifespan. The pipes are old and corroded, with visible signs of rust and mineral buildup. This is a concerning finding, as the integrity of these pipes is critical to ensuring the safe operation of fuel-burning appliances. Corroding vent pipes can allow carbon monoxide to seep back into the home, posing a significant risk to occupants. Furthermore, damaged or obstructed vent pipes can create a fire hazard by allowing combustible gases to accumulate and ignite nearby flammable materials. It is essential that these issues are addressed promptly to ensure the continued safety and well-being of those residing in this property.

- HCF-3 HEATING, COOLING and FIREPLACES:

The furnace had slots for two filters but only one was installed. Typically the upstream filter (the filter farthest from the furnace) will be designed to filter coarser particles from indoor air. The filter nearest the furnace is usually designed to filter finer particles. In the system the upstream filter

was missing. The Inspector recommends contacting the manufacturer to determine the proper filter configuration for the filter.

- HCF-6 HEATING, COOLING and FIREPLACES:

Some of the heating ductwork in the crawl space is physically damaged - see where the outer jacket and insulation is missing and see where the outer jacket and insulation is damaged. Have the ductwork in the crawl space further evaluated and replaced as recommended by a licensed heating contractor to ensure ducts are properly insulated to R-8 or better and not leaking.

- P-6 PLUMBING:

The leaky hose bib at the entry side of the house requires repair or replacement - it leaked from the faucet handle when the faucet was turned on and under pressure. This often requires tightening or replacing the packing around the handle stem.

- E-2 ELECTRICAL:

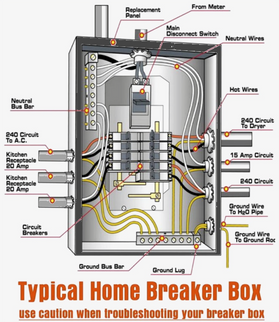

What Are Dedicated Circuits? Your home is wired with separate circuits to spread power consumption around. Circuit breakers are designed to trip if a power overload occurs and too much electricity is drawn simultaneously. When a circuit supports a single appliance, it’s a dedicated circuit with its breaker in your electrical box. Dedicated circuits ensure high-power appliances have access to adequate amperage so they can operate safely without forcing a circuit breaker to trip. The National Electrical Code requires dedicated circuits for all significant, fixed electrical appliances. These include:

- Refrigerators and freezers

- Electric stoves and wall ovens, fixed Microwaves

- Dishwashers

- Washers and dryers

- Furnaces, heat pumps, and central air conditioners

Testing today revealed that the Refrigerators or Dishwashers were not on a dedicated circuit or labeled. This may be an issue with tripping under normal conditions and numerous outlets beyond the serviced area, such as the kitchen. I recommend that you have the electrical wiring and panels evaluated by a licensed electrical contractor to correct and make necessary repairs for proper and safe operations.

- E-3 ELECTRICAL:

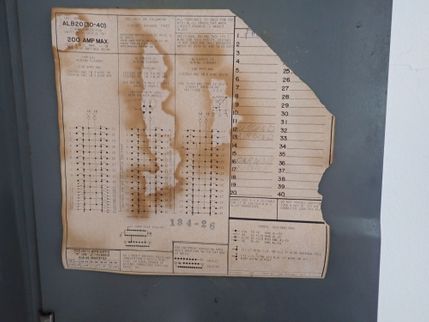

Several small repair items were noted in the electric panel. They are not all urgent but should be done in the context of other electrical repairs. I recommend having the panel further evaluated and repaired by a licensed electrician. Examples of observations noted during the inspection may include:

INTERIOR

- 🛠️Inadequate labeling of the electrical panel circuit breakers was noted during inspection - I can no longer read most of the labels. This should be corrected for improved safety.

- 🛠️Openings were noted inside the electric panel. These should be covered to seal up the panel inside the wall. One reason is that if there is a fire in a panel and there are holes, the fire may flash through the holes. These holes can usually be sealed with metal snap-in plugs. Recommend consulting a Electrical Contractor for replacement of the defect component.

DBL LUGGING

- Neutral wires are doubled or bundled together under the same lug on the neutral bus bar. This is unsafe due to the potential loss of neutral connection to the remaining shared circuits in the event of a loose connection or when servicing or isolating the circuits using this common connection. A loss of neutrality may result in the over-voltage condition of an energized circuit, and damage or potential fire may occur. Recommend qualified electrical contractor repair as necessary and per standard building guidelines. While this practice has been commonly installed by electricians and approved by local building authorities in the past, most service panel manufacturers have explicitly prohibited it for several years. Current building standards now enforce this restriction.

BREAKERS

- Circuit breakers in the service panel were of a brand different from the main panel brand. Because circuit breakers made by different manufacturers vary in design, panel manufacturers typically require that breakers manufactured by their company be used in their panels. Breakers from one manufacturer used in the panel of another manufacturer may result in poor connections, which can create a potential fire or shock/electrocution hazard. The Inspector recommends correction by a qualified electrical contractor If necessary.

- E-5 ELECTRICAL:

A ground fault circuit interrupter (GFCI) electrical receptacle did not respond to testing by the tester at the time of the inspection at the kitchen area and other locations. The outlet tripped when the button was pressed, which may indicate an "OPEN GROUND," which should be labeled "GFCI protected / NO Equipment ground". The Inspector recommends that this receptacle be replaced and/or wiring checked with a new GFCI receptacle by a qualified electrical contractor.

- E-6 ELECTRICAL:

Modern standards recommend smoke alarms in all bedrooms, in all hallways outside bedrooms and at least one on each floor of the building. At the time of inspection no alarms were found.

- E-7 ELECTRICAL:

The flexible electrical conduit whip should be secured to exterior wall by using a J-clip. Loose conduit may cause damage to where it is connected to disconnect and unit!

- HB-3 HALL BATH:

The angle stops (shut-offs) below the family bathroom sink are corroded and could lead to leaks and unreliable performance. Have these further evaluated by a plumber and repaired / updated as recommended.

- I-1 INTERIOR:

Complete installing missing floor transition thresholds.

- From master bedroom to master bathroom

- I-4 INTERIOR:

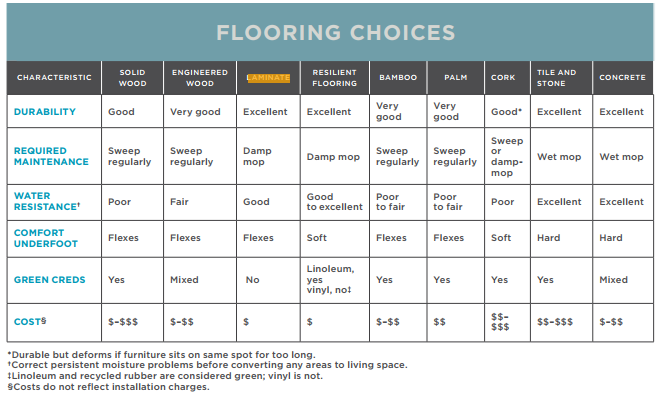

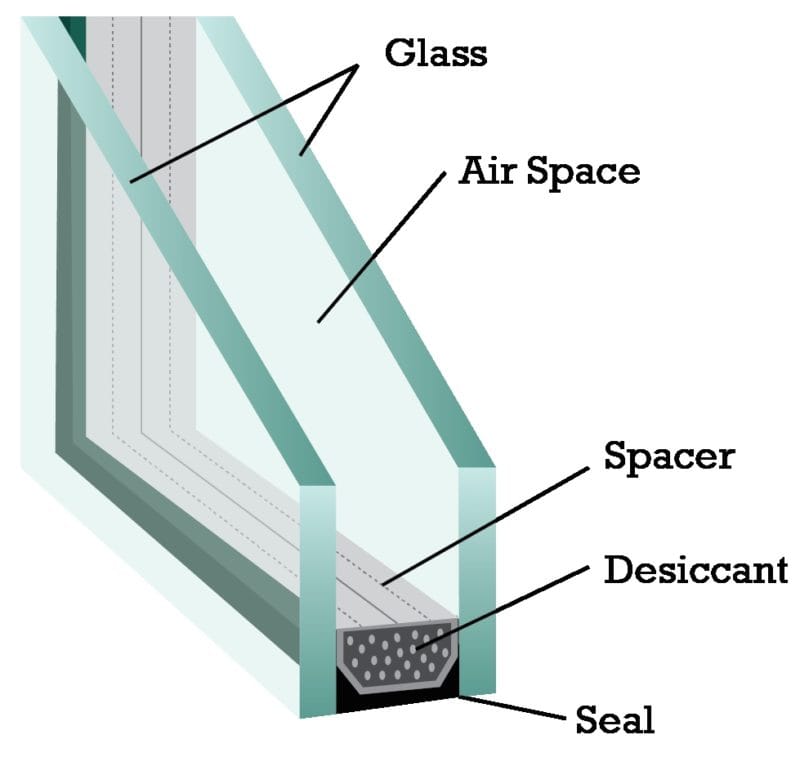

Condensation/Staining visible on the glass at a double-pane window/s indicated that the desiccant strip designed to absorb moisture from the space between the panes has become saturated and will no longer prevent condensation from forming. In some situations repair is possible, but if irreparable damage has occurred, the windowpane assembly will need replacement, which may be expensive. You should consult with a qualified contractor to discuss options and costs for repair or replacement.

- Kitchen nook

- First front bedroom down hall

- Front bedroom at end of hall

- I-5 INTERIOR:

Seal up the hole/s in the ceiling around the furnace to prevent air leakage between the conditioned interior space and the attic. I recommend consulting a contractor for evaluation and repairs concerning this issue.

- K-2 KITCHEN:

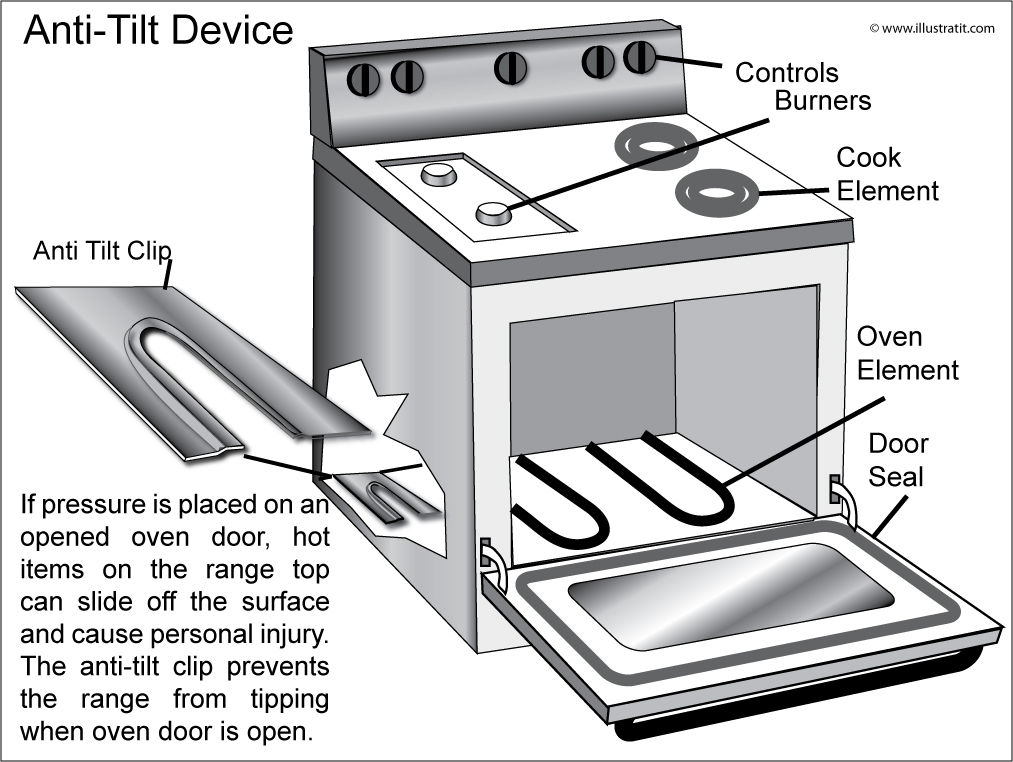

An anti-tip device is needed to prevent this range from tipping during operation of the oven door. This is a small clip that secured the back adjustable feet of the range to the floor.

- K-3 KITCHEN:

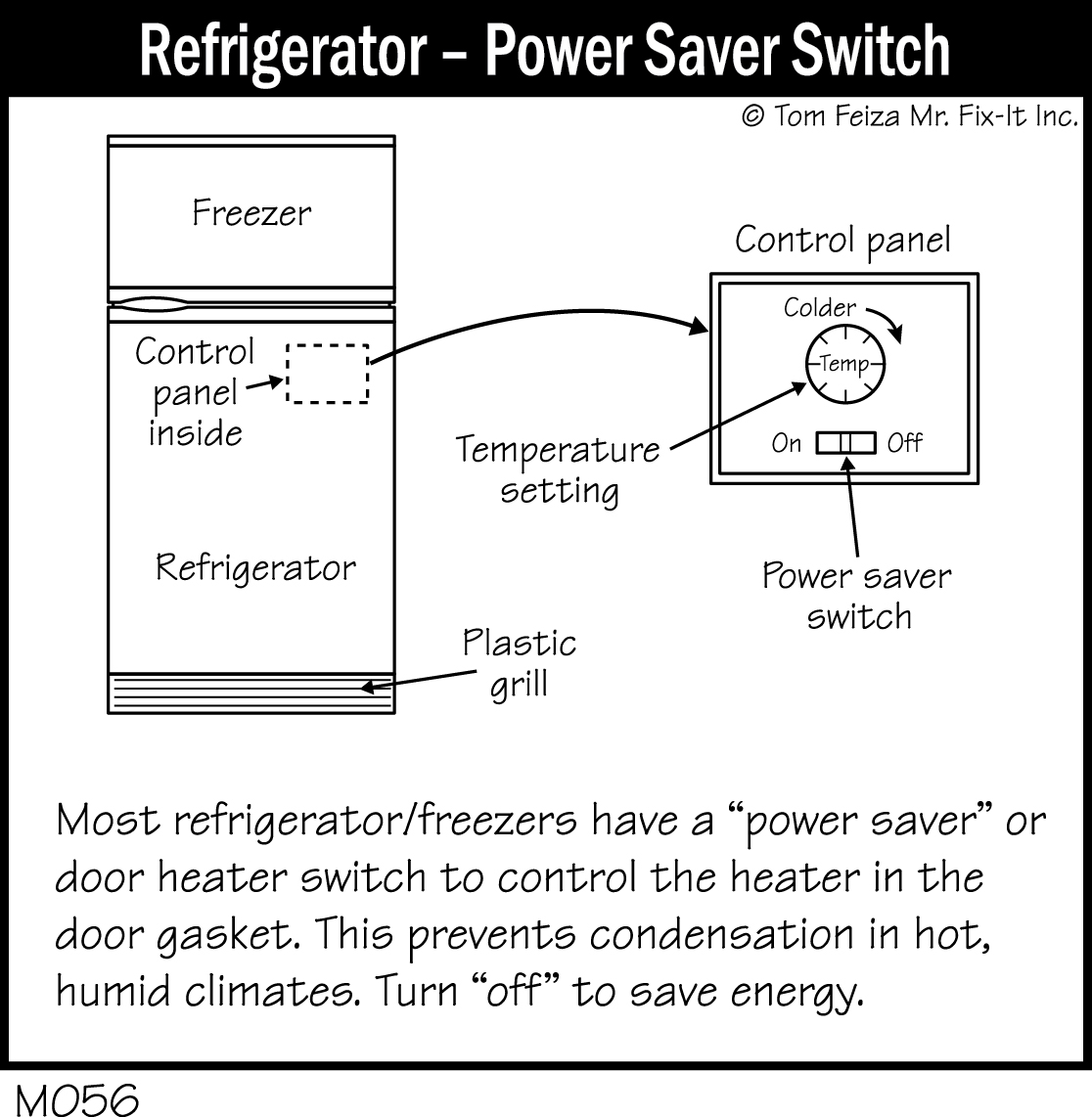

The refrigerator ice maker was off during inspection so I could not verify that it was operational. Repair or make operable as needed.

- CS-2 CRAWL SPACE:

The screens for the crawl space vents are damaged and could allow rodent entry. Use 1/4 inch wire mesh screen and be sure all openings are well sealed to prevent rodent entry. Do not apply multiple layers of screen as this will restrict air flow.

- CS-3 CRAWL SPACE:

Minor water was noted in the crawl space at the time of inspection. This condition can change seasonally so it is difficult to gauge the scope and urgency of a needed repair. Ideally, no water should ever be above the plastic vapor barrier as is the case now. I recommend additional inspection by a qualified drainage contractor. Minor moisture can often be handled with some gravel and a new vapor barrier. More persistent problems may require a sump pump or additional drainage work.

- CS-4 CRAWL SPACE:

Evidence of prior water entry into the crawl space was noted at one of the crawl space vents or silt stains along the foundation walls - see water stains. Inquire with the seller for any history here and monitor. This may be signs of past issues or may be an existing problem during heavy rain cycles. Take every precaution to make sure of drainage issues are addressed and improvements made. Recommend consulting a Contractor for evaluation and repairs concerning this issue.

Recommended Maintenance Items

- EG-4 EXTERIOR / GARAGE:

The brick or mortar has damaged mortar or cracked brick. Small cracks may possibly be sealed with a product such as "Geocel or Lexcel" and larger cracks or crumbling/loose mortar or bricks will require "re-pointing". Recommend consulting a contractor for methods of repair.

- Above garage door

- HCF-4 HEATING, COOLING and FIREPLACES:

Annual servicing of central heating equipment is recommended for safe and reliable heat. Records indicate that the furnace has been serviced within the last year. The furnace was tested during inspection and was operational. The design life of these forced air furnaces is 15-20 years and according to the data plate the age of this unit is

- Acme Plumbing & Heating Inc. - 2007 Old Henderson Rd, Owensboro, KY 42301 Hours: Open Closes 5PM - (270) 684-9434

- All-Weather Heating & Cooling Inc - 107 W 14th St, Owensboro, KY 42303 Hours: Open Closes 5PM - Phone: (270) 685-1515

- Brad Emberton's Heating & Cooling, LLC - 1420 Smith Ave, Owensboro, KY 42301 - (270) 729-2723

- Baird Scott & Co. - 1911 Old Henderson Rd, Owensboro, KY 42301 Hours: Open Closes 5PM - (270) 683-6427

- Dan 'K' Service Co., - 4321 Saddlebrooke Trail, Owensboro, KY 42303 - (270) 297-4144

- Four Seasons Heating & Cooling - 1722 Triplett St. Owensboro, Ky 42301 - 270-926-2900

- Frank's Plumbing and Heating - 814 E 4th St, Owensboro, KY 42303 - (270) 685-1949

- Hagerman Plumbing & Heating - 2119 W Parrish Ave, Owensboro, KY 42301 Hours: Open Closes 5PM - (270) 684-0296

- Harry Roberts Plumbing - Heating - Air Conditioning - 1521 Moseley St, Owensboro, KY 42303 Hours: Open Closes 4PM - Phone: (270) 926-8360

- Key Heating and Cooling, Inc. - 1919 James David Ct, Owensboro, KY 42301 - (270) 686-3012

- Owensboro Heating & Air, LLC - Owner: Chad Millay - Phone: 270-903-8483

- Schwartz Heating & Cooling Inc - 616 Breckenridge St, Owensboro, KY 42303 - (270) 691-1001

- Superb Heating & Cooling, LLC - 524 E 9th St, Owensboro, KY 42303 - (270) 685-5755

Improve Upgrades

- EG-2 EXTERIOR / GARAGE:

I did not find weep holes at the base of the exterior brick siding. Weep holes are designed to provide dry potential for the wall assembly and are typically located every 4-6 feet at the base of the wall assembly. A qualified mason should investigate further and repair the hole as recommended to ensure reliable performance from this wall assembly. Weep holes are important to give the wall assembly dry potential and to prevent pressure differences between the front and back sides of the brick.

- EG-11 EXTERIOR / GARAGE:

Install door closures or safety chains on exterior door to ensure secure entry/exit and prevent potential harm/

- HCF-7 HEATING, COOLING and FIREPLACES:

Duct tape has been used to seal the ductwork. Duct tape should never be used to seal ducts as it desiccates and falls off, causing leaks. Use duct mastic to seal all homes in the ductwork to improve indoor air quality and the efficiency of the heating system.

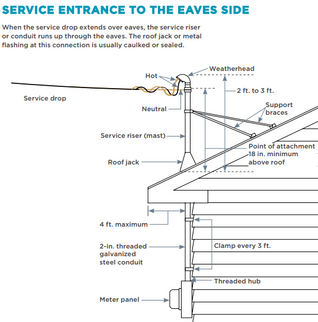

- E-4 ELECTRICAL:

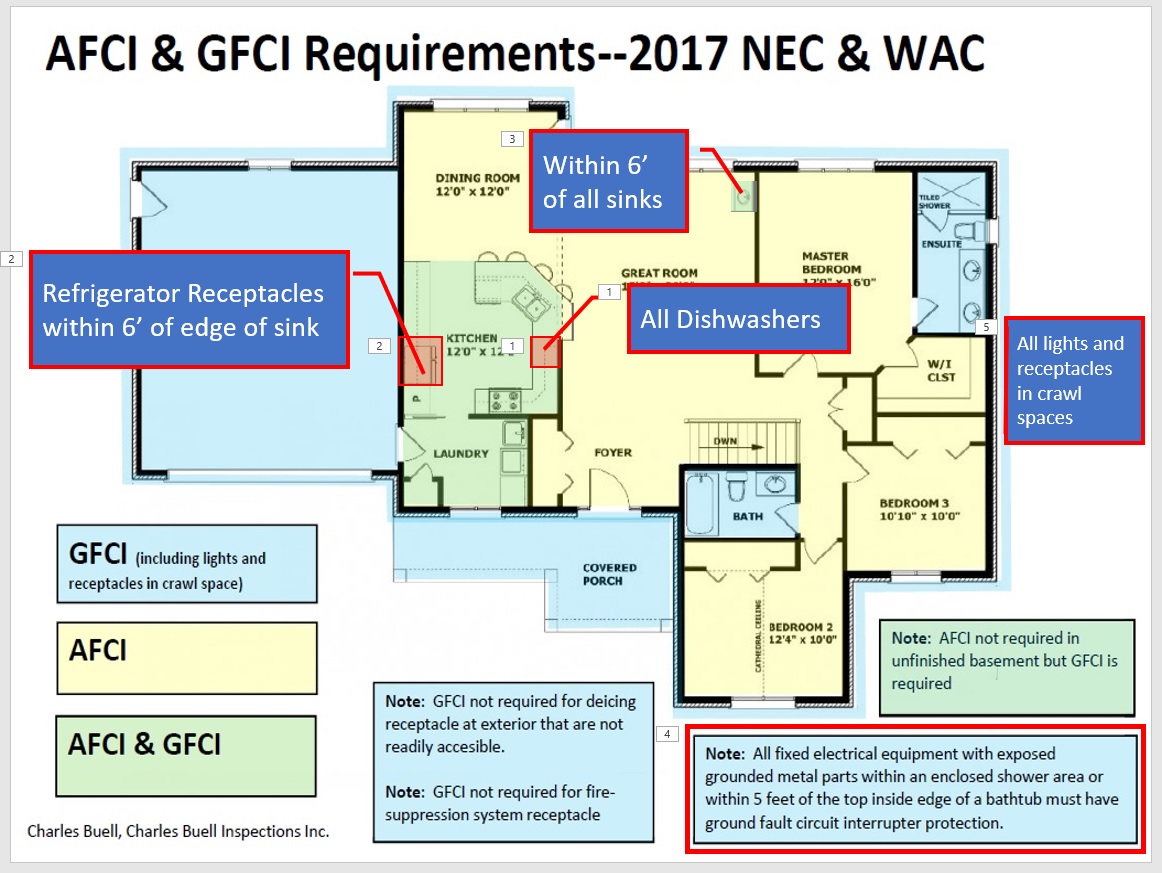

AFCI (arc fault protection) is now required on all branch circuits supplying outlets or devices installed in residential dwelling unit kitchens, family rooms, dining rooms, living rooms, parlors, libraries, dens, bedrooms, sunrooms, recreation rooms, closets, hallways, laundry areas, and similar rooms and areas. The goal of this protection is to reduce risks of electrical fires. Consult with a licensed electrician about improving circuit protection as desired. Please note that if you add circuits to the existing system, they should comply with modern AFCI standards.

- MB-4 MASTER BATH:

No ventilation fan was noted in the master bathroom; there is a window but no fan. Fans that vent to the exterior are recommended and will help reduce indoor humidity and risks for molds. Installation of a bath fan is recommended.

- CS-1 CRAWL SPACE:

Inadequate ventilation was noted for the crawl space. Standards recommend 1 square foot of ventilation for every 150 square feet of crawl space in combination with an approved vapor retarder material that covers all exposed soils in the crawl space. Vents should be located to provide adequate cross ventilation. Hire a licensed general contractor to further evaluate and repair.

Future Projects

- P-1 PLUMBING:

Determining the need for future repair or replacement is beyond the scope of this inspection. Major expense could be involved. We recommend consultation with experts familiar with this particular issue of defective ABS pipe.

Monitors

- SB-1 STRUCTURE and BASEMENT:

Water stains and decolorization to the subfloor are evident beneath multiple drains, indicating a history of moisture accumulation and potential structural concerns. At the time of the inspection no leaks were noticed, monitor this area for possible leaks with normal use.

Notes

- EG-5 EXTERIOR / GARAGE:

The window screens were missing, so you may ask the seller about their whereabouts.

- EG-8 EXTERIOR / GARAGE:

The overhead garage door was inspected, and a complete operating cycle was run, testing the electric laser eye safety feature and the auto reversing system. Garage doors should be regularly inspected and maintained if needed to ensure safe and reliable performance.

- HCF-1 HEATING, COOLING and FIREPLACES:

the home inspector will not energize any component if the pilot is off. This is beyond the scope of the inspection.

- HCF-5 HEATING, COOLING and FIREPLACES:

The air conditioning system was tested during the inspection today. I tested the system in cooling mode, and it appeared performing as intended. It is important that yearly maintenance service is performed on HVAC equipment for efficient and reliable performance.Proper refrigerant change is important for the system to perform as intended, and this is not visible or within the scope of a home inspection. The design life of an air conditioning system is 15-20 years.

- P-2 PLUMBING:

- Washers and Dryers are not typically operated but are checked for how they are installed, vented, drained etc.

- Appliances are not moved during the inspection.

- Timer and thermostat accuracy are not tested.

- E-1 ELECTRICAL:

The building's electrical system consists of the main panel. This panel contains breakers and may or may not include the main breaker.

✒️

- This building's electrical system is protected by an updated electric panel. No permit records or approval stickers were visible on the panel. Testing during the inspection indicated extensive new wiring in the building. Inquire with the seller regarding the extent of wiring work done to the home and any permit records or receipts.

- MB-3 MASTER BATH:

) While the shower drainage was tested at the time of inspection and no leaking was noted, this should not be construed to mean the shower will not leak in the future or that even current leaking might be concealed. This is especially true of recent repairs/installations where work was done in a less than professional manner. Functional testing of the shower during the inspection will not duplicate normal use. Any leaking noted should be properly repaired as soon as practical and hidden damage is always possible.

- HB-4 HALL BATH:

) While the tub and shower drainage was tested at the time of inspection and no leaking was noted, this should not be construed to mean the tub and shower will not leak in the future or that even current leaking might be concealed. This is especially true of recent repairs/installations where work was done in a less than professional manner. Functional testing of the tub and shower during the inspection will not duplicate normal use. Any leaking noted should be properly repaired as soon as practical and hidden damage is always possible.

- I-2 INTERIOR:

The floors show minor cosmetic concerns typical of a home of its age and type of construction. There is some unevenness/sloping, prior patching, staining, mechanical damage, squeaks, etc. No further recommendation‐‐‐‐repair/replace/maintain as desired.

Home Inspection Report

GENERAL COMMENTS

DISCLAIMERS

Recommended Contractors Information/Re-Inspections

Building Characteristics / Conditions

ROOF / ATTIC

📝Styles, Materials & Limitations

Roofing Materials and Flashings

Gutters and Downspouts

Attic Access and Observations

GROUNDS

📝Styles, Materials & Limitations

Driveways/Walkways/Flatwork

Drainage and Topography

Retaining Walls

EXTERIOR / GARAGE

📝 Styles / Materials

Siding and Trim

Exterior Window and Frames

Exterior Doors

Chimneys

Garage/Carport

DETACHED GARAGE

HEATING, COOLING and FIREPLACES

📝Styles, Materials & Limitations

Heating System

Cooling Systems / Heat Pumps

Heating / Cooling Distribution Systems

ELECTRICAL

📝Styles, Materials, & Limitations

Service Equipment-Main Panel

Receptacles and Fixtures

Smoke and CO Alarm Systems

HVAC Wiring and Disconnect

MASTER BATH

📝Styles / Materials

General Bath Condition and Overview

Sinks and Cabinets

Bathtub / Shower

Bathroom Ventilation

GENERAL COMMENTS

DISCLAIMERS

VACANCY STATUS : Property Vacant - How Long?

The following applies to vacant properties. Most often, vacant properties have little to no historical property condition report, and the problems/risk of repair is often increased by how a home performs when not in normal use. Also recognized that no disclosure data has been shared with us prior to the inspection.

Some systems and components of vacant and/or abandoned homes, such as piping, wiring and appliances that have not been used during real-life conditions, could fail without warning. Know that while some systems and components are reported as "working at the time of inspection," may, in fact, fail. It is difficult to know how they will respond to regular use after having sat for extended periods of time. Septic systems may initially function and then fail under a live load. Plumbing traps may operate with no signs of leaks and then let go when being actively used for a few days. Drains that operated during an inspection after real-life conditions may indicate blockage. Component seals may dry up and later leak. Sewer lines could take a few days to backup because of roots or other elements that allow test water to flow, only to fail when waste and tissue are flushed through the system.

For these and similar reasons - be aware that the risk of component failure is greater in these type homes.

UTILITIES STATUS: All Utilities are Operational

PERSONS PRESENT DURING THE INSPECTION: Client, Realtor Professional

COMPONENT LIFE EXPECTANCY-: YES

Components may be listed as having no deficiencies at the time of inspection, but may fail at any time due to their age or lack of maintenance, that couldn't be determined by the inspector. A life expectancy chart can be viewed by visiting http://prohitn.com/component-life-expectancies/

INACCESSIBLE AREA'S-: YES

In the report, there may be specific references to areas and items that were inaccessible or only partly accessible. Suspended ceilings for example would be one of those conditions. I can make no representations regarding conditions that may be present in these areas but were concealed or inaccessible for review. With access and an opportunity for inspection, reportable conditions or hidden damage may be found in these areas. If a request is made by the client for a second inspection, an additional fee will be charged.

✒️

- crawlspace or sections of the crawlspace

- attic

DRAINAGE SYSTEMS SURFACE OR BELOW: The surface water drainage system is below grade and cannot be viewed. Designs and materials for these systems vary widely, making it impossible to evaluate the integrity of the system with any certainty. Because it is inaccessible for inspection, we are unable to determine the presence, extent, or condition of any curtain drainage system that may have been installed.

CODE VIOLATIONS-: Code Violation Issues

We make no representations as to the extent or presence of code violations, nor do we warrant the legal use of this building. This information would have to be obtained from the local building and/or zoning department.

PHOTOGRAPHS-: Include

👉Several photos are included in your inspection report. These photos are for informational purposes only and do not attempt to show every instance or occurrence of a defect.

Recommended Contractors Information/Re-Inspections

CONTRACTORS / FURTHER EVALUATION: It is recommended that licensed professionals be used for repair issues as it relates to the comments in this report, and copies of receipts are kept for warranty purposes. The use of the term "Qualified Person" in this report relates to an individual, company, or contractor who is either licensed or certified in the field of concern. If I recommend evaluation or repairs by contractors or other licensed professionals, it is possible that they will discover additional problems since they will be invasive with their evaluation and repairs. Any listed items in this report concerning areas reserved for such experts should not be construed as a detailed, comprehensive, and / or exhaustive list of problems or areas of concern.

RE-INSPECTION Concerns: YES

When repairs are made on the home, I recommend that I be called back to verify that corrections have been satisfactorily made. A minimum assessment of $195.00 will be charged for each Work Order Evaluation Inspection that is requested that I conduct. Additional charges will accrue for anything in writing, beyond an email response, and for evaluations at more than 20 miles travel time—these costs are to be agreed upon at the time of the request for further evaluation. REMEDIAL WORK - For any element or condition requiring attention, quotes should be obtained before closing from qualified specialists or contractors to determine actual repair/replacement costs. Any cost estimates provided, whether oral or written, represent only an approximation of possible costs. Also, any cost estimates do not reflect all possible remedial needs or costs for the property; latent concerns or consequential damage may exist. If the need for remedial work develops or is uncovered after the inspection, contact Proview Professional Home Inspections to arrange an inspection to assess conditions before performing any repairs.

IF THERE ARE ITEMS WITHIN THIS REPORT THAT REQUIRE RE-INSPECTION, YOU ARE ENCOURAGED TO HAVE ME COMMUNICATE DIRECTLY WITH THOSE HIRED TO MAKE THE CORRECTIONS TO ENSURE THAT REPAIRS ARE PROPERLY MADE.

There are many things that can be done to improve safety and living conditions within any home. While many of these issues come to light in the course of the Standard Home Inspection there are likely to be other things that can be done to improve the home.

Building Characteristics / Conditions

APPROXIMATE YEAR OF CONSTRUCTION-Per the MLS/DCPVA: Prior 1980's, 1975

Structures built prior to the mid 1980s may contain lead and/or asbestos. Lead is commonly found in paint and in some plumbing components. The EPA does not recognize newer coats of paint as encapsulating older coats of lead-based paint. Asbestos is commonly found in various building materials such as insulation, siding, and/or floor and ceiling tiles. Laws were passed in 1978 to prohibit usage of lead and asbestos, but stocks of materials containing these substances remained in use for a number of years thereafter. Both lead and asbestos are known health hazards. Evaluating for the presence of lead and/or asbestos is beyond the scope of this inspection. Any mention of these materials in this report is made as a courtesy only, and meant to refer the client to a specialist. Consult with specialists as necessary, such as industrial hygienists, professional labs and/or abatement specialists for this type of evaluation.

Solid conductor aluminum wiring was used in residential construction for 15 and 20-amp circuits in the 1960's through the 1970's. This wiring has proven to be problematic and a fire hazard, primarily due to problems with loose connections and metal fatigue. I looked hard to find any signs of solid conductor aluminum here. No signs were found. There is always a chance that solid conductor aluminum wiring exists and is concealed from view. If this wiring is ever uncovered during subsequent renovation work, I recommend removal and replacement.

LOCATION REFERENCE: Photo Reference

🧭For the purpose of this report, all directions are given as if you are standing facing the front of the house. Items listed as multiple locations may not directly reference all affected locations. Examples may be given that should not be construed as the only affected areas. Further evaluation will need to take place to determine every affected location.

STYLE/TYPE OF HOME+INFO: 🔹STYLE (Traditional), 🔹TYPE (Single Family (1 story)), 🔹SFT OF PROPERTY (1901-2000), 🔹BEDROOMS (3), 🔹FULL BATHROOMS (2)

A traditional home is the most common style in the United States. It is a mix of many classic, simple designs typical of the country's many regions. Common features include little ornamentation, simple rooflines, symmetrically spaced windows. A typical traditional home is Colonial, Georgian, Cape Cod saltbox, some ranches.

WEATHER/SURFACE CONDITIONS : 🔹WEATHER CONDITIONS (Cloudy), 🔹TEMPERATURE (65° - 80°), 🔹SURFACE/SOIL CONDITIONS (Wet)

ANIMALS PRESENT-: No

ROOF / ATTIC

📝Styles, Materials & Limitations

COMPLIMENTARY PHOTOS: Photos Provided For Reference

ROOF DESIGN : Gable

Gable

ROOF MATERIALS: Architectural grade composition shingle

The roof on this building is done in an older dimensional grade composition shingle. These shingles are often rated as 30 year shingles, but in practice, as a roof assembly, I find that 18-22 years is more realistic, depending on the quality of the installation, the steepness of the roof and the exposure. This roof is roughly middle-aged and seems to be performing well to date. No visible evidence of repairs is needed at this time. Examples of observations noted during inspection includes:

% OF VIEW / INSPECTED: 🔹HOW INSPECTED (Walked on roof), 🔹% OF ROOF INSPECTED (100%)

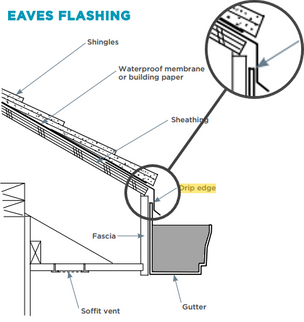

DRIP EDGE FLASHING: Present

A drip edge is an angled piece of flashing that is installed over top of a fascia board. The purpose of a drip edge is to help redirect water from the fascia and into the gutters. The gutters then carry this water away. Drip edges can be installed on the rake, eaves, and gable of your roof. They extend beyond the fascia and are a minimum of one-third of the gutter width. Metal drip edges are typically made of a non-porous, non-corroding metal, like galvanized steel, aluminum, or copper. They can also be constructed out of durable plastic, vinyl, or fiberglass.

GUTTER & DOWNSPOUT METHOD: 🔹MATERIAL USED (Aluminum), 🔹DRAINAGE METHOD (Above ground)

Aluminum gutters do not rust but they dent easily, particularly with tall, heavy ladders. Joints in aluminum gutters are usually riveted together and caulked. The caulking must be renewed every few years. Aluminum gutters usually have very few joints, since the gutters are typically fabricated on the job site from long rolls of aluminum stock. Aluminum gutter is also pre-finished and does not require regular painting. Life expectancy is estimated to be 20 to 25 years.

Four-inch gutters are good for relatively small roof areas; however, five-inch gutters are preferred because of their additional capacity. Five-inch gutters are also less likely to allow water to overshoot the gutters when the water is draining off a steeply pitched roof. While "rules of thumb" for both gutter size and number of downspouts needed often are based simply on the length of roof edge that is being drained, this approach is flawed in that it fails to consider the total roof area that is being drained. A roof that is very small in total area, even if very long, may get along just fine with a smaller 4-inch gutter, while a much larger roof area with the same length of roof eaves needs a 5-inch gutter or larger.

ATTIC ACCESS: 🔹POINTS OF ENTRY (Garage), 🔹TYPE OF ENTRY (Pulldown Stairs)

TRUSS / RAFTER TYPE: Truss - Engineered

SHEATHING MATERIAL: Solid Wood - Tongue and Groove - Up until the 1950s, virtually all roof sheathing was wood plank.

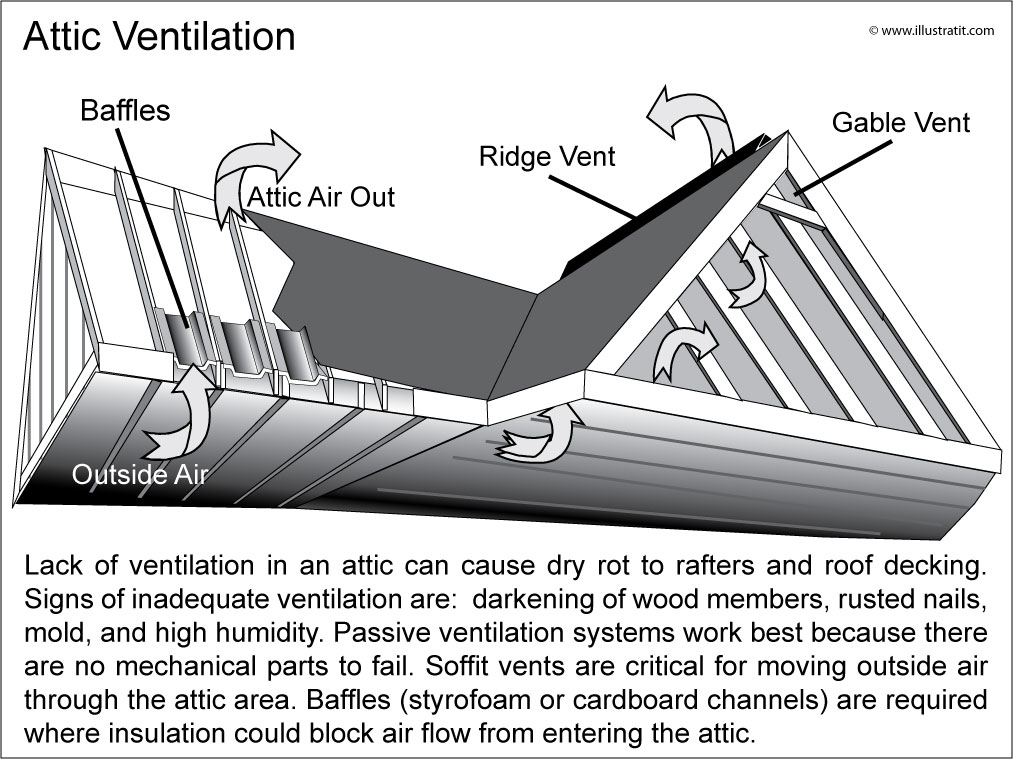

ATTIC VENTILATION METHOD: Soffit vents, Wind Turbines, Gable vents

The primary purpose for attic ventilation is heat reduction. With the ventilation necessary to accomplish this it will also remove very minor amounts of moisture that may find its way into the space as well. Its overall purpose is NOT TO REMOVE MOISTURE. We want to reduce heat to reduce cooling loads and improve indoor comfort. Ventilation of the home is examined by looking for eave, soffit, gable, roof and ridge vents. A properly ventilated attic/roof cavity keeps the house more comfortable in the summer, and prevents condensation that can damage roofing components.

Newer homes that are well insulated should have no less than one square foot of free vent area for each 150 square feet of ventilated area. The amount can be reduced to one square foot for each 300 square feet if the ventilation is equally divided between the lower and upper portions of the area being vented, or if a vapor barrier is installed on the warm side of the insulation. Determination of how or if vaulted ceilings are vented can be beyond the scope of the Standard Home Inspection.

INSULATION TYPE & R-VALUE: 🔹INSULATION TYPE (PRESENT, Fiberglass-Batt-[R-Value 2.9-4.2 per inch], Cellulose-[R-Value 3.4-3.6 per inch]), 🔹ATTIC FLOOR (R-Rating - 38)

Attic insulation is extremely important as it prevents most heat loss from your home during the winter months. The recommended amount of insulation present has increased over the years.

To choose the best insulation for your home from the many types of insulation on the market, you'll need to know where you want or need to install the insulation, and what R-value you want the installation to achieve. Other considerations may include indoor air quality impacts, life cycle costs, recycled content, embodied energy, and ease of installation, especially if you plan to do the installation yourself. Some insulation strategies require professional installation, while homeowners can easily handle others. Source - Energy.gov

Fiberglass insulation is one of the most common insulation materials available and is made from threads of glass glued together with phenolic resins. It is available in batt form, rigid board and loose fill. It is resistant to moisture, mildew, fungus and vermin, and some types are non-combustible. It is, however, a skin and eye irritant and inhaling small threads of fiberglass is not healthy. These irritations are only common during installation, and once the material is in place it is not considered to be a problem.

Cellulose fiber is essentially paper, finely shredded and chemically treated to resist moisture, fire, rot and vermin. It is usually blown in or poured. It is prone to settling. Due to its relatively low cost, this material is very popular. Usually gray in color, it has a similar texture to lint. Cellulose fiber absorbs water, which reduces its effectiveness.

Roofing Materials and Flashings

ROOFING OBSERVATIONS📄: 👉COMMON OBSERVATIONS (Exposed Fasteners)

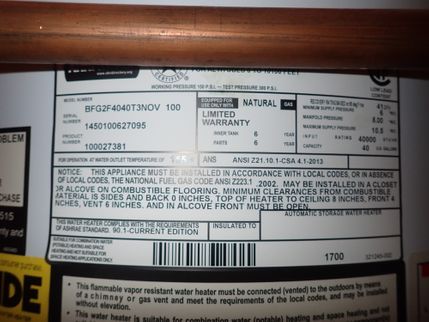

ROOF PENETRATIONS / FLASHINGS📄: 🔹ROOF PENETRATIONS (🔸ELECTRICAL MAST, Boot Flashing Damaged/Missing)

All exposed fasteners or "shiners" on the roof should be sealed with mastic. The photos provided may only show a representation of occurrences. I recommend having a professional roofing contractor inspect and repair the issues mentioned. Many roof problems get worse over time if not appropriately addressed. A good contractor will know how to make repairs correctly using the best products. For example, silicone should never be used; roof mastic or high-quality sealants like GEOCEL work much better for roof repairs. I'd advise getting the repairs done according to the contractor's recommendations to ensure the problems are fully resolved, and your roof will be safe and leak-free for years.

✒️

- 💦 At roof penetrations. Pipes, exhaust vents, and other objects that penetrate the roof often have exposed fasteners holding flashing or collars in place. Make sure all fasteners are secure with no corrosion.

Damaged boot flashing or damaged flashing at electric service mast which should be repaired to prevent moisture intrusion. Sealant may eventually crack and allow damage to the area around the mast. Recommend consulting a Contractor for evaluation and repairs concerning this issue.

Gutters and Downspouts

COMMON OBSERVATIONS📄: 🔹GUTTERS (Leaky Seams, Loose - Due to Hangers/Spikes), 🔹DOWNSPOUTS (Extensions Needed)

The gutters are no longer properly supported in locations. Gutters that are not properly supported can cause drainage concerns and additional damage to the framing behind them. Correction of this defect is important to prevent moisture-related issues in the future. Recommend consulting a for evaluation and repairs concerning this issue.

✒️

- This drainage system for supporting the gutters is using spikes. These spikes may become loose due to damage to the wood fascia becoming soft due to moisture.

Some of the downspouts discharged roof drainage next to the foundation. This condition can affect the ability of the soil to support the weight of the structure above and can cause damage related to soil/foundation movement. The Inspector recommends the installation of downspout extensions to discharge roof drainage a minimum of 6 feet from the foundation.

Attic Access and Observations

The attic access is one place that is often neglected and, if not properly constructed or located, can become a dangerous place to enter. Access may be scuttle access, dropdown stairs, privacy door, or attic doors. The following observations here may indicate improvements that are needed. Updates required or defective conditions that require repairs. Repairs or improvements may range from simple to complex and may require qualified persons to make such repairs. For evaluation and repairs concerning this issue, always practice safety when making repairs.

PULLDOWN STAIRWAY

- 🛠️The attic stair pulldown was noted to be broken/damaged or weak and may cause injury.. This unit should be repaired or replaced for safety reasons. Repair may be performed by a qualified person.

ACCESS - HEAT MIGRATION

- 🛠️ An attic stair pulldown has been installed in the heated part of the home. This will result in heat loss in the home as this entire hatch is now uninsulated and poorly air sealed. Use rigid foam to construct a box that fits over this access or such a device can be bought pre-assembled. Also, use weather strip to seal the door closed.

GROUNDS

📝Styles, Materials & Limitations

FLATWORK TYPE: 🔹DRIVEWAY (Concrete - Usually is 4" to 6" in thickness), 🔹WALKWAYS / SIDEWALKS (Concrete)

TOPOGRAHY AROUND HOUSE: PROPERTY DRAINAGE: What About the Property Drainage?

To maintain proper drainage away from the structure, soil adjacent to the foundation should slope at least 1 inch per foot for five feet away from the building. Paved areas should slope at least 1/4 inch per foot. Control of surface drainage is critical to keeping basements and crawl spaces dry. A clearance of 6 inches should be maintained from the soil to the bottom of wood siding or trim on the home, unless the material is pressure treated wood or other material approved for ground contact. Swales around homes can help manage water and reduce its impact on the home.

VEGETATION NEAR HOUSE: No

Driveways/Walkways/Flatwork

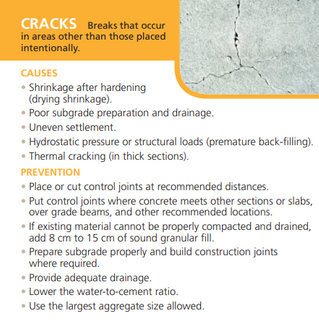

COMMON OBSERVATIONS📄: 🔹CRACKS/SURFACE DAMAGE (🔸CRACKS, Large Cracks)

Large crack/s at the concrete driveway flatwork should be filled to stop moisture intrusion. When moisture freezes, it will continue to expand the crack.

✒️

- Recommend that a qualified person install the proper size backer rod and then apply concrete self-leveling filler to protect the concrete. Make sure you remove any debris in the crack before applying the concrete filler product.

Drainage and Topography

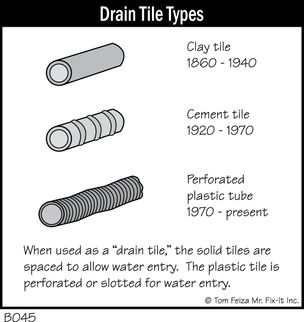

TYPES OF DRAINAGE TILES:

A surface drainage system is designed to collect and divert roof runoff and other surface water. It is installed in solid pipe and flows continuously downhill to a point of discharge. The downspouts drain into an underground drain tile. Depending the age of the house may determine the type of materials used unless they have been upgraded recently. Here is some information concerning the types most commonly used.

An examination of the grounds revealed standing water being an issue, at least during the inspection. The water does not appear to be directly affecting the structure; however, it may indicate poor drainage or the possibility of other concerns such as plumbing underground leakage. Therefore, it is a concern that should be evaluated due to its effect on the soils and structure. I recommend consulting with a Qualified Person for evaluation and repairs concerning this issue. Current conditions will require a more invasive means to determine the needs found.

LOCATIONS WITH PONDING WATER

- Elevation Concerns

- 🛠️ The surface water, if not properly controlled, can accumulate around the foundation or can pond on the lawn or over the entry path, foundation vents or crawlspace entries. If the house is inspected when it is not raining, you might not see any problems. However, based on the slope and overall grading of the land around the house, you can at least determine the potential for a problem. Surface water can run directly to the foundation, seep down along the foundation walls, and accumulate at the lower section. This usually results in water seepage into the basement or crawl space. A rule of thumb for grading this area is a drop of about 1 inch per foot. The lawn should slope away from the house for at least 10 feet and should be pitched so that there is approximately a 10-inch drop over that distance.

EXTERIOR / GARAGE

📝 Styles / Materials

SIDING MATERIAL: Brick

Brick may be made of clay or concrete. The characteristics of brick vary dramatically. Some brick surfaces are relatively soft and erode with time. Other bricks are extremely hard. Some can be easily damaged by mechanical action; others may crack due to water penetration and freeze-thaw action. Some bricks are highly porous; others are less so. Some bricks have a hard glazed outer surface; others are uniform throughout. Most bricks are not designed to be in contact with the soil and should be kept at least four inches above grade.

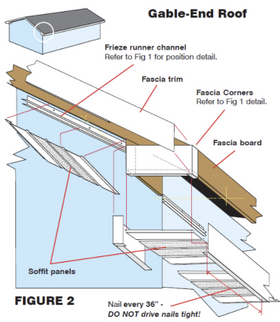

TRIM MATERIAL: 🔹FASCIA/FRIEZE (Wood), 🔹WINDOW EXTERIOR TRIM (Aluminum), 🔹DOOR EXTERIOR TRIM (Wood)

EAVES/SOFFITS: 🔹MATERIAL USED (Wood and Plywood), 🔹TYPE (Closed Soffits w/ No Ventilation)

A soffit is an exterior or interior architectural feature, generally the horizontal, aloft underside of any construction element. Its archetypal form, sometimes incorporating or implying the projection of beams, is the underside of eaves. The vertical band at the edge of the roof is called a fascia.

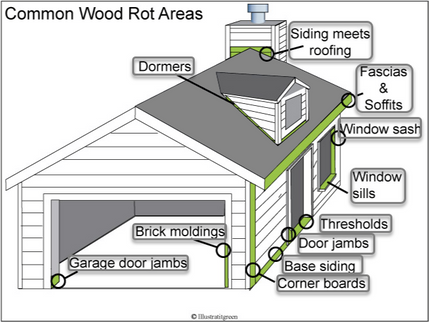

WINDOW MATERIAL: Vinyl

All surfaces of the envelope of the house should be inspected at least semi-annually, and maintained as needed. Any exterior element defect can result in leakage and/or subsequent damage. Exterior wood elements and wood composites are particularly susceptible to water-related damage, including decay, insect infestation, and mold. The use of proper treated lumber or alternative products may help minimize these concerns, but will not eliminate them altogether. While some areas of decay or damage may be reported, additional areas of concern may exist, subsequently develop, or be discovered during repair or maintenance work.

EXTERIOR DOOR: 🔹TYPE (Solid Wood), 🔹STORM DOOR/SCREENS (Present)

The 'Security' of any home is never absolute. At the time of inspection I assess the 'basic functionality' of door and window locking mechanisms. No assessment of the individual or overall effectiveness of security is implied. Glass, frames, locks and other elements can be prone to 'tampering’ and are 'limiting factors' of locking mechanisms/systems. All security devices and systems must be balanced against the ease of escape in the event of emergency. Concerns about the home s overall security system should be addressed by a licensed home security company. It is our advice to you that once you move in is to replace all exterior locks for your safety.

A storm door on the outside of your exterior door is installed, doors located in direct sunlight will get much more heat than those on the shaded areas, make sure it is ventilated. If the storm door is not ventilated it can cause heat to build up around your door and will potentially warp the door or damage the trim around the glass insert. If you have a storm door that does not have proper ventilation, your warranty will be void.

GARAGE DOOR/S: Attached, 🔹DOOR TYPE (Double Insulated), 🔹PARKING BAYS (2-BAY), 🔹OPENER TYPE (PRIOR <1982 [See Garage Observation], 1/2 Horsepower)

Complimentary photos provided when at the inspection.

The overhead garage door is the largest and heaviest moving object in a house. According to the U.S. Consumer Product Safety Commission (CPSC), approximately 4 children die each year from accidents caused by garage doors. Many more children have suffered brain damage or other serious injuries when the closing garage door contacts them, and fails to stop/reverse its direction. A typical garage door weighs anywhere from 155 to 400 pounds, but wooden garage doors can weigh even more. During times of wet weather, wooden garage doors can even absorb about 50 pounds of water from the air. This extra weight can cause additional wear and tear on the garage door opener. As the occupant, you will become accustomed to the noises associated with the operation of your garage door and opener. If any changes occur with the squeaks and chattering most garage door systems make, it is essential to take action promptly. Consult a qualified service technician and never attempt to make adjustments to the door springs and cables yourself.

Siding and Trim

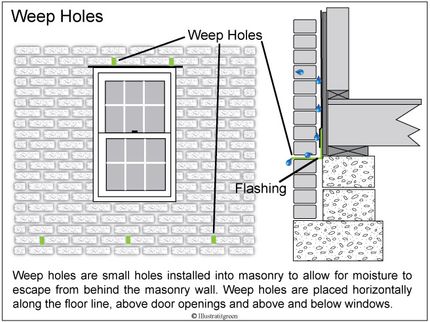

SIDING ISSUES📄: 🔸BRICK VENEER (Weep Holes Missing, Stair Step Cracks)

TRIM OBSERVATIONS📄: Wood Trim-Old House Touch Up Needed

FLASHING OBSERVATIONS📄: 🔹PENETRATIONS (Seal up Around Penetrations)

The exterior paint job requires localized touch-up due to peeling paint and bare wood exposed. This is typical on older homes. Be prepared to make repairs such as wood putty to fill in areas that need it. Have the exterior paint job touched up and completed by the painter. During inspection today, I noted:

Seal wall penetration/s. The hole/s in the exterior wall-covering cut to allow penetration of air-conditioning lines/gas lines or electrical lines should be sealed with an appropriate sealant to prevent moisture and insect entry in some cases mortar should be used if the hole is large.

The brick or mortar has damaged mortar or cracked brick. Small cracks may possibly be sealed with a product such as "Geocel or Lexcel" and larger cracks or crumbling/loose mortar or bricks will require "re-pointing". Recommend consulting a contractor for methods of repair.

- Above garage door

I did not find weep holes at the base of the exterior brick siding. Weep holes are designed to provide dry potential for the wall assembly and are typically located every 4-6 feet at the base of the wall assembly. A qualified mason should investigate further and repair the hole as recommended to ensure reliable performance from this wall assembly. Weep holes are important to give the wall assembly dry potential and to prevent pressure differences between the front and back sides of the brick.

Exterior Window and Frames

COMMON OBSERVATIONS📄: 🔹SCREENS (Missing)

Exterior Doors

COMMON OBSERVATIONS📄: 🔹HARDWARE (🔸DEADBOLT, Double Keyed [Both Sides])

The dead bolt/s for the exterior door/s are opened with a key rather than a thumb-toggle. This can inhibit easy fire egress. Keep the key for these deadbolts nearby and easily accessible or better - switch this deadbolt with a thumb-toggle dead bolt for improved safety.

- Front and rear entry

Chimneys

CHIMNEY OBSERVATIONS📄: 🔹EXTERIOR OF CHIMNEY (Missing Cricket/Saddle)

I recommend having a cricket and flashing installed for this chimney to divert water around the chimney. The current installation is vulnerable to leaks as the entire roof drains toward the chimney. Please note that modern standards require chimney cricket flashings when the chimney is at the bottom of a roof and more than 30 inches wide.

Garage/Carport

GARAGE DOOR OBSERVATIONS📄: 🔸OVERHEAD DOOR (🛠️Testing Procedure Note, Damaged Weather Strip), 🔸ADJUST SENSITIVITY (One), 🔸LASER EYES (Set Too High)

GFCI PROTECTION: No

Overall the garage as a whole has numerous defects that could be a potential safety hazard if the issues observed are not addressed accordingly. The items listed below require repair or replacement to ensure proper safety and performance. I recommend consulting with a licensed contractor or garage door specialist to evaluate and repair as needed.

OVERHEAD DOOR

- 🔹Automatic Opener

- 🛠️Adjust Sensitivity (One Door)--The overhead garage door does not reverse under resistance to closing. Adjustment of the sensitivity is recommended for improved safety. This typically involves adjusting a small plastic screw on the opener.

- 🔹Laser Eyes

- 🛠️Set Too High--The laser eye safety mechanism for the overhead garage door has been set too high - this sensor should be 5-6 inches off of the floor to perform as intended and prevent entrapment.

- 🔹Overhead Door

- 🛠️Damaged Weather-stripping--Repair the damaged weather stripping on the garage door. This is important to prevent water and rodent entry.

- 🛠️Damaged Gasket--Repair the damaged bottom panel gasket on the garage door. This is important to prevent water and rodent entry.

FUEL STORAGE and DISTRIBUTION

📝Styles, Materials & Limitations

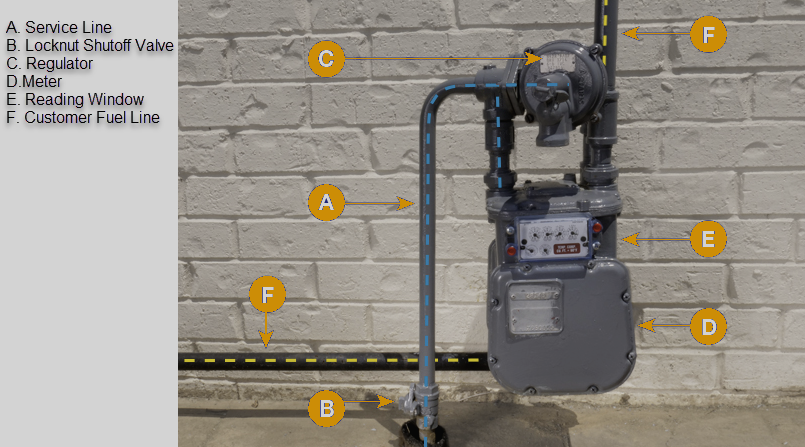

GAS METER & LOCATION: Side of structure

The gas meter is typically the property of the local utility. All concerns regarding the meter should be directed to the gas utility.

- Where the gas pipe comes out of the ground to the meter there is often a Yellow (usually) Tracer wire. This wire is not supposed to be connected to anything and is only there to assist anyone trying to locate the underground plastic pipe out to the street.

PIPE DISTRIBUTION MATERIAL: Black Steel

PROPANE STORAGE: None noted

OIL STORAGE: None Noted

Gas, Propane and Oil Piping

PIPE DISTRIBUTION: 🔹EXTERIOR (Corrosion on Pipes), 🔹FURNACE (Flex going through Sidewall or Wall, Drip Leg or Sediment Trap Missing)

Flexible gas connectors should not run through walls, floors or disappear into a concealed location or the walls of appliances such as a furnace. It has been determined that the vibrations of the housing and the sharp edges around the point of entry of the flexible tubing can cut the gas line. The flexible gas line is only 2-3 sheets of typing paper thick. The flex line must now attach to a black pipe outside of the housing to avoid being a safety hazard. A plumber can do this job for you... but do not let them tell you to just wrap a piece of foam rubber around it. If the vibrations can cut metal, foam rubber provides little, if any, protection. Use rigid steel pipe only. Have this further evaluated and repaired by a qualified plumber or gas appliance technician.

I did not see a sediment trap for the gas pipe at the furnace and water heater. Have this further evaluated and repaired as recommended by a qualified plumber. A sediment trap is recommended to trap sediment in the pipe and prevent fouling of gas equipment.

✒️

- Due to the age or condition of the unit/s, it may be the most cost-effective to correct these issues at the time of replacement.

HEATING, COOLING and FIREPLACES

📝Styles, Materials & Limitations

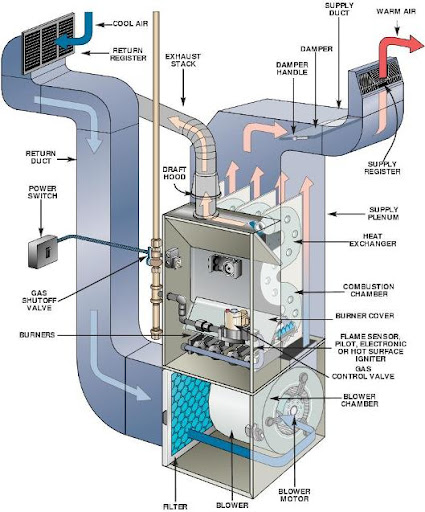

HEATING SYSTEM: 🔹NUMBER OF UNITS (1), 🔹THERMOSTAT (Auto Heat/temp@ ℉), 🔹THERMOSTAT LOCATION/S (Main Floor Hallway), 🔹MANUFACTURER (Arcoaire), 🔹HEATING METHOD (Forced Air Furnace)

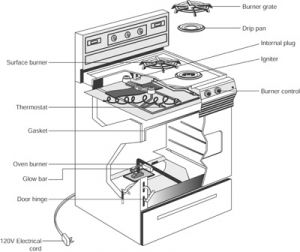

This house has an L.P. Gas forced air furnace. The key to all combustion equipment like this is the heat exchanger. This is the welded clam-shell piece of metal inside the furnace that contains the products of combustion so that moisture, carbon monoxide, and other products of combustion do not mix with interior air and get safely vented to the exterior. Heat exchanges on modern furnaces have an average life expectancy of 15-20 years. Unfortunately, heat exchangers are buried inside heating equipment; they are not visible and specifically excluded from a home inspection. The risk of using older gas equipment is you could get a crack and the heat exchanger and never even be aware of it. Be sure you have operable carbon monoxide alarms inside the house, and consider updating these forced air furnaces on a roughly 20-year schedule.