Introduction, Scope, Definitions & Compliance Statement

Introduction: The following numbered and attached pages are your property inspection report. The report includes information, pictures, video and recommendations. This inspection was performed in accordance with the current Standards of Practice and Code of Ethics (Spanish Estándares de la Práctica and Código de ética) of InterNACHI (International Association of Certified Home Inspectors) and the Code of Ethics of the CMI (Certified Master Inspectors®). These Standards contain certain and very important limitations, expectations and exclusions to the inspection. A copy is available prior to, during and after the inspection and it is part of the report.

What Really Matters in a Home Inspection: The process can be stressful. You will be asked to absorb a lot of information in a short time. This often includes a digital report, photographs and what the Inspector himself says during the inspection. All this combined with the Seller's disclosure and what you notice yourself makes the experience even more overwhelming. What should you do? Relax. Most of your inspection will be maintenance recommendations, life expectancies and minor imperfections. However, the issues that really matter will fall into four categories: 1. Major defects. 2. Things that may lead to Major defects. 3. Things that may hinder your ability to finance, legally occupy or insure the property. 4. Safety hazards. Anything in these categories should be corrected. Often a serious problem can be corrected inexpensively to protect both life and property (especially in categories 2 and 4). Realize that Sellers are typically under no obligation to repair anything mentioned in the report.

Use of Photos and Video: Your report includes photographs which help to clarify where the Inspector went, what was looked at, and the condition of a system or component at the time of the inspection. Some of the pictures may be of deficiencies or problem areas, these are to help you better understand what is documented in this report and may allow you see areas or items that you normally would not see. Not all areas of deficiencies or conditions will be supported with photos.

Thermal Imaging: An infrared camera may be used for specific areas or visual problems and should not be viewed as a full building thermal scan. Temperature readings on thermal images in this report are included as a courtesy and should not be wholly relied upon as a home inspection is qualitative, not quantitative. These values can vary +/- 4% or more of displayed readings, and these values will display surface temperatures when air temperature readings would actually need to be conducted on some items which is beyond the scope of a property inspection.

Scope: A property inspection is intended to assist in evaluating the overall condition of the dwelling. The inspection is based on observation of the visible, readily accessible, and apparent condition of the structure and its components on this day. The results of this inspection are not intended to make any representation regarding the presence or absence of concealed defects that are not reasonably ascertainable or readily accessible in a competently performed inspection.

No Warranty, Guarantee or Insurance by Baker Inspection Group is expressed or implied. This report does not include inspection for Code Compliance, Wood Destroying Organisms, Asbestos, Mold or Lead. A representative sampling of the building components is viewed in areas that are accessible at the time of the inspection. No destructive testing or dismantling of components is performed. Not all defects will be identified during this inspection. Unexpected repairs should be anticipated. The person conducting your inspection is not a Structural Engineer or other professional whose license authorizes the rendering of an opinion as to the structural integrity of a building or its other component parts.

This report has been produced in accordance with the AGREEMENT and is subject to the terms and conditions agreed upon therein. The report was produced exclusively for our CLIENT. Not to be used or interpreted by anyone other than our CLIENT or REPRESENTATIVE. If you’re reading this report but did not hire us, Baker Inspection Group, to perform the original inspection, please note that it is likely that conditions related to the home have probably changed. Minor problems noted may have become worse, recent events may have created new issues and items may even have been corrected and improved. Please call us at (209) 522-5320 so that we can arrange for a proper inspection. Thank You!

Getting the Information to You

This report is designed to deliver important and technical information in an easy way for anyone to access and understand. You can take a quick look at our "Summary Page” and quickly get critical information for important decision making. However, we strongly recommend that you take the time to read the full Report, which includes digital photographs, captions, diagrams, descriptions, videos and hot links to additional information.

The best way to get the layers of information that are presented in this report is to read your report online (the HTML version), which will allow you to expand your learning about your house. You will notice some words or series of words highlighted in blue and underlined – clicking on these will provide you with a link to additional information. The HTML version of this report also contains short video clips which often contain important information and critical context and sounds that can be difficult to capture in words and still pictures.

For the most reliable viewing experience, I recommend viewing the report on as large a screen as practical, as much detail can be lost on small devices like smart phones. For similar reasons, reports should only be printed in color to retain as much detail as possible.

This report can also be printed on paper or to a PDF document.

Chapters and Sections: This report is divided into chapters that parcel the property into logical inspection components. Each chapter is broken into sections that relate to a specific system or component. You can navigate between chapters with the click of a button on the left side margin.

Most sections will contain some descriptive information done in black font. Observation narratives, done in colored boxes, will be included if a system or component is found to be significantly deficient in some way or if we wish to provide helpful additional information. If a system or component of the home was deemed to be in satisfactory or serviceable condition, there may be no narrative observation comments in that section.

Observation Labels: All narrative observations are colored, numbered and labeled to help you find, refer to, and understand the severity of the observation. Observation colors and labels used in this report are:

- Description:Detailed description of various aspects of the property noted during the inspection.

- Note:Refers to aside information and / or any comments elaborating on descriptions of systems in the home of a more informational nature.

- Major Concern:Repair items that may cost significant money to correct now or in the near future, or items that require immediate attention to prevent additional damage or eliminate safety hazards. Baker Inspection Group always recommends Qualified Contractors to perform all repair work recommended in the inspection report.

- Pool Notes:Refers to aside information and / or any comments elaborating on descriptions of systems of the pool in a more informational nature.

- Pool Due Diligence:Observations that may require further investigation about a systems condition prior to closing and / or if it exceeds our Standards of Practice for a pool inspection.

- Pool Repair:Repair items that require correction now or in the near future, or items that require immediate attention to prevent additional damage or eliminate safety hazards.

- Pool Improvement / Maintenance:These are repair items that should be considered "routine pool ownership" items.

Report Summary: The Report Summary is designed as an overview of all the observations noted during the inspection. This helpful overview is not a substitution for reading the entire inspection report. The entire report must be read to get a complete understanding of this inspection report.

California Home Inspector Compliance Statement: I represent that I am a full member in good standing of the International Association of Certified Home Inspectors (InterNACHI) Member #10052303.

CLICK HERE for a link to the California Business and Professions Code Section 7195-7199 which pertains to Home Inspectors.

Scot Baker, Certified Master Inspector®, Owner of Baker Inspection Group

Full Inspection Report

Pool and Spa Area

General Pool Photos

Safety Barrier System

Decking, Coping, Features and Area

Surface, Tiling and Components

Water Level

Water Quality

General Comments

Building Conditions and Limitations

Standards of Practice: InterNACHI (International Association of Home Inspectors)

Inspection Type: Pool Inspection Only

Pool Inspection: Yes

Attending the Inspection: Inspector Only

Temperature at Start of Inspection: 45-50 (F)

Temperature at End of Inspection: 50-55 (F)

Ground/Soil Surface Condition: Dry

Significant Precipitation in Prior Three Days: No

Baker Inspection Group prefers our clients to be present during the entire inspection and at the end to discuss the findings of the inspection. For a few reasons, including: (1) We can answer all of your questions and address your concerns as they come up. (2) Both of us can see the condition of the property at the time of the inspection. (3) I can elaborate on what may be complicated or technical. Being that you were not present during the entire inspection, we encourage you to read the whole inspection report and not just the summary portions and to consult us as needed. Call us anytime (209) 522-5320. Please verify anything that we may have said orally, but may not have documented in the report.

Pools are fun, but children and adults can lose their life quickly. Over 4000 lives annually are lost with one-third under the age of 14. A child can drown in the time it takes to answer a phone. A swimming pool is 14 times more likely than a motor vehicle to be involved in the death of a child age 4 and under. An estimated 5,000 children ages 14 and under are hospitalized due to near-drownings each year; 15% die in the hospital and as many as 20% suffer severe, permanent brain damage. Of all preschoolers who drown, 70% are in the care of one or both parents at the time of the drowning and 75% are missing from sight for five minutes or less. Drowning surpasses all other causes of death to children age 14 and under in Arizona, California, Florida, Hawaii, Montana, Nevada, Oregon, Utah and Washington. A pool alarm with a loud speaker system to sound outside as well as inside the home could save a life. Even if you do not have children you should be concerned. 35% of children that drowned did so in someone else's pool. For more info, please do an Internet search on pool safety.

Pool and Spa Area

General Pool Photos

Safety Barrier System

At Least Two of the Following Required: Fail

Pool Enclosure: Yes

Removable Mesh Fencing: No

Safety Pool Cover: No

Pool Surface Alarm: No

Exterior Door Exit Alarms: N/A

Exterior Door Self Closing and Latching: N/A

Window Alarms: No

Other Means of Protection: No

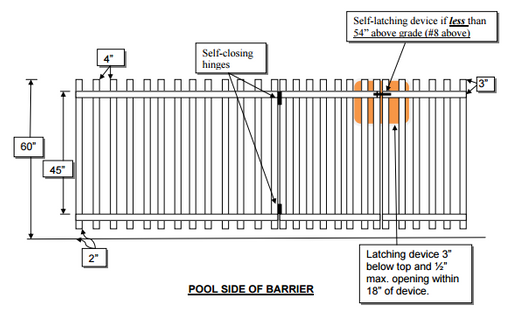

Beginning January 1st 2018, in accordance with SB 442, Newman. Public health: pools: drownings, Home Inspectors must report on the presence of seven pool safety features. Below is the wording of the new bill. In connection with the transfer, as defined in subdivision (e), of real property with a swimming pool or spa, an appropriate inspection shall include a noninvasive physical examination of the pool or spa and dwelling for the purpose of identifying which, if any, of the seven drowning prevention safety features listed in subdivision (a) of Section 115922 of the Health and Safety Code the pool or spa is equipped. SEC. 4. Section 115922 of the Health and Safety Code is amended to read: 115922. (a) Except as provided in Section 115925, when a building permit is issued for the construction of a new swimming pool or spa or the remodeling of an existing swimming pool or spa at a private single-family home, the respective swimming pool or spa shall be equipped with at least two of the following seven drowning prevention safety features: (1) An enclosure that meets the requirements of Section 115923 and isolates the swimming pool or spa from the private single-family home. (2) Removable mesh fencing that meets American Society for Testing and Materials (ASTM) Specifications F2286 standards in conjunction with a gate that is self-closing and self-latching and can accommodate a key lockable device. (3) An approved safety pool cover, as defined in subdivision (d) of Section 115921. (4) Exit alarms on the private single-family home’s doors that provide direct access to the swimming pool or spa. The exit alarm may cause either an alarm noise or a verbal warning, such as a repeating notification that “the door to the pool is open.” (5) A self-closing, self-latching device with a release mechanism placed no lower than 54-inches above the floor on the private single-family home’s doors providing direct access to the swimming pool or spa. (6) An alarm that, when placed in a swimming pool or spa, will sound upon detection of accidental or unauthorized entrance into the water. The alarm shall meet and be independently certified to the ASTM Standard F2208 “Standard Safety Specification for Residential Pool Alarms,” which includes surface motion, pressure, sonar, laser, and infrared type alarms. A swimming protection alarm feature designed for individual use, including an alarm attached to a child that sounds when the child exceeds a certain distance or becomes submerged in water, is not a qualifying drowning prevention safety feature. (7) Other means of protection, if the degree of protection afforded is equal to or greater than that afforded by any of the features set forth above and has been independently verified by an approved testing laboratory as meeting standards for those features established by the ASTM or the American Society of Mechanical Engineers (ASME). Section 115923. An enclosure shall have all of the following characteristics: (a) Any access gates through the enclosure open away from the swimming pool, and are self-closing with a self-latching device placed no lower than 60-inches above the ground. (b) A minimum height of 60-inches. (c) A maximum vertical clearance from the ground to the bottom of the enclosure of two-inches. (d) Gaps or voids, if any, do not allow passage of a sphere equal to or greater than four-inches in diameter. (e) An outside surface free of protrusions, cavities, or other physical characteristics that would serve as handholds or footholds that could enable a child below the age of five years to climb over.

The home had windows that when opened, had direct access to the pool. There were no safety alarms installed at the windows.

305.4 Structure Wall as a Barrier Where a wall of a dwelling or structure serves as part of the barrier and where doors or windows provide direct access to the pool or spa through that wall, one of the following shall be required: 1. Operable windows having a sill height of less than 48-inches above the indoor finished floor and doors shall have an alarm that produces an audible warning when the window, door or their screens are opened. The alarm shall be listed and labeled as a water hazard entrance alarm in accordance with UL 2017. In dwellings or structures not required to be Accessible units, Type A units or Type B units, the operable parts of the alarm deactivation switches shall be located 54-inches or more above the finished floor. In dwellings or structures required to be Accessible units, Type A units or Type B units, the operable parts of the alarm deactivation switches shall be located not greater than 54-inches and not less than 48-inches above the finished floor. Recommend that alarms compliant with modern safety standards, be installed for safety reasons.

Decking, Coping, Features and Area

Deck Material: Concrete

Surface, Tiling and Components

Vessel Type: Marcite

The pool surface was Marcite. Marcite is the most affordable option for a new pool or replastering an existing one. With properly maintained pool water, it will last 8 to 12 years. However, in regions with particularly “hard water” (water with high alkalinity and calcium), the pool water wreaks havoc on Marcite’s endurance. Although Marcite starts out as white, the wet mix can be dyed in a small range of blues and greys to create a dark-bottom pool, which is popular for lagoon-style designs. Because Marcite constantly reacts to chemicals, minerals, and the pH/alkalinity in pool water, this kind of finish is more susceptible to problems if your water chemistry is not properly and consistently balanced. Consequences can include staining, etching, mottling, erosion, and discoloration. It’s hard to overstate just how pivotal the role that water quality plays in extending—or shortening—the life of a Marcite finish. Because of its increased vulnerability to visual blemishes and its requirements for stringent water quality, Marcite deteriorates faster. Bottom line, it’s the pool finish that will get the job done—but do so with the least durability and the shortest lifespan.

The pool surface had visible wear at the time of the inspection.

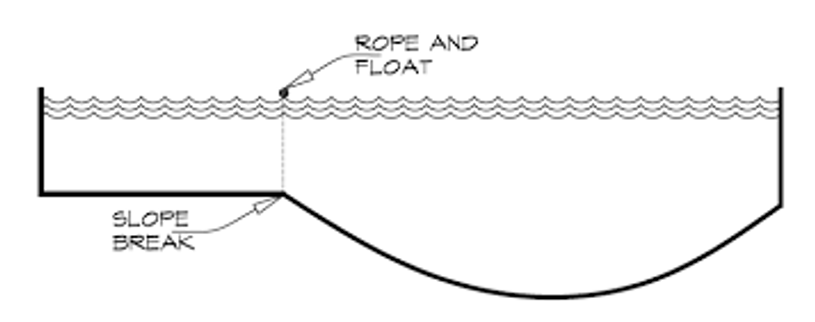

The swimming pool was missing the rope and float assembly installed at the floor slope change. These are installed to provide a visual indicator of where the pool transitions from the shallow to the deep end. Recommend the installation of a proper rope and float assembly as needed. 811.1 Rope and Float In pools where the point of first slope break occurs, a rope and float assembly shall be installed across the width of the pool.

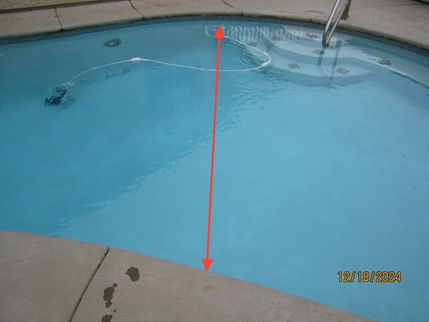

Water Level

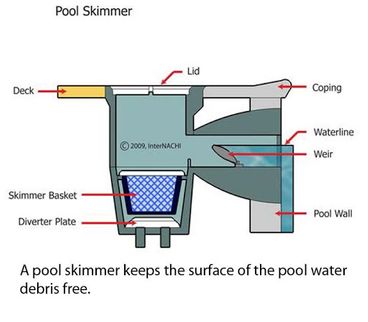

The pool appeared to be overfilled at the time of the inspection. For a pool skimmer and filter pump system to work effectively, the water level must be at about the half-way point on the skimmer. This allows for the most efficient flow of water through the filter system. If the water level is overflowing the skimmer, you will have to remove some of the excess water in order to restore the filter system to proper function.

Water Quality

The Inspector recommends that you have water in the pool tested to ensure that it lies within acceptable parameters.

Pool Mechanicals

Plumbing at Pool (Jets, Skimmer, Drains, etc.)

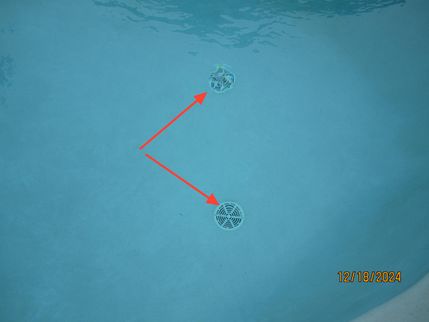

You should ask to see documentation that the pool drains are compliant with the Pool & Safety Act. Commencing January 1, 2007, a new law went into effect regarding the safety and security of swimming pools and spas located on private single-family residences. To eliminate safety hazards on new and existing swimming pools and spas, an approved anti entrapment cover be installed on all pool and spa drains any time a building permit is issued for the construction of a new swimming pool or spa or the remodel or modification of an existing swimming pool, toddler pool, or spa. Recommend further evaluation as needed.

Plumbing System

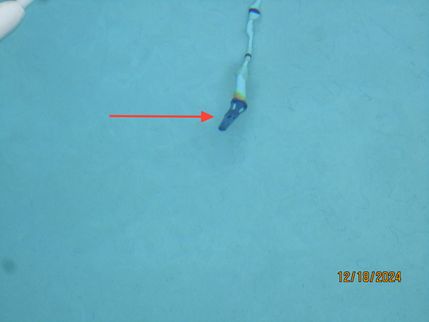

The pool system plumbing was leaking at the the electronic control valve. Recommend further evaluation and repairs as needed.

White plastic PVC pipes were exposed to direct sunlight. This type material is deteriorated by the ultra-violet (UV) radiation in sunlight, and this condition will result in premature failure of pipes compared to similar pipes designed to withstand exposure to UV. Such pipes should be painted over to protect them or replaced as needed.

Pump System

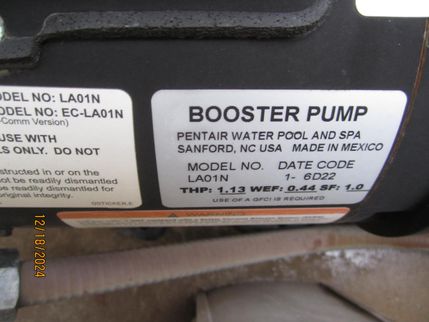

Pool Pump Type: Filter Pump, Sweep Pump, Two Pumps

Manufacturer: Sta-Rite, Pentair

At the time of the inspection, the Inspector observed the condition and operation of the swimming filter pump.

At the time of the inspection, the Inspector observed the condition and operation of the swimming pool sweep pump.

This shows the data plates for the filter pump and sweep pump.

Filtration and Cleaning Systems

Filter Type: Cartridge Filter, Sweep Present

The pool sweep was functional at the time of the inspection.

Heating System

Heating System: Solar

The solar heating controller or the electronic valve were not functional at the time of the inspection. Recommend further evaluation and repairs as needed.

Automatic Sanitation and Chemical Storage

Type: None Installed

Pool Electrical

Electrical Panel, Wiring, GFCI and Bonding

Pool Electrical Panel Disconnect Type: Breaker

Pool Electrical Panel Disconnect Ampacity: 30 Amps

Pool Electrical System (GFCI) Protection: Missing - Pool

Pool Electrical Panel Type: Main Lug (no main disconnect)

Pool Electrical Panel Ampacity: 100 Amps

Pool Electrical Panel Manufacturer: Intermatic, Pool Panel

Pool Overcurrent Protection Device: Breakers

Most metal components located within 5-feet of the pool water were bonded to the pool equipment as they should be.

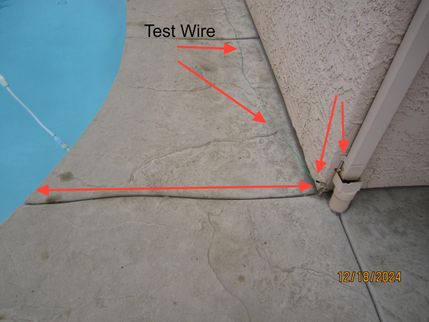

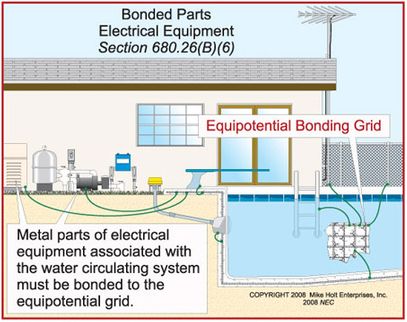

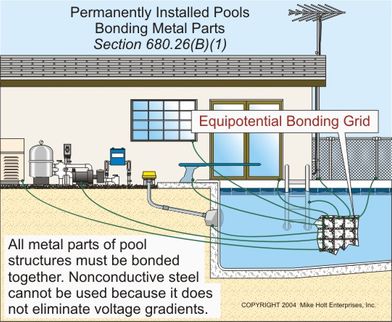

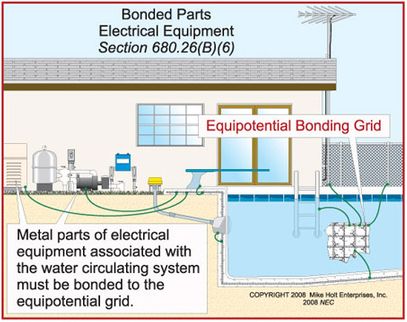

Although metal components were located within 5-feet of the pool water, they did not appear to be bonded (requires verification) to the pool equipment as they should be. This condition is a potential shock or electrocution hazard and should be corrected. 680.26 Equipotential Bonding (A) Performance. The equipotential bonding required by this section shall be installed to reduce voltage gradients in the pool area. (B) Bonded Parts. The parts specified in 680.26(B)(1) through (B)(7) shall be bonded together using solid copper conductors, insulated covered, or bare, not smaller than 8 AWG or with rigid metal conduit of brass or other identified corrosion-resistant metal. Connections to bonded parts shall be made in accordance with 250.8. An 8 AWG or larger solid copper bonding conductor provided to reduce voltage gradients in the pool area shall not be required to be extended or attached to remote panelboards, service equipment, or electrodes. (7) Fixed Metal Parts All fixed metal parts shall be bonded including, but not limited to, metal-sheathed cables and raceways, metal piping, metal awnings, metal fences, and metal door and window frames. Exception No 1: Those separated from the pool by a permanent barrier that prevents contact by a person shall not be required to be bonded. Exception No 2: Those greater than 5-feet horizontally from the inside walls of the pool shall not be required to be bonded. Exception No 3: Those greater than 12-feet measured vertically above the maximum water level of the pool, or as measured vertically above any observation stands, towers, or platforms, or any diving structures, shall not be required to be bonded.

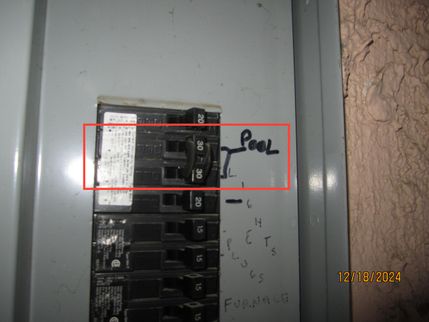

There was no ground fault circuit interrupter (GFCI) protection for the pool at the time of inspection. This can be achieved relatively inexpensively by replacing the breaker currently protecting the electrical circuit that contains the circuits of concern with a GFCI breaker. Recommend repairs as needed.

Pool components were lacking a bonding system. This condition is a potential hazard and should be corrected. 680.26 Equipotential Bonding (A) Performance. The equipotential bonding required by this section shall be installed to reduce voltage gradients in the pool area. (B) Bonded Parts. The parts specified in 680.26(B)(1) through (B)(7) shall be bonded together using solid copper conductors, insulated covered, or bare, not smaller than 8 AWG or with rigid metal conduit of brass or other identified corrosion-resistant metal. Connections to bonded parts shall be made in accordance with 250.8. An 8 AWG or larger solid copper bonding conductor provided to reduce voltage gradients in the pool area shall not be required to be extended or attached to remote panelboards, service equipment, or electrodes.

Pool Lighting

Pool Light: Functional

Safe Home Book

Safe Home Book

Baker Inspection Group is proud to include our SAFE HOME BOOK as part of your home inspection report. This publication is a compilation of well-researched articles especially for homeowners. They include valuable information and tips for helping keep families safe and their homes in top condition. Please enjoy it with our compliments.

©2013 International Association of Certified Home Inspectors & Master Inspector Certification Board.

THE SAFE HOME BOOK contains chapters on the following:

CHILD SAFETY Twelve safety devices to protect your children, crib safety, furniture and TV tip-over hazards, anti-tip brackets, window falls, safety glass, child-proofing windows and stairs, Garage doors and openers, trampoline safety, tree swings, treehouses.

LADDERS AND STAIRWAYS Ladder safety, Attic pull-down ladders, stairways, deck safety.

SWIMMING POOL SAFETY Home pools, swimming pool barriers, pool alarms, pool drain hazards, pool water pathogens, saunas.

HOME SECURITY Burglar-resistant homes, bump keys, the 10 best places to hide valuables in your home, window bars, Safe Rooms (panic rooms).

FIRE SAFETY Dryer vent safety, pilot lights, hearths and hearth extensions, holiday safety, firestops, clothes closet lighting, barbecue safety, kerosene heaters, attached Garage fire containment, non-conforming Bedrooms, window wells, fire extinguishers, smoke alarms, fire sprinklers, house numbers.

ELECTRICAL SAFETY Aluminum wiring, knob-and-tube wiring, ungrounded electrical receptacles, ground-fault circuit interrupters (GFCI), arc-fault circuit interrupters (AFCI), electric fences, generators.

ENVIRONMENTAL CONCERNS Asbestos, Asbestos cement siding, lead facts, formaldehyde, carbon monoxide, backdrafting, fireplace fuel, ventless fireplaces, mold, central humidifiers, Bathroom ventilation, sewer gases, pesticides, pet allergens, greywater, backflow prevention, carpeted Bathrooms, Chinese drywall, home heating oil tanks, underground fuel storage tanks, compost pile hazards, Hantavirus, plants and Indoor Air Quality.

MOTHER NATURE Earthquake preparedness, tornado inspections, wind mitigation, windbreaks, tree dangers, lightning, poison ivy, oak and sumac, rodents, bed bugs, venomous pests, snow guards, defensible space, emergency preparedness.

ELDERLY SAFETY Aging in place, aging in place checklist, anti-scald valves.

CLICK HERE to view

Checking Out Procedure

Check Out List

Lights: Client and Realtor Still in House

Heating and Cooling: Restored to Pre-Inspection Settings

Oven: Off

Appliances: Off / Finishing Cycle

CA PUBLIC RESOURCES CODE 25401.7 At the time a single-family residential dwelling is sold, a buyer or seller may request a home inspection, as defined in subdivision (a) of Section 7195 of the Business and Professions Code, and a Home Inspector, as defined in subdivision (d) of Section 7195 of the Business and Professions Code, shall provide, contact information for one or more of the following entities that provide home energy information: (a) A nonprofit organization. (b) A provider to the residential dwelling of electrical service, or gas service, or both. (c) A government agency, including, but not limited to, the commission.

UTILITY BILL, REBATES AND OTHER ASSISTANCE Online Consumer and Business Conservation Rebate Database: http://www.energy.ca.gov. California Department of Consumer Affairs: www.dca.ca.gov/energy-challenge.htm. California Energy Commission, for information on utility bill assistance programs: 800-772-3300 or http://www.energy.ca.gov/. California Public Utilities Commission Consumer Affairs Branch, for information on baseline and other optional rates and bill assistance programs: 800-649-7570 or www.cpuc.ca.gov. California Energy Alternative Rates (CARE): Call your local utility company for information and applications.

PRODUCT RECALLS Baker Inspection Group has included pictures of the appliance data plates for your informational needs. Links are provided below to enter the information to determine if any recalls have been issued for the appliances in the house.

United States Consumer Safety Product Commission Website CLICK HERE.

WeMakeItSafer Website CLICK HERE.

CONCLUSION We are proud of our service and trust you will be happy with the quality of your report. We have made every effort to provide you with an accurate assessment of the condition of the property and its components and to alert you to any significant defects or adverse conditions. However, we may not have tested every outlet, opened every window and door or identified every problem. Also because our inspection is essentially visual, latent defects could exist. We cannot see behind walls. Therefore, you should not regard our inspection as a guarantee or warranty. It is simply a report on the general condition of a property at a given point in time. As a homeowner, you should expect problems to occur. Roofs will leak, Crawlspaces may have water problems and systems may fail without warning. We cannot predict future events. For those reasons, you should keep a comprehensive insurance policy current. This report was written exclusively for our Client. It is not transferable to other people. The report is only supplemental to a Seller’s disclosure. Thank you for taking the time to read this report and call us if you have any questions.

PRE-CLOSING WALK-THROUGH The walk-through prior to closing is the time for Client to inspect the property. Conditions can change between the time of a home inspection and the time of closing. Restrictions that existed during the inspection may have been removed for the walk-through. Defects or problems that were not found during the home inspection may be discovered during the walk-through. Client should be thorough during the walk-through. Any defect of problem discovered the walk-through should be negotiated with the Owner/Seller of the property prior to closing. Purchasing the property with a known defect or problem releases BAKER INSPECTION GROUP of all responsibility. Client assumes responsibility for all known defects after settlement. The following are recommendations for the pre-closing walk-through your new house.

1. Check the heating and cooling system. Turn the thermostat to heat mode and turn the temperature setting up. Confirm that the heating system is running and making heat. Turn the thermostat to off and wait 20 minutes. Turn the thermostat to cool mode and turn the temperature setting down. Confirm the condenser is spinning and the system is making cool air. The cooling system should not be checked if the temperature is below 65 degrees. You should not operate a heat pump in the heating mode when it is over 66 degrees outside. 2. Operate all appliances. 3. Run water at all fixtures and flush all toilets. 4. Operate all exterior doors, windows and locks. 5. Test smoke and carbon monoxide detectors. 6. Ask for all remote controls to any Garage door openers, fans, gas fireplaces, etc. 7. Inspect areas that may have been restricted at the time of the inspection. 8. Ask Seller questions about anything that was not covered during the home inspection. 9. Ask Seller about prior infestation treatment and warranties that may be transferable. 10. Read Seller’s disclosure.

We recommend that you re-key all of the properties exterior door dead bolts and locks and purchase multiple hand held fire extinguishers and place them in the Kitchen and Garage accordingly.

We are always attempting to improve quality of our service and our report. Online reviews are very much appreciated and go a long way to help a small business like ours. If you could please take a moment and click a link below to give us a quick review or Facebook Like we would really be thankful.

Google Business Page YELP Zillow Facebook

We are a very social company, please come by and visit us online and give us a like or a follow.

Inspection Report Summary

Major Concerns

No Major Concerns were noted.Pool Due Diligences

- PM-1 Pool Mechanicals - Plumbing at Pool (Jets, Skimmer, Drains, etc.):

You should ask to see documentation that the pool drains are compliant with the Pool & Safety Act. Commencing January 1, 2007, a new law went into effect regarding the safety and security of swimming pools and spas located on private single-family residences. To eliminate safety hazards on new and existing swimming pools and spas, an approved anti entrapment cover be installed on all pool and spa drains any time a building permit is issued for the construction of a new swimming pool or spa or the remodel or modification of an existing swimming pool, toddler pool, or spa. Recommend further evaluation as needed.

- PE-2 Pool Electrical - Electrical Panel, Wiring, GFCI and Bonding:

Although metal components were located within 5-feet of the pool water, they did not appear to be bonded (requires verification) to the pool equipment as they should be. This condition is a potential shock or electrocution hazard and should be corrected. 680.26 Equipotential Bonding (A) Performance. The equipotential bonding required by this section shall be installed to reduce voltage gradients in the pool area. (B) Bonded Parts. The parts specified in 680.26(B)(1) through (B)(7) shall be bonded together using solid copper conductors, insulated covered, or bare, not smaller than 8 AWG or with rigid metal conduit of brass or other identified corrosion-resistant metal. Connections to bonded parts shall be made in accordance with 250.8. An 8 AWG or larger solid copper bonding conductor provided to reduce voltage gradients in the pool area shall not be required to be extended or attached to remote panelboards, service equipment, or electrodes. (7) Fixed Metal Parts All fixed metal parts shall be bonded including, but not limited to, metal-sheathed cables and raceways, metal piping, metal awnings, metal fences, and metal door and window frames. Exception No 1: Those separated from the pool by a permanent barrier that prevents contact by a person shall not be required to be bonded. Exception No 2: Those greater than 5-feet horizontally from the inside walls of the pool shall not be required to be bonded. Exception No 3: Those greater than 12-feet measured vertically above the maximum water level of the pool, or as measured vertically above any observation stands, towers, or platforms, or any diving structures, shall not be required to be bonded.

Pool Repair Items

- PSA-2 Pool and Spa Area - Safety Barrier System:

Beginning January 1st 2018, in accordance with SB 442, Newman. Public health: pools: drownings, Home Inspectors must report on the presence of seven pool safety features. Below is the wording of the new bill. In connection with the transfer, as defined in subdivision (e), of real property with a swimming pool or spa, an appropriate inspection shall include a noninvasive physical examination of the pool or spa and dwelling for the purpose of identifying which, if any, of the seven drowning prevention safety features listed in subdivision (a) of Section 115922 of the Health and Safety Code the pool or spa is equipped. SEC. 4. Section 115922 of the Health and Safety Code is amended to read: 115922. (a) Except as provided in Section 115925, when a building permit is issued for the construction of a new swimming pool or spa or the remodeling of an existing swimming pool or spa at a private single-family home, the respective swimming pool or spa shall be equipped with at least two of the following seven drowning prevention safety features: (1) An enclosure that meets the requirements of Section 115923 and isolates the swimming pool or spa from the private single-family home. (2) Removable mesh fencing that meets American Society for Testing and Materials (ASTM) Specifications F2286 standards in conjunction with a gate that is self-closing and self-latching and can accommodate a key lockable device. (3) An approved safety pool cover, as defined in subdivision (d) of Section 115921. (4) Exit alarms on the private single-family home’s doors that provide direct access to the swimming pool or spa. The exit alarm may cause either an alarm noise or a verbal warning, such as a repeating notification that “the door to the pool is open.” (5) A self-closing, self-latching device with a release mechanism placed no lower than 54-inches above the floor on the private single-family home’s doors providing direct access to the swimming pool or spa. (6) An alarm that, when placed in a swimming pool or spa, will sound upon detection of accidental or unauthorized entrance into the water. The alarm shall meet and be independently certified to the ASTM Standard F2208 “Standard Safety Specification for Residential Pool Alarms,” which includes surface motion, pressure, sonar, laser, and infrared type alarms. A swimming protection alarm feature designed for individual use, including an alarm attached to a child that sounds when the child exceeds a certain distance or becomes submerged in water, is not a qualifying drowning prevention safety feature. (7) Other means of protection, if the degree of protection afforded is equal to or greater than that afforded by any of the features set forth above and has been independently verified by an approved testing laboratory as meeting standards for those features established by the ASTM or the American Society of Mechanical Engineers (ASME). Section 115923. An enclosure shall have all of the following characteristics: (a) Any access gates through the enclosure open away from the swimming pool, and are self-closing with a self-latching device placed no lower than 60-inches above the ground. (b) A minimum height of 60-inches. (c) A maximum vertical clearance from the ground to the bottom of the enclosure of two-inches. (d) Gaps or voids, if any, do not allow passage of a sphere equal to or greater than four-inches in diameter. (e) An outside surface free of protrusions, cavities, or other physical characteristics that would serve as handholds or footholds that could enable a child below the age of five years to climb over.

- PSA-3 Pool and Spa Area - Safety Barrier System:

The home had windows that when opened, had direct access to the pool. There were no safety alarms installed at the windows.

305.4 Structure Wall as a Barrier Where a wall of a dwelling or structure serves as part of the barrier and where doors or windows provide direct access to the pool or spa through that wall, one of the following shall be required: 1. Operable windows having a sill height of less than 48-inches above the indoor finished floor and doors shall have an alarm that produces an audible warning when the window, door or their screens are opened. The alarm shall be listed and labeled as a water hazard entrance alarm in accordance with UL 2017. In dwellings or structures not required to be Accessible units, Type A units or Type B units, the operable parts of the alarm deactivation switches shall be located 54-inches or more above the finished floor. In dwellings or structures required to be Accessible units, Type A units or Type B units, the operable parts of the alarm deactivation switches shall be located not greater than 54-inches and not less than 48-inches above the finished floor. Recommend that alarms compliant with modern safety standards, be installed for safety reasons.

- PSA-4 Pool and Spa Area - Decking, Coping, Features and Area:

The pool decking was heaved in areas. This condition is a trip hazard. Recommend repairs as needed.

- PM-2 Pool Mechanicals - Plumbing at Pool (Jets, Skimmer, Drains, etc.):

The pool system automatic fill system was inoperable (no water at the anti-siphon) at the time of the inspection. Recommend further evaluation and repairs as needed.

- PM-3 Pool Mechanicals - Plumbing System:

An anti-siphon device was visible, there was no water present at the anti-siphon. Recommend further evaluation and repairs as needed.

- PM-4 Pool Mechanicals - Plumbing System:

The pool system plumbing was leaking at the the electronic control valve. Recommend further evaluation and repairs as needed.

- PM-5 Pool Mechanicals - Plumbing System:

An electronic control valve was not functional at the time of the inspection. Recommend further evaluation and repairs as needed.

- PM-8 Pool Mechanicals - Pump System:

The filter pump had corrosion visible. Recommend further evaluation and repairs as needed.

- PM-9 Pool Mechanicals - Pump System:

The pool filter pump had an amperage draw (7.9 and 8.0) that exceeded the maximum amperage draw (6.9) stated on the data plate. This indicates that the pump is showing wear and may need replacement in the future. Recommend further evaluation and repairs as needed.

- PM-10 Pool Mechanicals - Filtration and Cleaning Systems:

The pool filter was leaking. Recommend repairs as needed.

- PM-12 Pool Mechanicals - Heating System:

The solar heating controller or the electronic valve were not functional at the time of the inspection. Recommend further evaluation and repairs as needed.

- PE-1 Pool Electrical - Electrical Panel, Wiring, GFCI and Bonding:

There was no ground fault circuit interrupter (GFCI) protection for the pool at the time of inspection. This can be achieved relatively inexpensively by replacing the breaker currently protecting the electrical circuit that contains the circuits of concern with a GFCI breaker. Recommend repairs as needed.

- PE-3 Pool Electrical - Electrical Panel, Wiring, GFCI and Bonding:

Pool components were lacking a bonding system. This condition is a potential hazard and should be corrected. 680.26 Equipotential Bonding (A) Performance. The equipotential bonding required by this section shall be installed to reduce voltage gradients in the pool area. (B) Bonded Parts. The parts specified in 680.26(B)(1) through (B)(7) shall be bonded together using solid copper conductors, insulated covered, or bare, not smaller than 8 AWG or with rigid metal conduit of brass or other identified corrosion-resistant metal. Connections to bonded parts shall be made in accordance with 250.8. An 8 AWG or larger solid copper bonding conductor provided to reduce voltage gradients in the pool area shall not be required to be extended or attached to remote panelboards, service equipment, or electrodes.

Pool Improvement / Maintenance

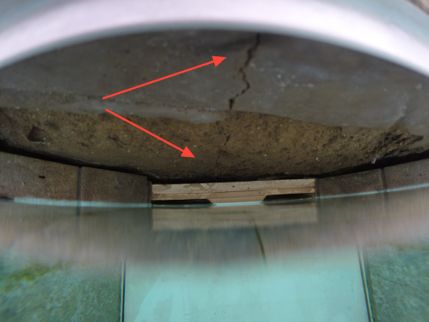

- PSA-5 Pool and Spa Area - Decking, Coping, Features and Area:

The pool had cracked decking at the skimmer opening. Recommend further evaluation and repairs as needed.

- PSA-6 Pool and Spa Area - Surface, Tiling and Components:

The pool surface had visible wear at the time of the inspection.

- PSA-7 Pool and Spa Area - Surface, Tiling and Components:

The swimming pool was missing the rope and float assembly installed at the floor slope change. These are installed to provide a visual indicator of where the pool transitions from the shallow to the deep end. Recommend the installation of a proper rope and float assembly as needed. 811.1 Rope and Float In pools where the point of first slope break occurs, a rope and float assembly shall be installed across the width of the pool.

- PSA-8 Pool and Spa Area - Water Level:

The pool appeared to be overfilled at the time of the inspection. For a pool skimmer and filter pump system to work effectively, the water level must be at about the half-way point on the skimmer. This allows for the most efficient flow of water through the filter system. If the water level is overflowing the skimmer, you will have to remove some of the excess water in order to restore the filter system to proper function.

- PSA-9 Pool and Spa Area - Water Quality:

The Inspector recommends that you have water in the pool tested to ensure that it lies within acceptable parameters.

- PM-6 Pool Mechanicals - Plumbing System:

White plastic PVC pipes were exposed to direct sunlight. This type material is deteriorated by the ultra-violet (UV) radiation in sunlight, and this condition will result in premature failure of pipes compared to similar pipes designed to withstand exposure to UV. Such pipes should be painted over to protect them or replaced as needed.