Introduction, Scope, Definitions & Compliance Statement

Introduction: The following numbered and attached pages are your property inspection report. The report includes video, pictures, information and recommendations. This inspection was performed in accordance with the current Standards of Practice and Code of Ethics (Spanish Estándares de la Práctica and Código de ética) of InterNACHI (International Association of Certified Home Inspectors) and the Code of Ethics of the CMI (Certified Master Inspectors®). The Standards contain certain and very important limitations, expectations and exclusions to the inspection. A copy is available prior to, during and after the inspection and it is part of the report.

What Really Matters in a Home Inspection: The process can be stressful. A property inspection is supposed to give you reassurance but often has the opposite effect. You will be asked to absorb a lot of information in a short time. This often includes a written report, checklist, photographs, environmental reports and what the Inspector himself says during the inspection. All this combined with the Seller's disclosure and what you notice yourself makes the experience even more overwhelming. What should you do? Relax. Most of your inspection will be maintenance recommendations, life expectancies and minor imperfections. These are nice to know about. However, the issues that really matter will fall into four categories: 1. Major defects. An example of this would be a significant structural failure. 2. Things that may lead to major defects. A small water leak coming from a piece of roof flashing, for example. 3. Things that may hinder your ability to finance, legally occupy or insure the property. Structural damage caused by WDO infestation, for example. 4. Safety hazards. Such as a lack of AFCI/GFCI outlet protection. Anything in these categories should be corrected. Often a serious problem can be corrected inexpensively to protect both life and property (especially in categories 2 and 4). Most Sellers are honest and are often surprised to learn of defects uncovered during an inspection. Realize that Sellers are under no obligation to repair everything mentioned in the report. No home is perfect.

Use of Photos and Video: Your report includes many photographs which help to clarify where the Inspector went, what was looked at, and the condition of a system or component at the time of the inspection. Some of the pictures may be of deficiencies or problem areas, these are to help you better understand what is documented in this report and may allow you see areas or items that you normally would not see. A pictured issue does not necessarily mean that the issue was limited to that area only but may be a representation of a condition that is in multiple places. Not all areas of deficiencies or conditions will be supported with photos.

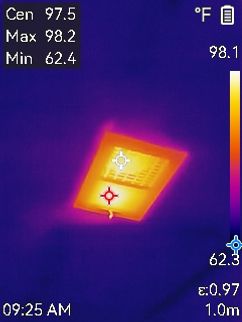

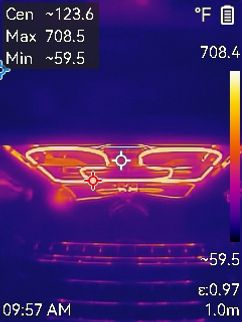

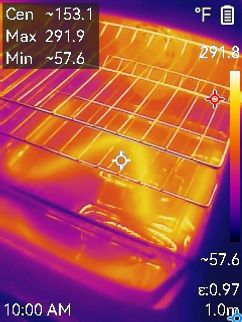

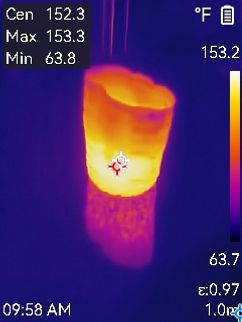

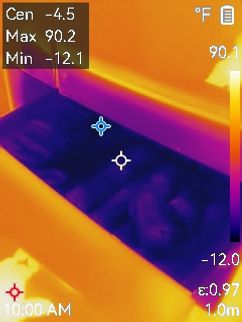

Thermal Imaging: An infrared camera may be used for specific areas or visual problems and should not be viewed as a full thermal scan of the entire home. Temperature readings displayed on thermal images in this report are included as a courtesy and should not be wholly relied upon as a home inspection is qualitative, not quantitative. These values can vary +/- 4% or more of displayed readings, and these values will display surface temperatures when air temperature readings would actually need to be conducted on some items which is beyond the scope of a property inspection.

Scope: A property inspection is intended to assist in evaluating the overall condition of the dwelling. The inspection is based on observation of the visible, readily accessible, and apparent condition of the structure and its components on this day. The results of this inspection are not intended to make any representation regarding the presence or absence of concealed defects that are not reasonably ascertainable or readily accessible in a competently performed inspection.

No Warranty, Guarantee or Insurance by Baker Inspection Group is expressed or implied. This report does not include inspection for Wood Destroying Organisms, Asbestos, Mold or Lead. A representative sampling of the building components is viewed in areas that are accessible at the time of the inspection. No destructive testing or dismantling of components is performed. Not all defects will be identified during this inspection. Unexpected repairs should be anticipated. The person conducting your inspection is not a Structural Engineer or other professional whose license authorizes the rendering of an opinion as to the structural integrity of a building or its other component parts.

This report has been produced in accordance with the AGREEMENT and is subject to the terms and conditions agreed upon therein. The report was produced exclusively for our CLIENT. Not to be used or interpreted by anyone other than our CLIENT or REPRESENTATIVE. If you’re reading this report but did not hire us, Baker Inspection Group, to perform the original inspection, please note that it is likely that conditions related to the home have probably changed, even if the report is fairly recent. Just as you cannot rely on an outdated weather report, you should not rely on an outdated inspection report. Minor problems noted may have become worse, recent events may have created new issues and items may even have been corrected and improved. Don’t rely on old information about one of the biggest purchases you’ll ever make. Remember that the cost of a property inspection is insignificant compared to the value of the property. Protect your family and your investment, and please call us directly at (209) 522-5320 to discuss the report you’re reading for this property so that we can arrange for a re-inspection. Thank You!

Getting the Information to You

This report is designed to deliver important and technical information in a way that is easy for anyone to access and understand. If you are in a hurry, you can take a quick look at our "Summary Page” and quickly get critical information for important decision making. However, we strongly recommend that you take the time to read the full Report, which includes digital photographs, captions, diagrams, descriptions, videos and hot links to additional information.

The best way to get the layers of information that are presented in this report is to read your report online (the HTML version), which will allow you to expand your learning about your house. You will notice some words or series of words highlighted in blue and underlined – clicking on these will provide you with a link to additional information. The HTML version of this report also contains streaming videos. Short video clips often contain important information and critical context and sounds that can be difficult to capture in words and still pictures.

For the most reliable viewing experience, I recommend viewing the report on as large a screen as practical, as much detail can be lost on small devices like smart phones. For similar reasons, reports should only be printed in color to retain as much detail as possible and minimize misinterpretation of photographs.

This report can also be printed on paper or to a PDF document.

Chapters and Sections: This report is divided into chapters that parcel the home into logical inspection components. Each chapter is broken into sections that relate to a specific system or component of the home. You can navigate between chapters with the click of a button on the left side margin.

Most sections will contain some descriptive information done in black font. Observation narrative, done in colored boxes, will be included if a system or component is found to be significantly deficient in some way or if we wish to provide helpful additional information about the system or the scope of our inspection. If a system or component of the home was deemed to be in satisfactory or serviceable condition, there may be no narrative observation comments in that section and it may simply say “tested,” or “inspected.”

Observation Labels: All narrative observations are colored, numbered and labeled to help you find, refer to, and understand the severity of the observation. Observation colors and labels used in this report are:

- Description:Detailed description of various aspects of the property noted during the inspection.

- Note:Refers to aside information and / or any comments elaborating on descriptions of systems in the home of a more informational nature.

- Major Concern:Repair items that may cost significant money to correct now or in the near future, or items that require immediate attention to prevent additional damage or eliminate safety hazards. Baker Inspection Group always recommends Qualified Contractors to perform all repair work recommended in the inspection report.

- Due Diligence:Observations that may require further investigation about a systems condition prior to closing and / or if it exceeds our Standards of Practice for a home inspection.

- Repair/Replace:Repair and maintenance items noted during the inspection that should be addressed in the immediate future or the item has already failed. Typically they are concerns that may be expensive to correct or will become expensive corrections if nothing is done. Baker Inspection Group always recommends Qualified Contractors to perform all repair work recommended in the inspection report.

- Improvement:Observations that are not necessarily defects, but which could be improved for safety, efficiency, or reliability reasons.

- Recommended Maintenance:These are repair items that should be considered "routine home ownership items," such as servicing the furnace, cleaning the gutters or changing the air filters in the furnace.

- Energy Efficiency & IAQ:Denotes observations that are needed to make the home more energy efficient as well as to bring the home up to modern insulation standards. This category typically includes windows and insulation. Other items, such as lighting and appliances, are not inspected for their energy status. It also covers issues related to Indoor Air Quality which is often related to efficiency.

Report Summary: The Report Summary is designed as a bulleted overview of all the observations noted during the inspection. This helpful overview is not a substitution for reading the entire inspection report. The entire report must be read to get a complete understanding of this inspection report as the Report Summary does not include photographs or photo captions.

California Home Inspector Compliance Statement: I represent that I am a full member in good standing of the International Association of Certified Home Inspectors (InterNACHI) Member #10052303.

CLICK HERE for a link to the California Business and Professions Code Section 7195-7199 which pertains to Home Inspectors.

Scot Baker, Certified Master Inspector®, Owner of Baker Inspection Group

Report Summary

Major Concerns

No Major Concerns were noted.Due Diligence Items

- SEF-1 Site and Exterior Features:

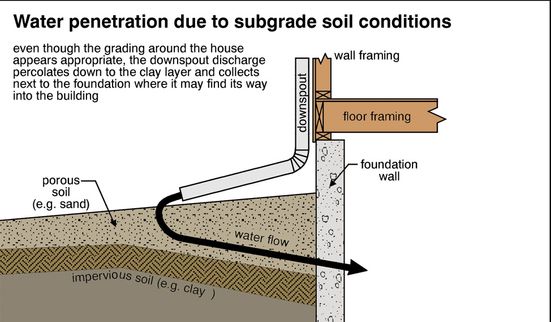

The home was situated on a generally flat lot. This could lead to seasonal drainage problems. Recommend disclosing any history of water problems on the site.

- RC-5 Roofing and Components:

The asphalt composition roof shingles have been repaired at the rooftop HVAC unit flashing. We were unable to determine if these repairs will prevent damage to the underlying roof structure from moisture intrusion. Recommend further evaluation and repairs as needed.

- AC-5 Attic and Components:

Thermostatically controlled vent fan in the Attic may work, but due to the low temperature the unit would not come on at its lowest setting. Baker Inspection Group did not inspect this unit.

- PS1-5 Plumbing System:

No main water shut off was found (possibly in the Garage) at the house. There was a shut off at the meter in the street, but this can be a time-consuming and difficult shut-off to access in an emergency. Disclose the location of the main water shut for future owners as it may be concealed behind finishes or stored items. If no readily accessible shut off exists, recommend further evaluation.

- PS1-12 Plumbing System:

Please note that when the sewage discharge type is listed here, it is listed based on public records and disclosure. It is always possible that the system is not as it is listed; for example, a property could be listed as a public sewer system when in fact it is on a private septic system. This is another reason why we recommend further evaluation of this system; the type of sewer discharge cannot be verified as part of a visual inspection of the property.

- PS1-13 Plumbing System:

A video camera sewer scope is recommended. An evaluation of the sewer line below the ground is beyond the scope of this inspection. A sewer scope is always recommended to further evaluate the sewer line and the below ground connections between the house and the municipal sewer line or septic tank. Sewer scopes are done using video cameras and can reveal the materials, condition and reliability of the sewer line.

- AP-1 Additional Plumbing:

An exterior irrigation system was noted. Sprinkler systems are beyond the scope of this inspection. Irrigation systems require annual attention / repair / servicing after every winter. When testing the system, be sure sprinkler heads are adjusted so the system is not watering the side of the house. Recommend further evaluation as needed.

- AP-2 Additional Plumbing:

The house had a water softener installed (not inspected). You should contact the Manufacturer to find out what maintenance is required.

- AP-3 Additional Plumbing:

A water filtration system was noted in the house - see in the Garage. Evaluation of this system and water quality is beyond the scope of this inspection. Recommend inquiring with the seller for any maintenance, warranty or installer information that pertains to this system. If the system has not been serviced recently, have the filter system serviced and filters cleaned or replaced as a part of the recommended maintenance schedule.

- CS-3 Cooling System:

The air conditioning system and condensate control system could not be tested during inspection. Outdoor temperatures should exceed 65 degrees F for at least 24-hours or the air conditioning equipment can be damaged by testing. Recommended prior to closing, if outside temperature permits, operating this system and having it serviced as needed.

- ES-5 Electrical System:

The service panel had a grounding electrode conductor (GEC) visible that was bonded to the service cabinet and exited the cabinet. The Inspector was unable to confirm proper connection to a grounding electrode. This condition is common because grounding electrodes are required by modern safety standards to be fully buried. Confirmation of proper, effective service grounding would require special instruments.

- ES-8 Electrical System:

The grounding electrode conductor was missing or not found at the gas piping. Have the entire grounding and bonding system checked to verify proper installation. This is an important safety system that ensures reliable discharge of fault current on metal components. We check for bonding at the metal piping where it enters the house, this is usually where the bonding connection is present. It is possible there is a connection elsewhere on the system, but it was not located.

- EDF-4 Electrical Distribution and Fixtures:

Multiple inoperative lights were noted at the front of the house. This is likely due to bulbs being burned out or functional with a photo sensor, but could be due to an inoperative fixture, circuit or switch. Replace bulbs or repair lights as needed.

- EDF-11 Electrical Distribution and Fixtures:

A security system was noted in the closet. Inspection of the security wiring is beyond the scope of this inspection. Inquire with the seller for any additional information.

- I-1 Interior:

Patching was visible to the ceiling at the Kitchen. Prior to closing, disclose the cause and the repairs made.

- K-7 Kitchen:

The Inspector operates dishwashers at the Inspector's discretion. The dishwasher in this Kitchen was full of dishes. Baker Inspection Group disclaims its proper operation. You should ask the seller about its condition.

- FW-2 Fireplaces and Woodstoves:

Accurate inspection of the chimney flue lies beyond the scope of the General Home Inspection. Although the Inspector may make comments on the condition of the portion of the flue readily visible, a full, accurate evaluation of the flue condition would require the services of a specialist. Because the accumulation of flammable materials in the flue as a natural result of the wood-burning process is a potential fire hazard, recommend you have the flue inspected by a Qualified Contractor.

- G-1 Garage:

Storage in the Garage inhibited the view of the Garage and limited visual inspection of this space. Recommend further inspection of the Garage when the area is cleared of personal belongings.

Repair or Replacement

- SEF-8 Site and Exterior Features:

Repair the loose fence posts in the rear of the house to properly secure the fence.

- RC-9 Roofing and Components:

The roof vent penetration flashings were bent and lifted at the rear of the roof. This may cause roof leakage. Moisture intrusion can damage materials and encourage mold growth. Recommend repairs as needed.

- RC-13 Roofing and Components:

A lost seal was found in the skylight glazing - often referred to as a failed insulated glass unit or failed IGU, this is the cloudy appearance that insulated glass has when moisture is trapped between the panes of glass. This requires glazing replacement to eliminate the cloudiness and condensation inside the glass. Recommend further evaluation and repairs as needed.

- EWC-1 Exterior Wall Components:

The sheathing, rafter tail and barge rafter at the front of the house were deteriorated. Recommend further evaluation and repairs or replacement as needed.

- EWC-3 Exterior Wall Components:

The exterior door at the Main Bedroom was deteriorated. Recommend further evaluation and repairs as needed.

- WH-5 Water Heater:

Signs of back-drafting or combustion roll out were noted at the water heater. This is a safety hazard that indicates the unit is not venting as intended. This could allow moisture and carbon monoxide to enter the house. Have this water heater serviced and repaired or replaced as recommended to ensure safe and reliable performance. Examples of specific observations noted during inspection include:

- WH-6 Water Heater:

The temperature and pressure relief valve (TPRV) discharge tube for the water heater was terminating into a drain pan. This is not recommended (UPC). Ideally, the discharge tube for a relief valve:

- Terminates to an exterior location or above a drain, though this is not always possible

- Terminates between 6-inch and 24-inches off the ground (UPC)

- Slopes to drain to prevent water pooling inside the discharge tube

- Is not made from pipe with an inside diameter less than 3/4-inch

- Terminates to a visible location that can be monitored for leaks and discharges

- Does not have a threaded termination point which would prevent accidental capping of this important discharge

- Does not terminate into a drain pan

Recommend having this relief valve discharge tube further investigated and repaired as recommended.

- HDV-5 HVAC Distribution and Ventilation:

The Kitchen fan vent was venting into the Attic. This is non-standard and could contribute to condensation and mold problems in the Attic. Repair the ducting to properly align with the termination roof jack.

- ES-7 Electrical System:

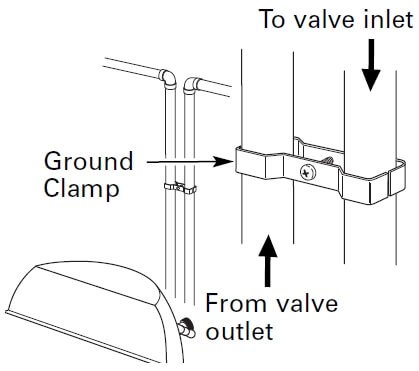

The main water supply pipe served as the grounding electrode for the home electrical service, but no jumper was installed at the water softener. The water softener may interrupt the electrical continuity of the pipes, compromising the effectiveness of the ground. A bonding jumper should be installed across the water softener as needed.

- EDF-1 Electrical Distribution and Fixtures:

The electrical wiring visible in the Attic had splices exposed to touch. This condition is a potential hazard. Splices should be contained within an approved junction box with a cover installed. Recommend repairs as needed.

- EDF-5 Electrical Distribution and Fixtures:

Reverse polarity was noted at the Kitchen electrical receptacle. This is when the hot and the neutral wires have been wired backwards. This is a potential safety issue that should be further evaluated and corrected as needed.

- EDF-6 Electrical Distribution and Fixtures:

The GFCI protected receptacle at the rear of the house did not respond to testing (the test buttons were frozen) and may be defective, it did not trip when tested. Have this receptacle repaired or replaced as needed.

- EDF-7 Electrical Distribution and Fixtures:

The house interior had ground fault circuit interrupter (GFCI) protection where needed except for the Kitchen and Garage which had partial. Although GFCI protection may not have been required at the time the home was built, for safety reasons, Baker Inspection Group recommends that electrical receptacles located in Basements, Cellars, Crawlspaces, Garages, and interior receptacles located within 6-feet of a plumbing fixture be provided with ground fault circuit interrupter (GFCI) protection in good working order to avoid potential electric shock or electrocution hazards. This can be achieved relatively inexpensively by: 1. Replacing an individual standard receptacle with a GFCI receptacle. 2. Replacing the electrical circuit receptacle located closest to the overcurrent protection device (usually a breaker) with a GFCI receptacle. 3. Replacing the breaker currently protecting the electrical circuit that contains the receptacles of concern with a GFCI breaker.

- EDF-8 Electrical Distribution and Fixtures:

Partial ground fault circuit interrupter (GFCI) protection of the exterior electrical receptacles was provided at the time of inspection. Although GFCI protection may not have been required at the time the home was built, for safety reasons, Baker Inspection Group recommends that electrical receptacles located in Basements, Crawlspaces, Garages, the home exterior, and interior receptacles located within 6 feet of a plumbing fixture be provided with ground fault circuit interrupter (GFCI) protection in good working order to avoid potential electric shock or electrocution hazards. This can be achieved relatively inexpensively by: 1. Replacing an individual standard receptacle with a GFCI receptacle. 2. Replacing the electrical circuit receptacle located closest to the overcurrent protection device (usually a breaker) with a GFCI receptacle. 3. Replacing the breaker currently protecting the electrical circuit that contains the receptacles of concern with a GFCI breaker.

- I-5 Interior:

Several panes of glass had a cloudy appearance which could indicate a lost or failed seal at the right side and rear of the house. Recommend having the window glass further evaluated as needed. Replace all glazing with lost seals as needed. A lost seal is a common term for when there is permanent cloudiness between the panes of glass or between the "insulated glass units," IGU's. This is a cosmetic defect that does not impact the short term performance of the window.

- I-6 Interior:

The window glass did not comply with modern safety standards where safety glass is recommended in specific locations such as beside doors. Updating this glazing to comply with modern safety glass standards is recommended; we did not find a safety glass label on the panes that were checked. All tempered and safety glass should be labeled. Recommend further evaluation and repairs as needed to update for improved safety.

- I-12 Interior:

Several Smoke alarms were noted to be missing. Replace the missing Smoke alarms in the house so that there is an operating Smoke alarm in every Bedroom and on every floor and one outside of all sleeping areas. No Smoke alarms were noted at the Bedrooms and right area.

- I-13 Interior:

Carbon Monoxide alarms were found and noted during inspection, but there did not appear to be enough Carbon Monoxide alarms. Be sure to check the Carbon Monoxide alarms regularly with the test button to ensure they are operational. The standard is one Carbon Monoxide alarm per floor and one outside all sleeping areas. I only found one in the left Hallway.

- K-9 Kitchen:

The garbage disposal wiring was missing the electrical housing (anti-strain device) clamp. Clamps are electrical connectors designed to protect and secure conductors where they pass through sheet metal. Recommend that a proper clamp be installed.

- B-2 Bathrooms:

At the Hallway Bathroom, the shower enclosure rear wall panel was cracked. Recommend further evaluation and repairs as needed.

- B-3 Bathrooms:

The mixing valves in the Hallway Bathroom bathtub and shower was installed so that hot and cold were backwards. This can lead to confusion when turning on and off the water and should be repaired as needed.

- LA-5 Laundry Area:

Foil or Mylar transition duct was noted in use to connect the clothes dryer to the rigid vent. This product is generally UL listed for use with a clothes dryer, however, most clothes dryer manufacturers do not recommend it as it has proven to be unreliable and a potential fire hazard. A corrugated metal flex duct is recommended. Repair as needed.

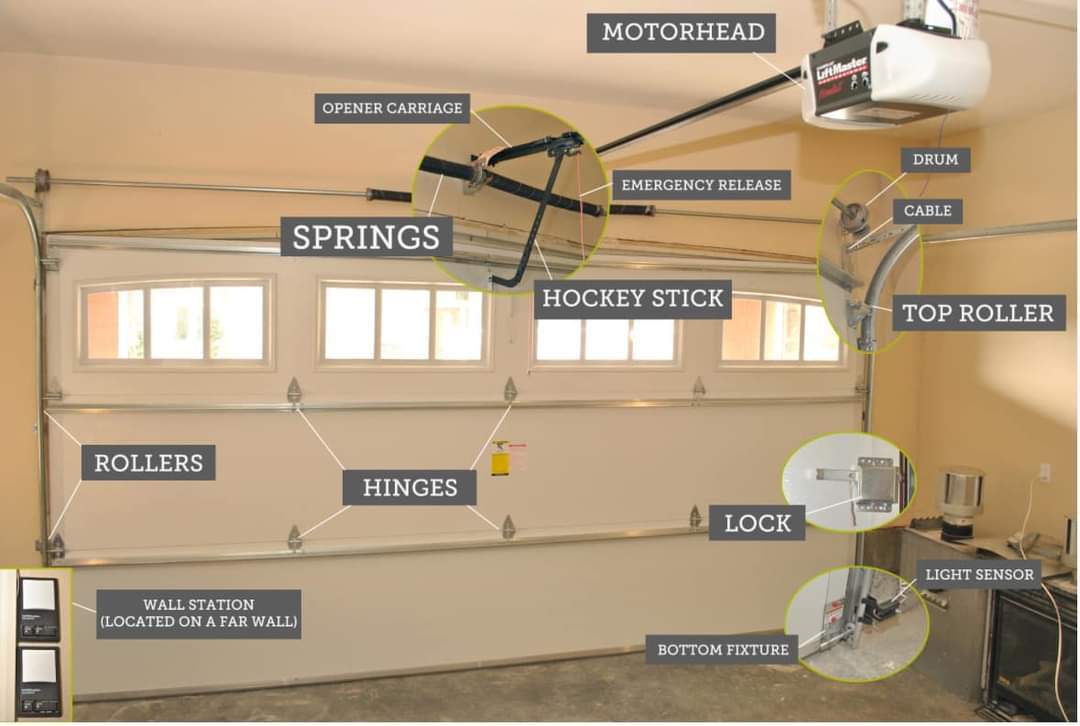

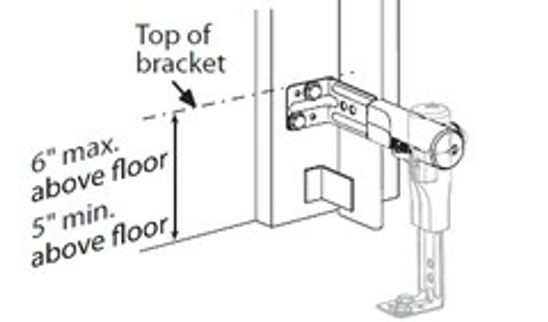

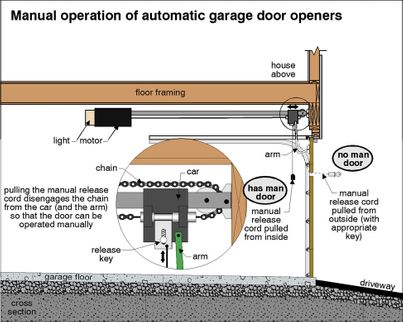

- G-4 Garage:

The laser eye safety mechanisms for the overhead Garage doors had been set too high, this sensor should be 5 to 6-inches off of the floor to perform as intended and prevent entrapment. Have this repaired as needed.

Improvement Items

- SEF-2 Site and Exterior Features:

Downspouts were discharging adjacent to the foundation. This can cause foundation settlement or concrete slab moisture problems. Make sure all downspouts discharge into a proper tight-line system that diverts water at least 5-feet away from the foundation.

- SEF-3 Site and Exterior Features:

Downspouts were discharging onto the base of a wooden post. This will facilitate decay and settlement. Install an extension to divert water away from the base of this post.

- SEF-6 Site and Exterior Features:

Cracks were noted in the driveway flatwork at the front of the house. No immediate repair appears necessary.

- SEF-9 Site and Exterior Features:

Localized areas of deteriorated fencing were note at the rear of the house. This is characteristic of older fencing. Implement repairs to the fencing as needed until the fencing is systematically updated. The urgency of this project is subjective.

- RC-6 Roofing and Components:

The patio roof is done in a torch down membrane that appears to be roughly 1/2 way into its useful service life and exhibited deterioration such as granule loss, delamination, bubbling or cracking. I find the typical life cycle of these roof membranes is 10 years of little to no maintenance and then a 2nd 10 years of higher-maintenance until the membrane is replaced. Recommend further evaluation as needed.

- RC-15 Roofing and Components:

The chimney crown was visibly deteriorated. Failure of the crown can allow moisture intrusion of the chimney structure that can cause damage. Recommend repairs as needed.

- EWC-4 Exterior Wall Components:

The wooden door jamb at the right side of the house was deteriorated at its base near the threshold. This is a common spot to have wood decay problems as water collects on the threshold and soaks into the end grain of the wood. Repair the damaged wood as needed.

- PS1-2 Plumbing System:

The water meter was full of soil and needs to be cleaned so the meter is readable and the piping accessible. Remove the soils from the water meter box as needed.

- PS1-8 Plumbing System:

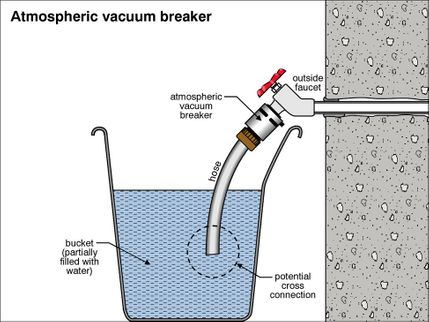

The hose bibs noted on this house were missing anti siphon devices and updating is recommended. Modern hose bibs are typically anti siphon style which can prevent water from your hoses backing into your water supply system. Consider installing anti siphon hose bibs or adding an anti siphon device to the existing hose bibs. The following video shows a vacuum breaker. Click Here

- WH-8 Water Heater:

Testing of the plumbing system today, the water tested as too hot - 142 degrees F. This is a scalding hazard. To prevent scalding, standards recommend indoor hot water temperatures do not exceed 120 degrees F. There is some evidence that hot water temperatures should be greater than 130 degrees F to prevent Legionnaires' disease from developing in the water heater. If this is a concern, you can heat the water in the tank to 140 degrees F and have a tempering valve installed at the hot water tank. Have this further evaluated and repaired or simply turn down the temperature as desired to eliminate a scald hazard. Please note that during inspection it is difficult to accurately test the water temperature as it can vary between fixtures. Testing is done in multiple locations during inspection and a median temperature is taken.

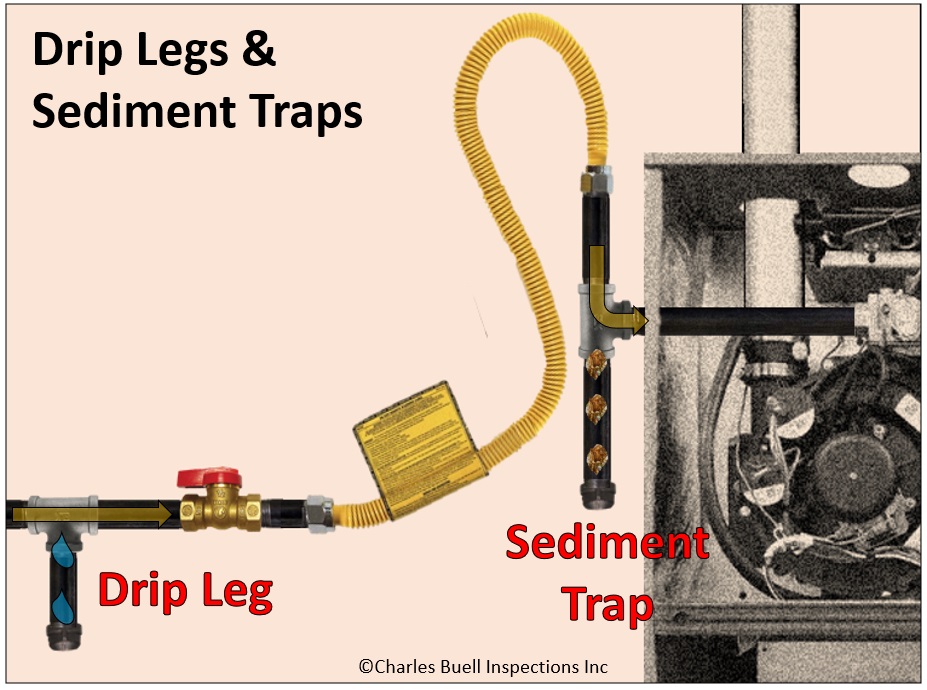

- FDS-3 Fuel Distribution System:

There was no sediment trap found for the gas pipe at the gas water heater. Sediment traps are designed to prevent fouling of gas equipment by allowing sediment to fall out of the gas supply. Sediment traps are required at all automatically controlled gas appliances. Recommend further evaluation and repairs as needed.

- HS-5 Heating System:

This gas forced air furnace is close to the end of its useful design life. The average service life of natural gas and propane forced air furnaces is 15-20 years. Furnace heat exchangers are not visible to inspection without expensive diagnostics, so is it difficult to know when the furnace could be posing a safety hazard to the occupants. Older furnaces are also less reliable and subject to the need for constant repairs. Recommend further evaluation as needed by a Qualified Contractor.

- CS-4 Cooling System:

This air conditioning system was past the mid point of it's design life expectancy. Air conditioning compressors have fairly unreliable service lives that can range from as little as 7 to as many as 30 years. Recommend further evaluation as needed by a Qualified HVAC Contractor.

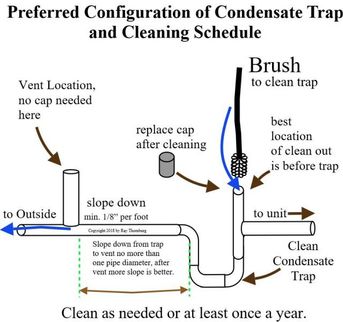

- CS-5 Cooling System:

The condensation line designed to properly dispose of condensate produced by the operation of the air-conditioning evaporator coils was improperly configured. Recommend repairs as needed.

- ES-4 Electrical System:

The service panel had damaged cover hardware that should be repaired as needed.

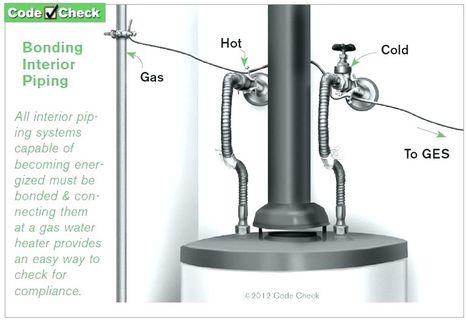

- ES-6 Electrical System:

Metal cold water distribution pipes appeared to be properly bonded. Metal hot water pipes were not bonded. Electrical bonding of the water pipes helps to ensure that safe conditions exist if the pipes should somehow come into contact with electrical wiring and become energized. Bonding of water pipes is required in new homes by generally-accepted modern safety standards. Although it may not have been required at the time the home was originally constructed, as a safety measure the Inspector recommends that the hot water pipes be bonded also.

- I-7 Interior:

Interior doors at the 4th Bedroom were difficult to close. Recommend repairs as needed.

- B-4 Bathrooms:

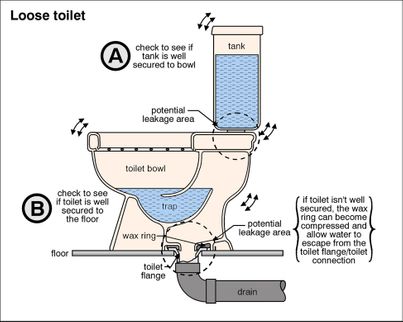

The loose toilet in the Main Bathroom needs to be reset and the wax ring and flange should be replaced to prevent hidden plumbing leaks. This is a simple job unless the bolts that fasten the toilet also require repair. Sometimes, loose toilets can even be shimmed for a tight and proper seal and sometimes simply caulking can help prevent the toilet from rocking and twisting.

- G-5 Garage:

The handle that attaches to the overhead Garage door detaching mechanism was located too high off the floor. These release handles should be accessible, less than 6-feet off the ground. Repair as needed for improved safety.

Recommended Maintenance

- SEF-4 Site and Exterior Features:

Important area drains were noted around the property at the rear of the house These are designed to capture surface runoff and divert water around the building. Be sure to keep these drains clear, especially before large rain storms.

- SEF-5 Site and Exterior Features:

Some of the downspouts on this home were noted to be discharging into area drains. No evidence of failure was noted, but these pipes are prone to clogging, backing up and below ground failure. Monitor after heavy rains. Failing sub-surface storm drains are one of the most common reasons for concrete slab and Crawlspace moisture problems and can even lead to structural settlement.

- RC-7 Roofing and Components:

The satellite dish penetrations should be maintained to avoid damage to the underlying home structure from moisture intrusion.

- RC-10 Roofing and Components:

The piping / vents at the roof required proper sealing around the perimeter of the piping / vent and the roof flashing.

- RC-11 Roofing and Components:

Visible fasteners on flashings are considered by manufacturers to be defects. Sealant should be applied at the nail heads to prevent leakage. Sealant will need to be examined annually and re-applied as needed.

- AC-6 Attic and Components:

The Attic vent screens were blocked at the right side. This condition will reduce the amount of air flowing through the roof structure to exhaust excessive heat and moisture to the exterior. Recommend the cleaning of any blocked vents to allow proper airflow and improve roof structure ventilation.

- FDS-4 Fuel Distribution System:

The gas piping at the rooftop of the house was corroded. To ensure reliable performance, recommend removing rust build-up and repainting with rust inhibitive paint.

- HS-3 Heating System:

Annual servicing of the gas forced air furnace is recommended for safe and reliable heat. The design life of these forced air furnaces is 15-20 years. Recommend keeping this furnace on a regular service schedule.

- CS-6 Cooling System:

The air-conditioner cabinet or components had corrosion visible. Recommend further evaluation to ensure proper and efficient operating conditions exist.

- CS-7 Cooling System:

The air-conditioner condenser cabinet had dirt and/or debris which may limit the system ability to dissipate heat. The cabinet should be cleaned in order to maintain cooling system efficiency and avoid problems from overheating of the compressor.

- I-2 Interior:

Cracks were noted in the ceiling and walls at the Main Bedroom and Family Room. These were straight line cracks and no other indications were found to indicate settlement. Cracking lines like these can be due to routine settlement or moderate seasonal expansion and contraction of the structure. Cracks like these can also be related to workmanship and nailing of framing and sheetrock or deflection from the framing. The seasonal types of cracking can be most problematic as they will tend to re-open after repair. Repair and paint cracks as needed and monitor.

- I-3 Interior:

Patching was visible on the walls at the rooms throughout the house. Recommend repairs as needed.

- LA-6 Laundry Area:

The clothes dryer exhaust duct should be cleaned for improved safety. This is important regular maintenance to eliminate a potential fire hazard.

The Full Inspection Report

Site and Exterior Features

Site Grading and Drainage

Grounds, Trees and Vegetation

Driveways and Walkways

Fences and Walls

Outbuildings and Exterior Features

Roofing and Components

Roofing Materials

Roof Flashings

Skylights

Roof Drainage System

Chimney Above Roof

Exterior Wall Components

Eaves

Siding and Trim

Doors

Chimney Exterior

Porches and Patios

Vent and Exhaust Terminations

Attic and Components

Accessibility

Roof Sheathing and Framing

Ventilation Type

Thermal Envelope

Radiant Barrier

Plumbing System

Water Meter

Supply Source and Material

Distribution Piping

Exterior Hose Bibs

Drain, Waste and Vent Systems

HVAC Distribution and Ventilation

Distribution Systems

Air Filters

Thermostat

Room Mechanical Ventilation Systems

Electrical System

Service Entrance and Meter

Service Voltage

Service Panel Type

Main Electrical Panel

Grounding System

Water Bonding

Gas Bonding

Electrical Disconnects

Electrical Distribution and Fixtures

Branch Wiring Circuits

Lighting, Switches and Receptacles

Ceiling Fans

Low Voltage Wiring

Kitchen

Countertops and Cabinets

Faucets, Sinks and Traps

Range, Cooktop and Oven

Microwave, Range Hood, Ventilation System

Dishwasher

Garbage Disposal

Refrigerator

Bathrooms

General Bathroom

Counters, Cabinets and Sink Components

Showers and Bathtubs

Toilets

Ventilation Method

General Comments

Building Conditions and Limitations

Standards of Practice: InterNACHI (International Association of Home Inspectors)

Inspection Type: Home Inspection

Attending the Inspection: Client and REALTOR®

Occupancy: Occupied

Building Type: Single Family [1 story]

Approximate Square Footage: 1924

Approx. Year of Original Construction (per MLS): 1983

Utilities: On

Structural Pest Inspection Included: No

Building Faces: North

Temperature at Start of Inspection: 50-55 (F)

Temperature at End of Inspection: 55-60 (F)

Weather During the Inspection: Cloudy

Ground/Soil Surface Condition: Damp

Significant Precipitation in Prior Three Days: Yes

In 1978, federal laws were passed to prohibit use of Lead and Asbestos in building materials. Manufacturers of building materials were allowed to sell existing stocks of materials that were manufactured with Lead and Asbestos, so even buildings constructed as late as the mid-1980's could possibly contain Lead or Asbestos. Identification and testing for Lead and Asbestos and other environmental testing is beyond the scope of this home inspection. If you wish to seek additional information, Baker Inspection Group recommends contacting an Environmental Lab.

Unless the wiring in the building has been fully updated, this building likely has wiring that predates the late 1980's. Branch circuit wiring installed in buildings built prior to the late 1980s is typically rated for a maximum temperature of only 60 degrees Celsius. This includes non-metallic sheathed (Romex) wiring, and both BX and AC metal-clad flexible wiring. Knob and tube wiring, typically installed in homes built prior to 1950, may be rated for even lower maximum temperatures. Newer electric fixtures including lighting and fans typically require wiring rated for 90 degrees Celsius. Connecting newer fixtures to older, 60 degree rated wiring is a potential fire hazard. Repairs for such conditions may involve replacing the last few feet of wiring to newer fixtures with new 90 degree rated wire, and installing a junction box to join the old and new wiring. It is beyond the scope of this inspection to determine if any such incompatible components are installed. Based on the age of this building, be aware that such components may be present.

Important Pest Notice and Disclaimer:

California termites can attack a home in the eaves, rafter tails, Attic and Crawlspace areas. Baker Inspection Group recommends that the client obtain a pest inspection and report from a Qualified and Licensed Pest Inspector before the end of the Inspection Period. California law allows only persons who possess a valid Structural Pest Control License, issued by the State of California Structural Pest Control Board, to inspect or make reports with respect to pest infestations including wood destroying insects, termites, and other organisms such as fungus (causing wood rot). This report is not a termite inspection and no responsibility is assumed for any infestation or damage caused by wood-destroying organisms. More information can be found here http://www.pestboard.ca.gov.

This home was occupied at the time of the inspection. Inspection of occupied homes presents some challenges as occupant belongings can obstruct visual inspection of and access to parts of the house. We do our best during inspection to work around belongings to discover as much as possible about the house without moving or damaging personal property, however, the presence of personal items does limit the inspection.

Site and Exterior Features

Site Grading and Drainage

Site Description: Flat (Flat Lot - Disclose)

Clearance to Grade: Non-Standard

Downspout Discharge: At Foundation, At Wooden Post, Area Drains

Some of the downspouts on this home were noted to be discharging into area drains. No evidence of failure was noted, but these pipes are prone to clogging, backing up and below ground failure. Monitor after heavy rains. Failing sub-surface storm drains are one of the most common reasons for concrete slab and Crawlspace moisture problems and can even lead to structural settlement.

Grounds, Trees and Vegetation

Trees/Vegetation Too Near Building: No

Driveways and Walkways

Driveway: Concrete

Walkways: Concrete

Fences and Walls

Exterior Fencing: Present, Not Inspected

The property has a fencing system in place. Inspection and evaluation of fencing is beyond the scope of a home inspection.

Roofing and Components

Roofing Materials

Roof Covering Materials: Presidential Grade Shingle, Torch-Down / Modified Bitumen

Roof Style: Gable, Shed

Roof Inspection Method: From the Roof Surface (walked/climbed)

The roofing material on this building appears to be a presidential grade shingle. These are a thick composition shingle and they are often rated as 50 year shingles. In practice these roofs have not been installed that long so it is difficult to know how long they will last.

The patio roofing material is a torch-down or modified bitumen membrane. The service life of these roofs can vary depending on the quality of the membrane and the quality of the installation, including how well the roof is sloped to drain. Torch-down roofs often have roughly 10 years of reliable service life beyond which regular repairs are often needed. With on-going maintenance these roofs can be made to last as long as 25 years.

The patio roof is done in a torch down membrane that appears to be roughly 1/2 way into its useful service life and exhibited deterioration such as granule loss, delamination, bubbling or cracking. I find the typical life cycle of these roof membranes is 10 years of little to no maintenance and then a 2nd 10 years of higher-maintenance until the membrane is replaced. Recommend further evaluation as needed.

Roof Flashings

Flashings, Valleys and Penetrations: Present and Visually Standard, Metal Valleys Noted

Roof flashings are used to keep a roofing system waterproof where the roofing material starts, stops, changes direction or is penetrated. During inspection, we look for standard flashing techniques that could be considered normal or standard in our region. Damaged, incomplete or non-standard flashings can be a sign of an older or less reliable roofing system and may require repair. Any non-standard flashings noted during inspection will be reported on below if found.

The roof vent penetration flashings were bent and lifted at the rear of the roof. This may cause roof leakage. Moisture intrusion can damage materials and encourage mold growth. Recommend repairs as needed.

Skylights

Type: Light Tube

A lost seal was found in the skylight glazing - often referred to as a failed insulated glass unit or failed IGU, this is the cloudy appearance that insulated glass has when moisture is trapped between the panes of glass. This requires glazing replacement to eliminate the cloudiness and condensation inside the glass. Recommend further evaluation and repairs as needed.

Roof Drainage System

Gutter and Downspouts: Yes, Gutter Guard System - Partial

The roof drainage system consisted of conventional gutters hung from the roof edges feeding downspouts.

Exterior Wall Components

Eaves

Siding and Trim

Siding Material: Stucco

This building had a hardcoat stucco siding system. When installed over a wood building, stucco should be installed with two layers of underlayment below the stucco and a weep screed system which allows air to dry any accumulated moisture behind the stucco. Stucco is one of the nicest and lowest-maintenance siding systems but it is installation-sensitive. Poor installation can lead to expensive moisture control problems. The critical weather barrier, which is installed beneath the stucco is not visible to inspect, limiting the Inspectors' ability to see how the system is performing. During our visual inspection, we look for clues to help make an educated guess about the future reliability of this system. More detailed information can be gained through destructive testing. This involves drilling holes in the stucco and using a moisture probe to determine if any sections of the building have moisture control problems. Destructive testing is beyond the scope of this inspection.

Doors

Chimney Exterior

Exterior Material: Block

Porches and Patios

Porch and Patio: Concrete

Vent and Exhaust Terminations

Present

Attic and Components

Accessibility

Attic Inspection Method: - (Inside the Attic)

The Attic access hatch requires insulation and weather stripping to prevent heat loss and heat migration into the Attic.

Roof Sheathing and Framing

Sheathing: 1x Spaced Boards and Radiant Sheathing

Rafters: Truss

Ventilation Type

Structure Ventilation Type: Eave, Gable and Roof Vents, Soffit Vents - Continuous, Thermostat Fan

The Attic has a power van for ventilation. This was set up on a thermostat, so it appears to be used for controlling summer heat. This can exacerbate problems of air leakage from the conditioned house space into the unconditioned Attic space. So, for example, if you are using cooling in the house, it can make the house hotter during the summer as conditioned air can get pulled out of the house into the Attic. In general, power ventilation is not recommended.

Thermostatically controlled vent fan in the Attic may work, but due to the low temperature the unit would not come on at its lowest setting. Baker Inspection Group did not inspect this unit.

The Attic vent screens were blocked at the right side. This condition will reduce the amount of air flowing through the roof structure to exhaust excessive heat and moisture to the exterior. Recommend the cleaning of any blocked vents to allow proper airflow and improve roof structure ventilation.

Thermal Envelope

Insulation Type: Batt and Blown-In

Approximate Insulation R-Value on Attic Floor: R-13 [Cellulose 3-1/2"], R-38 [Fiberglass 17"]

The Attic insulation could be improved to modern standards, which recommend R-49 on the floor. R-value is the measure of resistance to heat loss; the higher the R-value the better the insulation. During insulation repairs it is best practices to implement any air seal-up repairs to seal air leakage. Also, be sure you have completed any wiring or other projects that are needed in the Attic.

Radiant Barrier

Radiant Barrier Present: Installed at Sheathing

A radiant barrier is a layer of reflective material installed in a house to redirect the radiant heat created by the sun. In warm weather, a radiant barrier blocks radiant heat from entering a house. This increases the efficiency of your Attic-installed air handling system, resulting in increased energy savings and lower energy costs. When the sun beats down on your home, heat builds up in the roofing materials. Some of this heat is transferred into your Attic and eventually reaches your indoor living areas. This type of heat transfer, known as “radiant heat,” is as natural as the seasons. But it can create temperature variations inside your house and cause your cooling system to work harder.

Structure and Foundation

Ceiling, Wall and Floor Structures

Ceiling Framing: Bottom Chord of Truss

Wall Framing: Wood Frame

Foundation

Foundation Configuration: Concrete Slab-on-Grade

Foundation Type and Material: Poured Concrete

Evidence of Seismic Protection: Not Accessible

Plumbing System

Water Meter

The water meter was full of soil and needs to be cleaned so the meter is readable and the piping accessible. Remove the soils from the water meter box as needed.

Supply Source and Material

Water Supply: Public Water Supply

Main Water Pipe Material: Not Visible

Water Pressure: Tested, 70 PSI

Please note that when the water service type is listed here, it is listed based on public records, listing information and disclosure. It is always possible that the system is not as it is listed.

This shows the water pressure (70 PSI) tested during inspection. Generally, "normal water pressure," should be between 40-80 PSI, though pressures near or below 40 PSI can result in poor functional flow to fixtures. Water pressures in excess of 80 PSI risk damaging supply piping components and should be controlled with a pressure reducing valve.

No main water shut off was found (possibly in the Garage) at the house. There was a shut off at the meter in the street, but this can be a time-consuming and difficult shut-off to access in an emergency. Disclose the location of the main water shut for future owners as it may be concealed behind finishes or stored items. If no readily accessible shut off exists, recommend further evaluation.

Distribution Piping

Supply Pipe Materials: Copper

Functional Flow: Excellent

The visible water distribution pipes were 1/2-inch copper.

All plumbing fixtures in the home exhibited functional flow at the time of the inspection.

Exterior Hose Bibs

Hose Bibs: Tested All Accessible

Anti-Siphon Present: No

The hose bibs noted on this house were missing anti siphon devices and updating is recommended. Modern hose bibs are typically anti siphon style which can prevent water from your hoses backing into your water supply system. Consider installing anti siphon hose bibs or adding an anti siphon device to the existing hose bibs. The following video shows a vacuum breaker. Click Here

Drain, Waste and Vent Systems

System Type: Public Sewer - Buyer

Waste and Vent Pipe Materials: Acrylonitrile Butadiene Styrene (ABS)

Functional Drainage: All Plumbing Fixtures had Functional Drainage

Please note that the waste piping system was partially concealed behind finishes and not fully visible to inspect.

All of the plumbing fixtures in the house exhibited functional drainage at the time of the inspection.

Please note that when the sewage discharge type is listed here, it is listed based on public records and disclosure. It is always possible that the system is not as it is listed; for example, a property could be listed as a public sewer system when in fact it is on a private septic system. This is another reason why we recommend further evaluation of this system; the type of sewer discharge cannot be verified as part of a visual inspection of the property.

A video camera sewer scope is recommended. An evaluation of the sewer line below the ground is beyond the scope of this inspection. A sewer scope is always recommended to further evaluate the sewer line and the below ground connections between the house and the municipal sewer line or septic tank. Sewer scopes are done using video cameras and can reveal the materials, condition and reliability of the sewer line.

Water Heater

Water Heater

System Type and Capacity: Tank, Not Visible (insulating blanket)

Energy Source: Natural Gas [FVIR]

TPR Valve: Present - Not Tested

Water Heater Straps: Present

Age: Unknown

Manufacturer: Unable to Determine

This water heater appears to be using F.V.I.R technology. Prior to 2003 most gas water heaters had an open combustion system which made them a potential ignition source in places like garages where gasoline vapors could ignite. Starting in 2003, residential water heaters began using “F.V.I.R.” (Flammable Vapor Ignition Resistant) technology. This means that the combustion chamber is now sealed. In order to light the water heater, you must use the pilot mechanism and you can no longer use a match, like the old pilot lights. Effective July 1, 2003, all water heater manufacturers are required to build their 30,40 & 50 gallon atmospheric vent water heaters to new government standards. The American National Standards Institution (ANSI) have established these new standards to prevent accidental or unintended ignition of flammable vapors, such as those emitted by gasoline. By July 1, 2005, the ANSI Z21.10.1a-2002 standard will apply to virtually all gas fired residential water heaters with BTU ratings of 75,000 and below.

A temperature and pressure relief valve (TPRV) is required on all water heaters to discharge any excessive pressure within the tank. A discharge pipe should be attached to the valve and directed to a safe location away from body contact. Newer installations must be directed to the building exterior or to an approved indoor drain receptor. Most manufacturers suggest that homeowners test these valves at least once a year by lifting the lever to ensure the valve discharges properly and also recommend inspection of these safety devices every three years. The picture here shows a typical TPRV. They may also be found on the side of the heater on some models. We do not test these valves due to the possibility that they may leak after testing. A leaking or inoperative TPRV should be replaced immediately by a Qualified Plumber.

Signs of back-drafting or combustion roll out were noted at the water heater. This is a safety hazard that indicates the unit is not venting as intended. This could allow moisture and carbon monoxide to enter the house. Have this water heater serviced and repaired or replaced as recommended to ensure safe and reliable performance. Examples of specific observations noted during inspection include:

The temperature and pressure relief valve (TPRV) discharge tube for the water heater was terminating into a drain pan. This is not recommended (UPC). Ideally, the discharge tube for a relief valve:

- Terminates to an exterior location or above a drain, though this is not always possible

- Terminates between 6-inch and 24-inches off the ground (UPC)

- Slopes to drain to prevent water pooling inside the discharge tube

- Is not made from pipe with an inside diameter less than 3/4-inch

- Terminates to a visible location that can be monitored for leaks and discharges

- Does not have a threaded termination point which would prevent accidental capping of this important discharge

- Does not terminate into a drain pan

Recommend having this relief valve discharge tube further investigated and repaired as recommended.

Water Temperature

Water Temperature Measured During Inspection: Yes, 142 Degrees F

The water temperature was tested multiple times during inspection. It is common for water temperatures to fluctuate throughout the house depending on the distance from the water heater, the water heater settings, the type of water heater and any thermostatic controls used in the plumbing fixtures and mixing valves. For reporting, the median temperature is used.

Testing of the plumbing system today, the water tested as too hot - 142 degrees F. This is a scalding hazard. To prevent scalding, standards recommend indoor hot water temperatures do not exceed 120 degrees F. There is some evidence that hot water temperatures should be greater than 130 degrees F to prevent Legionnaires' disease from developing in the water heater. If this is a concern, you can heat the water in the tank to 140 degrees F and have a tempering valve installed at the hot water tank. Have this further evaluated and repaired or simply turn down the temperature as desired to eliminate a scald hazard. Please note that during inspection it is difficult to accurately test the water temperature as it can vary between fixtures. Testing is done in multiple locations during inspection and a median temperature is taken.

Additional Plumbing

Landscape Irrigation

Present, Not Inspected, Noted For Buyer

An exterior irrigation system was noted. Sprinkler systems are beyond the scope of this inspection. Irrigation systems require annual attention / repair / servicing after every winter. When testing the system, be sure sprinkler heads are adjusted so the system is not watering the side of the house. Recommend further evaluation as needed.

Water Filters

Type: Water Softener Not Inspected, Water Filter

A water filtration system was noted in the house - see in the Garage. Evaluation of this system and water quality is beyond the scope of this inspection. Recommend inquiring with the seller for any maintenance, warranty or installer information that pertains to this system. If the system has not been serviced recently, have the filter system serviced and filters cleaned or replaced as a part of the recommended maintenance schedule.

Fire Suppression

A fire hydrant was noted near the house. Sometimes you can get a discount on home owners insurance with a nearby fire hydrant.

Fuel Distribution System

General Comments

Type of Fuel: Natural Gas

Gas Meter

Present

Fuel Distribution Systems

Gas Piping Materials: Partially Visible-Black Steel

The house gas distribution pipes visible were black steel.

There was no sediment trap found for the gas pipe at the gas water heater. Sediment traps are designed to prevent fouling of gas equipment by allowing sediment to fall out of the gas supply. Sediment traps are required at all automatically controlled gas appliances. Recommend further evaluation and repairs as needed.

Heating System

Heating System

Heating Type: Gas-Fired Furnace Package Unit

Energy Source: Natural Gas

Listed Nominal Capacity: 82,500 BTU

Age: 2006

Manufacturer: Lennox

This house has a gas forced air furnace. A critical component to all combustion heating equipment is the heat exchanger. This is the welded metal assembly inside the furnace that contains the products of combustion so that moisture, carbon monoxide and other products of combustion do not mix with interior air and get safely vented to the exterior. Heat exchangers on modern furnaces have an average life expectancy of 15-20 years. Unfortunately, heat exchangers are concealed inside the heating equipment; they are not visible and specifically excluded from a home inspection. Cracks in heat exchangers may be concealed and can pose a potential safety hazard.

This gas forced air furnace is close to the end of its useful design life. The average service life of natural gas and propane forced air furnaces is 15-20 years. Furnace heat exchangers are not visible to inspection without expensive diagnostics, so is it difficult to know when the furnace could be posing a safety hazard to the occupants. Older furnaces are also less reliable and subject to the need for constant repairs. Recommend further evaluation as needed by a Qualified Contractor.

Annual servicing of the gas forced air furnace is recommended for safe and reliable heat. The design life of these forced air furnaces is 15-20 years. Recommend keeping this furnace on a regular service schedule.

Vents and Flues

Common Observations: Inspected

Cooling System

Cooling System

System Type: Air Source

Cooling Type: Air Conditioning Present, Package Unit

Listed Nominal Capacity: 4.0 Tons

Cooling Equipment Refrigerant Type: R-410A - Puron

Energy Source: Electric

Condensate Overflow Piping and Warning Device: Configured Improperly

Temperature Differential: Not Tested: Below 65 Degrees F.

Age: 2006

Manufacturer: Lennox

The location of the cooling system was at the rooftop.

The following list is a minimum set of requirements to be expected of air conditioning servicing. These are provided as a courtesy to show they types of check-ups that should be expected from a professional servicing.

Check compressor efficiency. Check refrigerant level. Clean the condenser coil. Change or clean air filters. Inspect contactors and wiring. Inspect drive-sheaves, pulleys and belts. Check and adjust for proper air flow. Clean the blower motor as needed. Lubricate all motors and shaft bearings. Check, calibrate and program the thermostats and be sure the thermostat has adequate batteries as needed. Check unit smoke detector, clean filter if applicable. Check safety disconnect, laser-temp -- check across contacts

The air conditioning system and condensate control system could not be tested during inspection. Outdoor temperatures should exceed 65 degrees F for at least 24-hours or the air conditioning equipment can be damaged by testing. Recommended prior to closing, if outside temperature permits, operating this system and having it serviced as needed.

This air conditioning system was past the mid point of it's design life expectancy. Air conditioning compressors have fairly unreliable service lives that can range from as little as 7 to as many as 30 years. Recommend further evaluation as needed by a Qualified HVAC Contractor.

HVAC Distribution and Ventilation

Distribution Systems

Heating/Cooling Duct Location: Attic

Distribution Method: Flex Duct, Insulated

Presence of Heat Source in Each Room: Present

Presence of Cooling Source in Each Room: Could Not Test During Inspection

The pictures illustrate that the heating equipment responded to operating controls at the thermostat when placed in the heating mode. Heated air was discharging from all supply air registers (representative amount shown) unless otherwise noted. No further equipment diagnostics were performed as part of this home inspection.

Air Filters

Air Filter Location: Hallway Ceiling, Bedroom Ceiling

Air Filter Type: Disposable

Air Filter Size: 10x20, 20x25, Two Filters

The furnace filters were located at the cold air return.

The heating and cooling system had disposable air filter(s) installed. These should be changed quarterly or more to ensure proper air flow at the furnace. Be sure to install the filters with the arrows pointing in the same direction as the air flow in the furnace.

Thermostat

Type: Programmable

Room Mechanical Ventilation Systems

Bathroom and Laundry Area Fan Ducting: Ducted to Exterior, Laundry Area - N/A

Kitchen Fan Ducting: Discharging - Attic Area

The Kitchen fan vent was venting into the Attic. This is non-standard and could contribute to condensation and mold problems in the Attic. Repair the ducting to properly align with the termination roof jack.

Electrical System

Service Entrance and Meter

Service Entrance: Below Ground

Meter Base Amperage: 200 Amps

Service Voltage

Service Voltage: 120/240 Volts

Service Panel Type

Type: Load Center

Main Electrical Panel

Service Disconnect Location: At Service Panel

Service Disconnect Type: Breaker

Service Disconnect Amperage: 125 Amps

Main Electrical Panel Amperage: Unable to Determine (label missing)

Main Electrical Panel Manufacturer: Gould

Service Overcurrent Protection Device: Breakers

Service Panel (AFCI) Protection: No

Service Panel (GFCI) Protection: No

Grounding System

Grounding Type: Panel Only

The service panel had a grounding electrode conductor (GEC) visible that was bonded to the service cabinet and exited the cabinet. The Inspector was unable to confirm proper connection to a grounding electrode. This condition is common because grounding electrodes are required by modern safety standards to be fully buried. Confirmation of proper, effective service grounding would require special instruments.

Water Bonding

Bonding Present: Noted - Cold Piping Only, Water Piping Bonding (Jumper, Water Softener - Missing)

The main water supply pipe served as the grounding electrode for the home electrical service, but no jumper was installed at the water softener. The water softener may interrupt the electrical continuity of the pipes, compromising the effectiveness of the ground. A bonding jumper should be installed across the water softener as needed.

Metal cold water distribution pipes appeared to be properly bonded. Metal hot water pipes were not bonded. Electrical bonding of the water pipes helps to ensure that safe conditions exist if the pipes should somehow come into contact with electrical wiring and become energized. Bonding of water pipes is required in new homes by generally-accepted modern safety standards. Although it may not have been required at the time the home was originally constructed, as a safety measure the Inspector recommends that the hot water pipes be bonded also.

Gas Bonding

Bonding Present: Not Visible

The grounding electrode conductor was missing or not found at the gas piping. Have the entire grounding and bonding system checked to verify proper installation. This is an important safety system that ensures reliable discharge of fault current on metal components. We check for bonding at the metal piping where it enters the house, this is usually where the bonding connection is present. It is possible there is a connection elsewhere on the system, but it was not located.

Electrical Distribution and Fixtures

Branch Wiring Circuits

Branch Wiring Method: Non-Metallic Sheathed Cable

Branch Wiring Material Type: Copper - Solid

Lighting, Switches and Receptacles

Inspection Method: Tested All Accessible

Receptacle Types: Three Wire Receptacles

Interior GFCI Protection : Yes, Partial in Areas

Exterior GFCI Protection: Yes - Partial

During the inspection we make every effort to test and inspect all accessible electric receptacles and switches. In general, the scope of testing is directly related to access; where personal belonging and furniture obstruct access to receptacles and fixtures, fewer of them can be reasonably tested during inspection. All defects found during inspection today will be listed in this report.

This house had switched electric receptacles at the Living and Family Rooms. These are instead of having a switched central light. All habitable rooms are required to have a switched light source and one way of providing this is a receptacle or several receptacles that can be turned on or off with a light switch. The recommended use for these receptacles is lights. Be careful about plugging computers or other devices into thee receptacles as the power can be disrupted with a switch.

Multiple inoperative lights were noted at the front of the house. This is likely due to bulbs being burned out or functional with a photo sensor, but could be due to an inoperative fixture, circuit or switch. Replace bulbs or repair lights as needed.

The house interior had ground fault circuit interrupter (GFCI) protection where needed except for the Kitchen and Garage which had partial. Although GFCI protection may not have been required at the time the home was built, for safety reasons, Baker Inspection Group recommends that electrical receptacles located in Basements, Cellars, Crawlspaces, Garages, and interior receptacles located within 6-feet of a plumbing fixture be provided with ground fault circuit interrupter (GFCI) protection in good working order to avoid potential electric shock or electrocution hazards. This can be achieved relatively inexpensively by: 1. Replacing an individual standard receptacle with a GFCI receptacle. 2. Replacing the electrical circuit receptacle located closest to the overcurrent protection device (usually a breaker) with a GFCI receptacle. 3. Replacing the breaker currently protecting the electrical circuit that contains the receptacles of concern with a GFCI breaker.

Partial ground fault circuit interrupter (GFCI) protection of the exterior electrical receptacles was provided at the time of inspection. Although GFCI protection may not have been required at the time the home was built, for safety reasons, Baker Inspection Group recommends that electrical receptacles located in Basements, Crawlspaces, Garages, the home exterior, and interior receptacles located within 6 feet of a plumbing fixture be provided with ground fault circuit interrupter (GFCI) protection in good working order to avoid potential electric shock or electrocution hazards. This can be achieved relatively inexpensively by: 1. Replacing an individual standard receptacle with a GFCI receptacle. 2. Replacing the electrical circuit receptacle located closest to the overcurrent protection device (usually a breaker) with a GFCI receptacle. 3. Replacing the breaker currently protecting the electrical circuit that contains the receptacles of concern with a GFCI breaker.

Ceiling Fans

Ceiling Fans: Present and Tested

The ceiling fans were tested and functional during the inspection.

Low Voltage Wiring

Current regulations require an “Inter-System Bonding Terminal” to be installed as a place for the low voltage utilities to run their ground wires to. It will be attached to a #6 minimum copper ground wire run to the location from the service equipment. Such a terminal was found during inspection.

Interior

Ceilings, Walls and Trim

Wall and Ceiling Materials: Sheetrock

Cracks were noted in the ceiling and walls at the Main Bedroom and Family Room. These were straight line cracks and no other indications were found to indicate settlement. Cracking lines like these can be due to routine settlement or moderate seasonal expansion and contraction of the structure. Cracks like these can also be related to workmanship and nailing of framing and sheetrock or deflection from the framing. The seasonal types of cracking can be most problematic as they will tend to re-open after repair. Repair and paint cracks as needed and monitor.

Patching was visible on the walls at the rooms throughout the house. Recommend repairs as needed.

Windows

Inspection Method: Tested All Accessible

During the inspection we inspected the headers and sills around all windows where accessible. No water stains, or signs of leakage were found. It is always good practice to monitor any exposed windows, especially those with South and West exposures to check for leaks during heavy wind-driven rains.

Several panes of glass had a cloudy appearance which could indicate a lost or failed seal at the right side and rear of the house. Recommend having the window glass further evaluated as needed. Replace all glazing with lost seals as needed. A lost seal is a common term for when there is permanent cloudiness between the panes of glass or between the "insulated glass units," IGU's. This is a cosmetic defect that does not impact the short term performance of the window.

The window glass did not comply with modern safety standards where safety glass is recommended in specific locations such as beside doors. Updating this glazing to comply with modern safety glass standards is recommended; we did not find a safety glass label on the panes that were checked. All tempered and safety glass should be labeled. Recommend further evaluation and repairs as needed to update for improved safety.

Doors

Inspection Method: Tested All Accessible

Smoke and Carbon Monoxide Alarms

Smoke Alarms: Present, Missing Several

Smoke Alarms Noted: Left Hallway Only

Carbon Monoxide Alarms: Present, Not Enough

Carbon Monoxide Alarms Noted: Left Hallway Only

Smoke alarms are not tested as part of a general home inspection. Recommend that all Smoke alarms be checked to confirm that they don't need battery replacement.

For reliability, Fire Marshals recommended updating Smoke alarms every 10 years and changing batteries bi-annually. The latest data indicate that we should be using photoelectric technology in our Smoke alarms for improved fire detection and to reduce problems with false alarms which can lead to disabling of this important safety system. Unfortunately, the alarms have to be removed to determine if they are photo-electric or ionization types. It is surprisingly complex to accurately test a Smoke alarm system and determine the reliability, age, and type of sensor technology used, especially as many houses can have half a dozen or more alarms throughout the house. A complete evaluation of Smoke alarms is beyond the scope of this inspection. For optimal fire safety, recommend taking control of these important safety devices and learning about how to service and maintain your Smoke alarm system to keep the building occupants safe.

Carbon Monoxide alarms were found and noted during inspection. Be sure to check these regularly. The standard is one per floor and one outside all sleeping areas.

The installation of a Carbon Monoxide alarm is recommended for all houses that have fuel burning appliances such as gas or oil furnaces, gas water heaters, gas ovens and cook-tops, gas fireplaces and wood stoves. The location should be: at least one alarm outside of all sleeping areas and one on each floor of the house. Best practices are to have these alarms hardwired with a battery back-up, though requirements are for the installation to meet manufacturer's specifications. Carbon Monoxide is a colorless, odorless gas that can cause sickness, nausea and even death. Carbon Monoxide alarms have a useful service life of roughly 6 years, so changing them more frequently than Smoke alarms is recommended.

Several Smoke alarms were noted to be missing. Replace the missing Smoke alarms in the house so that there is an operating Smoke alarm in every Bedroom and on every floor and one outside of all sleeping areas. No Smoke alarms were noted at the Bedrooms and right area.

Carbon Monoxide alarms were found and noted during inspection, but there did not appear to be enough Carbon Monoxide alarms. Be sure to check the Carbon Monoxide alarms regularly with the test button to ensure they are operational. The standard is one Carbon Monoxide alarm per floor and one outside all sleeping areas. I only found one in the left Hallway.

Kitchen

Countertops and Cabinets

This is a great document from the Natural Stone Institute that covers maintenance and installation recommendations for slab surface stone countertops.

Faucets, Sinks and Traps

Sink Functional: Tested

Range, Cooktop and Oven

Range, Cooktop and Oven: Electric Range

Manufacturer: Samsung

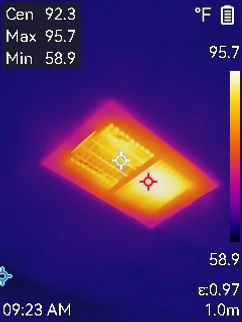

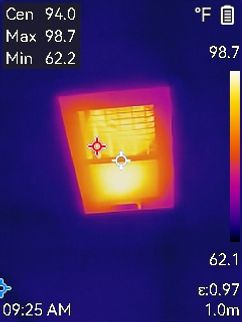

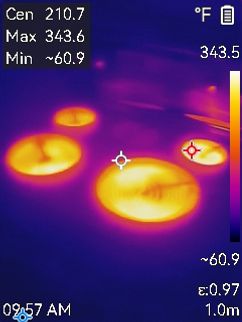

Thermal images show the range was tested and working during the inspection.

Microwave, Range Hood, Ventilation System

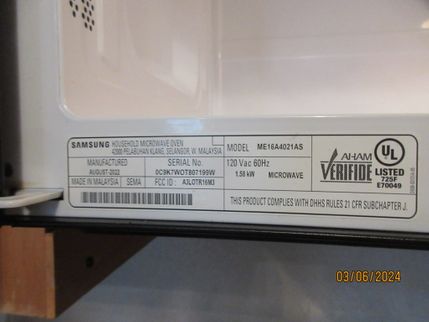

Type: Microwave Functional

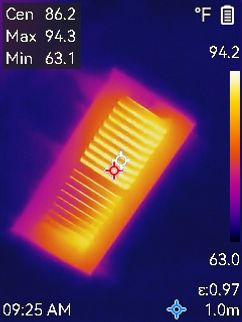

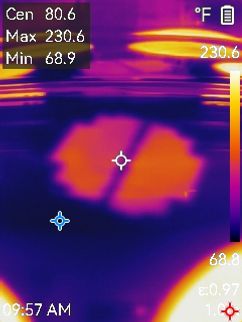

Thermal Images Testing Procedure Notes: Thermal Images - Microwave

Manufacturer: Samsung

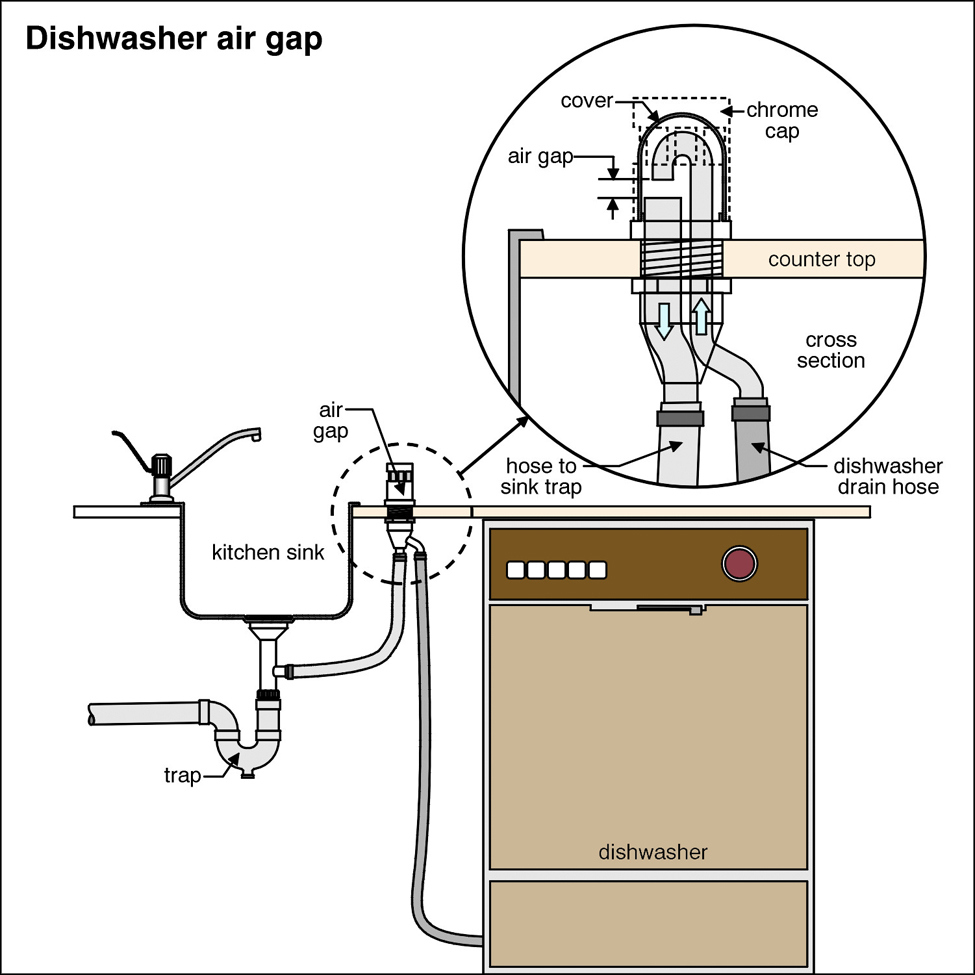

Dishwasher

Dishwasher: Not Operated (Recently Ran)

Dishwasher Air Gap: Present

Manufacturer: Whirlpool

Garbage Disposal

Garbage Disposal: Operated

Manufacturer: InSinkErator

Bathrooms

General Bathroom

During the inspection, I operated all the plumbing fixtures in the Bathrooms. I tapped for loose tiles and finishes in shower and tub enclosures. I do not test bathtub overflow drains as this risks damaging finishes around the tub. Monitor tubs while filling and avoid pushing water into the overflow. Even well-installed overflow drains can leak as the gaskets that seal the overflow will dry out over time and may no longer provide a watertight seal. I also do not perform shower pan testing, this is performed by blocking the drain and filling the shower pan with water and allowing it to sit for a determined amount of time. Monitor plumbing after moving into a new house as testing during inspection presents less stress on plumbing than daily use. Please note that vacant houses present additional risk as it can be difficult to distinguish how the plumbing system will respond to daily use. Any defects uncovered during inspection are listed in this report.

Counters, Cabinets and Sink Components

Sinks Functional: Tested

Showers and Bathtubs

Bathtub / Shower Functional: Tested

Toilets

Toilet Functional: Tested

The loose toilet in the Main Bathroom needs to be reset and the wax ring and flange should be replaced to prevent hidden plumbing leaks. This is a simple job unless the bolts that fasten the toilet also require repair. Sometimes, loose toilets can even be shimmed for a tight and proper seal and sometimes simply caulking can help prevent the toilet from rocking and twisting.

Ventilation Method

Type: Bath Fans Multiple

The Bathroom fans were operated today and they appeared to be working as intended.

Laundry Area

Clothes Dryer and Connections

Clothes Dryer: Not Tested

Power Source: Electric 240-Volt

Dryer 240-Volt Electrical Receptacle: 3-Prong Older

Dryer Gas Supply: None Visible

Dryer Venting: Behind Dryer (Foil / Mylar Duct), Ducted to Exterior

The electric receptacle to the clothes dryer was a three-prong or three-wire system. This is an older configuration. Modern electric dryers circuits require a four-wire system. These older three-wire circuits are still allowed, but be sure that you have a three prong outlet so the cord can be swapped out and the appliance appropriately bonded.

Foil or Mylar transition duct was noted in use to connect the clothes dryer to the rigid vent. This product is generally UL listed for use with a clothes dryer, however, most clothes dryer manufacturers do not recommend it as it has proven to be unreliable and a potential fire hazard. A corrugated metal flex duct is recommended. Repair as needed.

The clothes dryer exhaust duct should be cleaned for improved safety. This is important regular maintenance to eliminate a potential fire hazard.

Ventilation Method

Type: Garage Location - None Noted