Introduction, Scope, Definitions & Compliance Statement

Introduction: The following numbered and attached pages are your property inspection report. The report includes video, pictures, information and recommendations. This inspection was performed in accordance with the current Standards of Practice and Code of Ethics (Spanish Estándares de la Práctica and Código de ética) of InterNACHI (International Association of Certified Home Inspectors) and the Code of Ethics of the CMI (Certified Master Inspectors®). The Standards contain certain and very important limitations, expectations and exclusions to the inspection. A copy is available prior to, during and after the inspection and it is part of the report.

What Really Matters in a Home Inspection: The process can be stressful. A property inspection is supposed to give you reassurance but often has the opposite effect. You will be asked to absorb a lot of information in a short time. This often includes a written report, checklist, photographs, environmental reports and what the Inspector himself says during the inspection. All this combined with the Seller's disclosure and what you notice yourself makes the experience even more overwhelming. What should you do? Relax. Most of your inspection will be maintenance recommendations, life expectancies and minor imperfections. These are nice to know about. However, the issues that really matter will fall into four categories: 1. Major defects. An example of this would be a significant structural failure. 2. Things that may lead to major defects. A small water leak coming from a piece of roof flashing, for example. 3. Things that may hinder your ability to finance, legally occupy or insure the property. Structural damage caused by WDO infestation, for example. 4. Safety hazards. Such as a lack of AFCI/GFCI outlet protection. Anything in these categories should be corrected. Often a serious problem can be corrected inexpensively to protect both life and property (especially in categories 2 and 4). Most Sellers are honest and are often surprised to learn of defects uncovered during an inspection. Realize that Sellers are under no obligation to repair everything mentioned in the report. No home is perfect.

Use of Photos and Video: Your report includes many photographs which help to clarify where the Inspector went, what was looked at, and the condition of a system or component at the time of the inspection. Some of the pictures may be of deficiencies or problem areas, these are to help you better understand what is documented in this report and may allow you see areas or items that you normally would not see. A pictured issue does not necessarily mean that the issue was limited to that area only but may be a representation of a condition that is in multiple places. Not all areas of deficiencies or conditions will be supported with photos.

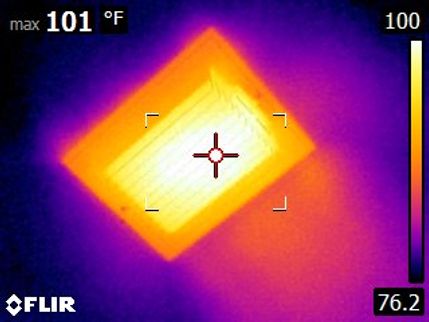

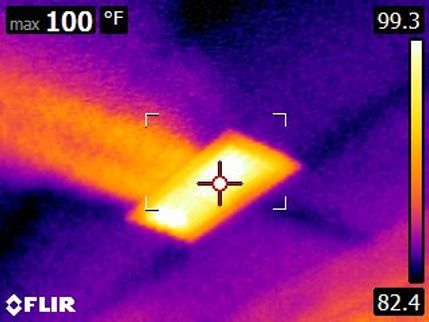

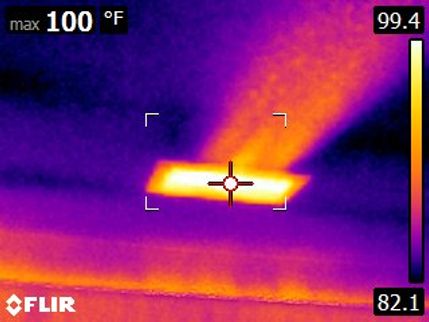

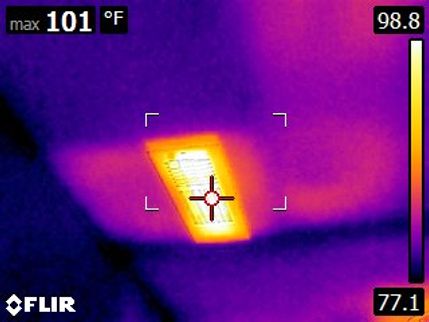

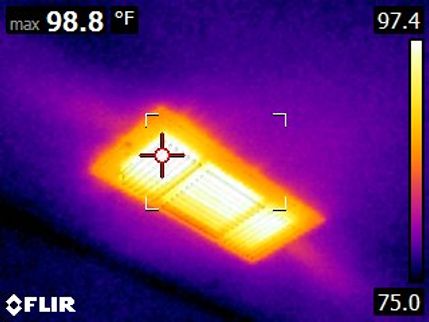

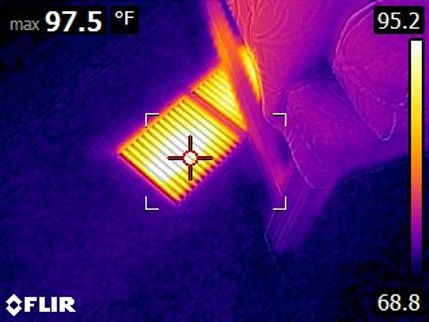

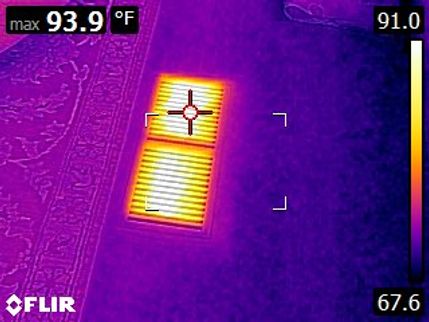

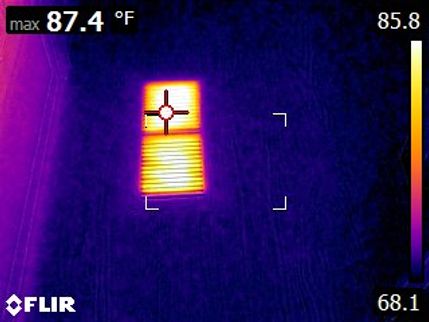

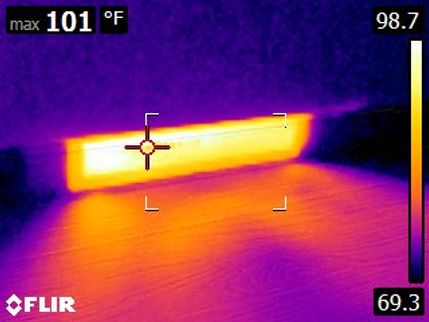

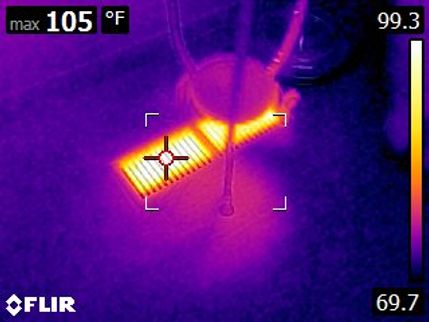

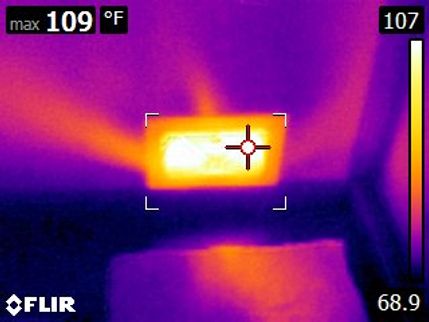

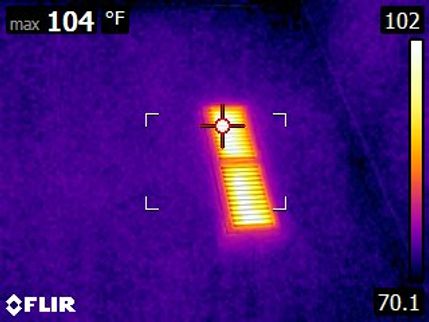

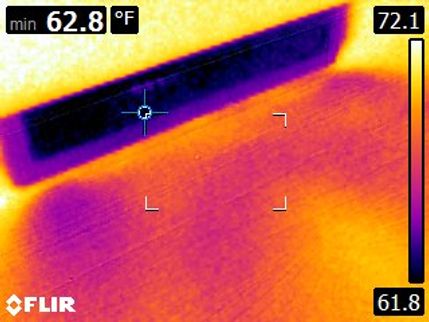

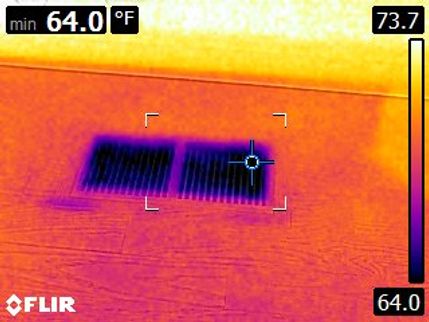

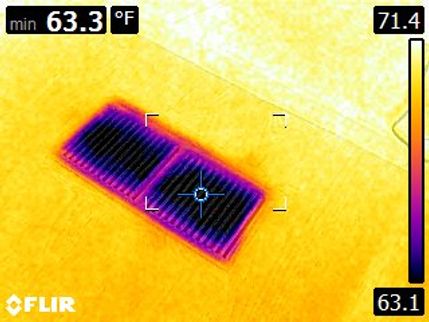

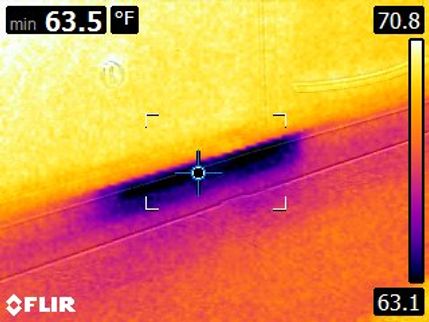

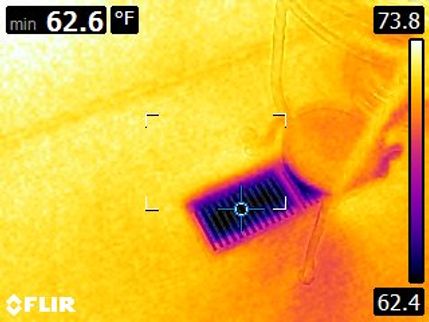

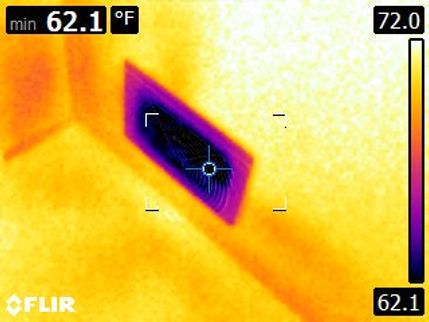

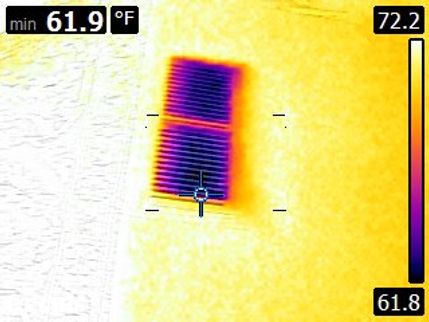

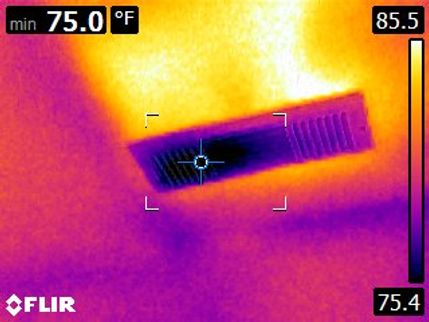

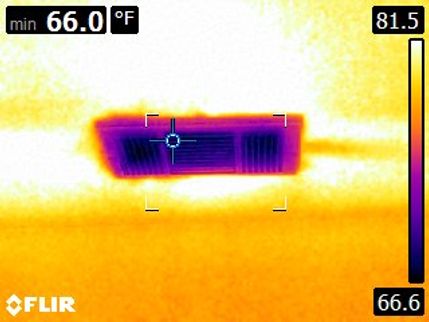

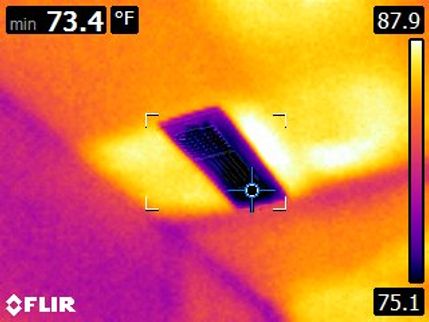

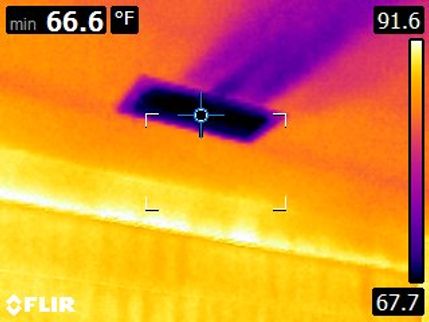

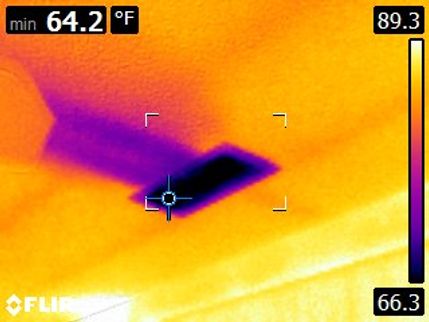

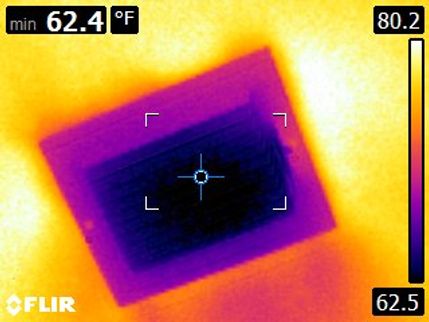

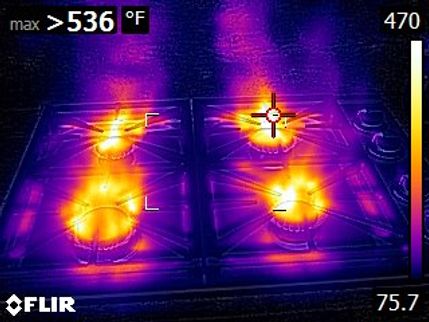

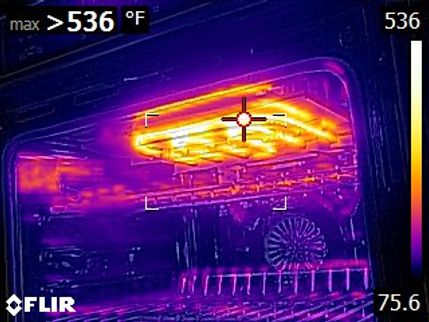

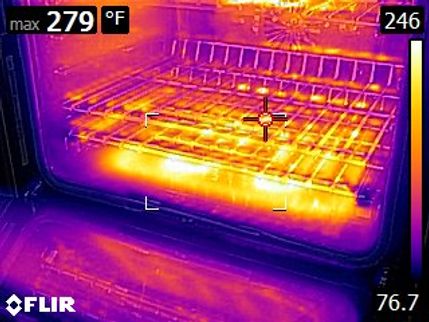

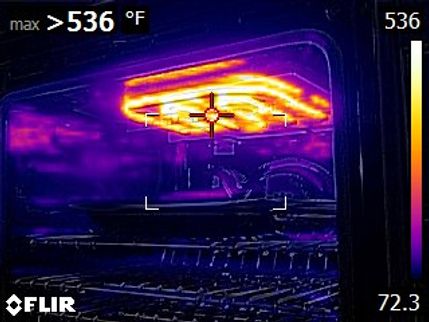

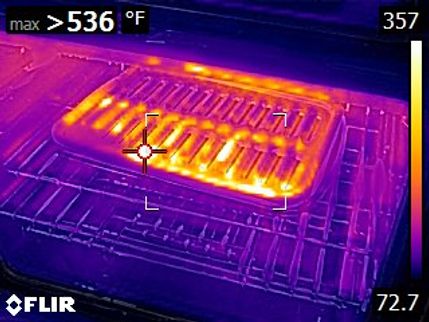

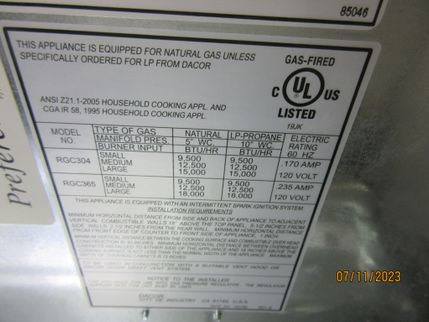

Thermal Imaging: An infrared camera may be used for specific areas or visual problems and should not be viewed as a full thermal scan of the entire home. Temperature readings displayed on thermal images in this report are included as a courtesy and should not be wholly relied upon as a home inspection is qualitative, not quantitative. These values can vary +/- 4% or more of displayed readings, and these values will display surface temperatures when air temperature readings would actually need to be conducted on some items which is beyond the scope of a property inspection.

Scope: A property inspection is intended to assist in evaluating the overall condition of the dwelling. The inspection is based on observation of the visible, readily accessible, and apparent condition of the structure and its components on this day. The results of this inspection are not intended to make any representation regarding the presence or absence of concealed defects that are not reasonably ascertainable or readily accessible in a competently performed inspection.

No Warranty, Guarantee or Insurance by Baker Inspection Group is expressed or implied. This report does not include inspection for Wood Destroying Organisms, Asbestos, Mold or Lead. A representative sampling of the building components is viewed in areas that are accessible at the time of the inspection. No destructive testing or dismantling of components is performed. Not all defects will be identified during this inspection. Unexpected repairs should be anticipated. The person conducting your inspection is not a Structural Engineer or other professional whose license authorizes the rendering of an opinion as to the structural integrity of a building or its other component parts.

This report has been produced in accordance with the AGREEMENT and is subject to the terms and conditions agreed upon therein. The report was produced exclusively for our CLIENT. Not to be used or interpreted by anyone other than our CLIENT or REPRESENTATIVE. If you’re reading this report but did not hire us, Baker Inspection Group, to perform the original inspection, please note that it is likely that conditions related to the home have probably changed, even if the report is fairly recent. Just as you cannot rely on an outdated weather report, you should not rely on an outdated inspection report. Minor problems noted may have become worse, recent events may have created new issues and items may even have been corrected and improved. Don’t rely on old information about one of the biggest purchases you’ll ever make. Remember that the cost of a property inspection is insignificant compared to the value of the property. Protect your family and your investment, and please call us directly at (209) 522-5320 to discuss the report you’re reading for this property so that we can arrange for a re-inspection. Thank You!

Getting the Information to You

This report is designed to deliver important and technical information in a way that is easy for anyone to access and understand. If you are in a hurry, you can take a quick look at our "Summary Page” and quickly get critical information for important decision making. However, we strongly recommend that you take the time to read the full Report, which includes digital photographs, captions, diagrams, descriptions, videos and hot links to additional information.

The best way to get the layers of information that are presented in this report is to read your report online (the HTML version), which will allow you to expand your learning about your house. You will notice some words or series of words highlighted in blue and underlined – clicking on these will provide you with a link to additional information. The HTML version of this report also contains streaming videos. Short video clips often contain important information and critical context and sounds that can be difficult to capture in words and still pictures.

For the most reliable viewing experience, I recommend viewing the report on as large a screen as practical, as much detail can be lost on small devices like smart phones. For similar reasons, reports should only be printed in color to retain as much detail as possible and minimize misinterpretation of photographs.

This report can also be printed on paper or to a PDF document.

Chapters and Sections: This report is divided into chapters that parcel the home into logical inspection components. Each chapter is broken into sections that relate to a specific system or component of the home. You can navigate between chapters with the click of a button on the left side margin.

Most sections will contain some descriptive information done in black font. Observation narrative, done in colored boxes, will be included if a system or component is found to be significantly deficient in some way or if we wish to provide helpful additional information about the system or the scope of our inspection. If a system or component of the home was deemed to be in satisfactory or serviceable condition, there may be no narrative observation comments in that section and it may simply say “tested,” or “inspected.”

Observation Labels: All narrative observations are colored, numbered and labeled to help you find, refer to, and understand the severity of the observation. Observation colors and labels used in this report are:

- Description:Detailed description of various aspects of the property noted during the inspection.

- Note:Refers to aside information and / or any comments elaborating on descriptions of systems in the home of a more informational nature.

- Due Diligence:Observations that may require further investigation about a systems condition prior to closing and / or if it exceeds our Standards of Practice for a home inspection.

- Major Concern:Repair items that may cost significant money to correct now or in the near future, or items that require immediate attention to prevent additional damage or eliminate safety hazards. Baker Inspection Group always recommends Qualified Contractors to perform all repair work recommended in the inspection report.

- Repair/Replace:Repair and maintenance items noted during inspection that should be addressed in the immediate future. Typically they are concerns that may be expensive to correct or will become expensive corrections if nothing is done, or the item may just fail totally. Baker Inspection Group always recommends Qualified Contractors to perform all repair work recommended in the inspection report.

- Improvement:Observations that are not necessarily defects, but which could be improved for safety, efficiency, or reliability reasons.

- Recommended Maintenance:These are repair items that should be considered "routine home ownership items," such as servicing the furnace, cleaning the gutters or changing the air filters in the furnace.

- Monitor:Items that should be watched, with guidance as to the frequency, to see if corrections may be needed in the future.

- Pool Repair:Repair items that require correction now or in the near future, or items that require immediate attention to prevent additional damage or eliminate safety hazards.

- Pool Improvement and Maintenance:

These are repair items that should be considered "routine pool ownership" items. - Energy Efficiency & IAQ:Denotes observations that are needed to make the home more energy efficient as well as to bring the home up to modern insulation standards. This category typically includes windows and insulation. Other items, such as lighting and appliances, are not inspected for their energy status. It also covers issues related to Indoor Air Quality which is often related to efficiency.

Report Summary: The Report Summary is designed as a bulleted overview of all the observations noted during the inspection. This helpful overview is not a substitution for reading the entire inspection report. The entire report must be read to get a complete understanding of this inspection report as the Report Summary does not include photographs or photo captions.

California Home Inspector Compliance Statement: I represent that I am a full member in good standing of the International Association of Certified Home Inspectors (InterNACHI) Member #10052303.

CLICK HERE for a link to the California Business and Professions Code Section 7195-7199 which pertains to Home Inspectors.

Scot Baker, Certified Master Inspector®, Owner of Baker Inspection Group

Report Summary

Due Diligence Items

- SEF-2 Site and Exterior Features:

The home is situated on a generally flat lot. This could lead to seasonal drainage problems. Recommend inquiring with the sellers and or building department for any history of water problems on the site.

- RCG-1 Roofing, Chimney and Gutters:

The roofing material on this building appears to be a torch down or modified bitumen membrane. The service life of these roofs can vary depending on the quality of the membrane and the quality of the installation, including how well the roof is sloped to drain. Torch down roofs often have roughly 10 years of reliable service life beyond which regular repairs are often needed. With on-going maintenance these roofs can be made to last as long as 25 years or more. The installation appears neat and professional. Inquire with the seller about any warranty information for this roof.

- SF-1 Structure and Foundation:

The floor sheathing staining visible in the Crawlspace appeared to have been caused by the leakage of plumbing fixtures. You should ask the seller about this condition.

- P-1 Plumbing:

The main water pipe from the street to the house appeared to be done with old galvanized steel pipe. This pipe could require updating at any time. Evaluation of this pipe is beyond the scope of this inspection as the pipe is not visible. Keep this pipe in mind for updating should you do any other digging in the front of the home between the house and the water meter.

- P-8 Plumbing:

A video camera sewer scope is recommended. An evaluation of the sewer line below the ground is beyond the scope of this inspection. A sewer scope is always recommended to further evaluate the sewer line and the below ground connections between the house and the municipal sewer line or septic tank. Sewer scopes are done using video cameras and can reveal the materials, condition and reliability of the sewer line.

- P1-1 Plumbing (additional):

An exterior irrigation system was noted. Sprinkler systems are beyond the scope of this inspection. Irrigation systems require annual attention / repair / servicing after every winter. When testing the system, be sure sprinkler heads are adjusted so the system is not watering the side of the house. Recommend further evaluation as needed.

- FDS-1 Fuel Distribution Systems:

The gas piping in this house includes corrugated stainless steel tubing (CSST). This piping can be recognized by its yellow coating. CSST is a flexible, corrugated stainless steel tubing which has been the subject of a lawsuit which has now been settled. Manufacturers of yellow corrugated stainless steel tubing believe that yellow corrugated stainless steel tubing is safer if properly bonded and grounded as required by the manufacturer’s installation instructions. Proper bonding and grounding of this product can only be determined by a Qualified Electrical Contractor.

Commons names are GASTITE, WARDFLEX, TRACPIPE, COUNTERSTRIKE or PARFLEX. Gas pipes in this home consisted of CSST. Installations of concern are those pipes installed after September 5, 2006. To see if you qualify to benefit from this settlement, you may contact the Settlement Administrator at the following address: CSST Settlement Administrator PO Box 4349 Portland, OR 97208-4349. You may also call the Toll Free Settlement Information Line at: 1 (800) 420-2916. Learn more about the class action lawsuit CLICK HERE

- EDF-2 Electrical Distribution and Fixtures:

The Garage had an electric vehicle charging station installed. Evaluation of these is beyond the scope of this inspection. Inquire with the seller for any additional information about this installation.

- EDF-9 Electrical Distribution and Fixtures:

This house had a smart doorbell installed. These are often tied into an internet connection and may include a camera and other features. Recommend inquiring with the sellers for any needed information about using this system and changing access and passwords that may be needed to control this house feature.

- EDF-10 Electrical Distribution and Fixtures:

Several transformers noted on the exterior of the house, likely for a low voltage lighting system. Inquire with the seller for any additional information about this system. Low voltage lighting systems are beyond the scope of this inspection and they do require periodic maintenance to keep them operating well.

- EDF-11 Electrical Distribution and Fixtures:

We were not able to determine if the low voltage illuminated house address sign was functional at the time of the inspection.

- EDF-12 Electrical Distribution and Fixtures:

A "smart box" low-voltage wiring panel was noted in the Hallway closet. This is designed to house the low voltage CATV and phone wires. Homeowners will often use these to create in house networks for internet and communication devices and may locate internet routers here. Inspection of low voltage wiring and communication wiring is beyond the scope of this inspection. Inquire with the seller for any additional information.

- I-1 Interior:

Several ceilings contained popcorn texture. This product may contain Asbestos as many of these products contained Asbestos prior to 1978. After 1978, remaining stocks of material containing Asbestos were sold and as the product was slowly phased out. Asbestos testing is beyond the scope of this inspection. The health risks posed by this substance are minimal unless the texture becomes friable or airborne. If you wish to remove the popcorn texture or have remodel plans that could involve cutting or removing this sheetrock, Asbestos testing is recommended. Consult with an Qualified Contractor for more information on Asbestos testing.

- I-4 Interior:

Water stains were noted on the ceiling at the 2nd Bedroom closet. Inquire with the seller for any history of prior leakage to get a better sense if repairs may be needed to prevent another leak. Many water leaks are intermittent or related to specific weather conditions or occupant behavior; it is impossible for us to distinguish these conditions during a one-time inspection or to know if repairs could be needed to prevent future leaks. Repair damaged finishes and paint as needed for a proper cosmetic appearance and implement additional repairs as needed to prevent future leaks.

- This conditioned appeared old at the time of inspection. Repairs are needed for cosmetic reasons.

- I-9 Interior:

The Inspector was not able to release the Master Bedroom window locking hardware and open the windows. Confirm with the seller prior to closing on the operation of the windows.

- I-10 Interior:

Window Blind Cord Safety Young children can strangle in the cord and bead chain loops. They can also wrap cords around their necks and strangle. Always ensure that the inner cord stop devices are within 3-inches of the headrail when the blind is in the fully lowered position. Read the adjustment instructions for your blinds. Always keep the cords and bead chains out of children's reach. Move cribs, playpens, and other furniture away from cords and bead chains. Children can climb furniture to get to cords. Do not tie cords together. Make sure cords do not twist together and create a loop.

- I-16 Interior:

A strong air freshener odor was noted inside the house during the inspection. These can be used to conceal odors such as mustiness or pet odors which could indicate a latent or concealed problem.

- I-17 Interior:

The central vacuum system was not tested during inspection. These systems are beyond the scope of this inspection. Recommend inquiring with the seller for any additional information:

- Is this system functioning

- Are there recommended maintenance or servicing tips for keeping the system clean and functioning

- Some of these system have a filter that requires cleaning and others require replacing a bag.

- LA-3 Laundry Area:

A laundry chute was visible in the Laundry area.

Major Concern Items

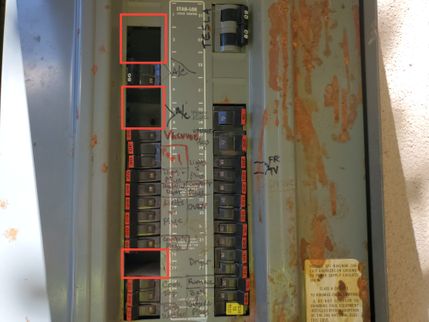

- ES-2 Electrical System:

A Federal Pacific Electric Stab Lok brand electric panel was noted. This is an obsolete brand of panel with a reputation for failing and malfunctioning breakers. Some Electricians and many home owners will claim that the panel has, "worked fine to date," but this is anecdotal evidence. Stab Lok electric panels are at greater risk of electrical fire and statistically less safe than any new electric panel. Recommend additional inspection of this electrical service by a Qualified Electrical Contractor; updating this panel is recommended for improved reliability and safety.

Repair or Replacement Items

- SEF-7 Site and Exterior Features:

Heaving was noted in the concrete driveway. Recommend further investigation and repair as needed to eliminate all trip hazards and ensure a reliable walking and driving surface.

- SEF-8 Site and Exterior Features:

Cracks were noted in driveway and walkway flatwork. Regular sealing of small to moderate cracks with a quality exterior flexible sealant can minimize water penetration and prolong the life of the flatwork. Large cracks can present a more urgent need for repair, especially if the cracks lead to displacement and trip hazards.

- No immediate repair appears necessary, though water will continue to deteriorate the surface until the flatwork is repaired or replaced.

- SEF-10 Site and Exterior Features:

One or more wood posts supporting the patio cover/roof structure had wood deterioration visible at the time of the inspection. Recommend further evaluation and repairs as needed.

- ESWD-1 Exterior Siding, Windows and Doors:

The barge rafter at the right side of the house was deteriorated. Recommend further evaluation and repairs or replacement as needed.

- ESWD-5 Exterior Siding, Windows and Doors:

The exterior walls at the front of the house had areas of deteriorated wood siding that should be repaired or replaced to help prevent damage from moisture intrusion.

- ESWD-7 Exterior Siding, Windows and Doors:

The damage to the lower portions of wood siding at the front of the house appeared to be the result of inadequate clearance from grade. The standard recommended minimum clearance from grade is 6-inches. Recommend that all such areas repaired as needed to provide adequate clearance. Failure to provide adequate clearance will result in continuing decay of siding in these areas.

- ESWD-8 Exterior Siding, Windows and Doors:

The Garage door at the rear of the house was deteriorated. Recommend further evaluation and repairs as needed.

- ESWD-9 Exterior Siding, Windows and Doors:

The deadbolt for the exterior door was opened with a key rather than a thumb-toggle. Switch this deadbolt with a thumb-toggle deadbolt for improved safety and fire egress. This is required for the main egress door, but recommended for all doors for improved fire safety.

- RCG-3 Roofing, Chimney and Gutters:

The gutters exhibited moderate to severe corrosion at the front and rear of the house of the home and may need to be replaced soon. Recommend further evaluation and repairs as needed.

- RCG-8 Roofing, Chimney and Gutters:

The right chimney trim above the roofline was deteriorated. Recommend repairs as needed.

- P-2 Plumbing:

Water distribution pipes visible at the Garage were corroded. Monitor the pipes on a regular basis to prevent future damage from active leaking. To avoid problems in the future you may wish to have the corroded sections replaced.

- P-4 Plumbing:

The leaky hose bib at the rear of the house requires repair or replacement - it leaked from the hose bib handle when water was turned on and under pressure. This often requires tightening the packing around the handle stem.

- P-5 Plumbing:

This was a very old water heater. The average life of these water heaters is 8-20 years. The service life of a water heater will depend on a variety of factors such as water quality and regular scheduled maintenance such as flushing the tank and replacing sacrificial anodes. Recommend further evaluation as needed by a Qualified Contractor.

- P-6 Plumbing:

The bottom water heater burn chamber exhibited signs of corrosion that is typically the product of corrosion of the water tank. This indicates that the water tank has suffered some corrosion. Recommend further evaluation as needed.

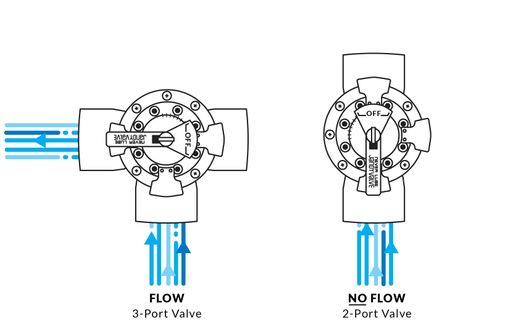

- P-9 Plumbing:

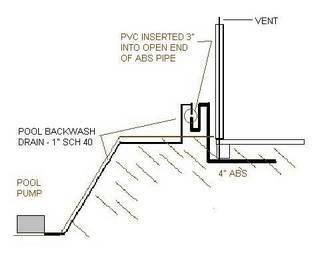

The pool drain line was directly connected to the house plumbing drain system. This is an improper condition, because the drain line had no air gap, this condition may allow sewer gas or bacteria to enter the pool filtration system. Recommend correction of this improper condition as needed.

- P-10 Plumbing:

The supports for the plastic drain or vent pipe visible at the Crawlspace were damaged. The maximum support spacing recommended by generally-accepted modern plumbing standards is 4-feet. Recommend repairs as needed.

- HCV-4 Heating, Cooling and Ventilation:

The upstairs Hallway Bathroom exhaust fan was ducting into the Attic. This is non-standard and could contribute to condensation and mold problems in the Attic. Repair all fans to be ducting to the exterior of the home. Best practices are to vent through the roof.

- ES-1 Electrical System:

Openings were noted in the electric panel housing that have not been sealed. This is unsafe as it does not adequately protect the energized area of the electric panel. Cover all open knock-outs with listed covers.

- ES-3 Electrical System:

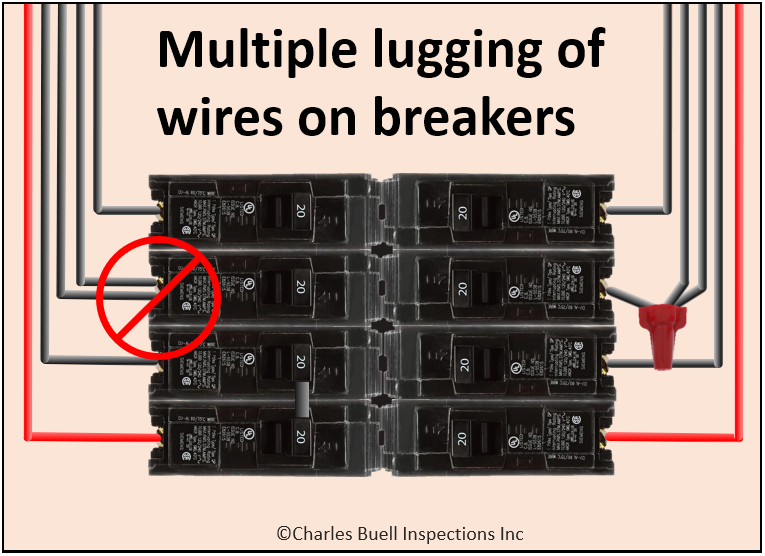

Recommend a Qualified Electrical Contractor correct the double-tapped or double-lugged circuits in the electric panel; this is when two conductors share the same breaker. Most breaker circuit breaker manufacturers do not allow two conductors / breaker. The breakers here do not look rated for two conductors. This condition risks poorly protected circuits and is a possible fire hazard. Please note that a pigtail is often used as a simple repair for this condition - see the attached illustration.

- ES-4 Electrical System:

The electric panel was corroded and requires further evaluation by to ensure safe and reliable performance. Corrosion inside the panel is an indication that the panel is having moisture problems and this could result in poor and unsafe wiring connections. Recommend further evaluation and repairs as needed.

- ES-5 Electrical System:

The service panel had damaged or missing cover hardware that should be repaired or replaced as needed.

- ES-7 Electrical System:

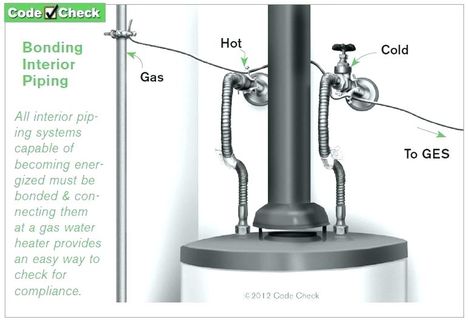

The grounding electrode conductor was not connected to the clamp at the gas piping. Have the entire grounding and bonding system checked to verify proper installation. This is an important safety system that ensures reliable discharge of fault current on metal components. We check for bonding at the metal piping where it enters the house, this is usually where the bonding connection is present. It is possible there is a connection elsewhere on the system, but it was not located.

- EDF-1 Electrical Distribution and Fixtures:

At the time of the inspection, cover plates were missing at the upstairs Attic area. This condition left energized electrical components exposed to touch. Recommend that listed cover plates be installed.

- EDF-3 Electrical Distribution and Fixtures:

Inoperative lights were noted at the front of the house and Garage If a new bulb does not correct the problem, recommend further evaluation and repairs as needed.

- EDF-5 Electrical Distribution and Fixtures:

Mystery switches were found at the rooms throughout the house. Recommend further evaluation and repairs as needed.

- EDF-6 Electrical Distribution and Fixtures:

Electric receptacles at the rear of the house were noted to be worn so that plugs make loose connections - this is often referred to as worn friction grabs. This is common with older receptacles that have been well-used and the plastic is worn down. Replacement of these is recommended so that plug-in appliances make tight connections to plugs and cords do not hang loose. Loose connections at receptacles can lead to arcing, shorting and fires, a safety hazard.

- EDF-7 Electrical Distribution and Fixtures:

The GFCI protected receptacle in the Kitchen did not respond to testing and may be defective, it did not trip when tested. Have this receptacle repaired or replaced as needed.

- I-5 Interior:

The large picture windows at the front of the house should be tempered or laminated glass for safety reasons. Large picture windows are required to be tempered or safety glass when the bottom edge is less than 18-inches from the ground, when the glass is greater than 9 sq. ft. and top edge is 36-inches or more above the ground. These are considered a potential, "walk-through hazard." Updating this glazing is recommended for improved safety. During inspection we looked for a tempered or laminated glass etching in the glass and none was found.

- I-6 Interior:

The window glass did not comply with modern safety standards where safety glass is recommended in specific locations such as beside doors. Updating this glazing to comply with modern safety glass standards is recommended; we did not find a safety glass label on the panes that were checked. All tempered and safety glass should be labeled. Recommend further evaluation and repairs as needed to update for improved safety.

- I-7 Interior:

Several panes of glass had a cloudy appearance which could indicate a lost or failed seal at the upstairs Office and right rooms. Recommend having the window glass further evaluated as needed. Replace all glazing with lost seals as needed. A lost seal is a common term for when there is permanent cloudiness between the panes of glass or between the "insulated glass units," IGU's. This is a cosmetic defect that does not impact the short term performance of the window.

- I-8 Interior:

The secondary window lock hardware at the upstairs was missing. Recommend replacement as needed.

- I-13 Interior:

Several cracked tiles were noted in the floor at the Main Bathroom closet. Have these cracked tiles replaced by a tile specialist. Please note that cracked tile can be an indication of poor tile preparation and additional cracking could continue.

- I-14 Interior:

Several Smoke alarms were noted to be missing. Repair or replace the missing Smoke alarms in the house so that there is an operating Smoke alarm in every Bedroom and on every floor and one outside of all sleeping areas. I did not find a smoke alarm at the downstairs main area.

- I-15 Interior:

Carbon Monoxide alarms were found and noted during inspection, but the downstairs unit was not located adequately. The default safety standard is one per floor and one outside of all sleeping areas. Be sure to install and check these important safety devices regularly with the test button to ensure they are operational.

- B-2 Bathrooms:

The shower head in the upstairs Hallway Bathroom was leaking and requires repair. Leaky shower heads are common and not a significant concern. Repair as needed to prevent leakage at the shower head.

- B-3 Bathrooms:

The upstairs Hallway Bathroom bathtub stopper appeared to be broken, it would not stay in the open position. Repair or replace as needed.

- G-1 Garage:

An unprotected opening was found in the Garage wall finishes. This should be repaired to complete the fire separation between the house and the Garage. Large holes should be repaired with the proper sheetrock materials. Small holes and openings should be sealed with mud or high temperature of "fire stop" caulking. Openings with doors should employ listed fire-rated doors.

- G-6 Garage:

Recommend having this double overhead Garage door serviced and repaired as recommended. During visual inspection and testing, the door would not stay open correctly. This is an indication that the torsion springs require adjustment, repair or replacement. The overhead door should be able to stay open on its own.

Improvement Items

- SEF-3 Site and Exterior Features:

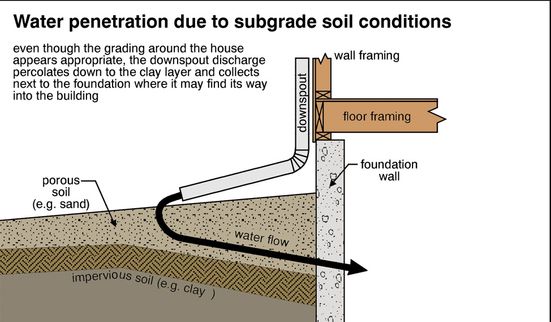

Downspouts were discharging adjacent to the foundation. This can cause foundation settlement or Crawlspace moisture problems. Make sure all downspouts discharge into a proper tight-line system that diverts water at least 5-feet away from the foundation.

- SEF-4 Site and Exterior Features:

A roof downspout is discharging onto the base of a wooden post. This will facilitate decay and settlement. Install an extension to divert water away from the base of this post.

- SEF-9 Site and Exterior Features:

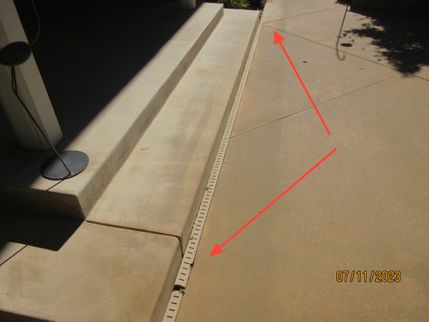

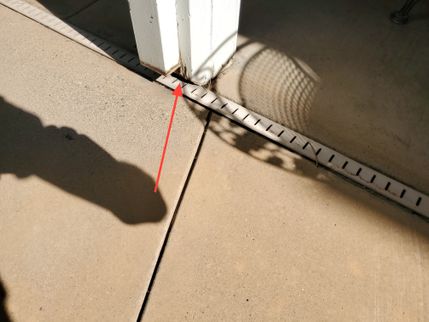

Recommend the removal of the rotted control joints in the concrete flatwork. This is a condition conducive to wood destroying organisms.

- RCG-4 Roofing, Chimney and Gutters:

The gutters were bent at the rear of the home at the time of the inspection. Recommend repairs as needed.

- RCG-5 Roofing, Chimney and Gutters:

Several of the downspouts on the upper gutter system are terminating onto the lower roof. This is industry standard practice but it will prematurely deteriorate the roofing shingles in these locations and it is not recommended by many shingle manufacturers. Recommend extending the downspouts into the lower gutters to better protect the roof.

- CC-1 Crawlspace and Cellar:

At the Crawlspace, a white, powdery substance was visible on the interior of the poured concrete foundation walls which is called “efflorescence". This condition is the result of moisture seeping through the foundation wall and indicates high moisture levels in soil near the foundation. Moisture in soil supporting the foundation can reduce its ability to support the weight of the structure above. The source of moisture should be identified and the condition corrected.

- CC-3 Crawlspace and Cellar:

No vapor barrier has been installed on the soils of this Crawlspace to contain the moisture in the ground. This is a conducive pest condition and can lead to high moisture conditions. Install a 6 mil. black plastic vapor barrier to cover all exposed earth.

- P-3 Plumbing:

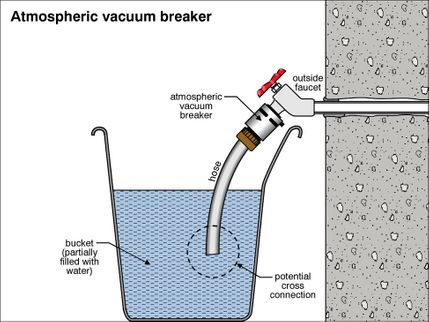

Older hose bibs were noted on this building and updating is recommended. Modern hose bibs are typically anti siphon style which can prevent water from your hoses backing into your water supply system. Consider installing anti siphon hose bibs. The following video shows a vacuum breaker. Click Here

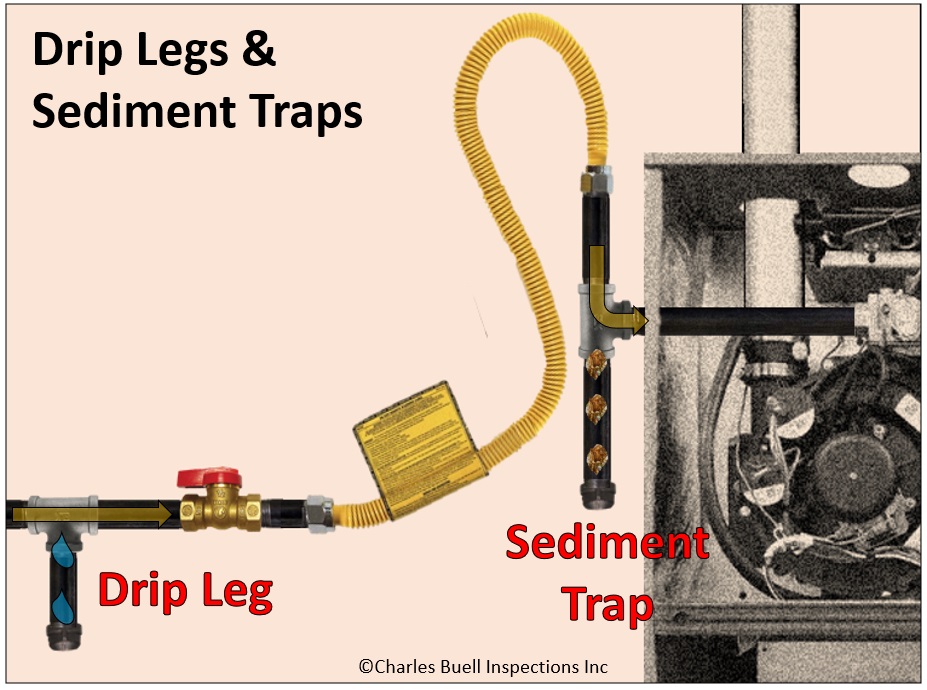

- FDS-2 Fuel Distribution Systems:

No sediment trap was found for the gas pipe at the gas water heater. Sediment traps are designed to prevent fouling of gas equipment by allowing sediment to fall out of the gas supply. Sediment traps are required at all automatically controlled gas appliances. Recommend further evaluation and repairs as needed.

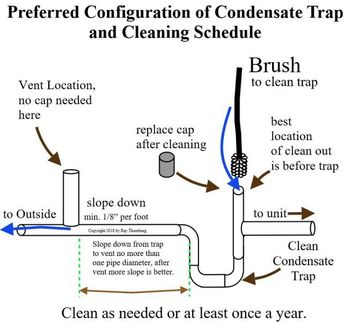

- HCV-1 Heating, Cooling and Ventilation:

The condensation line designed to properly dispose of condensate produced by the operation of the air-conditioning evaporator coils was improperly configured. Recommend repairs as needed.

The cooling system evaporator coil had no condensate overflow warning/shutoff device installed. If the condensate drainage system should fail, this condition could result in moisture damage to the home. Recommend that a proper condensate overflow/shutoff device be installed. Click here for information

- ES-6 Electrical System:

Metal cold water distribution pipes appeared to be properly bonded. Metal hot water pipes were not bonded. Electrical bonding of the water pipes helps to ensure that safe conditions exist if the pipes should somehow come into contact with electrical wiring and become energized. Bonding of water pipes is required in new homes by generally-accepted modern safety standards. Although it may not have been required at the time the home was originally constructed, as a safety measure the Inspector recommends that the water pipes be bonded.

- EDF-4 Electrical Distribution and Fixtures:

There were open bulb fixtures (missing globes) at the 2nd Bedroom closet. To prevent accidental damage to the bulb, recommend the installation of a proper globe or cover.

- EDF-8 Electrical Distribution and Fixtures:

The house interior had ground fault circuit interrupter (GFCI) protection. The Garage requires verification. Baker Inspection Group recommends that electrical receptacles located in Basements, Cellars, Crawlspaces, Garages, and interior receptacles located within 6-feet of a plumbing fixture be provided with ground fault circuit interrupter (GFCI) protection in good working order to avoid potential electric shock or electrocution hazards. This can be achieved relatively inexpensively by: 1. Replacing an individual standard receptacle with a GFCI receptacle. 2. Replacing the electrical circuit receptacle located closest to the overcurrent protection device (usually a breaker) with a GFCI receptacle. 3. Replacing the breaker currently protecting the electrical circuit that contains the receptacles of concern with a GFCI breaker.

- I-3 Interior:

Patching was visible on the ceiling at the Main Bedroom. Recommend repairs as needed.

- I-11 Interior:

The upstairs Bedrooms at this house had older / missing escape and rescue openings. Today, all bedrooms must have a second means of ingress and egress in case of emergency. This can be provided by a door but is typically provided by a window. Updating is recommended for improved safety, though updating is not a requirement. Unless there is a personal desire for these modern standards sooner, the logical time to improve this is during the next window replacement or updating.

Modern escape and rescue openings must comply with these basic guidelines:

- Minimum width of opening: 20-inches

- Minimum height of opening: 24-inches

- Minimum net clear opening at any grade floor level escape and rescue window: 5 sq. ft.

- Minimum net clear opening of other escape and rescue windows: 5.7 sq. ft.

- Maximum height of base of opening above interior side floor: 44-inches

- Windows should open easily without the use of keys or tools

And for window wells below grade:

- Minimum net clear area of 9 sq. ft.

- Minimum horizontal projection and width of 36-inches

- Wells with a vertical depth greater than 44-inches require a permanent ladder or steps usable with the window in the fully open position

- I-12 Interior:

Although it may have complied with standards that were generally accepted at the time of its original construction, the guard and handrail assembly at this staircase did not comply with generally-accepted current safety standards mandating that a stairway handrail or handrail assembly must: 1. provide a continuous, graspable handrail; 2. measure 1 1/4-inches to 2-inches across (if circular); 3. be 34 to 38-inches above the nosing of stair treads; 4. have baluster spacing which will not allow the passage of a 4 3/8-inch sphere; 5. be continuous for the full length of the flight of stairs; 6. return to the wall at the top and bottom or terminate at a newel post; 7. be a minimum of 1 1/2-inches from the wall; 8. have a graspable profile; and 9. not permit the passage of a 6-inch sphere at the triangle formed by the tread, riser and bottom rail of the handrail assembly.

- LA-2 Laundry Area:

No ventilation fan was found for the Laundry area, if the door is left open, the Bathroom next to the Laundry area has a ceiling fan. This is common in older homes and required in newer buildings. Installing a ventilation fan is recommended to help control indoor relative humidity. This fan can be run during operation of the Laundry and/or placed on a timer to come on automatically throughout the day using a timer.

- FW-2 Fireplaces and Woodstoves:

For improved child safety in front of the right gas log fireplace, consider installing a screen. These glass fronts and even materials around the fireplace can become very hot and pose a burn hazard.

- G-2 Garage:

Although it was operable at the time of the inspection, the Garage single door opener appeared to be at or near the end of its useful life. Typical lifespan for a Garage door opener is approximately 10 to 15 years. Total opener replacement is usually recommended rather than replacement of parts such as sprockets and circuit boards. Recommend further evaluation as needed.

- G-3 Garage:

The older model Garage single door opener was noted with no laser eyes in use as a safety feature. These are less safe than modern openers which will reverse when the laser beam is broken. This safety feature is especially important for children and pets. Updating the Garage door opener is recommended for improved safety.

- G-4 Garage:

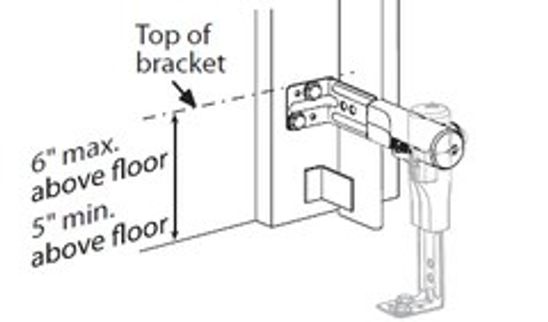

The detaching mechanisms that attaches the overhead Garage doors from the automatic opener tracks were located too high off the floor. These detachment mechanisms should be accessible, less than 6-feet off the ground. Repair as needed for improved safety.

- G-5 Garage:

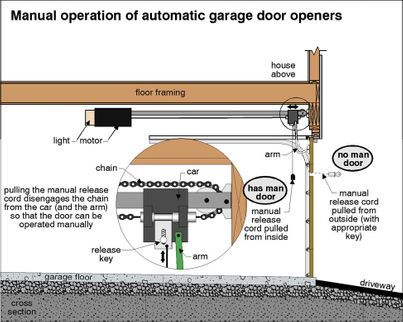

The automatic double Garage door opener did not respond to testing of the pressure-activated automatic-reverse feature. Overhead Garage doors are required to have at least one automatic-reverse device. This door did have an operable photo-sensor activated automatic reverse device installed.

Recommended Maintenance Items

- SEF-1 Site and Exterior Features:

The trees near the house have limbs that overhang the structure. Falling leaves clog flashings and gutters. Falling limbs due to conditions such as wood decay or high winds may cause injury or damage. We recommend having these trees evaluated and trimmed accordingly.

- SEF-6 Site and Exterior Features:

Recommend cleaning and servicing of the site drainage system to ensure all ground water and roof runoff is being reliably controlled and diverted away from the building.

- ESWD-2 Exterior Siding, Windows and Doors:

Bees / wasps nests were noted on the eaves at the rear of the house and require removal to ensure safety to occupants and to be sure they do not set up large nests that could damage the house.

- ESWD-3 Exterior Siding, Windows and Doors:

Cracking was visible in stucco covered exterior walls at the right side of the house at the time of the inspection. Cracks exceeding 1/16-inch in width should be filled with an appropriate material to prevent future damage from moisture and monitored in the future for continued activity.

- ESWD-4 Exterior Siding, Windows and Doors:

There were gaps visible in the exterior wall finishes at the front of the house that should have the appropriate sealant applied to help prevent damage from moisture intrusion.

- RCG-6 Roofing, Chimney and Gutters:

Leaks were noted in the gutters at the front and rear of the home that need to be repaired to control roof runoff. Seal-up all leaking areas and tune-up to ensure gutters are properly secured and sloped to drain.

- RCG-7 Roofing, Chimney and Gutters:

The gutters were filled with organic debris at the areas around the house and require cleaning to ensure proper control of roof runoff. Clean the gutters and ensure they are unobstructed and leak free, this should be routine house maintenance.

- CC-2 Crawlspace and Cellar:

Clean construction debris from the Crawlspace to eliminate a condition conducive to wood destroying organisms, especially the wood / cellulose debris.

- P-7 Plumbing:

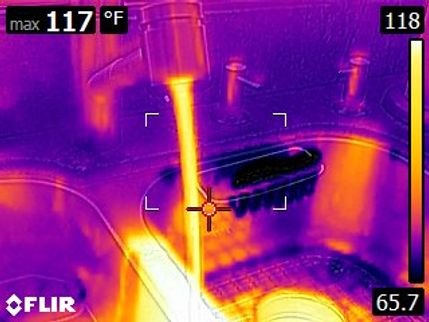

The water heater temperature seemed to be set too low at the time of inspection - just 117 degrees F. The range of 120-125 degrees F is the generally recommended temperature. This is nearly impossible to measure precisely during a home inspection as water temperature can vary between fixtures. I try and test the water temperature in several places and take the median reading. Adjust water heater temperature as needed. For best practice, set water temperature at the water heater to 130 degrees F and use a tempering valve to set water temp back to a safe 120 degrees F for domestic use. This high tank temperature will reduce risks of Legionella developing in the tank and the tempering valve will ensure a safe water temperature.

- I-2 Interior:

Cracks were noted in the ceiling at the Office. Cracking can be due to routine settlement or moderate seasonal expansion and contraction of the home. Cracks can also be related to workmanship - how the sheetrock was installed, and fastened. The seasonal types of cracking can be the most problematic as they will tend to re-open after repair. Repair and paint cracks as needed and monitor.

- B-1 Bathrooms:

A slow drain was noted at the upstairs Hallway Bathroom sink indicating that the drain may be obstructed. Repair as needed so the drain keeps up with the fixture supply. This typically involves cleaning out the trap.

- LA-1 Laundry Area:

The clothes dryer exhaust duct should be cleaned for improved safety. This is important regular maintenance to eliminate a potential fire hazard.

- G-7 Garage:

The double door hinges were loose and require securing. Recommend checking all of the door hardware to ensure all connections are tight.

Pool Repair Items

- PS-2 Pools and Spas:

Beginning January 1st 2018, in accordance with SB 442, Newman. Public health: pools: drownings, Home Inspectors must report on the presence of seven pool safety features. Below is the wording of the new bill.

In connection with the transfer, as defined in subdivision (e), of real property with a swimming pool or spa, an appropriate inspection shall include a noninvasive physical examination of the pool or spa and dwelling for the purpose of identifying which, if any, of the seven drowning prevention safety features listed in subdivision (a) of Section 115922 of the Health and Safety Code the pool or spa is equipped. SEC. 4. Section 115922 of the Health and Safety Code is amended to read: 115922. (a) Except as provided in Section 115925, when a building permit is issued for the construction of a new swimming pool or spa or the remodeling of an existing swimming pool or spa at a private single-family home, the respective swimming pool or spa shall be equipped with at least two of the following seven drowning prevention safety features: (1) An enclosure that meets the requirements of Section 115923 and isolates the swimming pool or spa from the private single-family home. (2) Removable mesh fencing that meets American Society for Testing and Materials (ASTM) Specifications F2286 standards in conjunction with a gate that is self-closing and self-latching and can accommodate a key lockable device. (3) An approved safety pool cover, as defined in subdivision (d) of Section 115921. (4) Exit alarms on the private single-family home’s doors that provide direct access to the swimming pool or spa. The exit alarm may cause either an alarm noise or a verbal warning, such as a repeating notification that “the door to the pool is open.” (5) A self-closing, self-latching device with a release mechanism placed no lower than 54-inches above the floor on the private single-family home’s doors providing direct access to the swimming pool or spa. (6) An alarm that, when placed in a swimming pool or spa, will sound upon detection of accidental or unauthorized entrance into the water. The alarm shall meet and be independently certified to the ASTM Standard F2208 “Standard Safety Specification for Residential Pool Alarms,” which includes surface motion, pressure, sonar, laser, and infrared type alarms. A swimming protection alarm feature designed for individual use, including an alarm attached to a child that sounds when the child exceeds a certain distance or becomes submerged in water, is not a qualifying drowning prevention safety feature. (7) Other means of protection, if the degree of protection afforded is equal to or greater than that afforded by any of the features set forth above and has been independently verified by an approved testing laboratory as meeting standards for those features established by the ASTM or the American Society of Mechanical Engineers (ASME). Section 115923. An enclosure shall have all of the following characteristics: (a) Any access gates through the enclosure open away from the swimming pool, and are self-closing with a self-latching device placed no lower than 60-inches above the ground. (b) A minimum height of 60-inches. (c) A maximum vertical clearance from the ground to the bottom of the enclosure of two-inches. (d) Gaps or voids, if any, do not allow passage of a sphere equal to or greater than four-inches in diameter. (e) An outside surface free of protrusions, cavities, or other physical characteristics that would serve as handholds or footholds that could enable a child below the age of five years to climb over.

- PS-3 Pools and Spas:

Exterior doors of a building that served as a part of the safety barrier had damaged or missing alarms. Such doors should be equipped with functioning alarms that complies with modern safety standards. Recommend repairs as needed for safety reasons.

1. All doors with direct access to the pool area are equipped with an alarm that sounds continuously for at least thirty (30) seconds immediately after the door and its screen, if present, are opened. It must be capable of providing a sound pressure level capable of being heard throughout the house during normal household activities. The alarm shall automatically reset under all conditions and be equipped with a manual means, such as a touch pad or switch, to temporarily deactivate the alarm for a single opening. Such deactivation shall last not longer than 15 seconds. The deactivation device shall be located at least 54-inches above the threshold of the door

- PS-4 Pools and Spas:

An exterior door of a building that served as a part of the safety barrier was not self closing or latching. Such doors should be equipped in a matter that complies with modern safety standards. Recommend correction as needed for safety reasons. All doors leading into the pool area should be equipped with self-closing and self-latching devices installed within the release mechanism located a minimum of 54-inches above the floor.

- PS-5 Pools and Spas:

The home had windows that when opened, had direct access to the pool. There were no safety alarms installed at the windows.

305.4 Structure Wall as a Barrier

Where a wall of a dwelling or structure serves as part of the barrier and where doors or windows provide direct access to the pool or spa through that wall, one of the following shall be required: 1. Operable windows having a sill height of less than 48-inches above the indoor finished floor and doors shall have an alarm that produces an audible warning when the window, door or their screens are opened. The alarm shall be listed and labeled as a water hazard entrance alarm in accordance with UL 2017. In dwellings or structures not required to be Accessible units, Type A units or Type B units, the operable parts of the alarm deactivation switches shall be located 54-inches or more above the finished floor. In dwellings or structures required to be Accessible units, Type A units or Type B units, the operable parts of the alarm deactivation switches shall be located not greater than 54-inches and not less than 48-inches above the finished floor. Recommend that alarms compliant with modern safety standards, be installed for safety reasons.

- PS-6 Pools and Spas:

The side gate access to the pool area improperly swung in towards the pool. Access gates should open away from the pool. Recommend repairs as needed.

- PS-12 Pools and Spas:

You should ask to see documentation that the pool drains are compliant with the Pool & Safety Act. Commencing January 1, 2007, a new law went into effect regarding the safety and security of swimming pools and spas located on private single-family residences. To eliminate safety hazards on new and existing swimming pools and spas, an approved anti entrapment cover be installed on all pool and spa drains any time a building permit is issued for the construction of a new swimming pool or spa or the remodel or modification of an existing swimming pool, toddler pool, or spa. Recommend further evaluation as needed.

- PS-16 Pools and Spas:

The pool system pump had corrosion visible. Recommend further evaluation and repairs as needed.

- PS-17 Pools and Spas:

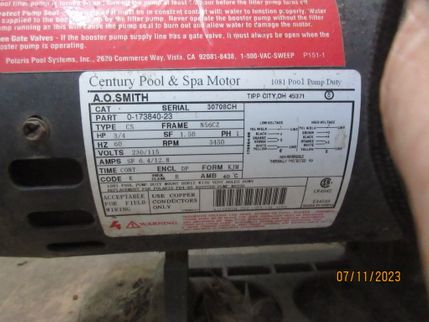

The pool sweep pump had an amperage draw (6.8 and 7.0) that exceeded the maximum amperage draw (6.4) stated on the data plate. This indicates that the pump is showing wear and may need replacement in the future. Recommend further evaluation and repairs as needed.

- PS-18 Pools and Spas:

The pool sweep was not functional at the time of the inspection. The hose had a leak in it. Recommend repairs as needed.

- PS-19 Pools and Spas:

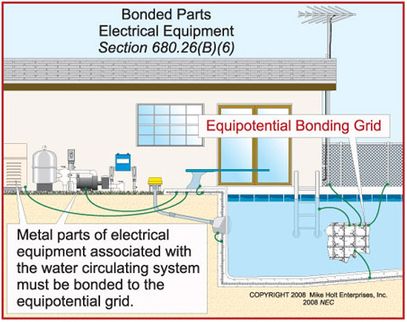

There was no ground fault circuit interrupter (GFCI) protection for the pool at the time of inspection. This can be achieved relatively inexpensively by replacing the breaker currently protecting the electrical circuit that contains the circuits of concern with a GFCI breaker. Recommend repairs as needed.

Pool Improvement and Maintenance Items

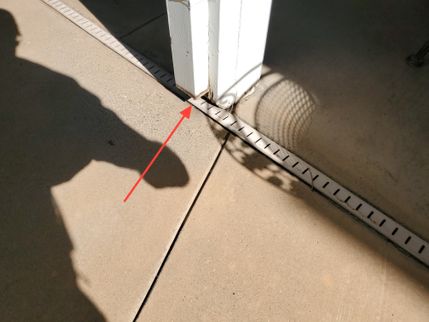

- PS-7 Pools and Spas:

The pool decking was cracked. Recommend repairs as needed.

- PS-9 Pools and Spas:

The Inspector recommends that you have water in the pool tested to ensure that it lies within acceptable parameters.

- PS-10 Pools and Spas:

The pool surface had visible surface wear at the time of the inspection. Recommend further evaluation and repairs as needed.

- PS-11 Pools and Spas:

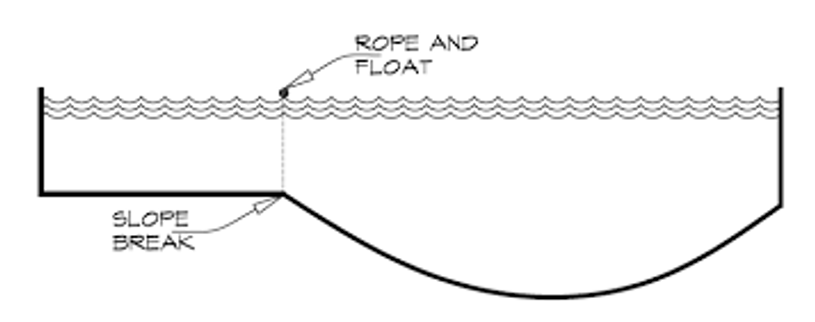

The swimming pool was missing the rope and float assembly installed at the floor slope change. These are installed to provide a visual indicator of where the pool transitions from the shallow to the deep end. Recommend the installation of a proper rope and float assembly as needed.

811.1 Rope and Float In pools where the point of first slope break occurs, a rope and float assembly shall be installed across the width of the pool.

- PS-13 Pools and Spas:

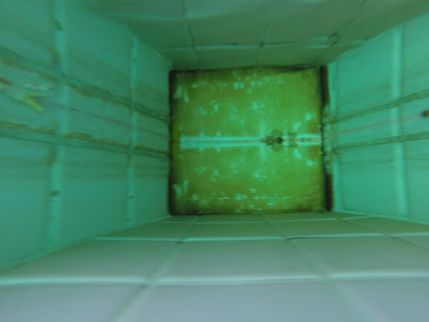

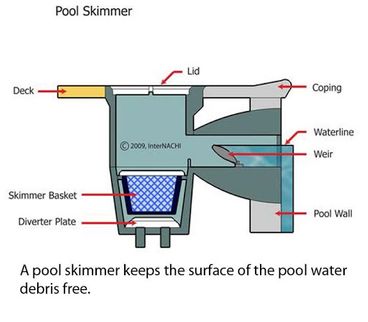

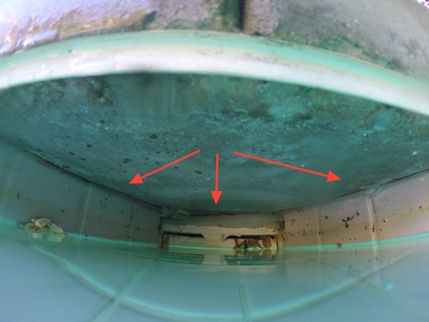

Recommend sealing all of the concrete and tile joints inside the skimmer opening.

- PS-14 Pools and Spas:

Chlorine tablets were present in the skimmer basket at the time of the inspection. This is not a recommended practice. Once your pump and filter turns off, the tablets keep dissolving in your skimmer, forming highly acidic water. This makes the parts of the skimmer brittle. Once the pump is turned back on, this same acidic water goes straight into the filter. This can compromise the internal parts of your filter (cartridges, o-rings, and gaskets), forcing you to replace them earlier than normally necessary.

- PS-15 Pools and Spas:

White plastic PVC pipes were exposed to direct sunlight. This type material is deteriorated by the ultra-violet (UV) radiation in sunlight, and this condition will result in premature failure of pipes compared to similar pipes designed to withstand exposure to UV. Such pipes should be painted over to protect them or replaced as needed.

The Complete Inspection Report

Site and Exterior Features

Grounds, Trees and Vegetation

Site Grading and Drainage

Driveways and Walkways

Porches and Patios

Chimney Exterior

Retaining Walls

Outbuildings and Exterior Features

Fences

Crawlspace and Cellar

Hatch and Accessibility

General Crawlspace Conditions

Piers and Footings

Vapor Barrier

Moisture Conditions

Plumbing

Water Meter

Supply Source and Material

Distribution Piping

Exterior Hose Bibs

Interior and Exterior Sinks

Water Heater

Water Temperature

Drain, Waste and Vent Systems

Heating, Cooling and Ventilation

Heating System

Cooling System

Distribution Systems

Air Filters

Thermostat

Room Mechanical Ventilation Systems

Electrical System

Service Entrance and Meter

Service Voltage

Service Panel Type

Main Electrical Panel

Grounding System

Water Bonding

Gas Bonding

Electrical Disconnects

Electrical Distribution and Fixtures

Branch Wiring Circuits

Lighting, Switches and Receptacles

Ceiling Fans

Low Voltage Wiring

Interior

Ceilings, Walls and Trim

Windows

Stairs and Railings

Floor Condition and Flooring Materials

Smoke and Carbon Monoxide Detectors

Interior Conditions

Central Vacuum

Kitchen

Faucets, Sinks and Traps

Range, Cooktop and Oven

Microwave, Range Hood, Ventilation System

Dishwasher

Garbage Disposal

Other Appliances

Refrigerator

Laundry Area

Faucets, Sinks and Traps

Clothes Washer and Connections

Clothes Dryer and Connections

Ventilation Method

Laundry Chute

Pools and Spas

General Pool Photos

Safety Barrier System

Decking, Coping, Features and Area

Water Level

Water Quality

Surface, Tiling and Components

Plumbing at Pool (Jets, Skimmer and Drains, etc.)

Plumbing System

Pump System

Filtration and Cleaning Systems

Heating System

Automatic Sanitation and Chemical Storage

Sub Panel, Wiring, GFCI and Bonding

Lights and GFCI Protection

Control System

General Comments

Building Conditions and Limitations

Standards of Practice: InterNACHI (International Association of Home Inspectors)

Inspection Type: - (Home and Pool Inspections)

Attending the Inspection: - (Client and REALTOR®)

Occupancy: - (Occupied)

This home was occupied at the time of the inspection. Inspection of occupied homes presents some challenges as occupant belongings can obstruct visual inspection of and access to parts of the house. We do our best during inspection to work around belongings to discover as much as possible about the house without moving or damaging personal property, however, the presence of personal items does limit the inspection.

Building Type: - (Single Family (2 story))

Approximate Square Footage: 2992

Approx. Year of Original Construction (per MLS): - (1980)

Unless the wiring in the building has been fully updated, this building likely has wiring that predates the late 1980's. Branch circuit wiring installed in buildings built prior to the late 1980s is typically rated for a maximum temperature of only 60 degrees Celsius. This includes non-metallic sheathed (Romex) wiring, and both BX and AC metal-clad flexible wiring. Knob and tube wiring, typically installed in homes built prior to 1950, may be rated for even lower maximum temperatures. Newer electric fixtures including lighting and fans typically require wiring rated for 90 degrees Celsius. Connecting newer fixtures to older, 60 degree rated wiring is a potential fire hazard. Repairs for such conditions may involve replacing the last few feet of wiring to newer fixtures with new 90 degree rated wire, and installing a junction box to join the old and new wiring. It is beyond the scope of this inspection to determine if any such incompatible components are installed. Based on the age of this building, be aware that such components may be present.

In 1978, federal laws were passed to prohibit use of Lead and Asbestos in building materials. Manufacturers of building materials were allowed to sell existing stocks of materials that were manufactured with Lead and Asbestos, so even buildings constructed as late as the mid-1980's could possibly contain Lead or Asbestos. Identification and testing for Lead and Asbestos and other environmental testing is beyond the scope of this home inspection. If you wish to seek additional information, Baker Inspection Group recommends contacting an Environmental Lab.

Utilities: On

Structural Pest Inspection Included: - (Yes)

Important Pest Notice and Disclaimer:

California termites can attack a home in the eaves, rafter tails, Attic and Crawlspace areas. Baker Inspection Group recommends that the client obtain a pest inspection and report from a Qualified and Licensed Pest Inspector before the end of the Inspection Period. California law allows only persons who possess a valid Structural Pest Control License, issued by the State of California Structural Pest Control Board, to inspect or make reports with respect to pest infestations including wood destroying insects, termites, and other organisms such as fungus (causing wood rot). This report is not a termite inspection and no responsibility is assumed for any infestation or damage caused by wood-destroying organisms. More information can be found here http://www.pestboard.ca.gov.

Pool Inspection: Yes

Pools are fun, but children and adults can lose their life quickly. Over 4000 lives annually are lost with one-third under the age of 14. A child can drown in the time it takes to answer a phone. A swimming pool is 14 times more likely than a motor vehicle to be involved in the death of a child age 4 and under. An estimated 5,000 children ages 14 and under are hospitalized due to near-drownings each year; 15% die in the hospital and as many as 20% suffer severe, permanent brain damage. Of all preschoolers who drown, 70% are in the care of one or both parents at the time of the drowning and 75% are missing from sight for five minutes or less. Drowning surpasses all other causes of death to children age 14 and under in Arizona, California, Florida, Hawaii, Montana, Nevada, Oregon, Utah and Washington.

A pool alarm with a loud speaker system to sound outside as well as inside the home could save a life. Even if you do not have children you should be concerned. 35% of children that drowned did so in someone else's pool. For more info, please do an Internet search on pool safety.

Building Faces: - (West)

Temperature During the Inspection: - (90-100 (F))

Weather During the Inspection: - (Clear)

Ground/Soil Surface Condition: - (Dry)

Significant Precipitation in Prior Three Days: No

Animals Present: - (Dogs Present- No Problem)

Site and Exterior Features

Grounds, Trees and Vegetation

Trees/Vegetation Too Near Building: Trees (Over Roof)

Site Grading and Drainage

Site Description: Flat (Flat Lot - Inquire With Sellers)

Downspout Discharge: - (At Foundation, At Wooden Post, Corrugated Storm Drains, Monitor)

Corrugated storm drain pipe appears to be used for sub-surface drainage work to divert roof runoff away from the building. This product is prone to failure as it is susceptible to crushing and clogging. No evidence was found during inspection that these drains are backing up and require repair. Monitor during heavy rains to ensure roof runoff is being reliably carried away from the structure.

Driveways and Walkways

Driveway: - (Concrete)

Walkways: - (Concrete)

Cracks were noted in driveway and walkway flatwork. Regular sealing of small to moderate cracks with a quality exterior flexible sealant can minimize water penetration and prolong the life of the flatwork. Large cracks can present a more urgent need for repair, especially if the cracks lead to displacement and trip hazards.

- No immediate repair appears necessary, though water will continue to deteriorate the surface until the flatwork is repaired or replaced.

Porches and Patios

Porch and Patio: - (Concrete)

Roof Structure: Post Deterioration

Chimney Exterior

Exterior Material: - (Stucco, Block)

Common Observations: Ash Door Not Accessible

Retaining Walls

Retaining Wall Material: - (Block)

Outbuildings and Exterior Features

Type: Not Included

This property had outbuildings or additional features. These are beyond the scope of this inspection. The focus of this inspection in on the house.

Fences

Exterior Fencing: Present, Not Inspected

The property has a fencing system in place. Inspection and evaluation of fencing is beyond the scope of a home inspection.

Exterior Siding, Windows and Doors

Eaves

Bees / wasps nests were noted on the eaves at the rear of the house and require removal to ensure safety to occupants and to be sure they do not set up large nests that could damage the house.

Siding and Trim

Siding Material: - (Stucco, T1-11 Wood Siding, Veneer, Fiber-Cement)

This building had a hardcoat stucco siding system. When installed over a wood building, stucco should be installed with two layers of underlayment below the stucco and a weep screed system which allows air to dry any accumulated moisture behind the stucco. Stucco is one of the nicest and lowest-maintenance siding systems but it is installation-sensitive. Poor installation can lead to expensive moisture control problems. The critical weather barrier, which is installed beneath the stucco is not visible to inspect, limiting the Inspectors' ability to see how the system is performing. During our visual inspection, we look for clues to help make an educated guess about the future reliability of this system. More detailed information can be gained through destructive testing. This involves drilling holes in the stucco and using a moisture probe to determine if any sections of the building have moisture control problems. Destructive testing is beyond the scope of this inspection.

At the time of the inspection, the Inspector observed the condition of the veneer covering exterior walls. Notable exceptions will be listed in this report. Inspection of stone typically includes examination of installation practices and visible condition.

The end joints between pieces of siding were not visible at the joint flashings. These are recommended behind the end joints in the siding for a weather-proof detail. In the absence of these flashings, keep end joints sealed with caulking. Caulking is an approved method for sealing these joints, but is higher maintenance, less reliable and more unsightly. Attached are some photos and diagrams showing how butt joint flashings can be retrofit.

The damage to the lower portions of wood siding at the front of the house appeared to be the result of inadequate clearance from grade. The standard recommended minimum clearance from grade is 6-inches. Recommend that all such areas repaired as needed to provide adequate clearance. Failure to provide adequate clearance will result in continuing decay of siding in these areas.

Cracking was visible in stucco covered exterior walls at the right side of the house at the time of the inspection. Cracks exceeding 1/16-inch in width should be filled with an appropriate material to prevent future damage from moisture and monitored in the future for continued activity.

Doors

Vent and Exhaust Terminations

Present

Roofing, Chimney and Gutters

Roofing Materials

Roof Inspection Method: - (From the Roof Surface (walked/climbed))

Roof Style: - (Gable)

Roof Covering Materials: - (Presidential Grade Shingle, Torch-Down / Modified Bitumen)

The roofing material on this building appears to be a torch down or modified bitumen membrane. The service life of these roofs can vary depending on the quality of the membrane and the quality of the installation, including how well the roof is sloped to drain. Torch down roofs often have roughly 10 years of reliable service life beyond which regular repairs are often needed. With on-going maintenance these roofs can be made to last as long as 25 years or more. The installation appears neat and professional. Inquire with the seller about any warranty information for this roof.

Roof Flashings

Flashings, Valleys and Penetrations: Present and Visually Standard, Metal Valleys Noted

Roof flashings are used to keep a roofing system waterproof where the roofing material starts, stops, changes direction or is penetrated. During inspection, we look for standard flashing techniques that could be considered normal or standard in our region. Damaged, incomplete or non-standard flashings can be a sign of an older or less reliable roofing system and may require repair. Any non-standard flashings noted during inspection will be reported on below if found.

Roof Drainage Systems

Gutter and Downspouts: - (Yes)

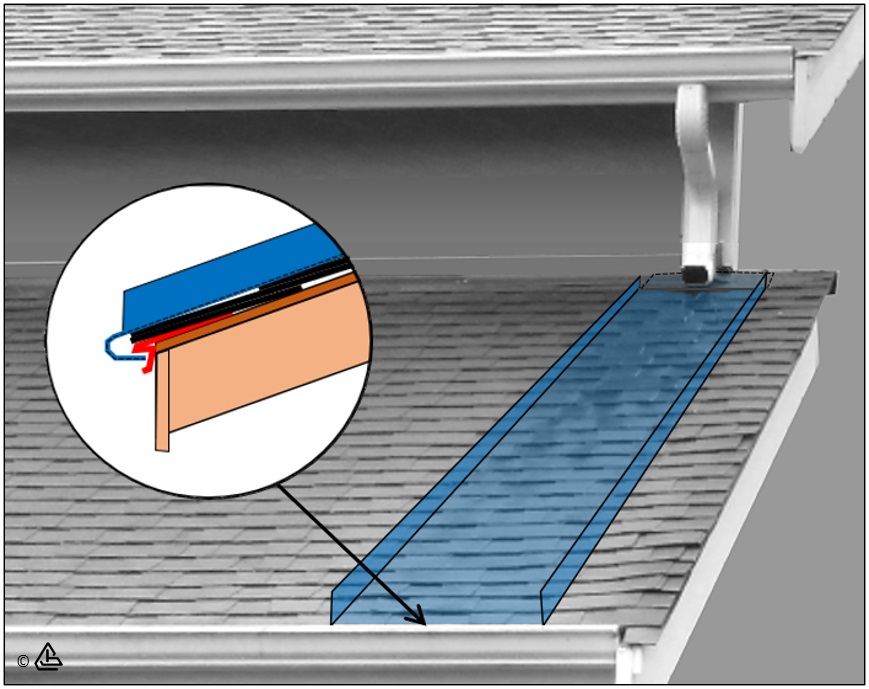

Several of the downspouts on the upper gutter system are terminating onto the lower roof. This is industry standard practice but it will prematurely deteriorate the roofing shingles in these locations and it is not recommended by many shingle manufacturers. Recommend extending the downspouts into the lower gutters to better protect the roof.

The gutters were filled with organic debris at the areas around the house and require cleaning to ensure proper control of roof runoff. Clean the gutters and ensure they are unobstructed and leak free, this should be routine house maintenance.

Attic

Accessibility

Attic Access Location: - (Noted)

The Attics were accessed at the upstairs right room closet and Garage pull down stairs.

Attic Inspection Method: - (Inside the Attic, Access Hatch (inadequate headroom))

The Garage Attic areas lacked adequate headroom for safe entry. As a result, inspection of the Attic space was done from the access hatch location only. Attics may contain potential fire or health hazards, other safety issues, damage, or defects that have the potential to cause damage to the home.

Roof Sheathing and Framing

Sheathing: - (1x Spaced Boards and Oriented Strand Board (OSB))

Rafters: - (Truss, Wood Joist)

Ventilation Type

Structure Ventilation Type: - (Eave, Gable and Roof Vents, Thermostat-Controlled Fan)

Common Observations: Power Vents (Operational, On Thermostat)

The electric Attic fan was activated by a thermostat. It was functional at the time of the inspection.

The Attic has a power van for ventilation. This was set up on a thermostat, so it appears to be used for controlling summer heat. This can exacerbate problems of air leakage from the conditioned house space into the unconditioned Attic space. So, for example, if you are using cooling in the house, it can make the house hotter during the summer as conditioned air can get pulled out of the house into the Attic. In general, power ventilation is not recommended.

Radiant Barrier

- (Installed at Sheathing)

A radiant barrier is a layer of reflective material installed in a home to redirect the radiant heat created by the sun. In warm weather, a radiant barrier blocks radiant heat from entering a home. This increases the efficiency of your Attic-installed air handling system, resulting in increased energy savings and lower energy costs. When the sun beats down on your home, heat builds up in the roofing materials. Some of this heat is transferred into your Attic and eventually reaches your indoor living areas. This type of heat transfer, known as “radiant heat,” is as natural as the seasons. But it can create temperature variations inside your home and cause your cooling system to work harder.

Thermal Envelope

Insulation Type: - (Blown-In Cellulose)

Approximate Insulation R-Value on Attic Floor: - (R-19)

The Attic insulation could be improved to modern standards, which recommend R-38 on the floor. R-value is the measure of resistance to heat loss; the higher the R-value the better the insulation. During insulation repairs it is best practices to implement any air seal-up repairs to seal air leakage. Also, be sure you have completed any wiring or other projects that are needed in the Attic.

Structure and Foundation

Ceiling, Wall and Floor Structures

Subfloor Material: - (Plywood)

Floor Framing: - (Wood Beams)

The floor sheathing staining visible in the Crawlspace appeared to have been caused by the leakage of plumbing fixtures. You should ask the seller about this condition.

Foundation

Foundation Configuration: - (Crawlspace)

Foundation Type and Material: - (Poured Concrete Foundation Walls)

Evidence of Seismic Protection: Not Accessible

Crawlspace and Cellar

Hatch and Accessibility

General Crawlspace Conditions

At the Crawlspace, a white, powdery substance was visible on the interior of the poured concrete foundation walls which is called “efflorescence". This condition is the result of moisture seeping through the foundation wall and indicates high moisture levels in soil near the foundation. Moisture in soil supporting the foundation can reduce its ability to support the weight of the structure above. The source of moisture should be identified and the condition corrected.

Piers and Footings

- (Wood Posts and Poured Concrete Footings, Not Continuous)

Vapor Barrier

No vapor barrier has been installed on the soils of this Crawlspace to contain the moisture in the ground. This is a conducive pest condition and can lead to high moisture conditions. Install a 6 mil. black plastic vapor barrier to cover all exposed earth.

Moisture Conditions

Conditions: - (No Water was Visible or Present at the Time of Inspection)

The Crawlspace was dry at the time of inspection. It is always a good idea to monitor Crawlspaces to see how they perform regarding drainage.

Plumbing

Water Meter

Supply Source and Material

Water Supply: - (Public Water Supply)

Please note that when the water service type is listed here, it is listed based on public records and disclosure. It is always possible that the system is not as it is listed.

Main Water Shut-Off Location: Water Shut-Off Location Noted

Main Water Pipe Material: - (Galvanized)

Water Pressure: Water Pressure Tested, - (54 PSI)

This shows the water pressure tested during inspection. Generally, "normal water pressure," should be between 40-80 PSI, though pressures near or below 40 PSI can result in poor functional flow to fixtures. Water pressures in excess of 80 PSI risk damaging supply piping components and should be controlled with a pressure reducing valve.

The main water pipe from the street to the house appeared to be done with old galvanized steel pipe. This pipe could require updating at any time. Evaluation of this pipe is beyond the scope of this inspection as the pipe is not visible. Keep this pipe in mind for updating should you do any other digging in the front of the home between the house and the water meter.

Distribution Piping

Supply Pipe Materials: - (Galvanized Steel, Copper)

Budget to replace the remaining galvanized steel supply pipe at some point in the near term and definitely during any remodel work to Kitchens, Laundry area or Bathrooms. The average life of this pipe can vary widely, but tends to be between 40-60 years. As this pipe gets old and corrodes, the insides of the pipe fill with rust, causing restrictions in the pipe. This can be tolerated for some time, but eventually the functional flow becomes so diminished that pipe replacement is necessary. This could change or worsen at any time.

Please note that the supply pipes were concealed behind insulation and finishes and visual inspection was limited. Determination of the supply piping materials used here is an educated guess based on the materials that were visible coming out of the wall and below fixtures.

Copper water supply pipes were installed. Copper pipes installed prior to the late 1980's may be joined with solder that contains lead, which is a known health hazard especially for children. Laws were passed in 1985 prohibiting the use of lead in solder, but prior to that solder normally contained approximately 50% lead. Note that testing for toxic materials such as lead, is beyond the scope of this inspection. Consider having a Qualified Lab test for lead, and if necessary take steps to reduce or remove lead from the water supply. Various solutions include:

- Flush water taps or faucets. Do not drink water that has been sitting in the plumbing lines for more than 6 hours

- Install appropriate filters at points of use

- Use only cold water for cooking and drinking, as hot water dissolves lead more quickly than cold water

- Treat well water to make it less corrosive

- Have a Qualified Plumbing Contractor replace supply pipes and/or plumbing components as necessary

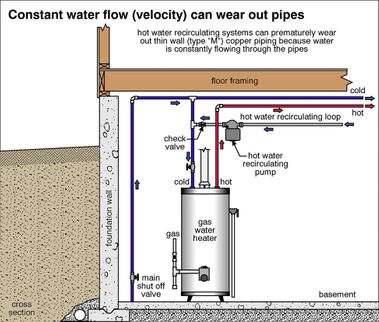

Circulation Pump: - (Present)

A point of use water circulation loop was noted. These pumps deliver hot water to the faucet more quickly when they are working. They do this by pushing the hot water line back into the cold water line. These have the advantage of near instantaneous hot water when the pump is working. The drawback is you may need to wait for cold water.

Functional Flow: - (Average)

All plumbing fixtures in the home exhibited functional flow at the time of the inspection.

Pipe Insulation: - (Present)

The visible portions of the supply piping appear to be insulated.

Exterior Hose Bibs

Hose Bibs: Operating, Leaking (At Handle When Turned On)

Anti-Siphon Present: No

Older hose bibs were noted on this building and updating is recommended. Modern hose bibs are typically anti siphon style which can prevent water from your hoses backing into your water supply system. Consider installing anti siphon hose bibs. The following video shows a vacuum breaker. Click Here

Interior and Exterior Sinks

Tested

Water Heater

System Type and Capacity: - (Tank, 47-50 Gallon (2-3 people))

Energy Source: - (Natural Gas)

Straps: - (Present)

TPR Valve: - (Present - Not Tested)

A temperature and pressure relief valve (TPRV) is required on all water heaters to discharge any excessive pressure within the tank. A discharge pipe should be attached to the valve and directed to a safe location away from body contact. Newer installations must be directed to the building exterior or to an approved indoor drain receptor. Most manufacturers suggest that homeowners test these valves at least once a year by lifting the lever to ensure the valve discharges properly and also recommend inspection of these safety devices every three years. The picture here shows a typical TPRV. They may also be found on the side of the heater on some models. We do not test these valves due to the possibility that they may leak after testing. A leaking or inoperative TPRV should be replaced immediately by a Qualified Plumber.

Bollard: - (Missing and Recommended)

A bollard is recommended to protect the water heater in the Garage from physical damage. When the water heater is located where it could be damaged by vehicles, "approved" protective bollards (or other means of protection) are required for safety. Recommend that a bollard be installed by a Qualified Contractor. Because current building standards do not specify what "approved" means, it is left up to jurisdictional interpretation.

Age: - (1999)

Manufacturer: - (Bradford White)

This was a very old water heater. The average life of these water heaters is 8-20 years. The service life of a water heater will depend on a variety of factors such as water quality and regular scheduled maintenance such as flushing the tank and replacing sacrificial anodes. Recommend further evaluation as needed by a Qualified Contractor.

Water Temperature

Water Temperature Measured During Inspection: Testing Note, 117 Degrees F