The Scope and Purpose of a Home Inspection

Purchasing property involves risk

The purpose of a home inspection is to help reduce the risk associated with the purchase of a structure by providing a professional opinion about the overall condition of the structure. A home inspection is a limited visual inspection and it cannot eliminate this risk. Some homes present more risks than others.

Definitions and scope of this inspection:

- A home inspection is a non-invasive, visual examination of the accessible areas of a residential property (as delineated below), performed for a fee, which is designed to identify defects within specific systems and components defined by these Standards that are both observed and deemed material by the inspector. The scope of work may be modified by the Client and Inspector prior to the inspection process.

- The home inspection is based on the observations made on the date of the inspection, and not a prediction of future conditions.

- The home inspection will not reveal every issue that exists or ever could exist, but only those material defects observed on the date of the inspection.

- A material defect is a specific issue with a system or component of a residential property that may have a significant, adverse impact on the value of the property, or that poses an unreasonable risk to people. The fact that a system or component is near, at, or beyond the end of its normal, useful life is not, in itself, a material defect.

- A home inspection report shall identify, in written format, defects within specific systems and components defined by these Standards that are both observed and deemed material by the inspector. Inspection reports may include additional comments and recommendations.

- This Inspection is conducted, following the Standards of Practice of the International Association of Certified Home Inspectors, Oct, 2022 revision.

Limitations:

An inspection is not technically exhaustive. An inspection will not identify concealed or latent defects. An inspection will not deal with aesthetic concerns, or what could be deemed matters of taste, cosmetic defects, etc. An inspection will not determine the suitability of the property for any use. An inspection does not determine the market value of the property or its marketability. An inspection does not determine the insurability of the property. An inspection does not determine the advisability or inadvisability of the purchase of the inspected property. An inspection does not determine the life expectancy of the property or any components or systems therein. An inspection does not include items not permanently installed. This Standards of Practice applies to properties with four or fewer residential units and their attached garages and carports.

Exclusions:

The inspector is not required to determine: Property boundary lines or encroachments. The condition of any component or system that is not readily accessible. The service life expectancy of any component or system. The size, capacity, BTU, performance or efficiency of any component or system. The cause or reason of any condition. The cause for the need of correction, repair or replacement of any system or component. Future conditions. Compliance with codes or regulations. The presence of evidence of rodents, birds, bats, animals, insects, or other pests. The presence of mold, mildew or fungus. The presence of airborne hazards, including radon. The air quality. The existence of environmental hazards, including lead paint, asbestos or toxic drywall. The existence of electromagnetic fields. Any hazardous waste conditions. Any manufacturers' recalls or conformance with manufacturer installation, or any information included for consumer protection purposes. Acoustical properties. Correction, replacement or repair cost estimates. Estimates of the cost to operate any given system.

The Inspector is not required to operate:

Any system that is shut down. Any system that does not function properly. Any system that does not turn on with the use of normal operating controls. Any shut-off valves or manual stop valves. Any electrical disconnect or over-current protection devices. Any alarm system. Moisture meters, gas detectors or similar equipment. Evaluate low-voltage electrical systems, such as, but not limited to: phone lines, cable lines, satellite dishes, antennae, lights, remote controls.

The Inspector is not required to:

Move any personal items or other obstructions, such as, but not limited to: Throw rugs, carpeting, wall coverings, furniture, ceiling tiles, window coverings, equipment, plants, ice, debris, snow, water, dirt, pets, or anything else that might restrict the visual inspection. Dismantle, open or uncover any system or component. Enter or access any area that may, in the inspector's opinion, be unsafe. Enter crawlspaces or other areas that may be unsafe or not readily accessible. Inspect underground items, such as, but not limited to: lawn-irrigation systems, wildfire sprinkler systems, or underground storage tanks (or indications of their presence), whether abandoned or actively used. Do anything that may, in the inspector's opinion, be unsafe or dangerous to him/herself or others, or damage property, such as, but not limited to: walking on roof surfaces, climbing ladders, entering attic spaces, or negotiating with pets. Inspect decorative items. Inspect common elements or areas in multi-unit housing. Inspect intercoms, speaker systems or security systems. Offer guarantees or warranties. Offer or perform any engineering services. Offer or perform any trade or professional service other than a home inspection. Research the history of the property, or report on its potential for alteration, modification, extendibility or suitability for a specific or proposed use for occupancy. Determine the age of construction or installation of any system, structure or component of a building, or differentiate between original construction and subsequent additions, improvements, renovations or replacements. Determine the insurability of a property. Perform or offer Phase 1 or environmental audits. Inspect any system or component that is not included in these Standards.

This is not an inspection for code compliance

IMPORTANT: Unlike some urban areas, Cook County does not have a building department that performs plan reviews or building inspections during the construction process. Footing, framing, and other inspections are not performed during the construction process in Cook County. This inspection is not a code inspection. It is the responsibility of the original builder of the home to properly build the home to meet current building practices. Systems within the structures and property are inspected based on their function, operation, and best building practices. The inspector disclaims hidden defects that were not visible and readily accessible during the inspection.

A home inspection is not an insurance policy

This report does not substitute for or serve as a warranty or guarantee of any kind. Home warranties can be purchased separately from insurance firms that provide this service.

This is just our opinion

Construction techniques and standards vary. There is no one way to build a house or install a system in a house. The observations in this report are the opinions of the home inspector. Other inspectors and contractors are likely to have some differing opinions. You are welcome to seek opinions from other professionals.

Your expectations:

The overall goal of a home inspection is to help ensure that your expectations are appropriate with the house you are proposing to buy. To this end we assist with discovery by showing and documenting observations during the home inspection. This should not be mistaken for a technically exhaustive inspection designed to uncover every defect with a building. Such inspections are available but they are generally cost-prohibitive to most homebuyers.

How to Read This Report

Getting the Information to You

This report is designed to deliver important and technical information in a way that is easy for anyone to access and understand. If you are in a hurry, you can take a quick look at our "Summary Page” and quickly get critical information for important decision making. However, we strongly recommend that you take the time to read the full Report, which includes digital photographs, captions, diagrams, descriptions, videos and hot links to additional information.

The best way to get the layers of information that are presented in this report is to read your report online (the HTML version), which will allow you to expand your learning about your house. You will notice some words or series of words highlighted in blue and underlined – clicking on these will provide you with a link to additional information. The HTML version of this report also contains streaming videos. Short video clips often contain important information and critical context and sounds that can be difficult to capture in words and still pictures.

For the most reliable viewing experience, I recommend viewing the report on as large a screen as practical, as much detail can be lost on small devices like smart phones. For similar reasons, reports should only be printed in color to retain as much detail as possible and minimize misinterpretation of photographs.

This report can also be printed on paper or to a PDF document.

Chapters and Sections

This report is divided into chapters that parcel the home into logical inspection components. Each chapter is broken into sections that relate to a specific system or component of the home. You can navigate between chapters with the click of a button on the left side margin.

Most sections will contain some descriptive information done in black font. Observation narrative, done in colored boxes, will be included if a system or component is found to be significantly deficient in some way or if we wish to provide helpful additional information about the system or the scope of our inspection. If a system or component of the home was deemed to be in satisfactory or serviceable condition, there may be no narrative observation comments in that section and it may simply say “tested,” or “inspected.”

Observation Labels

All narrative observations are colored, numbered and labeled to help you find, refer to, and understand the severity of the observation. Observation colors and labels used in this report are:

- Limitations:Conditions present at the time of inspection which limited the scope of this visual inspection

- Major Concern:Repair items that require immediate attention or that are not working at the time of the inspection.

- Safety:Conditions and items that are unsafe and in need of attention.

- Inspection Notes:Information and /or comments elaborating on descriptions of systems in the home that the inspector might find useful to purchase decisions or home ownership. .

- Moderate Concern:Repair and maintenance items noted during inspection. Please note that some repair items can be expensive to correct such as re-finishing siding or hardwood floors, but are considered repair items due to their cosmetic nature.

- Future Project:A repair that may be deferred for some time but should be on the radar for repair or replacement in the near future.

- Maintenance:These are repair items that should be considered "routine home ownership items," such as servicing the furnace, cleaning the gutters or changing the air filters in the furnace.

- Improve or Upgrade:Observations that are not necessarily defects, but can be improved or upgraded for safety, efficiency, or reliability reasons. Often these are items that reflect changes in building practices or codes.

- Needs Further Evaluation:Observation that requires further investigation to determine the severity and / or urgency of repair.

- Monitor:Items that should be watched to see if correction may be needed in the future.

- Efficiency:Denotes observations that are needed to make the home more energy efficient as well as to bring the home up to modern insulation standards. This category typically includes windows and insulation. Other items, such as lighting and appliances, are not inspected for their energy status.

Summary Page

The Summary Page is designed as a bulleted overview of all the observations noted during inspection. This helpful overview is not a substitution for reading the entire inspection report. The entire report must be read to get a complete understanding of this inspection report as the Summary Page does not include photographs or photo captions.

Summary

Major Concerns

- RGC-1 Roof, Gutters, and Chimney - Roof Materials:

DAMAGED SEWER VENT BOOT The plumbing boot was damaged and is subject to leakage. Water stains were observed on the 2nd floor that appear to be associated with this condition. Contact a licensed building contractor for repair. One option is to replace the entire boot. Another is to utilize a repair boot that slips over the existing plumbing boot.

Safety

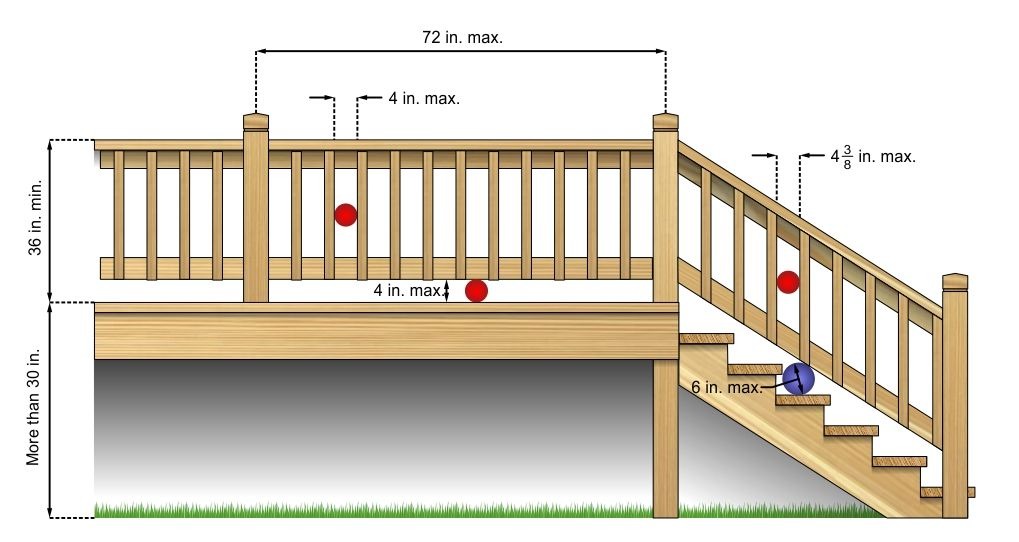

- PS2-1 Porch and Stoop - Front Porch:

MISSING GUARDRAIL

The guardrail and handrail for the stairs are missing. A 32 to 36 inches tall railing is recommended for deck stairs with three or more risers. Openings no larger than 4 3/8 inches are recommended. All posts and railing should also be adequately stiff to prevent a falling adult. Hire a licensed general contractor to evaluate and repair.

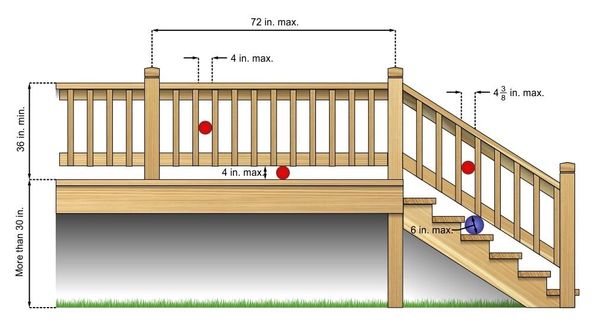

- PS2-2 Porch and Stoop - Rear Stoop:

MISSING GUARDRAIL A guardrail is needed for all decks more than 30-inches above the ground. The railing should be at least 36-inches tall with vertical openings no larger than 4-inches. No guardrail has been installed here and one is required where the deck is more than 30-inches above the ground.

- EDF-3 Electric Distribution and Finish - Receptacles and Fixtures:

GFCI PROTECTION RECOMMENDED

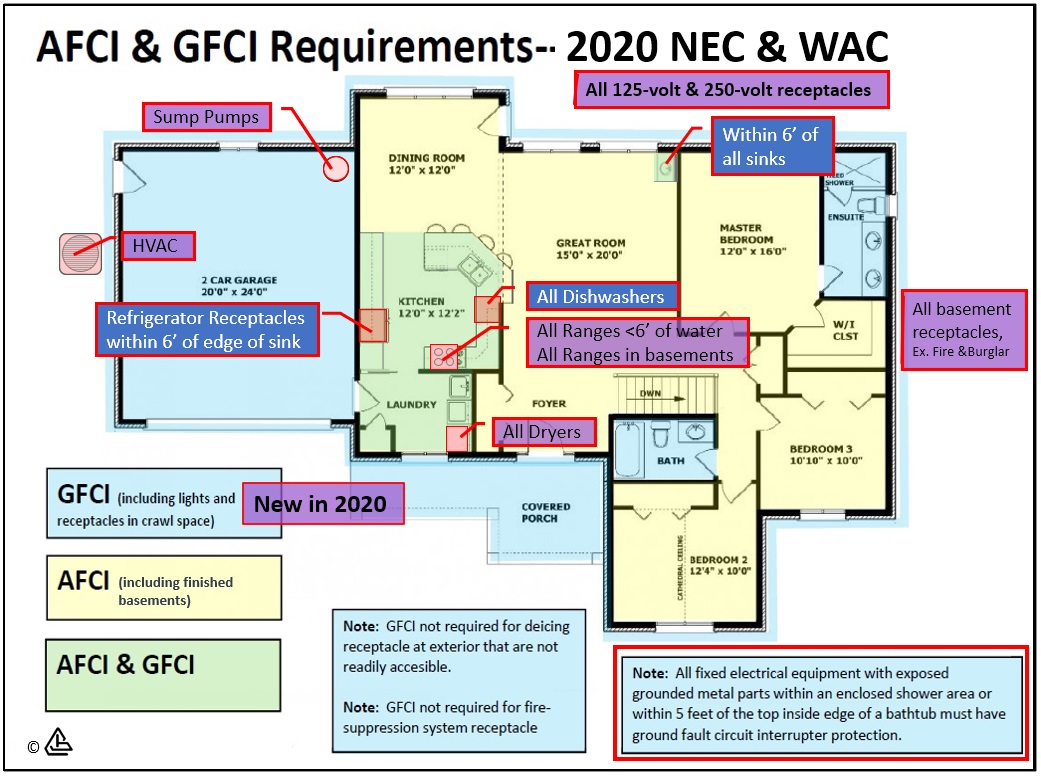

Since the 1970s, requirements for GFCI (Ground Fault Circuit Interruption) protection have changed, and locations requiring GFCI protection seem to get added with every code cycle. It is common for older residential buildings to have some or even many electric receptacles that do not meet modern safety standards. GFCIs have proven successful at reducing electrocutions, and it seems likely that someday, every circuit, receptacle, and appliance in the building will require GFCI protection. The first chart below shows how successful GFCIs have been at reducing risks from electrocution. The second illustration shows where GFCI protection is required as of the 2020 NEC and WAC. As a general best practice for safety. For improved safety, I always recommend bringing GFCI protection up to modern safety standards.

During inspection today, I noted that GFCI protection is inconsistent with modern minimum standards for safety in the following locations:

- EDF-4 Electric Distribution and Finish - Receptacles and Fixtures:

MISSING LIGHT FIXTURE

- Missing light fixture noted.

- Electric box not present.

- Safety: Energized wire present.

Recommendation

Hire a licensed electrical contractor to install a light fixture and electric box.

Moderate Concerns

- G1-1 Grounds - Drainage and Site:

POOR SITE GRADING

The grade of the yard slopes toward the building. In order to control surface water drainage, building practices recommend a minimum slope of one quarter-inch / foot away from the building . Negative grading, as this current condition is called, can lead to water leakage into the basement and structural problems with the foundation.

Recommendation

Have the condition evaluated and repaired by an excavation contractor. Often, a swale is used to create a low point away from the house into which water can be diverted away from and around the building. With the close proximity of the property line, a retaining wall may be required in order to reliably control drainage.

- G1-3 Grounds - Retaining Walls:

LEANING RETAINING WALL

The retaining wall in the front yard is in unreliable condition. Old walls like this can sometimes last for many years in this state, but repairs could be needed at any time. Hydrostatic pressure from heavy rains could cause further movement, which could necessitate retaining wall repair/replacement.

Recommendation

Monitor and repair as needed.

- E-1 Exterior - Siding and Trim:

LOCALIZED SIDING REPAIRS

Localized exterior siding repairs and maintenance are needed. Examples of observations noted during the inspection include:

- North wall: Loose siding

Recommendation

Hire a licensed building contractor to further evaluate and repair as needed.

- S-1 Structure - Floor, Wall and Ceiling Structure:

MISSING JOIST HANGERS Joist hangers are missing in several locations. Displacement and/or failure was not observed. Have this condition investigated and repaired as recommended by a licensed building contractor.

- S-2 Structure - Floor, Wall and Ceiling Structure:

JOIST HANGER FASTENER ISSUES The joist hangers are missing fasteners and are fastened with non-structural, not approved fasteners. This is non-standard and can cause the hangers to fail. Have this further investigated and repaired as recommended by a licensed building contractor.

- S-3 Structure - Roof Framing and Sheathing:

IMPROPERLY CUT RAFTER Multiple improperly cut rafters were noted in the attic space. This condition weakens the roof structure and requires repair. Hire a licensed building contractor to further evaluate and repair the roof structure.

- ES-2 Electric Service - Electric Service Panel:

SCREWS MISSING FOR ELECTRIC PANEL

The main panel is missing a screw to secure the dead front cover. Install missing screw as needed for improved safety. Note that screws with sharp ends are a safety hazard and not allowed. Proper, blunt end screws are available at local hardware suppliers.

- WH-1 Water Heater - Water Heater:

TPR DISCHARGE PIPE MISSING The discharge pipe for the water heater temperature and pressure relief valve is missing and requires repair to eliminate a scald hazard. This is an important safety feature. Should the TPRV need to discharge, scalding water and steam could come out. This water and steam needs to be directed away from people and terminate within 6 inches of the floor. Hire a licensed plumber to further evaluate and repair.

- RC-2 Room Components - Floors and Floor Materials:

WATER DAMAGED FLOORING NOTED

Localized water damage was noted on the hardwood floor. This is localized and appears to be associated with the damaged sewer vent flashing on the roof. Repair the damaged sewer vent flashing and then repair the water damaged floor as desired.

Future Projects

NoneMaintenance

- G1-2 Grounds - Drainage and Site:

DOWNSPOUT DISCHARGE NEAR FOUNDATION

Downspout discharges adjacent to the foundation. This can cause foundation settlement or basement moisture problems. Make sure the downspout discharge point is at least 5 feet away from the foundation. In some cases, a buried discharge pipe is required, terminating at a location that drains away from the foundation.

- RGC-2 Roof, Gutters, and Chimney - Chimneys:

CHIMNEY REPAIRS NEEDED

Repairs are needed to the masonry chimney. The conditions noted here could increase the risk of moisture problems. Neglecting maintenance on masonry chimneys can also lead to loose or damaged bricks and eventually a failing masonry system.

Recommendation

Hire a licensed masonry contractor to further evaluate and repair the masonry chimney as recommended. Observations noted during the inspection include:

- Minor cracks in grout

Improve Or Upgrade Items

- EDF-1 Electric Distribution and Finish - Branch Wiring:

OLDER CLOTH COVERED WIRE

Older cloth covered cable wiring was noted in use here. This is generally older wiring that should be considered for updating, especially in the course of renovation work. This wiring cable can become brittle over time so the jacket may be more vulnerable to deterioration and physical damage. The wiring was also likely rated for 60 degree Celsius, an older rating that makes the wiring more vulnerable to heat buildup.

- EDF-5 Electric Distribution and Finish - Receptacles and Fixtures:

OLDER TWO WIRE SYSTEM NOTED

The electrical branch wiring system here still employs some older two-wire system. This suggests there is still some older wiring here even though some wiring updates have been done. Though there is nothing wrong with this configuration you may find it inconvenient in some areas, especially in offices and media areas. In general, this indicates an older electrical system that has not been completely updated and may not safety or reliably meet modern demands and expectations for the wiring system.

Recommendation

I recommend consulting with a licensed electrical contractor about options for updating this older wiring.

Needs Further Evaluation

- GC-1 General Comments - Building Characteristics, Conditions and Limitations:

OLD BUILDINGS AND LEAD AND ASBESTOS

In 1978, federal laws were passed to prohibit use of lead and asbestos in building materials. Manufacturers of building materials were allowed to sell existing stocks of materials that were manufactured with lead and asbestos, so even buildings constructed as late as the mid-1980's could possibly contain lead or asbestos. Identification and testing for lead and asbestos and other environmental testing is beyond the scope of this home inspection. If you wish to seek additional information, I recommend contacting an environmental lab or industrial hygienist.

- ES-1 Electric Service - Electric Service Panel:

MULTIPLE BRANDS OF BREAKERS USED

There are different brands of breakers installed in the electric panel. Electric panels are only rated to have certain types and brands of breakers installed. Determining proper breaker use can necessitate referring to the manufacturers listing. Some of the breakers installed here could be incompatible with what is approved for the panel. The risk here is loose connections which can lead to arcing and overheating.

Recommendation

I recommend further evaluation of the panel by a licensed electrical contractor. Repair the mismatched breakers as recommended by the electrical contractor and the panel manufacturer.

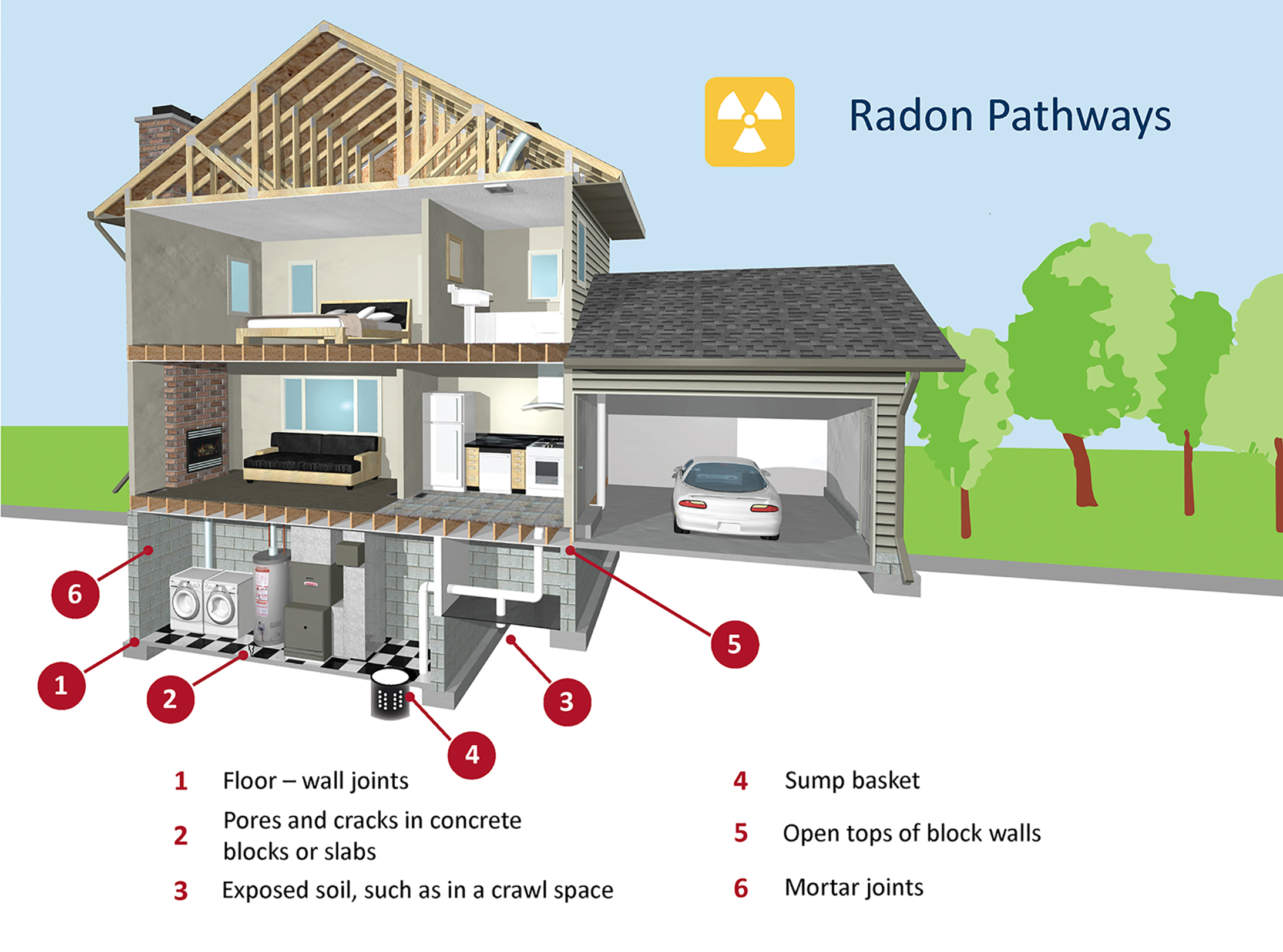

- AP-1 Additional Plumbing - Radon Mitigation System:

RADON MITIGATION SYSTEM NOT PRESENT

Radon is a Class 1 human carcinogen and the number one cause of lung cancer for non smokers.

Recommendation

Test the home for the presence radon. The Minnesota Department of Health and the EPA recommend all homes be tested for radon at the time of a real estate transaction and every two years thereafter. The MN Dept of Health reports that over 40% of tested Cook County homes have elevated levels of radon above the EPA action level of 4 pCi/L and pose a serious health risk. Just as important, a significant number of homes with radon mitigation systems in place have elevated radon levels.

More Information:

http://www.senty.com/radon-testing

Items for Monitoring

- P-1 Plumbing - Waste Pipe and Discharge:

PARTLY UPDATED WASTE PIPING - SOME METAL WASTE PIPE NOTED

Some of the waste plumbing systems in this building are made of old metal and have not been updated to plastic. No leaks were noted at the time of inspection, but updating and ongoing repairs could be needed at any time. Old metal pipes are susceptible to internal corrosion, which can make it difficult to identify older, weaker pipes until they begin to leak. During renovations to the building, be sure to have this old piping evaluated and updated as recommended by a licensed plumber. As a general rule, old cast iron pipes often last a very long time - even as long as 100 years. Galvanized and copper waste pipes can have a shorter useful service life - sometimes 50 years. The service life from this pipe is influenced by water quality and occupant behavior; the use of cleaning chemicals like Drain-O can be tough on metal pipes.

Efficiency Items

- IV-1 Insulation and Ventilation - Foundation Insulation:

NO FOUNDATION INSULATION The above grade foundation and rim joist area of a home are a significant source of heat loss in winter. Current new construction practices utilize insulation on the rim joist and foundation to R-15. At the time this home was constructed, foundation wall and rim joist insulation were not a component of construction practices. As a future project, consider adding insulation to the foundation wall and rim joist. I recommend not using fiberglass insulation in either of these locations, but instead utilize commercially applied closed cell spray foam or closed cell foam boards that are sealed to surrounding framing using cans of spray foam.

- RC-1 Room Components - Attic Access:

INSULATE ATTIC ACCESS HATCH

The attic access hatch requires insulation and weather stripping to prevent heat loss and heat migration into the attic. A leaky and/or poorly insulated hatch can reduce the overall, average attic insulation value by R-3 or more.

📸 The Complete Report

Insulation and Ventilation

Limitations

Attic Insulation

Attic and Roof Cavity Ventilation

Wall Insulation and Air Bypass

Foundation Insulation

Electric Distribution and Finish

Branch Wiring

Smoke and Carbon Monoxide Alarm Systems

Ceiling Fans

Receptacles and Fixtures

Heating, Cooling, Ventilation

Furnace

Vents and Flues

Air Filters

Distribution Systems

Mechanical Ventilation Systems

Kitchen Ventilation

Bathroom Ventilation

Plumbing

Water Service Supply

Distribution Pipe

Waste Pipe and Discharge

Exterior Hose Bibs

Sump Pumps and Drains

General Comments

Building Characteristics, Conditions and Limitations

Type of Building : Single Family (2-story)

Approximate Square Footage: 1250

Approximate Year of Original Construction: 1919

Unless the wiring in the building has been fully updated, this building likely has wiring that predates the late 1980's. Branch circuit wiring installed in buildings built prior to the late 1980's is typically rated for a maximum temperature of only 60 degrees Celsius. This includes non-metallic sheathed (Romex) wiring, and both BX and AC metal-clad flexible wiring. Knob and tube wiring, typically installed in homes built prior to 1950, may be rated for even lower maximum temperatures. Newer electric fixtures including lighting and fans typically require wiring rated for 90 degrees Celsius. Connecting newer fixtures to older, 60-degree-rated wiring is a potential fire hazard. Repairs for such conditions may involve replacing the last few feet of wiring to newer fixtures with new 90-degree-rated wire, and installing a junction box to join the old and new wiring. It is beyond the scope of this inspection to determine if any such incompatible components are installed. Based on the age of this building, be aware that such components may be present.

Occupancy: Unoccupied

Weather during the inspection: Clear

Approximate temperature during the inspection: 65*F

Ground/Soil surface conditions: Dry

For the Purposes of This Report, the Front Door Faces: West

OLD BUILDINGS AND LEAD AND ASBESTOS

In 1978, federal laws were passed to prohibit use of lead and asbestos in building materials. Manufacturers of building materials were allowed to sell existing stocks of materials that were manufactured with lead and asbestos, so even buildings constructed as late as the mid-1980's could possibly contain lead or asbestos. Identification and testing for lead and asbestos and other environmental testing is beyond the scope of this home inspection. If you wish to seek additional information, I recommend contacting an environmental lab or industrial hygienist.

This house was vacant / unoccupied at the time of inspection. Vacant and unoccupied houses present unique challenges for home inspection, especially the piping and wiring systems which have not be subject to regular use prior to the inspection. While these systems can be tested during inspection, this one-time test is different than regular use and it is difficult to know how these systems will respond to regular use after the inspection. For example, septic systems may initially function and then fail under regular daily use. Plumbing traps may operate with no signs of leaks and then let go when being actively used for a few days. Shower pans may only leak when someone is standing in the shower and taking a shower. Seals for plumbing fixtures can dry up and leak when not is use. Sewer lines with roots may allow water flow, but then fail when waste and tissue are flushed; it can take a few days for that to backup. Please understand we are trying our best to look for clues of past or existing problems to paint a realistic best-guess as to the reliability of these systems during inspection.

Grounds

The home inspector shall observe vegetation, grading, drainage, driveways, patios, walkways, and retaining walls with respect to their effect on the condition of the building. The home inspector is not required to observe fences, geological conditions, soil conditions, recreational facilities (including spas, saunas, steam baths, swimming pools, tennis courts, playground equipment, and other exercise, entertainment, or athletic facilities) or presence or condition of buried fuel storage tanks.

Drainage and Site

Site Description: Grade Toward Building

Clearance to Grade: Standard

Downspout Discharge: Above grade, Next to Foundation

POOR SITE GRADING

The grade of the yard slopes toward the building. In order to control surface water drainage, building practices recommend a minimum slope of one quarter-inch / foot away from the building . Negative grading, as this current condition is called, can lead to water leakage into the basement and structural problems with the foundation.

Recommendation

Have the condition evaluated and repaired by an excavation contractor. Often, a swale is used to create a low point away from the house into which water can be diverted away from and around the building. With the close proximity of the property line, a retaining wall may be required in order to reliably control drainage.

DOWNSPOUT DISCHARGE NEAR FOUNDATION

Downspout discharges adjacent to the foundation. This can cause foundation settlement or basement moisture problems. Make sure the downspout discharge point is at least 5 feet away from the foundation. In some cases, a buried discharge pipe is required, terminating at a location that drains away from the foundation.

Driveways/Walkways/Flatwork

Driveway materials: Asphalt

Walkway materials: Concrete

Retaining Walls

Retaining Wall Material: Stone

LEANING RETAINING WALL

The retaining wall in the front yard is in unreliable condition. Old walls like this can sometimes last for many years in this state, but repairs could be needed at any time. Hydrostatic pressure from heavy rains could cause further movement, which could necessitate retaining wall repair/replacement.

Recommendation

Monitor and repair as needed.

Porch and Stoop

The home inspector shall observe decks, balconies, stoops, steps, areaways, porches, applicable railings. The inspector shall describe the type of walking surface and the type of railings, if present. The inspector shall report as in need of correction, any improper spacing between intermediate balusters, spindles and rails.

Front Porch

Ledger Board: Standard

Guardrail: Standard, Incomplete, Missing

Decking Material: Treated wood

MISSING GUARDRAIL

The guardrail and handrail for the stairs are missing. A 32 to 36 inches tall railing is recommended for deck stairs with three or more risers. Openings no larger than 4 3/8 inches are recommended. All posts and railing should also be adequately stiff to prevent a falling adult. Hire a licensed general contractor to evaluate and repair.

Rear Stoop

Type: Entry stoop

Ledger Board: Standard

Decking Material: Treated wood

MISSING GUARDRAIL A guardrail is needed for all decks more than 30-inches above the ground. The railing should be at least 36-inches tall with vertical openings no larger than 4-inches. No guardrail has been installed here and one is required where the deck is more than 30-inches above the ground.

Exterior

The inspector shall inspect: The exterior wall covering materials; the eaves, soffits and fascia; a representative number of windows; all exterior doors; flashing and trim; adjacent walkways and driveways; stairs, steps, stoops, stairways and ramps; porches, patios, decks, balconies and carports; railings, guards and handrails; and vegetation, surface drainage, retaining walls and grading of the property, where they may adversely affect the structure due to moisture intrusion. The inspector shall describe: the type of exterior wall covering materials. The inspector shall report as in need of correction: any improper spacing between intermediate balusters, spindles and rails. The inspector is not required to: inspect or operate screens, storm windows, shutters, awnings, fences, outbuildings, or exterior accent lighting; inspect items that are not visible or readily accessible from the ground, including window and door flashing; inspect or identify geological, geotechnical, hydrological or soil conditions; inspect recreational facilities or playground equipment; inspect seawalls, break walls or docks. inspect erosion control or earth stabilization measures; inspect for safety type glass; inspect underground utilities; inspect underground items; inspect wells or springs; inspect solar, wind or geothermal systems; inspect swimming pools or spas; inspect wastewater treatment systems, septic systems or cesspools; inspect irrigation or sprinkler systems; inspect drainfields or dry wells; determine the integrity of multiple pane window glazing or thermal window seals.

Siding and Trim

Siding Material: Manufactured Wood

Trim Material: Manufactured wood

LOCALIZED SIDING REPAIRS

Localized exterior siding repairs and maintenance are needed. Examples of observations noted during the inspection include:

- North wall: Loose siding

Recommendation

Hire a licensed building contractor to further evaluate and repair as needed.

Eaves

Eave and fascia material: Wood

Exterior Vent and Exhaust Terminations

Exterior Siding and Vent Terminations: Present

Roof, Gutters, and Chimney

The inspector shall inspect from the ground level or the eaves: roof covering materials, gutters, downspouts, vents, flashing, skylights, chimney, and other roof penetrations. The inspector shall inspect the general structure of the roof from the readily accessible panels, doors, or stairs. The inspector shall describe the type of roof covering materials. The inspector shall report as in need of correction: observed indications of active roof leaks. The inspector is not required to: walk on any roof surface, predict the service life expectancy, inspect underground downspout diverter drainage pipes, remove snow, ice, debris or other conditions that prohibit the observation of the roof surfaces, move insulation, inspect antennae, satellite dishes, lightning arresters, de-icing equipment, or similar attachments, walk on any roof areas that appear, in the inspector's opinion, to be unsafe; walk on any roof areas that doing so might, in the inspector's opinion, cause damage; perform a water leakage test, warrant or certify the roof, or confirm proper fastening or installation of any roof covering material.

Roof Materials

Roof Covering Materials: Architectural grade composition shingle

Method of Inspecting Roof: Viewed at top of ladder

Roof Style: Gable

Flashings, Valleys and Penetrations: Roof Edge Flashing Noted, California Cut Valley, Sewer vent flashing (Damaged)

This building has a cut valley detail for the roofing valleys. These generally perform adequately, though some roofers and some shingle manufacturers do not recommend this type of valley detail. They are so common here, I do not consider them defective or in need of repair unless there is visible evidence that a repair is needed at the time or they are showing excessive ware. Generally, valleys done with metal flashing systems are more reliable.

DAMAGED SEWER VENT BOOT The plumbing boot was damaged and is subject to leakage. Water stains were observed on the 2nd floor that appear to be associated with this condition. Contact a licensed building contractor for repair. One option is to replace the entire boot. Another is to utilize a repair boot that slips over the existing plumbing boot.

Gutters and Downspouts

Gutter Materials: Seamless Aluminum Gutters

Downspout Materials: Aluminum

Chimneys

Chimney Chase Material: Brick

CHIMNEY REPAIRS NEEDED

Repairs are needed to the masonry chimney. The conditions noted here could increase the risk of moisture problems. Neglecting maintenance on masonry chimneys can also lead to loose or damaged bricks and eventually a failing masonry system.

Recommendation

Hire a licensed masonry contractor to further evaluate and repair the masonry chimney as recommended. Observations noted during the inspection include:

- Minor cracks in grout

Structure

The home inspector shall inspect structural components including the foundation, the basement, the crawlspace, structural components including joist condition, joist supporting structures, connections, floor sheathing, visible wall components, ceiling joists, and roof structure. The home inspector shall describe the type of foundation, floor structure, wall structure, ceiling structure, and roof structure. The inspector shall describe the location of the access to the under floor space. The inspector shall report as in need of correction: Observed indications of wood in contact with or near soil, Observed indications of active water penetration. Observed indications of possible foundation movement, such as sheetrock cracks, brick cracks, out-of-square door frames, and unlevel floors. And any observed cutting, notching and boring of framing members that may, in the inspector's opinion, present a structural or safety concern. The inspector is not required to: Enter any crawlspace that is not readily accessible, or where entry could cause damage or pose a hazard to him/herself. Move stored items or debris. Operate sump pumps with inaccessible floats. Identify the size, spacing, span or location or determine the adequacy of foundation bolting, bracing, joists, joist spans or support systems. Provide any engineering or architectural service. Report on the adequacy of any structural system or component.

Foundation

Foundation Description: Foundation type (Basement), Material (Poured concrete)

Foundation wall insulation: No foundation insulation observed

Rim joist insulation: No insulation present

Floor, Wall and Ceiling Structure

Exterior Wall Structure: Wall structure (Dinensional lumber, 2x4)

Floor Structure: Floor framing (Dimensional lumber, 2x6, 2x8)

Ceiling Structure: Dimensional lumber

MISSING JOIST HANGERS Joist hangers are missing in several locations. Displacement and/or failure was not observed. Have this condition investigated and repaired as recommended by a licensed building contractor.

JOIST HANGER FASTENER ISSUES The joist hangers are missing fasteners and are fastened with non-structural, not approved fasteners. This is non-standard and can cause the hangers to fail. Have this further investigated and repaired as recommended by a licensed building contractor.

Roof Framing and Sheathing

Roof structure: Rafters

Sheathing: 3/4 inch boards

IMPROPERLY CUT RAFTER Multiple improperly cut rafters were noted in the attic space. This condition weakens the roof structure and requires repair. Hire a licensed building contractor to further evaluate and repair the roof structure.

Insulation and Ventilation

Limitations

Attic was inspected from the attic hatch. No walkway present in the attic.

Attic Insulation

Insulation Type: Cellulose

Approximate Insulation R-Value on Attic Floor: 38

Attic and Roof Cavity Ventilation

Ventilation Method: Ridge vents, Soffit vents

Attic and roof cavity ventilation is a frequently misunderstood element of residential construction. All roof cavities are required to have ventilation. The general default standard is 1 to 150 of the attic area and ideally, this comes from at least 60% lower roof cavity ventilation and 40% upper, but this is an over-simplifications of the subject. As a good guiding principle the most important elements for healthy attic spaces, which are traditionally insulated and ventilated are:

- Make sure the ceiling between the living space and the attic is airtight

- Ventilate consistently across the whole lower part of the roof cavity with low, intake soffit venting

- Upper roof cavity venting is less important and if over-installed can exacerbate air migration into the attic from the living space.

- Avoid power ventilators which can depressurize the attic and exacerbate air migration from the house into the attic.

For more information, please see: Link

Wall Insulation and Air Bypass

Wall Insulation: 2 x 4 wall framing, assume R-19

Foundation Insulation

Foundation Wall Insulation: No wall insulation present

Rim Joist Insulation: None present

NO FOUNDATION INSULATION The above grade foundation and rim joist area of a home are a significant source of heat loss in winter. Current new construction practices utilize insulation on the rim joist and foundation to R-15. At the time this home was constructed, foundation wall and rim joist insulation were not a component of construction practices. As a future project, consider adding insulation to the foundation wall and rim joist. I recommend not using fiberglass insulation in either of these locations, but instead utilize commercially applied closed cell spray foam or closed cell foam boards that are sealed to surrounding framing using cans of spray foam.

Electric Service

The home inspector shall observe the following: service entrance conductors, service equipment, grounding equipment, main over current device, main and distribution panels, amperage and voltage ratings of the service, branch circuit conductors, their over current devices, the compatibility of over current device/conductor ampacities and voltages, the operation of a representative number of installed ceiling fans, lighting fixtures, switches and receptacles located inside the house, garage, and on the dwelling's exterior walls, the polarity and grounding of all receptacles within six feet of interior plumbing fixtures, and all receptacles in the garage or carport, and on the exterior of inspected structures, the operation of ground fault circuit interrupters and smoke detectors. The home inspector shall describe service amperage and voltage, service entry conductor materials, service type as being overhead or underground and location of main and distribution panels. The home inspector shall report any observed aluminum branch circuit wiring. The home inspector shall report on presence or absence of smoke detectors, and operate their test function using the test button, if accessible, except when detectors are part of a central system. The home inspector is not required to insert any tool, probe, or testing device inside the panels, test or operate any over current device except ground fault circuit interrupters, dismantle any electrical device or control other than to remove the covers of the main and auxiliary distribution panels nor observe low voltage systems, security system devices, heat detectors, carbon monoxide detectors, telephone, security, cable TV, intercoms, their ancillary wiring that is not a part of the primary electrical distribution system, nor built-in vacuum equipment.

Electric Service

Electric Service Panel

Panel Manufacturer: Square D

Main Electric Panel Location: Basement

Most Recent Inspection: 2010

Main Breaker Amperage: 100 amps

Overcurrent Protection Devices: Breakers

# of 110 Volt Circuits: 8

# of 220 Volt Circuits: 3

Circuit Breaker Size: 15,20,30,50

Wire Type: Main: Aluminum

Wire Type: Distribution: Copper

Service Panel Bonding & Ground: Bonding screw observed properly installed, Grounding conductor was observed exiting the panel

SCREWS MISSING FOR ELECTRIC PANEL

The main panel is missing a screw to secure the dead front cover. Install missing screw as needed for improved safety. Note that screws with sharp ends are a safety hazard and not allowed. Proper, blunt end screws are available at local hardware suppliers.

MULTIPLE BRANDS OF BREAKERS USED

There are different brands of breakers installed in the electric panel. Electric panels are only rated to have certain types and brands of breakers installed. Determining proper breaker use can necessitate referring to the manufacturers listing. Some of the breakers installed here could be incompatible with what is approved for the panel. The risk here is loose connections which can lead to arcing and overheating.

Recommendation

I recommend further evaluation of the panel by a licensed electrical contractor. Repair the mismatched breakers as recommended by the electrical contractor and the panel manufacturer.

Receptacles and Fixtures

Inspection Method: Representative Testing

A representative number of receptacles and switches were tested during inspection. Any defects found during inspection are noted in this report. Only visible and accessible receptacles and switches were tested during inspection and personal items and furnishings are not moved to access any receptacles or fixtures. Inspection/testing of the electrical system can be challenging. It should be anticipated that not all defects will be discovered and that some issues found may actually not be defects at all. Tools used to verify proper wiring and function can vary wildly in reliability/consistency. The kinds of tools that could be used to confidently analyze the system and its function cannot typically be done in the context of a Standard Home Inspection. I look for indications of issues, based on the age of the home, types of wiring systems used etc, as well as personal experience and by testing with a variety of common tools. Issues identified, will be further discussed with recommendations in the electrical section below.

Electric Distribution and Finish

Branch Wiring

Wire Material: Copper

Wiring Method: Non-metallic sheathed cable, Cloth cable sheathed wiring

OLDER CLOTH COVERED WIRE

Older cloth covered cable wiring was noted in use here. This is generally older wiring that should be considered for updating, especially in the course of renovation work. This wiring cable can become brittle over time so the jacket may be more vulnerable to deterioration and physical damage. The wiring was also likely rated for 60 degree Celsius, an older rating that makes the wiring more vulnerable to heat buildup.

Smoke and Carbon Monoxide Alarm Systems

Smoke Alarms: Present

During the home inspection, I try and test a representative sample of the smoke alarms by using the test button on the alarms. This is NOT an accurate test of the sensor, just a test to see if the unit is powered. For reliability, fire marshals recommended updating smoke alarms every ten years and changing batteries bi-annually. The latest data indicate that we should be using photoelectric technology in our smoke alarms for improved fire detection and reducing problems with false alarms, which can lead to disabling of this critical safety system. Unfortunately, the alarms must be removed to determine if they are photo-electric or ionization types. It is surprisingly complex to accurately test a smoke alarm system and determine the reliability, age, and type of sensor technology used, especially as many homes can have half a dozen or more alarms throughout the house. A complete evaluation of smoke alarms is beyond the scope of this inspection. For optimal fire safety, I recommend taking control of these critical safety devices and learning about how to service and maintain your smoke alarm system to keep the building occupants safe. For more information, please read this link. For more information, please read this link.

CO Alarms: Present

Carbon monoxide alarms were found and noted during the inspection. Be sure to check these regularly. The standard is 1/ floor and one outside all sleeping areas.

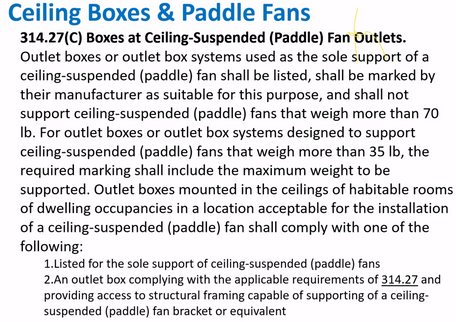

Ceiling Fans

Ceiling Fans: Present and Tested

The ceiling fans were tested and operating during the inspection. I do not inspect the ceiling fan mounting as this is inaccessible to inspection. It is important the ceiling fans get well-mounted to the ceiling with proper fan fixture boxes.

Receptacles and Fixtures

Inspection Method: Representative Testing

A representative number of receptacles and switches were tested during inspection. Any defects found during inspection are noted in this report. Only visible and accessible receptacles and switches were tested during inspection and personal items and furnishings are not moved to access any receptacles or fixtures. Inspection/testing of the electrical system can be challenging. It should be anticipated that not all defects will be discovered and that some issues found may actually not be defects at all. Tools used to verify proper wiring and function can vary wildly in reliability/consistency. The kinds of tools that could be used to confidently analyze the system and its function cannot typically be done in the context of a Standard Home Inspection. I look for indications of issues, based on the age of the home, types of wiring systems used etc, as well as personal experience and by testing with a variety of common tools. Issues identified, will be further discussed with recommendations in the electrical section below.

Electric Receptacles: Three wire receptacles, Two wire receptacles, Open Grounds in Old House

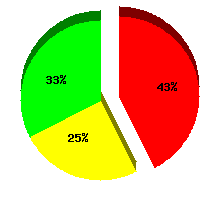

GFCI PROTECTION RECOMMENDED

Since the 1970s, requirements for GFCI (Ground Fault Circuit Interruption) protection have changed, and locations requiring GFCI protection seem to get added with every code cycle. It is common for older residential buildings to have some or even many electric receptacles that do not meet modern safety standards. GFCIs have proven successful at reducing electrocutions, and it seems likely that someday, every circuit, receptacle, and appliance in the building will require GFCI protection. The first chart below shows how successful GFCIs have been at reducing risks from electrocution. The second illustration shows where GFCI protection is required as of the 2020 NEC and WAC. As a general best practice for safety. For improved safety, I always recommend bringing GFCI protection up to modern safety standards.

During inspection today, I noted that GFCI protection is inconsistent with modern minimum standards for safety in the following locations:

MISSING LIGHT FIXTURE

- Missing light fixture noted.

- Electric box not present.

- Safety: Energized wire present.

Recommendation

Hire a licensed electrical contractor to install a light fixture and electric box.

OLDER TWO WIRE SYSTEM NOTED

The electrical branch wiring system here still employs some older two-wire system. This suggests there is still some older wiring here even though some wiring updates have been done. Though there is nothing wrong with this configuration you may find it inconvenient in some areas, especially in offices and media areas. In general, this indicates an older electrical system that has not been completely updated and may not safety or reliably meet modern demands and expectations for the wiring system.

Recommendation

I recommend consulting with a licensed electrical contractor about options for updating this older wiring.

Fuel Storage and Distribution

Propane Storage

Storage Type: Above ground tank

Propane Tank Size: 500 gallons

Propane Tank Location: East side of building

Propane Shutoff Location: At tank

Fuel gauge location: Located under the tank cover

Fuel gauge located under the propane tank cover.

Propane Pipe

Propane Pipe Materials: CSST, Copper

Heating, Cooling, Ventilation

Furnace

Energy Source: Propane

Heating Method: Propane forced air furnace

This house has a propane forced air furnace. A critical component to all combustion heating equipment is the heat exchanger. This is the welded metal assembly inside the furnace that contains the products of combustion so that moisture, carbon monoxide and other products of combustion do not mix with interior air and get safely vented to the exterior. Heat exchangers on modern furnaces have an average life expectancy of 15-20 years. Unfortunately, heat exchangers are concealed inside the heating equipment; they are not visible and specifically excluded from a home inspection. Cracks in heat exchangers may be concealed and can pose a potential safety hazard.

Manufacturer: Goodman

Age: 2019

Listed Max Capacity Per Data Plate: 80,000 btu's

Vents and Flues

Present

Air Filters

Filtration Systems: Disposable

CHANGE DISPOSABLE HVAC FILTERS QUARTERLY

The heating system has disposable air filters installed. These should be changed quarterly or more to ensure proper airflow at the furnace. Be sure to install the filters with the arrows pointing in the same direction as the airflow in the furnace.

Distribution Systems

Heat Source in Each Room: Present

Distribution Method: Forced Air / Ducts

Mechanical Ventilation Systems

Bath Fan Ducting: Ducted to exterior

Kitchen Fan Ducting: Ducted to exterior

Kitchen Ventilation

Fan Ducted to Exterior

Bathroom Ventilation

Type: Bath fan

Plumbing

The inspector shall inspect: The main water supply shut off valve. The main fuel supply shut off valve. The water heating equipment, including the energy source, venting connections, temperature/pressure-relief (TPR) valves, Watts 210 valves, and seismic bracing. Interior water supply, including all fixtures and faucets, by running the water. All toilets for proper operation by flushing. All sinks, tubs and showers for functional drainage. The drain, waste and vent system. Drainage sump pumps with accessible floats. The inspector shall describe: Whether the water supply is public or private based upon observed evidence. The location of the main water supply shut off valve. The location of the main fuel supply shut-off valve. The location of any observed fuel-storage system. The capacity of the water heating equipment, if labeled. The inspector shall report as in need of correction: Deficiencies in the water supply by viewing the functional flow in two fixtures operated simultaneously. Deficiencies in the installation of hot and cold water faucets. Active plumbing water leaks that were observed during the inspection. Toilets that were damaged, had loose connections to the floor, were leaking, or had tank components that did not operate. The inspector is not required to: Light or ignite pilot flames. Measure the capacity, temperature, age, life expectancy or adequacy of the water heater. Inspect the interior of flues or chimneys, combustion air systems, water softener or filtering systems, well pumps or tanks, safety or shut off valves, floor drains, lawn sprinkler systems, or fire sprinkler systems. Determine the exact flow rate, volume, pressure, temperature or adequacy of the water supply. Determine the water quality, potability or reliability of the water supply or source. Open sealed plumbing access panels. Inspect clothes washing machines or their connections. Operate any valve. Test shower pans, tub and shower surrounds or enclosures for leakage or for functional overflow protection. Evaluate the compliance with conservation, energy or building standards, or the proper design or sizing of any water, waste or venting components, fixtures or piping. Determine the effectiveness of anti-siphon, back flow prevention or drain-stop devices. Determine whether there are sufficient cleanouts for effective cleaning of drains. Evaluate fuel storage tanks or supply systems. Inspect wastewater treatment systems. Inspect water treatment systems or water filters. Inspect water storage tanks, pressure pumps, or bladder tanks. Evaluate wait time to obtain hot water at fixtures, or perform testing of any kind to water heater elements. Evaluate or determine the adequacy of combustion air. Test, operate, open or close: safety controls, manual stop valves, temperature/pressure relief valves, control valves, or check valves. Examine ancillary or auxiliary systems or components, such as, but not limited to, those related to solar water heating and hot water circulation. Determine the existence or condition of polybutylene, polyethylene, or similar plastic piping. Inspect or test for gas or fuel leaks, or indications thereof.

Water Service Supply

Distribution Pipe

Distribution Pipe Materials: Copper

Copper water supply pipes were installed. Copper pipes installed prior to the late 1980's may be joined with solder that contains lead, which is a known health hazard especially for children. Laws were passed in 1985 prohibiting the use of lead in solder, but prior to that solder normally contained approximately 50% lead. Note that testing for toxic materials such as lead, is beyond the scope of this inspection. Consider having a qualified lab test for lead, and if necessary take steps to reduce or remove lead from the water supply. Various solutions include:

- Flush water taps or faucets. Do not drink water that has been sitting in the plumbing lines for more than 6 hours

- Install appropriate filters at points of use

- Use only cold water for cooking and drinking, as hot water dissolves lead more quickly than cold water

- Treat well water to make it less corrosive

- Have a qualified plumber replace supply pipes and/or plumbing components as necessary

Functional Flow: Average

Hot water: Present in all fixtures

Plumbing Testing Proceedures: All Plumbing was Tested

MONITOR PIPES AND PLUMBING SYSTEMS AFTER MOVING IN

I recommend monitoring waste and supply plumbing and plumbing fixtures for several months after moving in. I ran all plumbing fixtures during the inspection. Any leaks or signs of active or past leaks will be noted elsewhere in this report. Daily use of plumbing presents more stress and challenges to piping systems than simply testing them during inspection.

Waste Pipe and Discharge

Limitations: Discharge pipes that are hidden within wall and ceiling cavities were not inspected.

Discharge Type: Public Sewer - Buyer

Waste and Vent Pipe Materials: PVC, Cast Iron

Functional drainage: Present in all fixtures

PARTLY UPDATED WASTE PIPING - SOME METAL WASTE PIPE NOTED

Some of the waste plumbing systems in this building are made of old metal and have not been updated to plastic. No leaks were noted at the time of inspection, but updating and ongoing repairs could be needed at any time. Old metal pipes are susceptible to internal corrosion, which can make it difficult to identify older, weaker pipes until they begin to leak. During renovations to the building, be sure to have this old piping evaluated and updated as recommended by a licensed plumber. As a general rule, old cast iron pipes often last a very long time - even as long as 100 years. Galvanized and copper waste pipes can have a shorter useful service life - sometimes 50 years. The service life from this pipe is influenced by water quality and occupant behavior; the use of cleaning chemicals like Drain-O can be tough on metal pipes.

Exterior Hose Bibs

Operating

Sump Pumps and Drains

Floor Drain: Basement Floor Drain Present

A floor drain was noted in the basement. I do not test floor drains, but I do recommend they be tested for function by the homeowner or a handy person by running a hose in them for a prolonged time or having them professionally scoped by a qualified plumber. The traps in these drains sometimes dry out, allowing sewer gases and vermin into the home. As a part of routine maintenance, I recommend making sure the drain trap has water in it and is properly covered.

Water Heater

Water Heater

Manufacturer: A.O.Smith

Energy Source: Electricity

System Type: Tank

Size: 40 gal

Age: 2018

TPR DISCHARGE PIPE MISSING The discharge pipe for the water heater temperature and pressure relief valve is missing and requires repair to eliminate a scald hazard. This is an important safety feature. Should the TPRV need to discharge, scalding water and steam could come out. This water and steam needs to be directed away from people and terminate within 6 inches of the floor. Hire a licensed plumber to further evaluate and repair.

Additional Plumbing

Sinks

Tested

Toilet

Low flow, 1.6 gallon/flush

Bathtub / Shower

Tested

Location: Main floor bathroom

Tub Type: Molded one piece

Stand Alone Shower

Tested

Location: Second floor bath

Shower Type: Molded one piece

Radon Mitigation System

Radon Warning Statement: The Minnesota Department of Health strongly recommends that ALL homebuyers have an indoor radon test performed prior to purchase or taking occupancy and recommends having the radon levels mitigated if elevated radon concentrations are found. Elevated radon concentrations can easily be reduced by a qualified, certified, or licensed, if applicable, radon mitigator. Every buyer of an interest in residential real property is notified that the property may present exposure to dangerous levels of indoor radon gas that may place the occupants at risk of developing radon-induced lung cancer. Radon, a Class A human carcinogen, is the leading cause of lung cancer in nonsmokers and the second leading cause overall. The seller of any interest in residential real property is required to provide the buyer with any information on radon test results of the dwelling.

RADON MITIGATION SYSTEM NOT PRESENT

Radon is a Class 1 human carcinogen and the number one cause of lung cancer for non smokers.

Recommendation

Test the home for the presence radon. The Minnesota Department of Health and the EPA recommend all homes be tested for radon at the time of a real estate transaction and every two years thereafter. The MN Dept of Health reports that over 40% of tested Cook County homes have elevated levels of radon above the EPA action level of 4 pCi/L and pose a serious health risk. Just as important, a significant number of homes with radon mitigation systems in place have elevated radon levels.

More Information:

http://www.senty.com/radon-testing

Room Components

The home inspector shall observe all entryway doors, a representative number of windows, doors, garage door operators, walls, ceiling, and floors, steps, stairways, balconies, and railings. The home inspector shall operate all entryway doors and a representative number of windows, operate garage doors manually or by using permanently installed controls for any garage door operator, and report whether or not any garage door operator will automatically reverse or stop when meeting reasonable resistance during closing. The home inspector shall report signs of abnormal or harmful water penetration into the building or signs of abnormal or harmful condensation on building components. The home inspector is not required to observe storm windows, storm doors, screening, shutters, awnings, and similar seasonal accessories, presence of safety glazing in doors and windows, garage door operator remote control transmitters, paint, wallpaper, and other finish treatments on the interior walls, ceilings, and floors, carpeting, draperies, blinds, or other window treatments.

Attic Access

Hatch location: Hall ceiling

Hatch cover condition: Poorly insulated with missing gasket

Common Recommendations and Observations: Hatch (Insulate and Weather Strip - 1)

Walls, Ceilings, Trim, Hallways and Closets

Wall and Ceiling Materials: Drywall, Wood

Floors and Floor Materials

Floor Materials: Tile, Vinyl, Wood

Common Observations: Hardwood, Softwood, Bamboo (Localized Water Damage - Dry - Repair As Desired)

WATER DAMAGED FLOORING NOTED

Localized water damage was noted on the hardwood floor. This is localized and appears to be associated with the damaged sewer vent flashing on the roof. Repair the damaged sewer vent flashing and then repair the water damaged floor as desired.

Interior Stairs and Railings

Rail Material: Wood

Stair tread: Carpet, Wood

Interior Doors

Interior Doors: Frame and Panel

Exterior Doors

Materials and Styles: Steel, Sliding glass, Aluminum clad wood, In swing

Windows

Window Styles: Casement, Double hung

Window Glazing: Double pane, Single pane

SINGLE PANE GLASS NOTED

Some of the windows in this building utilize single pane glass. These single pane windows do not comply with modern standards for safety and energy efficiency. Improvements generally require replacing the entire window. If you wish to update the remaining windows for improved energy efficiency and comfort, I recommend consulting with a licensed building contractor to devise a plan for updating the remaining uninsulated windows. Financial assistance may be available. For more information, contact Arrowhead Electric Co-op, Grand Marais PUC, or Link

Window Frame: Wood, Aluminum clad and wood

During inspection today I inspected the headers and sills around all windows where accessible. No water stains, signs of leakage were found. This is good. It is always a good practice to monitor any exposed windows, especially those with south and west exposures to check for leaks during heavy wind-driven rains.

Cabinets and Countertops

Countertop Material: Laminate

Cabinet: Construction (Frame & panel doors)

Vanity

Present

Garage Door and Automatic Opener

Overhead Garage Door Type: Metal

Automatic Garage Opener: Tested - Safety features functioned properly at the time of the inspection

Appliances

Range

Energy Source: Electric

Manufacturer Name: Whirlpool

Year Built: 2010

Refrigerator

Manufacturer Name: Whirlpool

Year Built: 2010

Dishwasher

High Loop / Air Gap: High Loop Present

Manufacturer Name: Whirlpool

Year built: 2010

Microwave

Manufacturer Name: General Electric

Year Built: 2020

Washer

Manufacturer Name: Whirlpool

Year Built: 2010

Dryer

Manufacturer Name: Whirlpool

Year Built: 2010

Power Source: Electric

.png)

.jpg)