Sang Park, License #HI12491, MRSA4846, JE319992

THIS REPORT IS FOR THE EXCLUSIVE USE OF THE CLIENT LISTED ON THIS REPORT. USE BY ANY OTHER PERSONS WITHOUT THE EXPRESS CONSENT OF FAIR WINDS BUILDING INSPECTION SERVICES, LLC. WILL BE A VIOLATION OF A CONTRACTUAL AGREEMENT AND WILL IMMEDIATELY NULLIFY THE REPORT.

The Scope and Purpose

This report outlines the scope and purpose of various inspections offered by Fair Winds Building Inspection Services. In addition to a standard home inspection, some clients may request ancillary inspections, such as a 4-Point Inspection, Wind Mitigation Inspection, or Swimming Pool Inspection. Your inspection may or may not include these ancillary inspections. The specific inspections performed for your property are listed in your agreement and detailed in the main part of this report. If you have any questions about which inspections were conducted, please refer to those sections or contact me directly.

Residential Inspection

The purpose of a home inspection is to help reduce the risk associated with the purchase of a structure by providing a professional opinion about the overall condition of the structure. A home inspection is a limited visual inspection and it cannot eliminate this risk completely. Some homes present more risks than others. I cannot control this, but I try to help educate you about the condition of the property during the inspection process. This is more difficult to convey in a report and one of many reasons why I recommend that you attend the inspection.

This inspection process followed the Florida Department of Business and Professional Regulation Standards of Practice (SOP). The SOP is provided at the end of the report for your reference. There may be comments made in this report that exceed the FL Standards of Practice; these comments (if present) were made as a courtesy to give you as much information as possible about the home. Exceeding the Standards of Practice will only happen when I feel I have the experience, knowledge, or evidence to do so. There should be no expectation that the Standards of Practice will be exceeded throughout the inspection. This inspection and report are not intended to be technically exhaustive. The observations in this report are the opinions of the home inspector. Other inspectors and contractors are likely to have some differing opinions. You are welcome to seek opinions from other professionals.

4-Point Inspection

A “four-point” inspection is a limited visual inspection of the residential structure. A four-point inspection is not exhaustive and is limited to a visual inspection of the four systems and components, which include: 1) the electrical panel and any visible wiring; 2) the plumbing system and any visible pipes; 3) the HVAC system and any visible connections; and, 4) the roof covering and any visible issues. This inspection is not as comprehensive as a full home inspection and is intended only to assess the general condition of these systems.

Wind Mitigation Inspection

A wind mitigation verification inspection is conducted to determine whether a home has specific features designed to withstand strong winds. This inspection is limited to the items listed on the Uniform Mitigation Verification Inspection Form and does not assess other home components. The purpose of this inspection is to verify wind-resistant construction features that may qualify the homeowner for insurance discounts. However, this inspection does not guarantee that a home can withstand severe weather events.

Swimming Pool and Spa Inspection

The purpose of pool and/or span inspection is a) to identify conditions that, in the professional opinion of the Inspector, are significantly deficient or b) to identify systems and components of the pool/spa that are at the end of their service lives in order to help reduce the risk associated with the pool/spa are included in the property. This inspection is a limited visual inspection and it cannot eliminate this risk. Some systems or components present more risks than others. We cannot control this, but we try to help educate you about what we don’t know during the inspection process. This is more difficult to convey in a report and one of many reasons why we recommend that you attend the inspection.

This inspection process followed the American Society of Home Inspectors (ASHI) Standards of Practice (SOP). The SOP is provided at the end of the report for your reference. There may be comments made in this report that exceed the Standards of Practice; these comments (if present) were made as a courtesy to give you as much information as possible about the home. Exceeding the Standards of Practice will only happen when I feel I have the experience, knowledge, or evidence to do so. There should be no expectation that the Standards of Practice will be exceeded throughout the inspection. This inspection and report are not intended to be technically exhaustive. The observations in this report are the opinions of the home inspector. Other inspectors and contractors are likely to have some differing opinions. You are welcome to seek opinions from other professionals.

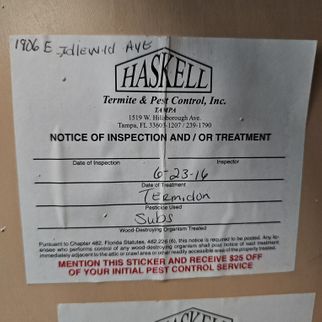

Wood-Destroying Organism (WDO) Inspection

The Inspector, or a subcontractor, will conduct a visual inspection of the readily accessible areas of the Property, including attics and crawlspaces, where access is permitted at the time of inspection. The inspection may involve probing or sounding in unobstructed and accessible areas to identify any visual evidence of wood-destroying organisms. Wood-destroying organisms include termites, carpenter ants, carpenter bees, powder post beetles, old house borers, and wood-decaying fungi. This inspection does not cover mold, mildew, fungi other than wood-decaying fungi, or other non-insect wood-destroying organisms. The Inspector is not responsible for repairing any damage or treating any infestation.

Additionally, wood-destroying organisms may be present in concealed or inaccessible areas. If the written report states that no visible evidence of wood-destroying organisms was found, it does not guarantee that none exist. Damage may have already begun in areas that were not visible or accessible during the inspection. The inspection will be performed in accordance with Florida Department of Agriculture and Consumer Services standards, as outlined in Chapter 482.226 of the Florida Statutes and Chapter 5E-14.142(2)(c) of the Florida Administrative Code. These regulations include specific limitations, exceptions, and exclusions. If any conflict arises, Florida law will take precedence.

System/Component Update Inspection

This inspection is limited to evaluating the specific items documented in this report to determine whether any visually identifiable deficiencies persist. It does not assess the quality, professionalism, or appropriateness of any repairs made. Repairs to previously identified deficiencies should be performed by licensed and qualified professionals with expertise in addressing the specific issues identified. I recommend that the client obtain copies of all paid receipts and warranties for completed work to verify that the repairs were performed by licensed professionals.

This inspection process followed the Florida Department of Business and Professional Regulation Standards of Practice (SOP). The SOP is provided at the end of the report for your reference. There may be comments made in this report that exceed the FL Standards of Practice; these comments (if present) were made as a courtesy to give you as much information as possible about the home. Exceeding the Standards of Practice will only happen when I feel I have the experience, knowledge, or evidence to do so. There should be no expectation that the Standards of Practice will be exceeded throughout the inspection. This inspection and report are not intended to be technically exhaustive. The observations in this report are the opinions of the home inspector. Other inspectors and contractors are likely to have some differing opinions. You are welcome to seek opinions from other professionals.

Mold Testing

Mold testing is offered as an optional, add-on service to the general home inspection. This service involves the collection of air and/or surface samples from specific, readily accessible areas of the property, as agreed upon prior to testing. Samples are submitted to a certified laboratory for analysis, and the resulting report reflects only the laboratory findings and documented observations made at the time of the inspection. This service is limited in scope and is not intended as a comprehensive mold assessment of the entire structure. It does not include destructive testing, hidden area investigation, full moisture mapping, or remediation protocols unless separately contracted under a written agreement.

The descriptions and observations in this report are based on a visual inspection of the property. I inspect the property without dismantling, damaging, or disfiguring and without moving furniture and interior furnishings. This inspection does not cover certain areas that are concealed, hidden, or inaccessible to view. Some systems cannot be tested during this inspection as testing risks damaging the system or the structure. For example, a heat pump is not generally tested if the outside temperature is above 85 degrees Fahrenheit according to most manufacturers' recommendations. The inspection procedures involved non-invasive investigation and non-destructive testing which would limit the scope of the inspection.

This inspection and report are not intended for city / local code compliance. During the construction process structures are inspected for code compliance by municipal inspectors. Framing is open at this time and conditions can be fully viewed. Framing is not open during inspections of finished homes, and this limits the inspection. All houses fall out of code compliance shortly after they are built, as the codes continually change. National codes are augmented at least every three years for all of the varying disciplines. Municipalities can choose to adopt and phase in sections of the codes on their own timetables. There are generally no requirements to bring older homes into compliance unless substantial renovation is being done.

How to Read This Report

Getting the Information to You

This report is designed to deliver important and technical information in a way that is easy for anyone to access and understand. If you are in a hurry, you can take a quick look at our "Summary Page” and quickly get critical information for important decision making. However, I strongly recommend that you take the time to read the full Report, which includes digital photographs, captions, diagrams, descriptions, videos and hot links to additional information.

The best way to get the layers of information that are presented in this report is to read your report online (the HTML version), which will allow you to expand your learning about your house. You will notice some words or series of words highlighted in blue and underlined – clicking on these will provide you with a link to additional information. The HTML version of this report also contains streaming videos. Short video clips often contain important information and critical context and sounds that can be difficult to capture in words and still pictures.

For the most reliable viewing experience, I recommend viewing the report on as large a screen as practical, as much detail can be lost on small devices like smart phones. For similar reasons, reports should only be printed in color to retain as much detail as possible and minimize misinterpretation of photographs.

This report can also be printed on paper or to a PDF document.

Chapters and Sections

This report is divided into chapters that parcel the home into logical inspection components. Each chapter is broken into sections that relate to a specific system or component of the home. You can navigate between chapters with the click of a button on the left side margin.

Most sections will contain some descriptive information done in black font. Observation narrative, done in colored boxes, will be included if a system or component is found to be significantly deficient in some way or if we wish to provide helpful additional information about the system or the scope of our inspection. If a system or component of the home was deemed to be in satisfactory or serviceable condition, there may be no narrative observation comments in that section and it may simply say “tested,” or “inspected.”

Observation Labels

All narrative observations are colored, numbered and labeled to help you find, refer to, and understand the severity of the observation. Observation colors and labels used in this report are:

- Major Concern:Repair items that may cost significant money to correct now or in the near future, or items that require immediate attention to prevent additional damage or eliminate safety hazards.

- Repair:Repair and maintenance items noted during inspection. Please note that some repair items can be expensive to correct such as re-finishing hardwood floors, but are considered simply repair items due to their cosmetic nature.

- Improve:Observations that are not necessarily defects, but which could be improved for safety, efficiency, or reliability reasons.

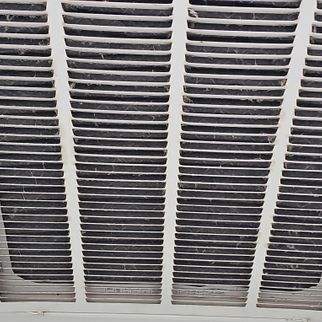

- Recommended Maintenance:These are repair items that should be considered "routine home ownership items," such as servicing the furnace, cleaning the gutters or changing the air filters in the furnace.

- Due Diligence:thoroughly investigating the property to ensure there are no hidden issues or surprises.

- Description:Detailed description of various aspects of the property noted during the inspection.

- Limitation:Explanation of inspection limitations

- Note:Refers to a side information and/or any comments elaborating on descriptions of systems in the home.

- SOP:State of Florida Department of Business and Professional Regulation Standards of Practice for home inspection

- Homeowner's Responsibility:Your responsibilities as a homeowner

Summary Page

The Summary Page is designed as a bulleted overview of all the observations noted during inspection. This helpful overview is not a substitution for reading the entire inspection report. The entire report must be read to get a complete understanding of this inspection report as the Summary Page does not include photographs or photo captions.

Property Orientation

All locations of the exterior components were given as if you are standing outside and facing the front of the house. The bedrooms and the bathrooms were numbered, going clockwise from the garage entrance door and/or at the top of the stairs when multiple bedrooms/bathrooms existed on the same floor, i.e. bedroom 1, bedroom 2, and master bedroom.

How to Build a Repair Request

To see how to build a custom PDF summary list, built from any number of items in this report, please review this video. The idea behind this feature is to allow the readers of this report to build their own custom lists. These could be used as a tool for inspection responses, or for requesting re-inspection of specific items or for documenting work that has been completed as part of a pre-listing inspection.

No house is perfect. Anything in these categories should be addressed as soon as possible. Often, a serious problem can be corrected inexpensively. Not all deficiencies will be identified during this inspection. This inspection is not a guarantee or warranty of any kind. Unexpected repairs should still be anticipated. All recommended evaluations, repairs, or replacements shall be done by licensed contractors.

Homeownership is both a joyful experience and an important responsibility, so be sure to call on your Fair Winds Building Inspection Services, LLC to help you devise an annual maintenance plan that will keep your family and your investment safe for years to come. Thank you very much for letting us be of service to you and your loved ones.

Summary

Major Concerns

- F-1 Foundation - Crawlspace - Underfloor:

Multiple deficiencies were observed in the crawlspace beneath the floor. Examples of observed issues include:

- R-1 Roof - Roof Structure:

Damaged roof frames were observed in the attic during the inspection. Recommend further evaluation by a licensed pest control contractor.

- R-2 Roof - Roof Structure:

A strut was missing at the purlin that supports the roof rafters. Struts are a critical component in roof framing, intended to transfer roof loads down to a load-bearing point. Best practice calls for struts to be installed at intervals of 4 feet or less and at an angle of 45 degrees or less from horizontal to provide adequate support and prevent sagging or deflection in the purlins. I recommend further evaluation and repair by a licensed contractor with experience in roof framing. Proper installation of the missing strut(s) is necessary to maintain structural integrity and ensure continued roof performance.

- R-3 Roof - Roof Covering:

The main roof covering had multiple deficiencies. Please note that roofs require regular maintenance to keep them performing reliably. Examples of observations and repair items noted during inspection include:

- Missing a ridge cab

- Torn tab

- Localized excess granule loss

- Indication of previous repair

- Uniform granule loss throughout the entire roof

- Granule loss by foot traffic

- Discoloration

- Loose shingles at the intersection of the main roof and the flat roof

These conditions may compromise the roof’s ability to shed water effectively and could lead to future leaks if not addressed. I recommend further evaluation and necessary repairs or replacement by a licensed roofing contractor to ensure the roof remains weather-tight and performs reliably over time.

Repairs

- E1-1 Exterior - Flashing and Trim:

Missing flashings were noted for the horizontal trim above windows, doors, and/or horizontal junctures. This can lead to concealed water entry and damage to those horizontal junctures that have not been flashed, especially when exposed to the weather. A metal flashing shall be provided for areas like this that could prevent water entry. Hire a licensed siding contractor to further evaluate and repair to ensure reliable performance.

- E1-2 Exterior - Eaves, Soffits and Fascia:

I observed damaged soffit during the inspection. I recommend repairing or replacing as recommended by a licensed roofing contractor.

- E1-3 Exterior - Doors:

The door unlocked automatically when pulled, both from the inside and outside, during testing. This indicates a malfunction in the locking mechanism that prevents the door from staying securely locked. I recommend having the door and its locking mechanism further evaluated by a qualified contractor. Repairs or replacement may be necessary to restore proper locking function and ensure the security of the home.

- E1-4 Exterior - Porches, Patios, Decks and/or Balconies:

The stair handrail was loose and needed re-fastening. This condition is a potential fall hazard. Recommends repair by a licensed contractor.

- I-1 Interiors - Windows:

A window was not locking correctly and require adjustment / repair for proper operation of the locking hardware.

- I-2 Interiors - Appliances:

I observed that the range was not fastened to the wall or on the floor. An anti-tip device was missing. This poses a safety hazard to children. Recommend correction.

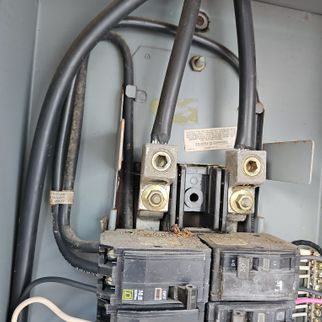

- E-1 Electrical - Main Service Disconnect and Main Panel:

A couple of concerns regarding the main electrical panel was noted:

- A double-pole 60-amp circuit breaker located at the top left of the panel was wired in an unconventional manner. The ungrounded (hot) conductors disappeared behind the circuit breakers, which raises concerns about proper wiring. Wires should be fully visible and properly routed within the panel to reduce fire and shock risks and allow for safe inspection and maintenance.

- The panel did not have a main breaker. This configuration required more than six hand movements to disconnect all power, which violates this safety requirement and increases risk during an emergency shutdown.

I recommend that a licensed electrician further evaluate this panel to:

- Identify and correct the unusual wiring of the 60-amp breaker.

- Install a main disconnect to allow safe shutdown of power to the property in case of an emergency.

Residential Inspection Report

Exterior

Vegetation, Surface Drainage, Retaining Walls & Grading

Fence

Irrigation System

Walkways & Driveways

Wall Covering

Flashing and Trim

Eaves, Soffits and Fascia

Doors

Windows

Porches, Patios, Decks and/or Balconies

Steps/Stairs

Interiors

General

Floors, Walls, and Ceilings

Doors

Windows

Smoke and Carbon Monoxide Detectors

Countertops & Cabinets

Appliances

Electrical

General

Service Drop

Service Head, Gooseneck & Drip Loops

Service Mast, Service Conduit & Raceway

Electric Meter & Base

Service Grounding and Bonding

Main Service Disconnect and Main Panel

Electrical Wiring

Switches, Fixtures & Receptacles

Ground Fault Circuit Interrupters (GFCI)

Building Info, Limitations, and Exclusions

General

Type of Building : Single Family (1 story)

Total Square Footage: 1,282 (Gross Square Footage)

Year of Original Construction: 1947

Attending the Inspection: Inspector only

Occupancy: Staged

I prefer to have the clients present at inspections so that the inspector can more easily explain complicated or technical issues. Potential buyers often look at a home from a different perspective after receiving the Inspection results. Because you were unable to attend, I strongly encourage you to read the whole report thoroughly. Please contact me if you have any questions.

All components and conditions which by the nature of their location are concealed, camouflaged, or difficult to inspect are excluded from the report. The report does not address

- concealed conditions, latent defects, consequential damages, and

- cosmetic imperfections that do not significantly affect a component’s performance of its intended function.

- the remaining life expectancy of systems and components.

- the causes of conditions and deficiencies.

- future conditions including but not limited to failure of systems and components.

- compliance of systems and components with past and present requirements and guidelines (codes, regulations, laws, ordinances, specifications, installation and maintenance instructions, use and care guides, etc.).

- the presence of environmental hazards including, but not limited to, allergens, toxins, carcinogens, electromagnetic radiation, noise, radioactive substances, and contaminants in building materials, soil, water, and air.

- whether items, materials, conditions, and components are subject to recall, controversy, litigation, product liability, and other adverse claims and conditions.

- the market value of the property and its marketability.

- the advisability of purchasing the property.

This home was furnished at the time of the inspection. Inspection of furnished homes presents some challenges as occupant belongings can obstruct visual inspection of and access to parts of the building. According to FL DBPR SOP, the inspection is limited to only those surfaces that are exposed and readily accessible. I did my best during the inspection to work around belongings to discover as much as possible about the house without moving or damaging personal property, however, the presence of personal items did limit the inspection. On your final walkthrough, or at some point after personal belongings have been removed, it is important that you inspect the exterior and interior portions of the residence that were concealed or otherwise inaccessible at the time of the inspection. Contact the Inspector immediately if any adverse conditions are observed that were not commented on in your inspection report.

Mold testing and mold inspection are not included in the scope of this standard home inspection. If you have concerns about mold, I am a licensed mold assessor and can collect samples and conduct mold testing for an additional fee. It is important to note that localized mold issues are often manageable by addressing and sealing the affected area that has experienced water intrusion. The most effective way to prevent and control mold growth is to diagnose and repair water problems promptly. Chronic or widespread water issues can lead to more complex and costly mold remediation, whereas localized water problems typically result in simpler and more contained mold repairs. For further evaluation or testing, please feel free to inquire about additional services.

Complimentary Services

Warranties

Each inspection performed comes with a 90 Day Structural and Mechanical Warranty that covers items that malfunction after the inspection and were confirmed to be in good working order by your inspector. It lasts for 90 Days or 22 Days after closing, whichever comes later, and carries a deductible of $0. Many items covered are the same items covered by your one-year warranty from closing, effectively making your deductible $0 on most claims with your Inspection from us! Click here to see the coverage terms.

Every single inspection we perform comes with a 5-Year Roof Leak Protection Plan ($500 Deductible) that covers the necessary repair for any new leak in your home’s roof system. Click here to see the coverage terms.

If you spot visible mold within the home after the inspection, MoldSafe will pay to remediate the issue! This coverage lasts for 90 Days and comes with a total aggregate limit of $2000 ($300 Deductible), which is automatically increased when you get a mold test with us. Make sure to address any known mold and moisture issues as noted in your inspection report as existing conditions or those stemming from a known issue are not covered. Click here to see the coverage terms.

Underground Sewer and Water lines are covered for 90 days from inspection ($300 Deductible) from issues like collapse and tree roots. While your inspector may recommend sewer camera inspections for some properties, on others where no drain backups or known issues are present this coverage will serve to protect against failures between your home and the municipal connection or well/septic systems. A sewer camera inspection with satisfactory results will automatically extend your coverage to 12 months. Click here to see the coverage terms.

For a period of 90 days following the inspection, RWS will cover the cost to treat for new termite and carpenter ant infestations in accordance with the terms and conditions ($250 Deductible). Thereafter, it is at the option of the contract holder to extend this coverage at a monthly expense as low as $14.97, which will be offered by RWS to the contract holder prior to the expiration. Click here to see the coverage terms.

We don’t just check your refrigerator to see if it’s cold...we check for known fire and safety hazards and deliver with free RecallChek reports for life with every full home inspection! Every repair with RecallChek is 100% FREE, Guaranteed! Click here to learn more.

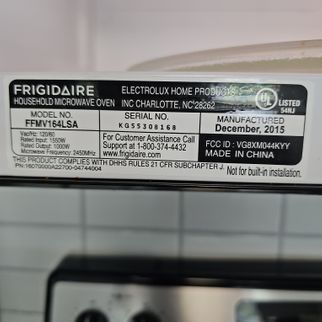

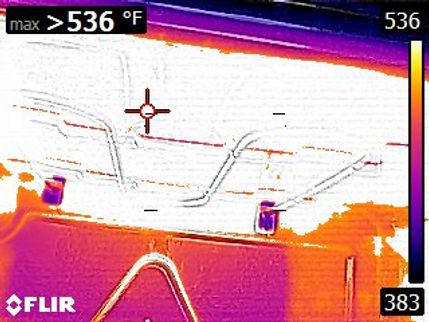

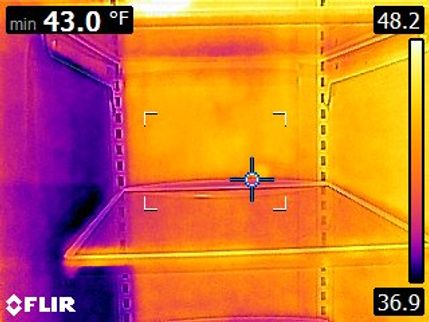

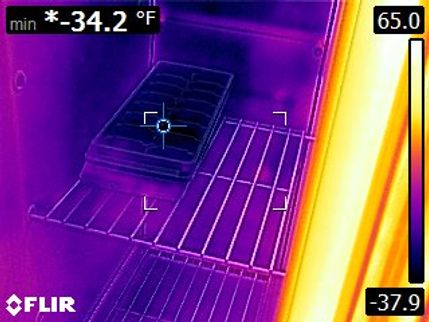

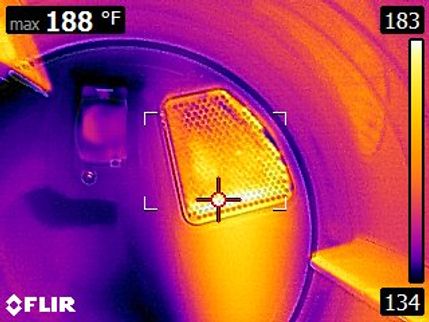

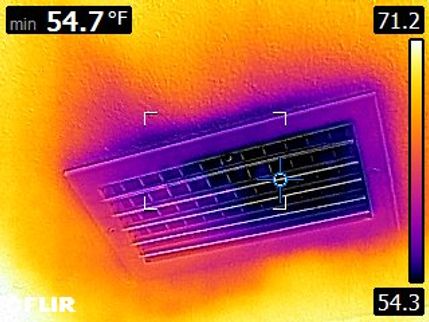

Thermal Imaging

As human beings, we are limited to seeing light only in the visible spectrum called white light. This is the light that bounces off everyday objects whether that light is being emitted by our Sun or an artificial source such as a light bulb.

Without assistance from technology, we are unable to see surface temperature variances, and it is the ability to see these variances that allow us to more accurately identify potential, and immediate, problems in your home that would have otherwise been missed. The unique aspect of seeing surface temperature variances is that such variances can be caused by issues that may lie below the surface of a floor, behind a wall, or above a ceiling - places that are "out of sight" and are thus out of mind. Also, surface temperature variances can be caused by airflows such as warm air seeping under a door or cold air leaking from central air ducts. The air itself changes the surface temperature of objects that come in contact with the air. Surface temperatures can also be changed by living organisms such as mold, mildew, and household pests. Because these organisms often thrive in places that cannot be seen by the naked eye (such as behind walls), the use of infrared thermography allows us to pinpoint exactly where a problem area is in your home without the need for any immediate invasive damage to the structure of your home.

Finally, thermal imaging technology allows us to more accurately identify damage to your home's electrical systems. By being able to pinpoint "hot spots" in the electrical panel and household wiring, we can provide you and your electrician with detailed imagery that will help the electrician identify defects and make repairs more quickly to save you money. In short, infrared thermography is purposefully designed to provide you with a level of service that increases the speed by which many household problems can be identified, reduces the collateral damage required to fix those problems, increases the accuracy rate of correctly identifying problems, and helps you to catch small problems sooner so that don't become expensive or unmanageable problems that can affect your family's health or your financial wellbeing.

Temperature readings displayed on thermal images in this report are included as a courtesy and should not be wholly relied upon as a home inspection is qualitative, not quantitative. These values can vary +/- 2% or more of displayed readings.

Buy Back Guarantee

If your home inspector misses anything, InterNACHI will buy your home back.

And now for the fine print:

- It's valid for home inspections performed for home buyers or sellers by participating InterNACHI members.

- The home must be listed for sale with a licensed real estate agent.

- The Guarantee excludes homes with material defects not present at the time of the inspection, or not required to be inspected, per InterNACHI's Residential Standards of Practice.

- The Guarantee will be honored for 90 days after closing.

- We'll pay you whatever price you paid for the home.

- Click the logo below for full terms and conditions.

Please click here for details.

$25,000 Honor Guarantee

InterNACHI® will pay up to $25,000 (USD; maximum collective aggregate) for the cost of replacement of personal property lost (and not recovered, restituted, or insured) during an inspection and stolen by an InterNACHI®-certified member who was convicted of or pleaded guilty (or no contest) to any criminal charge resulting from the member's taking of the client's personal property. Claimant agrees that the exclusive venue for any action against InterNACHI® arising out of this Honor Guarantee is the District Court in Boulder County, Colorado. InterNACHI's Honor Guarantee is valid throughout the U.S. and Canada. Click here for details.

Exterior

Vegetation, Surface Drainage, Retaining Walls & Grading

Inspection Status: Inspected

Overgrown vegetation and trees were observed at the front of the house. Trees, branches, and large shrubs in close proximity can damage the roof covering and provide rodents with access to the roof, as many rodents are capable of jumping up to 6 feet. I recommend maintaining at least a 6-foot clearance from the roof and keeping all vegetation, including smaller landscaping such as grasses, flowers, and shrubs, at least 1 foot away from the exterior walls to prevent moisture buildup and reduce the risk of pest intrusion. Pruning vegetation away from the structure is advised.

An arborist should be hired to further evaluate the large trees on the property and prune or remove as recommended. Whenever large trees are located near a house a higher level of maintenance should be expected to keep trees safe and healthy and to eliminate the risks of damage to the home or building materials from falling limbs and to eliminate rodent entry points. With larger trees such as oaks, pruning is recommended to eliminate the sail effect and reduce strain on these tress during high winds. If an arborist has not been out in the last few years, I recommend a new consultation.

Fence

Inspection Status: Not Inspected

This house was equipped with a fence. Evaluation of the fence is beyond the scope of this inspection and was not performed. The inspector will not be held liable for any errors or deficiencies not included in the report as a full inspection was not performed on the fence. If desired, a licensed professional can be retained to perform a detailed evaluation and to make any repairs necessary. Incidental observation revealed visible deficiencies and has been included in the report as a professional courtesy.

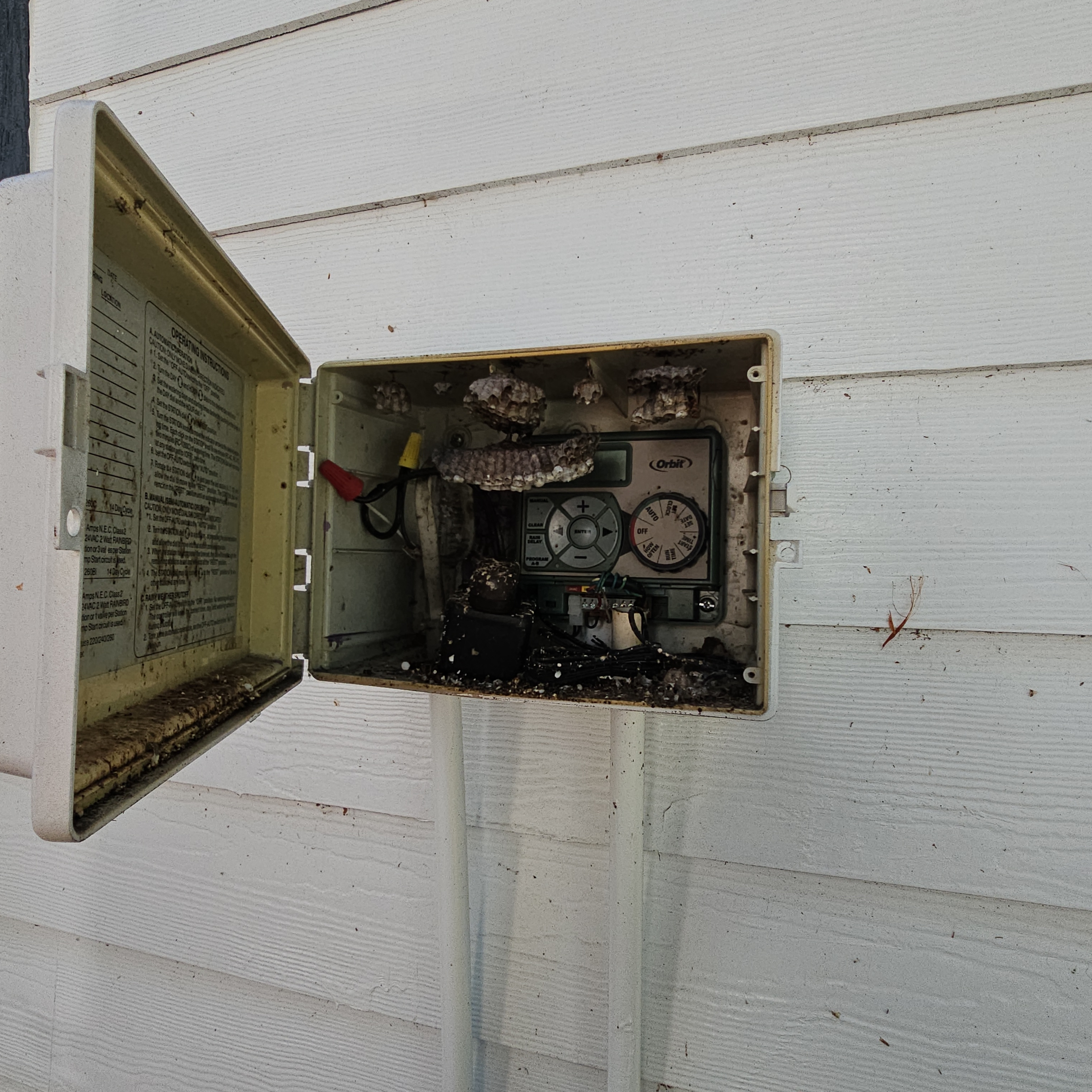

Irrigation System

Inspection Status: Not Inspected

At the time of inspection, the irrigation system controller was located on the exterior wall. Upon opening the enclosure, multiple wasp nests were observed inside the unit, indicating long-term inactivity and creating a potential hazard. Due to the presence of the nests and the condition of the controller, the irrigation system was not tested. I recommend that the irrigation controller be professionally evaluated, cleaned, and repaired or replaced as needed. Once safe access is established and the system is operational, the entire irrigation system should be tested by a qualified technician to ensure proper function.

Walkways & Driveways

Inspection Status: Inspected

Walkway Material: Concrete

Driveway Material: Concrete

Wall Covering

Inspection Status: Inspected

Exterior Wall Structure: Wood Framing

Material: Fiber Cement

The exterior of your home is slowly deteriorating and aging. The sun, wind, rain, and temperatures are constantly affecting it. Every wall penetration is a place for potential water intrusion, causing damages that are not visible until it becomes a major issue. The major issues often can be avoided with regular maintenance, saving thousands of dollars. Your job is to monitor the exterior of the building for its condition and weather tightness. Check the condition of all exterior materials and look for developing patterns of damage or deterioration.

During a heavy rainstorm (without lightning), grab an umbrella and go outside. Walk around your house and look around at the roof and property. A rainstorm is a perfect time to see how the roof, downspouts, and grading are performing. Observe the drainage patterns of your entire property, as well as the property of your neighbor. The ground around your house should slope away from all sides. Downspouts, surface gutters, and drains should be directing water away from the foundation.

Several areas of the exterior wall covering and surrounding components were observed to be in need of general maintenance. These conditions, while not currently urgent, should be addressed to prevent moisture intrusion, insect entry, and potential deterioration of building materials over time. Notable observations included:

- Damaged or deteriorated siding at multiple locations around the property.

- Exterior wall covering in direct contact with concrete surfaces, which can lead to trapped moisture and premature siding damage. A minimum clearance of 1 to 2 inches is typically recommended.

- Unsealed wall penetrations, particularly around utility lines and fixtures, which can allow water or pests to enter.

- Localized missing or failed caulking, which exposes the underlying material to weathering and decay.

- Presence of wasp nests

I recommend general exterior maintenance be performed, including sealing wall penetrations, repairing or replacing damaged siding, improving clearance where siding meets concrete, and addressing paint and caulking issues. Remove all insect nests and ensure components such as the irrigation system are safe to access and operable. A qualified contractor should further evaluate and complete all needed repairs to maintain the home’s exterior integrity and weather protection.

Flashing and Trim

Inspection Status: Inspected

Missing flashings were noted for the horizontal trim above windows, doors, and/or horizontal junctures. This can lead to concealed water entry and damage to those horizontal junctures that have not been flashed, especially when exposed to the weather. A metal flashing shall be provided for areas like this that could prevent water entry. Hire a licensed siding contractor to further evaluate and repair to ensure reliable performance.

Eaves, Soffits and Fascia

Inspection Status: Inspected

I observed damaged soffit during the inspection. I recommend repairing or replacing as recommended by a licensed roofing contractor.

Doors

Inspection Status: Inspected

The door unlocked automatically when pulled, both from the inside and outside, during testing. This indicates a malfunction in the locking mechanism that prevents the door from staying securely locked. I recommend having the door and its locking mechanism further evaluated by a qualified contractor. Repairs or replacement may be necessary to restore proper locking function and ensure the security of the home.

Several minor maintenance items were observed at exterior doors and related components. While these are not major deficiencies, addressing them will improve energy efficiency, security, and functionality. Observations included:

- Missing a door bell

- Not latching

- Displaced door hardware

- Damaged weatherstrip

- Missing a screen door

I recommend having a licensed handyman or door repair contractor complete the necessary minor repairs and adjustments. Regular upkeep of these components helps maintain comfort, safety, and energy efficiency in the home.

Windows

Inspection Status: Inspected

Multiple screens were missing and damaged at the time of inspection. I recommend repairing or replacing the window screen to keep the insects out of the living spaces.

Porches, Patios, Decks and/or Balconies

Inspection Status: Inspected

Material: Concrete

Typical cracks were noted in the porch concrete pad and appears to be cosmetic at this time. Repair as desired. Often people just live with these cracks. They can be filled with concrete sealers if desired. The cracking patterns noted here did not appear structural.

The stair handrail was loose and needed re-fastening. This condition is a potential fall hazard. Recommends repair by a licensed contractor.

Steps/Stairs

Inspection Status: Inspected

Material: Concrete

Foundation

General

Type: Crawlspace

Crawlspace - Underfloor

Inspection Status: Inspected

Underfloor Crawlspace Access Location: Exterior (Left)

Every effort was made to inspect the entire space. Visual inspection of crawl spaces is difficult and limited as access is often restricted by pipes and limited clearances. The crawlspace can be a revealing area in the house and often provides a general picture of how the entire structure works. In many crawlspaces, the structure is exposed overhead, as are the HVAC distribution system, plumbing supply, and DWV (drain, waste, and ventilation) pipes, and the electrical branch-circuit wiring.

Multiple deficiencies were observed in the crawlspace beneath the floor. Examples of observed issues include:

Crawlspace - Insulation

Inspection Status: Not Present

Ventilation in Crawlspace

Inspection Status: Inspected

Roof

General

Roof Type/Style: Gable, Hip, Combination

Inspection Method: Walking on the roof surface

Your job as the homeowner is to monitor the roof covering because any roof can leak. To monitor a roof that is inaccessible or that cannot be walked on safely, use binoculars. Look for deteriorating or loosening of flashing, signs of damage to the roof covering, and debris that can clog valleys and gutters.

Roofs are designed to be water-resistant. Roofs are not designed to be waterproof. Eventually, the roof system will leak. No one can predict when, where, or how a roof will leak.

Your job is to monitor the gutters and be sure that they function during and after a rainstorm. Look for loose parts, sagging gutter ends, and water leaks. The rainwater should be diverted far away from the house foundation.

As a homeowner, it is your responsibility to monitor the condition of the roof covering, as all roofs have the potential to develop leaks over time. Roofs are designed to be water-resistant, not waterproof, and no one can predict when or where a leak may occur. To minimize the risk of costly damage, the entire roof system should be inspected annually as part of routine home maintenance.

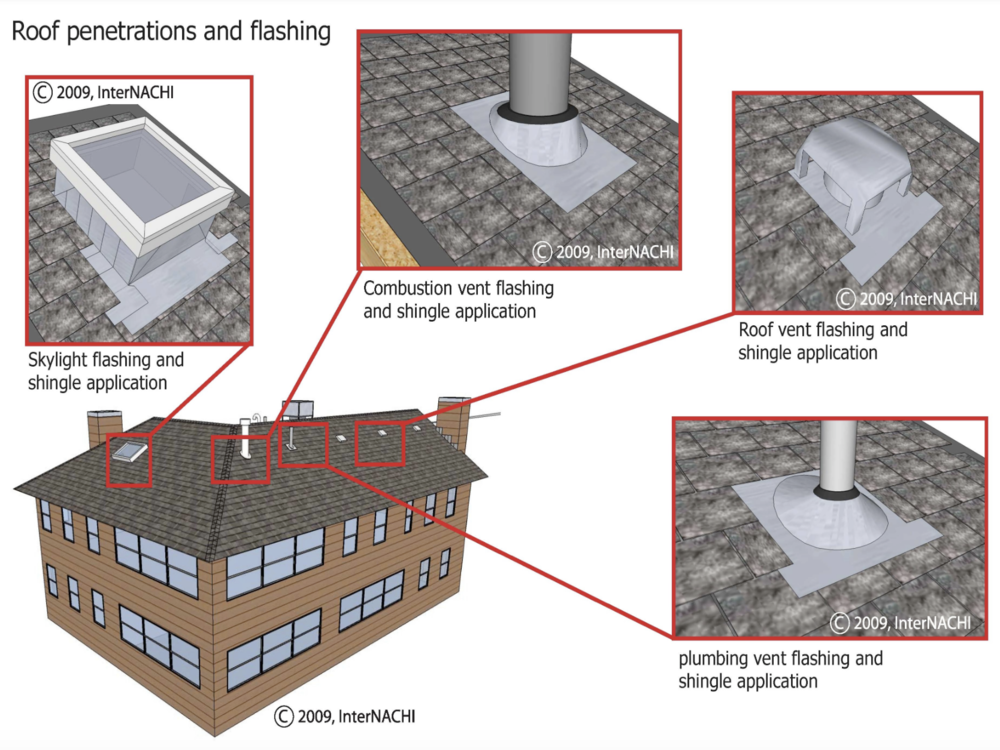

For roofs that are inaccessible or unsafe to walk on, use binoculars to check for signs of deterioration, loose or damaged flashing, and debris accumulation in valleys and gutters. Pay special attention to flashing around plumbing vent pipes, as these components can deteriorate over time and cause leaks. To ensure proper function, vent pipes should remain clear of debris and be periodically inspected for wear.

Additionally, monitor the gutters to ensure they function properly during and after rainfall. Look for loose parts, sagging gutter ends, and water leaks. Proper gutter maintenance is essential to prevent water damage to the roof and exterior walls. Rainwater should be diverted away from the house foundation to reduce the risk of erosion, foundation settlement, or moisture intrusion into the home.

Catching issues early can help prevent minor concerns from becoming major defects. Homeowners should regularly monitor the flashing around pipes that pass through the roof surface, as aging or damaged flashing is a common cause of roof leaks. Staying proactive with routine roof maintenance can extend the life of the roof and help prevent unexpected repair costs.

This was a visual inspection of the roof-covering materials and related components. It does not include a full evaluation of the entire roofing system, as certain elements, such as underlayment, decking, fastening, and most flashing, are not visible or accessible during an inspection.

I attempted to inspect the flashing related to vent pipes, wall intersections, eaves, gables, and the roof-covering materials. However, most flashing is not visible during a standard home inspection, as it is typically covered by the roof covering or other materials. Because of this, the inspection is limited, and certain deficiencies may not be observable. Additionally, I was unable to closely inspect all vent pipes that penetrate the roof due to access limitations, further restricting the evaluation of their condition. As a result, potential flashing deficiencies or vent pipe issues may not be apparent at the time of inspection.

Since flashing and other concealed components cannot be fully assessed, it is virtually impossible to detect a roof leak unless it is actively occurring or identified through specific water tests, which are beyond the scope of this inspection. To gain a better understanding of the roof’s condition, I recommend that you request roof-related disclosures from the seller and ensure your home insurance policy includes comprehensive roof coverage.

This inspection does not guarantee that a future roof leak will not occur. Even a roof that appears to be in good condition can develop leaks under certain circumstances. Fair Winds Building Inspection Services does not assume responsibility for any future roof leaks, as this inspection is not a warranty or guarantee of the roof system. If any adverse conditions arise that were not noted in this report, contact the Inspector immediately for further evaluation.

Roof Structure

Inspection Status: Inspected

The inspection of the roof structure in the attic was limited due to restricted access and obstructed views. I was not able to observe the roof framing in the space above the bedroom 2 (very shallow headroom) and the converted family room (flat roof). Insulation and ducts blocked the view of wood members and made it unsafe to traverse the attic floor. Very low pitched near the edges of the roof. A visual inspection was performed from point of access.

Damaged roof frames were observed in the attic during the inspection. Recommend further evaluation by a licensed pest control contractor.

A strut was missing at the purlin that supports the roof rafters. Struts are a critical component in roof framing, intended to transfer roof loads down to a load-bearing point. Best practice calls for struts to be installed at intervals of 4 feet or less and at an angle of 45 degrees or less from horizontal to provide adequate support and prevent sagging or deflection in the purlins. I recommend further evaluation and repair by a licensed contractor with experience in roof framing. Proper installation of the missing strut(s) is necessary to maintain structural integrity and ensure continued roof performance.

Roof Covering

Inspection Status: Inspected

Material: 3-Tab Shingles, Modified Bitumen

The roof covering material on this home was 3-tab asphalt shingles, According to the Florida Association of Building Inspectors, the life expectancy of this type of roof covering is 10 to 15 years. I attempted to inspect the roof from various locations and methods, including from the ground and a ladder. This roof covering appeared to be 7 to 10 years old. I was not able to locate a record of when this roof covering was replaced. I recommend regular inspection and maintenance to prolong the life of the roof covering material and detect any predisposing factors that may lead to water leaks.

The modified bitumen roof covering was installed on the low slope roof, lower than 2:12 slope. According to the Florida Association of Building Inspectors the typical life expectancy of this type of roof covering is 10 to 15 years, much shorter than the main roof covering, architectural shingle's (20 to 25 years). Modified bitumen installations are challenging to evaluate visually, as many of the critical installation details—such as flashing, overlaps, and sealing—are concealed beneath the surface. A review of the City of Tampa Building Department records indicates that the last roofing permit was issued in 2017. However, based on visual observation, this membrane roof appears newer than 8 years, suggesting the possibility of more recent work. I recommend asking the seller whether any roof replacement or repairs have been performed since the last recorded permit. Regardless, due to the shorter expected service life of this material, regular inspection and maintenance are strongly advised to help detect early signs of wear and reduce the risk of water intrusion.

The main roof covering had multiple deficiencies. Please note that roofs require regular maintenance to keep them performing reliably. Examples of observations and repair items noted during inspection include:

- Missing a ridge cab

- Torn tab

- Localized excess granule loss

- Indication of previous repair

- Uniform granule loss throughout the entire roof

- Granule loss by foot traffic

- Discoloration

- Loose shingles at the intersection of the main roof and the flat roof

These conditions may compromise the roof’s ability to shed water effectively and could lead to future leaks if not addressed. I recommend further evaluation and necessary repairs or replacement by a licensed roofing contractor to ensure the roof remains weather-tight and performs reliably over time.

Roof Penetrations

Inspection Status: Inspected

Flashing

Inspection Status: Inspected

Attic

General

Method Of Evaluation: From The Access Hatch

Location Of Access: Hallway

Type of Attic Ventilation: Ridge Vent, Soffit Vent

Average Depth of Attic Insulation: 3-6 inches

The attic inspection was limited due to restricted access and obstructed view, which prevented safe travel. I was not able to access the space above the bedroom 2 and the converted family room. Insulation and ductwork obstructed visibility of structural components, and the roof’s low pitch near the edges further restricted movement and visibility. A visual inspection was conducted from the access point to the extent possible.

Ventilation

Inspection Status: Inspected

Insulation

The attic insulation appeared to be old and compressed in general. For improved energy efficiency, I recommend re-insulate to modern standards or to the best possible levels. Be sure to seal up all air leakage points prior to insulating to modern standards and all projects such as wiring and bath fans have been completed.

Interiors

General

Floors, Walls, and Ceilings

Inspection Status: Inspected, Obstructed by Personal Belongings

Floor Structure: Wood Framing

Floor Material: Laminated, Tile

Interior Wall Material: Plaster

Ceiling Structure: Joists

Ceiling Material: Plaster

There are components of the floors, walls, and ceilings that are not visible or accessible at all, including concrete blocks, bricks, joists, and studs, because they are covered by either wall coverings or finished floors. The inspection was limited only to the visible portions of the components.

Minor damage and deterioration were observed inside the house, including

- missing sealant

- deteriorated sealant

- missing grout

- minor wall surface imperfections

- damaged door

- damaged door jamb

These conditions appear to be typical wear and tear and do not indicate structural concerns at the time of inspection. While no immediate repair is necessary, touch-up work such as localized repair and repainting, trim replacement may be performed for improved appearance and function as part of routine maintenance.

The laminate flooring was observed to have visible gaps between planks, which is often a sign of material shrinkage. This condition is typically caused by fluctuations in indoor humidity and temperature, especially when relative humidity drops, leading the material to contract. In some cases, improper installation—such as insufficient acclimation time before installation, lack of expansion gaps, or poor subfloor preparation—can also contribute to gapping over time.

I recommend consulting a licensed flooring contractor to assess the extent of the issue and determine whether repairs or replacement are warranted. Depending on the cause and severity, remediation may involve re-securing loose planks, refinishing, or replacing sections of the flooring. Maintaining consistent indoor humidity levels through seasonal adjustments or the use of a humidifier may also help minimize future movement and prolong the lifespan of the flooring.

Water stain was noted on the ceiling. This area was scanned with an infrared camera and no thermal anomaly was observed at the time of inspection. However, the presence of staining suggested a past leak. I recommend inquiring with the seller regarding any known history of water intrusion in this area to better assess whether previous repairs were made or if further action may be necessary. Because some leaks are intermittent or weather-related, they may not be detectable during a one-time inspection. Cosmetic repairs such as repainting and drywall patching are recommended, along with additional investigation or preventative repairs as needed to help avoid future leakage.

Doors

Inspection Status: Inspected

Windows

Inspection Status: Inspected

A window was not locking correctly and require adjustment / repair for proper operation of the locking hardware.

Smoke and Carbon Monoxide Detectors

Inspection Status: Inspected

The smoke detectors should be tested monthly and batteries should be replaced annually. Many smoke alarm manufacturers recommend replacing smoke alarms after about ten years. The sensors in these alarms degrade over time and may fail to function properly.

Countertops & Cabinets

Cabinetry Material: Laminate

Countertop Material: Solid Surface

The cabinets appeared to be secured using questionable screws. If the wrong screws have been used, this can lead to cabinet failure under heavy loads, a potential safety issue. Recommend verifying and replacing if needed.

A cabinet door hinge was loose. I recommend repairing.

Appliances

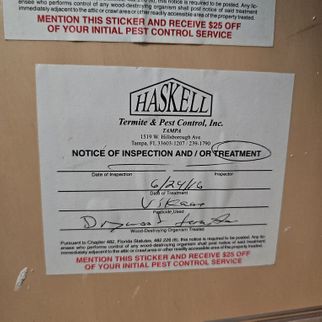

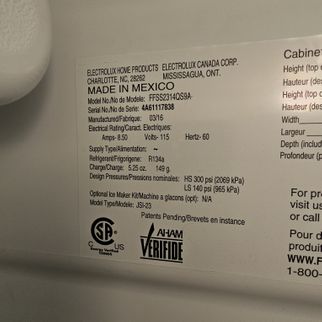

Built-In Microwave oven: Manufacturer (Frigidaire)

Microwave

Note: No provision for dishwasher

The refrigerator water dispenser did not produce water when the lever was pressed during the inspection, despite the water supply tubing being connected. I recommend having a licensed appliance technician further evaluate the system and perform any necessary repairs to restore proper functionality.

No dishwasher was present in the kitchen, and there was no designated space for its installation. If you wish to add a dishwasher, modifications will be necessary to accommodate it. This may include creating space, installing electrical connections, providing a water supply, and adding appropriate drain lines. I recommend consulting with a licensed general contractor or plumber to evaluate the feasibility and perform the necessary installations if desired.

Mechanical System

General

Most HVAC (heating, ventilating and air-conditioning) systems in houses are relatively simple in design and operation. They consist of four components: controls, fuel supply, heating or cooling unit, and distribution system. The adequacy of heating and cooling is often quite subjective and depends upon occupant perceptions that are affected by the distribution of air, the location of return-air vents, air velocity, the sound of the system in operation, and similar characteristics. It's your job to get the HVAC system serviced and replace the air filter regularly to ensure proper performance. Proper refrigerant change is important for the system to perform as intended.

While this inspection includes confirming the presence of conditioned air at supply registers, it does not verify balanced air distribution or measure airflow performance. Homes of any design—whether single- or multi-story—may experience uneven heating or cooling due to duct configuration, system sizing, or insulation factors. Airflow testing and system balancing require specialized tools and fall outside the scope of a standard home inspection. If comfort concerns exist or arise after move-in, consultation with a licensed HVAC contractor is recommended to assess the system and provide potential solutions.

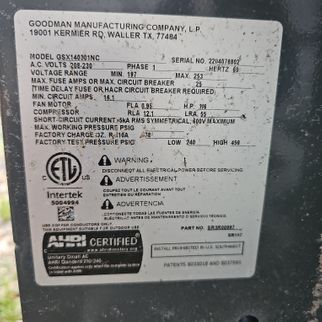

Cooling

Inspection Status: Inspected

Classification: Split System

Energy Source: Electric

Capacity: 30,000 BTU / 2.5 ton

Manufactured Date: Month (April), Year (2022)

Service disconnect: Within sight

Condensate Overflow Warning/Shutoff Device: Present

Condensate discharge: Confirmed

Heating

Inspection Status: Not Inspected

Type: Electrical Coil

Energy Source: Electric

Capacity: 5 kW

Manufactured Date: Month (January), Year (2022)

Service Switch: Inspected

Because the outside temperature was too hot to operate the heat pump without the possibility of damaging the system, I did not operate the heating system. Inspection restriction.

HVAC Distribution Systems

Inspection Status: Inspected

Thermostat Location: Hallway

Filter Type: Disposable

Exhaust System

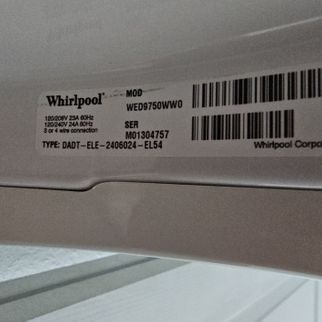

Inspection Status: Inspected

The visual examination will not detect the presence of lint accumulation inside the vent, which is a potential fire hazard. Recommend the cleaning of the dryer vent at the time of purchase and annually in the future to help ensure that safe conditions exist. Lint accumulation can occur even in approved, properly installed vents.

The exhaust fan/hood lights were inoperable at the time of inspection. This may be due to a burned-out bulb. I recommend replacing the light bulbs and testing the lights for proper operation. If the issue persists, further evaluation by a licensed appliance technician may be necessary to address potential wiring or fixture problems.

A bathroom exhaust vent termination was not visibly confirmed on the roof or within the attic at the time of inspection. Without proper venting to the exterior, moisture-laden air may accumulate inside the bathroom, increasing the risk of humidity-related issues such as mildew, mold growth, and material deterioration.

I recommend contacting a licensed ventilation contractor to verify whether the bathroom exhaust fan is properly vented to the exterior. If it is found to be venting into the attic or not vented at all, the ventilation contractor should install or modify the bathroom exhaust to ensure proper discharge to the exterior. This will help reduce the risk of humidity buildup and promote healthy indoor air conditions.

Electrical

General

Maximum Electrical Service Amperage: 150

Home branch circuit wiring consists of devices such as switches, outlets, connections for permanently-wired appliances and the electrical conductors which supply them with electricity. Most conductors are hidden behind the floor, wall and ceiling coverings and cannot be evaluated by the inspector. The inspector does not remove the cover plate and only examined the operation of the electrical systems or components observing proper responses to normal operating control such as on/off switch according to the Florida State DBPR Standards of Practice.

Service Drop

Inspection Status: Inspected

Service Entrance Conductor Type: Multi-Strand Aluminum

Service Head, Gooseneck & Drip Loops

Inspection Status: Inspected

Service Mast, Service Conduit & Raceway

Inspection Status: Inspected

Electric Meter & Base

Inspection Status: Inspected

Electric Meter Rating (Amp): 200

Service Grounding and Bonding

Inspection Status: Inspected

Type: Grounding Rod

Main Service Disconnect and Main Panel

Inspection Status: Inspected

Amperage: 150 Amp

Main Panel Location: Front exterior wall

It's your job to know where the main electrical panel is located, including the main service disconnect that turns everything off. You can replace light bulbs, but more than that, you ought to hire a licensed electrician. Electrical work is hazardous and mistakes can be fatal. Hire a professional whenever there's an electrical problem in your house.

A couple of concerns regarding the main electrical panel was noted:

- A double-pole 60-amp circuit breaker located at the top left of the panel was wired in an unconventional manner. The ungrounded (hot) conductors disappeared behind the circuit breakers, which raises concerns about proper wiring. Wires should be fully visible and properly routed within the panel to reduce fire and shock risks and allow for safe inspection and maintenance.

- The panel did not have a main breaker. This configuration required more than six hand movements to disconnect all power, which violates this safety requirement and increases risk during an emergency shutdown.

I recommend that a licensed electrician further evaluate this panel to:

- Identify and correct the unusual wiring of the 60-amp breaker.

- Install a main disconnect to allow safe shutdown of power to the property in case of an emergency.

- AFCI (arc fault circuit interrupter) is now required on all branch circuits supplying outlets or devices installed in residential dwelling unit kitchens, family rooms, dining rooms, living rooms, parlors, libraries, dens, bedrooms, sunrooms, recreation rooms, closets, hallways, laundry areas, and similar rooms and areas. The goal of this protection is to reduce risks of electrical fires. Consult with a licensed electrician about improving circuit protection as desired. I would consider this improvement in the context of other electrical repairs or upgrades. Please note that if you add or replace receptacle outlets to the existing system, they should comply with modern AFCI standards.

Electrical Wiring

Inspection Status: Inspected

Type: Copper

Switches, Fixtures & Receptacles

Inspection Status: Inspected

Electrical outlet cover plate was missing at the time of inspection. Recommend replacing to prevent from accidental electrical shock.

Ground Fault Circuit Interrupters (GFCI)

Inspection Status: Inspected

Plumbing

General

I recommend flushing the plumbing pipes and monitoring waste and supply plumbing for several months after moving in. This home did not appeared to be occupied at the time of inspection. Regular use of plumbing is quite different than running water through the plumbing fixtures for several minutes during the inspection as I did. I ran all plumbing fixtures during the inspection and found no leaks after testing - this is a good sign.

Most of the plumbing pipes are hidden from the view underground or within walls. The inspection is limited only to the visible pipes, for example, pipes under the bathroom sink.

Water Supply System

Inspection Status: Inspected

Water Supply Source: Public

Water Meter Location: Front Yard

Main Water Shutoff Valve Location: Front Exterior Wall

Main Water Supply Pipe Material: PVC

It's your job to know where the main water shutoff valves are located. And be sure to keep an eye out for any water and plumbing leaks.

Water Distribution Systems

Inspection Status: Inspected

Water Distribution Pipe Material: CPVC

A valve handle was broken at the time of the inspection. Recommend replacing the valve handle.

Drain, Waste, & Vent Systems

Inspection Status: Inspected

Drain, Waste, & Vent Pipe Material: PVC

Fixtures And Faucets

Inspection Status: Inspected

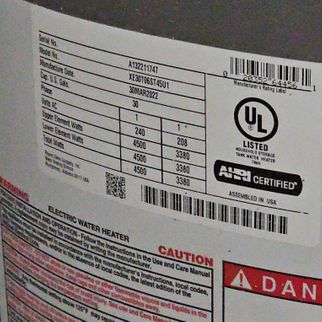

Water Heater

Inspection Status: Inspected

Water Heater Location: Laundry closet

Manufactured Date: Month (March), Year (2022)

Capacity: 30 ga

Power Source: Electric

Most manufacturers recommend that water heaters be flushed regularly to prevent sediment buildup and maintain efficiency. Refer to the owner's manual for the safety precautions and the specified interval for flushing.

The water heater has not been used recently. When hot water systems remain inactive for extended periods (typically two weeks or more), hydrogen gas can accumulate within the system. Hydrogen gas is highly flammable and poses an explosion risk. To reduce the potential for injury, I recommend opening the hot water faucet at the kitchen sink for several minutes before using any electrical appliances connected to the hot water system, such as a dishwasher or washing machine. If hydrogen gas is present, you may notice an unusual sound, similar to air escaping through the pipe, when the faucet is opened. Avoid smoking or using open flames near the faucet during this process.

Standards of Practice

61-30.801 Standards of Practice, General.

(1) Home inspections performed to these Standards of Practice are intended to provide the client with information regarding the overall condition of installed systems and components of the home based on observation of the visible and apparent condition of the structure and components at the time of the home inspection and to report on those systems and components inspected that, in the professional opinion of the inspector, are significantly deficient or at the end of their service lives. A home inspection does not include the prediction of future conditions.

(2) These standards shall not be construed as limiting the scope of the inspection process in those areas where the inspector is qualified and/or has special knowledge.

(3) The inspector shall inspect readily accessible, installed systems and components of homes listed in these Standards of Practice by using normal operating controls and opening readily operable access panels. Where multiple instances of the same component exist, a representative number shall be inspected.

(4) The inspector shall inspect and report as required by section 468.8323, F.S., when required by these standards, systems or components by their type and/or significant characteristics.

(5) If not self-evident to the client at the time of inspection, the inspector shall give a reason why, in his or her opinion, the system or component was reported as significantly deficient or near the end of its service life.

(6) The inspector shall make recommendations for correction and/or monitoring, or further evaluation of the deficiencies that the inspector observed.

(7) These Standards of Practice do not limit inspectors from:

(a) Including other inspection services, in addition to those required by these Standards of Practice;

(b) Specifying repairs, provided the inspector is appropriately qualified;

(c) Excluding systems and components from the inspection if agreed upon in writing by the inspector and client.

61-30.802 Standards of Practice, Structure.

(1) Structural system and components include the following:

(a) Foundation;

(b) Floor structure;

(c) Wall structure;

(d) Ceiling structure;

(e) Roof structure;

(f) Posts;

(g) Beams;

(h) Columns;

(j) Joists;

(k) Rafters;

(l) Trusses;

(m) Other framing; and

(n) Ventilation of foundation areas.

(2) The inspector shall inspect all of the visible structural systems and components by probing structural components where deterioration is visible or suspected or where clear indications of possible deterioration exist. Probing is not required when, in the opinion of the inspector, probing would only further damage any area already identified as defective or where no deterioration is visible or presumed to exist.

(3) The inspector is not required to enter or traverse any under-floor crawl space or attic, if in the opinion of the inspector:

(a) An unsafe or unsanitary condition exists;

(b) Enter areas in which inadequate clearance exists to allow the inspector safe entry or traversing;

(c) The potential exists to cause damage to insulation, ductwork, other components or stored items.

(4) The inspector is not required to provide any engineering or architectural services or offer an opinion as to the adequacy of any structural system or component.

61-30.803 Standards of Practice, Electrical Systems.

(1) Electrical systems and components include the following:

(a) Service entrance conductors, drip loop, cables, and raceways;

(b) Main service equipment and main disconnects;

(c) Service grounding;

(d) Interior components of main service panels and sub panels;

(e) Conductors;

(f) Over current protection devices;

(g) Readily accessible installed lighting fixtures, switches, and receptacles;

(h) Ground fault circuit interrupters;

(i) Amperage and voltage rating of electrical service;

(j) Main disconnect(s);

(k) Methods or types of wiring;

(l) Smoke detectors;

(m) Carbon monoxide detectors;

(n) Arc fault circuit interrupters.

(2) The inspector shall inspect all of the visible and readily accessible electrical systems and components.

(3) The inspector is not required to inspect:

(a) Remote control devices;

(b) Security alarm systems and components;

(c) Low voltage wiring, systems and components, ancillary wiring and systems and components not a part of the primary electrical power distribution system;

(d) Generators, photovoltaic solar collectors or battery or electrical storage devices and associated equipment.

(4) The inspector is not required to:

(a) Measure amperage, voltage or impedance;

(b) Perform a load calculation;

(c) Insert any tool, probe, or device into any electrical component;

(d) Determine the accuracy of circuit labeling.

61-30.804 Standards of Practice, HVAC Systems.

(1) HVAC systems and components include heating and air conditioning systems and components and HVAC distribution systems and components.

(2) Heating and air conditioning systems and components.

(a) The heating and air conditioning (HVAC) systems and components include the following:

1. Installed heating equipment;

2. Fuel storage and fuel distribution systems;

3. Vent systems, flues, and chimneys;

4. Ductwork and air distribution components;

5. Mechanical ventilation systems;

6. Heating system energy source(s);

7. Heating system capacity in BTUs or kilowatts.

(b) The inspector shall inspect all readily accessible heating and air conditioning systems and components.

(c) The inspector is not required to inspect:

1. Interiors of flues or chimneys which are not readily accessible;

2. Heat exchangers;

3. Humidifiers or dehumidifiers;

4. Electronic air filters, sanitizers, or UV lights;

5. Solar space heating systems;

6. Internal components such as coils and pans.

(3) HVAC distribution systems and components.

(a) The heating and air conditioning (HVAC) distribution systems and components include the following:

1. Energy source;

2. Cooling method by its distinguishing characteristics;

3. The presence of condensate over flow warning/shutoff devices.

(b) The inspector shall inspect readily accessible HVAC distribution systems.

(c) With regards to HVAC distribution systems, the inspector is not required to inspect:

1. Electronic air filters, sanitizers, or UV lights;

2. Humidistats;

3. Automatic HVAC zoned systems, dampers, controls, that are not readily accessible;

4. Removable window air conditioning systems.

(4) The inspector is not required to:

(a) Determine heat supply adequacy or distribution balance;

(b) Operate heat pump systems when ambient temperatures pose the potential for damage to the air conditioning system;

(c) Determine cooling supply adequacy, distribution balance or indoor air quality;

(d) Operate the air conditioning system when ambient temperatures pose the potential for damage to the air conditioning system.

61-30.805 Standards of Practice, Roof Covering.

(1) Roof covering systems and components include the following:

(a) Roofing materials;

(b) Flashings;

(c) Skylights, chimneys, and roof penetrations;

(d) Roof drainage systems;

(e) Ventilation of attics; and

(f) Insulation of attics.

(2) The inspector shall inspect all of the visible and readily accessible roof covering systems and components.

(3) The inspector is not required to inspect:

(a) Components or systems that are not readily accessible;

(b) Antenna or other installed accessories;

(c) Interiors of flues or chimneys which are not readily accessible.

(4) The inspector is not required to walk on the roof surface when, in the opinion of the inspector, the following conditions exist:

(a) Roof slope is excessive to safely walk on;

(b) There is no safe access to the roof;

(c) Climatic conditions render the roof unsafe to walk on;

(d) Condition of the roofing material or roof decking renders the roof unsafe to walk on;

(e) Walking on the roof may cause damage to the roof covering materials; and

(f) Walking will place any liability or danger to the homeowner or other representatives involved in the home inspection process.

61-30.806 Standards of Practice, Plumbing System.

(1) Plumbing systems and components include the following:

(a) Interior water supply piping and distribution systems including all fixtures, faucets, and components;

(b) Drain, waste and vent systems, including all plumbing fixtures;

(c) Plumbing related vent systems, flues, and chimneys;

(d) Drainage sumps, sump pumps, and related piping;

(e) Materials used for water supply, drain, waste, and vent piping;

(f) Water heating equipment including the energy source;

(g) Main water and main fuel shut-off valves.

(2) The inspector shall inspect all of the visible and readily accessible plumbing systems and components.

(3) The inspector is not required to inspect:

(a) Wells or water storage related equipment;

(b) Water conditioning systems;

(c) Solar water heating systems;

(d) Fire sprinkler systems;

(e) Private waste disposal systems;

(f) Irrigation system(s).

(4) The inspector is not required to:

(a) Test shower pans, tub and shower surround for leakage;

(b) Operate safety valves or shut-off valves;

(c) Determine whether water supply and waste disposal systems are public or private;

(d) Determine the quantity or quality of the water supply, or if the function flow at the time of the inspection or thereafter will meet the client’s needs.

61-30.807 Standards of Practice, Interior Components.

(1) The interior components that shall be inspected include the following:

(a) Interior walls, ceilings, and floors;

(b) Steps, stairways, and railings;

(c) Countertops and representative number of installed cabinets;

(d) Garage doors;

(e) Interior and exterior doors and windows and their operating locks and latches or other opening mechanisms;

(f) Insulation and vapor retarders in unfinished spaces;

(g) Fireplaces and solid fuel burning appliances;

(h) Vent systems, flues, and chimneys;

(i) Household appliances.

(2) The inspector shall inspect all of the visible and readily accessible interior components that have not been excluded in the scope of services disclosure. When inspecting doors and windows, the inspector may inspect a representative number of doors and windows. The inspector shall inspect household appliances to determine whether the appliances are significantly deficient using normal operating controls. Inspectors will not operate systems or appliances if they have been excluded in the scope of services disclosure or if there is a risk to the property being inspected. Inspectors will first review the system to be operated and use professional judgment as to whether it is safe to operate using normal operating controls and report accordingly.

(3) The inspector is not required to inspect:

(a) Paint, wallpaper, window treatments, and other specialty finish treatments;

(b) Carpeting;

(c) Window treatments;

(d) Central vacuum systems;

(e) Recreational facilities;

(f) Fire screens and doors, if not permanently attached;

(g) Seals and gaskets on fireplaces;

(h) Automatic fuel feed devices;

(i) Mantles and fireplace surrounds;

(j) Combustion make-up air devices;

(k) Heat distribution assists whether gravity controlled or fan assisted in fireplaces.

(4) The inspector is not required to:

(a) Open or operate any windows or doors and access covers that are permanently or temporarily secured by mechanical means, are painted shut, or are blocked by stored items or furniture;

(b) Ignite or extinguish fires;

(c) Light gas fireplaces or heaters, or other unlit pilot light devices;

(d) Determine draft characteristics for fireplaces and chimneys;

(e) Move fireplace inserts or stoves or firebox contents;

(f) Disturb insulation;

(g) Activate any system or appliance that is shut down, disconnected, or otherwise rendered inoperable;

(h) Operate or evaluate any system, component or appliance that does not respond to normal user controls;

(i) Operate any gas appliance that requires the manual lighting of a pilot light or burner device;

(j) Operate any system, appliance or feature that requires the use of special codes, keys, combinations, or devices or where user manual reference is required;

(k) Operate any system, component, or appliance where in the opinion of the inspector, damage may occur;

(l) Determine thermostat(s) calibration, adequacy of heating elements, operate or evaluate self cleaning cycles, door seals, indicator lights, timers, clocks or timed features, defrost cycles or frost free features, or other specialist features as it applies to the appliance device;

(m) Determine leakage from microwaves ovens;

(n) Determine the presence or operation of back draft damper devices in exhaust devices;

(o) Move any appliance;

(p) Confirm operation of every control or feature of

61-30.810 Standards of Practice, Exterior Components.

(1) Exterior systems and components include the following:

(a) Exterior wall cladding/siding, flashing and trim;

(b) All exterior doors;

(c) Attached decks, balconies, stoops, steps, porches, and their associated railings;

(d) Eaves, soffits and facias where accessible from the ground level;

(e) Walkways, patios, and driveways leading to the dwelling entrances.

(2) The inspector shall inspect all of the visible and readily accessible exterior systems and components.

(3) The inspector is not required to inspect:

(a) Window and door screening, shutters, awnings, and similar seasonal or protective accessories and devices;

(b) Fences;

(c) Recreational facilities;

(d) Outbuildings;

(e) Swimming pools, seawalls, break-walls, boat lifts and/or docks.

(4) The inspector is not required to move furniture, appliances, lawn and garden equipment, tools, stored items, wall decorations, floor covering, clothing or any items that block the view and access to components or structures.

61-30.811 Standards of Practice, Site Conditions that Affect the Structure.

(1) Site conditions that affect the structure include the following:

(a) Vegetation;

(b) Grading;

(c) Surface drainage; and

(d) Retaining walls on the property when any of these are likely to adversely affect the structure.

(2) The inspector shall inspect all of the visible and readily accessible site conditions that affect the structure.

(3) The inspector is not required to inspect: