Sang Park, License #HI12491, MRSA4846, JE319992

THIS REPORT IS FOR THE EXCLUSIVE USE OF THE CLIENT LISTED ON THIS REPORT. USE BY ANY OTHER PERSONS WITHOUT THE EXPRESS CONSENT OF FAIR WINDS BUILDING INSPECTION SERVICES, LLC. WILL BE A VIOLATION OF A CONTRACTUAL AGREEMENT AND WILL IMMEDIATELY NULLIFY THE REPORT.

The Scope and Purpose

This report outlines the scope and purpose of new construction phase inspection offered by Fair Winds Building Inspection Services. This phase inspection offered by Fair Winds Building Inspection Services is divided into 4 phases; foundation inspection, pre-drywall inspection, pre-closing inspection, and 11-month builder warranty inspection. Your inspection will include only one of these phase inspections. The specific inspections performed for your property are listed in your agreement and detailed in the main part of this report. If you have any questions about which inspections were conducted, please refer to those sections or contact me directly.

Foundation Inspection

A foundation inspection is a crucial step in the early stages of construction, conducted before the concrete slab is poured. This inspection ensures that the site preparation, foundation layout, and structural components comply with the Florida Building Code (FBC) and approved construction plans. The inspector evaluates soil compaction, proper grading, footing placement, and the installation of reinforcement materials such as rebar to confirm structural integrity. Electrical grounding and plumbing pipe positioning are also examined to verify compliance before the slab is poured. Identifying and addressing issues at this stage helps prevent costly foundation failures and structural deficiencies later in the construction process.

Pre-Drywall Inspection

The pre-drywall inspection is conducted to assess compliance with the Florida Building Code (FBC) and approved construction documents, including construction plans, HVAC duct layout, energy performance details, and product approval information. This inspection takes place immediately after framing is completed and before drywall installation begins. It focuses on verifying the proper installation of readily accessible systems and components using normal operating controls and opening readily operable access panels where applicable. The inspection includes, but is not limited to, the evaluation of exterior walls and filled cell locations, window and door installations, roof trusses, deck nailing, floor trusses, interior wall framing, plumbing rough-in, HVAC rough-in, and electrical rough-in. This phase ensures that critical structural, mechanical, and electrical components are properly installed before they are concealed, allowing for necessary corrections and adjustments before the project progresses..

Pre-Closing Inspection

A pre-closing inspection takes place shortly before the final walkthrough of a newly constructed home, ensuring that all systems and components meet Florida Building Code (FBC) standards and the Residential Construction Performance Guidelines published by the National Association of Home Builders (NAHB). This inspection assesses the overall workmanship, functionality of installed systems, and compliance with construction plans. The inspector evaluates the operation of major appliances, electrical outlets, plumbing fixtures, doors, windows, HVAC systems, and safety features such as smoke and carbon monoxide detectors. Finishing details, including flooring, cabinetry, paint, and trim work, are reviewed for quality and proper installation. This inspection provides homeowners the opportunity to document deficiencies that the builder must address before closing, ensuring that the home is delivered in acceptable condition and in accordance with industry performance standards.

11-Month Builder Warranty Inspection

An 11-month builder warranty inspection is conducted near the end of a builder’s one-year warranty period to document any construction defects, system malfunctions, or workmanship issues that have developed since move-in. This inspection follows the Residential Construction Performance Guidelines established by the National Association of Home Builders (NAHB) to assess whether the home meets industry standards. The inspector examines structural components for signs of settlement, foundation cracks, or shifting that may indicate underlying issues. Roofing, siding, and exterior elements are checked for defects, while interior finishes are evaluated for material failures, improper installation, or excessive wear. Mechanical systems, including plumbing, electrical, and HVAC, are tested to ensure proper functionality and efficiency. By identifying issues before the warranty expires, homeowners can request repairs from the builder, avoiding costly out-of-pocket expenses in the future.

This inspection process followed the Florida Department of Business and Professional Regulation Standards of Practice (SOP). The SOP is provided at the end of the report for your reference. There may be comments made in this report that exceed the FL Standards of Practice; these comments (if present) were made as a courtesy to give you as much information as possible about the home. Exceeding the Standards of Practice will only happen when I feel I have the experience, knowledge, or evidence to do so. There should be no expectation that the Standards of Practice will be exceeded throughout the inspection. This inspection and report are not intended to be technically exhaustive. The observations in this report are the opinions of the home inspector. Other inspectors and contractors are likely to have some differing opinions. You are welcome to seek opinions from other professionals.

The descriptions and observations in this report are based on a visual inspection of the property. I inspect the property without dismantling, damaging, or disfiguring and without moving furniture and interior furnishings. This inspection does not cover certain areas that are concealed, hidden, or inaccessible to view. Some systems cannot be tested during this inspection as testing risks damaging the system or the structure. For example, a heat pump is not generally tested if the outside temperature is above 85 degrees Fahrenheit according to most manufacturers' recommendations. The inspection procedures involved non-invasive investigation and non-destructive testing which would limit the scope of the inspection.

How to Read This Report

Getting the Information to You

This report is designed to deliver important and technical information in a way that is easy for anyone to access and understand. If you are in a hurry, you can take a quick look at our "Summary Page” and quickly get critical information for important decision making. However, I strongly recommend that you take the time to read the full Report, which includes digital photographs, captions, diagrams, descriptions, videos and hot links to additional information.

The best way to get the layers of information that are presented in this report is to read your report online (the HTML version), which will allow you to expand your learning about your house. You will notice some words or series of words highlighted in blue and underlined – clicking on these will provide you with a link to additional information. The HTML version of this report also contains streaming videos. Short video clips often contain important information and critical context and sounds that can be difficult to capture in words and still pictures.

For the most reliable viewing experience, I recommend viewing the report on as large a screen as practical, as much detail can be lost on small devices like smart phones. For similar reasons, reports should only be printed in color to retain as much detail as possible and minimize misinterpretation of photographs.

This report can also be printed on paper or to a PDF document.

Chapters and Sections

This report is divided into chapters that parcel the home into logical inspection components. Each chapter is broken into sections that relate to a specific system or component of the home. You can navigate between chapters with the click of a button on the left side margin.

Most sections will contain some descriptive information done in black font. Observation narrative, done in colored boxes, will be included if a system or component is found to be significantly deficient in some way or if we wish to provide helpful additional information about the system or the scope of our inspection. If a system or component of the home was deemed to be in satisfactory or serviceable condition, there may be no narrative observation comments in that section and it may simply say “tested,” or “inspected.”

Observation Labels

All narrative observations are colored, numbered and labeled to help you find, refer to, and understand the severity of the observation. Observation colors and labels used in this report are:

- Description:Detailed description of various aspects of the property noted during the inspection.

- Limitation:Explanation of inspection limitations

- SOP:State of Florida Department of Business and Professional Regulation Standards of Practice for home inspection

- Homeowner's Responsibility:Your responsibilities as a homeowner

- Builder:Observations that require builder to repair, adjust, or replace.

Summary Page

The Summary Page is designed as a bulleted overview of all the observations noted during inspection. This helpful overview is not a substitution for reading the entire inspection report. The entire report must be read to get a complete understanding of this inspection report as the Summary Page does not include photographs or photo captions.

Property Orientation

All locations of the exterior components were given as if you are standing outside and facing the front of the house. The bedrooms and the bathrooms were numbered, going clockwise from the garage entrance door and/or at the top of the stairs when multiple bedrooms/bathrooms existed on the same floor, i.e. bedroom 1, bedroom 2, and master bedroom.

How to Build a Repair Request

To see how to build a custom PDF summary list, built from any number of items in this report, please review this video. The idea behind this feature is to allow the readers of this report to build their own custom lists. These could be used as a tool for inspection responses, or for requesting re-inspection of specific items or for documenting work that has been completed as part of a pre-listing inspection.

No house is perfect. Anything in these categories should be addressed as soon as possible. Often, a serious problem can be corrected inexpensively. Not all deficiencies will be identified during this inspection. This inspection is not a guarantee or warranty of any kind. Unexpected repairs should still be anticipated. All recommended evaluations, repairs, or replacements shall be done by licensed contractors.

Homeownership is both a joyful experience and an important responsibility, so be sure to call on your Fair Winds Building Inspection Services, LLC to help you devise an annual maintenance plan that will keep your family and your investment safe for years to come. Thank you very much for letting us be of service to you and your loved ones.

Summary

Builders

- PI-1 Pre-Drywall Inspection - Foundation:

The depth of the control joints of the concrete slab. The typical thickness of the existing slab was 3-1/2" according to the specification on the construction drawing. The depth of the control joint shall be a minimum of 25% of the slab thickness. The builder will correct the deficiencies.

- PI-2 Pre-Drywall Inspection - Exterior:

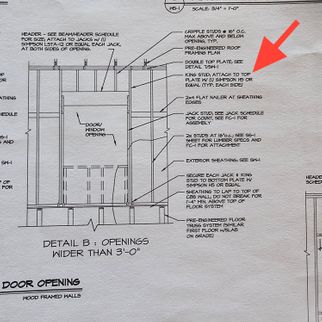

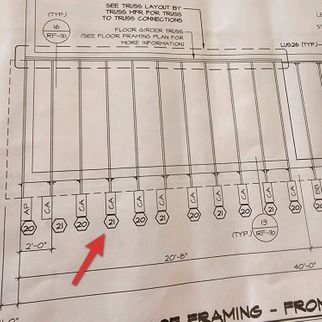

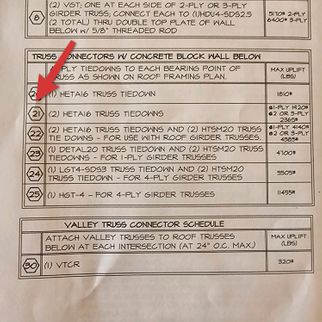

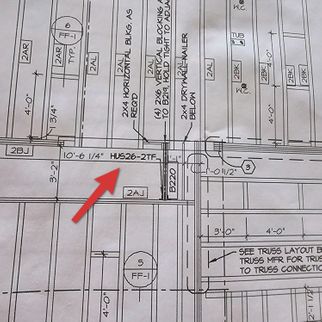

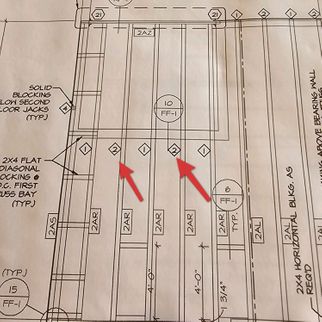

At the time of inspection, inadequate connection was observed on the exterior wall, which may affect the structural integrity of the building, particularly in high-wind conditions. Proper connections between structural components are essential to ensure load transfer and resistance to uplift forces. The builder will correct the deficiency according to the manufacturer’s installation instructions and the construction specification.

- PI-3 Pre-Drywall Inspection - Roof:

At the time of inspection, inadequate connection was observed on the exterior wall, which may affect the structural integrity of the building, particularly in high-wind conditions. Proper connections between structural components are essential to ensure load transfer and resistance to uplift forces. The builder will correct the deficiency according to the manufacturer’s installation instructions and the construction specification.

- PI-4 Pre-Drywall Inspection - Interior:

- (FBC R302.11) Fire blocking shall be provided in wood-framed construction in the following locations: 1.2.Horizontally at intervals not exceeding 10 feet (3048 mm). 4.At openings around vents, pipes, ducts, cables and wires at ceiling and floor level, with an approved material to resist the free passage of flame and products of combustion. The material filling this annular space shall not be required to meet the ASTM E136 requirements.

- PI-5 Pre-Drywall Inspection - Interior:

At the time of inspection, inadequate connection was observed on the exterior wall, which may affect the structural integrity of the building, particularly in high-wind conditions. Proper connections between structural components are essential to ensure load transfer and resistance to uplift forces. The builder will correct the deficiency according to the manufacturer’s installation instructions and the construction specification.

- PI-6 Pre-Drywall Inspection - Interior:

FBC R602.6.1 At the time of inspection, a stud guard was missing at a location where plumbing or electrical components pass through a framing member, leaving these components vulnerable to damage from fasteners or other construction activities. Protective steel plates (stud guards) are required when notches or bored holes in framing members reduce the clearance to less than 1-1/4 inches from the edge of the member. This protection helps prevent accidental punctures, which could lead to leaks, electrical hazards, or system failures. The builder will correct the deficiency.

Pre-Drywall Inspection

Building Info, Limitations, and Exclusions

General

Type of Building : Single Family (2-story)

Total Square Footage: 3991 (Gross Area)

Year of Original Construction: 2024

Attending the Inspection: Buyer

All components and conditions which by the nature of their location are concealed, camouflaged, or difficult to inspect are excluded from the report. The report does not address

- concealed conditions, latent defects, consequential damages, and

- cosmetic imperfections that do not significantly affect a component’s performance of its intended function.

- the remaining life expectancy of systems and components.

- the causes of conditions and deficiencies.

- future conditions including but not limited to failure of systems and components.

- compliance of systems and components with past and present requirements and guidelines (codes, regulations, laws, ordinances, specifications, installation and maintenance instructions, use and care guides, etc.).

- the presence of environmental hazards including, but not limited to, allergens, toxins, carcinogens, electromagnetic radiation, noise, radioactive substances, and contaminants in building materials, soil, water, and air.

- whether items, materials, conditions, and components are subject to recall, controversy, litigation, product liability, and other adverse claims and conditions.

- the market value of the property and its marketability.

- the advisability of purchasing the property.

Pre-Drywall Inspection

Foundation

Inspection Status: Inspected

Type: Slab on Grade

The depth of the control joints of the concrete slab. The typical thickness of the existing slab was 3-1/2" according to the specification on the construction drawing. The depth of the control joint shall be a minimum of 25% of the slab thickness. The builder will correct the deficiencies.

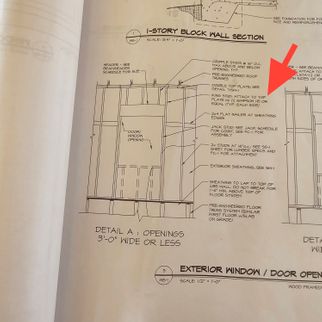

Exterior

Inspection Status: Inspected

Patio/Porch/Deck/Balcony Deck Material: Concrete pad

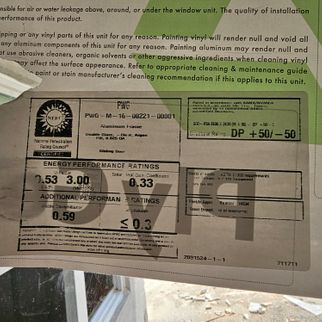

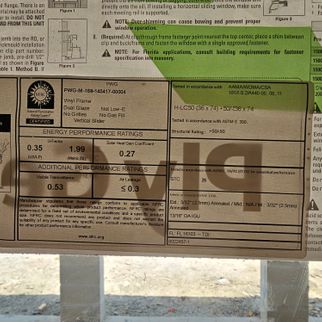

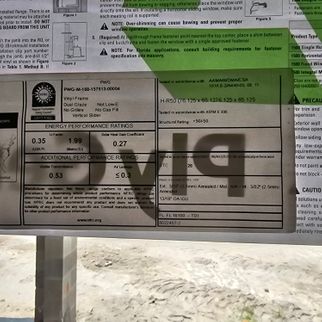

FL Product Approval: Door

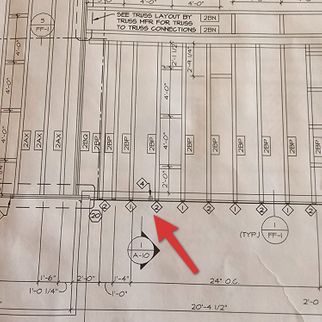

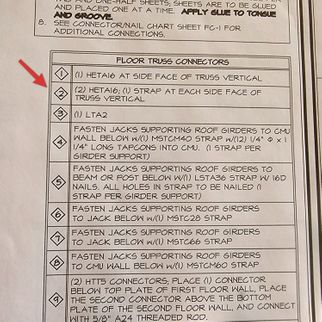

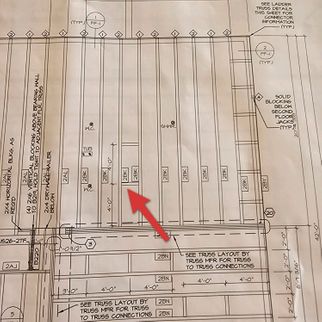

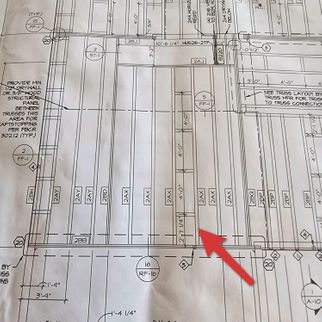

At the time of inspection, inadequate connection was observed on the exterior wall, which may affect the structural integrity of the building, particularly in high-wind conditions. Proper connections between structural components are essential to ensure load transfer and resistance to uplift forces. The builder will correct the deficiency according to the manufacturer’s installation instructions and the construction specification.

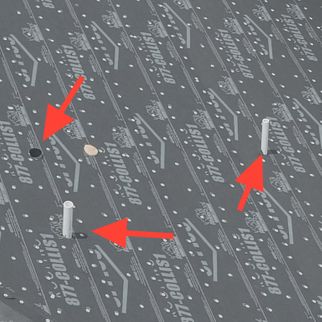

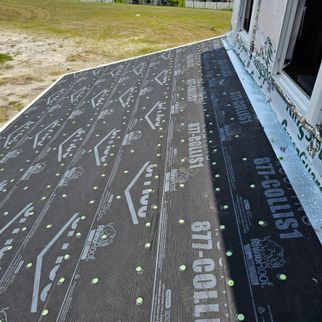

Roof

Inspection Status: Inspected

Inspection Method: From ground, At the ladder, Walking on the roof surface, Drone

Roof Type: Gable, Hip, Combination

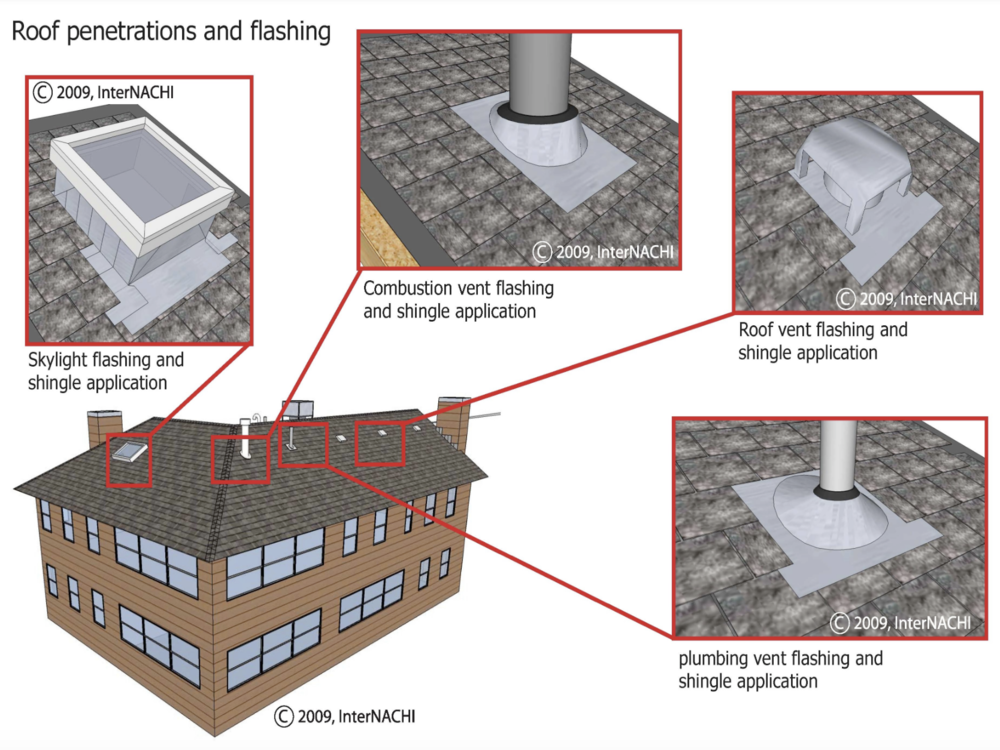

Penetrations: Mechanical exhaust vent, Plumbing exhaust vent

See the photos for the typical roof penetration components.

Flashing: Wall intersections, Eaves and gables

see the photos of typical flashings

As a homeowner, it is your responsibility to monitor the condition of the roof covering, as all roofs have the potential to develop leaks over time. Roofs are designed to be water-resistant, not waterproof, and no one can predict when or where a leak may occur. To minimize the risk of costly damage, the entire roof system should be inspected annually as part of routine home maintenance.

For roofs that are inaccessible or unsafe to walk on, use binoculars to check for signs of deterioration, loose or damaged flashing, and debris accumulation in valleys and gutters. Pay special attention to flashing around plumbing vent pipes, as these components can deteriorate over time and cause leaks. To ensure proper function, vent pipes should remain clear of debris and be periodically inspected for wear.

Additionally, monitor the gutters to ensure they function properly during and after rainfall. Look for loose parts, sagging gutter ends, and water leaks. Proper gutter maintenance is essential to prevent water damage to the roof and exterior walls. Rainwater should be diverted away from the house foundation to reduce the risk of erosion, foundation settlement, or moisture intrusion into the home.

Catching issues early can help prevent minor concerns from becoming major defects. Homeowners should regularly monitor the flashing around pipes that pass through the roof surface, as aging or damaged flashing is a common cause of roof leaks. Staying proactive with routine roof maintenance can extend the life of the roof and help prevent unexpected repair costs.

The evaluation of the upper roof was conducted using a drone. While this method was not as thorough as walking on the roof, it was the best and safest option given the limited access. Any comments in this report related to the roof covering, roof penetrations, gutters, chimneys, etc., were based on the visible perspective captured by the drone's camera. All relevant photos will be included in this report.

At the time of inspection, inadequate connection was observed on the exterior wall, which may affect the structural integrity of the building, particularly in high-wind conditions. Proper connections between structural components are essential to ensure load transfer and resistance to uplift forces. The builder will correct the deficiency according to the manufacturer’s installation instructions and the construction specification.

Interior

Inspection Status: Inspected

Floor Structure: Concrete pad, Wood truss

Ceiling Structure: Bottom cord of wood truss

Stairs Material: Wood

- (FBC R302.11) Fire blocking shall be provided in wood-framed construction in the following locations: 1.2.Horizontally at intervals not exceeding 10 feet (3048 mm). 4.At openings around vents, pipes, ducts, cables and wires at ceiling and floor level, with an approved material to resist the free passage of flame and products of combustion. The material filling this annular space shall not be required to meet the ASTM E136 requirements.

At the time of inspection, inadequate connection was observed on the exterior wall, which may affect the structural integrity of the building, particularly in high-wind conditions. Proper connections between structural components are essential to ensure load transfer and resistance to uplift forces. The builder will correct the deficiency according to the manufacturer’s installation instructions and the construction specification.

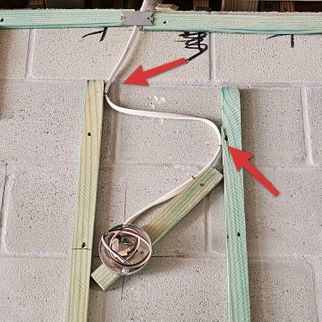

FBC R602.6.1 At the time of inspection, a stud guard was missing at a location where plumbing or electrical components pass through a framing member, leaving these components vulnerable to damage from fasteners or other construction activities. Protective steel plates (stud guards) are required when notches or bored holes in framing members reduce the clearance to less than 1-1/4 inches from the edge of the member. This protection helps prevent accidental punctures, which could lead to leaks, electrical hazards, or system failures. The builder will correct the deficiency.

Mechanical

Inspection Status: Inspected

AC Duct Material: Flexible duct, Fiberglass duct board

Exhaust System: Bathroom exhausts, Kitchen exhaust, Clothes dry exhaust

Photos of mechanical exhaust vents

An HVAC duct layout drawing was not provided by the builder at the time of inspection, despite multiple attempts to obtain it, which limits the ability to verify proper duct sizing, routing, and distribution throughout the home. Without this documentation, it is difficult to determine whether the HVAC system has been installed according to design specifications. The absence of a duct layout drawing also prevents a assessment of proper duct sizing.

Electrical

Inspection Status: Inspected

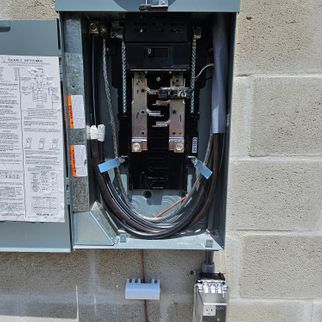

Maximum Electrical Service Amperage: 200

Electric Meter Rating (Amp): 200

Service Entrance Conductor Type: Multi-Strand Aluminum

Service Grounding Type: Ufer

Main Service Disconnect: Square D (200 Amp, Located on the exterior wall with the main panel)

Main Panel: Square D (200 Amp, Located on the exterior wall)

Branch Wiring Type: Copper

Plumbing

Inspection Status: Inspected

Water Supply Source: Public

Main Water Shutoff Valve Location: Not installed

Water Supply Pipe Material: Undetermined

Water Distribution Pipe Material: CPVC

Drain Waste Vent Pipe Material: PVC

Standards of Practice

61-30.801 Standards of Practice, General.

(1) Home inspections performed to these Standards of Practice are intended to provide the client with information regarding the overall condition of installed systems and components of the home based on observation of the visible and apparent condition of the structure and components at the time of the home inspection and to report on those systems and components inspected that, in the professional opinion of the inspector, are significantly deficient or at the end of their service lives. A home inspection does not include the prediction of future conditions.

(2) These standards shall not be construed as limiting the scope of the inspection process in those areas where the inspector is qualified and/or has special knowledge.

(3) The inspector shall inspect readily accessible, installed systems and components of homes listed in these Standards of Practice by using normal operating controls and opening readily operable access panels. Where multiple instances of the same component exist, a representative number shall be inspected.

(4) The inspector shall inspect and report as required by section 468.8323, F.S., when required by these standards, systems or components by their type and/or significant characteristics.

(5) If not self-evident to the client at the time of inspection, the inspector shall give a reason why, in his or her opinion, the system or component was reported as significantly deficient or near the end of its service life.

(6) The inspector shall make recommendations for correction and/or monitoring, or further evaluation of the deficiencies that the inspector observed.

(7) These Standards of Practice do not limit inspectors from:

(a) Including other inspection services, in addition to those required by these Standards of Practice;

(b) Specifying repairs, provided the inspector is appropriately qualified;

(c) Excluding systems and components from the inspection if agreed upon in writing by the inspector and client.

61-30.802 Standards of Practice, Structure.

(1) Structural system and components include the following:

(a) Foundation;

(b) Floor structure;

(c) Wall structure;

(d) Ceiling structure;

(e) Roof structure;

(f) Posts;

(g) Beams;

(h) Columns;

(j) Joists;

(k) Rafters;

(l) Trusses;

(m) Other framing; and

(n) Ventilation of foundation areas.

(2) The inspector shall inspect all of the visible structural systems and components by probing structural components where deterioration is visible or suspected or where clear indications of possible deterioration exist. Probing is not required when, in the opinion of the inspector, probing would only further damage any area already identified as defective or where no deterioration is visible or presumed to exist.

(3) The inspector is not required to enter or traverse any under-floor crawl space or attic, if in the opinion of the inspector:

(a) An unsafe or unsanitary condition exists;

(b) Enter areas in which inadequate clearance exists to allow the inspector safe entry or traversing;

(c) The potential exists to cause damage to insulation, ductwork, other components or stored items.

(4) The inspector is not required to provide any engineering or architectural services or offer an opinion as to the adequacy of any structural system or component.

61-30.803 Standards of Practice, Electrical Systems.

(1) Electrical systems and components include the following:

(a) Service entrance conductors, drip loop, cables, and raceways;

(b) Main service equipment and main disconnects;

(c) Service grounding;

(d) Interior components of main service panels and sub panels;

(e) Conductors;

(f) Over current protection devices;

(g) Readily accessible installed lighting fixtures, switches, and receptacles;

(h) Ground fault circuit interrupters;

(i) Amperage and voltage rating of electrical service;

(j) Main disconnect(s);

(k) Methods or types of wiring;

(l) Smoke detectors;

(m) Carbon monoxide detectors;

(n) Arc fault circuit interrupters.

(2) The inspector shall inspect all of the visible and readily accessible electrical systems and components.

(3) The inspector is not required to inspect:

(a) Remote control devices;

(b) Security alarm systems and components;

(c) Low voltage wiring, systems and components, ancillary wiring and systems and components not a part of the primary electrical power distribution system;

(d) Generators, photovoltaic solar collectors or battery or electrical storage devices and associated equipment.

(4) The inspector is not required to:

(a) Measure amperage, voltage or impedance;

(b) Perform a load calculation;

(c) Insert any tool, probe, or device into any electrical component;

(d) Determine the accuracy of circuit labeling.

61-30.804 Standards of Practice, HVAC Systems.

(1) HVAC systems and components include heating and air conditioning systems and components and HVAC distribution systems and components.

(2) Heating and air conditioning systems and components.

(a) The heating and air conditioning (HVAC) systems and components include the following:

1. Installed heating equipment;

2. Fuel storage and fuel distribution systems;

3. Vent systems, flues, and chimneys;

4. Ductwork and air distribution components;

5. Mechanical ventilation systems;

6. Heating system energy source(s);

7. Heating system capacity in BTUs or kilowatts.

(b) The inspector shall inspect all readily accessible heating and air conditioning systems and components.

(c) The inspector is not required to inspect:

1. Interiors of flues or chimneys which are not readily accessible;

2. Heat exchangers;

3. Humidifiers or dehumidifiers;

4. Electronic air filters, sanitizers, or UV lights;

5. Solar space heating systems;

6. Internal components such as coils and pans.

(3) HVAC distribution systems and components.

(a) The heating and air conditioning (HVAC) distribution systems and components include the following:

1. Energy source;

2. Cooling method by its distinguishing characteristics;

3. The presence of condensate over flow warning/shutoff devices.

(b) The inspector shall inspect readily accessible HVAC distribution systems.

(c) With regards to HVAC distribution systems, the inspector is not required to inspect:

1. Electronic air filters, sanitizers, or UV lights;

2. Humidistats;

3. Automatic HVAC zoned systems, dampers, controls, that are not readily accessible;

4. Removable window air conditioning systems.

(4) The inspector is not required to:

(a) Determine heat supply adequacy or distribution balance;

(b) Operate heat pump systems when ambient temperatures pose the potential for damage to the air conditioning system;

(c) Determine cooling supply adequacy, distribution balance or indoor air quality;

(d) Operate the air conditioning system when ambient temperatures pose the potential for damage to the air conditioning system.

61-30.805 Standards of Practice, Roof Covering.

(1) Roof covering systems and components include the following:

(a) Roofing materials;

(b) Flashings;

(c) Skylights, chimneys, and roof penetrations;

(d) Roof drainage systems;

(e) Ventilation of attics; and

(f) Insulation of attics.

(2) The inspector shall inspect all of the visible and readily accessible roof covering systems and components.

(3) The inspector is not required to inspect:

(a) Components or systems that are not readily accessible;

(b) Antenna or other installed accessories;

(c) Interiors of flues or chimneys which are not readily accessible.

(4) The inspector is not required to walk on the roof surface when, in the opinion of the inspector, the following conditions exist:

(a) Roof slope is excessive to safely walk on;

(b) There is no safe access to the roof;

(c) Climatic conditions render the roof unsafe to walk on;

(d) Condition of the roofing material or roof decking renders the roof unsafe to walk on;

(e) Walking on the roof may cause damage to the roof covering materials; and

(f) Walking will place any liability or danger to the homeowner or other representatives involved in the home inspection process.

61-30.806 Standards of Practice, Plumbing System.

(1) Plumbing systems and components include the following:

(a) Interior water supply piping and distribution systems including all fixtures, faucets, and components;

(b) Drain, waste and vent systems, including all plumbing fixtures;

(c) Plumbing related vent systems, flues, and chimneys;

(d) Drainage sumps, sump pumps, and related piping;

(e) Materials used for water supply, drain, waste, and vent piping;

(f) Water heating equipment including the energy source;

(g) Main water and main fuel shut-off valves.

(2) The inspector shall inspect all of the visible and readily accessible plumbing systems and components.

(3) The inspector is not required to inspect:

(a) Wells or water storage related equipment;

(b) Water conditioning systems;

(c) Solar water heating systems;

(d) Fire sprinkler systems;

(e) Private waste disposal systems;

(f) Irrigation system(s).

(4) The inspector is not required to:

(a) Test shower pans, tub and shower surround for leakage;

(b) Operate safety valves or shut-off valves;

(c) Determine whether water supply and waste disposal systems are public or private;

(d) Determine the quantity or quality of the water supply, or if the function flow at the time of the inspection or thereafter will meet the client’s needs.

61-30.807 Standards of Practice, Interior Components.

(1) The interior components that shall be inspected include the following:

(a) Interior walls, ceilings, and floors;

(b) Steps, stairways, and railings;

(c) Countertops and representative number of installed cabinets;

(d) Garage doors;

(e) Interior and exterior doors and windows and their operating locks and latches or other opening mechanisms;

(f) Insulation and vapor retarders in unfinished spaces;

(g) Fireplaces and solid fuel burning appliances;

(h) Vent systems, flues, and chimneys;

(i) Household appliances.

(2) The inspector shall inspect all of the visible and readily accessible interior components that have not been excluded in the scope of services disclosure. When inspecting doors and windows, the inspector may inspect a representative number of doors and windows. The inspector shall inspect household appliances to determine whether the appliances are significantly deficient using normal operating controls. Inspectors will not operate systems or appliances if they have been excluded in the scope of services disclosure or if there is a risk to the property being inspected. Inspectors will first review the system to be operated and use professional judgment as to whether it is safe to operate using normal operating controls and report accordingly.

(3) The inspector is not required to inspect:

(a) Paint, wallpaper, window treatments, and other specialty finish treatments;

(b) Carpeting;

(c) Window treatments;

(d) Central vacuum systems;

(e) Recreational facilities;

(f) Fire screens and doors, if not permanently attached;

(g) Seals and gaskets on fireplaces;

(h) Automatic fuel feed devices;

(i) Mantles and fireplace surrounds;

(j) Combustion make-up air devices;

(k) Heat distribution assists whether gravity controlled or fan assisted in fireplaces.

(4) The inspector is not required to:

(a) Open or operate any windows or doors and access covers that are permanently or temporarily secured by mechanical means, are painted shut, or are blocked by stored items or furniture;

(b) Ignite or extinguish fires;

(c) Light gas fireplaces or heaters, or other unlit pilot light devices;

(d) Determine draft characteristics for fireplaces and chimneys;

(e) Move fireplace inserts or stoves or firebox contents;

(f) Disturb insulation;

(g) Activate any system or appliance that is shut down, disconnected, or otherwise rendered inoperable;

(h) Operate or evaluate any system, component or appliance that does not respond to normal user controls;

(i) Operate any gas appliance that requires the manual lighting of a pilot light or burner device;

(j) Operate any system, appliance or feature that requires the use of special codes, keys, combinations, or devices or where user manual reference is required;

(k) Operate any system, component, or appliance where in the opinion of the inspector, damage may occur;

(l) Determine thermostat(s) calibration, adequacy of heating elements, operate or evaluate self cleaning cycles, door seals, indicator lights, timers, clocks or timed features, defrost cycles or frost free features, or other specialist features as it applies to the appliance device;

(m) Determine leakage from microwaves ovens;

(n) Determine the presence or operation of back draft damper devices in exhaust devices;

(o) Move any appliance;

(p) Confirm operation of every control or feature of

61-30.810 Standards of Practice, Exterior Components.

(1) Exterior systems and components include the following:

(a) Exterior wall cladding/siding, flashing and trim;

(b) All exterior doors;

(c) Attached decks, balconies, stoops, steps, porches, and their associated railings;

(d) Eaves, soffits and facias where accessible from the ground level;

(e) Walkways, patios, and driveways leading to the dwelling entrances.

(2) The inspector shall inspect all of the visible and readily accessible exterior systems and components.

(3) The inspector is not required to inspect:

(a) Window and door screening, shutters, awnings, and similar seasonal or protective accessories and devices;

(b) Fences;

(c) Recreational facilities;

(d) Outbuildings;

(e) Swimming pools, seawalls, break-walls, boat lifts and/or docks.

(4) The inspector is not required to move furniture, appliances, lawn and garden equipment, tools, stored items, wall decorations, floor covering, clothing or any items that block the view and access to components or structures.

61-30.811 Standards of Practice, Site Conditions that Affect the Structure.

(1) Site conditions that affect the structure include the following:

(a) Vegetation;

(b) Grading;

(c) Surface drainage; and

(d) Retaining walls on the property when any of these are likely to adversely affect the structure.

(2) The inspector shall inspect all of the visible and readily accessible site conditions that affect the structure.

(3) The inspector is not required to inspect:

(a) Geological, geotechnical or hydrological site conditions;

(b) Erosion control and earth stabilization measures.