Dear Client,

This is a Property Condition Report "PCR" using the ASTM E2018 as a standard guideline to describe the condition of building or buildings for the property inspected. This process involves observation of the property by a person or entity. It can include interviews of sources, and reviews of available documentation for the purpose of developing an opinion and preparing a PCR of a commercial real estate’s current physical condition. At the option of the user, a PCA may include a higher level of inquiry and due diligence than the baseline scope described within this guide or, at the user’s option, it may include a lower level of inquiry or due diligence than the baseline scope described in this guide. If there are such deviations from this guide’s scope it should be disclosed here on this page.

A PCR or written report, is prepared in accordance with the recommendations contained in this guide, that outlines the consultant’s observations, opinions as to the subject property’s condition. Opinions of probable costs to remedy any material physical deficiencies observed may also be included upon request.

In defining good commercial and customary practice for conducting a baseline PCA, the goal is to identify and communicate physical deficiencies to a user. The term physical deficiencies means the presence of conspicuous defects or material deferred maintenance of a subject property’s material systems, components, or equipment as observed during the field observer’s walk-through survey. This definition specifically excludes deficiencies that may be remedied with routine maintenance, miscellaneous minor repairs, normal operating maintenance, etc., and excludes de minimis conditions that generally do not present material physical deficiencies of the subject property. A walk-through survey, conducted during the field observer’s site visit of the subject property, that consists of nonintrusive visual observations, survey of readily accessible, easily visible components and systems of the subject property. Concealed physical deficiencies are excluded.

It is the intent of this guide that such a survey should not be considered technically exhaustive. It excludes the operation of equipment by the field observer and is to be conducted without the aid of special protective clothing, exploratory probing, removal of materials, testing, or the use of equipment, such as scaffolding, metering/testing equipment, or devices of any kind, etc. It is literally the field observer’s visual observations while walking through the subject property.

This report may include opinions of probable costs, recommendations for exploratory probing, and further analysis should this be deemed warranted by the consultant. The performance of such additional services are beyond this guide. Generally, the time frame for such repairs is within one year.

The purpose of the PCA is to observe and report, to the extent feasible pursuant to the processes prescribed herein, on the physical condition of the subject property.

Deviations from the Guide: None

Recommendations: It is recommended that the user of this report review both summaries and the entire report. The complete report may include additional information of concern.

Summary

Major Concerns

- -2 Roof and Roof Structure:

The roof covering had multiple soft areas where underlayment felt damaged or mushy from moisture. Sunken or depressed places were noted, and some standing water was visible at the enclosed structure.

The roof had debris, sharp bolts and razor blades also found.

Prior sealing and repairs were visible.

Signs of roof leaks were present inside, and the tenant also expressed leaks during rain storms inside.

- -3 Roof and Roof Structure:

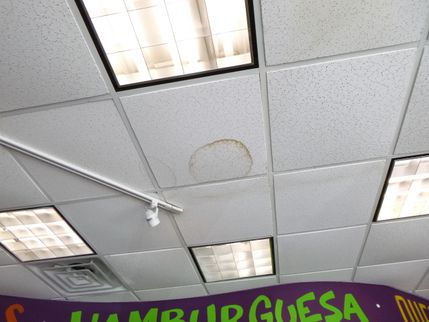

Damaged metal sheeting could be seen in attic above the kitchen. Evidence of leaking and moisture damage could be seen at the ceiling tile directly below this area.

- -2 Structural Frame and Building Envelope:

The rear entry door was damaged at the base from a/c condensate run off.

- PS-3 Plumbing System:

Floor drains on the interior were visibly clogged or holding water in some locations. The tenant also reported problems with clogging of the drain system.

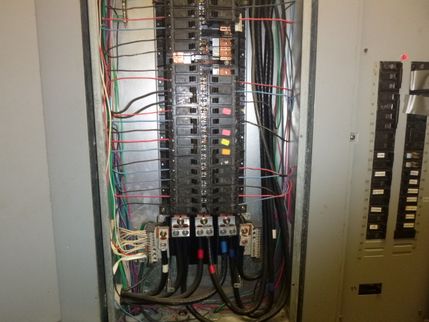

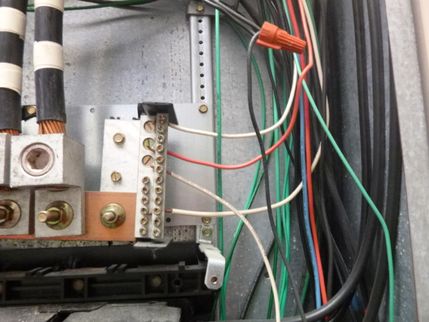

- ES1-3 Electrical System:

Wiring discrepancies were observed in the main panel. Items included:

- A double tapped breaker

- Unprofessional wiring practices

- A home made handle tie

- Improperly marked neutral

There was also visible signs of possible water entry at the base of a conduit pipe, due to a distinct mark or debris line on the wiring.

- ES1-5 Electrical System:

Exposed wire splices, or open j-boxes, were visible at random locations in the attic.

- ES1-6 Electrical System:

An outlet in the kitchen was damaged/burnt.

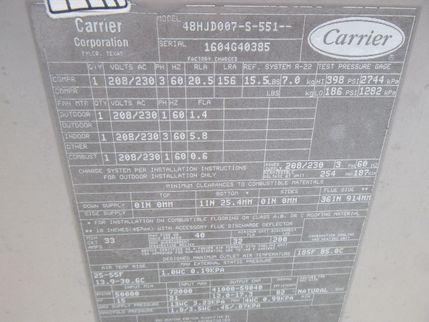

- HCAC1-2 Heating / Central Air Conditioning #1:

The cooling system for the front dining area was in overall poor condition, and not cooling sufficiently.

- HCAC21-4 Heating / Central Air Conditioning #2:

Ducts were not fully connected at the supply grates and blowing conditioned air into the attic.

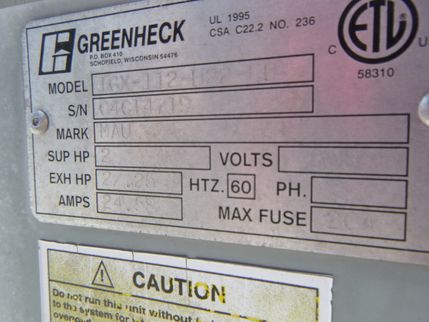

- AHRE-2 Additional HVAC and Refrigeration Equipment:

The make up air system appeared non-functional and original equipment. Gas to the unit was disconnected also.

- AHRE-3 Additional HVAC and Refrigeration Equipment:

The rear cooler was leaking around the door and moisture damage could be seen at the adjoining kitchen walls.

The cooler at the NW corner of the building was not in operation or abandoned.

Damage or corrosion could be seen at walls inside both of these coolers.

Coolers were not inspected for function and typically disclaimed, however the tenant expressed all equipment either not working or intermittently working.

Recommended Repairs

- ES-4 Exterior Site:

Soil erosion and neglect were noted at the rear landscaping area.

- ES-7 Exterior Site:

Lot lighting were not tested or controls were not located.

Lighting that was present had missing covers on some standards, and electrical wiring near by was exposed at some locations.

The sign also had prior impact damage, and soil erosion around the base of the supports.

- ES-8 Exterior Site:

Fencing and gates around the dumpsters were in poor condition.

- -4 Roof and Roof Structure:

Insulation was displaced or not installed above the ceiling tiles, multiple locations in the attic space. Examples are pictured.

- -5 Roof and Roof Structure:

Roof drainage was not installed, and remnants of downspouts were attached to the rear of the building.

- -3 Structural Frame and Building Envelope:

Metal awnings had visible separation

- -2 Common Interior Areas:

Moisture staining/damage could be seen at ceiling tiles, lights, and drywall, random locations of the restaurant. These areas were dry at the time of inspection. See "Roof" section.

- -3 Common Interior Areas:

Several baseboard tiles were damaged throughout the kitchen area.

- PS-7 Plumbing System:

A dish sink faucet was actively leaking.

- PS-8 Plumbing System:

A kitchen sink drain was duct-taped together

- HCAC1-3 Heating / Central Air Conditioning #1:

Drainage off the roof was causing stains or damage to structures below.

- HCAC21-3 Heating / Central Air Conditioning #2:

Filters were missing for the unit. Visible ducting into the kitchen had excess debris build up.

- AHRE-1 Additional HVAC and Refrigeration Equipment:

Corrosion was visible at the sheet metal ducts in the attic space.

Additional Evaluations

- PS-2 Plumbing System:

The grease trap was problematic or had issues according to the tenant.

- PS-9 Plumbing System:

Bathrooms were not present for the business, and shared with the gas station.

The bathrooms were in overall extremely poor condition, with a lingering odor present. All bathrooms were disclaimed.

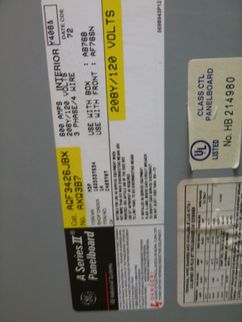

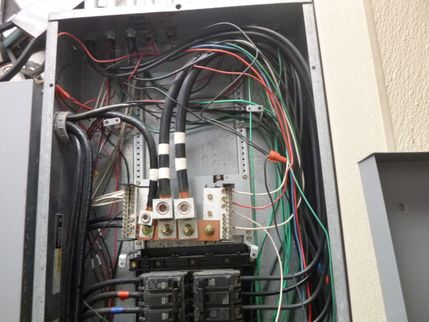

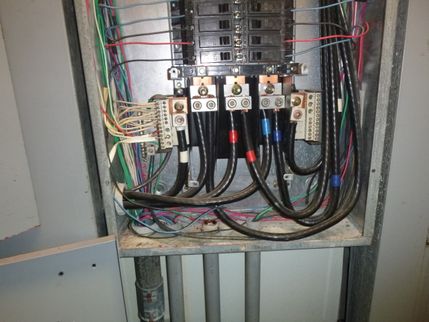

- ES1-4 Electrical System:

Some panel labeling was not correct or missing for other panels.

Panel screws were missing in a few locations also.

The 225 amp disconnect breaker appeared to be servicing both larger sub panels.

A open blank was also visible at the base of panel B

- HCAC21-2 Heating / Central Air Conditioning #2:

One of the cooling fans was not blowing hot air, and the unit failed to produce sufficient cool air inside the kitchen. Equipment needs review and service.

- AHRE-4 Additional HVAC and Refrigeration Equipment:

Roof mounted refrigeration equipment was not evaluated or was abandoned.

1 5 Year Deferred Maintenances

Monitor

- PS-5 Plumbing System:

Corrosion visible at the bottom of the electric water heater.

Safety Improvements

- -3 Fire Protection and Life Safety:

A sprinkler system was not present in the building. Regardless of prior requirements, installation of a system may be required depending on future building needs or modifications.

Having a system installed for obvious reasons should also be considered.

The Full Report

Information and General Limitations

Type of Building: Restaurant

Estimated Building Age: 2004

Outside Temperature : 75-85 degrees

Soil Conditions: Dry

Weather Conditions: Clear

Recent rain (within a week): No

Environmental Disclaimer! The following lists some common items that can exist in a building, but are outside the scope of our general inspection.

Mold, Radon, Chinese Drywall, Asbestos, Rodent, bat or pests including their feces/urine, Buried tanks or soil contamination.

Specific inspections intended to confirm or deny that any of the noted concerns are present during the inspection are not performed. These would require additional testing or an evaluation for positive conformation of their existence. In the event common signs or the potential presence are suspected by the inspector, we will report it and suggest further investigation. Mold would be a secondary result of moisture related building issues, and active visible moisture evidence would be documented if it found.

If additional testing is desired you can contact us to refer or perform these services.

Permit information is obtained so we can complete any needed insurance forms. Any permits on record for this building can be obtained or viewed by going online or contacting the local municipality.

Any additional construction or replacement of major systems that is not listed on the accessible permit information, may have been completed without one. A permit may exist but requires additional homework to obtain this information.

Our inspection is not intended to ensure permit enforceability, and evaluation of any un-permitted construction or additions can only be inspected by what is visibly deficient or incorrect. Hidden defects cannot be determined.

Our general inspection disclaims any permit related construction issues and we will not be responsible for any future permit or code related issues for un-permitted applications. If the inspection or sellers disclosure has documented any updated appliances, retrofits or upgrades to the structure, we advise you consult with the local municipality to ensure lack of permits will not impact you in the future. In some cases additional fines or removal of un-permitted structures may be required.

Utilities

Water Supply

Water source: Public Utility

Electricity

Power source: Power company

Natural or Propane gas

Source: Public Utility

Sanitary Sewer

Source: Public Utility

Exterior Site

Topography

Observations: Sloping

Storm Water Drainage

Observations: Perimeter Swales or Ditches, Underground Drains

Paving, Curbing and Parking

Lot and walkway materials: Asphalt, Concrete

Access/Egress locations: 2

Designated Handicap Parking: 1

Flatwork (sidewalks, plazas, patios)

Materials Present: Concrete

Landscaping and Appurtenances

Landscaping Condition: Slightly unkept

Lot Lighting and Signage

Illumination : A timer or daylight control sensor prevented testing

Roof and Roof Structure

Roofing Coverings, Penetrations and Components

Roof Shape/Design: Flat

Roofing Materials: TPO (white vinyl)

Estimated Covering Age: 2010

The roof covering had multiple soft areas where underlayment felt damaged or mushy from moisture. Sunken or depressed places were noted, and some standing water was visible at the enclosed structure.

The roof had debris, sharp bolts and razor blades also found.

Prior sealing and repairs were visible.

Signs of roof leaks were present inside, and the tenant also expressed leaks during rain storms inside.

Structural Framing and Attic Space (if accessable)

Materials: Steel trusses, Corrugated Metal Sheeting

Attic inspection Method: Ladder through random ceiling panels

Insulation and Ventilation Systems

Insulation Materials: 6 inches Batt Insulation

Attic Ventilation: None found

Bathroom Ventilation: No Bathrooms at this Unit

Structural Frame and Building Envelope

Foundation, and Structural Floors (visible only)

Foundation Materials/Design: Masonry, Concrete Slab

Structural floor design/materials: Concrete slab

Building Frame and Structural Walls (visible only)

Building design: Masonry Block

Egress Design: Sidewalks

Sidewall System (exterior wall cladding and components)

Siding Materials: Masonry

Fenestration System (i.e. windows, openings, doors etc.)

Window Materials: Gasket Sealed Single Pane

Exterior Entry/Door Materials: Tempered Glass and Metal Frame, Steel

Common Interior Areas

Ceilings

Building Materials: Suspended ceiling panels

Walls

Building Materials: Drywall, Fiberglass or Plastic Coverings

Interior Doors

Building Materials: Solid

Plumbing System

Water Supply/Distribution Piping

Material Used: Copper

Drain and Waste Systems

Materials Used: PVC

Floor drains on the interior were visibly clogged or holding water in some locations. The tenant also reported problems with clogging of the drain system.

Visible drain pipes and clean out were under 6 inches, and appeared to be 4 inch pipes.

Water Heating System(s)

Power Source: Electric

Manufacturer: RHEEM

Capacity: 20 Gallons

Manufacturer Age: 2019

Location: Kitchen (next to utility sink)

Interior Faucets and Fixtures

Bathrooms were not present for the business, and shared with the gas station.

The bathrooms were in overall extremely poor condition, with a lingering odor present. All bathrooms were disclaimed.

Fuel/Gas System

Materials: Black Iron

Electrical System

Service Entrance and Rating

Phase Rating: Three Phase

Service/Building Amperage: 600 AMP

Electrical Panels

Total Main and Distribution Panels : 6

Panel Phase Ratings : Multiple three phase panels

Panel Amperages: 600 AMP, 225 AMPS, 100 AMP

Panel Brand(s): GENERAL ELECTRIC

Wiring discrepancies were observed in the main panel. Items included:

- A double tapped breaker

- Unprofessional wiring practices

- A home made handle tie

- Improperly marked neutral

There was also visible signs of possible water entry at the base of a conduit pipe, due to a distinct mark or debris line on the wiring.

Electrical Wiring

Materials Visible: Copper

Distribution Wiring : THHN-THWN, EMT

Attic Wiring and Components

Heating / Central Air Conditioning #1

HVAC Equipment

System Design: Exterior Package Unit

Cooling Equipment Type: Electric

Heating Equipment Type: Natural Gas

Manufacturer: CARRIER

Estimated Tonnage/Size: 6 Tons

Estimated Age: Service Life Reached, 2004

The cooling system for the front dining area was in overall poor condition, and not cooling sufficiently.

Ducting and Distribution

Filter Locations: At the unit

Ducting Materials: Hard Metal-Insulated

Heating / Central Air Conditioning #2

HVAC Equipment

System Design: Split System (inside and outside equipment)

Cooling Equipment Type: Electric

Heating Equipment Type: Natural Gas

Manufacturer: CARRIER

Estimated Tonnage/Size: 8.5 Tons

Estimated Age: 2016

One of the cooling fans was not blowing hot air, and the unit failed to produce sufficient cool air inside the kitchen. Equipment needs review and service.

Ducting and Distribution

Filter Locations: At the unit

Ducting Materials: Hard Metal-Insulated

Filters were missing for the unit. Visible ducting into the kitchen had excess debris build up.

Condensate Drainage and Safety Controls

Safety shut Off Features: No float switch installed

Condensate drainage location: rear of the building

Additional HVAC and Refrigeration Equipment

Ventilation or Make Up Air Systems

COOLERS AND FREEZERS

The rear cooler was leaking around the door and moisture damage could be seen at the adjoining kitchen walls.

The cooler at the NW corner of the building was not in operation or abandoned.

Damage or corrosion could be seen at walls inside both of these coolers.

Coolers were not inspected for function and typically disclaimed, however the tenant expressed all equipment either not working or intermittently working.

Fire Protection and Life Safety

General Information and disclaimers

Sprinkler and alarm systems are not part of the general assessment, and in most cases require annual inspection and certification from a trade specialist. We disclaim these systems entirely, which include sprinklers and piping, alarm systems and monitoring, and ANSUL systems. Many of these systems will be tied together, and can be serviced at the same time. We advise you consult with the sellers for information on recent repairs/service and information regarding these systems.

ADA Disclaimer!

In regards to ADA compliance, the PCA does not provide any type of ADA compliance inspections, nor does it determine if the existing building is compliant based on municipal requirements. If an ADA inspection is desired, a separate evaluation would be needed for the building.

Emergency Lighting and Signs

Visible Devices: Emergency Lighting/Signs present

Sprinkler System

A sprinkler system was not present in the building. Regardless of prior requirements, installation of a system may be required depending on future building needs or modifications.

Having a system installed for obvious reasons should also be considered.