The Scope and Purpose of a Home Inspection

All New Jersey Home Inspectors shall comply with the Standards of Practice (13:40 -15.16) contained in the Home Inspection Advisory Committee Statutes and Regulations. The scope of the home inspection services performed in compliance with the requirements set forth in this inspection report shall provide the client with objective information regarding the condition of the systems and components of the home as determined at the time of inspection.

Purchasing property involves risk

The inspector makes every effort to find all areas of concern during the inspection of this home, some areas can go unnoticed for several reasons. The inspector cannot report on areas that are not visible or accessible at the time of the inspection. Areas that may be visible and accessible at the walkthrough and or taking ownership may not have been visible or accessible at the time of the inspection. Please be aware that the inspector has your best interest in mind. Any repair items mentioned in this inspection report should be considered before purchasing. Where repairs or replacements are suggested, recommend the use of NJ registered home improvement contractors / Licensed professionals (Electricians/Plumbers) in that field be called (prior to the expiration of inspection period) upon to make those repairs or at least to obtain an accurate price quote for the repairs needed. The inspector does not site-building codes and this inspection is NOT a CODE inspection. There may be issues stated in this report that differ from the outcome of a municipal building inspection. Furthermore, the inspector is not responsible to research (and reporting) to the local building department that the appropriate permits and approvals were obtained for any and all improvements done within this home. It is recommended that you obtain all the records from the seller and the building department that are related to this home. Furthermore, you may wish to file a New Jersey Open Public Records Act (OPRA) request from the municipality that this home is located on any and all copies of records the municipality possesses related to the subject property. For further information on OPRA, go to http://www.nj.gov/grc/public/request/

Suggest consulting with your local municipality and manufacture specifications as to the proper location and installation of these units.

Verification of compliance with current or past building code and/ or zoning regulations (permits) are outside the scope of General Home Inspection. Advise clients to contact the local municipality for information regarding work history of the property prior to the expiration of the inspection period.

A general inspection should not be seen as a termite or wood destroying organism (WDO) or wood destroying insect (WDI) inspections as required by some mortgage companies. When termite damage is visible at the time of inspection or when evidence of possible termite activity is noted, these areas are recorded for reference only, so that additional evaluation can be conducted during the WDO inspection by a licensed termite inspector. If prior repairs have been carried out, full confirmation and disclosure from the sellers is advised to ensure a proper repair. Checking the historical data with the seller with regard to previous termite activity is always advised. Therefore, it's recommended that you have the property inspected by a licensed termite inspector prior to closing.

Systems and conditions which are not within the scope of the building include, but are not limited to: formaldehyde, lead paint, asbestos, toxic or flammable materials, and other environmental hazards; pest infestation, playground equipment, swimming pools, sprinkler systems, efficiency measurement of insulation or heating and cooling equipment, internal or underground drainage or plumbing, any systems which are shut down or otherwise secured; water wells (water quality and quantity) zoning ordinances; septic systems; intercoms; security systems; heat sensors; cosmetics or building code conformity. Any general comments about these systems and conditions only and do not represent an inspection.

We do not search for underground oil tanks. This is outside the scope of a home inspection. If the client is concerned one may exist on this property, we recommend you have a tank sweep performed by a qualified person, prior to closing.

The inspector uses an infrared camera during the home inspection. The infrared camera is used on the interior of the building only to look for any moisture intrusion, or electric and plumbing defects that may be present. For an infrared camera to work properly, the inspector needs a proper temperature difference from the exterior to the interior of the building (Delta T). These differences in temperatures can be created by the utilization of air conditioning and heating system of the home. A home that has Stucco/EIFS fronts is not scanned from the outside during the home inspection. An infrared camera can be used to scan these types of fronts, but conditions have to be optimum. They have to be scanned at night after sundown to be able to properly diagnose these fronts.

A Pre-Settlement Walk-Thru inspection is required to be performed by the buyer prior to closing, typically on the day of closing. Circumstances and conditions may have changed since the home inspection. Items such as storage, furnishings, appliances, furniture, and personal items limited access and visibility, but have now been removed. It is recommended to retest all built-in appliances, operate and test all water supplies and drains, and make observations as to any damage or water penetrations that may not have been evident at the time of the home inspection. Any evidence of moisture should be followed by Mold Testing by a qualified contractor. Issues/concerns must be addressed with the seller, prior to closing.

IMPORTANT NOTICE: This is a CONFIDENTIAL home inspection report on the above-named property. This report and the information contained herein is the sole property of the person(s) or entity(s) identified above as "Customer" and AmeriSpec Home Inspection Services. Neither Customer nor AmeriSpec Home Inspection Services may assign this ownership to any third party without the express written consent of the other. This report is invalid if utilized by any other person, party or entity, including but not limited to insurance companies, lending institutions, real estate agents, and/or brokers, for any purpose. This report is not to be used as a property insurance inspection report for the purpose of qualifying and/or obtaining homeowners insurance coverage, nor is this report to be utilized by a lending institution as an appraisal or as an adjunct to an appraisal. Use of this report by any person, party, or entity other than those named as Customer on this report for any purpose at all is unauthorized and therefore prohibited. Any person, party, or entity engaging in such unauthorized and prohibitive use forfeits any and all rights to any claim against AmeriSpec Home Inspection Services and its principles and/or partners and/or employees for any reason whatsoever in relation to any and all information contained in this home inspection report.

"Home inspection" means a visual, functional, non-invasive inspection conducted for a fee or any other consideration and performed without moving personal property, furniture, equipment, plants, soil, snow, ice, or debris, using the mandatory equipment and including the preparation of a home inspection report of the readily-accessible elements of the following components of a residential building: structural components, exterior components, roofing system, plumbing system, electrical system, heating system, cooling system, interior components, insulation components and ventilation system, fireplaces, and solid fuel-burning appliances, or any other related residential housing component as determined by the Board, in consultation with the Committee, by rule, but excluding recreational facilities and outbuildings other than garages or carports.

What we are not allowed to do:

1. Enter any area or perform any procedure, which is, in the opinion of the home inspector or associate home inspector, unsafe and likely to be dangerous to the inspector or other persons,

2. Enter any area or perform any procedure which will, in the opinion of the home inspector or associate home inspector, likely damage the property or its systems or components.

3. Enter any area, which does not have at least 24 inches of unobstructed vertical clearance and at least 30 inches of unobstructed horizontal clearance.

4. Identify concealed conditions and latent defects.

5. Determine the life expectancy of any system or component.

6. Determine the cause of any condition or deficiency.

7. Determine future conditions that may occur including the failure of systems and components including consequential damage.

8. Determine the operating costs of systems or components.

9. Determine the suitability of the property for any specialized use.

10. Determine compliance with codes, regulations, and/or ordinances.

11. Determine the market value of the property or its marketability.

12. Determine advisability of purchase of the property.

A home inspection is not an insurance policy

This report does not substitute for or serve as a warranty or guarantee of any kind. Home warranties can be purchased separately from insuring firms that provide this service.

This is just our opinion

Construction techniques and standards vary. There is no one way to build a house or install a system in a house. The observations in this report are the opinions of the home inspector. Other inspectors and contractors are likely to have some differing opinions. You are welcome to seek opinions from other professionals.

The scope of this inspection

This inspection will include the following systems: exterior, roof, structure, drainage, foundation, attic, interior, plumbing, electrical, and heating. The evaluation will be based on limited observations that are primarily visual and non-invasive. This inspection and report are not intended to be technically exhaustive.

Your expectations

The overall goal of a home inspection is to help ensure that your expectations are appropriate for the house you are proposing to buy. To this end, we assist with the discovery by showing and documenting observations during the home inspection. This should not be mistaken for a technically exhaustive inspection designed to uncover every defect in a building. Such inspections are available but they are generally cost-prohibitive to most homebuyers.

Your participation is requested

Your presence is requested during this inspection. A written report will not substitute for all the possible information that can be conveyed verbally by a shared visual observation of the conditions of the property.

How to Read This Report

Getting the Information to You

This report is designed to deliver important and technical information in a way that is easy for anyone to access and understand. If you are in a hurry, you can take a quick look at our "Summary Page”. However, we strongly recommend that you take the time to read the full Report, which includes digital photographs, captions, diagrams, descriptions, videos, and hot links to additional information.

The best way to get the layers of information that are presented in this report is to read your report online, which will allow you to expand your learning about your house. You will notice some words or series of words highlighted in blue and underlined – clicking on these will provide you with a link to additional information.

This report can also be printed on paper or to a PDF document.

Chapters and Sections

This report is divided into chapters that parcel the home into logical inspection components. Each chapter is broken into sections that relate to a specific system or component of the home. You can navigate between chapters with the click of a button on the left side margin.

Most sections will contain some descriptive information done in black font. Observation narrative, done in colored boxes, will be included if a system or component is found to be significantly deficient in some way or if we wish to provide helpful additional information about the system or the scope of our inspection. If a system or component of the home was deemed to be in satisfactory or serviceable condition, there may be no narrative observation comments in that section and it may simply say “tested,” or “inspected.”

Observation Labels

All narrative observations are colored, numbered, and labeled to help you find, refer to, and understand the severity of the observation. Observation colors and labels used in this report are:

- Repair:Repair and maintenance items noted during inspection. Please note that some repair items can be expensive to correct such as re-finishing hardwood floors, but are considered simply repair items due to their cosmetic nature.

- Due Diligence:Observation such as a buried oil tank that may require further investigation to determine the severity and / or urgency of repair.

- Recommended Maintenance:These are repair items that should be considered "routine home ownership items," such as servicing the furnace, cleaning the gutters or changing the air filters in the furnace.

- Improve:Observations that are not necessarily defects, but which could be improved for safety, efficiency, or reliability reasons.

- Efficiency:Denotes observations that are needed to make the home more energy efficient as well as to bring the home up to modern insulation standards. This category typically includes windows and insulation. Other items, such as lighting and appliances, are not inspected for their energy status.

- Note:Refers to aside information and /or any comments elaborating on descriptions of systems in the home or limitations to the home inspection.

- Description:Detailed description of various aspects of the property noted during the inspection.

Summary Page

The Summary Page is designed as a bulleted overview of all the observations noted during the inspection. This helpful overview is not a substitution for reading the entire inspection report. The entire report must be read to get a complete understanding of this inspection report as the Summary Page does not include photographs or photo captions.

Summary

Repairs

- ESDW-2 Exterior Siding, Doors and Windows:

Observed a section of the substrate missing under the vinyl siding in the attic at the inspection time. The missing section needs to be replaced by an NJ-registered home improvement contractor.

- G-2 Garage:

The pulldown ladder in the garage does not appear to be a fire-rated model. This can be tricky to repair without replacing the pulldown ladder with a fire-rated model - see LINK as an example. You can try sheetrocking the ladder cover, but this often compromises the proper operation of the ladder, causing the ladder to sag and leaving a gap in the firewall. You can also try making a fire-rated sheetrock separation between the garage and the house in the attic above the garage, but this, too can be complicated. Have an NJ-registered home improvement contractor further evaluate and repair.

- G-3 Garage:

Observed a section of block missing at the right side garage door during the inspection. A repair is needed by an NJ-registered home improvement contractor.

- CS-2 Crawl Space:

Inadequate ventilation was noted for the crawl space. Standards recommend 1 square foot of ventilation for every 150 square feet of crawl space or 1/1500 in combination with an approved class 1 vapor retarder material that covers all exposed soils in the crawl space. Vents should be located to provide adequate cross-ventilation. Hire an NJ registered contractor to evaluate further and repair.

- EDFW-1 Electric Distribution and Finish Wiring:

The open electrical junction box in the basement needs to be covered for improved safety. This is as simple as installing a cover plate over the box to protect the wiring. An extension ring is sometimes needed if finishes cover the box—repair as needed for improved safety.

- EDFW-2 Electric Distribution and Finish Wiring:

The missing cover plates to electric receptacles, switches, and junction boxes should be installed to cover all access to the wiring at switches and receptacles. Where switches, receptacles, or junction boxes are positioned below wall or ceiling or cabinet finishes, an extension ring may be needed.

- EDFW-3 Electric Distribution and Finish Wiring:

GFCI (Ground Fault Circuit Interruption) protection is inconsistent with modern minimum standards for safety. GFCI protection is recommended for the electrical receptacles in the following locations: the two dedicated kitchen appliance circuits, all receptacles within 6 feet of a sink, bathrooms, exterior, garage, unfinished basements, laundry, and all wet locations. GFCIs protect against electrocution by limiting the duration of an electrical shock. These are essential modern safety feature that has proven to save lives. Hire an NJ-licensed electrician to evaluate further and update GFCI protection for improved safety. Examples of observations noted during the inspection include:

- HCFV-2 Heating, Cooling, Fireplaces and Ventilation:

The hole where the line is set exiting the foundation wall in the basement needs to be sealed properly. Currently, rags are stuffed in the hole. This could be an entryway for rodents. Have an NJ-registered home improvement contractor review and make necessary repairs.

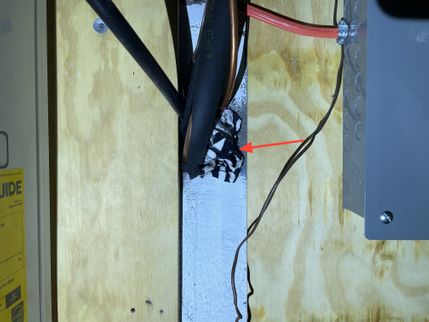

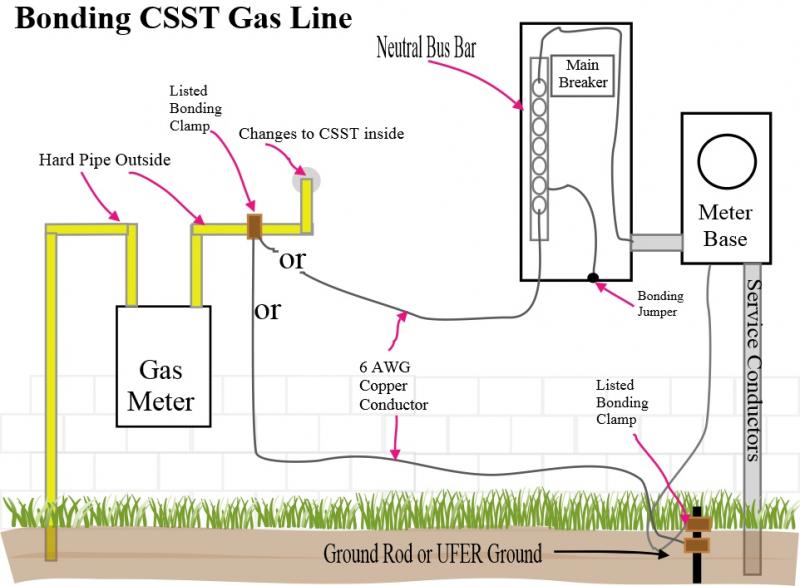

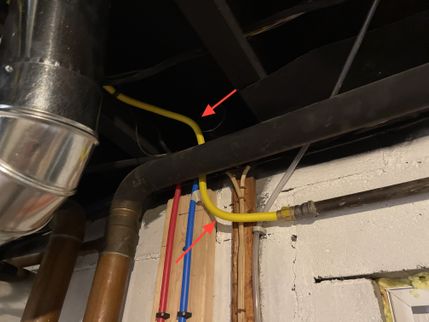

- FSD-2 Fuel Storage and Distribution:

CSST tubing was observed in this home. If this pipe is not properly bonded it can be damaged by lighting. In many CSST installations, the CSST tubing is not bonded to the electrical system, which violates the manufacturer's current installation instructions and requires that the gas system be directly bonded to the electrical systems with 6 AWG copper wire, near the service entrance to the building. Recommend having a licensed electrical bonded it for safety. The manufacturers of this pipe are gastite. Below are the instructions directly from the manufacturer's instructional manual.

For the manufacture instructional manual:

Direct bonding of Gastite® CSST is required for all gas-piping systems incorporating Gastite® CSST whether or not the connected gas equipment is electrically powered. This requirement is part of the manufacturer’s instruction for single-family and multi-family buildings. A person knowledgeable in electrical system design, the local electrical code, and these requirements should specify the bonding for commercial applications. Gastite® CSST installed inside or attached to a building or structure shall be electrically continuous and direct bonded to the electrical ground system of the premise in which it is installed. The gas piping system shall be considered to be directly bonded when installed in accordance with the following:

The piping is permanently and directly connected to the electrical service equipment enclosure, the grounded conductor at the electrical service, the grounding electrode conductor (were of sufficient size), or to one or more of the grounding electrodes used. For single and multi-family structures, a single bond connection shall be made downstream of the individual gas meter for each housing unit and upstream of any CSST connection. The bonding conductor shall be no smaller than a 6 AWG copper wire or equivalent. The bonding wire shall be attached in an approved manner in accordance with NEC Article 250.70 and the point of attachment for the bonding wire shall be accessible. Bonding/grounding clamps shall be installed in accordance with its listing per UL 467 and shall make metal-to-metal contact with the piping.

Also attached is a Youtube video explaining how to bond it:

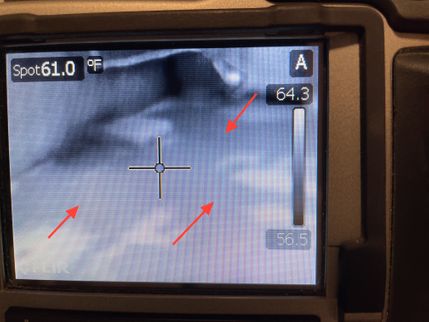

- P-3 Plumbing:

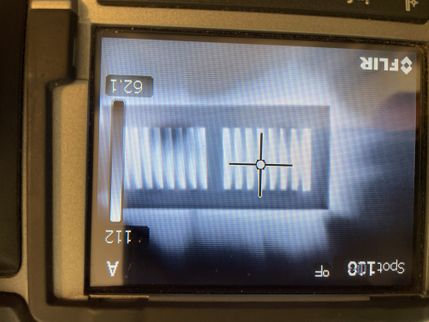

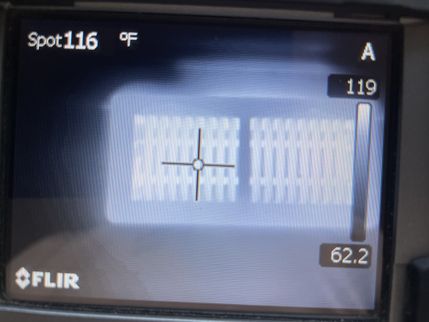

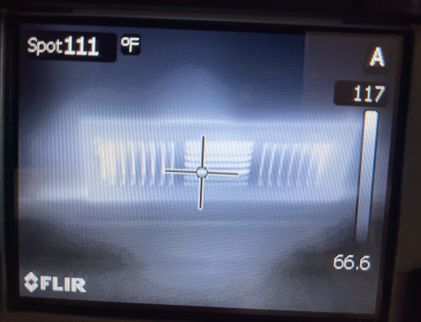

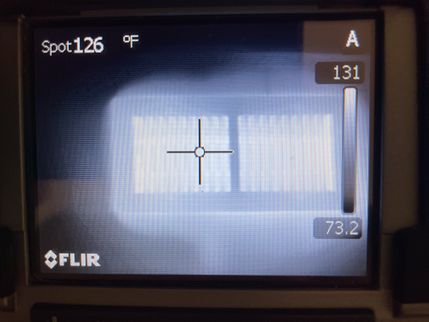

The water heater was leaking at the time of the inspection; the inspector observed water leaking from the bottom and standing water on the floor. Due to the water leaking, water is seeping under the basement floor. This can be seen with the infrared photo. The water must be cleaned up under the flooring to prevent further deterioration.

- P-4 Plumbing:

The tankless water heater appears to be missing a pressure relief valve. None was noted during inspection. Pressure relief valves are important and required safety devices for tankless water heaters. have this further evaluated and repaired as recommended by a licensed plumbing contractor.

- I-2 Interior:

Observed a gap between the finished ceiling and the light fixture in the basement. Repairs are needed.

- K-1 Kitchen:

There was no outlet installed for the microwave at the time of the inspection. Have an NJ licensed install an outlet before settlement.

- K-2 Kitchen:

The dishwasher did not complete a normal cycle during the inspection. It had power but it appears there was no water for it at the time of the inspection. Further evaluation is needed.

- 2B2-1 2nd floor Bathroom (2):

The stopper in the 2nd-floor bathtub is missing and requires repair or replacement - or a rubber stopper can be used.

Due Diligences

- RCG-1 Roof, Chimney and Gutters:

The roof is new; the client should consult with the seller if any warranties are in place with this installation before settlement.

- SB-2 Structure and Basement:

The basement has been finished; we do not verify if the necessary permits were pulled to do this work. Recommend having the client check with the local township to verify if the proper permits were issued and the proper inspections were performed. If no permits have been obtained, the seller should obtain a CCO Certificate of Continued Occupancy from the local municipality. A CCO inspection is a reasonable solution for ensuring that construction work is properly documented. Future owners are not held responsible for violations resulting from work performed without permits. The documentation for a CCO inspection should include a report describing the work completed without a permit. Construction officials should be aware that CCO inspections are limited to those visible portions of the home. For items that are not visible, there must be probable cause to warrant uncovering the work to allow for inspections. The code official is not compelled to perform a destructive inspection unless there is reason to believe a life-safety violation exists.

- FSD-1 Fuel Storage and Distribution:

We do not search for underground oil tanks. This is outside the scope of a home inspection. If the client is concerned one may exist on this property, we recommend you have a tank sweep performed by a qualified person before closing. (Homes in this area normally were fuled by oil when they were built.)

- P-1 Plumbing:

Water for this home appears to be supplied by a good system. Inspection of the well, water supply, and water quality is beyond the scope of this inspection. I recommend hiring a well specialist to inspect and evaluate the well and well water. Well, equipment: the pump and captive storage tank have limited service lives and often require updating on a 20-year schedule. There are other elements of a good system that should be evaluated as well, such as the good production, often tested in a drawdown test, water quality, and well depth.

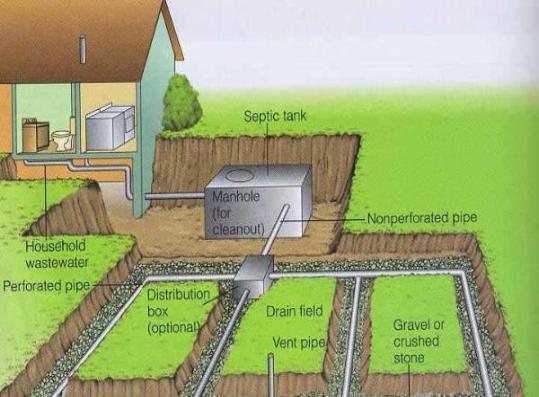

- P-2 Plumbing:

Based on visible components, this property appears to have a private on-site septic system. These are specialty systems and are excluded from this inspection. Comments in this report related to this system are made as a courtesy only and are not meant to be a substitute for a full evaluation by a qualified specialist. Generally, septic tanks should be pumped and inspected every 3 years. Depending on the type of system and municipal regulations, inspection and maintenance may be required more frequently, often annually. I recommend:

- Investigating any information about this system's maintenance and repair history

- Reviewing any documentation available for this system

- Learning inspection and maintenance requirements for this system

- Hire a qualified specialist to evaluate, perform maintenance and make repairs as needed

- AP-1 Additional Plumbing:

An ejector pump serves the basement bathroom. An NJ licensed plumber should be hired to ensure proper venting of this fixture. Since the basement is finished, it could not be determined if these fixtures are adequately vented. It is recommended that it be ensured that the proper permits were opened and closed for these installations before purchase.

- I-1 Interior:

An investor has flipped this home, it is recommended that the client obtain all close permits for the work that has been performed on this property before closing. Suppose the investor did not get the necessary permits to perform this work on this property. In that case, it is recommended that the permits be issued and the local municipality performs the proper inspections before settlement.

Recommended Maintenance Items

- RCG-3 Roof, Chimney and Gutters:

The gutters are clogged with organic debris and require cleaning to ensure proper control of roof runoff. Clean the gutters and ensure they are unobstructed, leak-free and properly sloped to drain. This is routine house maintenance; I would expect the need to clean gutters and downspouts regularly.

- P-5 Plumbing:

The water heater temperature seemed to be set too low at the time of inspection - just 110 degrees F. The range of 120-125 degrees F is the generally recommended temperature. This is nearly impossible to measure precisely during a home inspection as water temperature can vary between fixtures. Adjust water heater temperature as needed. For best practice, set water temperature at the water heater to 130 degrees F and use a tempering valve to set water temp back to a safe 120 for domestic use. This high tank temperature will reduce risks of Legionella developing in the tank and the tempering valve will ensure a safe water temperature.

Improves

- A-2 Attic:

The exhaust ductwork for the bathroom fans is uninsulated in the attic space. This can lead to seasonal condensation problems and is less energy efficient. Replace these exhaust vents with insulated exhaust ducts or insulate them to R-8 or better.

✒

- Please note that air leakage from these vents could contribute to seasonal condensation issues.

- ESDW-1 Exterior Siding, Doors and Windows:

Observed no kick-out flashing installed where the roof and the wall meet. This flashing is a critical component in diverting water away from the structure. Recommend adding this flashing detail by an NJ-registered home improvement contractor to avoid moisture penetration into the wall. Hidden damage may be present that was not visible to the inspector during the inspection may be present.

- G1-1 Grounds:

Downspouts are discharging adjacent to the foundation. This can cause foundation settlement or basement moisture problems. Ensure all downspouts discharge into a proper tight-line system that diverts water at least 5 feet from the foundation.

- G1-2 Grounds:

The home had neutral or negative drainage areas at grade, which will route runoff from precipitation to the foundation. Excessive moisture content in soil supporting the foundation can cause foundation and other structural damage from undermining, heaving, or settling, depending on soil composition, moisture content, and other conditions. The ground should slope away from the home ¼-inch per foot for a distance of at least six feet from the foundation. The Inspector recommends re-grading these areas to improve drainage near the foundation.

- DPB-1 Decks, Porches and Balconies:

The concrete patio does not have a positive slope at the rear of the home, which could cause or contribute to water intrusion. The concrete should slope away from the home home. I recommend correcting the landscape to drain water away from the home.

- G-4 Garage:

You may want to install automatic garage door openers as none have been installed for the garage doors.

- MB-1 Master Bathroom:

Consider installing a 1-hour timer for bath fans so they run after use. This will help to keep this space dry because the fan can run for a while after use without leaving the fan on all day.

- 2B2-2 2nd floor Bathroom (2):

Consider installing a 1-hour timer for bath fans so they run after use. This will help to keep this space dry because the fan can run for a while after use without leaving the fan on all day.

Efficiencies

- A-1 Attic:

The attic insulation could be improved to modern standards, which recommend R-49 on the floor and R-21 on the walls. R-value measures resistance to heat loss; the higher the R-value, the better the insulation. It is best practice to implement any air seal-up repairs during insulation repairs to seal air leakage. Also, be sure you have completed any wiring or other needed projects in the attic. Then, hire an insulation contractor to improve thermal barriers.

Notes

- SB-1 Structure and Basement:

This house is built on a concrete block foundation, often referred to in the trades as Concrete Masonry Unit (CMU). These foundations are standard in many parts of the country, and, depending on how they are installed, they can perform similar to poured concrete foundations. Unfortunately, most CMU foundations are not reinforced, making them prone to seismic damage. Reinforcement is impossible to verify during the inspection. Once they are complete, these foundations are difficult to retrofit, and it should be assumed that this foundation is not up to modern seismic standards. These foundations are also tricky to waterproof as they are porous and not as resistant to water as a poured concrete foundation.

- CS-1 Crawl Space:

The photos provided here show representative images of this crawl space at the time of inspection.

- HCFV-1 Heating, Cooling, Fireplaces and Ventilation:

There was water on the floor next to the condense pump when the inspector inspected the heater; the GFCI outlet was tripped. Once the outlet was reset the condense pump turned on and worked as intended during the inspection.

- I-3 Interior:

During this inspection, a thermal imaging camera was used to check walls, ceilings and appliances for thermal anomalies. Thermal imaging cameras use the infrared light spectrum to build a picture based on temperature differentials. Experienced thermogrophers look for clues in these thermal images that could lead us to otherwise-concealed moisture control problems or missing air or thermal barriers. We can also use them for appliance verification. We do not use infrared for electrical inspections. In older homes, incomplete air and thermal barriers are so common, we will only report on items that look significantly deficient and which seem worthy of correction.

This service is included with our home inspection; it is limited and is not a complete thermal mapping of the house. The use of an infrared camera is well beyond the minimum standards for a home inspection. We offer this service because we know it is valuable and can help us help our clients by improving our inspection services.

Please note that this tool has limitations when done in conjunction with a home inspection. Environmental conditions present limitations to the information that can be gathered during the course of a home inspection. For example, occupant behavior, the time of day, time of year and weather conditions can all impact the usefulness of the data that can be gathered.

Relevant thermal images will be included in this report.

- MB-2 Master Bathroom:

During inspection today, I operated all plumbing fixtures in the bathrooms. I ran a moisture meter around toilets and tile shower enclosures to check for concealed leaks and sounded for loose tile and finishes in shower and tub enclosures. I do not test bathtub overflow drains, which risks damaging finishes around the tub. Monitor tubs while filling and avoid pushing water into the flood. Even well-installed overflow drains can leak as the gaskets that seal the overflow will dry over time and may no longer provide a watertight seal. Monitor plumbing after moving into a new home as testing during inspection presents less stress on plumbing than daily use. Please note that vacant homes offer additional risk as it can be difficult to distinguish how the plumbing system will respond to everyday use. Any defects uncovered during an inspection are listed in this report.

- 2B2-3 2nd floor Bathroom (2):

During inspection today, I operated all plumbing fixtures in the bathrooms. I ran a moisture meter around toilets and tile shower enclosures to check for concealed leaks and sounded for loose tile and finishes in shower and tub enclosures. I do not test bathtub overflow drains, which risks damaging finishes around the tub. Monitor tubs while filling and avoid pushing water into the flood. Even well-installed overflow drains can leak as the gaskets that seal the overflow will dry over time and may no longer provide a watertight seal. Monitor plumbing after moving into a new home as testing during inspection presents less stress on plumbing than daily use. Please note that vacant homes offer additional risk as it can be difficult to distinguish how the plumbing system will respond to everyday use. Any defects uncovered during an inspection are listed in this report.

- BB-1 Basement Bathroom:

During inspection today, I operated all plumbing fixtures in the bathrooms. I ran a moisture meter around toilets and tile shower enclosures to check for concealed leaks and sounded for loose tile and finishes in shower and tub enclosures. I do not test bathtub overflow drains, which risks damaging finishes around the tub. Monitor tubs while filling and avoid pushing water into the flood. Even well-installed overflow drains can leak as the gaskets that seal the overflow will dry over time and may no longer provide a watertight seal. Monitor plumbing after moving into a new home as testing during inspection presents less stress on plumbing than daily use. Please note that vacant homes offer additional risk as it can be difficult to distinguish how the plumbing system will respond to everyday use. Any defects uncovered during an inspection are listed in this report.

📃 The Complete Inspection Report

General Comments

Building Characteristics, Conditions and Limitations

Type of Building : Single Family (1 story with Basement)

Approximate Square Footage: 2700

The approximate square footage listed here is listed as a courtesy and is based off of public records and disclosure. An evaluation of square footage of the buildings and property lines is beyond the scope of this inspection.

Approximate Year of Original Construction: 1973

Unless the wiring in the building has been fully updated, this building likely has wiring that predates the late 1980's. Branch circuit wiring installed in buildings built prior to the late 1980s is typically rated for a maximum temperature of only 60 degrees Celsius. This includes non-metallic sheathed (Romex) wiring, and both BX and AC metal-clad flexible wiring. Knob and tube wiring, typically installed in homes built prior to 1950, may be rated for even lower maximum temperatures. Newer electric fixtures including lighting and fans typically require wiring rated for 90 degrees Celsius. Connecting newer fixtures to older, 60-degree-rated wiring is a potential fire hazard. Repairs for such conditions may involve replacing the last few feet of wiring to newer fixtures with new 90-degree-rated wire, and installing a junction box to join the old and new wiring. It is beyond the scope of this inspection to determine if any such incompatible components are installed. Based on the age of this building, be aware that such components may be present.

In 1978, federal laws were passed to prohibit use of lead and asbestos in building materials. Manufacturers of building materials were allowed to sell existing stocks of materials that were manufactured with lead and asbestos, so even buildings constructed as late as the mid-1980's could possibly contain lead or asbestos. Identification and testing for lead and asbestos and other environmental testing is beyond the scope of this home inspection. If you wish to seek additional information, I recommend contacting an environmental lab or industrial hygienist.

Solid conductor aluminum wiring was used in residential construction for 15 and 20-amp circuits in the 1960's through the 1970's. This wiring has proven to be problematic and a fire hazard, primarily due to problems with loose connections and metal fatigue. I looked hard to find any signs of solid conductor aluminum here. No signs were found. There is always a chance that solid conductor aluminum wiring exists and is concealed from view. If this wiring is ever uncovered during subsequent renovation work, I recommend removal and replacement.

Attending the Inspection: Buyer and Buyer's Agent

Occupancy: Occupied

This home was occupied at the time of the inspection. Inspection of occupied homes presents some challenges as occupant belongings can obstruct visual inspection of and access to parts of the building. We do our best during inspection to work around belongings to discover as much as possible about the house without moving or damaging personal property, however, the presence of personal items does limit the inspection.

Weather during the inspection: Clear

Approximate temperature during the inspection: Below 55[F]

Ground/Soil surface conditions: Dry

For the Purposes of This Report, the Front Door Faces: North

Roof, Chimney and Gutters

Roof Materials

Method of Roof Inspection: Walked on roof

Roof Style: Gable, Hip

Flashings, Valleys and Penetrations: Present and Visually Standard

Roof flashings are used to keep a roofing system waterproof where the roofing material starts, stops, changes direction or is penetrated. During inspection, we look for standard flashing techniques that could be considered normal or standard in our region. Damaged, incomplete or non-standard flashings can be a sign of an older or less reliable roofing system and may require repair. Any non-standard flashings noted during inspection will be reported on below if found.

Roof Covering Materials: Architectural grade composition shingle

The shingles are comprised of asphalt or fiberglass materials impregnated with mineral granules that are designed to deflect the deteriorating ultra-violet rays of the sun. This roof has architectural shingles installed. This type is warranted by manufacturers to last for about twenty-five years. The actual service life of the roof will vary, depending on a number of interrelated factors including the quality of the material and the method of installation. Regular maintenance will certainly extend the life of any roof.

Approximate Age of Roof Covering: New

The roof is new; the client should consult with the seller if any warranties are in place with this installation before settlement.

This is a video of the roof.

Chimneys

Present

Chimney Material: Brick

Chimney Flue Liners: Clay

Gutters and Downspouts

Gutter and Downspout Materials: Seamless Aluminum

Gutter and downspouts are an integral part of a home's stormwater management system and should be monitored regularly for proper operation. It is recommended that the gutters and downspouts be cleaned and flushed as part of routine maintenance to reduce the potential for water backup and resultant damage to roofing materials and concealed portions of the home.

The gutters are clogged with organic debris and require cleaning to ensure proper control of roof runoff. Clean the gutters and ensure they are unobstructed, leak-free and properly sloped to drain. This is routine house maintenance; I would expect the need to clean gutters and downspouts regularly.

Attic

Attic Access

Viewed at access

The attic was inspected from the entrance due to insulation covering the bottom of the ceiling joist. No walkway was provided in the attic. Persons entering the attic must walk on ceiling or roof framing members which are often hidden from view beneath the insulation. This activity can be difficult and/or hazardous. The ceiling-covering material (drywall or plaster) will usually not support the weight of a person.

Roof Framing and Sheathing

Rafters: Timber frame

Sheathing: Plywood

Attic Insulation

Insulation Type: Fiberglass

Approximate Insulation R-Value on Attic Floor: Improve to Modern Standard

The attic insulation could be improved to modern standards, which recommend R-49 on the floor and R-21 on the walls. R-value measures resistance to heat loss; the higher the R-value, the better the insulation. It is best practice to implement any air seal-up repairs during insulation repairs to seal air leakage. Also, be sure you have completed any wiring or other needed projects in the attic. Then, hire an insulation contractor to improve thermal barriers.

Attic Fan Exhaust Vents

The exhaust ductwork for the bathroom fans is uninsulated in the attic space. This can lead to seasonal condensation problems and is less energy efficient. Replace these exhaust vents with insulated exhaust ducts or insulate them to R-8 or better.

✒

- Please note that air leakage from these vents could contribute to seasonal condensation issues.

Attic and Roof Cavity Ventilation

Attic Ventilation Method: Soffit vents, Ridge vents

Attic and roof cavity ventilation is a frequently misunderstood element of residential construction. All roof cavities are required to have ventilation. The general default standard is 1 to 150 of the attic area and ideally, this comes from at least 60% lower roof cavity ventilation and 40% upper, but this is a wild over-simplifications of the subject. As a good guiding principle the most important elements for healthy attic spaces, which are traditionally insulated and ventilated are:

- Make sure the ceiling between the living space and the attic is airtight

- Ventilate consistently across the whole lower part of the roof cavity with low, intake soffit venting

- Upper roof cavity venting is less important and if over-installed can exacerbate air migration into the attic from the living space.

- Avoid power ventilators which can depressurize the attic and exacerbate air migration from the house into the attic.

For more information, please see: Link

Exterior Siding, Doors and Windows

Exterior Elevations

The home inspector shall observe: Wall cladding, flashings, and trim; Entryway doors and a representative number of windows; Garage door operators; Decks, balconies, stoops, steps, areaways, porches, and applicable railings; Eaves, soffits, and fascias; and Vegetation, grading, drainage, driveways, patios, walkways, and retaining walls concerning their effect on the condition of the building. The home inspector shall: Describe wall cladding materials; Operate all entryway doors and a representative number of windows; Operate garage doors manually or by using permanently installed controls for any garage door operator; Report whether or not any garage door operator will automatically reverse or stop when meeting reasonable resistance during closing; and Probe exterior wood components where deterioration is suspected. The home inspector is not required to observe: Storm windows, storm doors, screening, shutters, awnings, and similar seasonal accessories; Fences; Presence of safety glazing in doors and windows; Garage door operator remote control transmitters; Geological conditions; Soil conditions; Recreational facilities (including spas, saunas, steam baths, swimming pools, tennis courts, playground equipment, and another exercise, entertainment, or athletic facilities); Detached buildings or structures; or Presence or condition of buried fuel storage tanks. The home inspector is not required to: Move personal items, panels, furniture, equipment, plant life, soil, snow, ice, or debris that obstruct access or visibility.

Siding and Trim

Trim Material: Wood

Siding Material: Vinyl

Vinyl siding has always been designed as an exterior cladding, not a weather-resistant barrier. Vinyl siding is designed to allow the material underneath it to breathe; therefore, it is not a watertight covering. Vinyl siding is only a part of a weathertight covering; it should have other shedding materials (ie" house wrap" or building paper and flashings) and water diversion materials ("J" channels, "drip cap flashing" etc.). I can only inspect what I can see; I cannot tell you what is behind the vinyl and how it was installed. The most likely areas of concern is of course around all openings (windows, doors, thru-wall penetrations). You should watch these areas during and after rainstorms for any evidence of water entry.

Observed a section of the substrate missing under the vinyl siding in the attic at the inspection time. The missing section needs to be replaced by an NJ-registered home improvement contractor.

Observed no kick-out flashing installed where the roof and the wall meet. This flashing is a critical component in diverting water away from the structure. Recommend adding this flashing detail by an NJ-registered home improvement contractor to avoid moisture penetration into the wall. Hidden damage may be present that was not visible to the inspector during the inspection may be present.

Eaves

Vinyl

Exterior Doors

Exterior Door Styles: Fiberglass

Exterior Window Frames

Window Frames: Vinyl

Grounds

Drainage and Site

Clearance to Grade: Standard

Downspout Discharge: Above grade, Next to Foundation

Site Description: Flat

Downspouts are discharging adjacent to the foundation. This can cause foundation settlement or basement moisture problems. Ensure all downspouts discharge into a proper tight-line system that diverts water at least 5 feet from the foundation.

The home had neutral or negative drainage areas at grade, which will route runoff from precipitation to the foundation. Excessive moisture content in soil supporting the foundation can cause foundation and other structural damage from undermining, heaving, or settling, depending on soil composition, moisture content, and other conditions. The ground should slope away from the home ¼-inch per foot for a distance of at least six feet from the foundation. The Inspector recommends re-grading these areas to improve drainage near the foundation.

Driveways/Walkways/Flatwork

Driveway: Asphalt

Window and Stairwells

Present

Exterior Stairs

Exterior Stairs: Standard

Decks, Porches and Balconies

Concrete Decks, Stoops, Landings and Porches

Concrete Structure: Present

The concrete patio does not have a positive slope at the rear of the home, which could cause or contribute to water intrusion. The concrete should slope away from the home home. I recommend correcting the landscape to drain water away from the home.

Garage

Garage General

Garage Type: Attached

The pulldown ladder in the garage does not appear to be a fire-rated model. This can be tricky to repair without replacing the pulldown ladder with a fire-rated model - see LINK as an example. You can try sheetrocking the ladder cover, but this often compromises the proper operation of the ladder, causing the ladder to sag and leaving a gap in the firewall. You can also try making a fire-rated sheetrock separation between the garage and the house in the attic above the garage, but this, too can be complicated. Have an NJ-registered home improvement contractor further evaluate and repair.

Observed a section of block missing at the right side garage door during the inspection. A repair is needed by an NJ-registered home improvement contractor.

Video of the interior of the garage.

Garage Doors and Automatic Openers

Overhead Garage Door Type: Vinyl

Automatic Garage Opener: None noted

Garage Occupant Door: Fire Rated

You may want to install automatic garage door openers as none have been installed for the garage doors.

Garage Floor

Garage Slab: Concrete

Garage Stairs

Garage Stairs: None noted

Structure and Basement

Foundation

Building Configuration: Basement

Foundation Description: Masonry block

This house is built on a concrete block foundation, often referred to in the trades as Concrete Masonry Unit (CMU). These foundations are standard in many parts of the country, and, depending on how they are installed, they can perform similar to poured concrete foundations. Unfortunately, most CMU foundations are not reinforced, making them prone to seismic damage. Reinforcement is impossible to verify during the inspection. Once they are complete, these foundations are difficult to retrofit, and it should be assumed that this foundation is not up to modern seismic standards. These foundations are also tricky to waterproof as they are porous and not as resistant to water as a poured concrete foundation.

Floor, Wall and Ceiling Framing

Wall Framing: Not visible

Wall Sheathing: Not visible

Floor Framing: Wood joists

Sub-Floor Material: Not visible

Ceiling Framing: Not visible

Basement

Finished

The basement has been finished; we do not verify if the necessary permits were pulled to do this work. Recommend having the client check with the local township to verify if the proper permits were issued and the proper inspections were performed. If no permits have been obtained, the seller should obtain a CCO Certificate of Continued Occupancy from the local municipality. A CCO inspection is a reasonable solution for ensuring that construction work is properly documented. Future owners are not held responsible for violations resulting from work performed without permits. The documentation for a CCO inspection should include a report describing the work completed without a permit. Construction officials should be aware that CCO inspections are limited to those visible portions of the home. For items that are not visible, there must be probable cause to warrant uncovering the work to allow for inspections. The code official is not compelled to perform a destructive inspection unless there is reason to believe a life-safety violation exists.

Basement Moisture

None noted

There was no evidence of recent or previous water infiltration into the basement. Nonetheless, some dampness is inevitable in any basement. It is not reasonable, in our opinion, to expect or require a basement to be completely dry year-round. However, preventive measures can be taken to reduce basement dampness and the risk of significant water infiltration. These preventative measures include, but are not limited to, maintaining the roof drainage system, keeping all gutters and downspouts free of obstructions, extending downspout shoes such that they discharge at least 5 ft. away from the foundation, providing adequate soil grading and ground cover at the foundation and throughout the site, installing a perimeter drainage (water-proofing) system, and running a dehumidifier in the basement. In this case, the basement is equipped with a perimeter drainage system. This system collects infiltrating water and diverts it to a sump pit. This drainage system will not stop water from entering through the foundation walls. However, it should prevent water from pooling onto the basement floor and causing consequential damage.

Crawl Space

General Crawl Space

Crawl Space: Present

The photos provided here show representative images of this crawl space at the time of inspection.

Crawl Space Access

Method of Inspection: Crawled

During inspection of the crawl space, every effort is made to inspect the entire space. Visual inspection of crawl spaces is difficult and limited as access is often restricted by pipes, ducts and sub-floor insulation as well as limited clearances.

Crawl Space Ventilation

Ventilation Method: Inadequate Ventilation

Inadequate ventilation was noted for the crawl space. Standards recommend 1 square foot of ventilation for every 150 square feet of crawl space or 1/1500 in combination with an approved class 1 vapor retarder material that covers all exposed soils in the crawl space. Vents should be located to provide adequate cross-ventilation. Hire an NJ registered contractor to evaluate further and repair.

Posts and Footings

Standard

Insulation

Insulation Type: Not visible

Approximate R-Value: None noted

Moisture Conditions

No water was visible or present at the time of inspection

Electric Service

Electric Service Voltage Tested

Service Voltage: 120/240

Electric Service

Service Entrance: Above Ground

Meter Base Amperage: 150

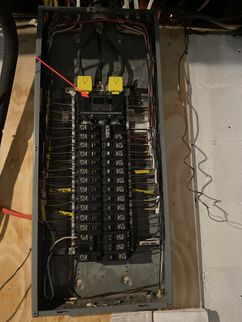

Electric Service Equipment

Service Entrance (SE) conductor Size: Aluminum, 2/0, 150 amps

Main Panel Amperage: 150 amps

Electric Service Amperage: 150 amps

Main Electric Panel Location: Basement

Panel Manufacturer: Square D

The main electrical panel is located in the basement.

Appliance Disconnects

Disconnects Noted: Air Conditioner

Electrical Grounding System

Present - Could Not Confirm

During a home or property inspection, every effort is made to inspect the visible components of the electrical system grounding. The grounding system is critical for safely discharging electrical surges, especially in the case of lightning strikes. There is no way in the context of a home inspection to verify the "effectiveness" of the grounding system as much of the system is not visible and there are not practical tests one can perform in the way we can test a furnace or a plumbing fixture. However, there are many things that can lead me to recommend further evaluation of the grounding system by a licensed electrical contractor and they will be documented in the observations below if discovered.

Electrical Bonding System

Present - Could Not Confirm

During the inspection, I attempt to visually document electrical system bonding. There is no way in the context of a home inspection to verify the "effectiveness" of system bonding. All metallic systems in the building are required to be "bonded" (connected) to the the building's electrical grounding system. Bonding creates a pathway to shunt static charges (that would otherwise build up on the system) to earth, and to provide a pathway to trip a breaker in the event that these bonded metallic components became energized. There are many things that can lead me to recommend further evaluation of this system by a licensed electrical contractor and they will be documented as repair items in the observations below if discovered.

Electric Distribution and Finish Wiring

Branch Wiring

Wire Material: Copper

The open electrical junction box in the basement needs to be covered for improved safety. This is as simple as installing a cover plate over the box to protect the wiring. An extension ring is sometimes needed if finishes cover the box—repair as needed for improved safety.

Receptacles and Fixtures

Inspection Method: Representative Testing

A representative number of receptacles and switches were tested during inspection. Any defects found during inspection are noted in this report. Only visible and accessible receptacles and switches were tested during inspection and personal items and furnishings are not moved to access any receptacles or fixtures.

Electric Receptacles: Three wire receptacles

The missing cover plates to electric receptacles, switches, and junction boxes should be installed to cover all access to the wiring at switches and receptacles. Where switches, receptacles, or junction boxes are positioned below wall or ceiling or cabinet finishes, an extension ring may be needed.

GFCI (Ground Fault Circuit Interruption) protection is inconsistent with modern minimum standards for safety. GFCI protection is recommended for the electrical receptacles in the following locations: the two dedicated kitchen appliance circuits, all receptacles within 6 feet of a sink, bathrooms, exterior, garage, unfinished basements, laundry, and all wet locations. GFCIs protect against electrocution by limiting the duration of an electrical shock. These are essential modern safety feature that has proven to save lives. Hire an NJ-licensed electrician to evaluate further and update GFCI protection for improved safety. Examples of observations noted during the inspection include:

Ceiling Fans

Ceiling Fans: None Noted

Smoke and Carbon Monoxide Alarm Systems

CO Alarms: Present

The installation of carbon monoxide alarms is recommended for all homes that have fuel burning appliances such as gas or oil furnaces, gas water heaters, gas ovens and cook-tops, gas fireplaces and wood stoves. In addition, Washington State law (WAC 51-51-0315) now requires UL 2034 approved carbon monoxide alarms in ALL homes and condominiums being sold in Washington State. The location should be: at least one alarm outside of all sleeping areas and one on each floor of the house. Best practices are to have these alarms hardwired with a battery back-up - though requirements are for the installation to meet manufacturer's specifications. Carbon monoxide is a colorless, odorless gas that can cause sickness, nausea and even death. Alarms have a useful service life of roughly 6 years, so changing them more frequently than smoke alarms is recommended.

Smoke Alarms: Present

During the home inspection, I try and test a representative sample of the smoke alarms by using the test button on the alarms. This is NOT an accurate test of the sensor just a test to see if the unit is powered. For reliability, fire marshals recommended updating smoke alarms every 10 years and changing batteries bi-annually. The latest data indicate that we should be using photoelectric technology in our smoke alarms for improved fire detection and to reduce problems with false alarms which can lead to disabling of this important safety system. Unfortunately, the alarms have to be removed to determine if they are photo-electric or ionization types. It is surprisingly complex to accurately test a smoke alarm system and determine the reliability, age, and type of sensor technology used, especially as many homes can have half a dozen or more alarms throughout the house. A complete evaluation of smoke alarms is beyond the scope of this inspection. For optimal fire safety, I recommend taking control of these important safety devices and learning about how to service and maintain your smoke alarm system to keep the building occupants safe. For more information, please read this link. For more information, please read this link.

Heating, Cooling, Fireplaces and Ventilation

Heating System

Energy Source: Natural gas

Heating Method: Gas forced air furnace

This house has a gas forced air furnace. A critical component to all combustion heating equipment is the heat exchanger. This is the welded metal assembly inside the furnace that contains the products of combustion so that moisture, carbon monoxide and other products of combustion do not mix with interior air and get safely vented to the exterior. Heat exchangers on modern furnaces have an average life expectancy of 15-20 years. Unfortunately, heat exchangers are concealed inside the heating equipment; they are not visible and specifically excluded from a home inspection. Cracks in heat exchangers may be concealed and can pose a potential safety hazard.

Manufacturer: York

Age: New

Last Service Record: None

Air Filters

Filtration Systems: Disposable

The heating and cooling system has disposable air filters installed. These should be changed quarterly or more to ensure proper air flow at the furnace. Be sure to install the filters with the arrows pointing in the same direction as the air flow in the furnace.

Cooling Systems and Heat Pumps

Air Conditioning Present

The following list is a minimum set of requirements to be expected of a heat pump or air conditioning servicing. I provide these as a courtesy to show the types of check-ups that should be expected from a professional servicing.

- Check compressor efficiency

- Check refrigerant level

- Clean the condenser coil

- Change or clean air filters

- Inspect contactors and wiring

- Inspect drive-sheaves, pulleys, and belts

- Check and adjust for proper airflow

- Clean the blower motor as needed

- Lubricate all motors and shaft bearings

- Check, calibrate and program the thermostats and be sure the thermostat has adequate batteries as needed

- Check unit smoke detector, clean filter if applicable

- Check safety disconnect, laser-temp -- check across contacts

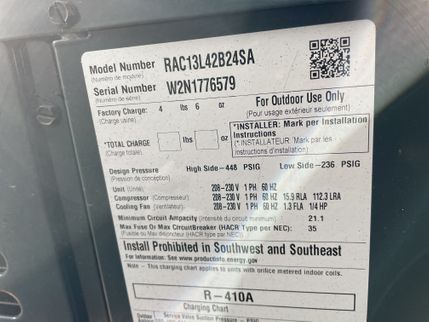

Manufacturer: Evon

Data Plate: Shown here

This shows the data plate from the exterior compressor. 📸

System Type: Air Source

Energy Source: Electric

Age: New

Heating and Cooling Distribution Systems

Heat Source in Each Room: Present

Distribution Method: Forced Air / Ducts

Mechanical Ventilation Systems

Bath Fan Ducting: Ducted to exterior, Uninsulated in Attic

Kitchen Fan Ducting: Ducted to exterior

Solid Fuel Fireplaces

Fireplace Types: Electric "faux fireplace"

The is an electric fireplace at the lower level of the home.

Fuel Storage and Distribution

Oil Storage

None noted

We do not search for underground oil tanks. This is outside the scope of a home inspection. If the client is concerned one may exist on this property, we recommend you have a tank sweep performed by a qualified person before closing. (Homes in this area normally were fuled by oil when they were built.)

Gas Meter

Present

Gas Shutoff Location: Side of structure

Gas Pipe Materials: Steel

Gas, Propane and Oil Piping

Gas Piping Materials Noted: Steel, CSST

CSST tubing was observed in this home. If this pipe is not properly bonded it can be damaged by lighting. In many CSST installations, the CSST tubing is not bonded to the electrical system, which violates the manufacturer's current installation instructions and requires that the gas system be directly bonded to the electrical systems with 6 AWG copper wire, near the service entrance to the building. Recommend having a licensed electrical bonded it for safety. The manufacturers of this pipe are gastite. Below are the instructions directly from the manufacturer's instructional manual.

For the manufacture instructional manual:

Direct bonding of Gastite® CSST is required for all gas-piping systems incorporating Gastite® CSST whether or not the connected gas equipment is electrically powered. This requirement is part of the manufacturer’s instruction for single-family and multi-family buildings. A person knowledgeable in electrical system design, the local electrical code, and these requirements should specify the bonding for commercial applications. Gastite® CSST installed inside or attached to a building or structure shall be electrically continuous and direct bonded to the electrical ground system of the premise in which it is installed. The gas piping system shall be considered to be directly bonded when installed in accordance with the following:

The piping is permanently and directly connected to the electrical service equipment enclosure, the grounded conductor at the electrical service, the grounding electrode conductor (were of sufficient size), or to one or more of the grounding electrodes used. For single and multi-family structures, a single bond connection shall be made downstream of the individual gas meter for each housing unit and upstream of any CSST connection. The bonding conductor shall be no smaller than a 6 AWG copper wire or equivalent. The bonding wire shall be attached in an approved manner in accordance with NEC Article 250.70 and the point of attachment for the bonding wire shall be accessible. Bonding/grounding clamps shall be installed in accordance with its listing per UL 467 and shall make metal-to-metal contact with the piping.

Also attached is a Youtube video explaining how to bond it:

Plumbing

Water Service Supply

Pipe Material: Plastic

Water Supply: Private well

Pressure Reducing Valve: None noted

Water for this home appears to be supplied by a good system. Inspection of the well, water supply, and water quality is beyond the scope of this inspection. I recommend hiring a well specialist to inspect and evaluate the well and well water. Well, equipment: the pump and captive storage tank have limited service lives and often require updating on a 20-year schedule. There are other elements of a good system that should be evaluated as well, such as the good production, often tested in a drawdown test, water quality, and well depth.

Distribution Pipe

Pipe Insulation: Not visible

Supply Pipe Materials: PEX

This building has PEX tubing used for supply piping. Crimp ring connections on PEX pipe have very specific installation guidelines and most of these connections will not be visible at the time of inspection (just like any other type of pipe fitting). It is beyond the scope of this inspection to evaluate a significant number of these connections.. Any leaking noted at fittings should result in more careful inspection of all of the plumbing system by a licensed plumber that is experienced in the installation of these types of connections

Functional Flow: Average

Waste Pipe and Discharge

Discharge Type: Septic System - Buyer

Waste and Vent Pipe Materials: Copper, PVC

Based on visible components, this property appears to have a private on-site septic system. These are specialty systems and are excluded from this inspection. Comments in this report related to this system are made as a courtesy only and are not meant to be a substitute for a full evaluation by a qualified specialist. Generally, septic tanks should be pumped and inspected every 3 years. Depending on the type of system and municipal regulations, inspection and maintenance may be required more frequently, often annually. I recommend:

- Investigating any information about this system's maintenance and repair history

- Reviewing any documentation available for this system

- Learning inspection and maintenance requirements for this system

- Hire a qualified specialist to evaluate, perform maintenance and make repairs as needed

Water Heater

System Type: Tank-less

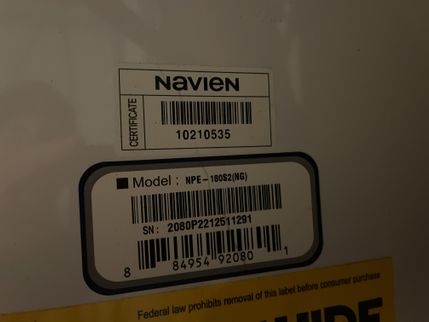

Data Plate: Shown Here

This shows the data plate for this water heater.

Size: Tankless

Age: New

Energy Source: Gas

Drain Pan: Not Needed

Relief Valve: PRV Missing for Tankless

The water heater was leaking at the time of the inspection; the inspector observed water leaking from the bottom and standing water on the floor. Due to the water leaking, water is seeping under the basement floor. This can be seen with the infrared photo. The water must be cleaned up under the flooring to prevent further deterioration.

The tankless water heater appears to be missing a pressure relief valve. None was noted during inspection. Pressure relief valves are important and required safety devices for tankless water heaters. have this further evaluated and repaired as recommended by a licensed plumbing contractor.

Water Temperature

Water Temperature Measured During Inspection: 105 Degrees F

The water heater temperature seemed to be set too low at the time of inspection - just 110 degrees F. The range of 120-125 degrees F is the generally recommended temperature. This is nearly impossible to measure precisely during a home inspection as water temperature can vary between fixtures. Adjust water heater temperature as needed. For best practice, set water temperature at the water heater to 130 degrees F and use a tempering valve to set water temp back to a safe 120 for domestic use. This high tank temperature will reduce risks of Legionella developing in the tank and the tempering valve will ensure a safe water temperature.

Exterior Hose Bibs

Winterized - not tested

The exterior hose bibs were winterized at the time of inspection and could not be tested. Inquire with the seller to see if they are generally operable.

Additional Plumbing

Sump Pumps and Drains

Floor Drain: None noted

Sump Pumps: None noted

Sewage Ejector Pumps

Location: Basement

An ejector pump serves the basement bathroom. An NJ licensed plumber should be hired to ensure proper venting of this fixture. Since the basement is finished, it could not be determined if these fixtures are adequately vented. It is recommended that it be ensured that the proper permits were opened and closed for these installations before purchase.

Interior

General Interior Photos

Our review of these areas is limited to visible and accessible rooms. Applying a few suggestions to interior and exterior stairs can help to reduce the risk of an accidental fall and injury. Graspable handrails mounted between 34 and 38 inches high are suggested for the entire length of all stairs. Occupants may not be able to regain their balance with rails that are too big to grip or that are too close to the wall. Guardrails at least 36 inches high are advised for any open sides of stairways, raised floor areas, balconies, and porches. Current child safety standards call for all openings in rail systems (such as at vertical balusters) to be small enough that a four-inch sphere cannot pass through. When you take occupancy, we suggest that you make sure that all rails are secure, upgrade as needed, and check for slip and fall hazards such as loose or damaged floor coverings. Personal belongings and furniture restrict access to receptacles, windows, walls, and flooring. This may be an excellent time to ensure you have functional smoke and carbon monoxide detectors in place.

An investor has flipped this home, it is recommended that the client obtain all close permits for the work that has been performed on this property before closing. Suppose the investor did not get the necessary permits to perform this work on this property. In that case, it is recommended that the permits be issued and the local municipality performs the proper inspections before settlement.

Floors and Floor Materials

Floor Materials: Carpet, Hardwood, Tile

Observed a gap between the finished ceiling and the light fixture in the basement. Repairs are needed.

Walls, Ceilings, Trim, Hallways and Closets

Wall and Ceiling Materials: Drywall

During this inspection, a thermal imaging camera was used to check walls, ceilings and appliances for thermal anomalies. Thermal imaging cameras use the infrared light spectrum to build a picture based on temperature differentials. Experienced thermogrophers look for clues in these thermal images that could lead us to otherwise-concealed moisture control problems or missing air or thermal barriers. We can also use them for appliance verification. We do not use infrared for electrical inspections. In older homes, incomplete air and thermal barriers are so common, we will only report on items that look significantly deficient and which seem worthy of correction.

This service is included with our home inspection; it is limited and is not a complete thermal mapping of the house. The use of an infrared camera is well beyond the minimum standards for a home inspection. We offer this service because we know it is valuable and can help us help our clients by improving our inspection services.

Please note that this tool has limitations when done in conjunction with a home inspection. Environmental conditions present limitations to the information that can be gathered during the course of a home inspection. For example, occupant behavior, the time of day, time of year and weather conditions can all impact the usefulness of the data that can be gathered.

Relevant thermal images will be included in this report.

Stairs and Railings

Standard

Interior Doors

Interior Doors: Hollow Core

Windows

Window Glazing: Double pane

Interior Window Frame: Vinyl

Only representative samples of windows in the rooms were opened due to furniture, and personal items placed along the walls. If any issues with windows are discovered and reported on, I recommend a careful walk-through inspection prior to closing and after the house is vacated, with close attention to all the windows. This would encompass the operation of the windows, checking locks and glass, proper fit, and operability.

Window Styles: Casement, Sliding, Double hung

Indoor Air Quality

We do not test indoor air quality during the home inspection. This is beyond the scope of a general home inspection. This report may contain the notation of visible moisture intrusion/fungal growth or conducive conditions to moisture intrusion/fungal growth. Those who wish further testing and evaluations are urged to contact indoor air quality experts prior to closing.

Kitchen

Sinks and Faucets

Tested

Video of the sink operating.

Cabinets and Countertops

Countertop Material: Granite

This is a great document From the Natural Stone Institute that covers maintenance and installation recommendations for slab surface stone countertops.

Cabinet Material: Wood

Disposers

Disposer: None noted

Dishwasher

Dishwasher: Not Operated (Water Shut Off)

There was no outlet installed for the microwave at the time of the inspection. Have an NJ licensed install an outlet before settlement.

The dishwasher did not complete a normal cycle during the inspection. It had power but it appears there was no water for it at the time of the inspection. Further evaluation is needed.

Ventilation Method

Fan Ducted to Exterior

Ranges, Ovens and Cooktops

Range/ Oven /Cook-tops: Gas and electric

General Kitchen Condition

Standard

Appliances are tested by turning them on for a short period. Appliance thermostats, timers, clocks, and other specialized cooking functions and features are not tested during this inspection. It is further recommended that appliances be operated once again during the final walk-through inspection prior to closing.

Built-in microwave ovens are tested using normal operating controls. The unit was tested and appeared to be serviceable at the time of inspection. Leak and/or efficiency testing is beyond the scope of this inspection. If concerned, the client should seek further review by a qualified technician prior to closing.

Master Bathroom

Sinks and Cabinets

Tested

Toilet

Tested

Bathtub / Shower

Tested

Bathroom Ventilation

Type: Bath fan

Consider installing a 1-hour timer for bath fans so they run after use. This will help to keep this space dry because the fan can run for a while after use without leaving the fan on all day.

General Bath Condition

Standard

During inspection today, I operated all plumbing fixtures in the bathrooms. I ran a moisture meter around toilets and tile shower enclosures to check for concealed leaks and sounded for loose tile and finishes in shower and tub enclosures. I do not test bathtub overflow drains, which risks damaging finishes around the tub. Monitor tubs while filling and avoid pushing water into the flood. Even well-installed overflow drains can leak as the gaskets that seal the overflow will dry over time and may no longer provide a watertight seal. Monitor plumbing after moving into a new home as testing during inspection presents less stress on plumbing than daily use. Please note that vacant homes offer additional risk as it can be difficult to distinguish how the plumbing system will respond to everyday use. Any defects uncovered during an inspection are listed in this report.

2nd floor Bathroom (2)

Sinks and Cabinets

Tested

Toilet

Tested

Bathtub / Shower

Tested

The stopper in the 2nd-floor bathtub is missing and requires repair or replacement - or a rubber stopper can be used.

Bathroom Ventilation

Type: Bath fan

Consider installing a 1-hour timer for bath fans so they run after use. This will help to keep this space dry because the fan can run for a while after use without leaving the fan on all day.

General Bath Condition

Standard

During inspection today, I operated all plumbing fixtures in the bathrooms. I ran a moisture meter around toilets and tile shower enclosures to check for concealed leaks and sounded for loose tile and finishes in shower and tub enclosures. I do not test bathtub overflow drains, which risks damaging finishes around the tub. Monitor tubs while filling and avoid pushing water into the flood. Even well-installed overflow drains can leak as the gaskets that seal the overflow will dry over time and may no longer provide a watertight seal. Monitor plumbing after moving into a new home as testing during inspection presents less stress on plumbing than daily use. Please note that vacant homes offer additional risk as it can be difficult to distinguish how the plumbing system will respond to everyday use. Any defects uncovered during an inspection are listed in this report.

Basement Bathroom

Sinks and Cabinets

Tested

Toilet

Tested

Bathtub / Shower

Tested

Bathroom Ventilation

Type: Operable window

General Bath Condition

Standard