The Scope and Purpose of a Home Inspection

Purchasing property involves risk

The purpose of a home inspection is to help reduce the risk associated with the purchase of a house by providing a professional opinion about its condition. A home inspection is a limited visual inspection and it cannot eliminate this risk. Some homes present more risks than others. We cannot control this, but we try to help educate you about what we don’t know during the inspection process. This is more difficult to convey in a report and one of many reasons why we recommend that you attend at least part of the inspection.

A home inspection is not an insurance policy

This report does not substitute for or serve as a warranty or guarantee of any kind. Home warranties can be purchased separately from insuring firms that provide this service.

A home inspection is visual and not destructive

The descriptions and observations in this report are based on a visual inspection of the structure. We inspect the aspects of the structure that can be viewed without dismantling, damaging or disfiguring the structure and without moving furniture and interior furnishings. Areas that are concealed, hidden or inaccessible to view are not covered by this inspection. Some systems cannot be tested during this inspection as testing risks damaging the building. For example, overflow drains on bathtubs are generally not tested because if they were found to be leaking they could damage the finishes below. Our procedures involve non-invasive investigation and non-destructive testing which will limit the scope of the inspection. Where moisture meter testing is indicated in this report a Protimeter Surveymaster was used.

This is not an inspection for code compliance

This inspection and report are not intended for city / local code compliance. During the construction process structures are inspected for code compliance by municipal inspectors. Framing is open at this time and conditions can be fully viewed. Framing is not open during inspections of finished homes, and this limits the inspection. All houses fall out of code compliance shortly after they are built, as the codes continually change. National codes are augmented at least every three years for all of the varying disciplines. Municipalities can choose to adopt and phase in sections of the codes on their own timetables. There are generally no requirements to bring older homes into compliance unless substantial renovation is being done.

This is just our opinion

Construction techniques and standards vary. There is no one way to build a house or install a system in a house. The observations in this report are the opinions of the home inspector. Other inspectors and contractors are likely to have some differing opinions. You are welcome to seek opinions from other professionals.

The scope of this inspection

This inspection will include the following systems: exterior, roof, structure, drainage, foundation, attic, interior, plumbing, electrical and heating. The evaluation will be based on limited observations that are primarily visual and non-invasive. This inspection and report are not intended to be technically exhaustive. We follow the InterNACHI Standards of Practice.

Your expectations

The overall goal of a home inspection is to help ensure that your expectations are appropriate with the house you are proposing to buy or sell. To this end we assist with discovery by showing and documenting observations during the home inspection. This should not be mistaken for a technically exhaustive inspection designed to uncover every defect with a building. Such inspections are available but they are generally cost-prohibitive to most homebuyers.

Your participation is requested

Your presence is requested during this inspection. A written report will not substitute for all the possible information that can be conveyed verbally by a shared visual observation of the conditions of the property.

How to Read This Report

Getting the Information to You

This report is designed to deliver important and technical information in a way that is easy for anyone to access and understand. If you are in a hurry, you can take a quick look at our "Summary Page” and quickly get critical information for important decision making. However, we strongly recommend that you take the time to read the full Report, which includes digital photographs, captions, diagrams, descriptions, videos and hot links to additional information.

The best way to get the layers of information that are presented in this report is to read your report online, which will allow you to expand your learning about the inspected property. You will notice some words or series of words highlighted in blue and underlined – clicking on these will provide you with a link to additional information.

This report can also be printed on paper or to a PDF document.

Chapters and Sections

This report is divided into chapters that parcel the home into logical inspection components. Each chapter is broken into sections that relate to a specific system or component of the home. You can navigate between chapters with the click of a button on the left side margin.

Most sections will contain some descriptive information done in black font. Observation narrative, done in colored boxes, will be included if a system or component is found to be significantly deficient in some way or if we wish to provide helpful additional information about the system or the scope of our inspection. If a system or component of the home was deemed to be in satisfactory or serviceable condition, there may be no narrative observation comments in that section and it may simply say “tested,” or “inspected.”

Observation Labels

All narrative observations are colored, numbered and labeled to help you find, refer to, and understand the severity of the observation. Observation colors and labels used in this report are:

- Procedure:Description of the procedure I follow while inspecting various components of a house.

- Note:Refers to aside information and/or any comments elaborating on descriptions of systems in the home or limitations to the home inspection. These also include contextual photos of the house and pictures of various components of the house while operating.

- Tier 1 - Major Concern:These represent priority items like major safety issues, active issues causing damage to the house, or items of significant expense that are looming in the near future.

- Tier 2 - Repair:These are lower priority deficiencies that may not need immediate attention, but should be addressed in the near/medium term future. These are usually deferred maintenance items, occupant safety concerns, or sub-par construction/installation problems.

- Tier 3 - Improve:These are things that are working but could be better. These are minor nuisance type concerns, or things related to safety, efficiency, or reliability issues. Often these are improvements that may not have been necessary--or even have existed--when the property being inspected was constructed (e.g. changes in building standards over time.)

- Future Project:A repair that may be deferred for some time but should be on the radar for repair or replacement in the future.

- Due Diligence:Observations that may require further investigation and/or clarification that could not be provided during the home inspection.

- Monitor:Items that should be watched to see if correction may be needed in the future.

- Recommended Maintenance:These are items that should be considered "routine home ownership," such as servicing the furnace, cleaning the gutters or changing the air filters in the furnace. Generally a house costs ~1% of the purchase price per year to maintain.

- Homeowner Info:These are pieces of "good to know" information about the house. For example, the location of the main water shut-off valve, gas shut-off valve(s), etc.

Summary Page

The Summary Page is designed as a quick-to-read bulleted overview of all the observations noted during inspection. This overview is not a substitution for reading the entire inspection report. The entire report must be read to get a complete understanding of this inspection report as the Summary Page does not include photographs or photo captions, and most of the comments in the report will have photos of what is being discussed. Click on the link next to each comment to jump to the section in the report with the photos and the captions which may provide additional detail on the specific comment.

Summary

Tier 1 - Major Concerns

- EDPB-5 Exteriors, Decks, Porches, and Balconies:

The siding was in poor condition, see others comments in this report for specific examples. Given the overall condition, I recommend evaluation and likely replacement of the siding by a qualified contractor.

Note: Due to the number of places where water was able to penetrate the siding, I suspect that rot/mold issues will likely be discovered while repairing the siding. Recommend budgeting for repairs of more than just the siding.

- EDPB-14 Exteriors, Decks, Porches, and Balconies:

The back deck was in poor condition overall. Due to issues with the structure, stairs, railing, and decking boards (specifics outlined in this report) I would recommend a full deck rebuild by a qualified contractor.

- B-2 Bathrooms:

Toilet was loosely mounted to the floor. This can allow the toilet to rock and slide when used, which damages the wax ring seal and can allow water to seep into the floor cavity. No leaks were detected, but the water was off so I could not accurately test the drain. The floor was slightly squishy around the toilet though, which is often a sign of water/rot damage. Recommend repair by a qualified plumber.

- SCSB-2 Structure and Crawl Space / Basement:

There were indications that the east / SE side of the house was settling, see photos. The floor was sloping that way on both the first and second levels (most notable in the dining room toward the SE corner.) Old plaster walls crack regularly, but the cracking on this side of the house was more than normal. There were a few cracks in the plaster that were v-shaped (wider at the top than the bottom) which is a sign of structural movement. There was erosion under the foundation on the south side, and a v-shaped crack in the foundation wall on the south side. All of this evidence made me concerned about the structure. Recommend further evaluation and possible repair by a qualified structural engineer.

- SCSB-3 Structure and Crawl Space / Basement:

A horizonal foundation crack was observed in the NW corner of the basement, see photo. Horizontal cracks like this are usually caused by hydrostatic pressure and can pose a serious threat to the structure. Recommend further evaluation and possible repair by a qualified structural engineer.

- P-3 Plumbing:

The water was shut off to the house. Washington State Law prohibits inspectors from opening closed shut-off valves, so I could not test any of the plumbing fixtures in the house. Looking for plumbing leaks is a significant part of a home inspection. Recommend a thorough inspection of all plumbing fixtures and accessible pipes to look for leaks prior to closing.

- P-6 Plumbing:

Galvanized steel plumbing was observed in the house. The life expectancy of galvanized steel is 60 years, so it is due for replacement. Over time, galvanized steel will rust from the inside, which will:

- Make the pipes brittle, increasing the chance of leaks

- Reduce "functional flow", which is when the water flow drops significantly when multiple devices are drawing water.

Recommend replacement of galvanized plumbing by a qualified plumber. This is often an expensive repair, though the cost can be significantly reduced if done during remodeling projects..

- P-9 Plumbing:

Seismic straps, which prevent the tank from falling in an earthquake, were not compliant with current building standards. Current building standards require two 1 1/2" steel straps, 16 gauge, installed 1/3rd down from the top and 1/3rd up from the bottom. This tank did not have any proper straps. Recommend installation by a qualified contractor.

Note: This is a component that many real estate appraisers look for specifically, so it can sometimes have an oversized impact during the financing/appraisal process of a transaction. I mark this as a Tier 1 level issue because of this.

- SS-1 Sewer Scope:

The sewer scope was inconclusive due to the amount of debris/sludge in the pipe. Without running water, I could not keep my camera lens clean; I could not even see enough of the pipe to determine the materials it was made of. Recommend cleaning of the line (hydro-jetting is preferred) then an additional scope of the sewer line by a qualified plumber.

Note: Having this much solid waste in the line is an indicator that there is a significant blockage in the waste line. It appeared that liquids were making it down the pipe, but solids were not. Depending on what a successful scope finds, this could be an expensive repair.

- E-6 Electrical:

This home appeared to employ some knob and tube wiring. This is an old soldered style of wiring that would not meet today's standards. Some insurance companies will not insure homes with this type of wiring. Many homes of this age in this area still employ at least a few knob and tube circuits, so finding some active knob and tube is not a surprise.

I recommend consulting with a licensed electrician about ways to improve this system and take pressure off existing knob and tube. Installation of additional circuits and of arc fault protected breakers can help make the system safer and more reliable. Complete removal and replacement of all knob and tube is recommended but considerably more expensive and not always necessary.

- E-13 Electrical:

The cover was not properly installed when I arrived. I tried to put it back on in a safer way, but there was only a single screw, and the cover just did not fit the box well, so it still had gaps. Access to the inside of the panel is a significant shock/electrocution concern. Recommend repair by a qualified electrician.

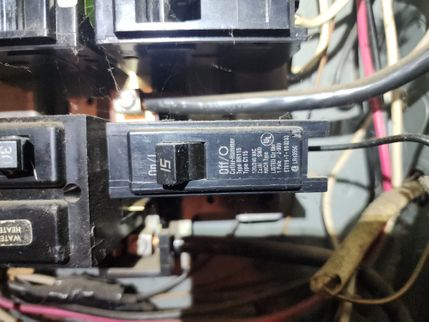

- E-18 Electrical:

One of the breakers had an undersized wire, see photos. It was a 30 amp breaker with a 12 gauge wire; 12 gauge wires are for 20 amp circuits max. This created a situation where the wire will melt before the breaker will trip, which is a significant fire hazard concern. Recommend repair by a qualified electrician.

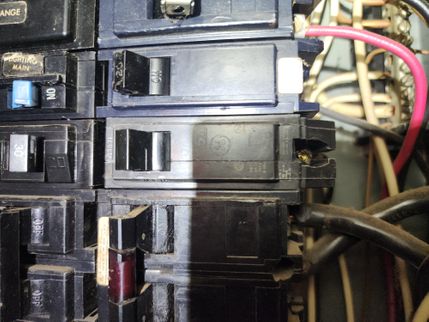

- E-20 Electrical:

The panel had missing breaker(s) where protective cover(s) were not installed. This allows access to the inside of the panel without removing the front cover and is an electrocution hazard. Recommend installing breaker covers as a DIY repair. They are plastic pieces with clips on them, and are sold at any Home Depot type store.

- E-34 Electrical:

There were no visible smoke detectors in the house. Recommend installing smoke detectors in hallways and bedrooms as significant safety feature for occupants. Each level should have at least one smoke detector. DIY project.

- E-35 Electrical:

There were no visible carbon monoxide detectors in the house. Modern building standards require a carbon monoxide detector in a common area on every floor of any residential dwelling. Recommend installation by homeowner as a DIY project.

- HCFV-3 Heating, Cooling, Fireplaces, and Ventilation:

None of the heaters I tested were working. They weren't labeled, but breakers that could be for heat were off in the electrical panel. Washington State Law prohibits inspectors from turning on breakers, so I could not test the heaters. Recommend verifying that they are working prior to closing.

- DG-1 Detached Garage:

The detached garage had several significant issues. The main issue were significant damage to the siding and likely structural rot of the framing, and damaged and rotten roof rafters. See further comments in this report for more details. Recommend evaluation of the detached garage by a qualified contractor. I suspect a full rebuild would be the most cost effective often.

Tier 2 - Repairs

- G-5 Grounds:

Siding to soil contact or proximity was observed in places. This is a conducive condition for rot, mold, and pests as it holds moisture against the siding. Modern building standards recommend 6 to 8 inches of exposed concrete foundation between the siding and the soil below. This is not always realistic in older houses, but one trick is to back-fill any excavated soil with gravel, which creates a drainage path. Creating this drainage gap is a DIY repair, however if damage (rot) is found during the project, I recommend repair by a qualified contractor.

- G-6 Grounds:

Downspout(s) was discharging adjacent to the foundation. This can cause moisture problems in the structure, or even foundation settling. Recommend rerouting all downspouts to discharge 5+ feet away from the foundation wall. This is usually a DIY repair, though the topography of the lot can sometimes complicate things enough to require a qualified contractor.

- G-7 Grounds:

There were no railings installed at stairway(s.) According to modern building standards, any stairs with four or more risers should have a railing. Recommend installation by a qualified contractor.

- G-12 Grounds:

Vegetation was touching--or was in close proximity--to the siding, see photo(s.) This can trap moisture against the siding which is a conducive condition for rot, or allow a pathway onto the roof/into the attic for rodents. Recommend pruning all vegetation back to give at least 12 inches of clearance to the siding. DIY repair.

- G-13 Grounds:

Some branches were touching the roof. When these branches move during wind, they can damage the roofing material. Also these branches provide a path onto the roof and into the attic space for rodents. Recommend evaluation and trimming of branches by a qualified contractor.

- G-14 Grounds:

A tree was growing close to the foundation wall, see photo(s.) Roots can affect the foundation and potentially result in structural concerns. Recommend removal of the tree by a qualified arborist.

- G-15 Grounds:

There were no railings installed at stairway(s.) According to modern building standards, any stairs with four or more risers should have a railing. Recommend installation by a qualified contractor.

- EDPB-2 Exteriors, Decks, Porches, and Balconies:

Some areas of siding and trim needed repainting, see example photo(s.) Worn paint is a conducive condition for rot and pests as it allows water to penetrate into, or behind, the siding. Recommend repair by a qualified contractor.

- EDPB-3 Exteriors, Decks, Porches, and Balconies:

Rot was observed on the exterior of the house, see photo(s.) Recommend repair by a qualified contractor.

- EDPB-4 Exteriors, Decks, Porches, and Balconies:

Some areas of siding needed resealing, see photo(s.) Worn gaps in sealants are a conducive condition for rot and pests as they allow water to penetrate into, or behind, the siding. This is normally a DIY repair using exterior grade caulk, though larger gaps may need repair by a qualified contractor.

- EDPB-6 Exteriors, Decks, Porches, and Balconies:

The siding was damaged in places, see example photos. This can allow water to penetrate the exterior envelope of the house, which is a rot, mold, and pest concern. Recommend repair by a qualified contractor.

- EDPB-9 Exteriors, Decks, Porches, and Balconies:

The basement windows were all broken/boarded up. This is ok, but some glass shards were left behind, see example photo. This is a cut hazard. Recommend removal as a DIY repair.

- EDPB-15 Exteriors, Decks, Porches, and Balconies:

The deck was leaning, which is likely a sign that the structure was not stable. Recommend repair by a qualified contractor.

- EDPB-16 Exteriors, Decks, Porches, and Balconies:

Some of the deck posts were non-treated wood, which is more vulnerable to wood decay. Modern building standards recommend pressure treated wood for structural components in decks. Recommend repair by a qualified contractor.

- EDPB-17 Exteriors, Decks, Porches, and Balconies:

Rot was observed in structural elements of the deck. This could cause the deck to collapse. The rot did not appear to be severe, and the deck still appeared to be structurally sound, however this can be hard to judge as rot can be worse than it appears on the surface. Decks can fail without warning by rotting through, so any observed structural rot is a significant concern. Recommend repair by a qualified contractor.

- EDPB-18 Exteriors, Decks, Porches, and Balconies:

The decking was getting old and beginning to rot. I would expect to continue to make spot repairs until the decking is systematically updated. Temporary repairs can be made by replacing the worst boards, re-setting loose nails, and cleaning and re-staining the wood but this deck will need attention in the near to medium term.

- EDPB-20 Exteriors, Decks, Porches, and Balconies:

The guardrail/railing was loose/deflecting and may not be adequately stiff to stop a falling adult. Recommend repair by a qualified contractor.

- RCG-2 Roof, Chimney, and Gutters:

There was moss on the roof. Moss growth is common in our climate, and most often grows in shady areas (mostly on north facing roof surfaces or under vegetation.) This can lead to the premature failure of the roof and subsequent leaks. Recommend regularly treating moss during its growing season (wet months) with a moss killer. This is generally a DIY repair, though the height and pitch of the roof may require a qualified contractor.

- RCG-3 Roof, Chimney, and Gutters:

Tree debris was observed on the roof. This can damage the roof surface and increase the chance of leaks. Recommend removing to prevent damage to roofing. DIY repair.

- RCG-4 Roof, Chimney, and Gutters:

The mortar in between the bricks was deteriorating in places, see example photo(s.) This can allow water to penetrate the siding, and can even get loose enough to allow bricks to fall out. Recommend repair (called repointing) by a qualified mason.

- RCG-5 Roof, Chimney, and Gutters:

The chimney flues were missing rain caps. This will prevent water and pests (birds) from getting into the flue and causing damage to the chimney. Recommend installation of a rain cap(s) by a qualified contractor.

- RCG-7 Roof, Chimney, and Gutters:

Several gutters were damaged or had gaps in them, see photos. Controlling water runoff is one of the most important ways to prevent basement moisture issues and even structural problems. Recommend repair by a qualified contractor.

- RCG-8 Roof, Chimney, and Gutters:

Gutters needed to be cleaned, see example photo(s.) Significant amounts of debris were observed. DIY project.

- CSB-1 Common Spaces and Bedrooms:

The door bell did not operate at time of inspection. Recommend repair by a qualified contractor.

- CSB-2 Common Spaces and Bedrooms:

The carpet was torn/loose in several places. This created trip hazards. Recommend having a qualified contractor replace the carpet.

- CSB-5 Common Spaces and Bedrooms:

One area of the floor in the living room was squishy, see photo/video. Recommend repair by a qualified contractor.

- CSB-10 Common Spaces and Bedrooms:

Suspected organic growth was observed in several areas of the living space in the house, see photos. This can affect the air quality in the house. Recommend repair by a qualified mold remediation contractor.

- CSB-14 Common Spaces and Bedrooms:

Railing was loose. Recommend DIY repair by tightening bracket.

- CSB-15 Common Spaces and Bedrooms:

Door did not have tempered glass. Glass in a door has a higher likelihood of breaking, so tempered glass is a safety requirement for modern building standards. Recommend replacement of the door or glass by a qualified contractor.

- CSB-19 Common Spaces and Bedrooms:

Door(s) was missing a knob, see photo. Recommend installing a knob as a DIY repair.

- CSB-24 Common Spaces and Bedrooms:

Rodent activity (droppings, nests, and/or tunneling) was observed, see photo(s.) Rodents can damage insulation, damage electrical wiring, and create hazardous air conditions from their waste. Recommend a pest control operator (exterminator) evaluate and treat.

- B-4 Bathrooms:

Grout/caulk was worn in tub/shower(s), see example photo(s.) This can allow water to penetrate into the wall. The surface was not spongy, which can be evidence of extreme rot, but there could be damage behind the wall that is impossible to detect during a non-invasive inspection. Recommend repairing as a preventative measure. This is a DIY project. If further evaluation is required, recommend removal of tile and further investigation by a qualified contractor.

- B-5 Bathrooms:

No exhaust fan was present in the bathroom. Bathrooms are high sources of humidity, and not having ventilation is a conducive condition for organic growth. Recommend installation of an exhaust fan by a qualified contractor.

- K-2 Kitchen:

Some of the cabinet doors were missing/not installed, see photos. Recommend repair by a qualified contractor.

- K-3 Kitchen:

Organic growth was observed on the cabinets under the kitchen sink, see photos. This an air quality concern. Recommend repair by a qualified mold remediation company.

- K-4 Kitchen:

The kitchen had no provisions for ventilation. An exhaust fan that ducts to the exterior is ideal, but even a fan that circulates air through a carbon filter is ok. Lack of ventilation to the exterior can increase moisture levels in the house and is a conducive condition for organic growth. Recommend installation of a ventilation fan by a qualified contractor.

- K-5 Kitchen:

An anti-tip bracket was missing from the range installation. Modern building standards recommend that all free-standing, slide-in ranges have an anti-tip device installed. It provides protection for the range tipping forward when excess weight is applied to an open oven door (example: kid climbing on the open door.) Anti-tip brackets are carried by any Home Depot-type store and are a DIY installation.

- LUR-1 Laundry / Utility Room:

No ventilation method was present in the laundry room. Modern building standards recommend a ventilation fan, though a window is often sufficient. Excessive moisture in a laundry room is a conducive condition for organic growth. Recommend evaluation and installation of some ventilation method by a qualified contractor.

- A-6 Attic:

Heavy rodent activity (droppings, nests, and/or tunneling) was observed in all three attic spaces, see photo(s.) Rodents can damage insulation, damage electrical wiring, and create hazardous air conditions from their waste. Recommend a pest control operator (exterminator) evaluate and treat.

- SCSB-5 Structure and Crawl Space / Basement:

All of the crawl space vents were blocked with spray foam insulation. This limits airflow through the crawl space, which is a conducive condition for organic growth. It looked like the previous owners tried to seal off and water proof the basement, but it was not done properly, and having the vents blocked was just exacerbating the moisture/humidity issues in the basement. Recommend removing the material blocking the vents as a DIY repair.

- SCSB-7 Structure and Crawl Space / Basement:

Suspected organic growth was observed in the basement, see photos. This can affect the air quality in the house. Recommend repair by a qualified mold remediation contractor.

- SCSB-8 Structure and Crawl Space / Basement:

Rodent activity (droppings, nests, and/or tunneling) was observed, see photo(s.) Rodents can damage insulation, damage electrical wiring, and create hazardous air conditions from their waste. Recommend a pest control operator (exterminator) evaluate and treat.

- SCSB-9 Structure and Crawl Space / Basement:

There was a possible rodent access point underneath the foundation at the SE corner of the basement, see photos (the dark one is with the light off--daylight was visible through the hole.) Recommend sealing this hole as a DIY repair.

- P-2 Plumbing:

The secondary water shut-off valve at the water meter was buried. The valve is normally installed on the street side of the meter. Recommend digging it out so it is accessible in case of an emergency. DIY repair.

- P-11 Plumbing:

The discharge tube for the water heater temperature and pressure relief valve was installed too high off the ground. Discharge tubes should always terminate by pointing toward the ground to eliminate a scald hazard (they will vent steam or hot water) and should be no more than 6" off the ground. Ideally, the discharge tube terminates to an exterior, unfinished location, or above a drain, though this is not always possible. The discharge location should be visible so it can be monitored. Recommend repair by a qualified plumber.

- E-3 Electrical:

Improperly performed wire termination(s) was observed, see photo(s.) Terminations should be done in a covered junction box to protect the wires and reduce the risk of electrical fires. Recommend repair by a qualified electrician.

- E-4 Electrical:

Wire(s) was not protected. Modern building standards recommend that electrical wire be installed in a guarded way, either through studs or in conduit, to help prevent damage to the wire. Recommend repair by a qualified electrician.

- E-5 Electrical:

Improperly performed wire splice(s) was observed, see photo(s.) Splices should be done in a covered junction box to protect the wires and reduce the risk of electrical fires. Recommend repair by a qualified electrician.

- E-8 Electrical:

There was an open junction box in the back entry way. This allowed easy access to wire splices, which should protected to keep them from coming loose. Normally, a box like this just has a door that can be closed. However, a wire was running out of the box (improperly) so the door could not be closed. Recommend repair by a qualified electrician.

- E-9 Electrical:

Junction box(es) did not have protective covers on them, see photo(s.) Recommend adding cover(s.) DIY repair.

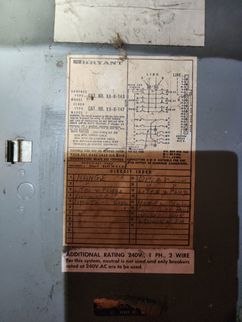

- E-14 Electrical:

Breaker(s) from a different brand from the panel manufacturer were present in the panel (Cutler-Hammer, GE, and Siemens brand breakers in a Bryant brand panel.) Most panel manufacturers require their same brand breakers to ensure a proper fit. Mismatched breakers can sometimes result in loose connections, which is an electrical fire hazard. Some brands are tested and claim to be cross compatible, though there is a debate about whether this is true or not (see this article.) Recommend evaluation and possible repair by a qualified electrician.

- E-19 Electrical:

One of the wires did not have a plastic/rubber bushing where it entered the panel, see photo. The bushings are to prevent the wires from rubbing on sharp metal edges, which could damage them. Recommend repair by a qualified electrician.

- E-22 Electrical:

Safety cover plate(s) was missing/damaged, see photo(s.) Recommend DIY installation of safety covers to prevent access to live wires. These covers are sold at any Home Depot type store.

- E-24 Electrical:

Outlet(s) was not functioning, see photo(s.) Recommend repair by a qualified electrician.

- E-26 Electrical:

Open grounds were observed in the house. This is a common condition in older buildings (prior to 1962) where three prong receptacles have been installed on an older two wire system. This creates a shock and fire hazard as it is false advertising; appliances that rely on an equipment ground to discharge a fault can be inadvertently plugged into ungrounded circuits. Proper repair can include:

- Running an equipment grounding conductor or a new three-wire circuit

- Filling the third prong of the receptacle

- Restoring a two-prong receptacle

- Installing GFCI protection for this circuit (if GFCI protection is used, the outlets on this circuit should be labeled so it is clear they are protected.)

Recommend repair by a qualified electrician.

Because many of the outlets in the house had open grounds, and it's possible I missed testing some, I recommend purchasing a simple outlet tester (often less than $10, like this one) to verify that electrical equipment that requires a ground is actually plugged into a grounded outlet.

Photographs of a tester are of the condition present in outlet from the previous photo.

- E-27 Electrical:

Reverse polarity was noted at an electrical receptacle. This is when the hot and the neutral wires have been connected to the wrong terminals in the outlet, which creates a shock hazard. Recommend repair by a qualified electrician.

Photographs of a tester are of the condition present in outlet from the previous photo.

- E-29 Electrical:

No 3-way switch was installed at the basement stair case. 3-way switches (controlled by two switches) should be installed at stairways so lights can be operated from the top and bottom. This helps prevent fall hazards on poorly lit staircases. Recommend installation of a 3-way switch by a qualified electrician.

Note: I think there was a 3-way switch for the stairs to the second level, but the light over the stairs did not have a bulb, so I could not be sure.

- E-30 Electrical:

Loose receptacle(s) was observed, see photo(s.) Movement of the receptacle can cause wires to pull loose, creating a potential fire hazard. Recommend outlet(s) be tightened to prevent movement. Securing loose receptacles can often be done by just tightening some set screws between the receptacle and the junction box, though sometimes it can get more complex if the box itself is loose. Typically this is a DIY repair.

- E-32 Electrical:

GFCI protection did not appear to be present in the kitchen and bathroom. This is a shock hazard for occupants. Recommend installation of GFCI protection by a qualified electrician.

- E-36 Electrical:

There was a low voltage wire (cable or phone) that was very low (about 6.5 feet) over the back deck, and was rubbing on the detached garage roof. Both of these conditions could result in damage to the cable. Recommend having a qualified contractor increase the height/tension of the cable.

- HCFV-7 Heating, Cooling, Fireplaces, and Ventilation:

The mortar in the fire box was worn, see photo. This is a fire hazard. Recommend repair by a qualified chimney sweep.

- HCFV-9 Heating, Cooling, Fireplaces, and Ventilation:

Debris was visible in the flue, see photos (looking up the chimney.) Recommend cleaning of the flue by a qualified chimney sweep prior to use.

- DG-3 Detached Garage:

Wood was stacked against the siding. This is a conducive condition for rot and pests (insects.) Recommend removal of the wood and observation of the siding underneath. If rot or insect activity is found, recommend evaluation and repair by a qualified contractor.

- DG-4 Detached Garage:

Rot/holes were observed on the exterior of the detached garage, see photo(s.) The wall structure was all covered on the inside, but given the water staining I saw, I suspect the structure was rotting. Recommend repair by a qualified contractor.

- DG-5 Detached Garage:

Many of the rafters were rotten, and a few were broken, see photos. This significantly weakens the roof structure. Recommend repair by a qualified contractor.

- DG-8 Detached Garage:

There was moss on the roof. Moss growth is common in our climate, and most often grows in shady areas (mostly on north facing roof surfaces or under vegetation.) This can lead to the premature failure of the roof and subsequent leaks. Recommend regularly treating moss during its growing season (wet months) with a moss killer. This is generally a DIY repair, though the height and pitch of the roof may require a qualified contractor.

- DG-10 Detached Garage:

The doors were sagging on their hinges and not easily operable. Recommend repair by a qualified contractor.

- DG-11 Detached Garage:

No tempered glass bug or logo was noted in the door, see photo(s.) Modern building standards recommend tempered or laminated glass in these locations for improved safety. Recommend hiring a qualified contractor to further evaluate and repair.

- DG-12 Detached Garage:

Several of the panes of glass were broken, see photos. Recommend repair by a qualified contractor.

Tier 3 - Improvements

- G-8 Grounds:

Guardrail was missing from a drop of more than 30 inches, see photo(s.) Modern building standards recommend guardrails for any drop in a walking area that higher than 30 inches. Recommend installation by a qualified contractor.

- G-11 Grounds:

Some branches were overhanging the roof. If feasible, these should be cut back to avoid damage to the roof material from falling branches, and also to help keep the gutters/roof surface clean of tree debris. Recommend evaluation and trimming of branches by a qualified contractor.

- G-16 Grounds:

The riser heights were not consistent and were not to modern standards. This is a trip and safety hazard. Modern building standards recommend that the height of the tallest riser not exceed the smallest riser by more than 3/8th of an inch. Recommend repair by a qualified contractor. Note that this is not always feasible to repair and sometimes means replacing the entire staircase.

- G-17 Grounds:

The front steps had settled. This was more of a nuisance concern than anything else as it is not a structural component of the house. Recommend repair by a qualified contractor.

- EDPB-7 Exteriors, Decks, Porches, and Balconies:

No tempered glass bug or logo was noted in the door, see photo(s.) Modern building standards recommend tempered or laminated glass in these locations for improved safety. Recommend hiring a qualified contractor to further evaluate and repair.

- EDPB-10 Exteriors, Decks, Porches, and Balconies:

The deck structural posts were constructed using undersized posts. 4x4 posts have been the standard for a long time, but the most current modern building standards recommend a minimum 6x6 pressure treated wood post for all deck structural elements. Recommend repair by a qualified contractor.

- EDPB-11 Exteriors, Decks, Porches, and Balconies:

Gaps in railings were too large. Modern building standards recommend gaps between balusters and the gap at the bottom of a railing be less than 4 inches. This is a safety improvement for children. Recommend repair by a qualified contractor.

- EDPB-12 Exteriors, Decks, Porches, and Balconies:

Stairs were missing a graspable handrail for safety. Modern building standards recommend a round railing 1 and 1/4 inches - 2 inches in diameter. If the railing is not round it must have a finger groove that is 3/4 of an inch down from the tallest point of the rail. The graspable handrail should also be 1.5 inches from the wall. Recommend installation of a graspable handrail by a qualified contractor.

- EDPB-13 Exteriors, Decks, Porches, and Balconies:

Guardrail was missing from a drop of more than 30 inches. Modern building standards recommend guardrails for any drop in a walking area that is higher than 30 inches. Recommend installation of a guardrail by a qualified contractor.

- EDPB-19 Exteriors, Decks, Porches, and Balconies:

Stairs wider than 44 inches only had a single handrail installed. Modern building standards recommend two handrails for stairs wider than 44 inches. Recommend installation of an additional handrail by a qualified contractor.

- EDPB-21 Exteriors, Decks, Porches, and Balconies:

Modern building standards recommend that staircase railings have a "return" to the wall to prevent clothing from snagging. The railing did not have a return installed, see photo(s.) Recommend evaluation and repair or replacement by a qualified contractor.

- CSB-8 Common Spaces and Bedrooms:

A thermal bridging pattern (often called ghosting) was noted inside the house throughout most of the first level. This is when black stains are covering the walls and ceilings in places, most notable in the living room. This is often caused by a combination of factors:

- Heat loss where walls are un-insulated, often at framing but sometimes from missing insulation

- High particulate content in the indoor air, often from burning candles, wood fires, or incense

- High indoor relative humidity

The black lines themselves are a cosmetic issue only, but can be an indicator of interior humidity issues or low levels of insulation. Recommend using stain killing paints to seal stains on the affected areas and then re-paint as a DIY repair. To prevent future problems use bath fans to try and control relative humidity in the home and refrain from burning candles/incense. In winter months, try to keep indoor relative humidity below 50%. If the ghosting pattern returns, further evaluation and repair by a qualified contractor may be needed.

- CSB-11 Common Spaces and Bedrooms:

Modern building standards recommend that staircase railings have a "return" to the wall to prevent clothing from snagging. The railing did not have a return installed, see photo(s.) Recommend evaluation and repair or replacement by a qualified contractor.

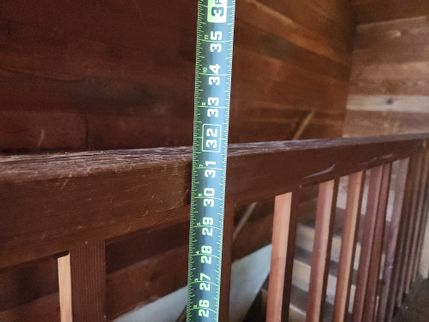

- CSB-12 Common Spaces and Bedrooms:

A guardrail was less than 36 inches high, which is the minimum height recommended by modern building standards. Recommend repair by a qualified contractor.

- CSB-13 Common Spaces and Bedrooms:

Guardrail balusters were spaced too far apart. Modern building standards recommend gaps between balusters be less than 4 inches. This is a safety improvement for children. Recommend repair by a qualified contractor.

- CSB-16 Common Spaces and Bedrooms:

Door(s) was swinging on its own in the following location(s): Kitchen to Back Entry, First Level North Bedroom, Second Level South Bedroom. As a simple DIY repair, one of the hinge pins can be removed, and bent slightly. This will create a bit of friction, usually enough to prevent the door from swinging closed, but not enough to affect its operation. If this does not fix the problem, then further repair by a qualified contractor may be needed.

- CSB-18 Common Spaces and Bedrooms:

Door(s) was sticking closed in the following location(s): Second Level North Bedroom. It could be forced closed, but was not operating smoothly. Recommend repair by a qualified contractor.

- CSB-20 Common Spaces and Bedrooms:

Recommend replacing the old windows in the house with modern vinyl double pane windows by a qualified contractor. This would be an energy efficiency upgrade.

- CSB-23 Common Spaces and Bedrooms:

A window was showing signs of a failed seal. This makes the window appear foggy or dirty, but the condensation is between the panes so it cannot be cleaned. It also causes a slight reduction in energy efficiency, but it is mostly a cosmetic concern. Recommend repair by a qualified contractor.

- B-1 Bathrooms:

Flexible/accordion drain lines are not recommended as they can be prone to clogging. Recommend monitoring and cleaning these drains regularly. For a more permanent solution, recommend contacting a qualified plumber to replace the flexible drain with straight pipes, which will not clog as easily.

- A-3 Attic:

Attic access hatch was too small. Modern standards recommend a minimum hatch size of 22 x 30 inches. Recommend repair by a qualified contractor.

- A-4 Attic:

There was less attic insulation than current building standards recommend. Recommend addition of more insulation by a qualified contractor. This would be an energy efficiency upgrade for the house.

- A-5 Attic:

Attic access hatch was not insulated. Recommend insulating attic access hatch cover with a batt of fiberglass insulation to reduce energy expenses. DIY repair.

- SCSB-1 Structure and Crawl Space / Basement:

Earthquake resistance devices were not observed in this house, which is quite common for older houses. Improvements include bolting the home to the foundation, adding sheer panels to pony walls and installing positive connections between posts and beams. Consult with a contractor or company specializing in seismic retrofits to further evaluate and improve the structure.

- SCSB-4 Structure and Crawl Space / Basement:

Accessible post and beam connections were only held together by gravity/friction (and maybe a nail or two), see example photos. This is typical for older houses, but modern building standards recommend reinforcing these connections with metal hardware attachments, especially in a seismic zone. Recommend evaluation and repair by a qualified contractor.

- P-10 Plumbing:

An expansion tank was not installed. This device helps reduce pressure on the plumbing system when the pipes and water expand from thermal expansion during water heating. Recommend installation of an expansion tank by a qualified plumber.

- P-12 Plumbing:

The water heater had an insulation wrap surrounding it. In my opinion, this extra insulation is not necessary, and often just hides problems like leaks. I recommend removing this insulation wrap so the water heater is more visible. DIY repair.

Note: This wrap also made it so I could not see any of the markings on the water heater, so I could not determine its brand, size, or most importantly, age and signs of problems (corrosion, leaks, etc.)

- E-11 Electrical:

Arc Fault Circuit Interrupter (AFCI) breakers were not observed on all the recommended circuits in the panel. Modern building standards require most living spaces be protected by AFCI breakers which are a fire prevention device. The current version of the National Electric Code states: "All 120-volt, single phase, 15- and 20-ampere branch circuits supplying outlets or devices installed in dwelling unit kitchens, family rooms, dining rooms, living rooms, parlors, libraries, dens, bedrooms, sunrooms, recreation rooms, closets, hallways, laundry areas, or similar rooms or areas shall be protected." Recommend having a qualified electrician install AFCI breakers where required as a safety improvement.

- E-12 Electrical:

No surge protection device was noted, which started being recommended by modern building standards in 2020. Recommend installation of a surge protector by a qualified electrician.

- E-16 Electrical:

Panel was missing a complete legend displaying which breakers control which circuits. Recommend the homeowner or an electrician creates one.

- E-17 Electrical:

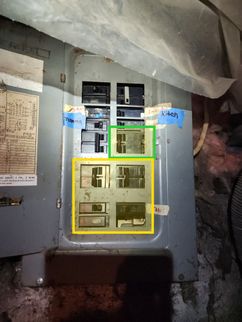

Modern building standards state that power to the entire structure should be able to be cut with six or less breakers. In a split bus panel like this, that means the top have (highlighted) should have six breakers or less. This panel had more than that. Recommend repair by a qualified electrician.

- E-23 Electrical:

I did not find any exterior receptacles during the inspection. Modern building standards require one in the front and one in the back of the house. Recommend installation of exterior outlets by a qualified electrician.

- E-25 Electrical:

Ungrounded, 2-prong electrical outlets were present in the house. Although this condition may have been commonly considered safe or acceptable at the time the home was originally constructed, these are ungrounded electrical systems, which can be unsafe. Recommend replacement by a qualified electrician.

- E-28 Electrical:

Modern building standards require bedrooms to have at least two outlets. Both first level bedrooms and the second level south bedroom only had one outlet. Recommend installation of a second outlet in each room by a qualified electrician.

- HCFV-8 Heating, Cooling, Fireplaces, and Ventilation:

The chimney did not appear to have a damper. This is an energy loss for the house. Recommend repair by a qualified chimney sweep.

- DG-9 Detached Garage:

No gutters or downspouts were installed on the roof. Gutters and downspouts are not required, but help divert water away from the structure, helping reduce the risk of rot, mold, and even structural issues. Recommend installation of gutters by a qualified contractor.

Future Projects

- CSB-6 Common Spaces and Bedrooms:

Squeaky floors were observed. This is most commonly caused by a loose subfloor, typical from nails working loose over time. It is a nuisance concern, not a significant defect. Fixing this is easy if the flooring is being replaced just by screwing down the subfloor. There are even some products designed to go through the existing flooring to reattach the subfloor (like this) though I do not have experience with them, and do not know if they are effective.

- P-7 Plumbing:

Some of the waste plumbing pipes used in this building were old metal pipes. While no leaks were noted at the time of inspection, updating and on-going repairs should be expected. Old metal pipes are subject to internal corrosion which can cause problems at any time. During any renovations to the home I recommend having this old piping evaluated and updated as recommended by a qualified plumber. As a general rule the old cast iron pipe often lasts a very long time, even as much as 100 years. Galvanized steel waste pipe can have a shorter useful service life, usually around 50 years.

- E-2 Electrical:

Unless the wiring in the building has been fully updated, this building likely has wiring that predates the late 1980's. Branch circuit wiring installed in buildings built prior to the late 1980s is typically rated for a maximum temperature of only 60 degrees Celsius. This includes non-metallic sheathed (Romex) wiring and fabric covered wiring. Knob and tube wiring, typically installed in homes built prior to 1950, may be rated for even lower maximum temperatures. Newer electric fixtures including lighting and fans typically require wiring rated for 90 degrees Celsius. Connecting newer fixtures to older, 60-degree-rated wiring is a potential fire hazard. Repairs for such conditions may involve replacing the last few feet of wiring to newer fixtures with new 90-degree-rated wire, and installing a junction box to join the old and new wiring. It is beyond the scope of this inspection to determine if any such incompatible components are installed. Based on the age of this building, be aware that such components may be present.

- E-7 Electrical:

This house had an older kitchen that was likely underwired compared to modern standard. Older houses often had just a few circuits for kitchens and older kitchens had fewer demands for electricity. Most modern kitchens have at least 7 circuits dedicated to kitchen wiring and may include requirements for AFCI and GFCI protection. Examples of modern kitchen wiring requirements include:

- Refrigerators should be on a 20-amp dedicated circuit and include GFCI protection when the refrigerator is within 6-feet of a sink or in a garage or unfinished basement.

- Dishwashers and sink disposers on dedicated 15-amp circuits

- Microwaves require a dedicated circuit and many models will require 20-amps.

- Small appliance, countertop receptacles: there should be 2, 20-amp circuits for countertops.

- Most electric ranges require 240 volt and 50-amp circuits, though this will vary by model and type

- Gas ranges and lighting will also require 15-amp circuits.

I recommend additional inspection and repair / updating of this kitchen wiring during renovation to ensure the kitchen performs reliably with all these more modern appliances.

- E-10 Electrical:

Grounded cloth covered circuits were observed. While old, this wiring is generally considered safe. With age, the wires can get brittle, which increases the chances of them breaking and sparking. Replacing these circuits with modern wiring would be a good safety upgrade at some point.

- E-21 Electrical:

Panel was rated for 125 amp service, which is less amperage than modern standard, which is 200 amp. This could be a limitation if circuits are added in the future.

- FSD-1 Fuel Storage and Distribution:

The house did not have a gas supply, but there was a spot on the north exterior where it looked like a gas meter could be installed. There was a short run of gas lines in the basement that was stubbed off next to the old oil furnace. It looked like a previous owner intended to bring gas to the house and replace the oil furnace with a gas one, but never completed the project. This might make it slightly easier to bring gas to the house in the future.

- HCFV-1 Heating, Cooling, Fireplaces, and Ventilation:

Electric baseboard heaters can get very hot during operation. Be sure to keep all drapes, curtains, furniture, electric cords and other flammable items away from these heaters when they are on (at least a 3 foot buffer zone.) Also be careful with small children to avoid a burn hazard. Consider upgrading to a wall mounted forced air electric heater (something like this) as they are safer.

- HCFV-4 Heating, Cooling, Fireplaces, and Ventilation:

There was an old thermostat in the living room. This was for the old oil furnace. It could be removed if desired, but leaving it will not harm anything.

Due Diligence

- GC-1 General Comments:

Please note that mold, mold testing, and indoor air quality are beyond the scope of this inspection. That being said, any suspected mold or conducive conditions for mold that I observed will be reported on. If mold or indoor air quality is a particular concern, I recommend additional inspection by a specialist.

- GC-2 General Comments:

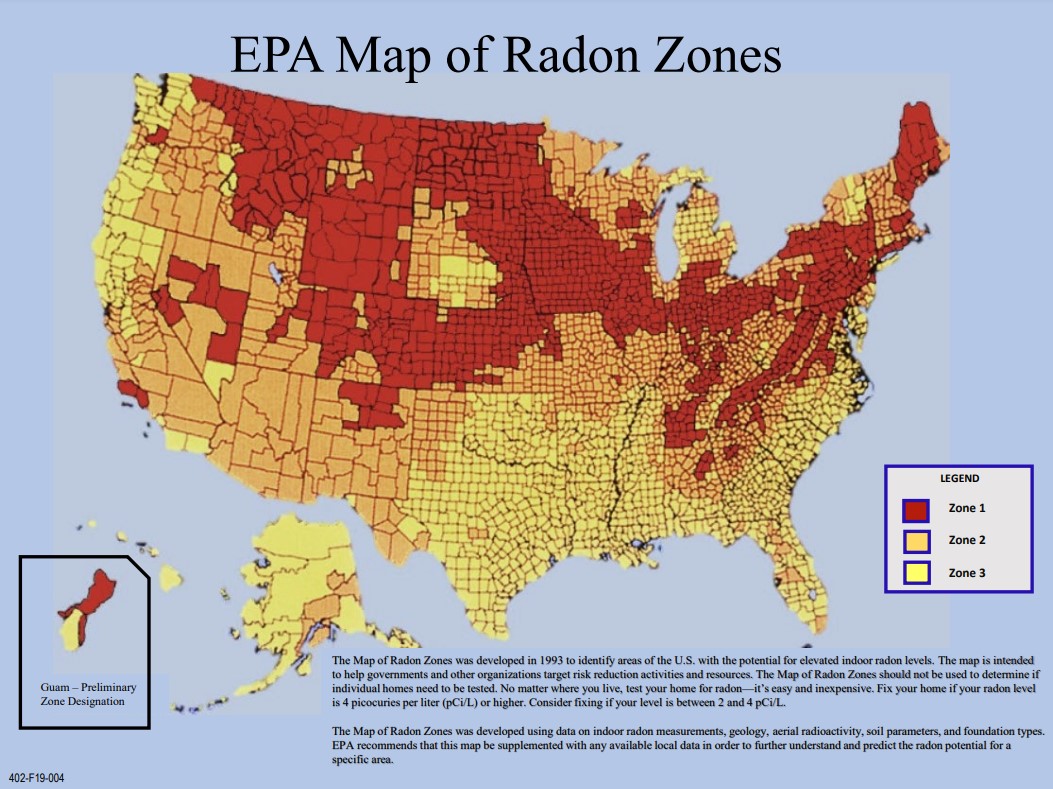

Radon level testing is not included as part of this inspection. While radon is a concern in many areas of the United States, according to the EPA, the Seattle area has low risk for radon levels (see EPA heat map of radon risk.) If radon levels are of specific concern, I recommend contacting a company that provides this service. Note that it takes 48+ hours to accurately measure radon levels.

- GC-4 General Comments:

In 1978, federal laws were past to prohibit use of lead and asbestos in building materials. Manufacturers of building materials were allowed to sell existing stocks of materials that were manufactured with lead and asbestos, so even buildings constructed as late as the mid-1980's could possibly contain lead or asbestos. Identification and testing for lead and asbestos and other environmental testing is beyond the scope of this home inspection. Visible materials likely to have asbestos or lead paint contamination (if any) are documented in this report, but more could be hidden behind walls, under flooring, etc. Asbestos materials are considered safe by the EPA if they are encapsulated, which usually means painted over, under other flooring, etc. When doing any remodeling or repairs, it's possible to find asbestos that was not visible during the inspection. If client has any concerns regarding asbestos materials, an asbestos testing lab should be consulted for further review to ensure safety.

- G-10 Grounds:

I recommend having an arborist evaluate the large trees on the property and prune or remove as recommended. Whenever large trees are located near a house, a higher level of maintenance should be expected to keep trees safe and healthy to reduce the risks of damage to the home and to reduce rodent entry points. With larger trees, pruning is recommended to reduce strain on these trees during high winds. If an arborist has not been out in the last few years, I recommend a new consultation.

- CSB-3 Common Spaces and Bedrooms:

Flooring in the home may contain asbestos, see photo(s). Asbestos identification and testing is beyond the scope of this inspection. If removal of this flooring is desired, I recommend testing this material prior to removing. Once asbestos becomes friable or air borne it becomes a safety hazard. As long as these tiles are not disturbed or are encapsulated, they should not pose a health risk, but they could pose a future disposal liability. Some of the edges of the tiles were chipped (see example photos) which could create a friable condition, and they should be encapsulated or removed if they do test positive for asbestos.

- CSB-4 Common Spaces and Bedrooms:

Minor to moderate floor settlement was noted in the house; this is pretty typical for a house of this age. Inquire with the seller about any history of repairs or movement. No signs of recent movement were visible at the time of inspection, however, the structure here is mostly concealed from view, it is not possible to predict if a future repair could be needed.

- CSB-7 Common Spaces and Bedrooms:

The ceiling was finished with acoustic ceiling tiles in the second level south bedroom. This product may contain asbestos as many of these products contained asbestos prior to 1978. Asbestos testing is beyond the scope of this inspection. The health risks posed by this substance are minimal unless the material becomes damaged, friable (dust), or air borne. If these tiles are ever going to be cut or removed, asbestos testing by a qualified contractor is recommended. Some of the tiles were damaged, which could create a friable condition.

- K-1 Kitchen:

Evidence of past leaking was observed. No active leaks were observed at the time of the inspection, but the water was shut off so I could not tell if it was actively leaking or not. Recommend verify that the supply lines, sink, and drain are not leaking prior to closing.

- K-6 Kitchen:

The oven/cooktop was not functioning. The breaker for the circuit was off in the electrical panel. Washington State Law prohibits inspectors from turning on breakers, so I could not test it. Recommend verifying that this outlet and appliance are working prior to closing.

- SCSB-6 Structure and Crawl Space / Basement:

Efflorescence was observed. This is a mineral deposit left behind on concrete/masonry when water has been seeping through it. This is a sign of active or previous water penetration through the foundation wall. While efflorescence on its own is not a concern, it is an indication of past issue. Recommend asking seller about any previous drainage work that may have been done on the exterior of the house. If the drainage has not been addressed recently, this is likely still an active problem. In that case, further evaluation and potential repair by a drainage contractor is recommended.

Note: Some of the white material in the walls looked like spray paint, but a lot of it was efflorescence.

- P-5 Plumbing:

I could not test the water pressure as the water was turned off. Once the water is back on, I recommend testing the water pressure using a pressure gauge. Normal water pressure is 40 to 60 PSI, but should not exceed 80 PSI.

- P-13 Plumbing:

Because the water heater/water was turned off, I could not test the water temperature. Recommend verifying that the water temperature at the tap does not exceed 120 degrees once the system is reactivated.

- E-1 Electrical:

I did not find a ground rod or UFER ground during visual inspection. The earthing system is an important safety feature which is a designed electrical path to dissipate a static discharge voltage (such as lightning) to earth. General standards are to have two grounding rods at least 6 feet apart if there is not a UFER ground employed. Recommend further evaluation by a qualified electrician.

Note: Whole house grounding is often not visible. It might be below the soil or in the walls/foundation. Not seeing visible grounding is not unusual.

- FSD-2 Fuel Storage and Distribution:

There was evidence that this building was once heated using heating oil. Recommend obtaining a decommissioning statement for this tank or evidence that it has been removed. If no such records exist, hire a tank locator service to further evaluate the property as there is a risk of a hidden pollution liability if the tank has not been properly removed or decommissioned. More information on buried oil tanks can be found by calling PLIA @ 800-822-3905 or going to: http://www.plia.wa.gov/heating/insurance.htm.

- HCFV-5 Heating, Cooling, Fireplaces, and Ventilation:

The NFPA (National Fire Protection Association) recommends an annual inspection of all chimneys, fireplaces, solid fuel-burning appliances, and vents. They also recommend an NFPA 211 Standard, Level II inspection upon sale or transfer of the property. A Level II inspection includes, not only cleaning the interior of the chimney pipe, but also the use of specialized tools and testing procedures such as video cameras, etc to thoroughly evaluate the serviceability of the entire flue lining and fireplace/chimney system. Level II inspections are not always needed, especially for short simple flues that can be inspected visually after a cleaning. If a chimney cleaning has not been performed over the past 12 months, such an inspection is recommended before home changes ownership for fire safety reasons. Implement any repairs as recommended.

Areas to Monitor

- G-1 Grounds:

Lot grading and drainage have a significant impact on the building, simply because of the direct and indirect damage that moisture can have on the foundation. It is very important that surface runoff water be adequately diverted away from the home. Areas of concern, if any, are noted in photos. Recommend monitoring the grounds, especially near the house, during the rainy season. If excess water or pooling is observed during the rainy season, further evaluation by a drainage specialist is recommended.

- G-4 Grounds:

The grade of the yard was slopping toward the building on the NW side. This can result in moisture issues in the structure, and even structural problems eventually. While no problems were noted during the inspection, I recommend monitoring this area for pooling water during the rainy season. If water is pooling against the foundation wall, I recommend further evaluation and possible repair by a qualified contractor.

- G-19 Grounds:

Rodent traps were observed on the grounds, but no rodent activity was noted. Rodents are common in Western Washington, and in my opinion, having rodent traps on the property is a good idea as a preventative measure. Recommend monitoring for future rodent activity.

- CSB-9 Common Spaces and Bedrooms:

Some cracking/damage was observed that appeared to be from water damage, though no obvious water sources were observed. Thermal imaging and moisture meter tests suggested normal moisture levels. I suspect this is old damage, however, it could be seasonal. Recommend monitoring these areas during the rainy season, and if moisture is observed, seeking further evaluation by a qualified contractor.

- CSB-22 Common Spaces and Bedrooms:

Double pane aluminum windows are notorious for failing seals. This makes the window appear foggy or dirty, but the condensation forms between the panes so it cannot be cleaned. It also causes a slight reduction in energy efficiency for the window. No failed seals were observed during the inspection (unless noted in this section) but they may be discovered in different weather conditions. If failed seals are found, recommend evaluation and repair by a window expert. Sometimes it is worth considering full window replacement. This is more expensive than just repairing the seals, but the improvements in efficiency and operation gained by installing moderns windows might make it a worthwhile upgrade.

- DG-7 Detached Garage:

Incomplete roof flashing; no drip edge flashing was installed. This flashing helps protect the fascia and sheathing by directing water into the gutters. The current installation had shingles extending 1+ inches over the fascias and into the gutters, which is an approved installation method and does not require drip edge flashing. However, in my experience, it is not as effective as a roof installation with drip edge flashing. Recommend monitoring overhanging shingles for damage/cracking and monitoring the wood sheathing around the perimeter of the roof for water damage/deterioration. If either of these conditions are observed, I recommend contacting a roofer for repair.

Recommended Maintenance

- G-2 Grounds:

Keep 6 to 8 inches of exposed concrete foundation between the siding and the soil below. This will help protect against moisture or pest intrusion into the siding and structure.

- G-3 Grounds:

Make sure to keep all downspouts discharging 5+ feet away from the foundation. Not doing so can cause moisture problems in the structure, or even foundation settling.

- G-9 Grounds:

When landscaping, keep plants, even at full growth, at least a foot (preferably 18 inches) from house siding and windows. Keep trees away from foundation and roof. Plants in contact or proximity to home can provide pathways for wood destroying insects, as well as cause rubbing damage to siding, screens, and roofs.

- EDPB-1 Exteriors, Decks, Porches, and Balconies:

Maintain all exterior finishes, caulking, and other sealants at any dissimilar material abutments and all penetrations to the walls and roof. This inexpensive task aids in the prevention of moisture intrusion and saves on expensive repairs.

- RCG-1 Roof, Chimney, and Gutters:

Architectural grade asphalt shingles have a life expectancy of 25 - 30 years with good maintenance. Maintenance includes removing tree debris and cleaning moss. DO NOT use a pressure washer to remove moss as it can severely damage a roof. Instead, use a moss killer treatment (spray or powered) found at any Home Depot-type store.

- RCG-6 Roof, Chimney, and Gutters:

Keep gutters and drains cleared of organic debris to prevent downspouts from being clogged, which will cause gutters to overflow. Overflow at gutters can lead to water pooling at the foundation, which can lead to rot, pests, and even structural failure eventually.

- CSB-21 Common Spaces and Bedrooms:

Aluminum windows tend to "sweat" as condensation builds up on the metal frame interior. Be sure to clean this off regularly as the water can create mildew and drip into the window sill, sometimes leading to rot or mold issues.

- B-3 Bathrooms:

Ongoing maintenance of the caulk and grout around any shower or tub is important to prevent leaking. If the caulk begins to crack or the grout begins to wear down and get thin, leaks can occur.

- A-2 Attic:

I recommend that owner looks around the attic at least twice a year just to become familiar with what's up there, and see potential issues early. Many attic issues are a result from excess water (either roof leaks or excess humidity coming from living space) which can quickly lead to rot, mold, and pest problems. The majority of these issues can be minimized or prevented if they are caught early on.

- P-8 Plumbing:

Regular scheduled maintenance is recommended for water heaters. In general, most homeowners seldom do preventative maintenance to their hot water heaters, which is why they have such short average service lives between 10 - 12 years. Generally the most important maintenance is regular draining of the tank to eliminate sludge build-up at the bottom of the tank. There are also sacrificial anodes rods that need to be periodically replaced to reduce corrosion inside the tank. These are DIY maintenance items.

- E-33 Electrical:

Smoke detectors are reliable for approximately 10 years before needing replacement. Carbon monoxide detectors are reliable for approximately 6 years before needing replacement. Batteries (if applicable) should be replaced in both every six months to ensure reliable performance.

- HCFV-2 Heating, Cooling, Fireplaces, and Ventilation:

Recommend cleaning electric heaters every 6 months to avoid dust buildup which is a potential fire hazard. Best practices are to turn power off to the heater and use compressed air to clean the dust from the heating elements. The fan blades (if any) can be wiped or vacuumed as needed, then restore power.

- DG-2 Detached Garage:

Maintain all exterior finishes, caulking, and other sealants at any dissimilar material abutments and all penetrations to the walls and roof. This inexpensive task aids in the prevention of moisture intrusion and saves on expensive repairs.

- DG-6 Detached Garage:

This style of roof (3-tab asphalt shingle) has a life expectancy of approximately 20 years with good maintenance. Maintenance includes removing tree debris and cleaning moss. DO NOT use a pressure washer to remove moss as it can severely damage a roof. Instead, use a moss killer treatment (spray or powered) found at any Home Depot-type store.

Homeowner Info

- GC-3 General Comments:

This is a generic life expectancy chart for many different materials in a house. Please note that many of these products were not present in the inspected house, however this list contains a lot of good information for homeowners to keep on general home maintenance.

- A-1 Attic:

This photo shows the location of the attic access hatch.

- P-1 Plumbing:

This shows the location of the water meter. The first photo is the location of the box, the second photo is a close-up of the interior of the box. If the secondary water shut-off valve was visible, it is circled.

- P-4 Plumbing:

This photo shows the location of the main water shut-off valve.

- E-15 Electrical:

Panel was of an older design, called a "split bus" panel. The breaker highlighted in green only shuts off power to the breakers highlighted in yellow. Essentially, this style of panel has the main electrical panel on the top half, and a built in sub panel on the bottom half. This style of panel is not inherently unsafe, but has been phased out because it is confusing for home owners. To turn off power to all the circuits in the house, all the breakers in the top section need to be turned off.

- E-31 Electrical:

During an inspection I test all ground fault circuit interrupter (GFCI) devices that are readily accessible. GFCIs are the electric receptacles with test and reset buttons that you commonly see around water; modern building standards require them in kitchens, bathrooms, garages, exterior outlets, or within 6 feet of a water source (like by a wet bar sink.) GFCIs are important safety devices that limit the duration of electrical shocks and have saved lives.

One GFCI outlet will protect all the outlets installed downstream from it, which can be confusing. I recommend being aware of where reset buttons are located in the house as GFCIs can trip and disable a circuit which can not be re-energized without resetting the button. I avoid testing if a receptacle or circuit is GFCI protected if it is not clear where the reset button is located. This is because reset buttons can be concealed behind stored items, so such a test risks disabling a circuit in the home.

- HCFV-6 Heating, Cooling, Fireplaces, and Ventilation:

The wood burning fireplace has a flue damper up inside. This is designed to keep cold air out of the house when the fireplace is not in use. Be sure to keep the flue damper closed during the heating season when the fireplace is not in use to prevent heat loss.

The Full Report

Grounds

Grounds Overview

General Grounds Photos

Lot and Drainage

Driveways / Walkways / Flatwork

Window Wells and Stairwells

Trees and Vegetation

Exterior Stairs

Fences

Miscellaneous

Exteriors, Decks, Porches, and Balconies

Exterior Overview

Siding and Trim

Exterior Vent and Exhaust Terminations

Exterior Doors

Exterior Windows Frames

Decks, Balconies, and Porches

Roof, Chimney, and Gutters

Roof System Overview

Method of Roof Inspection

General Roof Photos

Roof Materials

Chimneys

Gutters and Downspouts

Common Spaces and Bedrooms

Interior Areas Overview

General Interior Photos

Door Bell

Floors

Walls and Ceilings

Stairs and Railings

Interior Doors

Windows

Miscellaneous

Bathrooms

Bathroom Overview

General Bathroom Photos

Sinks and Cabinets

Toilets

Bathtubs / Showers

Bathroom Ventilation

Kitchen

Kitchen Overview

General Kitchen Photos

Sinks and Faucets

Cabinets and Countertops

Ventilation Method

Appliances

Laundry / Utility Room

Laundry / Utility Room Overview

General Laundry / Utility Room Photos

Washer

Dryer

Ventilation

Attic

Attic Overview

Attic Access

General Attic Photos

Roof Framing and Sheathing

Attic Insulation

Attic and Roof Cavity Ventilation

Miscellaneous

Structure and Crawl Space / Basement

Structure and Crawl Space Overview

Crawl Space Access

Foundation

Posts, Beams, and Footings

Crawl Space Ventilation

Insulation

Moisture Conditions

Miscellaneous

Plumbing

Plumbing Overview

Water Meter

Street Supply

Water Pressure

Interior Distribution Pipes

Waste Pipe and Discharge Plumbing

Water Heater

Water Temperature

Exterior Hose Spigots

Electrical

Electrical Overview

Electric Service

Electrical Grounding System

Electrical Bonding System

Branch Wiring

Electrical Panel

Outlets, Switches, and Fixtures

GFCI Outlets

Smoke and Carbon Monoxide Detector Systems

Low Voltage Wiring

Ceiling Fans

Heating, Cooling, Fireplaces, and Ventilation

HVAC Overview

Localized Heat Sources

Thermostat

Solid Fuel Fireplaces

Detached Garage

Detached Garage Overview

Detached Garage General Photos

Detached Garage Siding and Trim

Detached Garage General Roof Photos

Detached Garage Roof Materials

Detached Garage Gutters and Downspouts

Detached Garage Interior

Detached Garage Door and Automatic Opener

Detached Garage Exterior Window Frames

Detached Garage Floor

General Comments

Building Characteristics, Conditions and Limitations

Type of Building : Detached, Single Family Home, Two Level, Finished Basement

Approximate Year of Original Construction: 1918

Approximate Total Square Footage: 1512

Number of Bedrooms: 3

Number of Bathrooms: 1

Attending the Inspection: Client, Buyer's Agent, Fully Participated

Occupancy: Unoccupied

Weather during the inspection: Dry, Sunny

Approximate Temperature (Fahrenheit): 70

Ground/Soil surface conditions: Dry

For the Purposes of This Report, the House Faces: East

This house was vacant / unoccupied at the time of inspection. Vacant and unoccupied houses present unique challenges for home inspections, especially the piping and wiring systems which have not be subject to regular use prior to the inspection. While these systems can be tested during inspection, this one-time test is different than regular use and it is difficult to know how these systems will respond to regular use after the inspection. For example, septic systems may initially function and then fail under regular daily use. Plumbing traps may operate with no signs of leaks and then let go when being actively used for a few days. Shower pans may only leak when someone is standing in the shower and taking a shower. Seals for plumbing fixtures can dry up and leak when not is use. Sewer lines with roots may allow water flow, but then fail when waste and tissue are flushed; it can take a few days for that to backup. Please understand we are trying our best to look for clues of past or existing problems to paint a realistic best-guess as to the reliability of these systems during inspection.

The approximate square footage listed in the report is listed as a courtesy and is based off of public records and disclosure. An evaluation of square footage of the buildings and property lines is beyond the scope of this inspection.

The number of bedrooms identified is pulled from the MLS listing or public records. Any observed non-conforming bedrooms will be identified in this report. The simple requirements for a room to be considered a legal bedroom include:

- A heat source.

- An emergency escape and rescue opening (often referred to as fire egress opening.)

- At least 7 foot tall ceilings for at least half the room.

- Lighting.

- At least two outlets.

Note: A closet is not required for a room to be considered a bedroom by modern building standards. This is a common misconception. NWMLS may have a different definition of what is considered a bedroom.

During this inspection, a thermal imaging camera was used to check walls and ceilings for thermal anomalies and also to check specific appliances for verification of proper function. All thermal images will be immediately followed by a normal picture of the exact same frame. Thermal imaging cameras use the infrared light spectrum to build a picture of the house. Experienced thermogrophers look for clues in these thermal images that could lead us to otherwise concealed water leaks or missing air or thermal barriers. In older homes, incomplete air and thermal barriers are so common, we will only report on items that look significantly deficient and are worthy of correction. This service is included with our home inspection; it is limited and is not a complete thermal mapping of the house. The use of a thermal camera is well beyond the minimum standards for a home inspection, but we offer this service because we know it is valuable and can help us help our clients by improving our inspection services. Relevant thermal images will be included in this report. Please note that the weather had been dry leading up the inspection, so water leaks on the exterior of the building envelope may not be detectable, even with thermal imaging.