The Scope and Purpose of a Home Inspection

Purchasing property involves risk

The purpose of a home inspection is to help reduce the risk associated with the purchase of a structure by providing a professional opinion about the overall condition of the structure. A home inspection is a limited visual inspection and it cannot eliminate this risk. Some homes present more risks than others. We cannot control this, but we try to help educate you about what we don’t know during the inspection process. This is more difficult to convey in a report and one of many reasons why we recommend that you attend the inspection.

A home inspection is not an insurance policy

This report does not substitute for or serve as a warranty or guarantee of any kind. Home warranties can be purchased separately from insuring firms that provide this service.

A home inspection is visual and not destructive

The descriptions and observations in this report are based on a visual inspection of the structure. We inspect the aspects of the structure that can be viewed without dismantling, damaging, or disfiguring the structure and without moving furniture and interior furnishings. Areas that are concealed, hidden or inaccessible to view are not covered by this inspection. Some systems cannot be tested during this inspection as testing risks damaging the building. For example, overflow drains on bathtubs are generally not tested because if they were found to be leaking, they could damage the finishes below. Our procedures involve non-invasive investigation and non-destructive testing which will limit the scope of the inspection.

This is not an inspection for code compliance

This inspection and report are not intended for city / local code compliance. During the construction process structures are inspected for code compliance by municipal inspectors. Framing is open at this time and conditions can be fully viewed. Framing is not open during inspections of finished homes, and this limits the inspection. All houses fall out of code compliance shortly after they are built, as the codes continually change. National codes are augmented at least every three years for all of the varying disciplines. Municipalities can choose to adopt and phase in sections of the codes on their own timetables. There are generally no requirements to bring older homes into compliance unless substantial renovation is being done.

This is just our opinion

Construction techniques and standards vary. There is no one way to build a house or install a system in a house. The observations in this report are the opinions of the home inspector. Other inspectors and contractors are likely to have some differing opinions. You are welcome to seek opinions from other professionals.

The scope of this inspection

This inspection will include the following systems: exterior, roof, structure, drainage, foundation, attic, interior, plumbing, electrical, and heating. The evaluation will be based on limited observations that are primarily visual and non-invasive. This inspection and report are not intended to be technically exhaustive.

Your expectations

The overall goal of a home inspection is to help ensure that your expectations are appropriate for the house you are proposing to buy. To this end, we assist with discovery by showing and documenting observations during the home inspection. This should not be mistaken for a technically exhaustive inspection designed to uncover every defect in a building. Such inspections are available, but they are generally cost-prohibitive to most homebuyers.

Your participation is requested

Your presence is requested during this inspection. A written report will not substitute for all the possible information that can be conveyed verbally by a shared visual observation of the conditions of the property.

How to Read This Report

Getting the Information to You

This report is designed to deliver important and technical information in a way that is easy for anyone to access and understand. If you are in a hurry, you can take a quick look at our "Summary Page” and quickly get critical information for important decision-making. However, we strongly recommend that you take the time to read the full Report, which includes digital photographs, captions, diagrams, descriptions, videos, and hot links to additional information.

The best way to get the layers of information that are presented in this report is to read your report online, which will allow you to expand your learning about your house. You will notice some words or series of words highlighted in blue and underlined – clicking on these will provide you with a link to additional information.

This report can also be printed on paper or to a PDF document.

Chapters and Sections

This report is divided into chapters that parcel the home into logical inspection components. Each chapter is broken into sections that relate to a specific system or component of the home. You can navigate between chapters with the click of a button on the left-side margin.

Most sections will contain some descriptive information in black font. Observation narrative, done in colored boxes, will be included if a system or component is found to be significantly deficient in some way or if we wish to provide helpful additional information about the system or the scope of our inspection. If a system or component of the home was deemed to be in satisfactory or serviceable condition, there may be no narrative observation comments in that section, and it may simply say “tested” or “inspected.”

Observation Labels

All narrative observations are colored, numbered, and labeled to help you find, refer to, and understand the severity of the observation. Observation colors and labels used in this report are:

Summary Page

The Summary Page is designed as a bulleted overview of all the observations noted during your inspection. This helpful overview is not a substitute for reading the entire inspection report. The entire report must be read to get a complete understanding of this inspection report, as the Summary Page does not include photographs, photo captions, and other important information.

The following items or discoveries indicate that these systems or components do not function as intended, are safety concerns or adversely affect the habitability of the dwelling, warrant further investigation by a specialist, or require subsequent observation. This summary shall not contain recommendations for routine upkeep of a system or component to keep it in proper functioning condition or recommendations to upgrade or enhance the function or efficiency of the building.

This Summary is not the entire report. The complete report may include additional information of concern to the customer.

It is strongly recommended that the customer and/or Realtor(s) read the complete report as there could be additional items in the report that you may want on your inspection addendum.

All repairs and or replacements of items and components made to the property should be done by licensed, qualified contractors or tradesmen in that respective area. Clients are strongly encouraged to obtain estimates before making any decisions about the property.

SUMMARY/AREAS

REQUIRING FURTHER EVALUATION

IMPORTANT NOTE- PLEASE READ: The Summary pages are provided to allow the reader a brief overview of the report. These pages are not all encompassing. Reading these pages alone is not a substitute for reading the report in its entirety. The entire Inspection Report, including the Standards of Practice, limitations, Scope of Inspection and Pre-Inspection Agreement must be carefully read to fully assess the findings of the inspection.

This list is not intended to determine which items may need to be addressed per the contractual requirements of the sale of the property. Any areas of uncertainty regarding to the contract should be clarified by consulting an attorney or real estate agent. It is recommended that any deficiencies, and the components and/or systems related to these deficiencies, be evaluated and/or inspected and repaired as needed by licensed contractors/professionals PRIOR TO THE CLOSE OF ESCROW.

Further evaluation PRIOR to the close of escrow is recommended so a properly licensed professional can evaluate our concerns further and inspect the remainder of the system or component for additional concerns that may be outside our area of expertise or the scope of our inspection. Please call our office for any clarifications or further questions.

253-841-1128

Moisture Meter Testing

Where moisture meter testing is indicated in this report a Protimiter Survey Master was used. This meter does not assess surface moisture. The protimiter survey master assesses sub-surface moisture to a depth of approximately 3/4 of an inch.

INSPECTION STANDARDS

The performance of your inspection is governed by standards set by the Washington State Department of Licensing and is codified in the Washington Administrative Code (WAC) in chapter 308-408C sub sections 010 through 180. The following link will take you to this chapter: WAC 308-408C-010-180

Home inspectors are not required to report on the following: Life expectancy of any component or system; The causes of the need for a repair; The methods, materials, and costs of corrections; The suitability of the property for any specialized use; Compliance or non-compliance with codes, ordinances, statutes, regulatory requirements or restrictions; The market value of the property or its marketability; The advisability or inadvisability of purchase of the property; Any component or system that was not observed; The presence or absence of pests such as wood damaging organisms, rodents, or insects; or Cosmetic items, underground items, or items not permanently installed. Home inspectors are not required to: Offer warranties or guarantees of any kind; Calculate the strength, adequacy, or efficiency of any system or component; Enter any area or perform any procedure that may damage the property or its components or be dangerous to the home inspector or other persons; Operate any system or component that is shut down or otherwise inoperable; Operate any system or component that does not respond to normal operating controls; Disturb insulation, move personal items, panels, furniture, equipment, plant life, soil, snow, ice, or debris that obstructs access or visibility; Determine the presence or absence of any suspected adverse environmental condition or hazardous substance, including but not limited to mold, toxins, carcinogens, noise, contaminants in the building or in soil, water, and air; Determine the effectiveness of any system installed to control or remove suspected hazardous substances; Predict future condition, including but not limited to failure of components; Since this report is provided for the specific benefit of the customer(s), secondary readers of this information should hire a licensed inspector to perform an inspection to meet their specific needs and to obtain current information concerning this property.

The Full Report

Grounds

Grounds Overview Photos

General Grounds Header

Limitations

Grading and Drainage

Decks and Balconies

Stairs, Handrails and Guardrails

Exterior

Exterior Overview Photos

General Exterior Inspection Standards

Siding and Trim

Eave/Overhang System

Awnings and Extended Overhangs

Electrical Components

Vegetation/Scrap Wood/Trees

Exterior Testing Procedures

Roof

Roof Overview Photos

General Roof Inspection Standards

Roof Materials & Identified Concerns

Flashing

Roof Inspection Procedures

Attic

Attic Overview Photos

General Attic Inspection Standards

Attic Access

Roof Framing and Sheathing

Attic Insulation

Rodent/Pest/WDO

Attic and Roof Cavity Ventilation

Electrical Components

Attic Inspection Procedures

Electrical

Electrical Overview Photos

General Electrical Inspection Standards

Electric Service and Service Grounding

Service Equipment - Main Electrical Panel

Branch Wiring

Electrical Testing Procedures

Plumbing

Plumbing Overview Photos

General Plumbing Inspection Standards

Water Meter & Exterior Plumbing

Water Pressure Tested During Inspection

Water Heater/Boiler

Water Temperature

Gas Appliance Venting

Main Fuel Shut Off

Location of Main Water Shut Off

Water Supply and Distribution

Plumbing Testing Procedures

Heating & Cooling

Heating and Cooling Overview Photos

Heating and Cooling Limitations

Heating and Cooling Inspection Standards

Heating System

Furnace Forced Air

Baseboard and Wall Heaters

Gas Fireplace

Heating and Cooling Distribution Systems

Kitchen

Kitchen Overview Photos

Kitchen Inspection Procedures

Kitchen Inspection Limitations

Sinks and Faucets

Floors

Appliances

Electrical Components

General Comments

Building Characteristics, Conditions and Limitations

Type of Building : Single Family (2-story w/Basement)

Approximate Square Footage: 1700

Approximate Year of Original Construction: 1914

Attending the Inspection: Photo Review Completed On-Site

Photo Review Completed On-Site Seller

Seller

Occupancy: Occupied/Staged with Furnishings

Occupied/Staged with Furnishings

Rain in the Past 3 Days: No

No

OCCUPIED HOUSE LIMITATIONS

Your inspection today occurred when the structure was occupied (not vacant and empty) or was staged with furnishings as part of this real estate transaction. This inspection is limited to those areas that are 'visibly accessible.' Furnishings of any type (including floor coverings), storage of personal items, and accumulations of miscellaneous 'stuff' conceal areas from view. I cannot move items to inspect the areas where those items are situated. Anything is capable of concealing a noteworthy deficiency. I strongly recommend, if at all possible, that you walk through the property after ALL items have been removed (structure is empty) and before this transaction closing, looking for any defect that was not visible due to the items present at the time of this inspection. The Sterling Team will happily schedule a re-inspection after removing all items if you are uncomfortable doing this yourself. (A re-inspection fee may apply.)

NO RAIN PAST THREE DAYS

It does not appear that it has rained at this location during the past three days. This is noteworthy as a lack of recent rain can cause evidence of leaks, groundwater/drainage deficiencies, etc., to disappear. Upon taking possession of the property, closely monitor all areas during the first few rain events. Look for indications of leaks, drainage/drainage control system deficiencies, and groundwater accumulations.

Grounds

General Grounds Header

Today, I inspected the site upon which the building is located. In a general sense, I looked for concerns arising from the grade of the land and the potential for drainage that might adversely affect the building. Additionally, I looked for the presence of vegetation that is now or could, in the future, adversely affect the structure. Driveways, walkways, steps patios, and retaining walls that are contiguous with the structure, if present, were also inspected. The presence of current deficiencies with those components will be detailed in this section of your report.

Limitations

Grading and Drainage

UNDERGROUND DRAINS NOT INSPECTED

The inspection of underground drains, including yard drains, hard surface drains, the underground portion of roof drains and any other type of underground drainage system falls outside of the scope of established home inspection standards. (The Washington State Department of Licensing establishes these standards.) There appears to be a drainage system installed here. I did not test it for its performance or its capacity to accommodate anticipated loads. Some information about the drain's past performance may be obtained from the current home owner. If a full evaluation of the drain system is needed I recommend the employment of a qualified licensed drainage contractor.

Decks and Balconies

Deck and Balcony Common Observations: Deck Finish Peeling/Worn

Deck Finish Peeling/Worn

SUPPORTS IN QUESTION -FRONT POURCH

One or more of the supporting posts or footings is in question as to its ability to support the structure. I recommend additional inspection of the post and footing system by a licensed general contractor to further evaluate and repair as needed.

DECK FINISH PEELING/WORN

There is one or more locations where the finish (paint/stain) on the deck is peeling/worn and/or faded. A properly maintained coating of a quality finish material is the first line of defense for the wood decking material. Whether paint, stain, or other sealant, the finish should be maintained and kept free of debris. Unprotected wood that is exposed to the weather is more likely to rot/fail sooner than protected wood. I recommend further evaluation of the entire deck structure and correct as required. A qualified licensed contractor should complete this work.

WOOD DECK MAINTENANCE

Wood decks, whether treated or not, must be kept free of debris. Debris and materials, such as rugs or carpeting, hold moisture against the surface of the wood. If the wood cannot dry, it will eventually rot. Any organic growth on any deck surface should be cleaned away as soon as possible. Annual cleaning of the deck will prolong its life. Cleaning can be accomplished by scrubbing the deck with a sodium-hypochlorite (bleach) and Tri-Sodium-Phosphate (TSP) deck wash and then rinsing with a pressure washer. Any finish coating (paint, stain, sealant, etc.) should be maintained in good condition.

Stairs, Handrails and Guardrails

Handrail/Guardrail: Not Installed

Not Installed Baluster Spacing

Baluster Spacing

BALUSTER SPACING

The handrail balusters are spaced too far apart. The current spacing of these balusters may have complied with standards in effect at the time of original construction. However, the current spacing does not meet modern safety standards. Spacing of balusters that permit the passage of a four-inch, or larger, sphere is considered unsafe because small children can fit between the balusters. To enhance the safety of this guardrail, you may wish to reconfigure the balusters to meet the four-inch standard.

Exterior

General Exterior Inspection Standards

EXTERIOR INSPECTION INFORMATION

This report section details your inspector’s findings about the structure's exterior. The exterior siding system, also called the weather-resistant barrier, includes siding, trim, flashings, windows, doors, etc. The building exterior is examined visually from the ground. Areas of suspected decay/rot are probed to confirm or refute the suspicion. The purpose of the exterior envelope (siding system) is to keep water away from building components that have no water-resistive properties. Siding system failures can lead to damage that is often hidden from view. When one area of decay is identified, the likelihood of decay in other areas. Therefore, a qualified professional needs further evaluation of the entire structure. Moisture damage is often very costly to repair. The property owner can complete some siding system repairs. However, I recommend employing a professional, licensed siding contractor to evaluate further and repair more severe deficiencies such as rot and decay. All repair work should be completed before the close of escrow.

Siding and Trim

Siding Material: Wood Shingle

Trim Material: Wood

General Siding Concerns: In Contact With Any Prohibited Surface, Any Caulking Deficiency, Siding not Installed/Missing, Openings/Breaches

General Trim Concerns: Paint Deficient

SIDING or TRIM IN CONTACT WITH LANDSCAPING/HARD SURFACE/ROOFING ETC.

There are one or more locations where the exterior siding or trim is in contact with soil and landscape material. No siding or trim material should be in direct contact with any material that can potentially hold moisture against the siding. This prevents the siding from drying and promotes decay. In locations where material removal is impractical, such as hard surfaces, caulking may provide some protection against moisture absorption. A well-maintained coating of quality paint/stain is also essential.

CAULKING AT JOINTS DETERIORATED/NOT INSTALLED

The caulking at one or more siding joints has deteriorated or has not been installed. This results in openings allowing moisture to come into contact with unpainted wood or wood substrate materials. Wood rot will result when moisture (water) is allowed to remain in contact with wood. Such damage is usually hidden from view.

SIDING NOT INSTALLED

There are one or more area(s) where there is no siding installed over the sheathing material. Sheathing materials are not engineered to be a weather proof barrier. Without properly installed and maintained siding, moisture (water) can enter the structure. This will result in damage to structural components, personal property and will create the conditions that promote wood rot.

OPENINGS/BREACHES IN SIDING

The siding has openings/breaches in one or more location(s). Any opening in the siding can allow moisture to come into contact with unpainted wood and/or substrate materials. When moisture (water) is allowed to remain in contact with wood, wood rot will result. These openings should be caulked/repaired to prevent water intrusion.

DEFICIENT TRIM PAINT/STAIN

The trim, in one or more area(s), has paint/stain that is weathered/peeling and is inadequate/not applied. When one area of deficient paint is identified, the likelihood of other deficient areas increases. Paint and stain are critical layers of protection against moisture and UV light coming into direct contact with the trim. When moisture reaches wood, rot will eventually develop. Wood rot may already be present in areas I cannot see or access. I recommend further evaluation and correction as necessary. A qualified licensed painting contractor should complete this. FYI: The photos are representative of this deficiency, not a depiction of each instance of the deficiency present at the time of the inspection. To have a complete understanding of the condition of the siding, you may wish to have a professional siding contractor evaluate the entire building.

Eave/Overhang System

WEATHER-WORN AND/OR PEELING PAINT AT EAVES

The exterior eaves, soffit, fascia, and/or rafters are weather-worn and peeling in one or more locations and are in need of correction. Wood left unpainted and exposed to the weather has a higher potential for moisture damage. I recommend further evaluation of all the exterior wood components and that the necessary preparation be completed, such as scrapping, priming, and caulking, before painting. I recommend a qualified licensed painting contractor do this. FYI: The photos are only samples of this condition, not the total number of deficiencies. To understand the full extent of this deficiency, you may wish to have the entire building evaluated by a professional contractor.

Awnings and Extended Overhangs

EXTERIOR OVEHANG CONCERN

There is a over hang towards the rear of the house that has elevated moisture levels indicating an active roof leak. This over hang is also deteriorating and does not appear to be properly supported. I recommend further evaluation and correct as necessary.

Electrical Components

Electrical Outlet: Weather Proof Cover

Electrical Switch: Exterior Switch not Weatherproof

Light Fixture: Not Operating

EXTERIOR WALL SWITCH NOT WEATHER-PROOF

The light switch installed on the exterior is not of a proper weather-proof design. Exterior wall switches that are not weather-proof can permit water to enter the switch and/or the junction box. I recommend further evaluation and correct as needed. This should be completed by a qualified licensed electrical contractor.

WEATHERPROOF COVER

The weatherproof cover for one or more exterior outlets, switches, and/or junction boxes is missing or damaged. Properly installed and maintained weatherproof covers reduce the chance of water entering these components. I recommend further evaluation and corrections as necessary. A qualified licensed electrical contractor should complete this work.

LIGHT NOT OPERATING -UNDER FRONT POURCH

One or more light fixtures are not operating. This could result from a faulty light bulb, a faulty fixture or branch circuit deficiency, or a photocell controlling it. I recommend further evaluation and correction as necessary. A qualified licensed electrical contractor should complete this.

Vegetation/Scrap Wood/Trees

Vegetation/Scrap Wood/Trees: Tree Overhang

Tree Overhang

TREE BRANCHES OVERHANGING THE ROOF LINE

One or more tree branches are hanging over the roof line of the building. Naturally occurring debris from the tree(s) is more likely to land on the roof when the branches are overhanging. Debris on the roof has a detrimental impact on the roofing system's performance. The resulting shade from the tree(s) creates an environment that promotes organic growth, including moss. Falling tree limbs can damage the roof. Consider removing the overhanging limbs, and or the tree(s) themselves should be considered. A qualified licensed tree removal contractor should do any tree/limb removal.

Exterior Testing Procedures

Your inspector makes every effort to locate and identify all deficiencies of the exterior weather-resistant barriers. Providing you with accurate information is our primary concern. The nature of the inspection provided as a part of this assessment is limited by the codified standards of practice (W.A.C. 308-408C-090) and, in a general sense, by the restriction against the employment of destructive examination techniques. We cannot go beyond a visual examination of the visibly accessible components. There may be deficiencies present that are concealed from view. If we identify any deficiency and recommend further evaluation by a qualified contractor, serious consideration should be given to following that recommendation.

Roof

General Roof Inspection Standards

This section of the report details the inspector's findings while examining the top of the roof. Visible deficiencies of roofing materials and related components will be noted in this section. IT IS IMPORTANT TO UNDERSTAND that we often identify roof deficiencies, specifically roof leaks while inspecting the attic. The attic section follows the roofing section, and both should be closely reviewed to obtain a complete picture of the roof's current condition. Any mention of leak/moisture evidence should be carefully considered. Roof leaks cause extensive (often costly) damage to structural components and personal possessions. Your inspector's opinion about the roof's current condition is an estimation, not a guarantee of the actual condition of the roof at the time of the inspection. Your home inspector is not a roofing professional.

Roof Materials & Identified Concerns

Method of Roof Inspection: Walked on roof

Roof Style: Low slope, Gable

Roof Materials: Architectural Grade Composition Shingle, Low/No Slope Material

Roof Condition: Fair

ASPHALT COMPOSITION CONCERN

The roof covering is made up of asphalt composition, which, if maintained, can last for many years. Sometimes, homeowners, in an attempt to clean the roof, will use high-pressure power washers. Power or pressure washers should never be used on roofs since they cause premature granule loss and shorten the roof's life. Cleaning moss and other debris should be done with soft brooming or soft wash. Care should be taken to prevent premature wear of the roofing material.

THE GENERAL CONDITION OF THE ROOFING SYSTEM IS FAIR

Based on my visual inspection, the roofing system appears in fair condition. We consider roofs to be in fair condition when they are not new or nearly new but are not showing signs of nearing their end of serviceable life. Most roofs fall into the fair category. Roofs in fair condition show minor to moderate signs of aging typical for the material type and have limited deficiencies related to material and installation. If there are any deficiencies and they are not repaired, then this rating is moot. This assessment is merely the opinion of your inspector, who is not a professional roofer. Estimating this roof being in the referenced condition depends upon correcting all deficiencies. Additionally, hidden deficiencies may be present now or ones created in the future that will impact the actual condition of the roof system.

LOW SLOPE SHINGLED ROOF CONCERN

One or more areas of the roof are low-pitched, which is anything less than 4:12. For composition shingles applied to roof pitches between 2:12 and 4:12, there are special requirements for the shingle underlayment. My inspection cannot determine whether the underlayment was properly installed because the shingles cover it. Low-pitched areas of a roof are more prone to leaks. These areas should be closely monitored to detect any leaks early.

TWO LAYERS OF ROOFING INSTALLED

The roof has a total of two existing layers of composition asphalt shingles installed at the time of the inspection. Two is generally the maximum number of layers allowed. Two layers of roofing has the following detrimental impacts (among others): There is reduced shingle lifespan. It is highly likely that any manufacturer’s warranty will be void. Shingles are more susceptible to damage because they do not have a solid, smooth substrate to support them. When a new roof is required, all existing layers will need to be removed before new roofing material can be installed. The costs associated with this process are higher than the costs of a single layer tear-off/re-roof.

Flashing

FLASHING LIFTING

The chimney flashing is lifting in one or more locations. Any deficiency in the roof system's flashing components provide points of access for water to penetrate to the interior of the building. Roof leaks can cause extensive damage to building components and contents. I recommend that all flashing deficiencies be corrected to ensure the integrity of the roofing system. This work should be done by an experienced licensed roofing contractor.

Roof Inspection Procedures

Your inspector makes every effort to locate and identify all deficiencies of the roofing system. Providing you with accurate information is our primary concern. The nature of the inspection provided as a part of this assessment is limited by the codified standards of practice (W.A.C. 308-408C-090) and, in a general sense, by the restriction against the employment of destructive examination techniques. (This would include lifting shingles where doing so would break the sealed tar strip and/or risk breaking a brittle shingle.) We cannot go beyond a visual examination of the visible components of the roofing system. There may be deficiencies present that are concealed from view. If we identify any deficiency and recommend further evaluation by a qualified roofing contractor, serious consideration should be given to following that recommendation. Frequently, similar deficiencies are found in multiple locations on a roof, so the roofing contractor's assessment of the entire roof is best. Roofing contractors are not constrained by the same standards of practice controlling your inspector's examination, and they are better qualified to locate and identify deficiencies, including those hidden from open view. Any additional inspections and needed repair/replacement should be completed before closing escrow.

Chimneys

Chimney Header

CHIMNEY INSPECTION LIMITATION

This section of the report details findings made while examining the chimney. This is an inspection of only those portions of the chimney system that are visually accessible. The nature of chimneys is that a significant part of the system is not visually accessible. We will check those accessible areas and will describe any deficiencies here.

Chimneys

Chimney Material: Masonry

FAILING MORTAR AND/OR BRICK/BLOCK -ATTIC

Failing mortar and brick/block were noted at the masonry chimney in the attic area. This condition risks increased water entry and penetration into the masonry chimney, leading to water damage, loose bricks, and a failing structure. Hire a licensed masonry contractor to evaluate further and repair the masonry chimney as needed.

ORGANIC GROWTH NOTED

Organic growth was noted on the masonry chimney. This can be bad for the chimney and trap water in the masonry and hasten deterioration of brick and mortar. Consult with a qualified mason about options for cleaning and sealing the chimney, repairing failing mortar, or sealing any cracks as needed.

Chimney Inspection Procedures

Your inspector makes every effort to locate and identify all deficiencies of the roofing system. Providing you with accurate information is our primary concern. The nature of the inspection provided as a part of this assessment is limited by the codified standards of practice (W.A.C. 308-408C-090) and, in a general sense, by the restriction against the employment of destructive examination techniques. (This would include lifting shingles where doing so would break the sealed tar strip and/or risk breaking a brittle shingle.) We cannot go beyond a visual examination of the visible components of the roofing system. There may be deficiencies present that are concealed from view. If we identify any deficiency and recommend further evaluation by a qualified roofing contractor, serious consideration should be given to following that recommendation. Frequently, similar deficiencies are found in multiple locations on a roof, so the roofing contractor's assessment of the entire roof is best. Roofing contractors are not constrained by the same standards of practice controlling your inspector's examination and are better qualified to locate and identify deficiencies, including those hidden from open view.

Attic

General Attic Inspection Standards

Methods and Materials: Method used to inspect attic (Crawled), Roof Structure (Wood Rafters), Sheathing Material (Plywood, Skip Sheeting), Attic Insulation (Cellulose, Fiberglass Batt)

The following attic component section provides information about my findings while in the attic space. Frequently, roof leaks, not visible while inspecting the top of the roof, are discovered while inspecting the attic. The roofing and attic components should be carefully reviewed to ensure a complete understanding of the roof's current condition. Any mention of leak/moisture evidence should be carefully considered. Roof leaks cause extensive (often costly) damage to structural components and personal possessions.

Attic Access

Roof Framing and Sheathing

Common Observations: Sheathing (Visible Water Stain)

VISIBLE WATER STAIN

One or more water stains are visible in the attic. The stain and the surrounding areas are now dry. The stains appear old, but it is impossible to know how old. Any possibility of a roof leak should be thoroughly investigated. Roof leaks frequently cause costly damage to a building's structural components and contents. An inquiry with the current homeowner may reveal the history of this leak. A professional roofing contractor's complete evaluation of the roofing system is the most sure way to understand the roof's condition.

Attic Insulation

Insulation Observations: Sidewall Insulation Displaced

Rodent/Pest/WDO

Rodent/Pest/WDO: Rodent Evidence

Rodent Evidence

RODENT/ANIMAL EVIDENCE

There is evidence of rodent and animal activity present. The following items were observed:

- feces

- rodent trails

Vermin and other pests are part of the natural habitat; they often invade homes. Rats and mice can squeeze through tiny openings. It is not uncommon for them to reside within crawlspaces, attics, closets, and even the space inside walls. The presence of these pests poses a potential risk to the health of the occupants through exposure to the animals and the diseases they may carry.

Note about bait stations: The presence of bait stations does not necessarily indicate an active rodent problem. Bait stations are often employed as a preventative measure to mitigate the chance of an infestation. The current property owner may know about the bait stations and the pest control operator who maintains them.

Attic and Roof Cavity Ventilation

Attic Ventilation Method: Ridge vents, Power ventilator

POWER FAN ON THERMOSTAT

The attic has a power fan for ventilation. This was set up on a thermostat, which appears to be used for controlling summer heat. This will not help prevent seasonal condensation issues in the winter and can even exacerbate problems of air leakage from the conditioned house space into the unconditioned attic space. So, for example, if you are using cooling in the house, it can make the house hotter during the summer as conditioned air can get pulled out of the house into the attic. In general, power ventilation is not recommended unless used for a summer fan in a building that does not have cooling.

Electrical Components

Junction Box: Missing/Not Mounted/Damaged

Branch Circuit Wiring: Active Knob and Tube Wiring Present

ACTIVE KNOB AND TUBE WIRING

Energized (connected to power) "knob and tube" wiring is present here. This type of electrical wiring is very old and considered obsolete. Much or the wiring is hidden from view in the wall cavities. I did not areas with damaged insulation and buried in insulation. Knob and tube wiring that is still in good condition may continue to provide adequate service. However, knob and tube wiring, unless other wise upgraded, does not provide a ground leg conductor. Proper grounding provides a safety feature protecting against shock/electrocution hazards and damage to connected devices from voltage spikes. I recommend further evaluation and correct as necessary. This should be completed by a qualified licensed electrical contractor.

Note: Free air space around knob and tube wiring is critical to reduce known fire risks associated with this antiquated wiring. NEVER cover knob and tube wiring with anything, including any type of insulation.

JUNCTION BOX MISSING/NOT MOUNTED/DAMAGED

One or more electrical junction box(s) are not installed at a wire splice and/or a wire termination point.. All junction boxes should be properly installed at the required locations. I recommend further evaluation and correction as needed. A qualified licensed electrical contractor should complete this work.

Attic Inspection Procedures

Unless inaccessible, the attic space was inspected by traversing the attic and viewing those areas that I could safely reach without unnecessary disruption of installed insulation. I do not move insulation to inspect any component that may be concealed within it. Personal items stored within the attic space can limit my ability to access all areas and can hide deficiencies that would otherwise be visibly accessible. (Unless designed for it, attic spaces should not be used as storage areas. Such use can overload truss systems, impact unrestricted airflow, and compress the insulation, thereby reducing thermal efficiency.) Absent any indicators of existing deficiencies, I may choose to conduct the attic inspection from the access hatch. Traversing the attic disrupts the insulation (thermal barrier). The risk of damage to the thermal barrier or to other building components is sometimes not supported by the possible discovery of some deficiency not visible from the access point. I have your best interests as my primary concern and will make every reasonable effort to view all parts of the structure; however, I must respect the concerns of the current owner when it comes to causing damage in the course of my inspection.

Electrical

General Electrical Inspection Standards

WASHINGTON STATE INSPECTION STANDARDS

The home inspector shall observe: Service entrance conductors; Service equipment, grounding equipment, primary overcurrent device, and central and distribution panels; Amperage and voltage ratings of the service; Branch circuit conductors, their overcurrent devices, and the compatibility of their ampacities and voltages; The operation of a representative number of installed ceiling fans, lighting fixtures, switches and receptacles located inside the house, garage, and on the dwelling's exterior walls; The polarity and grounding of all receptacles within six feet of interior plumbing fixtures, and all receptacles in the garage or carport, and on the exterior of inspected structures; The operation of ground fault circuit interrupters. The home inspector shall describe Service amperage and voltage, Service entry conductor materials, Service type as being overhead or underground, and Location of main and sub-distribution panels. The home inspector shall report any observed aluminum branch circuit wiring. The home inspector shall report on the presence or absence of smoke detectors. The home inspector is not required to Insert any tool, probe, or testing device inside the panels; Test or operate any over-current device except ground fault circuit interrupters; Dismantle any electrical device or control other than to remove the covers of the primary and auxiliary distribution panels; or Observe: Low voltage systems; Security system devices, heat detectors, or carbon monoxide detectors; Telephone, security, cable TV, intercoms, or other ancillary wiring that is not a part of the primary electrical distribution system; or Built-in vacuum equipment. WASHINGTON STATE HOME INSPECTOR STANDARDS OF PRACTICE

Electric Service and Service Grounding

Service Entrance: Below Ground

UNDERGROUND ELECTRICAL SERVICE

The electrical service conductors supplying power to the central and sub-electrical panels are routed below ground. Those conductors are not visible for inspection.

Service Equipment - Main Electrical Panel

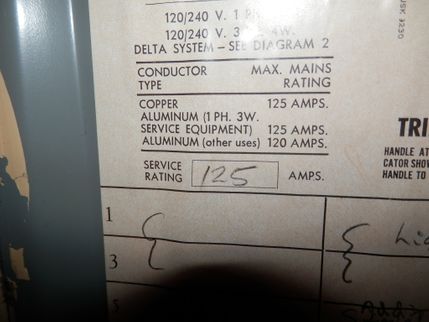

Main Panel Amperage: 125 amps

Main Electric Panel Location: Basement

ELECTRICAL PANEL MAIN DISCONNECT RATING

The electrical panel main disconnect is rated at 125 amps. Modern homes require more electricity due to televisions, computers, and other electrical equipment. Consideration should be given to upgrading the electrical service to 200 amps. I recommend further evaluation and correction as necessary, which should be completed by a qualified licensed electrical contractor.

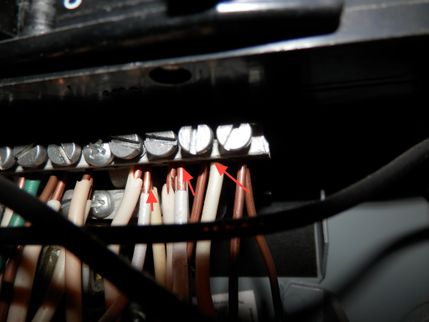

MULTIPLE WIRES UNDER THE SAME LUG SCREW

There are multiple neutral wires and/or neutral and ground wires under the same barrel lug screw of the bus bar in the electrical panel. This is not an acceptable condition by today's standards. Each neutral wire must have its own dedicated port on the bus bar. I recommend further evaluation, and correct as needed. A qualified licensed electrical contractor should complete this work.

Repair the over-fused circuits in the sub-panel. Over-fusing risks overheating the conductor and poses greater risk for electrical fires. What appears to be a #14's should be on a 20 amp breaker not a 15 amp breaker. Have a licensed electrician further evaluate and repair. Please note this condition also indicates non-professional work on the electric service and there is a risk of additional defects.

Branch Wiring

Wire Material: Copper

Wiring Method: Non-metallic sheathed cable

KNOB AND TUBE IN USE

This home still appears to employ some knob and tube wiring. This is an old soldered style of wiring that would not meet today's standards. Some insurance companies will not insure homes with this type of wiring. During testing today I noted several ungrounded outlets as well as a few knob and tube circuits. I recommend consulting with a licensed electrician about ways to improve this system and take pressure off the existing knob and tube. Installation of additional circuits and arc fault-protected breakers can help make the system safer and more reliable. Complete removal and replacement of all knobs and tubes is recommended but is considerably more expensive and not always necessary. Many homes of this age in this area still employ at least a few knob and tube circuits. You need to update to a level you feel comfortable with.

Electrical Testing Procedures

The electrical system was inspected and reported on with the above information. While the inspector makes every effort to find all areas of concern, some areas can go unnoticed. Outlet and junction box covers were not removed, and the inspection was only visual. Any outlet not accessible (behind the refrigerator for example) was not inspected or accessible. Please be aware that the inspector has your best interest in mind. Any repair items mentioned in this report should be considered before purchase. It is recommended that qualified contractors be used in your further inspection or repair issues as they relate to the comments in this inspection report.

Plumbing

General Plumbing Inspection Standards

Plumbing Material Identification: Main Water Supply (Copper, Not Visible), Water Distribution (Copper, Galvanized Iron, Not Visible), Drain Waste and Vent Material (ABS, Cast Iron, Not Visible)

WASHINGTON STATE INSPECTION STANDARDS

The home inspector shall observe the interior water supply and distribution system, including piping materials, supports, and insulation; fixtures and faucets; functional flow; leaks; and cross-connections; Interior drain, waste, and vent system, including traps; drain, waste, and vent piping; piping supports and pipe insulation; leaks; and functional drainage; Hot water systems including water heating equipment; normal operating controls; automatic safety controls; and chimneys, flues, and vents; Fuel storage and distribution systems including interior fuel storage equipment, supply piping, venting, and supports; leaks; and Sump pumps. The home inspector shall describe the water supply and distribution piping materials; Drain, waste, and vent piping materials; Water heating equipment; and Location of the primary water supply shutoff device. The home inspector shall operate all plumbing fixtures, including their faucets and all exterior faucets attached to the house, except where the flow end of the faucet is connected to an appliance. The home inspector is not required to: State the effectiveness of anti-siphon devices; Determine whether water supply and waste disposal systems are public or private; Operate automatic safety controls; Operate any valve except water closet flush valves, fixture faucets, and hose faucets; Observe: Water conditioning systems; Fire and lawn sprinkler systems; On-site water supply quantity and quality; On-site waste disposal systems; Foundation irrigation systems; Spas, except as to functional flow and functional drainage; Swimming pools; Solar water heating equipment; or Observe the system for proper sizing, design, or use of proper materials. This may not be the entire narrative from the state standards of practice. To see the entire narrative from the state, click here. WASHINGTON STATE HOME INSPECTOR STANDARDS OF PRACTICE

INFORMATION ABOUT GALVANIZED IRON PIPING

Some or all of the potable water distribution pipes within this building are galvanized iron pipes. Galvanized iron pipe is no longer used as an approved water distribution pipe material. Almost all galvanized pipes still in use are considered well into, or past, their expected service life. These particular pipes may continue to provide trouble-free service for some time. However, using a modern material, re-piping may be needed in the near future or may actually be needed now. Galvanized pipe ages from the inside, making it difficult to know the actual condition and estimate the remaining service life. These pipes may produce rusty-looking water from time to time. The water volume in such pipes will gradually be reduced by a build-up of minerals and corrosion within them. If you do not employ a qualified, licensed plumbing contractor to open a few pipes to assess their current condition (expect the plumber to recommend replacement), monitor them regularly for visible leaks, and watch for reduced water volume at faucets. These are indications of a possible need for re-piping.

Water Meter & Exterior Plumbing

Water Meter: Water Meter OK

Water Meter OK

Water Pressure Tested During Inspection

Normal Water Pressure

Normal Water Pressure

WATER PRESSURE NORMAL

The water pressure is within the recommended range of 45 - 65 PSI. A pressure value between 65 and 80 PSI is considered acceptable. Any pressure value over 80 PSI is considered to be too high. Any value less than 45 is considered too low. If a pressure-reducing valve (PRV) is present, an adjustment of overall pressure can be made.

Water Heater/Boiler

Water Heater Type & Power Source: Gas Fired Tank

Gas Fired Tank

Expansion Tank Information: No Thermal Expansion Tank Present

No Thermal Expansion Tank Present

Water Heater Manufacturer: Water Heater Manufacturer (Bradford-White)

Temperature Pressure Relief Valve (TPR) and Piping: Improper Drain Installation

Improper Drain Installation

GAS FIRED TANK-STYLE WATER HEATER

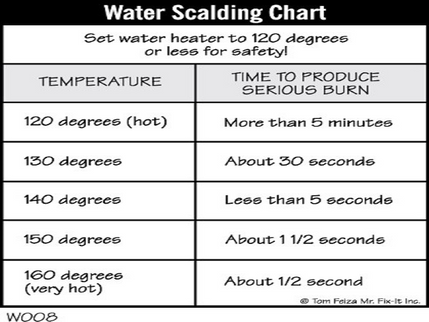

Adjustment of hot water temperature is done at the water heater. Consult the manufacturer's directions to adjust the water temperature to a safe level between 100 and 120 degrees Fahrenheit. The average service life expectancy for this type of water heater is 8-12 years. To expect this length of service, regular maintenance is critical. Ideally, service the water heater every year. Some experts suggest that servicing the appliance every other year is okay. Follow the manufacturer's recommendations for service intervals and procedures. Water heater service can be a 'do-it-yourself' project. (YouTube has some great how-to videos.) Any qualified plumbing contractor can do this if you choose a professional to perform the service.

BRADFORD WHITE DATE CODE

The date of manufacture is identified by a code within the product’s serial number. The manufacturer’s standard coding protocols are listed below. Bold alphanumeric characters show the build date year. Based on my interpretation of the code (or an actual listed date), this appliance is 9 years(s) old. Current Plumbing industry standards establish average service life expectancy for various water heating appliances.

- Gas Fired Water Heater - 8 to 12 years

- Electric Water Heater - 10 to 15 years

- Tankless (On-Demand) Water Heater - 20 years

This Water Heating appliance is nearing or has reached the end of its normally expected service lifespan. The unit may continue to operate normally well past it's average life span, many do, or it may fail soon. The nature of all mechanical devices is that the older they get the more likely they are to break down. It is not possible to predict the point in time that this unit will quit working or otherwise fail. You might consider having a qualified licensed plumbing professional evaluate the unit. That person may be able to provide a better assessment of remaining life in the water heater. Should you choose to wait to replace the unit, you should check the water heater frequently for signs of leaks. Catching a leak early can help prevent extensive water damage. Without regard for how you decide to proceed, it would be wise to plan for the financial considerations involved in the repair or replacement of the water heater.

Example:

D G6322957

A 1984/2004 L 1994/2014

B 1985/2005 M 1995/2015

C 1986/2006 N 1996/2016

D 1987/2007 P 1997/2017

E 1988/2008 S 1998/2018

F 1989/2009 T 1999/2019

G 1990/2010 W 2000/2020

H 1991/2011 X 2001/2021

J 1992/2012 Y 2002/2022

K 1993/2013 Z 2003/2023

THERMAL EXPANSION TANK INFORMATION

I did not see that a thermal expansion tank was installed on this plumbing system. Expansion tanks look like miniature water heaters, are plumbed into the hot water distribution system and are normally located near/adjacent to the water heater. These devices serve to protect the hot water plumbing pipes, and all fixtures attached to it, from damage due to the naturally occurring expansion of water as it is heated. Not all jurisdictions require the installation of an expansion tank. I do not know the requirements for this particular location. Even if not required, the installation of an expansion tank can help reduce the likelihood of damage associated with thermal expansion within the hot water system. You may wish to consult with a qualified, licensed plumbing contractor regarding the merits of a thermal expansion tank.

IMPROPER T&P DRAIN INSTALLATION

The temperature pressure relief valve serving the water heater/boiler has not been installed correctly. Specific guidelines exist for the proper, safe installation of this critical safety equipment. Today, I found the drain line is discharging to the interior of the house. This can damage floors, walls and personal belongings. Improperly installed TPR systems should be taken seriously and repaired without delay. A qualified, licensed plumbing contractor should be employed for further evaluations and repairs.

Water Temperature

Normal Water Temperature

Normal Water Temperature

Gas Appliance Venting

Combustion Air Concern

Combustion Air Concern

COMBUSTION AIR IN QUESTION

Gas appliances installed in enclosed spaces generally require a primary and secondary source of combustion air. This installation does not appear to have two separate sources and/or the sources do not appear to be of sufficient size to admit the quantity of air necessary for proper combustion. Too little combustion air can cause a flame that is more likely to produce hazardous gasses like carbon monoxide. This is common in older homes. This appliance installation should be further evaluated for air supply. This evaluation, and any required repair work, should be completed by a qualified licensed contractor.

Main Fuel Shut Off

MAIN FUEL SHUT-OFF VALVE

The main fuel shut-off is at the gas meter outside. If you smell gas or know that a gas supply line has broken, immediately shutting off the gas supply will limit the amount of gas accumulation. The risk of a gas explosion increases as the level of gas concentration increases. If you smell a strong odor of gas, get everyone out of the building and call the fire department first, then the gas utility supplier. (In most areas of western Washington, the gas utility provider is Puget Sound Energy.) The shutoff valve requires some force to rotate from the open to the closed position. You cannot do this by hand; a wrench is required. You may consider storing a suitable wrench (cheaply stamped wrenches intended for this purpose are available) near the gas meter/shutoff valve so you don't have to search for one in an emergency.

Location of Main Water Shut Off

Location of Main Water Shutoff

Location of Main Water Shutoff

Water Supply and Distribution

Water Distribution: Dissimilar Metals No Dielectric Union

Dissimilar Metals No Dielectric Union

DISSIMILAR METALLIC PLUMBING COMPONENTS IN CONTACT

This location has metallic plumbing pipes of two different material types in direct contact with each other. It is not uncommon for copper and galvanized pipes to be joined (although this condition applies to ANY metallic pipe). Any dissimilar metal pipes must be connected using a special connector that prevents accelerated galvanic corrosion. Galvanic corrosion is a natural electrochemical process that is significantly accelerated when metals of differing composition are not electrically isolated from one another. Dielectric unions should be installed between all plumbing joints connecting dissimilar metals.

Plumbing Testing Procedures

While your inspector makes every effort to find all areas of concern, some deficiencies can escape detection. Washing machine drain lines, for example, cannot be evaluated for their ability to handle the volume during the drain cycle. There is no way that we can, within the limited scope of a standard home inspection, load the drains to the same extent that daily use does. Too many variables influence whether or not a drain deficiency presents at any given time. Things such as additional waste flow from multiple fixtures throughout the home (sinks/showers/tubs/toilets) and the amount and nature of material suspended in the flow can all impact the performance of the drain system. In the presence of a partial blockage, these variables can make the difference between a problem presenting and the appearance of regular operation. We test drains with clear water, no soap, and no suspended debris. There is no practical way for us to evaluate drain performance. Please be aware that your inspector has your best interest in mind. Any deficiency or recommended attention item(s) mentioned in this report should be thoughtfully considered before you purchase the home. It is recommended that qualified contractors be used in your further inspection or repair issues related to the comments in this inspection report.

Heating & Cooling

Heating and Cooling Limitations

This home's heating and cooling system was inspected and reported on with the above information. While the inspector makes every effort to find all areas of concern, some can go unnoticed. The inspection is not meant to be technically exhaustive. The inspection does not involve removal and inspection behind service doors or dismantling that would otherwise reveal something only a licensed heat contractor would discover. Please be aware that the inspector has your best interest in mind. Any repair items mentioned in this report should be considered before purchase. It is recommended that qualified contractors be used in your further inspection or repair issues related to the comments in this inspection report.

Recommendation for Further Evaluation and Correction of Deficiencies: If any area(s) of concern are noted with this HVAC system, they will be detailed in this chapter. Your Inspector is not a professional HVAC technician and cannot be expected to be as knowledgeable as an HVAC Professional. Please understand that any noted deficiency or concern should be referred to a qualified, licensed HVAC contractor for a complete evaluation and the completion of any subsequent repair, even if that specific language is not included within any specific comment.

Heating and Cooling Inspection Standards

CENTRAL HVAC DATE OF MANUFACTURE AND EXPECTED SERVICE LIFE

We will make a reasonable effort to identify the brand and date of manufacture for all central HVAC components (furnace, heat pump, air conditioner). {We do not research the date of manufacture for zone heating appliances such as baseboards and wall heaters.} Some manufacturers identify the date of manufacture on the appliance data label. Most use a coding system incorporated into the product serial number. Some codes are quite clear, while others are difficult to decipher. To further complicate the dating process, some manufacturers do not publish their coding systems, requiring personal contact with the manufacturer to obtain a build date. The date of manufacture of these major appliances is important when trying to understand how long you can expect one to continue to operate as expected and when to anticipate the costly replacement of an aging, failed appliance. All mechanical devices have a finite service life expectancy. HVAC equipment is no exception. If I cannot positively establish a build date, you may wish to contact the manufacturer with the model and serial numbers to learn the actual date of manufacture. An experienced HVAC professional can sometimes provide an accurate build date or approximate one. We utilize an external source to obtain date coding. While we have found this source to be very reliable, we cannot guarantee absolute accuracy.

The inspector shall observe permanently installed heating and cooling systems, including Heating equipment; Cooling Equipment that is central to the home; Normal operating controls; Automatic safety controls; Chimneys, flues, and vents, where readily visible; Solid fuel heating devices; Heat distribution systems including fans, pumps, ducts and piping, with supports, insulation, air filters, registers, radiators, fan coil units, convectors; and the presence of an installed heat source in each room. The inspector shall describe the energy source, heating equipment, and distribution type. The inspector shall operate the systems using normal operating controls. The inspector shall open readily openable access panels provided by the manufacturer or installer for routine homeowner maintenance. The inspector is not required to operate heating systems when weather conditions or other circumstances may cause equipment damage; operate automatic safety controls; Ignite or extinguish solid fuel fires; or observe the interior of flues; fireplace inserts flue connections; humidifiers; electronic air filters; or the uniformity or adequacy of heat supply to the various rooms.

Recommendation for Further Evaluation and Correction of Deficiencies: If any area(s) of concern are noted with this HVAC system, they will be detailed in this chapter. Your Inspector is not a professional HVAC technician and cannot be expected to be as knowledgeable as an HVAC Professional. Please understand that any noted deficiency or concern should be referred to a qualified, licensed HVAC contractor for a complete evaluation and the completion of any subsequent repair, even if that specific language is not included within any specific comment. Repair attempts made by anyone not fully trained and licensed as an HVAC technician are strongly discouraged, as errors can potentially have dangerous consequences. Improperly repaired/installed HVAC components can pose a fire risk and expose occupants to poisonous gasses. Unless you are an HVAC professional, limit your work on this equipment to regularly changing air filters. Refer all other work to an expert.

Heating System

Energy Source: Natural gas, Electricity

Heating Method: Gas forced air furnace, Baseboard or Wall Heaters

Last Service Record: Current Service Date Shown on Sticker

Filtration System: Disposable

This house has a gas, forced-air furnace. A critical component of all combustion equipment like this is the heat exchanger. This is the welded clam-shell piece of metal inside the furnace that contains the combustion products so that moisture, carbon monoxide, and other combustion products do not mix with interior air and get safely vented to the exterior. Heat exchangers on modern furnaces have an average life expectancy of 15-20 years. Unfortunately, heat exchangers are buried inside heating equipment; they are not visible and expressly excluded from a home inspection. The risk of using older combustion, forced-air equipment is you could get a crack in the heat exchanger and never be aware of it. Cracked heat exchangers can pose a safety hazard, and while heat exchangers can be replaced, typically, the repair involves furnace replacement.

SAFE CLEARANCE FROM ELECTRIC ZONE HEATERS

The recommended safe clearance around electric zones heating appliances, such as baseboards and fan-assisted wall heaters, is 12 inches. Be sure to keep any combustible material, such as furniture draperies and bedding, AT LEAST 12 inches from these heaters. Be mindful of anything that might fall against these heaters without your knowledge. Electric zone heaters quickly get hot enough to start a fire. If you ever use portable space heaters, follow this same safety protocol.

The U.S. Consumer Product Safety Commission (CPSC) urges consumers to examine their in-wall electric heaters to determine if they are among the 1.9 million Cadet and Encore brand heaters recalled in February 2000. Although the Cadet Manufacturing Co. heaters were sold and distributed primarily in California, Idaho, Montana, Oregon, and Washington from about 1978 through 2000, some were sold in other states. A four-year-old boy died on September 14, 2002, in Alexandria, Va., when one of the recalled Cadet heaters allegedly was involved in a house fire. (Consumers-to-Check-for-Recalled-Cadet-In-Wall-Heaters)

SERVICE STICKER SHOWS CURRENT HVAC SERVICE

The service sticker on the interior HVAC component indicates that service has been performed within the previous 12 months. I recommend obtaining copies of any documentation from the current homeowner showing the HVAC contractor's information and what service(s) were performed. Maintenance of all HVAC components is essential to ensure optimal performance and efficiency. Additionally, system deficiencies can be identified during the service visit before they result in a system failure. It is recommended that all parts/components of the HVAC system be serviced annually. Service/maintenance should always be completed by a qualified licensed HVAC technician/contractor.

Furnace Forced Air

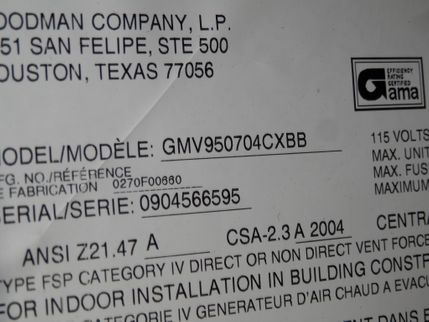

Furnace Manufacturer: Goodman

Today's Furnace Operation: Furnace responded when tested

Furnace responded when tested

GOODMAN (Janitrol) DATE CODE

The date of manufacture is identified by a code within the product’s serial number. The manufacturer’s common coding protocols are listed below. Bold alpha numeric characters show the build date year. Based on my interpretation of the code (or an actual clearly listed date), this appliance is 15 year(s) old. Current HVAC industry standards establish average service life expectancy for various central HVAC appliances.

- Gas Fired Furnaces - 16 to 18 years

- Electric Furnaces - 20 to 30 years

- Air Conditioners - 10 to 15 years

- Heat pumps - 10 to 15 years

This HVAC appliance is within its expected service lifespan. Multiple factors affect the actual service lifespan of any HVAC appliance. Many of those factors are beyond your control. What you do have control over is routine service and maintenance of this important (and expensive) appliance. Of all the factors impacting lifespan, service and maintenance is the single most important one. Service/maintenance, according to the HVAC industry, should be performed once per year. Strictly adhere to the manufacturer's recommended service interval and always choose a trusted, qualified HVAC contractor for this important maintenance task.

Example:

97 04011000

Baseboard and Wall Heaters

Today's Wall & Baseboard Operation: Electric Zone Heat Responded

Electric Zone Heat Responded

Gas Fireplace

Today's Gas Fireplace Operation : Gas Fireplace Responded to Normal Controls

Gas Fireplace Responded to Normal Controls

GAS FIREPLACE RESPONDED TO NORMAL CONTROL

Today, the gas fireplace was turned on using the remote control device. Industry standards suggest that you have your gas fireplace serviced regularly. Annual service is recommended. Professional servicing ensures the trouble-free, safe operation of this appliance.

Heating and Cooling Distribution Systems

Heat Source in Each Room: Present

Distribution Method: Forced Air / Ducts, Wall Mounted Forced Air Electric Heaters, Electric Baseboard Heaters

Kitchen

Kitchen Inspection Procedures

The home inspector shall observe and operate the essential functions of the following kitchen appliances: Permanently installed dishwasher, through its normal cycle; Range, cook top, and permanently installed oven; Trash compactor; Garbage disposal; Ventilation equipment or range hood; and Permanently installed microwave oven. The home inspector is not required to observe clocks, timers, self-cleaning oven functions, thermostats for calibration or automatic operation, Non-built-in appliances, or refrigeration units. The home inspector is not required to operate Appliances in use or Any appliance that is shut down or otherwise inoperable.

Appliances are, for the most part, operated but not taken apart to have their interior parts inspected. Such parts can stop working at any time without notice. Appliances are only inspected to see if they operate properly at the time of the inspection. Appliances breaking down is part of the risk when buying a home.

Kitchen Inspection Limitations

The home's built-in appliances were inspected and reported on with the above information. While the inspector makes every effort to find all areas of concern, some can go unnoticed. Please be aware that the inspector has your best interest in mind. Any repair items mentioned in this report should be considered before purchase. It is recommended that qualified contractors be used in your further inspection or repair issues related to the comments in this inspection report.

Sinks and Faucets

Tested

Floors

Moisture Meter Findings: No Elevated Moisture

No Elevated Moisture

NO ELEVATED MOISTURE DETECTED

Today, I used an electronic moisture meter to check all areas commonly found to have elevated moisture content. This includes the non-carpeted floor inside exterior doors and the surrounding point-of-use plumbing fixtures (sinks, tubs, showers, etc.) and appliances (dishwashers, washing machines, etc.) connected to a water source. (I do not randomly check other areas without some visible indication of moisture issues.) Unless otherwise noted in this report, I did not find moisture levels that were 'out of normal' for wood construction materials. Informational Note: The moisture meter I use does not check surface moisture. It uses an electromagnetic signal to detect moisture content in sub-surface components down to approximately 3/4 of an inch.

Appliances

Refrigerator: Operating

Dishwasher: Operated

Dishwasher Air Gap: Just a high loop

Range/ Oven /Cook-tops: Gas

Built-In Microwave: Not Present

Garbage Disposal: Operated

HIGH LOOP NOTED

No air gap noted for the dishwasher waste line but they did run a high loop. Not all jurisdictions disallow the installation of an high loop. I do not know the requirements for this particular location, but is generally it is satisfactory and many jurisdictions in the state allow for simply a "high loop" installation.

Electrical Components

GFCI Electrical Outlet: Not Installed at Recommended Location

GFCI NOT INSTALLED

One or more location(s), which would now require a GFCI-protected outlet, have no such protection installed. Beginning in 1971, Ground Fault Circuit Interrupter (GFCI) devices were required to be installed at various specified locations. Those locations now include exterior and interior outlets such as garages, kitchens, bathrooms, some utility rooms, and other areas where water source(s) are near electrical outlets. GFCI protection is a safety device that protects people and electrical devices when an electrical imbalance occurs. The requirements have progressively changed since 1971, so it is possible that the referenced area did not require GFCI at the time of construction. The addition of GFCI protection would be a safety enhancement. (Note: Any remodel involving electrical work or even replacement of components, like an outlet, must comply with current standards. I recommend further evaluation and correction as necessary. A qualified licensed electrical contractor should complete this.

Interior

Interior Inspection Procedures

WASHINGTON STATE INSPECTION STANDARDS

The home inspector shall observe walls, ceiling, and floors; steps, stairways, balconies, and railings; counters and a representative number of installed cabinets; and a representative number of doors and windows. The home inspector shall Operate a representative number of windows and interior doors and report signs of abnormal or harmful water penetration into the building or signs of abnormal or harmful condensation on building components. The home inspector is not required to observe paint, wallpaper, and other finish treatments on the interior walls, ceilings, and floors; carpeting; or draperies, blinds, or other window treatments. WASHINGTON STATE HOME INSPECTOR STANDARDS OF PRACTICE

Interior Limitations

The home's interior was inspected and reported on with the above information. While the inspector makes every effort to find all areas of concern, some can go unnoticed. The inspection did not involve moving furniture and inspecting behind furniture, area rugs, or areas obstructed from view. Please be aware that the inspector has your best interest in mind. Any repair items mentioned in this report should be considered before purchase. It is recommended that qualified contractors be used in your further inspection or repair issues as they relate to the comments in this inspection report.

Walls, Ceiling & Trim

Walls and Ceilings: Wall Damage

Wall Damage Dry Moisture Stain

Dry Moisture Stain Wet Moisture Stain

Wet Moisture Stain

Finishing Trim: Moisture Stained Trim - Dry

Moisture Stained Trim - Dry

MOISTURE DAMAGED TRIM

There is one or more area where the finishing trim has become damaged from exposure to moisture. This area is dry today. I am unable to determine if the damage is recent or is from past moisture exposure. The current owner may be able to provide additional information about the history of this damage. Aside from aesthetic value, trim serves to keep moisture and debris from reaching the raw edge of floor coverings, sub-floor materials and wall board. If this is a recent or ongoing problem, ensure that the source of the moisture has been identified and measures taken to stop its recurrence. Any time there is visible moisture damage, there is the possibility of additional hidden damage present. You should consider repairing/replacing damaged trim. Always keep a well maintained coating of paint/finish applied and caulk where appropriate.

DRY MOISTURE STAIN

I noted the presence of moisture staining on the wall/ceiling. The stains are dry today. I cannot tell how old the stains are or if they represent an ongoing, recurrent problem. The current owner may be able to provide information about the history of this staining. If this is an ongoing problem, the source of the moisture should be identified and stopped prior to undertaking any repairs. As with any moisture staining visible on the surface of a wall or ceiling, there is the possibility of moisture-related damage being present within the wall/ceiling cavity.

WET MOISTURE STAIN

I noted the presence of moisture staining on the wall/ceiling. The stained area is wet. This indicates a recent or ongoing leak. The source of the leak should be found and stopped as soon as possible. I cannot tell how long this location has been leaking. As with any leak, hidden damage may be present within the wall/ceiling cavity. The longer that building materials, including structural component, are allowed to remain wet, the greater the chance that permanent damage will occur. I recommend further evaluation to determine the source of the leak and assess whether any hidden damage is present. This work should be completed by a qualified, licensed contractor.

Fairly routine light plaster cracks were noted in walls and ceilings. This is characteristic of old plaster walls and ceilings and does not require repair unless the keys that bond the plaster to the lath fail. Light surface cracking can be repaired prior to painting as desired. When larger problems develop with how the plaster is bonding to the lath, more extensive repairs can be needed.

UNEVEN CEILING

The area(s) shown here have visibly, or otherwise detectably, uneven ceiling and or walls . (Not straight and level.) The unevenness results from structural movement and/or poor initial construction. It is not possible for me to know if structural settlement/movement is ongoing or if the movement, causing the unevenness, stopped long ago. Any structural movement that produces readily detectable unevenness in the structure is a cause for concern. Repairs required to re-level floors and or walls and ceilings , if needed, stop ongoing settlement/movement are normally quite expensive. I recommend that you employ a structural engineer to determine the history of foundation movement and a contractor specializing in foundation repairs to fully understand the scope of needed repairs and their associated costs.

Doors and Windows

Any Door: Exterior Door

Exterior Door Hinged Door

Hinged Door

Common Window Concerns: Not Locking

Not Locking

Any Window: Difficult to Operate, Safety Glass Concern

LIMITATION REGARDING FOGGED WINDOWS

The windows are tested for functionality and to ensure that they lock and that there are no broken panes. However, it is not within the Washington State home inspection standards to detect breached thermal seals (fogged windows). If there are visually discernible fogged windows, we may document them in the report as a courtesy. Despite our best efforts, we may be unable to determine all of the windows that are or may become fogged. The cleanliness of the windows and the weather play a factor in determining if the thermal seal has been breached.