The Scope and Purpose of a Home Inspection

Purchasing property involves risk

The purpose of a home inspection is to help reduce the risk associated with the purchase of a structure by providing a professional opinion about the overall condition of the structure. A home inspection is a limited visual inspection and it cannot eliminate this risk. Some homes present more risks than others. We cannot control this, but we try to help educate you about what we don’t know during the inspection process. This is more difficult to convey in a report and one of many reasons why we recommend that you attend the inspection.

A home inspection is not an insurance policy

This report does not substitute for or serve as a warranty or guarantee of any kind. Home warranties can be purchased separately from insuring firms that provide this service.

A home inspection is visual and not destructive

The descriptions and observations in this report are based on a visual inspection of the structure. We inspect the aspects of the structure that can be viewed without dismantling, damaging or disfiguring the structure and without moving furniture and interior furnishings. Areas that are concealed, hidden or inaccessible to view are not covered by this inspection. Some systems cannot be tested during this inspection as testing risks damaging the building. For example, overflow drains on bathtubs are generally not tested because if they were found to be leaking they could damage the finishes below. Our procedures involve non-invasive investigation and non-destructive testing which will limit the scope of the inspection.

This is not an inspection for code compliance

This inspection and report are not intended for city / local code compliance. During the construction process structures are inspected for code compliance by municipal inspectors. Framing is open at this time and conditions can be fully viewed. Framing is not open during inspections of finished homes, and this limits the inspection. All houses fall out of code compliance shortly after they are built, as the codes continually change. National codes are augmented at least every three years for all of the varying disciplines. Municipalities can choose to adopt and phase in sections of the codes on their own timetables. There are generally no requirements to bring older homes into compliance unless substantial renovation is being done.

This is just our opinion

Construction techniques and standards vary. There is no one way to build a house or install a system in a house. The observations in this report are the opinions of the home inspector. Other inspectors and contractors are likely to have some differing opinions. You are welcome to seek opinions from other professionals.

The scope of this inspection

This inspection will include the following systems: exterior, roof, structure, drainage, foundation, attic, interior, plumbing, electrical and heating. The evaluation will be based on limited observations that are primarily visual and non-invasive. This inspection and report are not intended to be technically exhaustive.

Your expectations

The overall goal of a home inspection is to help ensure that your expectations are appropriate with the house you are proposing to buy. To this end we assist with discovery by showing and documenting observations during the home inspection. This should not be mistaken for a technically exhaustive inspection designed to uncover every defect with a building. Such inspections are available but they are generally cost-prohibitive to most homebuyers.

Your participation is requested

Your presence is requested during this inspection. A written report will not substitute for all the possible information that can be conveyed verbally by a shared visual observation of the conditions of the property.

How to Read This Report

Getting the Information to You

This report is designed to deliver important and technical information in a way that is easy for anyone to access and understand. If you are in a hurry, you can take a quick look at our "Summary Page” and quickly get critical information for important decision making. However, we strongly recommend that you take the time to read the full Report, which includes digital photographs, captions, diagrams, descriptions, videos and hot links to additional information.

The best way to get the layers of information that are presented in this report is to read your report online, which will allow you to expand your learning about your house. You will notice some words or series of words highlighted in blue and underlined – clicking on these will provide you with a link to additional information.

This report can also be printed on paper or to a PDF document.

Chapters and Sections

This report is divided into chapters that parcel the home into logical inspection components. Each chapter is broken into sections that relate to a specific system or component of the home. You can navigate between chapters with the click of a button on the left side margin.

Most sections will contain some descriptive information done in black font. Observation narrative, done in colored boxes, will be included if a system or component is found to be significantly deficient in some way or if we wish to provide helpful additional information about the system or the scope of our inspection. If a system or component of the home was deemed to be in satisfactory or serviceable condition, there may be no narrative observation comments in that section and it may simply say “tested,” or “inspected.”

Observation Labels

All narrative observations are colored, numbered and labeled to help you find, refer to, and understand the severity of the observation. Observation colors and labels used in this report are:

- Inspection Limited :A limitation modifier is used in home inspection reports to indicate when the inspector's ability to fully assess a component or system was restricted due to factors outside their control. This helps clarify the scope of the inspection and informs the client that further evaluation is needed.

- How to Create a Repair List:Detailed description of various aspects of the property with an aspect of safety present.

- Safety Item:Significant repairs involves either multiple or singular components that will require considerable expense or replacement.

- Repair Item:Repair and maintenance items noted during inspection. Please note that some repair items can be expensive to correct such as re-finishing hardwood floors, but are considered simply repair items due to their cosmetic nature.

- Recommended Maintenance:These are repair items that should be considered "routine home ownership items," such as servicing the furnace, cleaning the gutters or changing the air filters in the furnace.

- Improvement:Observations that are not necessarily defects, but which could be improved for safety, efficiency, or reliability reasons.

- Monitor:Items that should be watched to see if correction may be needed in the future.

- Due Diligence Item:Observation such as a buried oil tank that may require further investigation to determine the severity and / or urgency of repair.

- Efficiency & IAQ:Denotes observations that are needed to make the home more energy efficient as well as to bring the home up to modern insulation standards. This category typically includes windows and insulation. Other items, such as lighting and appliances, are not inspected for their energy status.

- Description:Detailed description of various aspects of the property noted during the inspection.

- Routine Maintenance:Items that should be considered regular home maintenance. Such concerns need ongoing monitoring and you should address quickly when repairs become warranted.

- Note:Refers to aside information and /or any comments elaborating on descriptions of systems in the home or limitations to the home inspection.

Summary Page

The Summary Page is designed as a bulleted overview of all the observations noted during inspection. This helpful overview is not a substitution for reading the entire inspection report. The entire report must be read to get a complete understanding of this inspection report as the Summary Page does not include photographs or photo captions.

Summary

Inspection Limited

- P-1 Plumbing - Water Meter:

The water meter was located underneath bushes on the street side of the house. This restricted the ability to inspect the water meter I recommend cutting back the bushes and verifying that the water meter is Not buried in soil and is easily accessible.

Verify that no water is running inside the house and then inspect the meter. If the meter is spinning with the water off inside the house, this is often an indicator that there is a leak in the plumbing distribution system. If you observe that the meter is spinning I recommend contacting a qualified plumber for further evaluation.

How To Create A Repair Lists

- FR-1 For Realtors - How to Create a Repair/Request List From This Report::

The "CREATE REQUEST LIST" function, located under the report header, allows any party to build a request list from any of the items in the report. These lists can then be given to appropriate parties as desired.

Safety Items

- G1-2 Garage - General Comments:

Multiple unprotected openings were found in the garage wall fire separation. This should be repaired to complete the fire separation. Standards recommend complete sheetrock walls and ceilings between the garage and all habitable space. Use type C or type X sheetrock as needed to complete large openings in the fire separation and seal up all small gaps in the walls with fire stop caulking or drywall mud as needed.

Repair Items

- E1-3 Exterior - Decks, Balconies and Porches:

Overall, this is an older deck. Numerous repairs are needed to the decking systems on this house to ensure safe and reliable performance. Some of these repairs can be made, while other issues simply are the way they are until the deck is rebuilt. I recommend additional inspection and repair of these decks by a qualified general contractor. Options include a full re-building or implementing repairs as are feasible to prolong the useful life of the deck.

Examples of observations and defects noted during inspection include:

- Missing joist hangers

- Loose or damaged guardrails

- No graspable handrail has been installed

- Undersized posts

- Notched posts

- Riser gaps are greater than 4 inches

- E1-4 Exterior - Electrical:

During inspection, I attempted to test the receptacle near the entry door. This receptacle was not on at time of inspection, and I was unable to locate another GFCI receptacle wired in series.

There could be a receptacle hidden in the home that is wired in series and needs to be reset before this receptacle can be reset or it is possible this GFCI has failed and needs to be replaced.

Consult with a licensed electrician for further evaluation and repair as needed.

- E1-5 Exterior - Electrical:

Multiple loose lights were noted at the exterior. Make sure these fixtures are weather proof and well secured to prevent water entry and physical damage to the junction box and / or wiring.

- E-2 Electrical - Electrical Bonding System:

The equipment grounding conductor is missing / not found at the gas pipe. Have the entire grounding and bonding system checked to verify proper installation. This is an important safety system that ensures reliable discharge of fault current on metal components.

- P-2 Plumbing - Exterior Hose Bibs:

The leaky hose bibs around the home require repair or replacement - they leaked from the faucet handle when the faucet was turned on and under pressure. This often requires tightening the packing around the handle stem.

- HCFV-2 Heating, Cooling, Fireplaces and Ventilation - Cooling Systems and Heat Pumps:

The refrigerant line insulation for the heat pump is damaged and requires repair. This is important to ensure efficient performance from this heat pump.

- LAP-3 Laundry and Additional Plumbing - Sump Pumps and Drains:

The sump pump located in the crawl space was tested by manually lifting the float switch, but it did not activate, indicating that it is inoperable. A non-functioning sump pump increases the risk of water accumulation in the crawl space, which can contribute to elevated moisture levels, potential wood deterioration, and microbial growth.

Additionally, an alarm system was present in the crawl space to alert of water intrusion, but it was found unplugged. An active alarm is a critical safeguard in case of sump pump failure and should remain operational.

The sump pump was plugged into a GFCI-protected receptacle, which is in line with modern safety standards. However, this receptacle was wired in series with a kitchen GFCI receptacle. When GFCIs are wired in series, a trip at one location can disable power to multiple devices, which is not ideal for critical systems like a sump pump.

Recommendations:

- Replace the inoperable sump pump to ensure proper water management in the crawl space.

- Install a dedicated GFCI receptacle with an audible alarm to provide an immediate alert in the event of sump pump failure.

- Reconfigure the electrical wiring to eliminate GFCIs wired in series, ensuring that a trip in the kitchen does not disable the sump pump.

A licensed electrician should further evaluate and make necessary corrections to improve reliability and safety.

- FSD-1 Fuel Storage and Distribution - Gas, Propane and Oil Piping:

No sediment trap was found for the gas pipe at the gas water heater or furnace. Sediment traps are designed to prevent fouling of gas equipment by allowing sediment to fall out of the gas supply. Have this further evaluated and repaired as recommended by a qualified plumber. Sediment traps are required at all automatically controlled gas appliances.

- MB-1 Master Bathroom - Sinks and Cabinets:

A slow drain was noted at the master bathroom sink indicating that the drain may be obstructed. Repair as needed so the drain keeps up with the fixture supply. This typically involves cleaning out the trap.

Maintenance Items

- G-3 Grounds - Drainage and Lot Location:

The disconnected downspout requires immediate repair to prevent water damage to the side of the building.

- E1-1 Exterior - Siding and Trim:

Overall the siding/trim have multiple deficiencies and repairs are needed to the exterior. Hire a licensed general contractor to further evaluate and repair all damaged siding as needed.

Examples of observations noted during inspection include:

- All penetrations should be sealed to prevent moisture and pest entry

- Areas of minor paint failure

- Extend condensate lines so condensation does not cause moisture damage to the exterior

- R1-1 Roof - Roof Materials:

Tune up repairs are recommended to prolong the reliable and useful service life of this roof. This is an older roof, but there appears to be useful remaining service life. The roofing material on this building is done in an architectural grade composition shingle. These shingles are often rated as 25-30 year shingles, though I find in practice, as a roof assembly, 18-22 years is more realistic depending on the quality of the installation, the amount of exposure and the pitch of the roof. Please note that roofs are not a single shingle, they are an assembly and they require regular maintenance to keep them performing reliably. Hire a qualified roofing contractor to further evaluate and repair this roof to ensure reliable roof performance.

Examples of observations and repair items noted during inspection include:

- Granule loss in shingles

- Organic growth on roof needs to be cleaned

- Exposed nail heads

- No drip edge has been installed

- Ridge cap shingles are beginning to crack

- Plumbing vents not secure

- Nail pops

- Shingle bond is failing in multiple areas

- G1-3 Garage - General Comments:

The overhead garage door is dented and damaged and requires repair or replacement. Hire a garage door specialist to further evaluate and repair.

- G1-4 Garage - General Comments:

A bollard is recommended in the garage to protect the furnace and water heater from physical damage from cars. A bollard is a metal post that acts to protect appliances in the garage such as furnaces and water heaters, from physical damage that could be caused by a car. This is a safety hazard that should be corrected as soon as possible. Hire a qualified contractor to repair.

- HCFV-3 Heating, Cooling, Fireplaces and Ventilation - Air Filters:

The dirty air filter for the forced air furnace should be replaced. Plan on replacing air filters every 2-3 months during the heating season.

- HCFV-4 Heating, Cooling, Fireplaces and Ventilation - Mechanical Ventilation Systems:

The ductwork for the bathroom exhaust fans was observed to be taped to the roof jack vents rather than being mechanically fastened. While tape may provide a temporary seal, it is not a long-term solution for securing duct connections. Over time, exposure to heat, humidity, and natural aging can cause tape to degrade, loosen, or fail entirely. This can result in vent separation, leading to moist air discharging into the attic rather than being properly expelled outside. Such a condition increases the risk of moisture buildup, which can contribute to mold growth, wood deterioration, and reduced indoor air quality.

It is recommended that the ductwork be properly secured using mechanical fasteners, such as clamps or zip ties, and sealed with an appropriate HVAC-rated sealant or foil tape. This will help ensure a durable connection that maintains proper ventilation performance and reduces the risk of moisture-related issues. A qualified contractor should evaluate and make necessary corrections.

- K-3 Kitchen - Appliances:

During testing of the gas range, I observed that the igniter would not turn off when the rear right burner was active. Had a qualified appliance repair specialist further evaluate and repair as needed.

- I-1 Interior - Walls, Ceilings, Trim and Closets:

Cracks were noted in the walls. These are straight line cracks and no other indications were found to indicate settlement. Cracking lines like these can be due to routine settlement or moderate seasonal expansion and contraction of the structure. Cracks like these can also be related to workmanship and nailing of framing and drywall or deflection from the framing. The seasonal types of cracking can be most problematic as they will tend to re-open after repair. Repair and paint cracks as needed and monitor.

- I-2 Interior - Interior Doors:

Some of the interior doors are missing doorstops. This can result in wall damage. I recommend installing door stops behind all doors.

- FB-1 Family Bathroom - General Bath Condition:

A well-sealed countertop/backsplash not only preserves the aesthetic appeal of the bathroom but also plays a vital role in preventing water infiltration. Water leaks, even minor ones, can lead to multiple deficiencies ranging from mold and mildew growth to structural damage within cabinets, walls, and subfloors.

Improvement Items

- G-4 Grounds - Retaining Walls:

Moss growth was observed on the concrete block retaining wall. While moss itself is not structurally damaging, its presence can retain moisture, potentially accelerating surface deterioration, especially in areas prone to freeze-thaw cycles. Additionally, excessive moss can contribute to organic debris buildup and inhibit proper drainage.

To maintain the integrity of the retaining wall, removal is recommended using a gentle cleaning method, such as scrubbing with a stiff brush and a mild detergent solution or applying a moss-killing treatment designed for masonry surfaces. Pressure washing should be used with caution to avoid damaging the mortar or block surface.

To help prevent regrowth, consider improving drainage around the wall, trimming vegetation to increase sunlight exposure, and applying a preventative treatment if necessary. Regular maintenance will help extend the life of the wall and maintain its appearance.

- G1-5 Garage - General Comments:

Modern standards require that a heat sensor be installed in new garages that are attached or located under new or existing dwellings.

R314.2.3 New attached garages. A heat detector or heat alarm rated for the ambient outdoor temperatures and humidity shall be installed in new garages that are attached to or located under new and existing dwellings. Heat detectors and heat alarms shall be installed in a central location and in accordance with the manufacturer's instructions.

- P-5 Plumbing - Water Heater:

The CPVC piping has been connected directly to the temperature pressure relief valve (TPRV) with a threaded plastic fitting. The Plastic Pipe Fitters Association, PPFA, recommends a metal transition fitting rather than a threaded CPVC fitting as thermal expansion can damage the threaded fittings on the hot water side.

- LAP-1 Laundry and Additional Plumbing - Washer:

A moisture alarm with water shut-off features is recommended under the washing machine to protect against accidental leaks in the supply hoses. Pans can be effective when there is a drain, but even these will not protect against a burst supply connector. A moisture alarm with automatic shut-off will. This is a regular improvement suggestion that I make to most of my clients.

- CS-2 Crawl Space - Crawl Space Ventilation:

Crawl space vents are vulnerable to having surface water run into the vents. Improve the grade around the vents so surface water is directed away from the vents.

Monitors

- G-1 Grounds - Grounds, Trees and Vegetation:

Rodent bait stations were noted at the exterior of the building. Inquire with the seller regarding the extent of rodent control work done in the past.

- G-2 Grounds - Drainage and Lot Location:

Important catch basins were noted around the property - see side yard. These are designed to capture surface runoff and divert water around the building. Be sure to keep these drains clear, especially before large rain storms.

- G1-6 Garage - General Comments:

A small spot consistent with a minor roof leak was observed in the garage attic space.

- SB-1 Structure and Basement - Foundation:

Concrete cracking can indicate poorly compacted soils below the house which could require a repair, but small cracks can also be a sign of routine concrete shrinkage. It is not possible to determine or verify the cause of these cracks during a visual inspection. The easiest way to prevent on-going settlement in buildings is by controlling roof runoff and site drainage to promote dry soils around the foundation; wet soils do not bear weight well. This will also help to prevent crawl space moisture problems. In my experience, small cracks like these are common in concrete foundations of this age. I recommend sealing and to monitor all cracks. If continued movement is noted, I recommend seeking additional inspection by a structural engineer or qualified contractor to determine an accurate scope and urgency for repair to ensure a reliable connection between the foundation and well-compacted, weight-bearing soils.

Due Diligence Items

- G-5 Grounds - Fences:

Although fences are generally outside the scope of a standard home inspection, aside from their direct impact on the home, I do report on safety concerns and notable conditions as a courtesy when warranted. Regular maintenance and periodic inspections of fences are recommended to ensure safety and longevity.

Please note that fence upkeep and replacement can sometimes involve neighboring property owners, especially for shared or boundary fences. This report does not determine ownership of any fences on property borders; therefore, it is advisable to exercise due diligence by confirming ownership and maintenance responsibilities with neighbors or through property records.

- E1-2 Exterior - Siding and Trim:

This house has been recently painted. It is not uncommon for the sellers of a home to prep a house for selling. One common example of this is new paint, which can cover deficiencies resulting in latent defects that could not be observed at time of inspection. Recommend monitoring for future defects. Below are some of the deficiencies I observed during the inspection of the exterior. I recommend sealing any holes or punctures, as well as improving any venting that may allow for rodent entry.

- G1-1 Garage - General Comments:

Garage receptacles should be GFCI protected. If you place a refrigerator or freezer in the garage I recommend installing a GFCI receptacle that emits an audible alarm if it has been tripped. This will help alert you to the fact that your appliances are not powered and will help prevent unwanted food loss.

- E-1 Electrical - Electrical Bonding System:

Imagine your home's electrical system as a delicate network. To keep it safe and functional, two essential safety measures are employed: grounding and bonding.

Grounding:

Think of grounding as a safety net. It's a direct connection between your electrical system and the earth. If a dangerous surge of electricity, like lightning, strikes your home, the grounding system provides a path for this excess energy to flow harmlessly into the earth.

Bonding:

Bonding, on the other hand, is like linking arms with your friends. It connects all the metal components in your home, such as plumbing pipes and metal conduit, to the grounding system. This ensures that if a stray electrical current were to accidentally touch one of these metal components, it would be safely diverted to the ground.

Why are both important?

Both grounding and bonding work together to protect your home and its occupants from electrical hazards. By understanding these concepts, you can appreciate the importance of regular electrical inspections and maintenance to ensure your home's safety.

- P-3 Plumbing - Water Service Supply (From the Utility):

The main water shut off appears to be located in the crawl space. This is an inconvenient location. Inquire with the sellers if there is another shut off. If not, I would add a new shut off in a more accessible location.

- P-4 Plumbing - Water Heater:

The average life of these water heaters can vary widely between 8-20 years depending on water quality and maintenance schedule such as frequency of flushing the tank and replacing sacrificial anodes.

- LAP-2 Laundry and Additional Plumbing - Dryer:

Anytime there is a change in ownership I always recommend cleaning the dryer duct work. Keeping your dryer duct clean and free of lint is an important safety measure for your home. This should be considered regular maintenance.

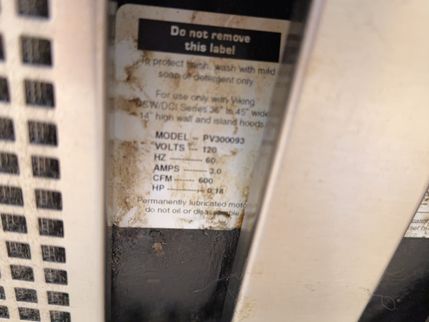

- K-1 Kitchen - Ventilation Method:

High-Capacity Kitchen Exhaust Fan May Require Make-Up Air

The kitchen exhaust fan was observed to have a rated capacity exceeding 400 cubic feet per minute (CFM). Per the International Residential Code (IRC) M1503.4, exhaust systems capable of removing more than 400 CFM must be provided with make-up air to prevent negative pressure within the home. Without proper make-up air, excessive exhaust can lead to issues such as backdrafting of combustion appliances, reduced indoor air quality, and pressure imbalances affecting heating and cooling performance.

Make-up air systems help maintain balanced airflow by introducing fresh air when high-CFM exhaust fans operate. The system should be mechanically controlled and automatically activated when the exhaust fan is in use.

Recommendation: A qualified HVAC contractor should further evaluate and, if necessary, install a compliant make-up air system to ensure safe and efficient operation of the kitchen ventilation system in accordance with current building codes.

- A-1 Attic - Attic Access:

Both attic spaces had smells that were consistent of mold remediation. Inquire with the sellers about any history of mold remediation in the attic space.

- A-3 Attic - Attic and Roof Cavity Ventilation:

Attic ventilation is a complex aspect of home design that plays a crucial role in regulating temperature and moisture levels. While combining different types of venting—such as ridge vents, soffit vents, and gable vents—can enhance airflow, it can also create complications. Improperly balanced ventilation can lead to issues like air pressure differentials, which may hinder the effectiveness of the vents and even promote moisture buildup or mold growth. Additionally, conflicting airflow patterns can cause hot or humid air to stagnate, undermining the benefits of ventilation. Careful planning and consultation with a professional can help ensure that ventilation systems work harmoniously to protect the home's integrity and comfort.

- CS-1 Crawl Space - Crawl Space Access:

During inspection today I was able to crawl the entire crawl space. The sub-floor has been insulated so I pulled insulation back in places to inspect the sub-floor, rim joist and floor frame. Please note that most of the framing was concealed from view by insulation.

- CS-3 Crawl Space - Moisture Conditions:

Visible evidence suggests that this crawl space has had water proofing done subsequent to the original build. Inquire with the seller about any prior drainage work done. This space was dry at the time of inspection.

Efficiency Iaqs

- A-2 Attic - Attic Insulation:

The attic insulation could be improved to modern standards, which recommend R-49 on the floor and R-21 on walls. R-value is the measure of resistance to heat loss; the higher the R-value the better the insulation. During insulation repairs it is best practices to implement any air seal-up repairs to seal air leakage. Also, be sure you have completed any wiring or other projects that are needed in the attic. Then, hire an insulation contractor to improve thermal barriers.

Routine Maintenance

- HCFV-1 Heating, Cooling, Fireplaces and Ventilation - Heating System:

Annual servicing of the gas forced air furnace is recommended for safe and reliable heat. The furnace was tested during inspection and was operational. The design life of these forced air furnaces is 15-20 years, although they can last much longer with routine maintenance. I recommend having it serviced and keeping it on an annual service schedule until updated. Furnace was operational at time of inspection.

- K-2 Kitchen - Ventilation Method:

The kitchen exhaust fan plays a crucial role in ventilating cooking fumes, moisture, and grease from your home. Over time, grease and debris can accumulate on the fan blades and housing, reducing its efficiency and potentially creating a fire hazard.

One simple way to check if your exhaust fan needs cleaning is to turn it on and place a paper towel against the grill. If the suction is strong enough to hold the paper towel in place, the fan is likely clean enough. If the towel falls, it's a good indication that cleaning is needed.

Regular cleaning of the exhaust fan, including the fan blades, housing, and filter (if applicable), is an important part of home maintenance. This will help ensure proper ventilation, reduce fire risk, and prolong the life of the appliance.

It is recommended to clean the kitchen exhaust fan regularly, depending on usage. Refer to the manufacturer's instructions for specific cleaning recommendations and safety precautions.

- I-3 Interior - Windows:

Keeping interior windows caulked is essential for maintaining energy efficiency, comfort, and overall home integrity. Properly caulked windows help seal gaps that can lead to drafts, reducing heating and cooling costs. Additionally, effective caulking prevents moisture intrusion, which can cause mold growth and damage to surrounding structures. Regular maintenance of window caulking ensures a more comfortable living environment and extends the lifespan of your windows.

- MB-2 Master Bathroom - General Bath Condition:

Maintaining the integrity of tub and shower enclosures by ensuring they are properly sealed should be considered regular maintenance for homeowners. A well-sealed enclosure not only preserves the aesthetic appeal of the bathroom but also plays a vital role in preventing water infiltration. Water leaks, even minor ones, can lead to multiple deficiencies ranging from mold and mildew growth to structural damage within walls and subfloors. By regularly inspecting and maintaining the seals on tub and shower enclosures, homeowners can avoid these potential hazards, ensuring a safe, healthy, and damage-free environment for all occupants.

The Full Report

Grounds

Standards of Practice

General Grounds Photos

Grounds, Trees and Vegetation

Driveways/Walkways/Flatwork

Drainage and Lot Location

Window Well and Stairwells

Retaining Walls

Exterior Stairs

Fences

Carports and Outbuildings

Irrigation

Exterior

Exterior Elevations

Siding and Trim

Eaves and Soffit

Exterior Flashings

Exterior Doors

Exterior Window Frames

Decks, Balconies and Porches

Electrical

Exterior Foundation

Electrical

Standards of Practice

Electric Service

Electrical Grounding System

Electrical Bonding System

Electric Service Permits Found

Service Equipment

Branch Wiring

Receptacles and Fixtures

Smoke and Carbon Monoxide Alarm Systems

Plumbing

Standards of Practice

Water Meter

Water Pressure Tested During Inspection

Exterior Hose Bibs

Location of Main Water Shut Off

Water Service Supply (From the Utility)

Distribution Pipe (In the Home)

Water Heater

Heating, Cooling, Fireplaces and Ventilation

Standards of Practice

Heating System

Cooling Systems and Heat Pumps

Heating and Cooling Distribution Systems

Air Filters

Mechanical Ventilation Systems

Gas Fireplaces

Fuel Storage and Distribution

General Comments

Gas Meter

Gas, Propane and Oil Piping

Oil Storage

Propane Storage

Kitchen

Sinks and Faucets

Cabinets and Countertops

Ventilation Method

Appliances

Electrical

General Kitchen Condition

Interior

Standards of Practice

Floors and Floor Materials

Walls, Ceilings, Trim and Closets

Wall Insulation and Air Bypass

Stairs and Railings

Interior Doors

Windows

Pests and Rodents

Indoor Air Quality

Master Bathroom

Sinks and Cabinets

Toilet

Bathtub / Shower

Bathroom Ventilation

Electrical

General Bath Condition

Family Bathroom

Sinks and Cabinets

Toilet

Bathtub / Shower

Electrical

Bathroom Ventilation

General Bath Condition

For Realtors

How to Create a Repair/Request List From This Report:

"Create Request List" : General Note

General Note

The "CREATE REQUEST LIST" function, located under the report header, allows any party to build a request list from any of the items in the report. These lists can then be given to appropriate parties as desired.

General Comments

Building Characteristics, Conditions and Limitations

Style of Home: Traditional

Type of Building : Single Family (1 1/2 story)

Approximate Square Footage: 1501 - 2,000 Sq Ft

Approximate Year of Original Construction: 2003

Attending the Inspection: Buyer's Agent

Occupancy: Unoccupied

This house was vacant / unoccupied at the time of inspection. Vacant and unoccupied houses present unique challenges for home inspection, especially the piping and wiring systems which have not be subject to regular use prior to the inspection. While these systems can be tested during inspection, this one-time test is different than regular use and it is difficult to know how these systems will respond to regular use after the inspection. For example, septic systems may initially function and then fail under regular daily use. Plumbing traps may operate with no signs of leaks and then let go when being actively used for a few days. Shower pans may only leak when someone is standing in the shower and taking a shower. Seals for plumbing fixtures can dry up and leak when not is use. Sewer lines with roots may allow water flow, but then fail when waste and tissue are flushed; it can take a few days for that to backup. Please understand we are trying our best to look for clues of past or existing problems to paint a realistic best-guess as to the reliability of these systems during inspection.

Animals Present: No

Weather during the inspection: Cloudy

Approximate temperature during the inspection: Below 40[F]

Ground/Soil surface conditions: Damp

For the Purposes of This Report, the Front Door Faces: West

West

Grounds

Standards of Practice

General : SOP Note

The inspection of the site includes the building perimeter, land grade, and water drainage directly adjacent to the foundation; trees and vegetation that adversely affect the structure; walks, grade steps, driveways, patios, and retaining walls contiguous with the structure.

(1) The inspector will:

(a) Describe the material used for driveways, walkways, patios and other flatwork around the home.

(b) Inspect

(i) For serviceability of the driveways, steps, walkways, patios, flatwork and retaining walls contiguous with the structure.

(ii) For proper grading and drainage slope.

(iii) Vegetation in close proximity to the home.

(c) Describe any deficiencies of these systems or components.

(2) The inspector is not required to:

• Inspect fences, privacy walls or retaining walls that are not contiguous with the structure.

• Report the condition of soil, trees, shrubs or vegetation unless they adversely affect the structure.

• Evaluate hydrological or geological conditions.

• Determine the adequacy of bulkheads, seawalls, breakwalls, and docks.

Grounds, Trees and Vegetation

Trees/Vegetation too near building: No

Common Observations: Bait Stations Noted - Inquire With Seller

Driveways/Walkways/Flatwork

Driveway: Asphalt

Walkways: Concrete

Patios: Concrete

Drainage and Lot Location

Clearance to Grade: Standard

Downspout Discharge: Below grade, Downspouts Disconnected

Site Description: Flat

Monitor Catch Basins

Monitor Catch Basins

Window Well and Stairwells

None Noted

Retaining Walls

Retaining Wall Material: Block

Moss growth was observed on the concrete block retaining wall. While moss itself is not structurally damaging, its presence can retain moisture, potentially accelerating surface deterioration, especially in areas prone to freeze-thaw cycles. Additionally, excessive moss can contribute to organic debris buildup and inhibit proper drainage.

To maintain the integrity of the retaining wall, removal is recommended using a gentle cleaning method, such as scrubbing with a stiff brush and a mild detergent solution or applying a moss-killing treatment designed for masonry surfaces. Pressure washing should be used with caution to avoid damaging the mortar or block surface.

To help prevent regrowth, consider improving drainage around the wall, trimming vegetation to increase sunlight exposure, and applying a preventative treatment if necessary. Regular maintenance will help extend the life of the wall and maintain its appearance.

Exterior Stairs

Standard

Fences

Present

Although fences are generally outside the scope of a standard home inspection, aside from their direct impact on the home, I do report on safety concerns and notable conditions as a courtesy when warranted. Regular maintenance and periodic inspections of fences are recommended to ensure safety and longevity.

Please note that fence upkeep and replacement can sometimes involve neighboring property owners, especially for shared or boundary fences. This report does not determine ownership of any fences on property borders; therefore, it is advisable to exercise due diligence by confirming ownership and maintenance responsibilities with neighbors or through property records.

Carports and Outbuildings

None noted

Irrigation

Common Observations:

An exterior irrigation system was noted for this home. Sprinkler and irrigation systems are beyond the scope of this inspection. My own experience with irrigation systems is that they require annual attention / repair / servicing after every winter. Disclose any information about how to winterize this system as this should be done prior to cold weather. When testing the system, be sure sprinkler heads are adjusted so the system is not watering the side of the house. Hire a specialist to further evaluate this system as desired.

Exterior

Exterior Elevations

Standards of Practice: SOP Note

An inspection of the exterior includes the visible wall coverings, trim, protective coatings and sealants, windows and doors, attached porches, decks, steps, balconies, handrails, guardrails, carports, eaves, soffits, fascias and visible exterior portions of chimneys, per the Washington State standards of Practice.

The inspector is not required to inspect the following items. If any of the below items are mentioned in this report, they have been made as a courtesy only and are not covered under the scope of this inspection.

- Buildings, decks, patios, fences, retaining walls, and other structures detached from the dwelling.

- Safety type glass or the integrity of thermal window seals.

- Flues or verify the presence of flue liners beyond what can be safely and readily seen from the roof or the firebox of a stove or fireplace.

• Test or evaluate the operation of security locks, devices or systems.

• Enter areas beneath decks with less than five feet of clearance from the underside of joists to grade.

• Evaluate the function or condition of shutters, awnings, storm doors, storm windows, screens, and similar accessories.

Siding and Trim

Trim Material: Wood

Siding Material: Wood clapboard, Cedar shakes

Localized Siding Repairs Needed, Recent Paint Note

Overall the siding/trim have multiple deficiencies and repairs are needed to the exterior. Hire a licensed general contractor to further evaluate and repair all damaged siding as needed.

Examples of observations noted during inspection include:

- All penetrations should be sealed to prevent moisture and pest entry

- Areas of minor paint failure

- Extend condensate lines so condensation does not cause moisture damage to the exterior

This house has been recently painted. It is not uncommon for the sellers of a home to prep a house for selling. One common example of this is new paint, which can cover deficiencies resulting in latent defects that could not be observed at time of inspection. Recommend monitoring for future defects. Below are some of the deficiencies I observed during the inspection of the exterior. I recommend sealing any holes or punctures, as well as improving any venting that may allow for rodent entry.

Eaves and Soffit

Type: Plywood

Exterior Flashings

Horizontal banding flashing: Present

Penetration Block Flashing: Caulked

Window head flashings: Present

Door head flashings: Present

Garage overhead door head-flashings: Present

Exterior Doors

Solid core, Sliding glass

Exterior Window Frames

Vinyl

Decks, Balconies and Porches

Present

To see a prescriptive guide for residential wood deck construction click this link:

Deck Structure: Ground contact treated lumber

Deck Ledger Board: Not applicable

Guardrail: Standard

Decking Material: Hardwood

Most Common Observations: Numerous Repairs Needed

Numerous Repairs Needed

Overall, this is an older deck. Numerous repairs are needed to the decking systems on this house to ensure safe and reliable performance. Some of these repairs can be made, while other issues simply are the way they are until the deck is rebuilt. I recommend additional inspection and repair of these decks by a qualified general contractor. Options include a full re-building or implementing repairs as are feasible to prolong the useful life of the deck.

Examples of observations and defects noted during inspection include:

- Missing joist hangers

- Loose or damaged guardrails

- No graspable handrail has been installed

- Undersized posts

- Notched posts

- Riser gaps are greater than 4 inches

Electrical

GFCI Test: Working

Video shows the receptacles at the exterior were GFCI protected and operating as intended.

Lights: Loose - Multiple

During inspection, I attempted to test the receptacle near the entry door. This receptacle was not on at time of inspection, and I was unable to locate another GFCI receptacle wired in series.

There could be a receptacle hidden in the home that is wired in series and needs to be reset before this receptacle can be reset or it is possible this GFCI has failed and needs to be replaced.

Consult with a licensed electrician for further evaluation and repair as needed.

Multiple loose lights were noted at the exterior. Make sure these fixtures are weather proof and well secured to prevent water entry and physical damage to the junction box and / or wiring.

Exterior Foundation

Foundation Description: Poured concrete

Roof

Standards of Practice

General : SOP Note

An inspection of the roof includes the roof covering materials; gutters and downspout systems; visible flashings; roof vents; skylights, and any other roof penetrations; and the portions of the chimneys and flues visible from the exterior.

(1) The inspector will:

• Traverse the roof to inspect it.

• Inspect the gutters and downspout systems, visible flashings, soffits and fascias, skylights, and other roof penetrations.

• Report the manner in which the roof is ventilated.

• Describe the type and general condition of roof coverings.

• Report multiple layers of roofing when visible or readily apparent.

• Describe any deficiencies of these systems or components.

(2) The inspector is not required to:

• Traverse a roof where, in the opinion of the inspector, doing so can damage roofing materials or be unsafe. If the roof is not traversed, the method used to inspect the roof must be reported.

• Remove snow, ice, debris or other material that obscures the roof surface or prevents access to the roof.

• Inspect gutter and downspout systems concealed within the structure; related underground drainage piping; and/or antennas, lightning arresters, or similar attachments.

• Operate powered roof ventilators.

• Predict remaining life expectancy of roof coverings.

Gutters and Downspouts

Gutter and Downspout Materials: Seamless Aluminum

Roof Materials

Roof Pitch and General Photos: Note, General Photos

Method of Roof Inspection: Walked on roof

Roof Style: Gable

Flashings: Present and Visually Standard

Roof flashings are used to keep a roofing system water proof where the roofing material starts, stops, changes direction or is penetrated. During inspection, we look for standard flashing techniques that could be considered normal or standard in our region. Damaged, incomplete or non-standard flashings can be a sign of an older or less reliable roofing system and may require repair. Any non-standard flashings noted during inspection will be reported on below if found.

Roof Covering Materials: Architectural grade composition shingle

Overlay Roof: No

MOST COMMON OBSERVATIONS: General Moss Note, Composition - Localized Failure Noted - Repair or Replace, Composition - Older - Tune Up Repairs Needed

Moss removal should be considered regular maintenance for your roof. Moss is bad for the roof covering and decking as it can trap moisture on the roof and can inhibit drainage off the roof. Products such as Tide are not recommended as the bleach in these products can deteriorate the shingles. Pressure washers should not be used to clean the moss as they can damage the shingles unless the moss has been killed prior to washing. Only very low pressure should be used to clean the roof of moss and chemicals should be used to kill the moss prior to removal. One product people use to kill the moss is baking soda.

Tune up repairs are recommended to prolong the reliable and useful service life of this roof. This is an older roof, but there appears to be useful remaining service life. The roofing material on this building is done in an architectural grade composition shingle. These shingles are often rated as 25-30 year shingles, though I find in practice, as a roof assembly, 18-22 years is more realistic depending on the quality of the installation, the amount of exposure and the pitch of the roof. Please note that roofs are not a single shingle, they are an assembly and they require regular maintenance to keep them performing reliably. Hire a qualified roofing contractor to further evaluate and repair this roof to ensure reliable roof performance.

Examples of observations and repair items noted during inspection include:

- Granule loss in shingles

- Organic growth on roof needs to be cleaned

- Exposed nail heads

- No drip edge has been installed

- Ridge cap shingles are beginning to crack

- Plumbing vents not secure

- Nail pops

- Shingle bond is failing in multiple areas

Chimneys

None noted

Skylights

None noted

Garage

Standards of Practice

General: SOP Note

The inspection of attached garages and carports includes their framing, siding, roof, doors, windows, and installed electrical/mechanical systems pertaining to the operation of the home.

(1) The inspector will:

• Inspect the condition and function of the overhead garage doors and associated hardware.

• Test the function of the garage door openers, their auto-reverse systems and secondary entrapment devices (photoelectric and edge sensors) when present.

• Inspect the condition and installation of any pedestrian doors.

• Inspect fire separation between the house and garage when applicable.

• Report as a fire hazard the presence of any ignition source (gas and electric water heaters, electrical receptacles, electronic air cleaners, motors of installed appliances, etc.) that is within eighteen inches of the garage floor.

• Describe any deficiencies of these systems or components.

(2) The inspector is not required to:

• Determine whether or not a solid core pedestrian door that is not labeled is fire rated.

• Verify the functionality of garage door opener remote controls.

• Move vehicles or personal property.

• Operate any equipment unless otherwise addressed in the SOP.

General Comments

Attached

Automatic Garage Opener: Present

Garage Door Type: Metal

Garage Slab: Concrete

Garage Attic: Present - Inspected

Most Common Observations: Garage GFCI Note, Breach in Fire Separation (Multiple)

Common Observations: Overhead Door (Metal, Dented), Bollard Needed

Common Garage Limitations: Storage in Garage Note

Storage in the garage inhibited the view of most of the garage and limited visual inspection of this space.

Common Notes: Heat Sensors

Garage receptacles should be GFCI protected. If you place a refrigerator or freezer in the garage I recommend installing a GFCI receptacle that emits an audible alarm if it has been tripped. This will help alert you to the fact that your appliances are not powered and will help prevent unwanted food loss.

Multiple unprotected openings were found in the garage wall fire separation. This should be repaired to complete the fire separation. Standards recommend complete sheetrock walls and ceilings between the garage and all habitable space. Use type C or type X sheetrock as needed to complete large openings in the fire separation and seal up all small gaps in the walls with fire stop caulking or drywall mud as needed.

A bollard is recommended in the garage to protect the furnace and water heater from physical damage from cars. A bollard is a metal post that acts to protect appliances in the garage such as furnaces and water heaters, from physical damage that could be caused by a car. This is a safety hazard that should be corrected as soon as possible. Hire a qualified contractor to repair.

Modern standards require that a heat sensor be installed in new garages that are attached or located under new or existing dwellings.

R314.2.3 New attached garages. A heat detector or heat alarm rated for the ambient outdoor temperatures and humidity shall be installed in new garages that are attached to or located under new and existing dwellings. Heat detectors and heat alarms shall be installed in a central location and in accordance with the manufacturer's instructions.

Receptacles and Fixtures

Inspection Method: Random Testing

Electric Receptacles: Three wire receptacles

COMMON GFCI COMMENTS: GFCI Working

This video shows the receptacles at this location were GFCI protected and operating as intended.

Electrical

Standards of Practice

General: Sop Note

The inspection of the electrical system includes the service drop through the main panel; subpanels including feeders; branch circuits, connected devices, and lighting fixtures.

(1) The inspector will:

(a) Describe in the report the type of primary service, whether overhead or underground, voltage, amperage, over-current protection devices (fuses or breakers) and the type of branch wiring used.

(b) Report

(i) The existence of a connected service-grounding conductor and service-grounding electrode when same can be determined.

(ii) When no connection to a service grounding electrode can be confirmed.

(c) Inspect the main and branch circuit conductors for proper over-current protection and condition by visual observation after removal of the readily accessible main and subelectric panel cover(s).

(d) Report, if present, solid conductor aluminum branch circuits. Include a statement in the report that solid conductor aluminum wiring may be hazardous and a licensed electrician should inspect the system to ensure it's safe.

(e) Verify

(i) The operation of a representative number of accessible switches, receptacles and light fixtures.

(ii) The grounding and polarity of a representative number of receptacles; particularly in close proximity to plumbing fixtures or at the exterior.

(iii) Ground fault circuit interrupter (GFCI) protection and arc-fault circuit interrupter (AFCI) protection where required.

(f) Report the location of any inoperative or missing GFCI and/or AFCI devices when they are recommended by industry standards.

(g) Advise clients that homes without ground fault protection should have GFCI devices installed where recommended by industry standards.

(h) Report on any circuit breaker panel or subpanel known within the home inspection profession to have safety concerns.

(i) Describe any deficiencies of these systems or components.

(2) The inspector is not required to:

(a) Insert any tool, probe or testing device into the main or subpanels.

(b) Activate electrical systems or branch circuits that are not energized.

(c) Operate circuit breakers, service disconnects or remove fuses.

(d) Inspect ancillary systems, including but not limited to:

(i) Timers.

(ii) Security systems.

(iii) Low voltage relays.

(iv) Smoke/heat detectors.

(v) Antennas.

(vi) Intercoms.

(vii) Electrical deicing tapes.

(viii) Lawn sprinkler wiring.

(ix) Swimming pool or spa wiring.

(x) Central vacuum systems.

(xi) Electrical equipment that's not readily accessible.

(e) Dismantle any electrical device or control, except for the removal of the deadfront covers from the main service panel and subpanels.

(f) Move any objects, furniture, or appliances to gain access to any electrical component.

(g) Test every switch, receptacle, and fixture.

(h) Remove switch and receptacle cover plates.

(i) Verify the continuity of connected service ground(s).

Electric Service

Electrical Grounding System

Present - Could Not Confirm

During a home inspection, the visible components of the electrical system’s grounding system are thoroughly examined. A properly functioning grounding system is crucial for safely dissipating electrical surges, particularly during lightning strikes. However, it’s important to note that the effectiveness of the entire grounding system cannot be definitively verified during a home inspection. Many components of the system are concealed within walls and underground, making them inaccessible for testing. Additionally, there are no practical, non-invasive tests available to assess the overall performance of a grounding system.

Electrical Bonding System

Electrical Grounding and Bonding : A Simplified Explanation

Present - Could Not Confirm, Bonding Noted on Water Pipes

During the inspection, a visual assessment of the electrical system’s bonding was conducted. It’s important to note that while a visual inspection can identify potential bonding issues, it cannot definitively verify the overall effectiveness of the bonding system.

All metallic systems within a building, including plumbing, HVAC, and structural steel, should be bonded together and connected to the electrical grounding system. This bonding serves two primary purposes:

- Static Charge Dissipation: Bonding provides a path for static charges to safely dissipate into the earth, preventing the buildup of potentially harmful static electricity.

- Fault Current Path: In the event of a fault, bonding ensures that current can flow safely to the ground, potentially tripping a circuit breaker and mitigating the risk of electric shock or fire.

Common Observations: Bonding (Bonding Not Found - Gas Pipe)

Imagine your home's electrical system as a delicate network. To keep it safe and functional, two essential safety measures are employed: grounding and bonding.

Grounding:

Think of grounding as a safety net. It's a direct connection between your electrical system and the earth. If a dangerous surge of electricity, like lightning, strikes your home, the grounding system provides a path for this excess energy to flow harmlessly into the earth.

Bonding:

Bonding, on the other hand, is like linking arms with your friends. It connects all the metal components in your home, such as plumbing pipes and metal conduit, to the grounding system. This ensures that if a stray electrical current were to accidentally touch one of these metal components, it would be safely diverted to the ground.

Why are both important?

Both grounding and bonding work together to protect your home and its occupants from electrical hazards. By understanding these concepts, you can appreciate the importance of regular electrical inspections and maintenance to ensure your home's safety.

The equipment grounding conductor is missing / not found at the gas pipe. Have the entire grounding and bonding system checked to verify proper installation. This is an important safety system that ensures reliable discharge of fault current on metal components.

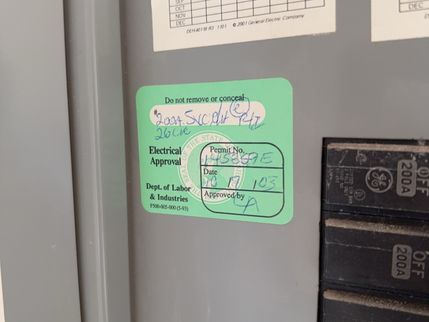

Electric Service Permits Found

Service Equipment

Main Electric Panel Location: Laundry

Panel Manufacturer: GE

Main Panel Amperage: 200 amps

Electric Service Amperage: 200 amps

Voltage: 120/240

Service Entrance (SE) conductor Size: Aluminum, 4/0, 200 amps

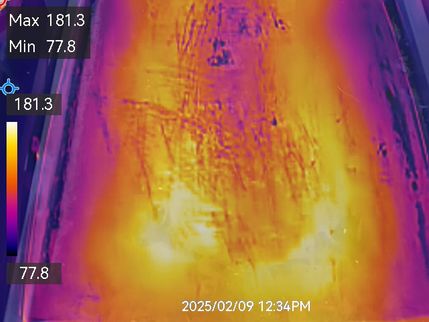

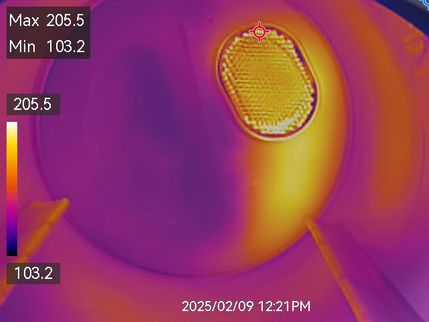

Thermal Images: Note

Notes and Limitations: Modern AFCI and GFCI Note, Surge Protection Recommended, Panel Full

AFCI (arc fault protection) is now required on all branch circuits supplying outlets or devices installed in residential dwelling unit kitchens, family rooms, dining rooms, living rooms, parlors, libraries, dens, bedrooms, sunrooms, recreation rooms, closets, hallways, laundry areas, and similar rooms and areas. The goal of this protection is to reduce risks of electrical fires. Consult with a licensed electrician about improving circuit protection as desired. Please note that if you add or replace receptacle outlets to the existing system, they should comply with modern AFCI standards.

The electric panel is full, there is no more room on the bus bar to add breakers. You may be able to use tandem breakers if you want to expand the panel, but this could be tricky or impossible to also follow modern requirements for AFCI's. This could make this panel obsolete or force the need for a sub-panel depending on plans for future wiring here.

Branch Wiring

Wire Material: Copper, Multi-strand Copper, Multi-strand Aluminum

Wiring Method: Non-metallic sheathed cable

Receptacles and Fixtures

Inspection Method: Random Testing

Electric Receptacles: Three wire receptacles

Dimmer Switches: Thermal Images

COMMON GFCI COMMENTS: GFCI - Testing Procedure Note

During the inspection, all accessible Ground Fault Circuit Interrupter (GFCI) outlets were tested. GFCIs are crucial safety devices that can significantly reduce the risk of electric shock. They are commonly found in bathrooms, kitchens, and exterior outlets.

It's important to be familiar with the location of GFCI reset buttons in your home. If a GFCI trips, it can disable an entire circuit until the reset button is pressed. To avoid unintentionally tripping GFCIs that are not readily accessible, it's best to leave them untested. Reset buttons can sometimes be hidden behind stored items, and accidentally tripping them can inconvenience homeowners.

Please note that GFCIs are mechanical devices, and like any mechanical device, they can fail. It's possible that some GFCIs may not function properly during testing and may require replacement.

Smoke and Carbon Monoxide Alarm Systems

CO Alarms Noted: On Main Floor

CO Alarms: Present

Carbon monoxide alarms were found and noted during inspection. Be sure to check these regularly. The standard is 1/ floor and 1 outside all sleeping areas.

Carbon monoxide alarms are crucial safety devices for homes with fuel-burning appliances. In Washington State, it's now mandatory to install UL 2034-approved carbon monoxide alarms in all homes and condos being sold. Here's what you need to know:

Placement:

- Install at least one alarm outside of sleeping areas.

- Place one alarm on each floor of the house.

Type:

- Hardwired alarms with battery backup are recommended but follow the manufacturer's instructions for installation.

Importance:

- Carbon monoxide is a deadly, odorless gas. Alarms can save lives.

Maintenance:

- Replace alarms every 6 years.

- Alarms will begin to "yellow" naturally and is an indication that replacement is recommended.

By following these guidelines, you can significantly reduce the risk of carbon monoxide poisoning and protect your family.

CO Test: Test Results

Smoke Alarms Noted: On Main Floor, In All Bedrooms

Smoke Alarms: Present

Smoke alarms are essential safety devices that can significantly reduce the risk of fire-related injuries and fatalities. To ensure optimal performance, it's recommended to:

Update Alarms Regularly:

- Replace smoke alarms every 10 years, as recommended by fire marshals.

Test Batteries:

- Test batteries twice a year.

Strategic Placement:

- Install smoke alarms in all bedrooms, hallways outside bedrooms, and on every floor of the home.

Choose the Right Technology:

- Opt for photoelectric smoke alarms, which are more effective at detecting smoldering fires and less prone to false alarms.

While a comprehensive evaluation of your smoke alarm system is beyond the scope of a standard home inspection, taking the initiative to understand and maintain your alarms is crucial. By following these guidelines, you can significantly enhance your home's safety.

Plumbing

Standards of Practice

General: SOP Note

An inspection of the plumbing system includes visible water supply lines; visible waste/soil and vent lines; fixtures and faucets; domestic hot water system and fuel source.

(1) The inspector will:

(a) Describe the visible water supply and distribution piping materials; drain, waste and vent materials; water-heating equipment.

(b) Report

(i) The presence and functionality of sump pumps/waste ejector pumps when visible or confirm the float switch activates the pump when the sump is dry.

(ii) The presence and location of a main water shutoff valve and/or fuel shutoff valve(s), or report that they were not found.

(iii) The presence of the temperature and pressure relief (TPR) valve and associated piping.

(iv) Whether or not the water temperature was tested and state that the generally accepted safe water temperature is one hundred twenty degrees Fahrenheit.

(c) Inspect the condition of accessible and visible water supply pipes, drain/waste plumbing and the domestic hot water system when possible.

(d) Operate fixtures in order to observe functional flow.

(e) Check for functional drainage from fixtures.

(f) Describe any deficiencies of these systems or components in the inspection report.

(2) The inspector is not required to:

(a) Operate any valves, including faucets of freestanding or built-in appliances or fixtures, if the outlet end of the valve or faucet is connected or intended to be connected to an appliance.

(b) Inspect

(i) Any system that is shut down or winterized.

(ii) Any plumbing components not readily accessible.

(iii) Floor drains and exterior drain systems, including but not limited to, exterior stairwell drains and driveway drains.

(iv) Fire sprinkler systems.

(v) Water-conditioning equipment, including softeners and filter systems.

(vi) Private water supply systems.

(vii) Gas supply systems.

(viii) Interior components of exterior pumps or sealed sanitary waste lift systems.

(ix) Ancillary systems or components such as, but not limited to, those related to solar water heating and hot water circulation.

(c) Test

(i) Pressure or temperature/pressure relief valve.

(ii) Shower pans for leaks or use special equipment to test/scan shower or tub surrounds for moisture in surrounding substrate materials.

(d) Determine

(i) The potability of any water supply whether public or private.

(ii) The condition and operation of water wells and related pressure tanks and pumps.

(iii) The quantity of water from on-site water supplies.

(iv) The quality or the condition and operation of on-site sewage disposal systems such as waste ejector pumps, cesspools, septic tanks, drain fields, related underground piping, conduit, cisterns, and related equipment.

(e) Ignite pilot lights.

Water Meter

The water meter was located underneath bushes on the street side of the house. This restricted the ability to inspect the water meter I recommend cutting back the bushes and verifying that the water meter is Not buried in soil and is easily accessible.

Verify that no water is running inside the house and then inspect the meter. If the meter is spinning with the water off inside the house, this is often an indicator that there is a leak in the plumbing distribution system. If you observe that the meter is spinning I recommend contacting a qualified plumber for further evaluation.

Water Pressure Tested During Inspection

Water Pressure: Test Results

Test Results

This shows the water pressure tested during inspection.

Water Pressure: 60 PSI

Exterior Hose Bibs

Operating

Operating Leaking

Leaking At Handle When Turned On

At Handle When Turned On

The leaky hose bibs around the home require repair or replacement - they leaked from the faucet handle when the faucet was turned on and under pressure. This often requires tightening the packing around the handle stem.

Location of Main Water Shut Off

Water Service Supply (From the Utility)

Pipe Material: Plastic

Water Supply: Public water

Water Pressure: 60 PSI

Pressure Reducing Valve: Present

Main Water Shut-off Location: Crawl space

Common Observations: Main Water Shut Off (Located in Crawl - Inconvenient Spot)

The main water shut off appears to be located in the crawl space. This is an inconvenient location. Inquire with the sellers if there is another shut off. If not, I would add a new shut off in a more accessible location.

Distribution Pipe (In the Home)

Pipe Insulation: Present

Supply Pipe Materials: Copper

Functional Flow: Average

Circulation Pump: Present - Set Timer As Desired

The water heating system has a circulation pump. These are designed to run the hot water in a loop to reduce wait times for hot water and conserve water. This appeared to be operating at the time of inspection. For improved efficiency these are often put on timers so the pump can be timed to go off at night and in the middle of the day. I noted a timer for the pump - I recommend setting as desired so the pump is operating during your likely hot water demand times.

Angle Stops Testing Note

Angle Stops Testing Note Ammeter Note

Ammeter Note

Angle stops are shut-off valves located beneath plumbing fixtures like sinks and toilets. They allow for the isolation of water supply to individual fixtures, making maintenance and repairs more convenient. Home inspectors typically do not test angle stops during inspections, as this can potentially lead to leaks and water damage.

Water Heater

Thermal Images: No Leaks

System Type: Tank

Manufacturer: Rheem

Water Temperature: 119 Degrees F

Size: 50 gal

Age: 2019

Energy Source: Gas

Temperature Pressure Relief Value: Present - Not Tested, Plastic Threads in TPRV

The Temperature and Pressure Relief Valve (TPRV) is a critical safety device for your water heater. It's designed to release excess pressure and prevent potential explosions if the thermostat fails. While it's important to have this valve, it's not recommended to test it yourself, as it could lead to unintended water discharge and potential damage.

Manufacturers typically recommend annual testing of the TPRV by a qualified professional. This ensures that the valve functions correctly and can effectively release pressure when needed.

By scheduling regular professional inspections and maintenance, you can maintain the safety and efficiency of your water heater and its components.

Straps : Present

The average life of these water heaters can vary widely between 8-20 years depending on water quality and maintenance schedule such as frequency of flushing the tank and replacing sacrificial anodes.

The CPVC piping has been connected directly to the temperature pressure relief valve (TPRV) with a threaded plastic fitting. The Plastic Pipe Fitters Association, PPFA, recommends a metal transition fitting rather than a threaded CPVC fitting as thermal expansion can damage the threaded fittings on the hot water side.

Sewer Scope

Waste Pipe and Discharge

Scope Findings

Pipe Material(s): Plastic

Plastic

No Anomalous Findings: No Anomalous Findings Public Sewer

No Anomalous Findings Public Sewer

Root Intrusion: None

None

Offset Joints: Minor

Minor

Sags: Minor

Minor

Debris/Grease: Minor

Minor

Cracks and Fractures: None

None

Holes: None

None

Video

Common Observations : Note

All measurements listed in this section are estimates only and should be used for informational purposes only.

The sewer lateral was accessed through a 3-inch ABS cleanout located in the crawlspace

Cold water was run throughout the inspection. The camera moved smoothly through the lateral and connected to the main at 59 feet.

Heating, Cooling, Fireplaces and Ventilation

Standards of Practice

General: SOP Note

The inspection of the heating system includes the fuel source; heating equipment; heating distribution; operating controls; flue pipes, chimneys and venting; auxiliary heating units.

(1) The inspector will:

(a) Describe the type of fuel, heating equipment, and heating distribution systems.

(b) Operate the system using normal readily accessible control devices.

(c) Open readily accessible access panels or covers provided by the manufacturer or installer, if readily detachable.

(d) Inspect

(i) The condition of normally operated controls and components of systems.

(ii) The condition and operation of furnaces, boilers, heat pumps, electrical central heating units and distribution systems.

(iii) Visible flue pipes and related components to ensure functional operation and proper clearance from combustibles.

(iv) Each habitable space in the home to determine whether or not there is a functioning heat source present.

(v) Spaces where fossil fuel burning heating devices are located to ensure there is air for combustion.

(vi) Electric baseboard and in-wall heaters to ensure they are functional.

(e) Report any evidence that indicates the possible presence of an underground storage tank.

(f) Describe any deficiencies of these systems or components.

(2) The inspector is not required to:

(a) Ignite pilot lights.

(b) Operate:

(i) Heating devices or systems that do not respond to normal controls or have been shut down.

(ii) Any heating system when circumstances are not conducive to safe operation or when doing so will damage the equipment.

(c) Inspect or evaluate

(i) Heat exchangers concealed inside furnaces and boilers.

(ii) Any heating equipment that is not readily accessible.

(iii) The interior of chimneys and flues.

(iv) Installed heating system accessories, such as humidifiers, air purifiers, motorized dampers, heat reclaimers; solar heating systems; or concealed distribution systems.

(d) Remove covers or panels that are not readily accessible or removable.

(e) Dismantle any equipment, controls, or gauges except readily identifiable access covers designed to be removed by users.

(f) Evaluate whether the type of material used to insulate pipes, ducts, jackets and boilers is a health hazard.

(g) Determine:

(i) The capacity, adequacy, or efficiency of a heating system.

(ii) Determine adequacy of combustion air.

(h) Evaluate thermostats or controls other than to confirm that they actually turn a system on or off.

Heating System

Energy Source: Natural gas

Heating Method: Gas forced air furnace

The heat exchanger is a critical component of a gas furnace. It's a welded metal component that safely contains the combustion process, preventing harmful gases from entering the living space.

While heat exchangers typically last 15-20 years, they are not directly visible during a home inspection. It's important to be aware of their potential lifespan and consider scheduling professional maintenance to ensure their continued safety and efficiency.

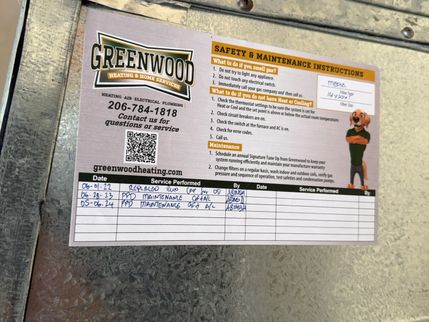

Manufacturer: Rheem

Capacity: 75,000 but’s

Age: 2015

Last Service Record: Recent Service Records Noted

Basic Servicing Recommended: Gas Forced Air

Gas Forced Air

Annual servicing of the gas forced air furnace is recommended for safe and reliable heat. The furnace was tested during inspection and was operational. The design life of these forced air furnaces is 15-20 years, although they can last much longer with routine maintenance. I recommend having it serviced and keeping it on an annual service schedule until updated. Furnace was operational at time of inspection.

Cooling Systems and Heat Pumps

Manufacturer: Goodman

System Type: Air Source

Size: 3 Tons

Energy Source: Electric

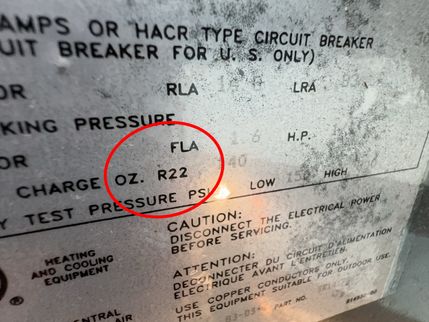

Age: 2004

Common Observations: R-22 Note, Ducted Heat Pump (Damaged Refrigerant Insulation)

The heat pump compressor system currently uses the R-22 type of refrigerant. On January 1, 2010, the Environmental Protection Agency placed a ban on the manufacture of new HVAC systems using R-22 refrigerant. General phase out of R-22 refrigerant is estimated to be complete by the year 2020. New, more efficient systems will utilize non-ozone-depleting refrigerants such as 410-A. Unfortunately, 410-A cannot be utilized in some older systems which previously used R-22 without making substantial and costly changes to the equipment. A loophole in current regulations allowed the manufacturer of units after 2010 that were delivered with no refrigerant. These units were designed for R-22 refrigerant to be installed in the field. Maintenance of this unit could pose unexpected challenges due to the growing scarcity of R-22 refrigerant and replacement of the unit may become necessary prior to the end of its expected life.

Common LImitations: Too Cold to Test AC

The air condition system and condensate control system could not be tested during inspection. Outdoor temperatures should exceed 65 degrees F for at least 24-hours or the air conditioning equipment can be damaged by testing. I recommend having this system serviced and inspected prior to the next cooling season.

Heating and Cooling Distribution Systems

Heat Source in Each Room: Present

Distribution Method: Forced Air / Ducts

Air Filters

Filtration Systems: Disposable

Your heating system has disposable air filters installed. These should be changed quarterly or more to ensure proper air flow at the furnace. Be sure to install the filters with the arrows pointing in the same direction as the air flow in the furnace.