Electrical Items

Jason Coe, New York State License #16000158429

Electrical System Summary

The electrical system was visually inspected and tested to the extent permitted by accessibility and safety considerations at the time of the inspection. A representative number of switches and receptacles were tested for proper function, grounding, and polarity. The electrical panel(s), visible wiring, and grounding systems were examined for condition, safety concerns, and general compliance with modern standards. The following summarizes our findings of the buildings HVAC system:

Electrical Items

Moderate Repairs

- ES-1 Electric Service - Electric Service Equipment:

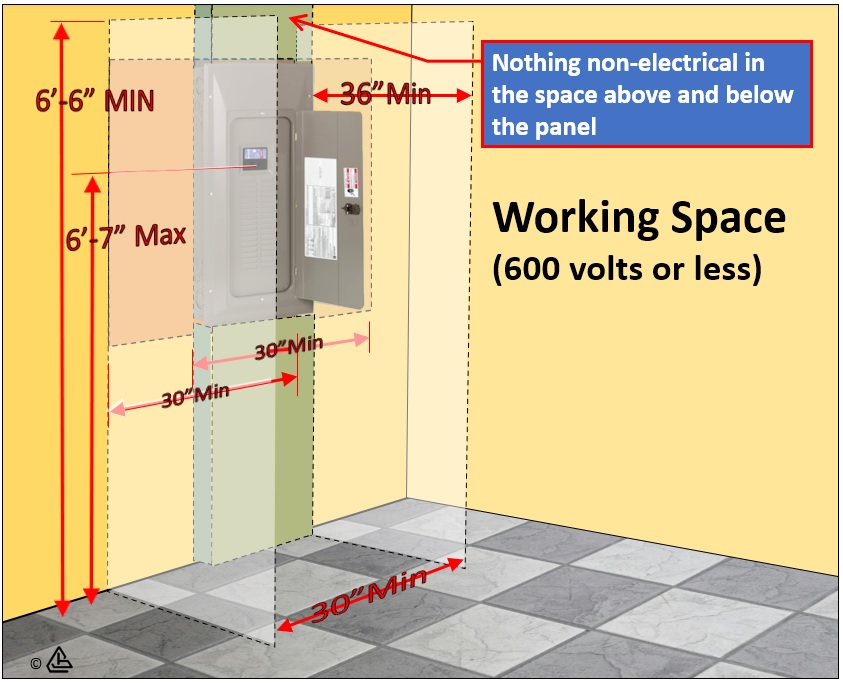

ELECTRIC PANEL WORKING CLEARANCE

An inadequate working clearance was noted in front of the electric panel. This presents a potential safety hazard, especially for people working on or inspecting the electric panel. A 30-inch wide and 36-inch deep unobstructed working clearance is recommended for improved safety. Panel was located over a fixed desk that would require leaning to remove the dead front cover.

⚡💡 - EDF-2 Electric Distribution and Finish - Smoke and Carbon Monoxide Alarm Systems:

A smoke alarm was noted in the utility room; however, it was not tested during the inspection. The detector appeared discolored and aged, and the utility area contains older equipment that may pose an increased fire risk. Smoke alarms typically have a service life of about 10 years, after which replacement is recommended.

Recommendation: Replace the smoke alarm in the utility room along with all other smoke detection devices to ensure reliable operation. Installing new, properly located smoke alarms (and carbon monoxide alarms where required) will enhance overall life-safety protection.

⚡💡 - SB1-2 Storage Buildings - Electrical:

Damaged junction boxes and conduit were observed on the exterior of the detached storage units. These components appear to be installed very close to grade, placing them at ongoing risk of mechanical damage from snow plows, shoveling, or routine ground maintenance.

Recommendation: Have a licensed electrician evaluate the damaged junction boxes and conduit, repair as needed, and consider relocating or elevating the electrical components to reduce the likelihood of future mechanical damage. Ensuring proper installation height and protection will improve safety and durability.

⚡💡

Repairs

- EDF-1 Electric Distribution and Finish - Branch Wiring:

OPEN ELECTRICAL JUNCTION BOXES

The open electrical junction boxes need to be covered for improved safety. This is as simple as installing a cover plate over the box to protect the wiring. Sometimes, an extension ring is needed if finishes are covering the box. Repair as needed for improved safety.

⚡💡

Deferred Maintenance

- ES-3 Electric Service - Subpanel:

SCREWS MISSING FOR ELECTRIC PANEL

The sub-panel is missing proper screws to secure the dead front cover. Install missing screws as needed for improved safety and please note that screws with sharp ends are not recommended.

⚡💡

Improve Or Upgrade Items

- Electric Distribution and Finish - Receptacles and Fixtures:

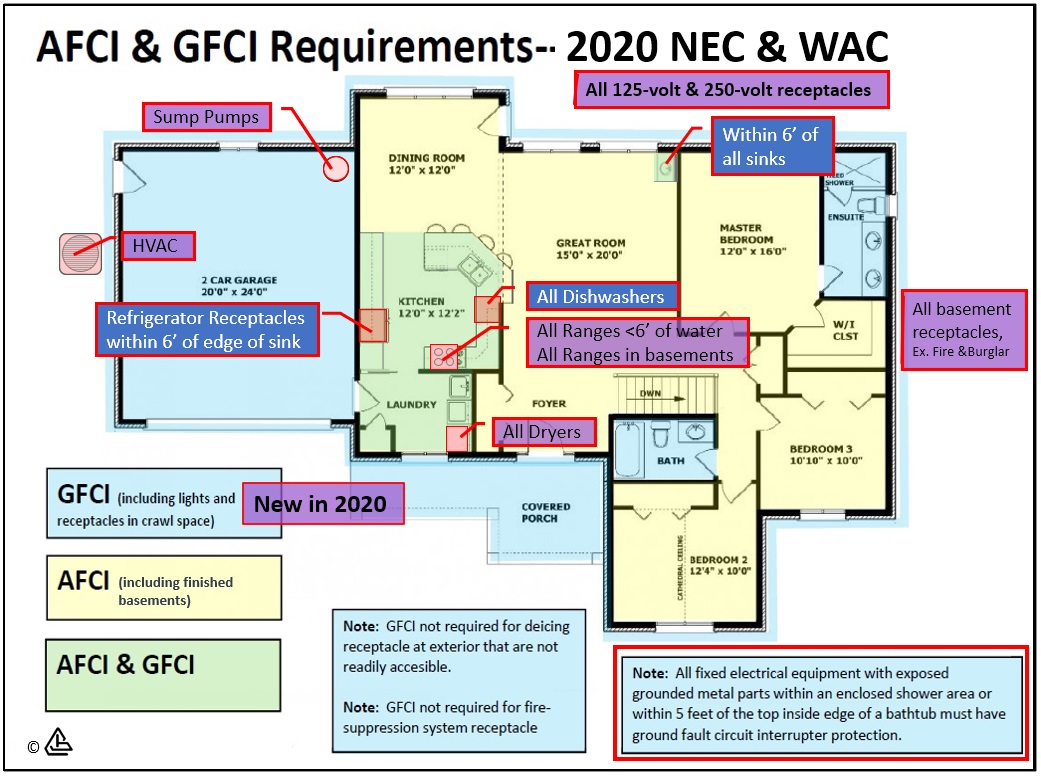

GFCI PROTECTION RECOMMENDED

Since the 1970s, requirements for GFCI (Ground Fault Circuit Interruption) protection have changed, and locations requiring GFCI protection continue to expand. It is common for older residential buildings to have some or even many electric receptacles that do not meet modern safety standards. GFCIs have proven successful at reducing electrocutions, and it seems likely that someday, every circuit, receptacle, and appliance in the building will require GFCI protection. The attached illustration shows where GFCI protection is required as of the date of this inspection. As a general best practice for safety, we always recommend bringing GFCI protection up to modern safety standards.

During inspection today, it was noted that GFCI protection is inconsistent with modern minimum standards receptacles and switches in the utility room

⚡💡

Limitations

- Utility Area - Electrical:

The receptacles in the utility area were selectively powered at the time of the inspection. The car wash equipment had been de-energized, and some receptacles appeared to share circuits with that equipment. As a result, not all receptacles could be tested for proper operation or GFCI protection. The receptacles that were energized appeared serviceable.

Recommendation: Once all circuits are fully energized, have the remaining receptacles tested for functionality and safety. Any deficiencies identified should be corrected by a qualified electrician.

⚡💡