Jason Coe, New York State License #16000158429

The Scope and Purpose of an Inspection

Purchasing property involves risk

The purpose of an inspection is to help reduce the risks associated with purchasing a property by providing a professional evaluation of its general condition. It's important to understand that an inspection is limited to a visual assessment and cannot eliminate all risks. Some properties naturally present more potential issues than others, which may be beyond the scope of the inspection. Our goal is to inform and educate you—not only about what we can observe, but also about the limitations of what may not be visible during the inspection. These subtleties can be difficult to convey fully in writing, which is why we highly recommend that clients attend the inspection whenever possible.

A inspection is not an insurance policy or warranty.

This report is not a substitute for, nor should it be interpreted as, a warranty or guarantee. Warranties are separate products that may be purchased through third-party providers who specialize in that type of coverage.

The purpose of this report is not to offer any assurance—express or implied—regarding the current or future performance or adequacy of the structure, its systems, or their components. It does not serve as a warranty of merchantability or fitness for a particular purpose and should not be relied upon as such.

Any opinions offered regarding the adequacy, capacity, or expected lifespan of components are general estimates based on typical performance of similar systems or materials. Actual results may vary significantly, and it is not uncommon for real-world performance to differ from these projections.

A inspection is visual only and not destructive.

The findings and descriptions in this report are based on a visual inspection of the property. Our assessment is limited to components that are readily accessible and visible, without the need for disassembly, damage, or alteration of the structure, and without moving furniture or personal belongings. Any areas that are concealed, obstructed, or inaccessible are excluded from the inspection. In some cases, specific systems or components are not tested if doing so could risk damage—such as bathtub overflow drains, which are typically not tested to avoid potential water damage to finished areas. This inspection is non-invasive and non-destructive by nature, which places inherent limitations on its scope.

This is not an inspection for code compliance.

This inspection and report are not intended to determine compliance with local, state, or federal building codes. Code compliance is typically assessed by municipal inspectors during the construction phase, when framing and other structural elements are fully exposed and accessible. In contrast, inspections of finished structures are limited, as framing and other components are concealed. It’s also important to note that building codes are updated regularly—typically every three years—across various disciplines. Municipalities adopt and implement these updates on their own schedules. As a result, nearly all homes fall out of full code compliance over time. However, there is generally no requirement to bring older homes up to current code unless major renovations are undertaken.

This is just our opinion.

Construction methods and standards can vary widely—there is no single way to construct a building or install a system. The observations in this report reflect the professional judgment of the inspector. It's normal for other inspectors or contractors to have differing opinions. We encourage you to seek additional input from other qualified professionals if you wish. This report is intended only as a general guide to help the client make their own evaluation of the overall condition of the property, and is not intended to reflect the value of the premises, nor make any representation as to the advisability of sale/purchase.

The scope of this inspection

This inspection will cover the following systems: exterior, roof, structure, drainage, foundation, attic, interior, plumbing, electrical, and heating. The evaluation is based on limited observations that are primarily visual and non-invasive. No disassembly of equipment, opening of walls, moving of furniture, appliances or stored items, or excavation was performed. It is not intended to be a technically exhaustive assessment.

Photographic Documentation

Photographic documentation is included throughout the report, accompanied by written narratives to help convey key information. The photos are representative of conditions observed during the inspection but may not capture every instance of those conditions present on the property.

Your expectations

The primary goal of an inspection is to help ensure your expectations align with the condition of the property you are planning to buy, sell or maintain. Our role is to assist in this process by identifying and documenting visible observations during the inspection. However, this should not be mistaken for a technically exhaustive evaluation intended to uncover every possible defect. While more in-depth inspections are available, they are typically cost-prohibitive for most buyers or sellers.

Statement of Confidentiality

This Confidential Inspection Report is subject to the terms, conditions, and disclaimers of the contract. This report is only valid as of the date and time it was conducted and may be relied upon by the contracted parties. Each report section herein contains a listing of deficiencies observed at the time of inspection and a classification of the type and degree of each deficiency.

Statement of Limitations

All components and conditions which by the nature of their location are concealed, camouflaged or difficult to inspect are excluded from the report. The inspection is performed in compliance with the current versions of the following Standards of Practice as applicable to the property:

New York State Standards of Practice for Home Inspectors (NYS SOP), a copy of which is available at the following website: NYS Standards of Practice

InterNACHI Home Inspections Standards of Practice, a copy of which is available at the following website: InterNACHI SOP

Certified Commercial Property Inspectors Association Standards of Practice, a copy of which is available at the following website: CCPIA SOP

Systems and conditions which are not within the scope of the inspection include, but are not limited to: formaldehyde, lead paint, asbestos, mold or methamphetamine contamination, toxic or flammable materials, and other environmental hazards; pest infestation, playground equipment, efficiency measurement of insulation or heating and cooling equipment, internal or underground drainage or plumbing, any systems which are shut down or otherwise secured; water wells (water quality and quantity) zoning ordinances; intercoms; security systems; heat sensors; cosmetics or building code conformity. Any general comments about these systems and conditions are informational only and do not represent an inspection.

Statement of Non-Collusion

We hereby certify that this inspection report has been prepared independently and without any collusion, influence, or involvement from any third party with a financial interest in the sale, purchase, or financing of the property. No party has offered, requested, or received any form of compensation, inducement, or special consideration that would compromise the objectivity, accuracy, or impartiality of this inspection.

This report reflects the unbiased findings and professional judgment of the inspector, based solely on the conditions observed at the time of the inspection.

Statement of Liability

A thorough effort was made to identify all visible defects on your behalf; however, in the event of an oversight, the maximum liability shall be limited to the amount of the inspection fee paid. Any disputes or disagreements arising from this inspection or report shall be resolved through binding, non-appealable arbitration, conducted by the American Arbitration Association in accordance with its then-current Construction Industry Arbitration Rules, unless otherwise mutually agreed by the parties.

In the event of a claim, the client agrees to provide the inspection company with the opportunity to inspect the issue prior to any repairs being made. Failure to do so may result in the waiver of the claim. The client also agrees not to alter, repair, or remove any conditions or items that may serve as evidence in relation to the complaint, except in the case of an emergency.

Your participation is requested.

We strongly encourage our clients to be present during the inspection. A written report cannot fully capture all the insights and information that can be communicated through shared, real-time visual observations of the property's condition.

Authorizing Agent.

Inspected by: Jason Coe, State of New York License #: 16000158429.

Inspector Jason Coe, Duly Authorized agent of JBC Home Inspections, LLC.

How to Read This Report

Getting the Information to You

This report is intended to present important technical information in a format that is clear and accessible to all readers. If you're short on time, the "Summary Page” provides a quick overview of key findings to support prompt decision-making. However, we strongly recommend reviewing the full Report, which includes detailed descriptions, digital photos, captions, diagrams, videos, and links to additional resources for a more comprehensive understanding.

The most effective way to access the full depth of information in this report is by reading it online. This format allows you to explore and expand your understanding of the property. You’ll notice certain words or phrases highlighted in blue and underlined—clicking on these links will take you to additional resources and further details.

This report can also be saved as a PDF file and printed on paper if preferred.

Key Definitions

Serviceable – At the time of inspection, the component or system was observed to be performing its intended function without any visible evidence of significant defect, damage, or unsafe condition. “Serviceable” does not imply new condition or guarantee continued performance, nor does it serve as a warranty. The designation is based on a limited visual inspection and is not a prediction of future reliability.

Oil Canning – A visible waviness or buckling effect in flat or slightly curved metal surfaces, often seen in roofing, siding, or metal panels. It is usually caused by thermal expansion, improper installation, uneven fastening, or residual stresses in the metal during manufacturing. Oil canning is generally a cosmetic condition and does not necessarily indicate structural failure, but in some cases it may be a sign of installation or fastening issues that could warrant further evaluation.

Spalling - The deterioration and breakdown of a concrete surface, characterized by cracking, chipping, or peeling away. This can expose the underlying aggregate or even the reinforcement bars within the concrete. Spalling can be caused by a variety of factors, including moisture, temperature changes, and corrosion of the steel reinforcement.

Efflorescence - the process where water carries dissolved mineral salts to the surface of porous building materials such as concrete and masonry. This process leaves behind a white, powdery, or crystalline residue after the water evaporates. This generally signifies that a moisture problem is present and can lead to more significant structural problems, mold growth or other damage if not addressed.

Swale - a shallow, vegetated channel or depression designed to collect, convey, and filter stormwater runoff by slowing its velocity and allowing it to infiltrate the soil, thereby reducing erosion and pollution.

Qualified - For the purposes of this inspection report, the term qualified in reference to contractors refers to an individual or firm that is properly trained, experienced, licensed where required, and insured to perform evaluation, repair, or replacement of the specific system or component referenced. Selection, verification of credentials, and oversight of any contractor are the responsibility of the client.

Chapters and Sections

This report is organized into chapters that divide the building into logical inspection areas. Each chapter is further broken down into sections focused on specific systems or components of the building. You can easily navigate between chapters using the buttons located in the left-side margin.

Most sections include descriptive information in black text. Observation narratives, highlighted in colored boxes, are provided when a system or component is found to have significant deficiencies or when we want to offer additional useful details about the system or the scope of our inspection. If a system or component is considered to be in satisfactory or serviceable condition, that section may have no observation comments and may simply state “tested” or “inspected.”

Observation Labels

All narrative observations are color-coded, numbered, and labeled to help you easily locate, reference, and understand the severity of each issue. The observation colors and labels used in this report are:

Summary Page

The Summary Page offers a bulleted outline of the key observations made during the inspection. While this summary can be a helpful reference, it is not a substitute for reading the complete inspection report. To gain a full understanding of the findings, the entire report should be reviewed, as the Summary Page does not contain supporting photographs or their associated captions.

Summary

Major Concerns

- LG-2 Landscaping/ Grounds - Drainage, Site, and Grading:

One area of the foundation appeared to be missing or deteriorated near the downspout discharge location. Water runoff in this area may be contributing to the deterioration. In addition, more-than-typical stepped cracking was observed in the exterior masonry adjacent to this section of the foundation. These conditions may indicate localized settlement, moisture-related deterioration, or long-term drainage issues.

Recommendation: Have a qualified foundation or masonry contractor further evaluate the damaged foundation area and stepped cracking. Repairs may be needed to restore structural integrity and prevent further deterioration. Improving drainage at the downspout discharge is also recommended to reduce moisture exposure to the foundation.

- A-2 Attic - Piping:

The propane piping in the attic was observed to be leaking at the time of the inspection. Any leak in propane gas piping represents a significant safety hazard, as propane is highly flammable and can accumulate in enclosed spaces, increasing the risk of fire or explosion.

Recommendation: Have a licensed propane service technician or qualified plumber immediately evaluate and repair the leak. Do not operate any gas-fueled equipment connected to this system until the piping has been properly repaired and tested for safe operation.

🔥❄️🚽🚿🚰

Moderate Repairs

- E-2 Exterior - Siding and Trim:

MASONRY SIDING REPAIRS

A number of repairs are needed to the masonry siding system. Examples of specific observations noted during inspection include:

- Cracking masonry was noted

- Step cracking was observed in the masonry

- Spalling masonry was noted

- Organic growth was noted on the masonry

- Damaged lintels were noted - repair is needed

Recommendation

Hire a qualified general contractor or masonry specialist to further evaluate and repair the masonry siding as needed.

✒️

- Please note that the conditions observed during inspection can indicate structural movement in the building.

- E-5 Exterior - Exterior Doors:

Extensive corrosion was noted at the exterior metal entry door. Significant rust can weaken the door structure, compromise weather resistance, and allow further deterioration if not addressed. Corrosion at this level often indicates long-term moisture exposure.

Recommendation: Have a qualified contractor evaluate the extent of the corrosion and determine whether repair or full door replacement is appropriate. Addressing the issue will help restore proper function, security, and weather protection.

- E-6 Exterior - Exterior Doors:

Damaged glass was observed in the sectional overhead door(s). Broken or cracked glazing can reduce the door’s integrity and pose a safety hazard.

Recommendation: Have a qualified door or glass contractor evaluate and replace the damaged glass to restore proper safety and function of the door system.

- E-9 Exterior - Fuel:

Although no leaks were noted at the propane tanks, the plastic protective sleeve covering the copper tubing was observed to be damaged and separating from the line. This sleeve protects the tubing from abrasion, corrosion, and physical damage where it enters or exits the equipment. A compromised sleeve may expose the copper line to unnecessary wear over time.

Recommendation: Have a qualified propane service provider or licensed plumber evaluate the damaged sleeve and replace or repair it as needed. Ensuring proper protection of the copper tubing will help maintain the safety and longevity of the propane supply system.

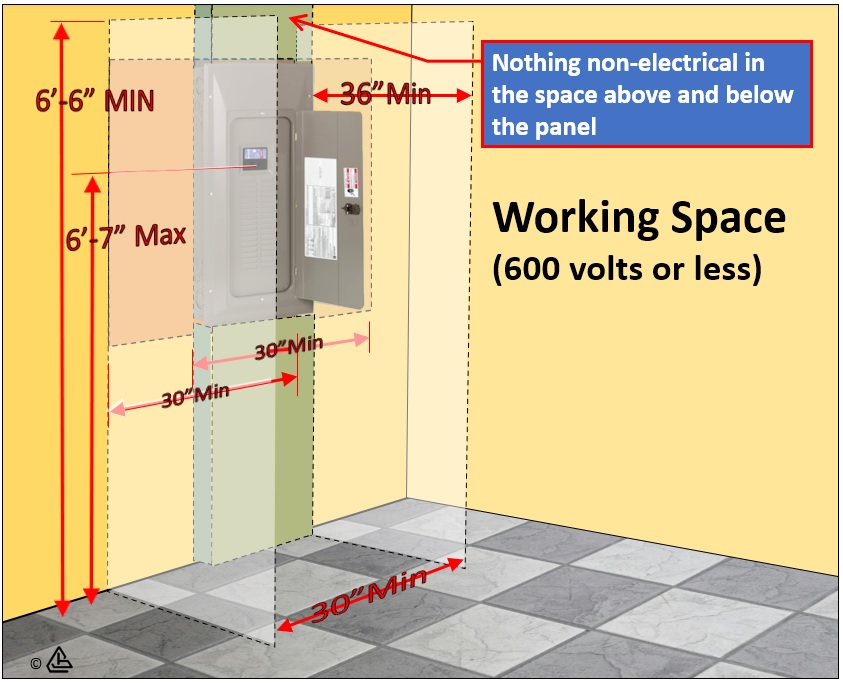

- ES-1 Electric Service - Electric Service Equipment:

ELECTRIC PANEL WORKING CLEARANCE

An inadequate working clearance was noted in front of the electric panel. This presents a potential safety hazard, especially for people working on or inspecting the electric panel. A 30-inch wide and 36-inch deep unobstructed working clearance is recommended for improved safety. Panel was located over a fixed desk that would require leaning to remove the dead front cover.

⚡💡 - EDF-2 Electric Distribution and Finish - Smoke and Carbon Monoxide Alarm Systems:

A smoke alarm was noted in the utility room; however, it was not tested during the inspection. The detector appeared discolored and aged, and the utility area contains older equipment that may pose an increased fire risk. Smoke alarms typically have a service life of about 10 years, after which replacement is recommended.

Recommendation: Replace the smoke alarm in the utility room along with all other smoke detection devices to ensure reliable operation. Installing new, properly located smoke alarms (and carbon monoxide alarms where required) will enhance overall life-safety protection.

⚡💡 - HCFV-1 Heating, Cooling, Fireplaces and Ventilation - Water Heating Systems:

A Raypak boiler equipped with an economizer was observed servicing the commercial car wash. An economizer captures waste heat from the boiler’s flue gases and uses it to preheat incoming water, improving system efficiency and reducing fuel consumption. This type of equipment is common in high-demand environments such as car washes, where substantial volumes of hot water are required.

The system could not be tested at the time of the inspection because utilities were off, and its operational condition could not be verified. Both the boiler and economizer units also appear to be original to the building and show rusting at the base, which may indicate age-related deterioration and potential end-of-life considerations.

Recommendation: Have a qualified boiler technician evaluate the boiler and economizer once utilities are restored to determine their operational status, assess the extent of corrosion, and provide recommendations for repair or replacement as needed.

🔥❄️🚽🚿🚰 - HCFV-2 Heating, Cooling, Fireplaces and Ventilation - Vents and Flues:

CORRODED B-VENT ABOVE THE ROOFLINE

The B-vent flue for the appliance was observed to be corroded above the roofline, indicating deterioration of the vent material. Corrosion at this location can compromise proper venting of combustion gases and may allow water intrusion or flue-gas leakage. This condition requires correction.

Recommendation: Have a qualified heating contractor further evaluate the flue and replace the corroded section as needed. Installing the proper vent cap design can help reduce future corrosion by minimizing water entry into the top of the vent pipe.

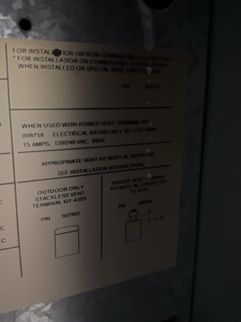

🔥❄️ - WH-1 Water Heaters - Water Heater:

The discharge tube for the water heater relief valve is installed too high off the ground. The discharge tube for the temperature and pressure relief (TPR) valve does not appear to meet standard installation guidelines. Discharge tubes should terminate by pointing downward to reduce scald hazards and should typically end 6 to 24 inches above the floor (UPC), although local requirements and manufacturer instructions may vary. Proper installation helps ensure safe operation in the event of a discharge.

A properly installed relief-valve discharge tube should:

- Terminate to an exterior location or an approved drain (when feasible)

- Slope downward continuously to prevent water from pooling inside the tube

- Be constructed of material with an inside diameter of at least 3/4 inch

- Discharge into a visible location so leaks or discharges can be observed

- Avoid threaded ends that might allow improper capping

- Not terminate into a drain pan

Recommendation: Have a licensed plumber further evaluate and correct the relief-valve discharge tube to ensure it meets current safety standards and manufacturer requirements.

🚽🚿🚰 - WH-3 Water Heaters - Water Temperature:

The base of the water heater was observed to be heavily rusted. Significant corrosion at the bottom of a water heater often indicates long-term moisture exposure and may suggest that the tank is nearing the end of its service life or may be at risk of leaking.

Recommendation: Have a licensed plumber evaluate the water heater to determine the extent of deterioration and recommend repair or replacement as needed. Replacement is often advised when rust is present at the tank base.

🚽🚿🚰 - SB1-2 Storage Buildings - Electrical:

Damaged junction boxes and conduit were observed on the exterior of the detached storage units. These components appear to be installed very close to grade, placing them at ongoing risk of mechanical damage from snow plows, shoveling, or routine ground maintenance.

Recommendation: Have a licensed electrician evaluate the damaged junction boxes and conduit, repair as needed, and consider relocating or elevating the electrical components to reduce the likelihood of future mechanical damage. Ensuring proper installation height and protection will improve safety and durability.

⚡💡

Repairs

- LG-3 Landscaping/ Grounds - Drainage, Site, and Grading:

DOWNSPOUTS DISCHARGE NEAR FOUNDATION

Several downspouts were observed discharging directly adjacent to the foundation. This condition can contribute to excessive moisture around the structure and may lead to foundation settlement, soil erosion, or concrete slab moisture problems over time. Proper water management is essential to protecting the foundation and reducing the risk of moisture intrusion.

Recommendation: Extend all downspouts so they discharge into a properly installed drainage system or direct water at least 5 feet away from the foundation. This will help minimize moisture-related issues and promote long-term foundation stability.

- LG-4 Landscaping/ Grounds - Driveways/Walkways/Flatwork/Patios:

The concrete aprons around the building were observed to have cracks. Cracking in exterior flatwork is common over time due to settlement, temperature changes, and normal wear, but wider or worsening cracks may allow moisture intrusion or lead to further deterioration.

Recommendation: Monitor the cracked areas over time and perform sealing or repairs as needed to prevent moisture penetration and reduce continued cracking. If the cracks widen, settle, or become a trip hazard, evaluation by a qualified concrete contractor is recommended.

- E-3 Exterior - Siding and Trim:

The paint on the masonry was observed to be peeling in several locations and is common due to normal weathering.

Recommendation: Monitor these areas and plan for scraping, surface preparation, and repainting as part of routine exterior maintenance. If peeling continues to worsen or if moisture intrusion is suspected, further evaluation by a qualified contractor may be warranted.

- E-4 Exterior - Siding and Trim:

SEAL UP HOLES IN SIDING

Holes were noted in the siding system that require sealing to prevent water and air infiltration and potential paths for insect or rodent entry. Seal and paint as needed to block these openings.

- E-7 Exterior - Exterior Doors:

EXTERIOR ENTRY DOOR NOT LATCHING

The exterior entry door is not latching well when closed and requires adjustment to make sure it stays shut without the dead bolt.

- EDF-1 Electric Distribution and Finish - Branch Wiring:

OPEN ELECTRICAL JUNCTION BOXES

The open electrical junction boxes need to be covered for improved safety. This is as simple as installing a cover plate over the box to protect the wiring. Sometimes, an extension ring is needed if finishes are covering the box. Repair as needed for improved safety.

⚡💡 - P-2 Plumbing - Waste Pipe and Discharge:

No cleanout was noted for the sewer line. It is possible there is an accessible cleanout for the sewer line that is concealed behind finishes or belongings. Sewer line cleanouts are necessary for clearing drain obstructions and for inspecting the building sewer with a sewer camera. While code allows cleanouts to be in crawl spaces, a preferred method is to extend them to an area that is more readily accessible. Underfloor cleanouts are required to be no farther than 20 ft. from the access opening, with a 30 in. wide, 18 in. high path from the access to the cleanout. When those conditions cannot be met, the cleanout must be extended to the exterior. Recommend installation of an adequate accessible cleanout as by a qualified plumbing contractor.

🚽🚿🚰 - SB1-3 Storage Buildings - Siding and Trim:

The foam inserts at the eaves were observed to be coming loose in several locations. These inserts help prevent wind-driven rain, snow, debris, and pests from entering the roof panel corrugations while still allowing for proper ventilation. Loose or missing inserts can reduce weather protection and may allow moisture or small animals to infiltrate the roof assembly.

Recommendation: Have a qualified contractor resecure or replace the loose foam inserts to ensure proper sealing at the eaves. This will help maintain weather resistance and reduce the potential for moisture intrusion or pest entry.

- SB1-4 Storage Buildings - Siding and Trim:

Mechanical damage and denting were noted in several sections of the metal siding. These dents appear consistent with impact or contact damage and are generally cosmetic; however, in some cases, deformation can affect panel alignment or weather protection.

Recommendation: Monitor the affected areas and repair or replace damaged panels as needed, particularly if dents worsen, compromise weather-resistance, or contribute to water intrusion. A contractor familiar with metal siding systems can further evaluate and advise on appropriate corrective measures.

Deferred Maintenance

- E-8 Exterior - Exterior Doors:

Weather stripping on exterior door is missing or damaged.

Recommendation: Recommend replacing weather stripping to improve building thermal performance.

- RCG-1 Roof, Chimney and Gutters - Gutters, Downspouts, and Drip Edges:

Downspout extensions are missing and/or not long enough to carry water runoff away from the building foundation. Downspout extensions should be at 3 to 6 feet long, depending on the slope of the yard. The longer the extensions, the better it will protect the building.

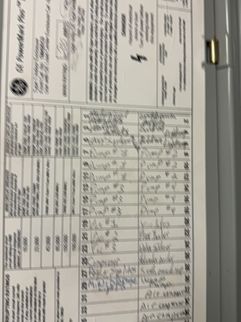

- ES-3 Electric Service - Subpanel:

SCREWS MISSING FOR ELECTRIC PANEL

The sub-panel is missing proper screws to secure the dead front cover. Install missing screws as needed for improved safety and please note that screws with sharp ends are not recommended.

⚡💡 - WH-2 Water Heaters - Water Heater:

OLD WATER HEATER

This water heater is past its typical design life. Replacement is recommended for improved reliability as this unit could fail at any point. The average life of these water heaters is 8-20 years. The service life of a water heater will depend on a variety of factors such as water quality and regular scheduled maintenance such as flushing the tank and replacing sacrificial anodes.

🚽🚿🚰

Cosmetic

- SB1-5 Storage Buildings - Siding and Trim:

Localized staining and streaking were observed on the metal siding. Although this type of staining is common with metal-panel construction—often resulting from weather runoff, oxidation, or normal age-related wear—it may also indicate areas where moisture consistently drains or accumulates.

Recommended: This condition appears cosmetic. Cleaning and routine maintenance can help improve appearance. If staining continues to worsen or if corrosion becomes visible, consider further evaluation by a contractor familiar with metal siding systems to determine whether additional sealing or corrective measures are needed.

Sample Commercial Inspection Report

Landscaping/ Grounds

General Grounds Photos

Drainage, Site, and Grading

Driveways/Walkways/Flatwork/Patios

Retaining Walls

Fences

Exterior

Exterior Elevation Photos

Siding and Trim

Foundation

Exterior Hose Bib(s)

Exterior Electrical (General)

Soffits/ Fascia/ Eaves

Exterior Doors

Fuel

Electric Service

Electric Service

Electric Service Equipment

Subpanel

Generator Equipment

Electrical Bonding System

Inspection Details

Building Characteristics, Conditions and Limitations

Type of Building: Commercial, Car Wash

Approximate Square Footage: 2800

The approximate square footage listed here is listed as a courtesy and is based off of public records and disclosure. An evaluation of square footage of the buildings and property lines is beyond the scope of this inspection.

Approximate Year of Original Construction: 1998

Attending the Inspection: Seller

Occupancy: Unoccupied

Unoccupied

This building was vacant or unoccupied at the time of the inspection. Vacant buildings pose unique challenges, particularly with plumbing and electrical systems that have not been in regular use. While these systems can be tested during the inspection, a one-time test cannot fully replicate the effects of ongoing daily use, making it difficult to predict future performance.

For instance, a septic system may appear to function properly during the inspection but could fail once subjected to continuous use. Plumbing traps might seem fine initially but start leaking after a few days of regular use. Shower pans may only leak when someone is actively showering. Fixture seals can dry out and begin to leak when left unused. Sewer lines with root intrusion might allow limited water flow but clog once waste and toilet paper are introduced, with backups taking several days to appear.

Please understand that we do our best to identify signs of past or existing issues and provide a realistic, informed assessment of how these systems are likely to perform.

For the Purposes of This Report, the Front Door Faces: Northeast

Approximate temperature during the inspection: Below 32[F]

Weather during the inspection: Cloudy

Cloudy

Ground/Soil surface conditions: Snow-covered

Snow-covered

Utilities: On

On Off

Off Fuel

Fuel Propane

Propane Electric

Electric Water

Water Municipal

Municipal Sewage/ Disposal

Sewage/ Disposal Municipal Sewer

Municipal Sewer

The following utilities were noted to be off at the time of the visit:

✒️

- water

- electric (secondary panel)

Landscaping/ Grounds

General Grounds Photos

Drainage, Site, and Grading

Site Description/ Grading: Properly Sloped

Properly Sloped

The grading/hardscaping around the building appeared to be properly sloped at the time of the inspection. The soil, flatwork, and landscaping were sloped away from the foundation, which helps direct surface water away from the structure. The grading was considered serviceable at the time of the visit.

Recommendation: No immediate action is required. We recommend maintain proper grading and drainage to ensure continued protection of the foundation. Regrade areas as needed over time due to natural settling.

Downspout Discharge: Above grade

Above grade Next to Foundation

Next to Foundation

One area of the foundation appeared to be missing or deteriorated near the downspout discharge location. Water runoff in this area may be contributing to the deterioration. In addition, more-than-typical stepped cracking was observed in the exterior masonry adjacent to this section of the foundation. These conditions may indicate localized settlement, moisture-related deterioration, or long-term drainage issues.

Recommendation: Have a qualified foundation or masonry contractor further evaluate the damaged foundation area and stepped cracking. Repairs may be needed to restore structural integrity and prevent further deterioration. Improving drainage at the downspout discharge is also recommended to reduce moisture exposure to the foundation.

DOWNSPOUTS DISCHARGE NEAR FOUNDATION

Several downspouts were observed discharging directly adjacent to the foundation. This condition can contribute to excessive moisture around the structure and may lead to foundation settlement, soil erosion, or concrete slab moisture problems over time. Proper water management is essential to protecting the foundation and reducing the risk of moisture intrusion.

Recommendation: Extend all downspouts so they discharge into a properly installed drainage system or direct water at least 5 feet away from the foundation. This will help minimize moisture-related issues and promote long-term foundation stability.

Driveways/Walkways/Flatwork/Patios

Driveway: Concrete

Concrete Asphalt

Asphalt

Walkways: None noted

None noted

Patios: None noted

None noted

The concrete aprons around the building were observed to have cracks. Cracking in exterior flatwork is common over time due to settlement, temperature changes, and normal wear, but wider or worsening cracks may allow moisture intrusion or lead to further deterioration.

Recommendation: Monitor the cracked areas over time and perform sealing or repairs as needed to prevent moisture penetration and reduce continued cracking. If the cracks widen, settle, or become a trip hazard, evaluation by a qualified concrete contractor is recommended.

Retaining Walls

Retaining Wall Material: None Noted

None Noted

Fences

Type: None Noted

None Noted

Exterior

Siding and Trim

Siding Material: Concrete block

Concrete block Vinyl

Vinyl

Trim Material: Vinyl

Vinyl

MASONRY SIDING REPAIRS

A number of repairs are needed to the masonry siding system. Examples of specific observations noted during inspection include:

- Cracking masonry was noted

- Step cracking was observed in the masonry

- Spalling masonry was noted

- Organic growth was noted on the masonry

- Damaged lintels were noted - repair is needed

Recommendation

Hire a qualified general contractor or masonry specialist to further evaluate and repair the masonry siding as needed.

✒️

- Please note that the conditions observed during inspection can indicate structural movement in the building.

The paint on the masonry was observed to be peeling in several locations and is common due to normal weathering.

Recommendation: Monitor these areas and plan for scraping, surface preparation, and repainting as part of routine exterior maintenance. If peeling continues to worsen or if moisture intrusion is suspected, further evaluation by a qualified contractor may be warranted.

Foundation

Material: Slab on Grade

Slab on Grade

The foundation system appears to be a slab-on-grade or frost wall configuration. The foundation itself could not be fully observed, as it is located below grade and the structure does not include a basement or crawl space that would allow interior access. Evaluation is therefore limited to the visible portions of the exterior.

Recommendation: No action is required at this time. Continue to monitor exterior conditions and grading around the structure as part of routine maintenance.

Exterior Hose Bib(s)

Winterized - not tested

Winterized - not tested

WINTERIZED HOSE BIBS

The exterior hose bibs were winterized at the time of inspection and could not be tested. Inquire with the seller to see if they are generally operable and where the shut off is located.

Exterior Electrical (General)

Inspection Method: Tested All Accessible

Tested All Accessible

During the inspection, every effort is made to test and inspect all accessible electric receptacles and switches. In general, the scope of testing is directly related to access. Where personal belonging and furniture obstruct access to receptacles and fixtures, fewer of them can be reasonably tested during inspection. Deficiencies observed during the inspection visit are listed in this report. It should be anticipated that not all defects will be discovered and that some issues found may actually not be defects at all. Tools used to verify proper wiring and function can vary wildly in reliability/consistency. The kinds of tools that could be used to confidently analyze the system and its function cannot typically be done in the context of a Standard Inspection. We look for indications of issues, based on the age of the building, types of wiring systems used etc, as well as personal experience and by testing with a variety of common tools.

We attempted to test the exterior receptacles; however, the power to these receptacles was off at the time of the inspection. As a result, their functionality and GFCI protection could not be confirmed.

Recommendation: Once power is restored, have the exterior receptacles tested for proper operation and safety. If any issues are found, a qualified electrician should make the necessary repairs.

Soffits/ Fascia/ Eaves

Type and Materials: Vinyl

Vinyl

Soffits: Serviceable

Serviceable

Exterior Doors

Exterior Door Styles: Hollow Metal

Hollow Metal

Extensive corrosion was noted at the exterior metal entry door. Significant rust can weaken the door structure, compromise weather resistance, and allow further deterioration if not addressed. Corrosion at this level often indicates long-term moisture exposure.

Recommendation: Have a qualified contractor evaluate the extent of the corrosion and determine whether repair or full door replacement is appropriate. Addressing the issue will help restore proper function, security, and weather protection.

Damaged glass was observed in the sectional overhead door(s). Broken or cracked glazing can reduce the door’s integrity and pose a safety hazard.

Recommendation: Have a qualified door or glass contractor evaluate and replace the damaged glass to restore proper safety and function of the door system.

Fuel

Type: Propane

Propane

Gas Meter: None noted

None noted

Propane: Present

Present

Propane-Storage Type: Above ground tank

Above ground tank

Propane-Tank Location: East side of building

East side of building

Propane-Shutoff Location: At tank

At tank

Although no leaks were noted at the propane tanks, the plastic protective sleeve covering the copper tubing was observed to be damaged and separating from the line. This sleeve protects the tubing from abrasion, corrosion, and physical damage where it enters or exits the equipment. A compromised sleeve may expose the copper line to unnecessary wear over time.

Recommendation: Have a qualified propane service provider or licensed plumber evaluate the damaged sleeve and replace or repair it as needed. Ensuring proper protection of the copper tubing will help maintain the safety and longevity of the propane supply system.

Roof, Chimney and Gutters

Roofing

Method of Roof Inspection: Could not view - snow and ice

Could not view - snow and ice

SNOW AND ICE LIMITED ROOF INSPECTION

The roof was not fully visible during the inspection due to snow and ice cover. We recommend scheduling a follow-up inspection once the snow has cleared to properly assess the roof's condition.

Roof Style: Gable

Gable

Roof Covering Materials: Asphalt shingle

Asphalt shingle

Gutters, Downspouts, and Drip Edges

Gutter and Downspout Materials: Seamless Aluminum

Seamless Aluminum

Downspout extensions are missing and/or not long enough to carry water runoff away from the building foundation. Downspout extensions should be at 3 to 6 feet long, depending on the slope of the yard. The longer the extensions, the better it will protect the building.

Plumbing Vents

Type: None observed

None observed

Electric Service

Electric Service

Service Entrance: Below Ground

Below Ground

The electric service meter and lateral appeared serviceable. The electrical service supplying the building was observed to be a 3-phase system. Three-phase service is common in commercial and industrial facilities and is typically used to support larger mechanical loads, motor-driven equipment, and higher-capacity electrical systems.

No deficiencies were noted related to the service type. If upgrades, new equipment installations, or load changes are planned, consultation with a licensed electrician is recommended to confirm adequate capacity and compatibility.

Electric Service Equipment

Main Panel Amperage: 200 amps

200 amps

Main Electric Panel Location: Office

Office

ELECTRIC PANEL WORKING CLEARANCE

An inadequate working clearance was noted in front of the electric panel. This presents a potential safety hazard, especially for people working on or inspecting the electric panel. A 30-inch wide and 36-inch deep unobstructed working clearance is recommended for improved safety. Panel was located over a fixed desk that would require leaning to remove the dead front cover.

Subpanel

Sub Panel: Present

Present

Sub Panel Amperage: Listing not visible

Listing not visible

Sub Panel Location: Utility room

Utility room

Sub Panel Manufacturer: Eaton

Eaton

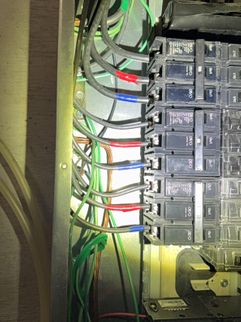

A 3-phase subpanel was observed, supplied by a 5-wire feeder consisting of three ungrounded (hot) conductors, one neutral conductor, and one equipment grounding conductor. This configuration is consistent with modern wiring practices for 3-phase distribution and allows for proper separation of neutrals and equipment grounds at the subpanel.

No deficiencies related to the feeder configuration were observed. If future electrical upgrades or added loads are planned, consultation with a licensed electrician is recommended to verify capacity and proper panel configuration.

Generator Equipment

None noted

None noted

Electric Distribution and Finish

Branch Wiring

Wire Material: Copper

Wiring Method: Non-metallic sheathed cable, Rigid conduit, Armored flexible cable

OPEN ELECTRICAL JUNCTION BOXES

The open electrical junction boxes need to be covered for improved safety. This is as simple as installing a cover plate over the box to protect the wiring. Sometimes, an extension ring is needed if finishes are covering the box. Repair as needed for improved safety.

Receptacles and Fixtures

Inspection Method: Tested All Accessible

During the inspection, every effort is made to test and inspect all accessible electric receptacles and switches. In general, the scope of testing is directly related to access. Where personal belonging and furniture obstruct access to receptacles and fixtures, fewer of them can be reasonably tested during inspection. Deficiencies observed during the inspection visit are listed in this report. It should be anticipated that not all defects will be discovered and that some issues found may actually not be defects at all. Tools used to verify proper wiring and function can vary wildly in reliability/consistency. The kinds of tools that could be used to confidently analyze the system and its function cannot typically be done in the context of a Standard Inspection. We look for indications of issues, based on the age of the building, types of wiring systems used etc, as well as personal experience and by testing with a variety of common tools.

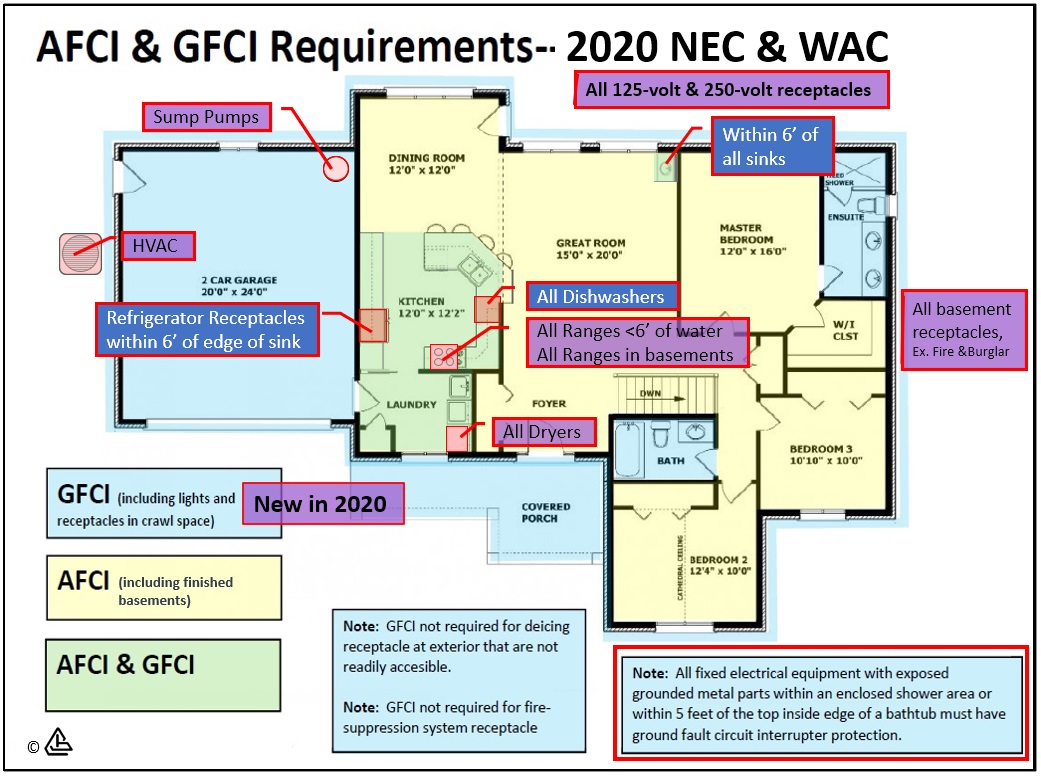

GFCI PROTECTION RECOMMENDED

Since the 1970s, requirements for GFCI (Ground Fault Circuit Interruption) protection have changed, and locations requiring GFCI protection continue to expand. It is common for older residential buildings to have some or even many electric receptacles that do not meet modern safety standards. GFCIs have proven successful at reducing electrocutions, and it seems likely that someday, every circuit, receptacle, and appliance in the building will require GFCI protection. The attached illustration shows where GFCI protection is required as of the date of this inspection. As a general best practice for safety, we always recommend bringing GFCI protection up to modern safety standards.

During inspection today, it was noted that GFCI protection is inconsistent with modern minimum standards receptacles and switches in the utility room

Smoke and Carbon Monoxide Alarm Systems

Smoke Alarms: Present

A smoke alarm was noted in the utility room; however, it was not tested during the inspection. The detector appeared discolored and aged, and the utility area contains older equipment that may pose an increased fire risk. Smoke alarms typically have a service life of about 10 years, after which replacement is recommended.

Recommendation: Replace the smoke alarm in the utility room along with all other smoke detection devices to ensure reliable operation. Installing new, properly located smoke alarms (and carbon monoxide alarms where required) will enhance overall life-safety protection.

Heating, Cooling, Fireplaces and Ventilation

Thermostat

Type: Analog

Analog Programmable

Programmable

The thermostat(s) was/were not connected at the time of the inspection which prevented us from testing the heating equipment.

Water Heating Systems

Energy Source: Propane

Propane

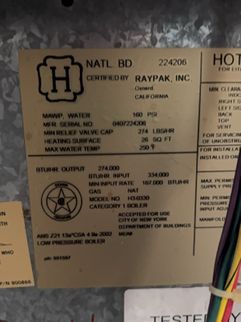

Manufacturer: Raypak

Raypak

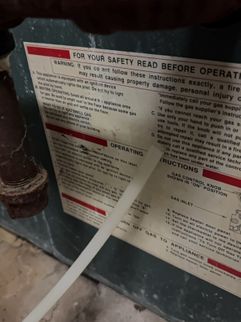

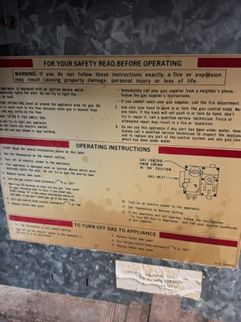

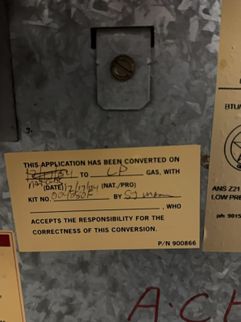

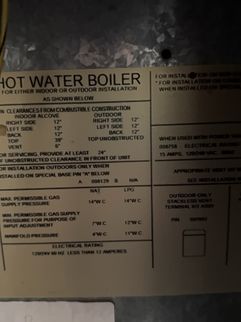

A Raypak boiler equipped with an economizer was observed servicing the commercial car wash. An economizer captures waste heat from the boiler’s flue gases and uses it to preheat incoming water, improving system efficiency and reducing fuel consumption. This type of equipment is common in high-demand environments such as car washes, where substantial volumes of hot water are required.

The system could not be tested at the time of the inspection because utilities were off, and its operational condition could not be verified. Both the boiler and economizer units also appear to be original to the building and show rusting at the base, which may indicate age-related deterioration and potential end-of-life considerations.

Recommendation: Have a qualified boiler technician evaluate the boiler and economizer once utilities are restored to determine their operational status, assess the extent of corrosion, and provide recommendations for repair or replacement as needed.

Vents and Flues

Natural draft

Natural draft

CORRODED B-VENT ABOVE THE ROOFLINE

The B-vent flue for the appliance was observed to be corroded above the roofline, indicating deterioration of the vent material. Corrosion at this location can compromise proper venting of combustion gases and may allow water intrusion or flue-gas leakage. This condition requires correction.

Recommendation: Have a qualified heating contractor further evaluate the flue and replace the corroded section as needed. Installing the proper vent cap design can help reduce future corrosion by minimizing water entry into the top of the vent pipe.

Plumbing

Water Meter

Location of Water Meter Note

Location of Water Meter Note

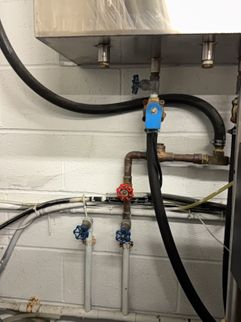

WATER METER LOCATION

This shows the location of the water meter in the utility room.

Water Service Supply

Pipe Material: Copper

Copper

Water Supply: Public water

Public water

Water Pressure: Hose Bibs Winterized - Could Not Test

The only hose bib on the exterior of the building had been winterized, so the water supply could not be turned on or tested. As a result, water pressure and exterior fixture operation could not be evaluated, which limited the scope of the inspection.

Recommendation: Once the hose bib is de-winterized and the water supply is restored, the exterior water pressure and functionality should be tested. Have any issues evaluated and repaired by a qualified plumbing contractor.

Distribution Pipe

Supply Pipe Materials: Copper

Copper

Functional Flow: Shut Off - Could not test during inspection

Shut Off - Could not test during inspection

Please note that the water to the building was shut off at the time of the inspection. This significantly limited the scope of the evaluation, as the plumbing system could not be tested or operated under normal conditions. Inspections are visual assessments that rely on the use of standard operating controls, and attempting to reactivate a plumbing system during an inspection carries the risk of causing damage. Water systems are often shut off due to leaks, winterization, or other failures, and restoring water service is outside the scope of an inspection.

Waste Pipe and Discharge

Discharge Type: Public Sewer

Public Sewer

Waste and Vent Pipe Materials: Not visible

Not visible

Please note that the waste piping system is concealed and appears to be below the concrete slab and not visible to inspection.

Location of Sewer Cleanout: Not Found

Not Found

No cleanout was noted for the sewer line. It is possible there is an accessible cleanout for the sewer line that is concealed behind finishes or belongings. Sewer line cleanouts are necessary for clearing drain obstructions and for inspecting the building sewer with a sewer camera. While code allows cleanouts to be in crawl spaces, a preferred method is to extend them to an area that is more readily accessible. Underfloor cleanouts are required to be no farther than 20 ft. from the access opening, with a 30 in. wide, 18 in. high path from the access to the cleanout. When those conditions cannot be met, the cleanout must be extended to the exterior. Recommend installation of an adequate accessible cleanout as by a qualified plumbing contractor.

Oil-Water Separator

This facility was constructed in 1998. Commercial car wash operations have historically been required to include an oil–water separator or other approved pretreatment system under prevailing plumbing codes and municipal sewer regulations well before that time. Buyers may wish to verify whether an oil–water separator was originally installed, remains in service, or was subject to any exemptions granted by the local sewer authority. If documentation is not available or if the system cannot be located on site, we recommend consulting the local wastewater authority or a qualified plumbing contractor for confirmation of compliance with current and past requirements.

Additional Plumbing

Water Filters

WATER FILTERATION NOTED

A water filtration system was noted in the building in the basement. Evaluation of this system and water quality is beyond the scope of this inspection. We recommend disclosing any maintenance, warranty or installer information that pertains to this system. If the system has not been serviced recently, have the filter system serviced and filters cleaned or replaced as a part of the recommended maintenance schedule.

Backflow Prevention

Backflow Prevention Note: ✒️

BACKFLOW PREVENTION NOTED

Backflow prevention is required for specific types of plumbing systems. The goal is to prevent the inadvertent contamination of water supplies. Common places where backflow prevention is required is at water boiler heating systems, irrigation systems and fire suppression systems. Please note that most water utilities and jurisdictions require annual inspection of backflow prevention. These safety devices can seem unimportant but they can be critical for keeping water supplies safe. LINK FOR MORE INFORMATION.

A backflow preventer was not observed on the water supply system serving the commercial car wash. Backflow prevention is commonly required in facilities of this type to protect the municipal water supply from potential contamination, particularly where detergents, chemicals, or pressurized wash equipment are used. It is possible that a device is located in an inaccessible area or that one was not included in the original construction.

Recommendation: Buyers may wish to verify the presence or absence of a backflow prevention device with the local water authority or a licensed plumbing contractor. If no device exists, installation of an approved assembly may be required to meet current standards and ensure proper protection of the potable water system.

Water Heaters

Water Heater

System Type: Tank

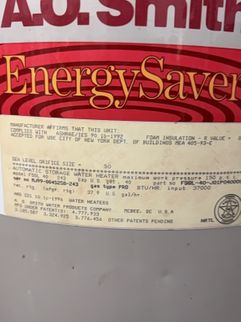

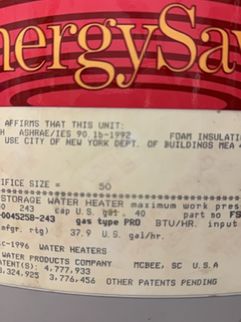

Manufacturer: A.O.Smith

Capacity: 40 gal

Energy Source: Propane

Location: Utility Area

Age: 1996

OLD WATER HEATER

This water heater is past its typical design life. Replacement is recommended for improved reliability as this unit could fail at any point. The average life of these water heaters is 8-20 years. The service life of a water heater will depend on a variety of factors such as water quality and regular scheduled maintenance such as flushing the tank and replacing sacrificial anodes.

Relief Valve: Present - Not Tested, Inadequate Discharge - General Note

A temperature and pressure relief valve (TPRV) is required on all water heaters to discharge any excessive pressure within the tank. A discharge pipe should be attached to the valve and directed to a safe location away from body contact. Newer installations must be directed to the building exterior or to an approved indoor drain receptor. Most manufacturers suggest that homeowners test these valves at least once a year by lifting the lever to ensure the valve discharges properly and also recommend inspection of these safety devices every three years. The picture here shows a typical TPRV. They may also be found on the side of the heater on some models. I do not test these valves due to the possibility that they may leak after testing. A leaking or inoperative TPRV should be replaced immediately by a licensed plumber.

Due to inconsistencies between both UPC and IPC Plumbing codes, and water heater manufacturer's instructions, and TPRV manufacturer instructions, it is not actually possible to install the drain from the Water Heater TPRV "properly." There are conflicts with distance of termination to the floor/ground, types of pipes approved, and diameters of pipes approved. Additional confusion is added when jurisdictional inspectors approve installations/materials specifically not allowed by both codes and manufacturers. My recommendations will vary depending on the installation and will be included in the applicable narratives below.

Most codes defer to manufacturer instructions and I favor those recommendations. The yellow tag on the valve states clearly the termination should be 6" above the floor which is more consistent with the UPC code requirements.

The discharge tube for the water heater relief valve is installed too high off the ground. The discharge tube for the temperature and pressure relief (TPR) valve does not appear to meet standard installation guidelines. Discharge tubes should terminate by pointing downward to reduce scald hazards and should typically end 6 to 24 inches above the floor (UPC), although local requirements and manufacturer instructions may vary. Proper installation helps ensure safe operation in the event of a discharge.

A properly installed relief-valve discharge tube should:

- Terminate to an exterior location or an approved drain (when feasible)

- Slope downward continuously to prevent water from pooling inside the tube

- Be constructed of material with an inside diameter of at least 3/4 inch

- Discharge into a visible location so leaks or discharges can be observed

- Avoid threaded ends that might allow improper capping

- Not terminate into a drain pan

Recommendation: Have a licensed plumber further evaluate and correct the relief-valve discharge tube to ensure it meets current safety standards and manufacturer requirements.

Water Temperature

The base of the water heater was observed to be heavily rusted. Significant corrosion at the bottom of a water heater often indicates long-term moisture exposure and may suggest that the tank is nearing the end of its service life or may be at risk of leaking.

Recommendation: Have a licensed plumber evaluate the water heater to determine the extent of deterioration and recommend repair or replacement as needed. Replacement is often advised when rust is present at the tank base.

Storage Buildings

Electrical

Damaged junction boxes and conduit were observed on the exterior of the detached storage units. These components appear to be installed very close to grade, placing them at ongoing risk of mechanical damage from snow plows, shoveling, or routine ground maintenance.

Recommendation: Have a licensed electrician evaluate the damaged junction boxes and conduit, repair as needed, and consider relocating or elevating the electrical components to reduce the likelihood of future mechanical damage. Ensuring proper installation height and protection will improve safety and durability.

HVAC Source

Description: None - Detached Unheated Storage

None - Detached Unheated Storage

Doors

Type: Overhead Coiling

Overhead Coiling

Siding and Trim

Trim Material: Metal

Metal

Siding Material: Concrete Slab on Grade

Concrete Slab on Grade

The foam inserts at the eaves were observed to be coming loose in several locations. These inserts help prevent wind-driven rain, snow, debris, and pests from entering the roof panel corrugations while still allowing for proper ventilation. Loose or missing inserts can reduce weather protection and may allow moisture or small animals to infiltrate the roof assembly.

Recommendation: Have a qualified contractor resecure or replace the loose foam inserts to ensure proper sealing at the eaves. This will help maintain weather resistance and reduce the potential for moisture intrusion or pest entry.

Mechanical damage and denting were noted in several sections of the metal siding. These dents appear consistent with impact or contact damage and are generally cosmetic; however, in some cases, deformation can affect panel alignment or weather protection.

Recommendation: Monitor the affected areas and repair or replace damaged panels as needed, particularly if dents worsen, compromise weather-resistance, or contribute to water intrusion. A contractor familiar with metal siding systems can further evaluate and advise on appropriate corrective measures.

Localized staining and streaking were observed on the metal siding. Although this type of staining is common with metal-panel construction—often resulting from weather runoff, oxidation, or normal age-related wear—it may also indicate areas where moisture consistently drains or accumulates.

Recommended: This condition appears cosmetic. Cleaning and routine maintenance can help improve appearance. If staining continues to worsen or if corrosion becomes visible, consider further evaluation by a contractor familiar with metal siding systems to determine whether additional sealing or corrective measures are needed.

Utility Area

General Photos

Electrical

Inspection Method: Tested All Accessible

Tested All Accessible

During the inspection, every effort is made to test and inspect all accessible electric receptacles and switches. In general, the scope of testing is directly related to access. Where personal belonging and furniture obstruct access to receptacles and fixtures, fewer of them can be reasonably tested during inspection. Deficiencies observed during the inspection visit are listed in this report. It should be anticipated that not all defects will be discovered and that some issues found may actually not be defects at all. Tools used to verify proper wiring and function can vary wildly in reliability/consistency. The kinds of tools that could be used to confidently analyze the system and its function cannot typically be done in the context of a Standard Inspection. We look for indications of issues, based on the age of the building, types of wiring systems used etc, as well as personal experience and by testing with a variety of common tools.

Lighting: Serviceable

Serviceable

The lights appeared serviceable and functioning at the time of the visit.

The receptacles in the utility area were selectively powered at the time of the inspection. The car wash equipment had been de-energized, and some receptacles appeared to share circuits with that equipment. As a result, not all receptacles could be tested for proper operation or GFCI protection. The receptacles that were energized appeared serviceable.

Recommendation: Once all circuits are fully energized, have the remaining receptacles tested for functionality and safety. Any deficiencies identified should be corrected by a qualified electrician.

Finishes

Walls: Paint

Paint Concrete Block

Concrete Block OSB

OSB

Ceilings: Paint

Paint OSB

OSB

Floors: Concrete

Concrete

Floor Settlement: Typical slope to drain

Typical slope to drain

Typical Wash Bay

Weep/ Drip Tray

The open wash bays appear to have a drip tray—likely part of the former car wash’s weep or freeze-protection system. The tray and associated piping appear to be unused and consistent with equipment that was taken out of service. These components no longer serve an operational purpose but remain in place as remnants of prior systems.

Recommendation: As part of ongoing decommissioning or future redevelopment planning, buyers may wish to verify whether these components should be removed, abandoned in place, or formally documented as inactive. A qualified contractor can assist with proper removal or termination to ensure the site is clean, safe, and free of unnecessary legacy equipment.

Powder Bathroom/ Half Bath

General Bath

The bathroom is located out in the open utility room space. Although the area is private and not open to the public, buyers may wish to inquire about the appropriateness of this configuration, including whether the bathroom was originally permitted or intentionally designed for this location. Utility rooms typically contain mechanical equipment and exposed services that are not commonly integrated with bathroom facilities. If additional privacy, ventilation, or separation is desired, consultation with a qualified contractor or design professional may be helpful to determine feasible improvements.

Sinks and Cabinets

Winterized

Winterized

The water supply to the sink was turned off at the time of the inspection, and the fixture could not be operated using normal controls. As a result, its functionality and leak conditions could not be evaluated.

Recommendation: Once the water supply is restored, test the sink for proper operation and check for any leaks. Have a qualified plumber make any necessary repairs if issues are discovered.

Toilet

Winterized

Winterized

The water supply to the toilet was turned off at the time of the inspection, and the fixture could not be operated using normal controls. As a result, its functionality and leak conditions could not be evaluated.

Recommendation: Once the water supply is restored, test the toilet for proper operation and check for any leaks. Have a qualified plumber make any necessary repairs if issues are discovered.

Bathroom Ventilation

Type: None noted

None noted

Attic

General Attic Photos

Attic Pulldown Ladders

None Noted

None Noted

Roof Framing and Sheathing

Rafters: Truss

Truss

Sheathing: Plywood

Plywood

BRIGHT COLOR TO ROOF SHEATHING

The attic space was inspected today, and the majority of the wood framing exhibited a clean, bright appearance, which is typically indicative of dry conditions and a lack of prior moisture-related issues. Attic ventilation also appeared to be unrestricted in the areas that were visible, which helps maintain proper humidity and temperature levels. The bright, dry condition of the wood suggests that the attic has not experienced significant moisture problems.

Recommendation: No corrective action is needed at this time. Continue to monitor the attic periodically to ensure ventilation remains unobstructed and that moisture conditions do not develop over time.

Attic Insulation

Insulation Type: Fiberglass

Fiberglass Cellulose

Cellulose

Approximate Insulation R-Value on Attic Floor: Inconsistent

Inconsistent

The insulation in the attic was observed to be inconsistent, with insulation present primarily above the drive-thru wash bays. The remainder of the building appears to be unconditioned space, so the lack of insulation in those areas may not represent a significant concern based on current building use.

Recommendation: No immediate corrections are required; however, if future plans include conditioning additional areas of the building or improving energy performance, consultation with an insulation contractor would be advisable to discuss appropriate upgrades.

Attic and Roof Cavity Ventilation

Attic Ventilation Method: Open between wash bays at top of CMU walls

Open between wash bays at top of CMU walls

Piping

The propane piping in the attic was observed to be leaking at the time of the inspection. Any leak in propane gas piping represents a significant safety hazard, as propane is highly flammable and can accumulate in enclosed spaces, increasing the risk of fire or explosion.

Recommendation: Have a licensed propane service technician or qualified plumber immediately evaluate and repair the leak. Do not operate any gas-fueled equipment connected to this system until the piping has been properly repaired and tested for safe operation.

.jpg)

(1) (1).jpg)