Plumbing Items

Jason Coe, New York State License #16000158429

Plumbing System Summary

The plumbing system was visually inspected and functionally tested where accessible and practical during the inspection. The evaluation included visible supply lines, drain/waste/vent piping, water heating equipment, and a representative number of plumbing fixtures throughout the home. The following summarizes our findings of the buildings HVAC system:

Plumbing Items

Major Concerns

- A-2 Attic - Piping:

The propane piping in the attic was observed to be leaking at the time of the inspection. Any leak in propane gas piping represents a significant safety hazard, as propane is highly flammable and can accumulate in enclosed spaces, increasing the risk of fire or explosion.

Recommendation: Have a licensed propane service technician or qualified plumber immediately evaluate and repair the leak. Do not operate any gas-fueled equipment connected to this system until the piping has been properly repaired and tested for safe operation.

🔥❄️🚽🚿🚰

Moderate Repairs

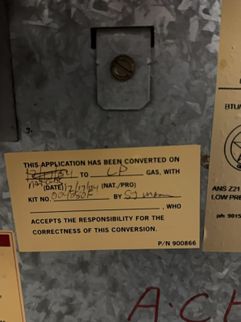

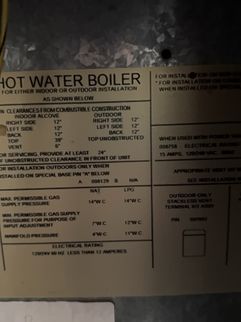

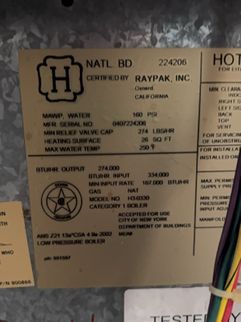

- HCFV-1 Heating, Cooling, Fireplaces and Ventilation - Water Heating Systems:

A Raypak boiler equipped with an economizer was observed servicing the commercial car wash. An economizer captures waste heat from the boiler’s flue gases and uses it to preheat incoming water, improving system efficiency and reducing fuel consumption. This type of equipment is common in high-demand environments such as car washes, where substantial volumes of hot water are required.

The system could not be tested at the time of the inspection because utilities were off, and its operational condition could not be verified. Both the boiler and economizer units also appear to be original to the building and show rusting at the base, which may indicate age-related deterioration and potential end-of-life considerations.

Recommendation: Have a qualified boiler technician evaluate the boiler and economizer once utilities are restored to determine their operational status, assess the extent of corrosion, and provide recommendations for repair or replacement as needed.

🔥❄️🚽🚿🚰 - WH-1 Water Heaters - Water Heater:

The discharge tube for the water heater relief valve is installed too high off the ground. The discharge tube for the temperature and pressure relief (TPR) valve does not appear to meet standard installation guidelines. Discharge tubes should terminate by pointing downward to reduce scald hazards and should typically end 6 to 24 inches above the floor (UPC), although local requirements and manufacturer instructions may vary. Proper installation helps ensure safe operation in the event of a discharge.

A properly installed relief-valve discharge tube should:

- Terminate to an exterior location or an approved drain (when feasible)

- Slope downward continuously to prevent water from pooling inside the tube

- Be constructed of material with an inside diameter of at least 3/4 inch

- Discharge into a visible location so leaks or discharges can be observed

- Avoid threaded ends that might allow improper capping

- Not terminate into a drain pan

Recommendation: Have a licensed plumber further evaluate and correct the relief-valve discharge tube to ensure it meets current safety standards and manufacturer requirements.

🚽🚿🚰 - WH-3 Water Heaters - Water Temperature:

The base of the water heater was observed to be heavily rusted. Significant corrosion at the bottom of a water heater often indicates long-term moisture exposure and may suggest that the tank is nearing the end of its service life or may be at risk of leaking.

Recommendation: Have a licensed plumber evaluate the water heater to determine the extent of deterioration and recommend repair or replacement as needed. Replacement is often advised when rust is present at the tank base.

🚽🚿🚰

Repairs

- P-2 Plumbing - Waste Pipe and Discharge:

No cleanout was noted for the sewer line. It is possible there is an accessible cleanout for the sewer line that is concealed behind finishes or belongings. Sewer line cleanouts are necessary for clearing drain obstructions and for inspecting the building sewer with a sewer camera. While code allows cleanouts to be in crawl spaces, a preferred method is to extend them to an area that is more readily accessible. Underfloor cleanouts are required to be no farther than 20 ft. from the access opening, with a 30 in. wide, 18 in. high path from the access to the cleanout. When those conditions cannot be met, the cleanout must be extended to the exterior. Recommend installation of an adequate accessible cleanout as by a qualified plumbing contractor.

🚽🚿🚰

Deferred Maintenance

- WH-2 Water Heaters - Water Heater:

OLD WATER HEATER

This water heater is past its typical design life. Replacement is recommended for improved reliability as this unit could fail at any point. The average life of these water heaters is 8-20 years. The service life of a water heater will depend on a variety of factors such as water quality and regular scheduled maintenance such as flushing the tank and replacing sacrificial anodes.

🚽🚿🚰

Due Diligence Items

- Plumbing - Oil-Water Separator:

This facility was constructed in 1998. Commercial car wash operations have historically been required to include an oil–water separator or other approved pretreatment system under prevailing plumbing codes and municipal sewer regulations well before that time. Buyers may wish to verify whether an oil–water separator was originally installed, remains in service, or was subject to any exemptions granted by the local sewer authority. If documentation is not available or if the system cannot be located on site, we recommend consulting the local wastewater authority or a qualified plumbing contractor for confirmation of compliance with current and past requirements.

🚽🚿🚰 - Additional Plumbing - Backflow Prevention:

A backflow preventer was not observed on the water supply system serving the commercial car wash. Backflow prevention is commonly required in facilities of this type to protect the municipal water supply from potential contamination, particularly where detergents, chemicals, or pressurized wash equipment are used. It is possible that a device is located in an inaccessible area or that one was not included in the original construction.

Recommendation: Buyers may wish to verify the presence or absence of a backflow prevention device with the local water authority or a licensed plumbing contractor. If no device exists, installation of an approved assembly may be required to meet current standards and ensure proper protection of the potable water system.

🚽🚿🚰 - Powder Bathroom/ Half Bath - General Bath:

The bathroom is located out in the open utility room space. Although the area is private and not open to the public, buyers may wish to inquire about the appropriateness of this configuration, including whether the bathroom was originally permitted or intentionally designed for this location. Utility rooms typically contain mechanical equipment and exposed services that are not commonly integrated with bathroom facilities. If additional privacy, ventilation, or separation is desired, consultation with a qualified contractor or design professional may be helpful to determine feasible improvements.

🚽🚿🚰

Recommended Disclosure Items

- Additional Plumbing - Water Filters:

WATER FILTERATION NOTED

A water filtration system was noted in the building in the basement. Evaluation of this system and water quality is beyond the scope of this inspection. We recommend disclosing any maintenance, warranty or installer information that pertains to this system. If the system has not been serviced recently, have the filter system serviced and filters cleaned or replaced as a part of the recommended maintenance schedule.

🚽🚿🚰

Limitations

- Plumbing - Water Service Supply:

The only hose bib on the exterior of the building had been winterized, so the water supply could not be turned on or tested. As a result, water pressure and exterior fixture operation could not be evaluated, which limited the scope of the inspection.

Recommendation: Once the hose bib is de-winterized and the water supply is restored, the exterior water pressure and functionality should be tested. Have any issues evaluated and repaired by a qualified plumbing contractor.

🚽🚿🚰 - Powder Bathroom/ Half Bath - Sinks and Cabinets:

The water supply to the sink was turned off at the time of the inspection, and the fixture could not be operated using normal controls. As a result, its functionality and leak conditions could not be evaluated.

Recommendation: Once the water supply is restored, test the sink for proper operation and check for any leaks. Have a qualified plumber make any necessary repairs if issues are discovered.

🚽🚿🚰 - Powder Bathroom/ Half Bath - Toilet:

The water supply to the toilet was turned off at the time of the inspection, and the fixture could not be operated using normal controls. As a result, its functionality and leak conditions could not be evaluated.

Recommendation: Once the water supply is restored, test the toilet for proper operation and check for any leaks. Have a qualified plumber make any necessary repairs if issues are discovered.

🚽🚿🚰