Jason Coe, New York State License #16000158429

The Scope and Purpose of an Inspection

Purchasing property involves risk

The purpose of an inspection is to help reduce the risks associated with purchasing a property by providing a professional evaluation of its general condition. It's important to understand that an inspection is limited to a visual assessment and cannot eliminate all risks. Some properties naturally present more potential issues than others, which may be beyond the scope of the inspection. Our goal is to inform and educate you—not only about what we can observe, but also about the limitations of what may not be visible during the inspection. These subtleties can be difficult to convey fully in writing, which is why we highly recommend that clients attend the inspection whenever possible.

A inspection is not an insurance policy or warranty.

This report is not a substitute for, nor should it be interpreted as, a warranty or guarantee. Warranties are separate products that may be purchased through third-party providers who specialize in that type of coverage.

The purpose of this report is not to offer any assurance—express or implied—regarding the current or future performance or adequacy of the structure, its systems, or their components. It does not serve as a warranty of merchantability or fitness for a particular purpose and should not be relied upon as such.

Any opinions offered regarding the adequacy, capacity, or expected lifespan of components are general estimates based on typical performance of similar systems or materials. Actual results may vary significantly, and it is not uncommon for real-world performance to differ from these projections.

A inspection is visual only and not destructive.

The findings and descriptions in this report are based on a visual inspection of the property. Our assessment is limited to components that are readily accessible and visible, without the need for disassembly, damage, or alteration of the structure, and without moving furniture or personal belongings. Any areas that are concealed, obstructed, or inaccessible are excluded from the inspection. In some cases, specific systems or components are not tested if doing so could risk damage—such as bathtub overflow drains, which are typically not tested to avoid potential water damage to finished areas. This inspection is non-invasive and non-destructive by nature, which places inherent limitations on its scope.

This is not an inspection for code compliance.

This inspection and report are not intended to determine compliance with local, state, or federal building codes. Code compliance is typically assessed by municipal inspectors during the construction phase, when framing and other structural elements are fully exposed and accessible. In contrast, inspections of finished structures are limited, as framing and other components are concealed. It’s also important to note that building codes are updated regularly—typically every three years—across various disciplines. Municipalities adopt and implement these updates on their own schedules. As a result, nearly all homes fall out of full code compliance over time. However, there is generally no requirement to bring older homes up to current code unless major renovations are undertaken.

This is just our opinion.

Construction methods and standards can vary widely—there is no single way to construct a building or install a system. The observations in this report reflect the professional judgment of the inspector. It's normal for other inspectors or contractors to have differing opinions. We encourage you to seek additional input from other qualified professionals if you wish. This report is intended only as a general guide to help the client make their own evaluation of the overall condition of the property, and is not intended to reflect the value of the premises, nor make any representation as to the advisability of sale/purchase.

The scope of this inspection

This inspection will cover the following systems: exterior, roof, structure, drainage, foundation, attic, interior, plumbing, electrical, and heating. The evaluation is based on limited observations that are primarily visual and non-invasive. No disassembly of equipment, opening of walls, moving of furniture, appliances or stored items, or excavation was performed. It is not intended to be a technically exhaustive assessment.

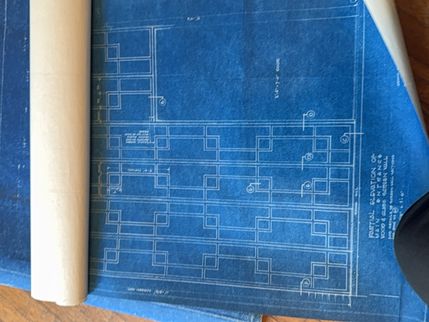

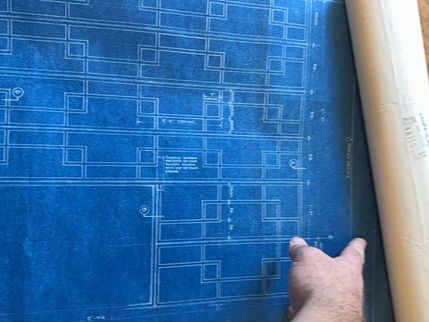

Photographic Documentation

Photographic documentation is included throughout the report, accompanied by written narratives to help convey key information. The photos are representative of conditions observed during the inspection but may not capture every instance of those conditions present on the property.

Your expectations

The primary goal of an inspection is to help ensure your expectations align with the condition of the property you are planning to buy, sell or maintain. Our role is to assist in this process by identifying and documenting visible observations during the inspection. However, this should not be mistaken for a technically exhaustive evaluation intended to uncover every possible defect. While more in-depth inspections are available, they are typically cost-prohibitive for most buyers or sellers.

Statement of Confidentiality

This Confidential Inspection Report is subject to the terms, conditions, and disclaimers of the contract. This report is only valid as of the date and time it was conducted and may be relied upon by the contracted parties. Each report section herein contains a listing of deficiencies observed at the time of inspection and a classification of the type and degree of each deficiency.

Statement of Limitations

All components and conditions which by the nature of their location are concealed, camouflaged or difficult to inspect are excluded from the report. The inspection is performed in compliance with the current versions of the following Standards of Practice as applicable to the property:

New York State Standards of Practice for Home Inspectors (NYS SOP), a copy of which is available at the following website: NYS Standards of Practice

InterNACHI Home Inspections Standards of Practice, a copy of which is available at the following website: InterNACHI SOP

Certified Commercial Property Inspectors Association Standards of Practice, a copy of which is available at the following website: CCPIA SOP

Systems and conditions which are not within the scope of the inspection include, but are not limited to: formaldehyde, lead paint, asbestos, mold or methamphetamine contamination, toxic or flammable materials, and other environmental hazards; pest infestation, playground equipment, efficiency measurement of insulation or heating and cooling equipment, internal or underground drainage or plumbing, any systems which are shut down or otherwise secured; water wells (water quality and quantity) zoning ordinances; intercoms; security systems; heat sensors; cosmetics or building code conformity. Any general comments about these systems and conditions are informational only and do not represent an inspection.

Statement of Non-Collusion

We hereby certify that this inspection report has been prepared independently and without any collusion, influence, or involvement from any third party with a financial interest in the sale, purchase, or financing of the property. No party has offered, requested, or received any form of compensation, inducement, or special consideration that would compromise the objectivity, accuracy, or impartiality of this inspection.

This report reflects the unbiased findings and professional judgment of the inspector, based solely on the conditions observed at the time of the inspection.

Statement of Liability

A thorough effort was made to identify all visible defects on your behalf; however, in the event of an oversight, the maximum liability shall be limited to the amount of the inspection fee paid. Any disputes or disagreements arising from this inspection or report shall be resolved through binding, non-appealable arbitration, conducted by the American Arbitration Association in accordance with its then-current Construction Industry Arbitration Rules, unless otherwise mutually agreed by the parties.

In the event of a claim, the client agrees to provide the inspection company with the opportunity to inspect the issue prior to any repairs being made. Failure to do so may result in the waiver of the claim. The client also agrees not to alter, repair, or remove any conditions or items that may serve as evidence in relation to the complaint, except in the case of an emergency.

Your participation is requested.

We strongly encourage our clients to be present during the inspection. A written report cannot fully capture all the insights and information that can be communicated through shared, real-time visual observations of the property's condition.

Authorizing Agent.

Inspected by: Jason Coe, State of New York License #: 16000158429.

Inspector Jason Coe, Duly Authorized agent of JBC Home Inspections, LLC.

How to Read This Report

Getting the Information to You

This report is intended to present important technical information in a format that is clear and accessible to all readers. If you're short on time, the "Summary Page” provides a quick overview of key findings to support prompt decision-making. However, we strongly recommend reviewing the full Report, which includes detailed descriptions, digital photos, captions, diagrams, videos, and links to additional resources for a more comprehensive understanding.

The most effective way to access the full depth of information in this report is by reading it online. This format allows you to explore and expand your understanding of the property. You’ll notice certain words or phrases highlighted in blue and underlined—clicking on these links will take you to additional resources and further details.

This report can also be saved as a PDF file and printed on paper if preferred.

Key Definitions

Serviceable – At the time of inspection, the component or system was observed to be performing its intended function without any visible evidence of significant defect, damage, or unsafe condition. “Serviceable” does not imply new condition or guarantee continued performance, nor does it serve as a warranty. The designation is based on a limited visual inspection and is not a prediction of future reliability.

Oil Canning – A visible waviness or buckling effect in flat or slightly curved metal surfaces, often seen in roofing, siding, or metal panels. It is usually caused by thermal expansion, improper installation, uneven fastening, or residual stresses in the metal during manufacturing. Oil canning is generally a cosmetic condition and does not necessarily indicate structural failure, but in some cases it may be a sign of installation or fastening issues that could warrant further evaluation.

Spalling - The deterioration and breakdown of a concrete surface, characterized by cracking, chipping, or peeling away. This can expose the underlying aggregate or even the reinforcement bars within the concrete. Spalling can be caused by a variety of factors, including moisture, temperature changes, and corrosion of the steel reinforcement.

Efflorescence - the process where water carries dissolved mineral salts to the surface of porous building materials such as concrete and masonry. This process leaves behind a white, powdery, or crystalline residue after the water evaporates. This generally signifies that a moisture problem is present and can lead to more significant structural problems, mold growth or other damage if not addressed.

Swale - a shallow, vegetated channel or depression designed to collect, convey, and filter stormwater runoff by slowing its velocity and allowing it to infiltrate the soil, thereby reducing erosion and pollution.

Qualified - For the purposes of this inspection report, the term qualified in reference to contractors refers to an individual or firm that is properly trained, experienced, licensed where required, and insured to perform evaluation, repair, or replacement of the specific system or component referenced. Selection, verification of credentials, and oversight of any contractor are the responsibility of the client.

Chapters and Sections

This report is organized into chapters that divide the building into logical inspection areas. Each chapter is further broken down into sections focused on specific systems or components of the building. You can easily navigate between chapters using the buttons located in the left-side margin.

Most sections include descriptive information in black text. Observation narratives, highlighted in colored boxes, are provided when a system or component is found to have significant deficiencies or when we want to offer additional useful details about the system or the scope of our inspection. If a system or component is considered to be in satisfactory or serviceable condition, that section may have no observation comments and may simply state “tested” or “inspected.”

Observation Labels

All narrative observations are color-coded, numbered, and labeled to help you easily locate, reference, and understand the severity of each issue. The observation colors and labels used in this report are:

Summary Page

The Summary Page offers a bulleted outline of the key observations made during the inspection. While this summary can be a helpful reference, it is not a substitute for reading the complete inspection report. To gain a full understanding of the findings, the entire report should be reviewed, as the Summary Page does not contain supporting photographs or their associated captions.

Summary

Major Concerns

- LG-4 🏕️Landscaping/ Grounds - Retaining Walls:

The retaining wall and brick masonry structure along the property were observed to be in poor and unstable condition. Significant cracking, displacement, and separation were visible along the face and corner of the wall, with sections of brick veneer pulling away from the underlying concrete block backing. The cracks extend through both the veneer and the block wall, indicating structural movement and potential failure of the retaining system.

This type of movement is typically associated with soil pressure, inadequate drainage behind the wall, foundation settlement, or frost heaving. The extent of visible cracking suggests that the wall may no longer be providing proper lateral support for the soil behind it.

The observed displacement and cracking represent a significant structural defect and potential collapse hazard, particularly if the wall continues to move or if loads such as soil, water, or freeze-thaw pressures increase.

RECOMMENDATION: Have a licensed structural engineer or qualified masonry contractor evaluate the retaining wall immediately to determine the extent of structural compromise and necessary corrective action. Repairs may include partial or full reconstruction, installation of proper drainage and reinforcement, and replacement of damaged masonry units. Until professional evaluation and stabilization are completed, avoid placing additional loads near or above the affected area.

- LG-5 🏕️Landscaping/ Grounds - Outbuildings, Trellises, Storage Sheds, Barns:

The pool shed/ storage shed roof has collapsed. The remaining structure is fully exposed to the weather and the walls were noted to be loose. This structure no longer appears to be safe to use.

RECOMMENDATION: Raze the balance of the shed and have a qualified general contractor build a new structure as desired. We recommend maintaining the water and electrical to this location for convenience.

- E-2 🏡Exterior - Siding and Trim:

A number of serious masonry and structural deficiencies were observed during the inspection, including:

- Failed and missing mortar joints

- Displaced and separated sections of brickwork

- Stepped cracking consistent with significant movement or settlement

- Vegetation growth within mortar joints, accelerating deterioration and moisture retention

- Corroded lintels

These conditions indicate substantial structural movement and distress within the masonry wall system. The extent of displacement and cracking suggests that portions of the wall may have lost structural integrity and could be at risk of progressive failure or collapse if not corrected.

The observed damage represents a significant safety and stability issue requiring prompt professional attention.

RECOMMENDATION: Have a licensed structural engineer evaluate the affected areas to determine the extent of structural compromise and develop a comprehensive repair or reconstruction plan. Repairs should be completed by a qualified masonry or general contractor under professional supervision to restore stability and prevent further movement or failure.

Example images of masonry issues around the home. Additional images may be found in other sections of the report

- GC-2 🚗Garage/ Carport - Garage General:

Water-damaged finishes were observed in the garage, indicating an active moisture condition at the time of the inspection. Staining and deterioration suggest ongoing water infiltration, which may be related to roof deficiencies (see the “Roof, Chimney, and Gutters” section of this report for related findings).

Active water intrusion can lead to continued material deterioration, organic growth, and potential structural damage if not corrected.

RECOMMENDATION: Have a qualified contractor identify and repair the source of the water infiltration and replace or repair any damaged materials as needed once the area has fully dried. Continued monitoring is recommended after repairs to confirm that the issue has been resolved.

- RCG-2 🧱Roof, Chimney and Gutters - Roofing:

A number of issues were observed related to the roof coverings:

- Some roof and parapet surfaces have a silver coating. This is consistent with a roofing product that may contain asbestos. This material should be tested by a qualified environmental hygienist before any disturbance or replacement.

- The roof slope to the drains does not appear to meet current standards of ¼ inch per foot, which may inhibit proper drainage and contribute to ponding water.

- The roof covering on the west side shows significant deterioration and damage, while the east side exhibits surface cracking and “alligatoring,” indicating age-related wear and weathering.

- The top edges of the counterflashing are not properly sealed; old sealant is deteriorated and should be removed and replaced to maintain a watertight condition.

- Dorner window sills sit on the roof and do not provide adequate surface area for counterflashing.

- The tin roof over the garage has a lot of seams that need resealing

- The drainage channel at the perimeter of the garage tin roof is not adequate and does not appear to remove water to the ground

The combined deficiencies indicate a roof system that is beyond its service life and may be contributing to moisture infiltration or interior damage.

RECOMMENDATION: As part of a comprehensive roofing rehabilitation or replacement project, have a qualified roofing contractor:

- Test any suspect coating for asbestos prior to disturbance,

- Evaluate and correct roof slope and drainage as needed,

- Replace deteriorated roofing materials and repair damaged areas, and

- Reseal counterflashing to ensure full weather protection.

The underlying roof substrates and counterflashing reglets should also be inspected for moisture damage or deterioration during the roofing work and replaced as needed to restore full system performance.

🧱 - RCG-3 🧱Roof, Chimney and Gutters - Roofing:

The bottom section of the second-floor bay window was observed to be deteriorated, with open gaps and exposed areas allowing direct exposure to the elements. These openings create a potential pathway for water intrusion, which can lead to further deterioration of adjacent materials. Due to the concealed nature of the assembly, there may also be underlying framing or structural damage that could not be visually confirmed during the inspection.

RECOMMENDATION: As part of the roofing replacement or repair project in this area, have a qualified contractor remove and replace the deteriorated bay window components using modern, durable, and weather-resistant materials. The underlying framing should be inspected and repaired or replaced as needed before reinstalling finishes to ensure a watertight and structurally sound assembly.

🧱 - RCG-4 🧱Roof, Chimney and Gutters - Chimneys:

CHIMNEY REPAIRS NEEDED

Visual inspection of the chimney revealed the need for a number of repairs. Hire a qualified structural engineer, mason and/or chimney sweep to further evaluate the chimney and implement repairs as needed. Specific observations noted during inspection include:

Chimney Structure

- The entire masonry chimney seems to be leaning - this can be an indication of structural failure. Extensive repairs could be needed.

Chimney Masonry

- Step cracking was noted in the masonry - this can be an indication of structural movement in the masonry chimney.

- Damaged was noted to the concrete cap - this can lead to moisture control problems

- Spalling brick was noted - this can be an indication of moisture control problems or incorrect mortar repairs in the past

- Failing mortar was noted - this can lead to moisture control and structural problems with the chimney

Flue Damper

- The flue damper inside the fireplace is inoperative and requires repair.

- RCG-7 🧱Roof, Chimney and Gutters - Dormers/ Parapets:

Several deficiencies were noted at the dormers and parapets around the building, including:

- Missing counterflashing along the sidewalls of the dormers

- Inappropriate siding material installed on the dormers (painted plywood, not intended for long-term exterior exposure)

- Unsealed or deteriorated coping joints requiring resealing

- Damaged parapet finishes with visible deterioration

These combined conditions likely allow water intrusion at roof-to-wall and parapet connections, which is contributing to the interior finish damage observed elsewhere in the home (see related sections of this report).

RECOMMENDATION: Have a qualified roofing or exterior envelope contractor evaluate the dormers and parapets to install proper counterflashing, replace inappropriate siding materials, reseal coping joints, and repair or refinish damaged parapet areas. Addressing these conditions will help prevent further water intrusion and interior damage. This work should be done as part of a larger roof replacement effort.

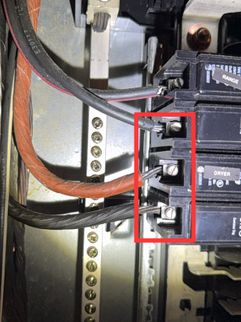

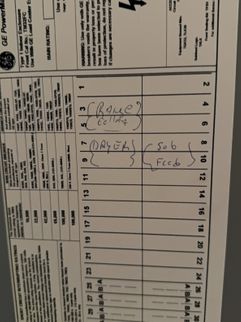

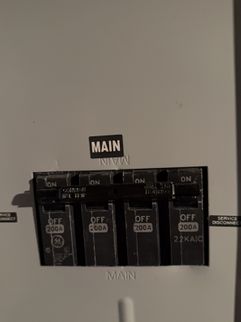

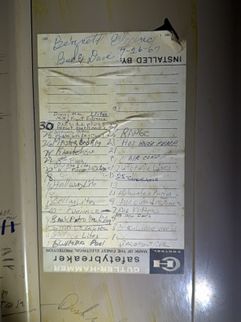

🧱 - ES-4 ⚡Electric Service - Sub Panel:

INCORRECT 3 CONDUCTOR FEED - SUB-PANEL

Currently, all sub-panels are required to be fed with four conductors (two hots, one neutral, and one ground). While the grounding conductor can sometimes be provided through metal conduit, no metal conduit was observed in this case. The sub-panel here appears to be fed by only three wires. Since this sub-panel is located within the same building as the main panel, installing a new four-wire feed is recommended for improved safety. We advise further evaluation and repair by a licensed electrical contractor. It’s important for sub-panels that neutrals and equipment grounds are kept separate to prevent stray voltage, which typically requires a four-wire feed. Although three-wire feeds may be permitted in some outbuilding situations, they are never allowed when the sub-panel is inside the same structure as the main panel.

⚡💡 - ES-5 ⚡Electric Service - Sub Panel:

DOUBLE LUGGED NEUTRALS

Hire a licensed electrician to correct the double-lugged neutral (grounded) conductors observed in the electrical panel. This condition occurs when two conductors share the same terminal lug, which is not permitted unless the terminal is specifically rated for multiple conductors. According to code, each grounded conductor must terminate in an individual terminal not shared with another wire. Double-lugged neutrals increase the risk of poor connections, arcing, and overheating. This should be evaluated and addressed by a qualified electrician.

⚡💡 - ES-6 ⚡Electric Service - Sub Panel:

An improperly terminated electrical conductor was observed within the system. Although testing indicated that the conductor was not energized at the time of inspection, its exposed end presents a potential safety hazard if it were to accidentally come into contact with energized components. Such contact could result in arcing, electrical shock, or fire.

Exposed or improperly terminated conductors pose a significant safety concern and should be corrected immediately.

RECOMMENDATION: Have a licensed electrical contractor properly terminate, cap, or remove the conductor in accordance with National Electrical Code (NEC) standards to eliminate the risk of accidental energization or electrical hazard.

⚡💡 - ES-7 ⚡Electric Service - Sub Panel:

Within the electrical panel, one or more stranded conductors were observed to have individual wire strands cut, damaged, or not fully secured under the lug connection. All strands of a conductor must be properly terminated beneath the lug or connector to ensure a secure and complete electrical connection. Missing or damaged strands can reduce the current-carrying capacity of the wire and may lead to overheating, arcing, or connection failure over time.

Improper termination of stranded conductors is a fire and shock hazard and should be corrected immediately to ensure safe system performance.

RECOMMENDATION: Have a licensed electrical contractor evaluate the affected connections and re-terminate or replace the damaged conductors as needed. All wire strands should be fully captured under the lug or connector and torqued to manufacturer specifications in accordance with National Electrical Code (NEC) 110.14 to ensure a safe and compliant installation.

⚡💡 - EDF-1 💡Electric Distribution and Finish - Branch Wiring:

RUNNING SPLICE

Open electrical splices were observed in the home’s wiring system. Electrical splices are connection points where conductors are joined together, and by code they are required to be contained within a listed junction box equipped with a secure cover. The observed splices were not enclosed, leaving exposed wiring connections visible and unprotected. This is an improper and unsafe condition that increases the risk of electrical shock, arcing, or fire.

Open or “running” splices are often a sign of amateur or incomplete electrical work, which raises concern that additional, concealed wiring issues may exist elsewhere in the electrical system. This condition does not meet modern safety standards as defined by the National Electrical Code (NEC 300.15), which mandates that all electrical connections be enclosed within approved boxes to prevent accidental contact and contain sparks or heat generated by loose connections.

RECOMMENDATION: Have a licensed electrical contractor further evaluate the electrical system, correct all open splices by properly enclosing them within approved junction boxes, and inspect the remainder of the system for additional wiring deficiencies or unsafe conditions. Documentation of completed repairs is recommended for safety and insurance purposes.

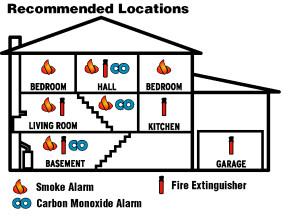

⚡💡 - EDF-3 💡Electric Distribution and Finish - Smoke and Carbon Monoxide Alarm Systems:

SMOKE ALARM REPAIRS NEEDED

No smoke alarms were noted anywhere. Smoke alarms were observed to be removed and/or batteries removed. These are an important safety feature and are recommended inside all bedrooms and in hallways outside of all sleeping areas. It is also recommended that there be at least one smoke alarm on each floor of the house. We recommend having smoke alarms installed to meet modern safety standards.

⚡💡 - EDF-4 💡Electric Distribution and Finish - Smoke and Carbon Monoxide Alarm Systems:

Smoke detector/carbon monoxide detector coverage in the home does not appear to meet current building standards. According to modern requirements, detectors should be installed inside each sleeping room, outside each sleeping area (such as in hallways), and on every level of the home, including basements, as well as in common areas like living rooms, family rooms, and dens.

RECOMMENDATION: Install additional smoke and CO detectors/ alarms for proper coverage and improved safety.

⚡💡 - HCFV-4 🔥❄️Heating, Cooling, Fireplaces and Ventilation - Vents and Flues:

The boiler vent connection to the chimney stack did not appear to be fully seated or properly sealed. A visible gap was noted at the connection point, which can allow combustion gases, including carbon monoxide, to escape into the surrounding area instead of venting safely outdoors.

Improper vent connections can pose a serious safety hazard and may affect both boiler performance and indoor air quality.

RECOMMENDATION: Have a licensed HVAC or chimney professional inspect and properly reconnect or reseal the vent pipe to ensure a secure, airtight connection at the chimney. The full venting system should be evaluated for corrosion, backdrafting, and proper draft performance to confirm safe operation.

🔥❄️ - P-1 🚰Plumbing - Waste Pipe and Discharge:

A damaged waste pipe was observed in the laundry area, with the open end stuffed with rags as a makeshift seal. While no sewer odor was detected at the time of inspection, this condition is unsafe and may allow sewer gases or moisture to enter the building.

Improperly sealed drain lines pose a sanitation and air quality hazard and are not compliant with plumbing standards.

RECOMMENDATION: Have a licensed plumbing contractor properly cap, repair, or replace the damaged waste pipe to ensure a sealed and code-compliant connection. This will prevent sewer gas infiltration and maintain a safe and sanitary environment.

🚽🚿🚰 - WH-1 🚰Water Heaters - Water Heater:

The discharge tube for the water heater temperature and pressure relief valve is missing and requires repair to eliminate a scald hazard. This is an important safety feature. Should the TPRV need to discharge, scalding water and steam could come out. This water and steam needs to be directed away from people.

RECOMMENDATION: Have a licensed plumber further evaluate and repair.

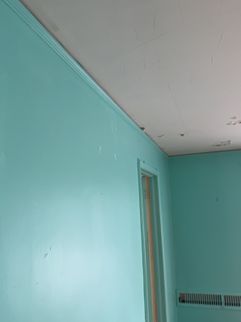

- TFH-3 Third Floor Hall - Walls, Ceilings, Trim, Hallways and Closets:

Water damage was observed around the dormer area in the third-floor hall ceiling. The moisture has caused the plaster to loosen and separate from its keyway, with sections showing signs of delamination and partial detachment. In some areas, the plaster is close to falling, presenting a potential safety concern if it dislodges further.

This interior damage is consistent with the roof and dormer deficiencies noted during the inspection, including deteriorated flashing and exterior water intrusion.

The condition indicates ongoing water infiltration that has already compromised interior finishes and may continue to worsen if not addressed.

RECOMMENDATION: Have a qualified roofing contractor identify and repair the source of the leak at the dormer and flashing assembly. Once the area is confirmed dry, a qualified plaster or general contractor should repair or replace the damaged ceiling sections to restore integrity and prevent debris from falling. Continued monitoring after repairs is recommended to confirm the leak has been fully resolved. We recommend this work be performed after the roofing is corrected.

- LR-4 📺Living Room - Finishes:

Water-damaged finishes were observed in the Living Room, indicating an active moisture condition at the time of the inspection. Staining and deterioration suggest ongoing water infiltration, which may be related to roof deficiencies (see the “Roof, Chimney, and Gutters” section of this report for related findings).

Active water intrusion can lead to continued material deterioration, organic growth, and potential structural damage if not corrected.

RECOMMENDATION: Have a qualified contractor identify and repair the source of the water infiltration and replace or repair any damaged materials as needed once the area has fully dried. Continued monitoring is recommended after repairs to confirm that the issue has been resolved.

- SR-4 Sun Room - Finishes:

A significant floor slope and evidence of settlement were observed in the sunroom area. The floor exhibited a noticeable tilt, suggesting movement or subsidence of the supporting structure or foundation beneath this portion of the building. This interior condition appears to correlate with the stepped cracking observed on the adjacent exterior wall, which is a common indicator of differential settlement or shifting in the foundation or footing.

The combination of interior and exterior movement suggests that the settlement may be progressive or related to soil conditions, drainage issues, or inadequate structural support beneath the sunroom addition.

The observed slope and cracking represent a potential structural issue that may continue to worsen over time if not addressed. Further movement could lead to additional cracking, misalignment of doors and windows, or damage to finishes.

RECOMMENDATION: Have a licensed structural engineer or qualified foundation specialist further evaluate the sunroom floor structure and foundation to determine the extent and cause of settlement. Corrective actions may include stabilizing or underpinning the foundation, improving site drainage, or reconstructing affected portions as necessary to restore stability and prevent further movement.

- WR-3 Weight Room - Finishes:

The lower 12 to 18 inches of drywall in the lower level of the home were observed to have visible organic growth, indicating a chronic or recurring moisture issue in this area. A musty odor was also noted, which further supports the presence of elevated humidity or prolonged damp conditions. The combination of visible growth and odor suggests that moisture intrusion or poor ventilation has persisted for some time.

Organic growth can indicate unsanitary conditions and may include mold or microbial contamination, which can affect indoor air quality and lead to further deterioration of building materials if not properly remediated.

RECOMMENDATION: Have a qualified mold remediation or environmental specialist evaluate the affected area to determine the extent and type of organic growth and perform appropriate cleaning or removal. The source of moisture—such as leaks, poor drainage, or high humidity—should also be identified and corrected to prevent recurrence. Once the area is fully dried and remediated, damaged drywall and insulation should be replaced as necessary to restore a clean and safe interior environment.

- BSR-2 Basement Storage Room - Finishes:

The lower 12 to 18 inches of drywall in the basement storage area(s) of the home were observed to have visible organic growth, indicating a chronic or recurring moisture issue in this area. A musty odor was also noted, which further supports the presence of elevated humidity or prolonged damp conditions. The combination of visible growth and odor suggests that moisture intrusion or poor ventilation has persisted for some time.

Organic growth can indicate unsanitary conditions and may include mold or microbial contamination, which can affect indoor air quality and lead to further deterioration of building materials if not properly remediated.

RECOMMENDATION: Have a qualified mold remediation or environmental specialist evaluate the affected area to determine the extent and type of organic growth and perform appropriate cleaning or removal. The source of moisture—such as leaks, poor drainage, or high humidity—should also be identified and corrected to prevent recurrence. Once the area is fully dried and remediated, damaged drywall and insulation should be replaced as necessary to restore a clean and safe interior environment.

- PB11-3 🛏️Primary Bedroom (1) - Finishes:

Water-damaged finishes were observed in the Living Room, indicating an active moisture condition at the time of the inspection. Staining and deterioration suggest ongoing water infiltration, which may be related to roof deficiencies (see the “Roof, Chimney, and Gutters” section of this report for related findings).

Active water intrusion can lead to continued material deterioration, organic growth, and potential structural damage if not corrected.

RECOMMENDATION: Have a qualified contractor identify and repair the source of the water infiltration and replace or repair any damaged materials as needed once the area has fully dried. Continued monitoring is recommended after repairs to confirm that the issue has been resolved.

- B2-3 🛏️Bedroom (2) - Finishes:

Water-damaged finishes were observed in Bedroom 2, indicating an active moisture condition at the time of the inspection. Staining and deterioration suggest ongoing water infiltration, which may be related to roof deficiencies (see the “Roof, Chimney, and Gutters” section of this report for related findings).

Active water intrusion can lead to continued material deterioration, organic growth, and potential structural damage if not corrected.

RECOMMENDATION: Have a qualified contractor identify and repair the source of the water infiltration and replace or repair any damaged materials as needed once the area has fully dried. Continued monitoring is recommended after repairs to confirm that the issue has been resolved.

- B3-2 🛏️Bedroom (3) - Finishes:

Water-damaged finishes were observed in Bedroom 3, indicating an active moisture condition at the time of the inspection. Staining and deterioration suggest ongoing water infiltration, which may be related to roof deficiencies (see the “Roof, Chimney, and Gutters” section of this report for related findings).

Active water intrusion can lead to continued material deterioration, organic growth, and potential structural damage if not corrected.

RECOMMENDATION: Have a qualified contractor identify and repair the source of the water infiltration and replace or repair any damaged materials as needed once the area has fully dried. Continued monitoring is recommended after repairs to confirm that the issue has been resolved.

- B4-2 🛏️Bedroom (4) - Finishes:

Water-damaged finishes were observed in the Bedroom 4, indicating an active moisture condition at the time of the inspection. Staining and deterioration suggest ongoing water infiltration, which may be related to roof deficiencies (see the “Roof, Chimney, and Gutters” section of this report for related findings).

Active water intrusion can lead to continued material deterioration, organic growth, and potential structural damage if not corrected.

RECOMMENDATION: Have a qualified contractor identify and repair the source of the water infiltration and replace or repair any damaged materials as needed once the area has fully dried. Continued monitoring is recommended after repairs to confirm that the issue has been resolved.

- B6-3 🛏️Bedroom (6) - Finishes:

Water-damaged finishes were observed in Bedroom 6, indicating an active moisture condition at the time of the inspection. Staining and deterioration suggest ongoing water infiltration, which may be related to roof deficiencies (see the “Roof, Chimney, and Gutters” section of this report for related findings).

Active water intrusion can lead to continued material deterioration, organic growth, and potential structural damage if not corrected.

RECOMMENDATION: Have a qualified contractor identify and repair the source of the water infiltration and replace or repair any damaged materials as needed once the area has fully dried. Continued monitoring is recommended after repairs to confirm that the issue has been resolved.

- BP-2 🧑🍳🔪Butler Pantry - Finishes:

Water-damaged finishes were observed in the Butler Pantry, indicating an active moisture condition at the time of the inspection. Staining and deterioration suggest ongoing water infiltration, which may be related to roof deficiencies (see the “Roof, Chimney, and Gutters” section of this report for related findings).

Active water intrusion can lead to continued material deterioration, organic growth, and potential structural damage if not corrected.

RECOMMENDATION: Have a qualified contractor identify and repair the source of the water infiltration and replace or repair any damaged materials as needed once the area has fully dried. Continued monitoring is recommended after repairs to confirm that the issue has been resolved.

- B21-6 🚽🛁🚿Bathroom-Full (2) - Moisture Damage to Finishes:

Water-damaged finishes were observed in the bathroom, indicating an active moisture condition at the time of the inspection. Staining and deterioration suggest ongoing water infiltration, which may be related to roof deficiencies (see the “Roof, Chimney, and Gutters” section of this report for related findings).

Active water intrusion can lead to continued material deterioration, organic growth, and potential structural damage if not corrected.

RECOMMENDATION: Have a qualified contractor identify and repair the source of the water infiltration and replace or repair any damaged materials as needed once the area has fully dried. Continued monitoring is recommended after repairs to confirm that the issue has been resolved.

- B31-5 🚽🛁🚿Bathroom-Full (3) - Bathtub / Shower:

The shower fixtures were not operated during the inspection due to visible buildup of mineral scale and what appeared to be organic growth on the components. Operating the fixtures in this condition could have caused damage or clogging to the plumbing system. The observed buildup suggests a lack of maintenance and potential deterioration of internal parts.

The condition indicates that the fixtures are likely beyond normal service life and may not operate properly or hygienically without significant repair or replacement.

RECOMMENDATION: Have a licensed plumbing contractor further evaluate and service the shower assembly, including internal supply lines and valves. Full replacement of the shower unit, valve, and trim is recommended to ensure safe, reliable operation and to restore proper sanitation and water flow.

🚽🚿🚰 - B51-1 🚽🛁🚿Bathroom-Full (5) - General Bath:

For the purpose of this report, Bathroom 5 is located in the basement. This bathroom appears to have been unused for an extended period of time. The bathtub drain was sealed with tape, preventing operation or testing during the inspection. The toilet and sink are located in a narrow alcove behind the tub/shower, with insufficient clearances for safe or comfortable use. The configuration does not meet current building standards for fixture spacing or function.

The condition of this bathroom, combined with its layout and apparent disuse, suggests that it may not be safe, sanitary, or compliant with modern standards. Repairs alone are unlikely to fully correct the deficiencies without significant modification.

RECOMMENDATION: Have a licensed general contractor or design professional evaluate this basement bathroom for complete replacement, reconfiguration, or removal. Any upgrades should include reinstallation of proper drainage, venting, and fixture clearances to ensure compliance with current plumbing and building standards. Rebuilding the bathroom to modern standards will improve both safety and usability of the space.

Moderate Repairs

- E-5 🏡Exterior - Exterior Electrical (General):

The exterior electrical receptacles were observed to be missing Ground Fault Circuit Interrupter (GFCI) protection and in-use (weatherproof) covers. Current electrical safety standards require all exterior outlets to be GFCI-protected to reduce the risk of electric shock in wet or damp environments. Additionally, exterior receptacles must have weather-resistant (WR) outlets and in-use covers designed to protect them from rain and moisture even when cords are plugged in.

While the outlets may function, the absence of GFCI protection and weatherproof covers presents a potential safety hazard, particularly in outdoor areas exposed to moisture.

RECOMMENDATION: Have a licensed electrical contractor install GFCI-protected exterior receptacles with proper weather-resistant devices and in-use covers in accordance with the National Electrical Code (NEC 210.8 and 406.9). This will improve safety, prevent moisture intrusion, and bring the exterior electrical system into compliance with current standards.

⚡💡 - E-7 🏡Exterior - Soffits/ Fascia/ Eaves:

The wood fascias and trim around the building were observed to be in poor condition, with extensive paint failure, exposed bare wood, and areas of rot and deterioration. The wood surfaces appear to have been subjected to long-term moisture exposure, likely from roof runoff or inadequate flashing. The deteriorated paint and visible decay indicate that the protective finish has failed, leaving the wood vulnerable to further water damage.

If not repaired, ongoing moisture exposure can lead to further wood decay, potential damage to underlying framing, and may allow water intrusion into the wall assembly below.

RECOMMENDATION: Have a qualified contractor or carpenter further evaluate and repair or replace the damaged fascia and trim components as needed. The affected areas should be properly sealed, primed, and repainted to protect against further weathering. Additionally, review roof and flashing details to ensure water is being properly diverted away from the fascia to prevent recurrence. (See also "Roof, Chimney and Gutters section of the report")

- E-8 🏡Exterior - Exterior Doors:

Several of the steel doors around the building were observed to be inoperable, likely due to rusting or being painted shut. In addition, doors that were functional were noted to be missing proper weatherstripping, and some locking hardware did not fully engage or operate as intended. These conditions reduce both security and energy efficiency and may allow moisture or air infiltration around the door assemblies.

While not an immediate safety hazard, the condition of the doors indicates a need for maintenance and repair to ensure proper operation and protection from the elements.

RECOMMENDATION: Have a qualified contractor evaluate and free or repair the rusted or painted-shut doors, replace or adjust door hardware, and install appropriate weatherstripping to ensure each door operates properly, seals tightly, and provides adequate security and weather resistance.

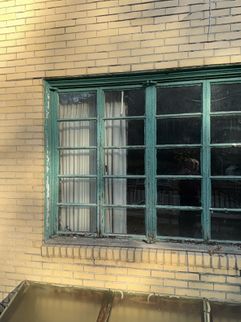

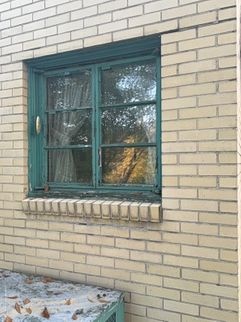

- E-9 🏡Exterior - Exterior Window Frames:

Cracked or damaged glass was observed at several window and door locations around the building. The affected panes may present safety, security, and energy efficiency concerns, as well as potential for water intrusion if the cracks worsen or the glazing fails.

While the condition does not appear to pose an immediate hazard, damaged glass should be addressed to prevent further breakage and ensure proper weather protection.

RECOMMENDATION: Have a qualified glass or window contractor evaluate all affected areas and replace or repair damaged glass panes as needed to restore safety, appearance, and proper building envelope performance.

- E-10 🏡Exterior - Exterior Window Frames:

Rotted wood was observed on the exterior window trim. This condition can lead to further deterioration, moisture intrusion, and potential damage to surrounding materials if not addressed.

RECOMMENDATION: Have a qualified general contractor repair or replacement the affected trim and/or window to prevent further damage and maintain the integrity of the window system.

- GC-3 🚗Garage/ Carport - Garage Doors and Automatic Openers:

DOOR BETWEEN THE GARAGE AND HOUSE

The door between the garage and the house does not appear to be a fire-rated door assembly. A properly rated door is an important fire safety feature, designed to slow or prevent the spread of fire and smoke from the garage into the living areas of the home.

Current standards require garage-to-house doors to have a minimum 20-minute fire-resistance rating, typically indicated by a UL or equivalent listing label, and to be self-closing and self-latching. Alternatively, a solid wood door at least 1⅜ inches thick also meets the minimum fire rating requirement.

While the door is functional, the lack of a confirmed fire rating represents a potential safety concern in the event of a fire.

RECOMMENDATION: Have a qualified contractor or door specialist evaluate the existing door and, if not compliant, replace it with a properly rated 20-minute fire door equipped with self-closing and latching hardware. This upgrade will help improve fire safety and bring the condition closer to current residential building standards.

- GC-5 🚗Garage/ Carport - Garage Stairs:

HANDRAIL REPAIRS

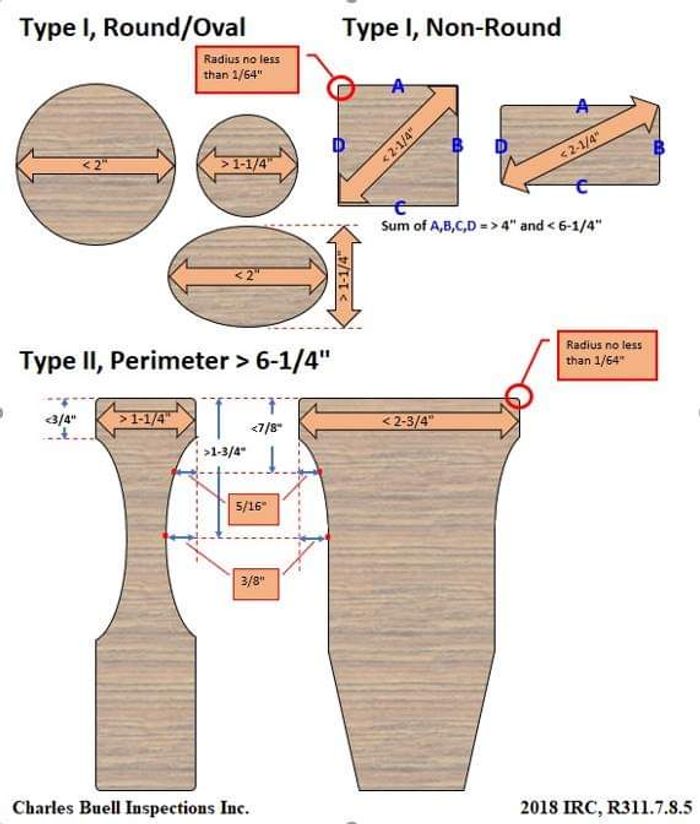

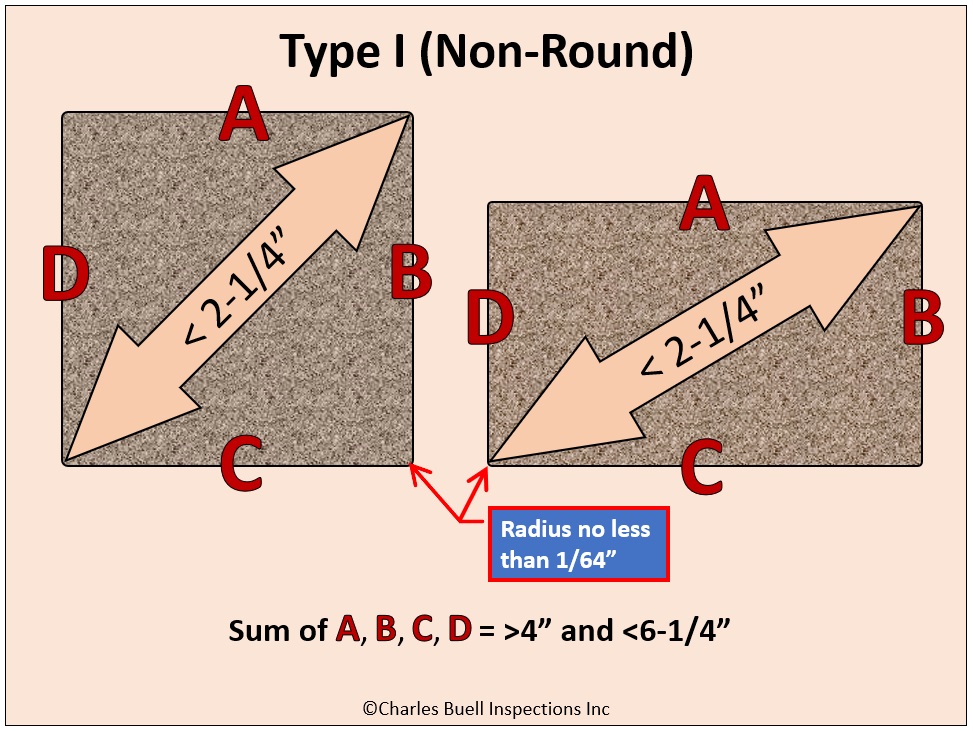

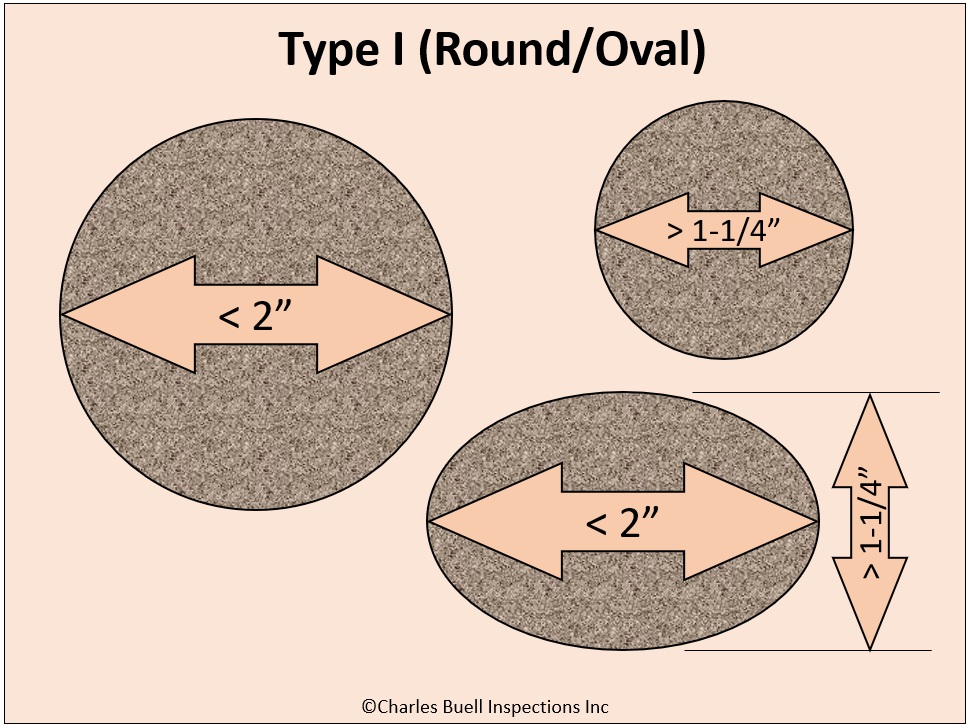

The graspable handrail for the interior stairs is missing. This should be a round railing 1 and 1/4 inches - 2 inches in diameter. If the railing is not round it must have a finger groove that is 3/4 of an inch down from the tallest point of the rail. The graspable handrail should also be 1.5 inches from the wall and have returns into the wall. Have a qualified contractor build suitable railings to reduce the potential for falls.

- RCG-5 🧱Roof, Chimney and Gutters - Gutters, Downspouts, Roof Drains, and Drip Edges:

The areas surrounding the roof drains were observed to be filled with leaves and debris, which can restrict positive water flow and impede proper roof drainage. In addition, the drain strainers were found to be loose and unsecured, making them susceptible to dislodging and allowing debris to enter the drain body, potentially causing blockages and water ponding on the roof surface.

Obstructed or poorly secured drains increase the risk of standing water, which can accelerate roof membrane deterioration and contribute to leaks or structural loading.

RECOMMENDATION: As part of a comprehensive roofing replacement effort, have a qualified roofing contractor:

- Clean and clear all debris from the roof drains and surrounding areas,

- Replace the existing roof drain bodies with properly fitted and secured units, and

- Install a secondary spillout wall scupper to provide emergency overflow drainage in the event of a blockage or backup.

- Have the roof drains scoped for any internal damage or debris build-up

These improvements will help ensure reliable roof drainage and reduce the risk of water-related damage to the roofing system.

🧱 - RCG-6 🧱Roof, Chimney and Gutters - Plumbing Vents:

The flashing around the plumbing vent penetrations was observed to be flaking, deteriorated, and in need of maintenance or replacement. In addition, the plumbing vent stacks were noted to be too short, with their terminations located less than 12 inches above the finished roof surface, which does not meet current standards for proper clearance.

Insufficient vent height can allow snow, debris, or roof runoff to obstruct the vent openings, reducing the plumbing system’s ability to vent properly and potentially causing slow drainage or trap siphoning inside the home.

RECOMMENDATION: Have a qualified roofing or plumbing contractor replace the deteriorated flashing and extend the vent pipes to meet the current standard of at least 12 inches above the finished roof surface, ensuring proper sealing and long-term weather resistance.

🚽🚿🚰🧱 - ES-1 ⚡Electric Service - Electric Service:

TREES AND VEGETATION ARE IN CONTACT WITH THE ELECTRIC SERVICE CONDUCTORS

Trees and vegetation are in contact with the overhead electrical service drop. This can lead to insulation damage, potentially exposing the conductors and increasing the risk of arcing or fire. It is recommended that the utility provider conduct a follow-up inspection of the service drop. Tree limbs, branches, and other vegetation should be trimmed back as necessary, and any damaged conductors should be repaired accordingly.

✒️

- Sometimes the utility will add chaffing gear to protect the conductors where trees cannot be removed.

⚡💡 - ES-2 ⚡Electric Service - Electric Service Equipment:

Some of the electrical conductors within the main service panel were observed to be over-stripped, exposing more bare wire than is appropriate beyond the terminal connections. Excessive exposure of conductor material increases the risk of accidental contact, arcing, or short circuits, particularly in confined spaces within the panel.

While the system was functional at the time of inspection, this condition represents a potential safety hazard that should be corrected to ensure proper insulation and safe termination.

RECOMMENDATION: Have a licensed electrical contractor evaluate the panel and re-strip and re-terminate any affected conductors to meet current electrical safety standards. Proper insulation and secure terminations will help prevent accidental contact and maintain the integrity of the electrical system.

⚡💡 - ES-8 ⚡Electric Service - Sub Panel:

OPENINGS IN DEAD FRONT COVER

Openings were noted in the dead front cover to the electric panel. This is unsafe as it does not adequately protect the energized area of the electric panel. Cover all open knock-outs with listed covers.

⚡💡 - HCFV-1 🔥❄️Heating, Cooling, Fireplaces and Ventilation - Thermostat:

The only thermostat observed was located in the second-floor hallway. The unit did not appear to have power and did not respond to any of the control inputs at the time of inspection. As a result, the heating and cooling system could not be fully tested for proper operation.

A non-operational thermostat prevents verification of system performance and may indicate a power supply issue, wiring defect, or failed control unit.

RECOMMENDATION: Have a qualified HVAC technician or electrician evaluate the thermostat power supply and wiring to determine the cause of the malfunction. Repair or replace the thermostat as needed to restore full control and functionality of the heating and cooling system.

🔥❄️ - HCFV-7 🔥❄️Heating, Cooling, Fireplaces and Ventilation - Solid Fuel Fireplaces:

The flue damper for the fireplace was locked / rusted closed / not responding to normal operating controls. Have this further investigated and repaired by a qualified chimney sweep.

🔥❄️ - LR-2 📺Living Room - Doors:

INTERIOR DOOR SAFETY GLASS

Some of the doors in this building have glazing or glass elements that do not appear to be done with safety glass - no listing was visible. Safety glass is recommended for all door glazing and is a modern safety requirement. Tempered glass will shatter into harmless fragments rather than sharp shards and laminated glass has the additional benefit of resisting breakage like auto glass. Installing safety glass in all doors with openings larger than 3-inches is recommended for improved safety.

- LR-3 📺Living Room - Windows:

A sampling of the living room windows revealed that several units appear to be painted or rusted shut and could not be operated using normal controls. This condition limits ventilation and suggests that the window hardware or framing components may also be deteriorated.

While the condition does not pose an immediate hazard, inoperable windows can compromise safety, comfort, and energy performance.

RECOMMENDATION: Have a qualified general or glazing contractor further evaluate the affected window units and perform repairs to restore proper operation where feasible. Given the apparent age and condition, replacement of the windows should also be considered to improve energy efficiency, weather resistance, and functionality. Any replacement should be selected and detailed to maintain the building’s original architectural aesthetic.

- O1-2 Office - Electrical:

The ceiling fan and light switch did not respond to normal testing.

RECOMMENDATION: Have a qualified electrical contractor evaluate further and provide repairs.

- O1-3 Office - Doors:

A exterior door in the office did not respond to testing and appeared to be painted or rusted shut and could not be operated using normal controls. This condition limits ventilation and suggests that the hardware or framing components may also be deteriorated.

While the condition does not pose an immediate hazard, inoperable doors can compromise safety, comfort, and energy performance.

RECOMMENDATION: Have a qualified general or glazing contractor further evaluate the affected units and perform repairs to restore proper operation where feasible. Given the apparent age and condition, replacement of the doors should also be considered to improve energy efficiency, weather resistance, and functionality. Any replacement should be selected and detailed to maintain the building’s original architectural aesthetic.

- SR-2 Sun Room - Doors:

The sliding doors were observed to be difficult to operate and did not move smoothly along their tracks. The doors exhibited resistance when opening and closing, which may be due to dirt or debris buildup in the track, worn rollers, or misalignment of the door panels. This condition limits proper function and may place additional stress on the hardware, leading to further deterioration if not corrected.

While not a safety hazard, the issue affects usability and may worsen over time if maintenance is deferred.

RECOMMENDATION: Have a qualified contractor or door specialist inspect the sliding doors to clean the tracks, adjust alignment, and replace worn rollers or hardware as needed. Regular cleaning and lubrication of the track system are recommended to maintain smooth operation and prevent premature wear. Replacement may also be warranted.

- SR-3 Sun Room - Windows:

The sunroom windows appears to be painted or rusted shut and could not be operated using normal controls. This condition limits ventilation and suggests that the window hardware or framing components may also be deteriorated.

While the condition does not pose an immediate hazard, inoperable windows can compromise safety, comfort, and energy performance.

RECOMMENDATION: Have a qualified general or glazing contractor further evaluate the affected window units and perform repairs to restore proper operation where feasible. Given the apparent age and condition, replacement of the windows should also be considered to improve energy efficiency, weather resistance, and functionality. Any replacement should be selected and detailed to maintain the building’s original architectural aesthetic.

- WR-2 Weight Room - Windows:

A sampling of the living room windows revealed that several units appear to be painted or rusted shut and could not be operated using normal controls. This condition limits ventilation and suggests that the window hardware or framing components may also be deteriorated.

While the condition does not pose an immediate hazard, inoperable windows can compromise safety, comfort, and energy performance.

RECOMMENDATION: Have a qualified general or glazing contractor further evaluate the affected window units and perform repairs to restore proper operation where feasible. Given the apparent age and condition, replacement of the windows should also be considered to improve energy efficiency, weather resistance, and functionality. Any replacement should be selected and detailed to maintain the building’s original architectural aesthetic.

- DR-3 🍽️Dining Room - Windows:

The metal casement windows appear to be original to the building and do not meet modern standards for energy efficiency or performance. The exterior finishes show signs of deterioration and weathering, and the window hardware was found to be unreliable or difficult to operate, consistent with similar units observed throughout the home.

While the windows remain in place, their condition and performance are below current standards and may contribute to heat loss, air infiltration, and operational difficulties.

RECOMMENDATION: Consider replacing the existing metal casement windows with new, energy-efficient units that maintain the original architectural style and proportions of the building. A qualified window or glazing contractor should be consulted to ensure proper installation and to select materials that improve thermal performance while preserving the home’s historic character.

- PR-2 ☎️Phone Room - Windows:

The window in the phone room appeared to be painted or rusted shut and could not be operated using normal controls. This condition limits ventilation and suggests that the window hardware or framing components may also be deteriorated.

While the condition does not pose an immediate hazard, inoperable windows can compromise safety, comfort, and energy performance.

RECOMMENDATION: Have a qualified general or glazing contractor further evaluate the affected window units and perform repairs to restore proper operation where feasible. Given the apparent age and condition, replacement of the windows should also be considered to improve energy efficiency, weather resistance, and functionality. Any replacement should be selected and detailed to maintain the building’s original architectural aesthetic.

- PB11-2 🛏️Primary Bedroom (1) - Windows:

A sampling of the Primary Bedroom windows revealed that metal bay window units appeared to be painted or rusted shut and could not be operated using normal controls. This condition limits ventilation and suggests that the window hardware or framing components may also be deteriorated.

While the condition does not pose an immediate hazard, inoperable windows can compromise safety, comfort, and energy performance.

RECOMMENDATION: Have a qualified general or glazing contractor further evaluate the affected window units and perform repairs to restore proper operation where feasible. Given the apparent age and condition, replacement of the windows should also be considered to improve energy efficiency, weather resistance, and functionality. Any replacement should be selected and detailed to maintain the building’s original architectural aesthetic.

- B2-2 🛏️Bedroom (2) - Doors:

A exterior door in Bedroom 2 did not respond to testing and appeared to be painted or rusted shut and could not be operated using normal controls. This condition limits ventilation and suggests that the hardware or framing components may also be deteriorated.

While the condition does not pose an immediate hazard, inoperable doors can compromise safety, comfort, and energy performance.

RECOMMENDATION: Have a qualified general or glazing contractor further evaluate the affected units and perform repairs to restore proper operation where feasible. Given the apparent age and condition, replacement of the doors should also be considered to improve energy efficiency, weather resistance, and functionality. Any replacement should be selected and detailed to maintain the building’s original architectural aesthetic. See "Exterior Door" section of the report.

- B5-2 🛏️Bedroom (5) - Electrical:

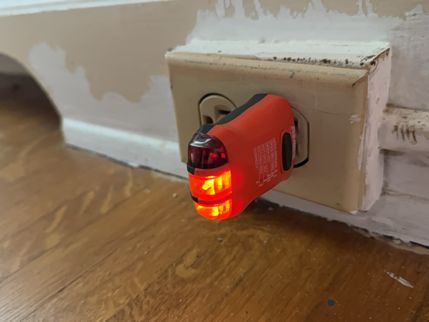

OPEN GROUNDS

Hire a licensed electrician to address and eliminate all open grounds. This is a common issue in older homes built before 1962, where three-prong outlets have been added to an original two-wire system. This condition poses a safety risk, as it can be misleading—allowing appliances that depend on an equipment ground for safe fault discharge to be connected to ungrounded circuits. This effectively disables a key safety feature. Proper corrective measures may include, but not be limited to,:

- Running an equipment grounding conductor or a new three-wire circuit

- Restoring a two-prong receptacle or

- Installing GFCI protection for this circuit and labeling the open-ground receptacles

If GFCI protection is used, the outlets on this circuit should be labeled, so it is clear they are ungrounded and GFCI protected. Examples of locations where open grounds were found include:

⚡💡 - B5-3 🛏️Bedroom (5) - Electrical:

LOOSE ELECTRIC RECEPTACLES

The electric receptacle in the bedroom was found to be loosely mounted to the wall. Loose receptacles can place strain on wiring connections, potentially leading to damage or arcing.

RECOMMENDATION: Have a qualified electrical contractor evaluate further and provide repairs.

⚡💡 - B5-4 🛏️Bedroom (5) - Finishes:

Evidence of water infiltration was observed in the form of staining on the wall and ceiling surfaces near the dormer area. The plaster in this location shows early signs of deterioration and moisture damage. While this condition does not appear to be widespread or consistent with other areas of the home, it should be addressed promptly to prevent further deterioration or potential mold growth.

RECOMMENDATION: Have a qualified roofing or general contractor identify and repair the source of the leak at the dormer. Once the area is fully dried, the damaged plaster should be repaired or refinished to restore the surface and prevent further moisture-related deterioration. Continued monitoring after repairs is recommended.

- B6-2 🛏️Bedroom (6) - Electrical:

OPEN GROUNDS

Hire a licensed electrician to address and eliminate all open grounds. This is a common issue in older homes built before 1962, where three-prong outlets have been added to an original two-wire system. This condition poses a safety risk, as it can be misleading—allowing appliances that depend on an equipment ground for safe fault discharge to be connected to ungrounded circuits. This effectively disables a key safety feature. Proper corrective measures may include, but not be limited to,:

- Running an equipment grounding conductor or a new three-wire circuit

- Restoring a two-prong receptacle or

- Installing GFCI protection for this circuit and labeling the open-ground receptacles

If GFCI protection is used, the outlets on this circuit should be labeled, so it is clear they are ungrounded and GFCI protected. Examples of locations where open grounds were found include:

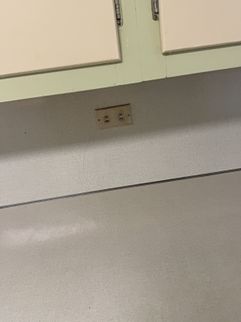

⚡💡 - K-2 🧑🍳🔪Kitchen - Electrical:

There were no GFCI receptacles observed in the kitchen. A receptacle within 6 feet of a water source is required to be GFCI protected to reduce risk of shock. Current standards require all receptacles in the kitchen to be GFCI protected.

RECOMMENDATION: Have a qualified electrical contractor replace the receptacle(s) with a GFCI protected receptacle.

⚡💡 - K-4 🧑🍳🔪Kitchen - Sinks and Faucets/ Plumbing:

S-TRAP AT THE KITCHEN SINK WASTE PIPING

The waste plumbing to the kitchen sink is not properly vented and has an S-trap configuration. This trapping is no longer allowed as it risks siphoning the trap and allowing sewer gas to enter the home.

RECOMMENDATION: Hire a licensed plumber to repair with proper venting loop or an air admittance valve.

🚽🚿🚰 - BP-3 🧑🍳🔪Butler Pantry - Electrical:

There were no GFCI receptacles observed in the butler pantry. A receptacle within 6 feet of a water source is required to be GFCI protected to reduce risk of shock. Current standards require all receptacles in the kitchen to be GFCI protected.

RECOMMENDATION: Have a qualified electrical contractor replace the receptacle(s) with a GFCI protected receptacle.

- BP-6 🧑🍳🔪Butler Pantry - Windows:

The windows in the Butler’s Pantry consist of a combination of glass block units and original single-pane metal windows. The metal windows include both casement and awning styles. These windows do not meet current energy-efficiency standards, and the glass block assemblies are not thermally broken, offering limited insulation value.

RECOMMENDATION: Consider upgrading the existing windows to modern, energy-efficient units that maintain the architectural character of the space. Replacement of the glass block with insulated glazing units or thermally broken materials can further improve comfort and energy performance. A qualified window or glazing contractor should be consulted to ensure proper material selection and installation.

- LF-2 👕👖Laundry Facilities - Electrical:

There was no GFCI receptacle in the laundry area. A receptacle within 6 feet of a water source is required to be GFCI protected to reduce risk of shock.

RECOMMENDATION: Have a qualified electrical contractor replace the receptacle with a GFCI protected receptacle.

⚡💡 - PBHB-2 🚽Powder Bathroom/ Half Bath - Electrical:

No electrical outlet was observed in the half bathroom at the time of inspection. Current electrical safety standards (NEC 210.52(D)) require at least one GFCI-protected receptacle in all bathrooms to safely accommodate electrical devices such as hair dryers, razors, or electric toothbrushes.

While this may have been acceptable at the time of original construction, the absence of a GFCI outlet represents a modern safety and convenience deficiency.

RECOMMENDATION: Have a licensed electrical contractor install a GFCI-protected receptacle in the half bathroom in accordance with current National Electrical Code requirements. This upgrade will improve safety and functionality for bathroom use.

⚡💡 - PBHB-3 🚽Powder Bathroom/ Half Bath - Sinks and Cabinets:

The sink was tested during the inspection, and it was noted that the hot water flow stopped after several seconds of operation. Additionally, the drain stopper mechanism was not functioning properly and did not hold or release water as intended. These conditions indicate that repairs or component replacement may be necessary for proper operation.

While the sink remains partially usable, the issues with the hot water supply and drain mechanism affect normal function and convenience.

RECOMMENDATION: Have a qualified plumbing contractor further evaluate the sink’s hot water supply and stopper assembly to determine the cause of the malfunction and perform repairs or replacements as needed to restore full functionality.

- PB1-2 🚽🛁🚿Primary Bathroom (1) - Electrical:

There was no GFCI receptacle in the primary bathroom. A receptacle within 6 feet of a water source is required to be GFCI protected to reduce risk of shock.

RECOMMENDATION: Have a qualified electrical contractor replace the receptacle with a GFCI protected receptacle.

⚡💡 - PB1-3 🚽🛁🚿Primary Bathroom (1) - Electrical:

OPEN GROUNDS

Hire a licensed electrician to address and eliminate all open grounds. This is a common issue in older homes built before 1962, where three-prong outlets have been added to an original two-wire system. This condition poses a safety risk, as it can be misleading—allowing appliances that depend on an equipment ground for safe fault discharge to be connected to ungrounded circuits. This effectively disables a key safety feature. Proper corrective measures may include, but not be limited to,:

- Running an equipment grounding conductor or a new three-wire circuit

- Restoring a two-prong receptacle or

- Installing GFCI protection for this circuit and labeling the open-ground receptacles

If GFCI protection is used, the outlets on this circuit should be labeled, so it is clear they are ungrounded and GFCI protected. Examples of locations where open grounds were found include:

⚡💡 - PB1-4 🚽🛁🚿Primary Bathroom (1) - Sinks and Cabinets:

CORRODED P-TRAP

The waste piping below the primary bath sink is corroded. Although no active leakage was noted at the time of inspection, the visible corrosion indicates age-related deterioration and an increased risk of future leakage or failure.

RECOMMENDATION: Have a qualified plumbing contractor replace the corroded waste piping to ensure long-term reliability and prevent potential leaks. Proactive replacement at this stage will help avoid future water damage and improve the overall performance of the plumbing system.

- PB1-7 🚽🛁🚿Primary Bathroom (1) - Bathtub / Shower:

OLD SHOWER TILE - MAIN BATH

The tile in the bathroom shower surround appears aged and may require updating or repair in the near future. The condition of materials behind the tile—such as the substrate and waterproofing—is not visible during a standard inspection, making it difficult to determine the system’s overall reliability.

RECOMMENDATION: Have a qualified tile or bathroom renovation specialist further evaluate the shower surround to determine whether localized repairs or full replacement are needed. Additional inspection may reveal either minor maintenance needs or concealed moisture damage, which could require a more comprehensive upgrade.

Examples of concerns noted during inspection include:

- Staining or evidence of water intrusion

- PB1-9 🚽🛁🚿Primary Bathroom (1) - Moisture Damage to Finishes:

Moisture damage was observed on the finishes in the primary bathroom. The condition may be related to roofing deficiencies or inadequate mechanical ventilation, both of which can allow moisture to accumulate and damage interior materials over time.

RECOMMENDATION: Have a qualified general contractor further evaluate and repair the affected finishes. At the same time, the source of the moisture—whether from roof leaks or condensation due to poor ventilation—should be identified and corrected to prevent future damage. Installing or improving mechanical ventilation may also be recommended to reduce humidity levels and maintain proper air circulation.

- B21-2 🚽🛁🚿Bathroom-Full (2) - Electrical:

There was no GFCI receptacle in the full bathroom. A receptacle within 6 feet of a water source is required to be GFCI protected to reduce risk of shock.

RECOMMENDATION: Have a qualified electrical contractor replace the receptacle with a GFCI protected receptacle.

⚡💡 - B21-4 🚽🛁🚿Bathroom-Full (2) - Bathtub / Shower:

The shower diverter was observed to be sticking and difficult to operate, and it could not be fully engaged during testing. This may cause reduced water pressure or improper flow from the showerhead, indicating wear or internal malfunction.

The diverter remains partially functional but is not operating as intended and may worsen with continued use.

RECOMMENDATION: Have a qualified plumbing contractor further evaluate the shower diverter assembly and perform repairs or replacement as needed to ensure smooth operation and proper water distribution between the tub spout and showerhead.

🚽🚿🚰 - B21-5 🚽🛁🚿Bathroom-Full (2) - Bathroom Ventilation:

A sampling of the living room windows revealed that several units appear to be painted or rusted shut and could not be operated using normal controls. This condition limits ventilation and suggests that the window hardware or framing components may also be deteriorated.

While the condition does not pose an immediate hazard, inoperable windows can compromise safety, comfort, and energy performance.

RECOMMENDATION: Have a qualified general or glazing contractor further evaluate the affected window units and perform repairs to restore proper operation where feasible. Given the apparent age and condition, replacement of the windows should also be considered to improve energy efficiency, weather resistance, and functionality. Any replacement should be selected and detailed to maintain the building’s original architectural aesthetic.

- B31-2 🚽🛁🚿Bathroom-Full (3) - Electrical:

No electrical outlet was observed in the half bathroom at the time of inspection. Current electrical safety standards (NEC 210.52(D)) require at least one GFCI-protected receptacle in all bathrooms to safely accommodate electrical devices such as hair dryers, razors, or electric toothbrushes.

While this may have been acceptable at the time of original construction, the absence of a GFCI outlet represents a modern safety and convenience deficiency.

RECOMMENDATION: Have a licensed electrical contractor install a GFCI-protected receptacle in the half bathroom in accordance with current National Electrical Code requirements. This upgrade will improve safety and functionality for bathroom use.

⚡💡 - B31-3 🚽🛁🚿Bathroom-Full (3) - Sinks and Cabinets:

During the inspection, the sink fixtures were tested, and it was noted that the hot and cold water handles were seized and inoperable. The handles could not be turned using normal force, preventing full testing of the water flow. This condition suggests internal corrosion, mineral buildup, or mechanical failure within the faucet assembly.

RECOMMENDATION: Have a qualified plumbing contractor further evaluate and repair or replace the faucet assembly as needed. Replacement may be the most practical option to restore full function and reliability of the sink fixture.

🚽🚿🚰 - B31-4 🚽🛁🚿Bathroom-Full (3) - Toilet:

The toilet was tested during the inspection and found to be securely mounted with no visible leaks. However, a loud gurgling sound was noted during draining, which may indicate inadequate venting or partial obstruction in the drain line. Improper venting can cause slow drainage, trap siphoning, or odors over time.

While the fixture is currently functional, the condition suggests a venting or drain performance issue that should be investigated further.

RECOMMENDATION: Have a licensed plumbing contractor evaluate the toilet drain line and venting system to determine the cause of the gurgling and perform necessary repairs to ensure proper drainage and vent function.

🚽🚿🚰 - B31-6 🚽🛁🚿Bathroom-Full (3) - Bathroom Ventilation:

A sampling of the living room windows revealed that several units appear to be painted or rusted shut and could not be operated using normal controls. This condition limits ventilation and suggests that the window hardware or framing components may also be deteriorated.

While the condition does not pose an immediate hazard, inoperable windows can compromise safety, comfort, and energy performance.

RECOMMENDATION: Have a qualified general or glazing contractor further evaluate the affected window units and perform repairs to restore proper operation where feasible. Given the apparent age and condition, replacement of the windows should also be considered to improve energy efficiency, weather resistance, and functionality. Any replacement should be selected and detailed to maintain the building’s original architectural aesthetic.

- B31-7 🚽🛁🚿Bathroom-Full (3) - Moisture Damage to Finishes: