Thank you for choosing Soundside Inspections for your home inspection needs. I understand that purchasing a home is one of the most significant decisions you'll make, and I appreciate the trust you've placed in me. I am committed to providing you with a thorough and detailed inspection of your prospective property. My goal is to equip you with the knowledge and information you need to make an informed decision about your investment and a guide to use if you decide to make this your home.

Your satisfaction is my top priority. If you have any questions or require further clarification regarding this report, please do not hesitate to reach out to me. Once again, thank you for choosing Soundside Inspections.

The Scope and Purpose of a Home Inspection

Purchasing property involves risk

The purpose of a home inspection is to help reduce the risk associated with the purchase of a structure by providing a professional opinion about the overall condition of the structure. A home inspection is a limited visual inspection and it cannot eliminate this risk. Some homes present more risks than others. We cannot control this, but we try to help educate you about what we don’t know during the inspection process. This is more difficult to convey in a report and one of many reasons why we recommend that you attend the inspection.

A home inspection is not an insurance policy

This report does not substitute for or serve as a warranty or guarantee of any kind. Home warranties can be purchased separately from insuring firms that provide this service.

A home inspection is visual and not destructive

The descriptions and observations in this report are based on a visual inspection of the structure. We inspect the aspects of the structure that can be viewed without dismantling, damaging or disfiguring the structure and without moving furniture and interior furnishings. Areas that are concealed, hidden or inaccessible to view are not covered by this inspection. Some systems cannot be tested during this inspection as testing risks damaging the building. For example, overflow drains on bathtubs are generally not tested because if they were found to be leaking they could damage the finishes below. Our procedures involve non-invasive investigation and non-destructive testing which will limit the scope of the inspection.

This is not an inspection for code compliance

This inspection and report are not intended for city / local code compliance. During the construction process structures are inspected for code compliance by municipal inspectors. Framing is open at this time and conditions can be fully viewed. Framing is not open during inspections of finished homes, and this limits the inspection. All houses fall out of code compliance shortly after they are built, as the codes continually change. National codes are augmented at least every three years for all of the varying disciplines. Municipalities can choose to adopt and phase in sections of the codes on their own timetables. There are generally no requirements to bring older homes into compliance unless substantial renovation is being done. I may reference local codes as they apply to general safety recommendations or requirements.

This is just our opinion

Construction techniques and standards vary. There is no one way to build a house or install a system in a house. The observations in this report are the opinions of the home inspector. Other inspectors and contractors are likely to have some differing opinions. You are welcome to seek opinions from other professionals.

The scope of this inspection

This inspection will include the following systems: exterior, roof, structure, drainage, foundation, attic, interior, plumbing, electrical, and heating. The evaluation will be based on limited observations that are primarily visual and non-invasive. This inspection and report are not intended to be technically exhaustive.

Your expectations

The overall goal of a home inspection is to help ensure that your expectations are appropriate for the house you are proposing to buy. To this end, we assist with discovery by showing and documenting observations during the home inspection. This should not be mistaken for a technically exhaustive inspection designed to uncover every defect within a building. Such inspections are available but they are generally cost-prohibitive to most homebuyers.

Your participation is requested

Your presence is requested during this inspection. A written report will not substitute for all the possible information that can be conveyed verbally by a shared visual observation of the conditions of the property.

How to Read This Report

Getting the Information to You

This report is designed to deliver important and technical information in a way that is easy for anyone to access and understand. If you are in a hurry, you can take a quick look at our "Summary Page” and quickly get critical information for important decision making. However, we strongly recommend that you take the time to read the full Report, which includes digital photographs, captions, diagrams, descriptions, videos, and hot links to additional information.

The best way to get the layers of information that are presented in this report is to read your report online (the HTML version), which will allow you to expand your learning about your house. You will notice some words or series of words highlighted in blue and underlined – clicking on these will provide you with a link to additional information. The HTML version of this report also contains streaming videos. Short video clips often contain important information and critical context and sounds that can be difficult to capture in words and still pictures.

For the most reliable viewing experience, I recommend viewing the report on as large a screen as practical, as much detail can be lost on small devices like smartphones. For similar reasons, reports should only be printed in color to retain as much detail as possible and minimize misinterpretation of photographs.

This report can also be printed on paper or as a PDF document.

Chapters and Sections

This report is divided into chapters that parcel the home into logical inspection components. Each chapter is broken into sections that relate to a specific system or component of the home. You can navigate between chapters with the click of a button on the left side margin.

Most sections will contain some descriptive information done in black font. Observation narrative, done in colored boxes, will be included if a system or component is found to be significantly deficient in some way or if we wish to provide helpful additional information about the system or the scope of our inspection. If a system or component of the home was deemed to be in satisfactory or serviceable condition, there may be no narrative observation comments in that section and it may simply say “tested,” or “inspected.”

Observation Labels

All narrative observations are colored, numbered, and labeled to help you find, refer to, and understand the severity of the observation. Observation colors and labels used in this report are:

- Major Concern:Repair items that require immediate attention to prevent additional damage or eliminate safety hazards.

- Repair:Repair items that require attention to prevent future damage, but are not an immediate risk to health and safety. These items may range from small to costly repairs.

- Recommended Maintenance:These are repair items that should be considered "routine home ownership items," such as paint and caulk upkeep, cleaning the gutters, or changing the air filters in the furnace.

- Improve:Observations that are not necessarily defects, but could be improved for safety, efficiency, comfort, or reliability reasons.

- Due Diligence:Defects that may not be able to be reasonably remedied due to specific constraints within the property. Such as a steep staircase in an older home. Suggestions will be made to enhance safety in these areas. Or. Items required by the Washington State Standards of Practice to comment on.

- Efficiency:Denotes observations that are needed to make the home more energy efficient as well as to bring the home up to modern insulation standards. This category typically includes windows and insulation. Other items, such as lighting and appliances, are not inspected for their energy status.

- Note:Refers to aside information and /or any comments elaborating on descriptions of systems in the home or limitations to the home inspection.

- Description:Detailed description of various aspects of the property noted during the inspection.

Pest Inspection

I am not a licensed Washington State Structural Pest Inspector. While I can identify conducive conditions for wood-destroying organisms and general signs of insect activity, I cannot provide specific identification of insects or diagnose infestations. My observations and recommendations should not be considered as a substitute for a professional inspection conducted by a qualified Structural Pest Inspector.

Summary Page

The Summary Page is designed as a bulleted overview of all the observations noted during the inspection. This helpful overview is not a substitute for reading the entire inspection report. The entire report must be read to get a complete understanding of this inspection report as the Summary Page does not include photographs or photo captions.

Summary

Major Concerns

- P-3 Plumbing:

A leak in the connection below the pressure-reducing valve was noted. Though the leak was minor at the time of the inspection it has the potential for failure in the future. I recommend a qualified plumber evaluate and repair or replace the fixture as necessary.

- ES-2 Electric Service:

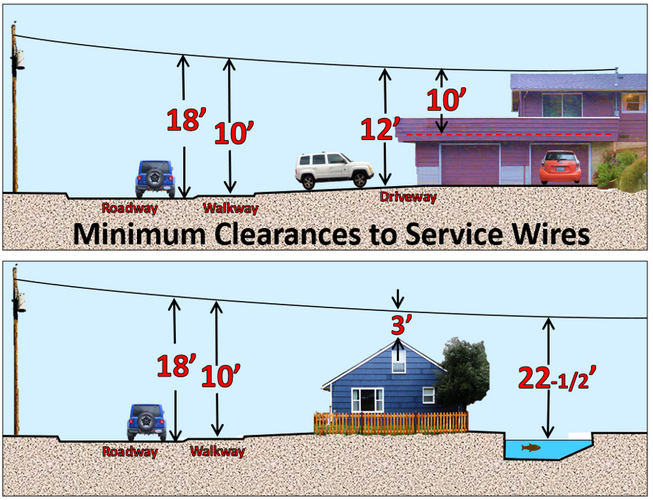

The electrical service conductors servicing the home are too close to a walkway surface. Local safety standards say the conductors should be a minimum of 10 feet above walkways and areas where people will be outdoors to ensure there is no contact between people and these cables. Although the service conductors from the street to the service head (where the service conductors attach to the home) are generally the responsibility of the utility company, I recommend a qualified electrician evaluate the condition, location, and height of the service head as it may need to be raised to meet the 10 foot requirement.

- ES-4 Electric Service:

This home has a Magnetrip panel on the exterior of the home that appears to have been the original electrical panel for the home. When the electrical was updated, instead of removing this panel and running the entrance cables to the location of the new panel inside the home, this panel was kept as the main panel making the panel inside the home a sub-panel. Magnetrip panels have a reputation for failing and malfunctioning breakers as well as a unique copper bus bar design that can allow breakers to make loose connections which can lead to arcing and fires. These panels are considered a latent fire hazard. The panel was rusted with duct tape covering unused openings and an opening too large for the main breaker being used. I recommend a qualified electrician evaluate and remove the panel from the electrical system of the home for improved safety.

Repairs

- G1-2 Grounds:

Several of the downspouts of the home terminated too close to the foundation. This can allow water to accumulate near the foundation, leading to soil erosion and hydrostatic pressure causing cracks, shifting, or settling in the foundation, and water intrusion into the crawlspace, causing moisture issues and flooding during heavy rainfall. Downspouts should be extended to discharge water 4 to 6 feet away from the house through an above-ground or below-ground drainage system. I recommend a qualified drainage specialist to evaluate and repair or replace the current drainage system to adequately move water away from the homes foundation.

- G1-3 Grounds:

There were inadequate foundation vent wells and crawlspace access wells seen around the home. Wells help provide a clear space for vents or hatches that are at or below grade. This helps to keep vegetation clear of the vent for proper ventilation to promote moisture control, temperature regulation, and drainage to prevent water from entering the crawlspace during rain. I recommend a qualified foundation specialist or contractor evaluate and install adequate wells for these site conditions.

- ESDW-2 Exterior Siding, Doors and Windows:

Loose, missing, and damaged siding shingles were observed around the home during the inspection. These issues can compromise the integrity of the siding and lead to potential water intrusion. I recommend a qualified general contractor evaluate, repair, or replace all damaged shingles and properly seal them to prevent further damage. Please note that whenever there is damage to the siding system, there is a risk of uncovering additional concealed damage in the course of repairs.

- ESDW-4 Exterior Siding, Doors and Windows:

There was wood siding in contact with the roof surface at the south and north sides of the home. A 1 to 2-inch gap is recommended between the siding material and the roof surface, installed with step flashing on the roof side and counter flashing on the wall side. Siding contact with the roof surface can lead to water damage to the siding material, exterior wall sheathing, and framing members. This work is easiest to do during a re-roofing. I recommend a qualified general contractor evaluate, amend the roof contact, and repair any damaged areas that may be found during work.

- ESDW-5 Exterior Siding, Doors and Windows:

There was a drain waste vent terminating too close to a window. Drain waste vents carry sewer gases from the waste system away from the home and aid in a balanced waste drainage system. Local safety standards state that "Each vent shall terminate not less than 10 feet (3048 mm) from, or not less than 3 feet (914 mm) above, an openable window, door, opening, air intake, or vent shaft". This can allow harmful sewer gases into the home. I recommend a qualified plumbing contractor extend the drain waste vent away from the window for improved safety.

- DPB-1 Decks, Porches and Balconies:

Some of the treads of the stairs leading up to the rear door had significant rot. This creates an unsafe walking surface as softened wood can become slippery when wet and icy during cold weather. It also creates a conducive condition for wood-destroying insects near the home.I recommend a qualified contractor evaluate, repair, or replace any stair treads with rot to ensure a safe and stable walking surface.

- DPB-2 Decks, Porches and Balconies:

The handrail/guardrail leading to the rear door was rotted and loose. Handrails are required on stairs with 4 or more risers and guardrails on stairs or decks over 30 inches from the ground and are intended to hold the weight of an adult. Rotted wood near the home also creates a conducive condition for wood-destroying insects. These help to prevent a fall or to help prevent serious injury in case of a fall. I recommend a qualified contractor evaluate and repair or replace any rotted materials as necessary to ensure safety.

- P-2 Plumbing:

The static water pressure in the home tested above 80 psi (pounds per square inch), the maximum water pressure recommended. High water pressure can stress the supply plumbing system and make it more vulnerable to leaks. A pressure-reducing valve was noted on the main water inlet suggesting that it may require adjustment or there could be issues with thermal expansion due to water heating. It is also possible that the hose bibs, where I tested the water pressure, are not protected by this device and that the rest of the house is protected. I recommend a qualified plumbing contractor evaluate and adjust or repair the pressure-reducing valve as necessary.

- P-4 Plumbing:

The insulation on the water pipes in the crawlspace was incomplete. Proper insulation of water pipes is essential to minimize the risk of freezing in colder temperatures. I recommend a qualified contractor or plumber evaluate and install insulation suitable for our local environment.

- P-5 Plumbing:

The hose bib at the east side of the house was leaking when turned on and under pressure. This can lead to water wastage and potential water damage to the immediate surroundings. I recommend a qualified plumber evaluate, repair, or replace as necessary.

- RCG-1 Roof, Chimney and Gutters:

The roof of this property appeared to be approaching the end of its intended life based on general industry standards and visual observations, such as cracking or curling and loss of granules of the shingles, and microbial growth. A roof's exact age is often difficult to determine based solely on observation. There is a difference between the intended life span of roofing materials and the functional life. Roofing materials may function much longer than their intended life, though they may also function much less than intended. A roof's remaining functional lifespan can vary depending on several factors, including the type of roofing material, installation quality, maintenance history, and local environmental conditions. While it is challenging to provide an exact timeframe for the remaining service life of the roof it is advisable to consider budgeting for a roof replacement in the near future. I recommend a qualified roofing contractor evaluate the roof and repair or replace it as necessary.

- RCG-3 Roof, Chimney and Gutters:

The water heater exhaust vent had damaged boot flashing. Flashing prevents water intrusion around the vent that can damage the roof sheathing, roof structure, and interior finishes. This repair would be best done along with re-roofing. The support for the vent was also inadequate.I recommend a qualified general or roofing contractor evaluate and repair or replace the flashing and support to prevent further damage.

- ES-5 Electric Service:

The electrical panel is installed with a "back-fed" configuration. Back-feeding means that the electrical service wires supply power to the panel through a typical breaker position on the bus bars, and not a factory installed main breaker at the top of the panel. Though this panel has a main breaker installed but is not being used. Back feeding is a common configuration though this panel is missing a required screw to secure the breaker to the panel to reduce the risk of it coming loose and becoming a fire and shock hazard. I recommend a qualified electrician evaluate for correct installation of the main breaker and evaluate that this panel is adequate for being a main panel after the exterior panel is removed.

- EDFW-1 Electric Distribution and Finish Wiring:

Abandoned wiring was noted in the crawl space It is beyond the scope of this inspection to determine if the wire is still connected to a power source. These wires were tested with a voltage sensor, but they could be shut off by a switch or temporarily disconnected. I recommend a qualified electrician evaluate and safely terminate and remove any unnecessary or abandoned wiring in the home.

- EDFW-2 Electric Distribution and Finish Wiring:

The exterior receptacles on the west side of the home did not have GFCI (Ground Fault Circuit Interrupter) protection or exterior rated outlet covers. Exterior receptacles should have GFCI protection and an approved exterior-rated cover to enhance electrical safety. The receptacles were not energized at the time of the inspection. I recommend a qualified electrician evaluate the electrical continuity of the rectacles and replace with an appropriate outlet and cover.

- A-2 Attic:

The attic and roof cavity ventilation look to be inadequate. Standards recommend open ventilation levels in a ratio of 1 to 150 of the attic area. During re-roofing, I recommend a qualified roofing contractor evaluate the level of ventilation on this roof and improve with ridge, soffit, core or other vents as recommended. Additional ventilation will likely be recommended by a roofing contractor when re-roofing.

- CS-1 Crawl Space:

The crawlspace had several issues during the inspection, including missing insulation, inconsistent vapor barrier, and the presence of building materials. These conditions may contribute to challenges such as inadequate moisture control, compromised energy efficiency, and potential for pest intrusion. I recommend a qualified contractor or crawlspace specialist evaluate for a full remediation of the crawlspace. Additional repairs could be needed that are latent or concealed.

- CS-2 Crawl Space:

Signs of rodent activity were observed in the crawl space. Evidence such as droppings, gnawed materials, prints, or torn-down insulation indicate rodents have been present. Rodents can cause damage to insulation and wiring and leave droppings that are unhealthy for human contact. It is difficult to tell how recently this activity has occurred. I recommend a pest control professional evaluate and implement appropriate rodent control measures, such as trapping and sealing entry points.

- CS-4 Crawl Space:

Multiple issues were found with the footings, posts, and beams during the inspection. These structural elements are integral to the stability and support of the home's structure. This is evident inside the home by the uneven floors. This is typical in older homes with usual settlement, deferred maintenance, and less-than-professional repairs. I recommend a qualified contractor or foundation specialist evaluate and repair or replace all necessary structural components.

Note: As footings settle slowly over the years, building materials can settle with them without showing signs of cracking, or cracks may have been repaired. Leveling the floors of the home may make wall-covering materials and trim crack, or doors stick.

- SB-2 Structure and Basement:

Medium cracks in the concrete block foundation mortar were observed during the inspection on the west side of the home, most likely from settlement. These cracks are around 1/8 to 1/4 of an inch wide and are not an immediate structural concern. it is not possible to determine in a single visit whether the observed cracking in the foundation will worsen over time or will remain the same. I recommend the cracks be sealed against moisture and pest intrusion and monitored for changes in width or movement.

Recommended Maintenance Items

- ESDW-3 Exterior Siding, Doors and Windows:

Caulking repairs are needed to the exterior of the house generally around windows, corner seams, and penetrations of the siding. This is commonly recommended maintenance between complete exterior paint jobs to prevent water intrusion that could result in damage to the siding, wall sheathing, and framing members. I recommend a qualified person, contractor, or paint specialist remove the failing caulk and replace it.

- RCG-2 Roof, Chimney and Gutters:

Moss and lichen growth was noted on the roof. The presence of moss will accelerate the deterioration of roofing material. Moss grows under the successive course lines of the roofing, lifting and spreading the material. When it rains, this moss acts like a sponge to retain the moisture on the roof and allows it to seep into and under the roofing and moisten the vapor barrier and even the sheathing. Under these conditions, the roof is much slower to dry and retains a more substantial amount of moisture which aids aging. I would recommend this roof be cleaned and treated with a moss inhibitor by a qualified roofing contractor.

- Note: Pressure washing a composition roof can damage the roofing material by removing the protective granular surface and should never be done.

- HCFV-2 Heating, Cooling, Fireplaces and Ventilation:

There was no record of any professional maintenance visits in the last year. Regular gas appliance maintenance by a qualified HVAC (heating, ventilation, and air conditioning) technician is essential for the efficient and safe operation of the heating system. It involves a series of preventive measures and inspections to ensure that the gas burner stove is functioning properly and to catch any potential issues before they become major problems. I recommend scheduling a maintenance visit with a qualified HVAC technician before the next heating season begins and continue annually.

- WH-2 Water Heaters:

There was a record of a professional maintenance visit on 04/10/23. Regular water heater maintenance by a qualified plumber is essential for the efficient and safe operation of the water heating system. It involves a series of preventive measures and inspections to ensure that the water heater is functioning properly and to catch any potential issues before they become major problems. Flushing the tank is one of the most important parts of water heater maintenance. Water heaters should be flushed at least once a year to prevent sediment from building up inside the water heater's tank. I recommend scheduling an annual maintenance visit with a qualified plumber.

- MB-2 Main Bathroom:

The toilet in the main bath has not been caulked to the floor. It is recommended that the toilet be caulked to the floor with a gap on the back that remains un-caulked so water can escape in case the toilet leaks. This simple improvement helps keep your toilet from moving and damaging the wax ring that seals the toilet to the drainage system. I recommend a qualified plumber evaluate the wax ring for damage, replace it as needed, and caulk the toilet in place.

Improves

- HCFV-1 Heating, Cooling, Fireplaces and Ventilation:

There was no heat source found in one or more of the bedrooms. Though local codes do not specifically require a heat source in every room it does require that all finished rooms be capable of being heated to a minimum of 68F with the door closed. If desired, I recommend a qualified contractor evaluate and install a heat source in the bedrooms for improved comfort.

- WH-1 Water Heaters:

No drain pan was installed beneath the water heater. A drain pan is recommended under water heaters that are located in finished spaces or where a leak could damage finishes or flood the home. For improved protection, a drain pan with a drain pipe discharging to the exterior of the home or to an unfinished location is best. Where a drain is difficult to install, a pan with a moisture alarm and a water detection shut-off device can be used in its place. I recommend a qualified plumber evaluate and install an adequate pan and drainage system or shut-off device to prevent water damage in the home.

- I-3 Interior:

There were windows in the laundry room and exterior doors with old single-pane glass. These do not comply with modern standards of energy efficiency and can cause condensation on the inside of the glass, leading to microbial growth and water damage to the window frame and sill. New windows or replacement of the single pane glass with double pane glass by a qualified window specialist would be an improvement.

- K-2 Kitchen:

A "high loop" was used in place of an air gap for the dishwasher. A high loop and air gaps are designed to prevent the back flow of contaminated water into the dishwasher if the sewer line backs up. Air gaps are more effective at this than a high loop. The absence of either can pose sanitation and contamination risks. I recommend a qualified plumber evaluate and install an air gap for improved safety.

- LF-2 Laundry Facilities:

A moisture alarm with a water shut-off feature, or a leak detection device on the supply lines is recommended for the washing machine to protect against leaks or ruptures in the supply hoses. These devices can help protect against an unmitigated amount of water from entering the home if a supply line were to burst.

- LF-3 Laundry Facilities:

There was no ventilation fan in the laundry room. This is common in older buildings and required in newer buildings. Proper ventilation is important in a laundry room to help remove excess moisture, odors, and airborne particles generated during the washing and drying of clothes. The absence of a ventilation fan may result in poor indoor air quality and potential moisture-related issues. If desired, I recommend a qualified general contractor or HVAC specialist evaluate for options for ventilation in the laundry room to improve both comfort and indoor air quality.

- CS-3 Crawl Space:

Though the crawl space access is covered, a tighter fitting screen with openings not larger than 1/4 of an inch in the foundation opening is needed to keep smaller pests from entering the crawl space. Small rodents can fit through incredibly small openings due to their flexible bodies. Mice, for example, can squeeze through openings as small as a quarter of an inch, while rats can fit through holes as small as one inch in diameter. I recommend a qualified contractor evaluate and install a tight-fitting screen to help prevent infestations and damage to the crawl space area.

- SB-1 Structure and Basement:

No seismic protection was seen during the inspection. Improvements such as bolting the building to the foundation, adding sheer panels to pony walls, and installing positive connections between posts and beams and posts and footings can strengthen the building and better prepare the structure for a seismic event. I recommend a qualified contractor or company specializing in seismic retrofits evaluate and install protections for improved seismic stability.

Due Diligences

- ES-1 Electric Service:

No permit stickers or paper work related to electrical work were found on the electric panel. Inquire with the seller for any additional information about this installation.

- I-2 Interior:

There was a ship ladder accessing the second floor room. Local safety standards state that "Ship's ladders shall not be used as an element of a means of egress. Ship's ladders shall be permitted provided that a required means of egress stairway or ramp serves the same space at each adjoining level or where a means of egress is not required". Current space constraints may make it challenging to build a staircase that meets local standards. The main priority should be ensuring the safety of individuals using the ladder. Homeowners can take practical steps to enhance safety, such as adequate lighting, handrails, and ensuring steps are in good repair. I recommend a qualified contractor evaluate the ladder for the best safety measures for the specific circumstances.

Efficiencies

- CS-5 Crawl Space:

The sub-floor insulation in the crawl space could be improved to modern standards. Insulating the sub-floor to R-30 or better is recommended for improved energy efficiency. If you do improve insulation, check for any air leakage points in the sub-floor. These are common around plumbing, wiring and HVAC penetrations and can lead to heat loss.

Notes

- G1-4 Grounds:

Outbuildings, including detached structures such as garages and sheds, were generally excluded from this inspection. This inspection specifically pertains to the primary dwelling, any structure attached by footings or roof lines, and its immediate surroundings.

- P-1 Plumbing:

The two homes on this property share a water supply.

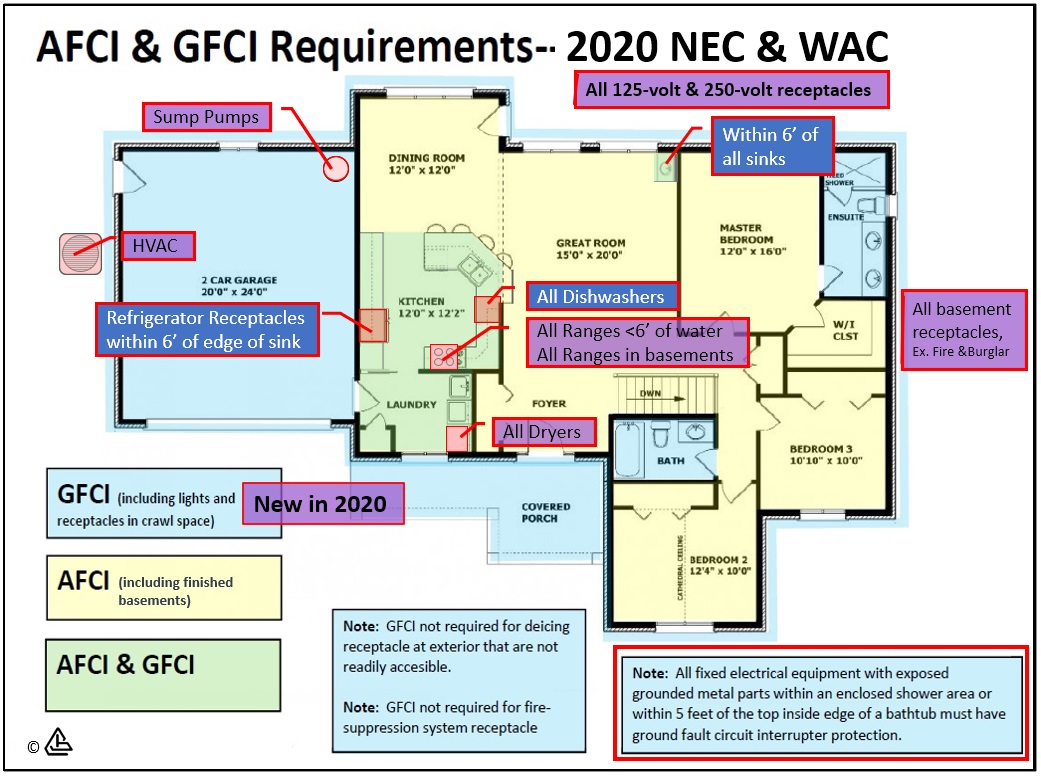

- ES-3 Electric Service:

MODERN AFCI PROTECTION IS A SAFETY IMPROVEMENT

AFCI (arc fault protection) is now required on all branch circuits supplying outlets or devices installed in residential dwelling unit kitchens, family rooms, dining rooms, living rooms, parlors, libraries, dens, bedrooms, sunrooms, recreation rooms, closets, hallways, laundry areas, and similar rooms and areas. The goal of this protection is to reduce risks of electrical fires. Consult with a licensed electrician about improving circuit protection as desired. I would consider this improvement in the context of other electrical repairs or upgrades. Please note that if you add or replace receptacle outlets to the existing system, they should comply with modern AFCI standards.

- ES-6 Electric Service:

During the inspection, I attempt to visually document electrical system bonding. There is no way in the context of a home inspection to verify the "effectiveness" of system bonding. All metallic systems in the building are required to be "bonded" (connected) to the building's electrical grounding system. Bonding creates a pathway to shunt static charges (that would otherwise build up on the system) to earth, and to provide a pathway to trip a breaker in the event that these bonded metallic components became energized.

- EDFW-3 Electric Distribution and Finish Wiring:

Carbon monoxide detectors were found and noted during the inspection. I did not test the functionality of these during the inspection. I recommend testing them regularly and replacing them once they have expired. Local safety standards require carbon monoxide alarms to be installed in the following locations:

- Outside of each separate sleeping area in the immediate vicinity of the bedrooms.

- On each level of the dwelling.

- In accordance with the manufacturer's recommendations.

- Where a fuel-burning appliance is located within a bedroom, or its attached bathroom, a carbon monoxide alarm shall be installed within the bedroom.

- EDFW-4 Electric Distribution and Finish Wiring:

Smoke alarms were found and noted during the inspection. I did not test the functionality of these during the inspection. I recommend testing them regularly and replacing them once they have expired. Local safety standards require smoke alarms to be installed in the following locations:

- In each sleeping room.

- Outside each separate sleeping area in the immediate vicinity of the bedrooms.

- On each additional story of the dwelling, including basements and habitable attics but not including crawl spaces and uninhabitable attics. In dwellings or dwelling units with split levels and without an intervening door between the adjacent levels, a smoke alarm installed on the upper level shall suffice for the adjacent lower level, provided that the lower level is less than one full story below the upper level.

- Smoke alarms shall be installed not less than 3 feet (914 mm) horizontally from the door or opening of a bathroom that contains a bathtub or shower unless this would prevent the placement of a smoke alarm required by these standards.

- In napping areas in a family home child care.

- In the hallway and in the room open to the hallway in dwelling units where the ceiling height of a room open to a hallway serving bedrooms exceeds that of the hallway by 24 inches (610 mm) or more.

- Within the room to which a loft is open, in the immediate vicinity of the loft.

- HCFV-3 Heating, Cooling, Fireplaces and Ventilation:

This gas wood stove was the main heat source for the home.

- LF-1 Laundry Facilities:

Access to the rear of the washer and dryer units was limited at the time of the inspection due to a shelf above the washer and dryer. A full visual inspection of these appliances, including their connections and ventilation, is essential to ensure their safe and efficient operation. Defects or issues may exist within these inaccessible areas that were not visible during the inspection. I recommend this area be made accessible for future inspections or consult with a qualified appliance specialist as necessary to address any potential hidden concerns.

- A-1 Attic:

Note that parts of this house have a vaulted ceiling configuration - there is no attic space and no access to inspect the roof framing, thermal barriers, ventilation, or fan exhaust ductwork in these vaulted parts of the building.

- A-3 Attic:

The roof was installed with a ridge vent but little to no effective lower vent. Ridge vents are at the highest point in the roofing system. Lower vents are critical in creating adequate air movement through the attic space. This house had small soffit vents on the east side of the home that were obstructed with insulation and no vents were installed on the west side of the home.

📃 The Complete Inspection Report

Grounds

General Grounds Photos

Drainage and Site

Wells and Basement Stairwells

Driveways/Walkways/Flatwork

Grounds, Trees and Vegetation

Outbuildings, Trellises, Storage Sheds, Barns

Exterior Siding, Doors and Windows

Exterior Elevations

Siding and Trim

Eaves, Fascia, and Soffits

Exterior Vent and Exhaust Terminations

Exterior Doors

Exterior Window Frames

Electric Service

Electric Service Permits Found

Electric Service Voltage Tested

Electric Service

Electric Service Equipment

Sub Panel

Electrical Grounding System

Electrical Bonding System

Electric Distribution and Finish Wiring

Branch Wiring

Receptacles and Fixtures

Smoke and Carbon Monoxide Alarm Systems

Heating, Cooling, Fireplaces and Ventilation

Heating Systems

Air Filters

Cooling Systems and Heat Pumps

Heating and Cooling Distribution Systems

Mechanical Ventilation Systems

Gas Fireplaces

Interior

General Interior Photos

Floors and Floor Materials

Walls, Ceilings, Trim, Hallways and Closets

Wall Insulation and Air Bypass

Stairs and Railings

Interior Doors

Windows

Kitchen

General Kitchen Photos

Sinks and Faucets

Cabinets and Countertops

Dishwasher

Ventilation Method and Microwave

Ranges, Ovens and Cooktops

Refrigerators

General Kitchen Condition

Main Bathroom

General Bathroom Photos

Sinks and Cabinets

Toilet

Bathtub / Shower

Bathroom Ventilation

General Bath Condition

General Comments

Building Characteristics, Conditions and Limitations

Style of Home: Traditional

Type of Building : Single Family (1 1/2 story)

Approximate Square Footage: 1000

The approximate square footage listed here is listed as a courtesy and is based off of public records and disclosure. An evaluation of square footage of the buildings and property lines is beyond the scope of this inspection.

Approximate Year of Original Construction: 1910

Unless the wiring in the building has been fully updated, this building likely has wiring that predates the late 1980's. Branch circuit wiring installed in buildings built prior to the late 1980s is typically rated for a maximum temperature of only 60 degrees Celsius. This includes non-metallic sheathed (Romex) wiring, and both BX and AC metal-clad flexible wiring. Knob and tube wiring, typically installed in homes built prior to 1950, may be rated for even lower maximum temperatures. Newer electric fixtures including lighting and fans typically require wiring rated for 90 degrees Celsius. Connecting newer fixtures to older, 60-degree-rated wiring is a potential fire hazard. Repairs for such conditions may involve replacing the last few feet of wiring to newer fixtures with new 90-degree-rated wire, and installing a junction box to join the old and new wiring. It is beyond the scope of this inspection to determine if any such incompatible components are installed. Based on the age of this building, be aware that such components may be present.

In 1978, federal laws were passed to prohibit use of lead and asbestos in building materials. Manufacturers of building materials were allowed to sell existing stocks of materials that were manufactured with lead and asbestos, so even buildings constructed as late as the mid-1980's could possibly contain lead or asbestos. Identification and testing for lead and asbestos and other environmental testing is beyond the scope of this home inspection. If you wish to seek additional information, I recommend contacting an environmental lab or industrial hygienist.

Attending the Inspection: Client's representative

Occupancy: Occupied

This home was occupied at the time of the inspection. Inspection of occupied homes presents some challenges as occupant belongings can obstruct visual inspection of and access to parts of the building. I do my best during the inspection to work around belongings to discover as much as possible about the house without moving or damaging personal property, however, the presence of personal items does limit the inspection.

Animals Present: No

Weather during the inspection: Cloudy

Approximate temperature during the inspection: Below 50[F]

Ground/Soil surface conditions: Wet

For the Purposes of This Report, the Front Door Faces: South

Grounds

General Grounds Photos

Drainage and Site

Clearance to Grade: Standard

Downspout Discharge: Above grade, Next to Foundation

Site Description: Flat

Several of the downspouts of the home terminated too close to the foundation. This can allow water to accumulate near the foundation, leading to soil erosion and hydrostatic pressure causing cracks, shifting, or settling in the foundation, and water intrusion into the crawlspace, causing moisture issues and flooding during heavy rainfall. Downspouts should be extended to discharge water 4 to 6 feet away from the house through an above-ground or below-ground drainage system. I recommend a qualified drainage specialist to evaluate and repair or replace the current drainage system to adequately move water away from the homes foundation.

Wells and Basement Stairwells

Foundatiuon Vent Wells: None Noted

There were inadequate foundation vent wells and crawlspace access wells seen around the home. Wells help provide a clear space for vents or hatches that are at or below grade. This helps to keep vegetation clear of the vent for proper ventilation to promote moisture control, temperature regulation, and drainage to prevent water from entering the crawlspace during rain. I recommend a qualified foundation specialist or contractor evaluate and install adequate wells for these site conditions.

Driveways/Walkways/Flatwork

Driveway: Gravel

Walkways: Concrete

Patios: None noted

Grounds, Trees and Vegetation

Trees/Vegetation too near building: Yes - Prune Vegetation off House

Outbuildings, Trellises, Storage Sheds, Barns

Not inspected, Not included-No sub-panel present

Outbuildings, including detached structures such as garages and sheds, were generally excluded from this inspection. This inspection specifically pertains to the primary dwelling, any structure attached by footings or roof lines, and its immediate surroundings.

Exterior Siding, Doors and Windows

Exterior Elevations

Siding and Trim

Trim Material: Wood

Siding style: Shingles

Siding Material: Painted shingles

Loose, missing, and damaged siding shingles were observed around the home during the inspection. These issues can compromise the integrity of the siding and lead to potential water intrusion. I recommend a qualified general contractor evaluate, repair, or replace all damaged shingles and properly seal them to prevent further damage. Please note that whenever there is damage to the siding system, there is a risk of uncovering additional concealed damage in the course of repairs.

There was wood siding in contact with the roof surface at the south and north sides of the home. A 1 to 2-inch gap is recommended between the siding material and the roof surface, installed with step flashing on the roof side and counter flashing on the wall side. Siding contact with the roof surface can lead to water damage to the siding material, exterior wall sheathing, and framing members. This work is easiest to do during a re-roofing. I recommend a qualified general contractor evaluate, amend the roof contact, and repair any damaged areas that may be found during work.

Caulking repairs are needed to the exterior of the house generally around windows, corner seams, and penetrations of the siding. This is commonly recommended maintenance between complete exterior paint jobs to prevent water intrusion that could result in damage to the siding, wall sheathing, and framing members. I recommend a qualified person, contractor, or paint specialist remove the failing caulk and replace it.

Eaves, Fascia, and Soffits

Eave type: Open rafters

Fascia Material: Wood

Soffit Material: Wood

Exterior Vent and Exhaust Terminations

Exterior Siding and Vent Terminations: Present

There was a drain waste vent terminating too close to a window. Drain waste vents carry sewer gases from the waste system away from the home and aid in a balanced waste drainage system. Local safety standards state that "Each vent shall terminate not less than 10 feet (3048 mm) from, or not less than 3 feet (914 mm) above, an openable window, door, opening, air intake, or vent shaft". This can allow harmful sewer gases into the home. I recommend a qualified plumbing contractor extend the drain waste vent away from the window for improved safety.

Exterior Doors

Exterior Door Styles: Solid core

Exterior Door Material: Wood

Exterior Window Frames

Window Frame Material: Vinyl, Wood

Screens: Present in windows

Decks, Porches and Balconies

Decks, Porches and Balconies

Present

Structure: Porch on foundation

Ledger Board: Not applicable

Exterior Stairs

Front Porch Stairs: Wood

Back Porch, Stairs: Wood

Some of the treads of the stairs leading up to the rear door had significant rot. This creates an unsafe walking surface as softened wood can become slippery when wet and icy during cold weather. It also creates a conducive condition for wood-destroying insects near the home.I recommend a qualified contractor evaluate, repair, or replace any stair treads with rot to ensure a safe and stable walking surface.

The handrail/guardrail leading to the rear door was rotted and loose. Handrails are required on stairs with 4 or more risers and guardrails on stairs or decks over 30 inches from the ground and are intended to hold the weight of an adult. Rotted wood near the home also creates a conducive condition for wood-destroying insects. These help to prevent a fall or to help prevent serious injury in case of a fall. I recommend a qualified contractor evaluate and repair or replace any rotted materials as necessary to ensure safety.

Fuel Storage and Distribution

Plumbing

Water Meter

Location of Water Meter Note

This shows the location of the water meter on the north side of the property.

The two homes on this property share a water supply.

Water Service Supply

Pipe Material: Copper

Water Supply: Public water

Water Pressure: 130 PSI

Pressure Reducing Valve: Present

Main Water Shut-off Location: Crawl space, Water Shut Off Location Noted

This shows the location of the main water shut-off located at the northwest corner of the crawlspace.

A leak in the connection below the pressure-reducing valve was noted. Though the leak was minor at the time of the inspection it has the potential for failure in the future. I recommend a qualified plumber evaluate and repair or replace the fixture as necessary.

The static water pressure in the home tested above 80 psi (pounds per square inch), the maximum water pressure recommended. High water pressure can stress the supply plumbing system and make it more vulnerable to leaks. A pressure-reducing valve was noted on the main water inlet suggesting that it may require adjustment or there could be issues with thermal expansion due to water heating. It is also possible that the hose bibs, where I tested the water pressure, are not protected by this device and that the rest of the house is protected. I recommend a qualified plumbing contractor evaluate and adjust or repair the pressure-reducing valve as necessary.

Distribution Pipe

Pipe Insulation: Missing in Crawl Space

Supply Pipe Materials: Copper

- Copper water supply pipes were installed. Copper pipes installed before the late 1980s may be joined with solder that contains lead, which is a known health hazard, especially for children. Laws were passed in 1985 prohibiting the use of lead in solder, but before that solder normally contained approximately 50% lead. Note that testing for toxic materials such as lead, is beyond the scope of this inspection. Consider having a qualified lab test for lead, and if necessary take steps to reduce or remove lead from the water supply.

The insulation on the water pipes in the crawlspace was incomplete. Proper insulation of water pipes is essential to minimize the risk of freezing in colder temperatures. I recommend a qualified contractor or plumber evaluate and install insulation suitable for our local environment.

Waste Pipe and Discharge

Exterior Hose Bibs

Operating, Leaking (At Handle When Turned On)

The hose bib at the east side of the house was leaking when turned on and under pressure. This can lead to water wastage and potential water damage to the immediate surroundings. I recommend a qualified plumber evaluate, repair, or replace as necessary.

Roof, Chimney and Gutters

Roof Materials

Method of Roof Inspection: Walked on roof, Viewed from window

Roof Style: Gable

Valleys : None

Flashing: Barge Board Ends Flashing Missing

Roof Covering Materials: Architectural grade composition shingle

Roofing Material Condition: At the end of its useful life

Overlay Roof: No

Attic Vent Exteriors: Ridge Vents

The roof of this property appeared to be approaching the end of its intended life based on general industry standards and visual observations, such as cracking or curling and loss of granules of the shingles, and microbial growth. A roof's exact age is often difficult to determine based solely on observation. There is a difference between the intended life span of roofing materials and the functional life. Roofing materials may function much longer than their intended life, though they may also function much less than intended. A roof's remaining functional lifespan can vary depending on several factors, including the type of roofing material, installation quality, maintenance history, and local environmental conditions. While it is challenging to provide an exact timeframe for the remaining service life of the roof it is advisable to consider budgeting for a roof replacement in the near future. I recommend a qualified roofing contractor evaluate the roof and repair or replace it as necessary.

Moss and lichen growth was noted on the roof. The presence of moss will accelerate the deterioration of roofing material. Moss grows under the successive course lines of the roofing, lifting and spreading the material. When it rains, this moss acts like a sponge to retain the moisture on the roof and allows it to seep into and under the roofing and moisten the vapor barrier and even the sheathing. Under these conditions, the roof is much slower to dry and retains a more substantial amount of moisture which aids aging. I would recommend this roof be cleaned and treated with a moss inhibitor by a qualified roofing contractor.

- Note: Pressure washing a composition roof can damage the roofing material by removing the protective granular surface and should never be done.

Chimneys and Vents

Present

Vent Materials: Metal

The water heater exhaust vent had damaged boot flashing. Flashing prevents water intrusion around the vent that can damage the roof sheathing, roof structure, and interior finishes. This repair would be best done along with re-roofing. The support for the vent was also inadequate.I recommend a qualified general or roofing contractor evaluate and repair or replace the flashing and support to prevent further damage.

Gutters and Downspouts

Gutter and Downspout Materials: Aluminum

Electric Service

Electric Service Permits Found

No permit stickers or paper work related to electrical work were found on the electric panel. Inquire with the seller for any additional information about this installation.

Electric Service Voltage Tested

Service Voltage: 120/240

Electric Service

Service Entrance: Above Ground

The electrical service supplying the house is provided through an overhead line at the south side of the property.

Meter Base Amperage: 100

The electrical service conductors servicing the home are too close to a walkway surface. Local safety standards say the conductors should be a minimum of 10 feet above walkways and areas where people will be outdoors to ensure there is no contact between people and these cables. Although the service conductors from the street to the service head (where the service conductors attach to the home) are generally the responsibility of the utility company, I recommend a qualified electrician evaluate the condition, location, and height of the service head as it may need to be raised to meet the 10 foot requirement.

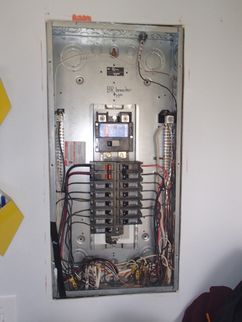

Electric Service Equipment

Service Entrance (SE) conductor Size: Copper, #2, 125 amps

Main Panel Amperage: 60 amps

Electric Service Amperage: 60 amps

Main Electric Panel Location: Exterior

The main electrical panel is located on the exterior of the east side of the home.

Panel Manufacturer: Magnetrip

Circuit Breakers/Fuses: Circuit Breakers

GFCI/AFCI: AFCI Breakers Not Present

This home has a Magnetrip panel on the exterior of the home that appears to have been the original electrical panel for the home. When the electrical was updated, instead of removing this panel and running the entrance cables to the location of the new panel inside the home, this panel was kept as the main panel making the panel inside the home a sub-panel. Magnetrip panels have a reputation for failing and malfunctioning breakers as well as a unique copper bus bar design that can allow breakers to make loose connections which can lead to arcing and fires. These panels are considered a latent fire hazard. The panel was rusted with duct tape covering unused openings and an opening too large for the main breaker being used. I recommend a qualified electrician evaluate and remove the panel from the electrical system of the home for improved safety.

MODERN AFCI PROTECTION IS A SAFETY IMPROVEMENT

AFCI (arc fault protection) is now required on all branch circuits supplying outlets or devices installed in residential dwelling unit kitchens, family rooms, dining rooms, living rooms, parlors, libraries, dens, bedrooms, sunrooms, recreation rooms, closets, hallways, laundry areas, and similar rooms and areas. The goal of this protection is to reduce risks of electrical fires. Consult with a licensed electrician about improving circuit protection as desired. I would consider this improvement in the context of other electrical repairs or upgrades. Please note that if you add or replace receptacle outlets to the existing system, they should comply with modern AFCI standards.

Sub Panel

Sub Panel: Present

Sub Panel Voltage: 240 volt

Service Conductor Size: Aluminum, #2, 60 amps

Sub Panel Amperage: 60 amps

Sub Panel Manufacturer: Eaton

The electrical panel is installed with a "back-fed" configuration. Back-feeding means that the electrical service wires supply power to the panel through a typical breaker position on the bus bars, and not a factory installed main breaker at the top of the panel. Though this panel has a main breaker installed but is not being used. Back feeding is a common configuration though this panel is missing a required screw to secure the breaker to the panel to reduce the risk of it coming loose and becoming a fire and shock hazard. I recommend a qualified electrician evaluate for correct installation of the main breaker and evaluate that this panel is adequate for being a main panel after the exterior panel is removed.

Electrical Grounding System

Grounding Rod Noted

The grounding rod was located on the west side of the home. The connection of the grounding wire to the rod was secure, but there is no way of telling the depth of the grounding rod.

Electrical Bonding System

Present - Could Not Confirm, Bonding Noted on Water Pipes

Bonding connections were noted on the water pipes.

During the inspection, I attempt to visually document electrical system bonding. There is no way in the context of a home inspection to verify the "effectiveness" of system bonding. All metallic systems in the building are required to be "bonded" (connected) to the building's electrical grounding system. Bonding creates a pathway to shunt static charges (that would otherwise build up on the system) to earth, and to provide a pathway to trip a breaker in the event that these bonded metallic components became energized.

Electric Distribution and Finish Wiring

Branch Wiring

Wire Material: Copper

Wiring Method: Non-metallic sheathed cable

Abandoned wiring was noted in the crawl space It is beyond the scope of this inspection to determine if the wire is still connected to a power source. These wires were tested with a voltage sensor, but they could be shut off by a switch or temporarily disconnected. I recommend a qualified electrician evaluate and safely terminate and remove any unnecessary or abandoned wiring in the home.

Receptacles and Fixtures

Inspection Method: Tested All Accessible

I attempted to inspect all accessible receptacles and light switches using common electrical testing tools during the inspection. Electrical systems can be complex, and hidden defects may not always be evident during a routine assessment. While efforts were made to ensure the functionality of accessible components, this note serves as a reminder that the inspection is not exhaustive, and additional evaluation by a qualified electrician may be warranted for a thorough understanding of the electrical system's condition.

Electric Receptacles: Three wire receptacles

The exterior receptacles on the west side of the home did not have GFCI (Ground Fault Circuit Interrupter) protection or exterior rated outlet covers. Exterior receptacles should have GFCI protection and an approved exterior-rated cover to enhance electrical safety. The receptacles were not energized at the time of the inspection. I recommend a qualified electrician evaluate the electrical continuity of the rectacles and replace with an appropriate outlet and cover.

Smoke and Carbon Monoxide Alarm Systems

CO Alarms: Present

CO Alarms Noted: On Main Floor

On Main Floor On 2nd Floor

On 2nd Floor

Smoke Alarms: Present

Smoke Alarms Noted: On Main Floor

On Main Floor On 2nd Floor

On 2nd Floor In All Bedrooms

In All Bedrooms

Carbon monoxide detectors were found and noted during the inspection. I did not test the functionality of these during the inspection. I recommend testing them regularly and replacing them once they have expired. Local safety standards require carbon monoxide alarms to be installed in the following locations:

- Outside of each separate sleeping area in the immediate vicinity of the bedrooms.

- On each level of the dwelling.

- In accordance with the manufacturer's recommendations.

- Where a fuel-burning appliance is located within a bedroom, or its attached bathroom, a carbon monoxide alarm shall be installed within the bedroom.

Smoke alarms were found and noted during the inspection. I did not test the functionality of these during the inspection. I recommend testing them regularly and replacing them once they have expired. Local safety standards require smoke alarms to be installed in the following locations:

- In each sleeping room.

- Outside each separate sleeping area in the immediate vicinity of the bedrooms.

- On each additional story of the dwelling, including basements and habitable attics but not including crawl spaces and uninhabitable attics. In dwellings or dwelling units with split levels and without an intervening door between the adjacent levels, a smoke alarm installed on the upper level shall suffice for the adjacent lower level, provided that the lower level is less than one full story below the upper level.

- Smoke alarms shall be installed not less than 3 feet (914 mm) horizontally from the door or opening of a bathroom that contains a bathtub or shower unless this would prevent the placement of a smoke alarm required by these standards.

- In napping areas in a family home child care.

- In the hallway and in the room open to the hallway in dwelling units where the ceiling height of a room open to a hallway serving bedrooms exceeds that of the hallway by 24 inches (610 mm) or more.

- Within the room to which a loft is open, in the immediate vicinity of the loft.

Heating, Cooling, Fireplaces and Ventilation

Heating Systems

Air Filters

Air Filtration System: None present

Cooling Systems and Heat Pumps

Cooling System or Heat Pump: None present

Heating and Cooling Distribution Systems

Heat Source in Each Room: Incomplete

There was no heat source found in one or more of the bedrooms. Though local codes do not specifically require a heat source in every room it does require that all finished rooms be capable of being heated to a minimum of 68F with the door closed. If desired, I recommend a qualified contractor evaluate and install a heat source in the bedrooms for improved comfort.

Mechanical Ventilation Systems

Whole House Fans, Ventilation and HRVs: No Mechanical Ventilation Found

Bath Fan Ducting: Ducted to exterior

Kitchen Fan Ducting: Ducted to exterior

Gas Fireplaces

Fireplace Types: Gas wood stove, Photos, Main heat source

General photos of gas appliance.

Fan Present: Yes

Gas Rating Sticker Noted: Natural Gas

Battery Cradle: Not Applicable

System Responded to Testing: Yes

There was no record of any professional maintenance visits in the last year. Regular gas appliance maintenance by a qualified HVAC (heating, ventilation, and air conditioning) technician is essential for the efficient and safe operation of the heating system. It involves a series of preventive measures and inspections to ensure that the gas burner stove is functioning properly and to catch any potential issues before they become major problems. I recommend scheduling a maintenance visit with a qualified HVAC technician before the next heating season begins and continue annually.

This gas wood stove was the main heat source for the home.

Water Heaters

Water Heater

System Type: Tank

Manufacturer: Bradford-White

Size: 40 gal

Age: 2022

Energy Source: Gas

Last Service Visit: None

Straps : Present

Pad: None Needed

Drain Pan: None Noted - Recommended

Expansion Tank: Present

Relief Valve: Present - Not Tested

A temperature and pressure relief valve (TPRV) is required on all water heaters to discharge any excessive pressure within the tank. A discharge pipe should be attached to the valve and directed to a safe location away from body contact. Newer installations must be directed to the building exterior or an approved indoor drain receptor. Most manufacturers suggest that these valves be tested at least once a year to ensure the valve discharges properly. This can be done by a qualified plumber during recommended annual maintenance visits. The picture here shows a typical TPRV. They may also be found on the side of the heater on some models. I do not test these valves due to the possibility that they may leak after testing. A leaking or inoperative TPRV should be replaced immediately by a qualified plumber.

There was a record of a professional maintenance visit on 04/10/23. Regular water heater maintenance by a qualified plumber is essential for the efficient and safe operation of the water heating system. It involves a series of preventive measures and inspections to ensure that the water heater is functioning properly and to catch any potential issues before they become major problems. Flushing the tank is one of the most important parts of water heater maintenance. Water heaters should be flushed at least once a year to prevent sediment from building up inside the water heater's tank. I recommend scheduling an annual maintenance visit with a qualified plumber.

No drain pan was installed beneath the water heater. A drain pan is recommended under water heaters that are located in finished spaces or where a leak could damage finishes or flood the home. For improved protection, a drain pan with a drain pipe discharging to the exterior of the home or to an unfinished location is best. Where a drain is difficult to install, a pan with a moisture alarm and a water detection shut-off device can be used in its place. I recommend a qualified plumber evaluate and install an adequate pan and drainage system or shut-off device to prevent water damage in the home.

Water Temperature

Water Temperature Measured During Inspection: 124 Degrees F

120 degrees is considered to be the recommended "hot water" temperature in a home to prevent bacteria from developing inside the water heater but not hot enough to scald.

Interior

Floors and Floor Materials

Floor Materials: Wood

Floor Settlement: Moderate

Walls, Ceilings, Trim, Hallways and Closets

Wall and Ceiling Materials: Drywall, Lath and Plaster, Wood

Wall Insulation and Air Bypass

Wall Insulation: Not Visible

Stairs and Railings

Lofts (Ladder Note)

There was a ship ladder accessing the second floor room. Local safety standards state that "Ship's ladders shall not be used as an element of a means of egress. Ship's ladders shall be permitted provided that a required means of egress stairway or ramp serves the same space at each adjoining level or where a means of egress is not required". Current space constraints may make it challenging to build a staircase that meets local standards. The main priority should be ensuring the safety of individuals using the ladder. Homeowners can take practical steps to enhance safety, such as adequate lighting, handrails, and ensuring steps are in good repair. I recommend a qualified contractor evaluate the ladder for the best safety measures for the specific circumstances.

Interior Doors

Interior Doors: Solid Core

Windows

Window Glazing: Double pane, Single pane

Interior Window Frame: Vinyl, Wood

Window Styles: Sliding, Single hung

There were windows in the laundry room and exterior doors with old single-pane glass. These do not comply with modern standards of energy efficiency and can cause condensation on the inside of the glass, leading to microbial growth and water damage to the window frame and sill. New windows or replacement of the single pane glass with double pane glass by a qualified window specialist would be an improvement.

Kitchen

Sinks and Faucets

Tested

The kitchen sink is tested by running water for a period of time to inspect for leaks at the faucet and basin, slow drainage, or other defects.

As my time in the house is limited to one visit, this does not mean the sink is void of defects that may present themselves with constant use. I do my best to use the sink as intended and check for these defects at the time of the inspection.

Cabinets and Countertops

Countertop Material: Plastic laminate

Cabinet Material: Wood

Dishwasher

Dishwasher: Not Operated (Dishes/storage)

The dishwasher was not tested during the inspection due to the presence of dishes. For a thorough assessment of the dishwasher's complete functionality and performance, I recommend evaluation by a qualified appliance technician.

Dishwasher Air Gap: Just a high loop

A "high loop" was used in place of an air gap for the dishwasher. A high loop and air gaps are designed to prevent the back flow of contaminated water into the dishwasher if the sewer line backs up. Air gaps are more effective at this than a high loop. The absence of either can pose sanitation and contamination risks. I recommend a qualified plumber evaluate and install an air gap for improved safety.

Ventilation Method and Microwave

Ventilation Hood: Fan Ducted to Exterior, Test note

The cooktop and oven were tested and operated with normal controls. This is not an exhaustive test, simply when the range was turned on it produced heat in a reasonable amount of time. I cannot attest to the accuracy of the stove temperature or the efficiency of the burners. If desired, the range should be evaluated by a qualified appliance repair technician to better determine its overall functionality.

Ranges, Ovens and Cooktops

Range: Tested, Electric

The cooktop and oven were tested and operated with normal controls. This is not an exhaustive test, simply when the range was turned on it produced heat in a reasonable amount of time. I cannot attest to the accuracy of the stove temperature or the efficiency of the burners. If desired, the range should be evaluated by a qualified appliance repair technician to better determine its overall functionality.

Refrigerators

Refrigerator: Operating

General Kitchen Condition

Standard

Laundry Facilities

Laundry Photos

Laundry Room Observations.: Limited access

Access to the rear of the washer and dryer units was limited at the time of the inspection due to a shelf above the washer and dryer. A full visual inspection of these appliances, including their connections and ventilation, is essential to ensure their safe and efficient operation. Defects or issues may exist within these inaccessible areas that were not visible during the inspection. I recommend this area be made accessible for future inspections or consult with a qualified appliance specialist as necessary to address any potential hidden concerns.

Washer

Tested

A short test of the clothes washer was conducted during the inspection, involving a short run to assess basic functionality and drainage and check for potential leaks. This test is not exhaustive, for further evaluation I recommend a maintenance visit from a qualified appliance technician.

A moisture alarm with a water shut-off feature, or a leak detection device on the supply lines is recommended for the washing machine to protect against leaks or ruptures in the supply hoses. These devices can help protect against an unmitigated amount of water from entering the home if a supply line were to burst.

Dryer

Tested

The clothes dryer was tested during the inspection by running a short cycle to confirm that it functioned and produced heat. This test was not exhaustive and did not comprehensively assess the entire functionality or exhaust venting system of the dryer. Proper dryer exhaust venting is critical for safe and reliable performance from the dryer. For further evaluation I recommend a maintenance visit from a qualified appliance technician.

Power Source: Electric

Exhaust Duct: Ducted to Exterior

Laundry Ventilation

Type: None noted - older building

There was no ventilation fan in the laundry room. This is common in older buildings and required in newer buildings. Proper ventilation is important in a laundry room to help remove excess moisture, odors, and airborne particles generated during the washing and drying of clothes. The absence of a ventilation fan may result in poor indoor air quality and potential moisture-related issues. If desired, I recommend a qualified general contractor or HVAC specialist evaluate for options for ventilation in the laundry room to improve both comfort and indoor air quality.

Main Bathroom

Sinks and Cabinets

Tested

The bathroom sink was tested by running water for a period of time to inspect for leaks at the faucet and basin, slow drainage, or other defects.

As my time in the house is limited to one visit, this does not mean the sink is void of defects that may present themselves with consistent use. I do my best to use the sink as intended and check for these defects at the time of the inspection.

Toilet

Tested

The toilet was tested by repeated flushings and checked for consistent functionality and taking relative moisture readings on the bathroom floor further away from the toilet and next to the toilet to look for elevated moisture levels that could indicate a hidden leak under the floor.

As my time in the house is limited to one visit, this does not mean the toilet is void of defects that may present themselves with consistent use. I do my best to use the toilet as intended and check for these defects at the time of the inspection.

The toilet in the main bath has not been caulked to the floor. It is recommended that the toilet be caulked to the floor with a gap on the back that remains un-caulked so water can escape in case the toilet leaks. This simple improvement helps keep your toilet from moving and damaging the wax ring that seals the toilet to the drainage system. I recommend a qualified plumber evaluate the wax ring for damage, replace it as needed, and caulk the toilet in place.

Bathtub / Shower

Tested

The bathroom bathtub/shower was tested by running water for a period of time to inspect for leaks at the faucet, shower head, and drain pan, slow drainage, or other defects.

As my time in the house is limited to one visit, this does not mean the bathtub/shower is void of defects that may present themselves with consistent use. I do my best to use the sink as intended and check for these defects at the time of the inspection.

Tub Type: Clawfoot

Bathroom Ventilation

Type: Bath fan

General Bath Condition

Standard

Attic

Attic Access

Limited Access - Vaulted Ceiling - Partial

Note that parts of this house have a vaulted ceiling configuration - there is no attic space and no access to inspect the roof framing, thermal barriers, ventilation, or fan exhaust ductwork in these vaulted parts of the building.

Roof Framing and Sheathing

Rafters: Not visible

Sheathing: Not visible

Attic Insulation

Insulation Type: Fiberglass

Attic and Roof Cavity Ventilation

Attic Ventilation Method: Ridge vents

The attic and roof cavity ventilation look to be inadequate. Standards recommend open ventilation levels in a ratio of 1 to 150 of the attic area. During re-roofing, I recommend a qualified roofing contractor evaluate the level of ventilation on this roof and improve with ridge, soffit, core or other vents as recommended. Additional ventilation will likely be recommended by a roofing contractor when re-roofing.

The roof was installed with a ridge vent but little to no effective lower vent. Ridge vents are at the highest point in the roofing system. Lower vents are critical in creating adequate air movement through the attic space. This house had small soffit vents on the east side of the home that were obstructed with insulation and no vents were installed on the west side of the home.

Crawl Space

General Crawl Space

Crawl Space: Present

The crawlspace had several issues during the inspection, including missing insulation, inconsistent vapor barrier, and the presence of building materials. These conditions may contribute to challenges such as inadequate moisture control, compromised energy efficiency, and potential for pest intrusion. I recommend a qualified contractor or crawlspace specialist evaluate for a full remediation of the crawlspace. Additional repairs could be needed that are latent or concealed.

Signs of rodent activity were observed in the crawl space. Evidence such as droppings, gnawed materials, prints, or torn-down insulation indicate rodents have been present. Rodents can cause damage to insulation and wiring and leave droppings that are unhealthy for human contact. It is difficult to tell how recently this activity has occurred. I recommend a pest control professional evaluate and implement appropriate rodent control measures, such as trapping and sealing entry points.

Crawl Space Access

Method of Inspection: Crawled partial

During inspection of the crawl space, every effort is made to inspect the entire space. Visual inspection of crawl spaces is difficult and limited as access is often restricted by pipes, ducts and sub-floor insulation as well as limited clearances.

Crawl Space Access Hatch Location: Exterior access hatch, 📸

Attached photos show crawl space access points.

Though the crawl space access is covered, a tighter fitting screen with openings not larger than 1/4 of an inch in the foundation opening is needed to keep smaller pests from entering the crawl space. Small rodents can fit through incredibly small openings due to their flexible bodies. Mice, for example, can squeeze through openings as small as a quarter of an inch, while rats can fit through holes as small as one inch in diameter. I recommend a qualified contractor evaluate and install a tight-fitting screen to help prevent infestations and damage to the crawl space area.

Vapor Barrier

Vapor Barrier Material: Plastic on earth, Old Clear Plastic, Old and Rodent Damaged, Clear Plastic, Incomplete

Crawl Space Ventilation

Ventilation Method: Exterior wall vents

Posts and Footings

Non-standard

Common Defects: Posts (Decay Found, One Post, Multiple)

Common Issues: No positive connection-post and beam

No positive connection-post and beam Non-consistent post

Non-consistent post No vapor barrier under post

No vapor barrier under post Settled footing

Settled footing Rotted post/beam

Rotted post/beam Post in concrete

Post in concrete Post to soil contact

Post to soil contact Multiple issues

Multiple issues

Multiple issues were found with the footings, posts, and beams during the inspection. These structural elements are integral to the stability and support of the home's structure. This is evident inside the home by the uneven floors. This is typical in older homes with usual settlement, deferred maintenance, and less-than-professional repairs. I recommend a qualified contractor or foundation specialist evaluate and repair or replace all necessary structural components.