🪠PLUMBING CONCERNS

🪠FOR THE PLUMBING CONTRACTOR This list of Plumbing concerns can be given to the plumbing contractor to assist in bidding on necessary repairs.

🪠PLUMBING CONCERNS

REPAIR/REPLACE ITEMS

- P-1 🚿PLUMBING:

CONDITIONS RELATED TO THE WATER SUPPLY:

There were issues documented below in bulleted lists, narratives and/or pictures related to the the water supply system. The water meter is typically the property and responsibility of the water utility but there are some maintenance items the homeowner can take care of. Maintaining the meter accessible and clear of debris both inside the compartment and outside the compartment is important for proper access in an emergency. The below conditions related to the house water supply should be evaluated, repaired and maintained as deemed necessary by a licensed plumber.

WATER PRESSURE:

- ◽🚩Water pressure above 80 psi. The water pressure tested above 95 psi at the west outside faucet. Since there is a pressure reducing valve present, the valve should be adjusted/repaired as necessary. When pressure reducing valves are installed expansion tanks should be installed in the system as well to allow for expansion and contraction within the system. Excessive water pressure can make piping vulnerable to leakage and may be harmful to valves and fittings.

- ◽Accurate water pressure reading not possible due to leaks at valve(s)

MAIN WATER LINE AND PROTECTION:

- ◽Not visible--type and size of pipe not determined

PRESSURE REGULATOR:

- ◽Tank--or Thermal Expansion Device--Missing/ Required

BACK-FLOW PROTECTION:

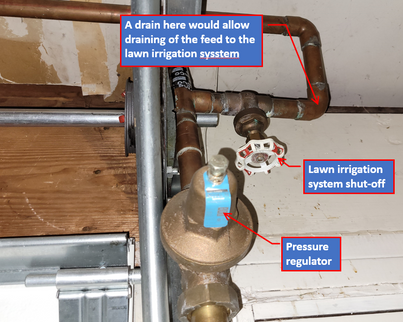

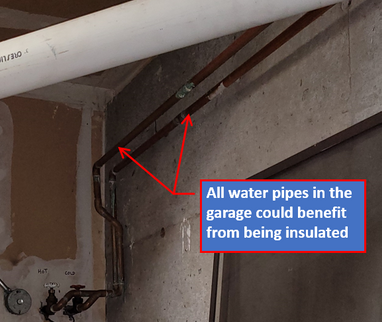

- ◽Present but no punch card. There is a back-flow device present at the SW corner of the home. These valves are required to be inspected annually and they prevent dirty sprinkler system water from being pulled back into the city water supply. These are important safety devices that require maintenance. The inspection record punch card was not seen. I recommend inspection of the device by an approved back-flow testing company unless verification of inspection can be provided.

There is currently no way to drain the irrigation system and the exposed pipe at the SW corner of the home is subject to freezing. Adding a drain valve to the system is recommended.

🛑 Safety 🔧 Maintenance (annual) 👁🗨 Monitor annually 🔍 Due Diligence

- P-2 🚿PLUMBING:

INTERIOR SUPPLY PLUMBING:

There were issues documented below in bulleted lists, narratives, and/or pictures related to the Water Supply Plumbing. The below conditions should be evaluated, repaired and maintained as deemed necessary by a licensed plumber.

WATER SUPPLY PIPING:

- Piercing valves present. Piercing valves or saddle fittings were noted on the supply piping system. These are frequently used to deliver water to the refrigerator or ice maker. These types of plumbing connections are prone to leaking/failure. As an upgrade, I recommend installation of a more reliable "T" with shut-off. Typically these valves, even while readily available and commonly used, have no "listing" for use in water supply systems.

- ◽The piercing valve for the hot water tap was located under the kitchen sink.

COPPER PIPE:

- ◽Green corrosion on joints typical of flux, considered cosmetic

- 🚩Possibility of pipes with Leaded Solder. The information immediately below regarding copper piping can be ignored if it can be determined that the piping was replaced after 1986 (typically). Into the late 1980's copper pipe connections were soldered with solder containing some lead. Most water supplies are not considered corrosive enough (either too acidic or too alkaline) to release the lead into the water so as to pose a health risk. Only testing of the water by an EPA certified lab can determine the presence of lead. Lead is a known health hazard, especially for children. Laws were passed in 1985 prohibiting the use of lead in solder, but prior to that solder normally contained lead. Evaluating for the presence of lead in this structure is not included in this inspection. The client (s) should consider having a qualified lab test for lead, and if necessary take steps to reduce or remove lead from the water supply, including:

- 1. Flush water taps or faucets. Do not drink water that has been sitting in the plumbing lines for more than six hours.

- 2. Install appropriate filters at points of use.

- 3. Use only cold water for cooking and drinking. Hot water dissolves lead more quickly than cold water.

- 4. Use bottled or distilled water.

- 5. Treat well water to make it less corrosive.

- 6. Replace plumbing pipes

- Additional information can be found at: http://www.epa.gov/safewater/lead/index.html

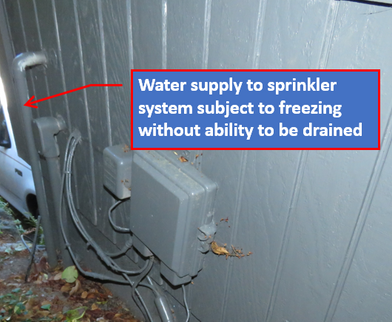

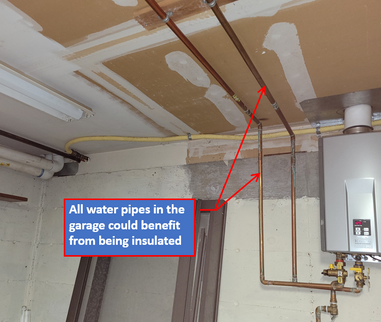

INSULATION GARAGE SPACE HOT:

- ◽Not insulated

INSULATION GARAGE SPACE COLD:

- ◽Not insulated

🛑 Safety 🔧 Maintenance (annual) 👁🗨 Monitor annually 🔍 Due Diligence

- P-3 🚿PLUMBING:

FROST-FREE/ANTI-SIPHON OUTSIDE FAUCET:

There were issues documented below in bulleted lists, narratives, and/or pictures related to the outside faucet that should be evaluated and repaired as deemed necessary by a licensed plumber.

FROST-FREE ANTI-SIPHON:

- ◽Leaking of valve stem during back-pressure-test noted. It is common for hose faucets to leak around the valve stem resulting in the wasting of water. Usually this can be corrected by tightening the valve stem nut slightly . I recommend further evaluation/repairs by a licensed plumber.

- ◽Frost Cover. The insulated covers for the outside faucets are not necessary and can mask small leaks that could freeze and fill up the cover damaging the valve. I recommend not using these covers.

🛑 Safety 🔧 Maintenance (as needed) 👁🗨 Monitor during use 🔍 Due Diligence

- P-4 🚿PLUMBING:

BUILDING DRAINAGE SYSTEMS:

There were issues documented below in bulleted lists, narratives, and/or pictures related to the drainage system of the home: I recommend evaluation, repairs and maintenance as deemed necessary by a licensed plumber (or in some cases by other qualified parties).

PUBLIC SEWER:

- 🚩Sewer scoping was done. Proper function of the house drain to the city sewer is beyond the scope of this inspection. I recommend that proper function be both determined and maintained. The best method to verify function is to have them inspected with a remote camera device. At the time of inspection the interior plumbing drains were scoped by a scoping company.

- ◽At the time of inspection some plumbing drains were scoped by a scoping company. See their report for pipe condition.

FLOOR DRAINS:

- ◽Function not determined

- 🚩Presence of water in trap not determined due to lack of access. At the time of inspection the trap for the floor drain was not evaluated as to whether there was water in it or not (no access). I recommend verification of water in the trap and providing a means of keeping water in the trap. There are oil-like trap seal products available or mechanical type trap primers can be installed.

- ◽Letting the condensate drain from the furnace act as a trap primer is another possible way to keep water in this trap.

- ◽Determining their presence is sometimes difficult but are usually not present on drains of this age home.

- ◽Ttrap seal products, that prevent the evaporation of trap water, are also available.

🛑 Safety 🔧 Maintenance (as needed) 👁🗨 Monitor annually 🔍 Due Diligence

- P-5 🚿PLUMBING:

GAS PIPING:

There were issues documented below in bulleted lists, narratives, and/or pictures related to the following concerns were noted related to the gas piping on the property. I recommend evaluation, repairs and maintenance as deemed necessary by a licensed plumber.

BLACK STEEL AND GALVANIZED PIPE:

- ◽Pipe not sealed where it enters building

- Piping not adequately supported. There is gas pipe that is not adequately supported and subject to physical damage. All gas pipe is required to be supported such as to limit movement that could break joints or loosen unions etc. I recommend evaluation/repairs to the inadequately supported pipe at:

- ◽Run to the furnace

YELLOW CSST:

- ◽See electrical section of report regarding bonding

🛑 Safety 🔧 Maintenance (as needed) 👁🗨 Monitor annually 🔍 Due Diligence

- P-6 🚿PLUMBING:

GAS TANKLESS WATER HEATER:

There were issues documented below in bulleted lists, narratives, and/or pictures related to the water heater has the conditions discussed below that should be further evaluated and repaired as deemed necessary by a licensed plumber (or in some cases, repairs can be made by other qualified parties):

WATER HEATER CONDITIONS:

- ❌Approaching its expected life. The water heater at more than 14 years old is approaching the end of its useful life. I recommend factoring replacement of the heater by a licensed plumber in the near future.

INSTALLATION INSTRUCTIONS:

- Instructions. Newer installations of water heaters require the installation and maintenance instructions to be located at the furnace. None were noted at the time of inspection and they can typically be found on line by searching the model number of the unit:

- ◽None seen

ELECTRICAL CONNECTIONS:

- ◽Extension cord present

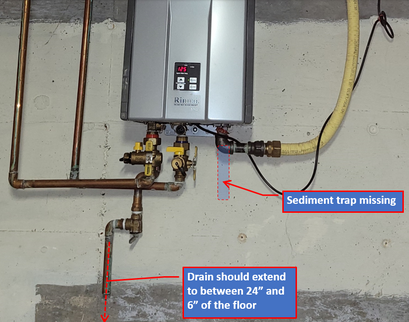

DRIP LEGS/SEDIMENT TRAPS:

- ◽None present. Many appliances require sediment traps located as close to the appliance as practical. None is present on this appliance and I recommend evaluation/repairs as deemed necessary by a licensed plumber in the context of other plumbing repairs at the home.

PRV:

- Present

DRAIN:

- ◽Drain pipe missing. There is currently no drain on the water heater TPRV (Temperature Pressure Relief Valve) as currently required. The drain should terminate at the exterior of the building at a location that can be monitored and it should terminate between 24" and 6" of the ground.

🛑 Safety 🔧 Maintenance (as needed) 👁🗨 Monitor annually 🔍 Due Diligence

- P-7 🚿PLUMBING:

THERMAL EXPANSION DEVICES:

There were issues documented below in bulleted lists, narratives, and/or pictures related to the thermal expansion device that should be further evaluated and repaired as deemed necessary by a licensed plumber:

THERMAL EXPANSION DEVICES:

- ◽No means of backflow protection was located

- ◽🚩Expansion Tank is not present but is required by current standards when any time of back-flow prevention is installed on the system. Water heaters installed after the year 2006 in most jurisdictions (and certainly this one) require installation of an expansion tank (or expansion device) on the plumbing system whenever there is any type of back-flow valve, pressure reducing valve ahead of the water heating equipment. Missing thermal expansion devices can be an indication of work done by unqualified individuals, without proper permits or that it has been verified that there is no other means of back flow prevention including the water meter.

🛑 Safety, 🔧 Maintenance (as needed), 👁🗨 Monitor during use and 🔍 Due Diligence

DUE DILIGENCE ITEMS

- 🚿PLUMBING:

YARD IRRIGATION SYSTEM:

While Irrigation Systems are generally excluded from inspections, some components will be reported on as a courtesy. Have the installation evaluated and maintained as deemed necessary by a qualified irrigation system installation contractor or licensed plumber where applicable.

🔧 Maintenance (as needed) 👁🗨 Monitor during use 🔍 Due Diligence