The Scope and Purpose of a Property Inspection

Purchasing property involves risk

The purpose of a property inspection is to help reduce the risk associated with the purchase of a structure by providing a professional opinion about the overall condition of the structure. A property inspection is a limited visual inspection and it cannot eliminate this risk. Some structures present more risks than others. We cannot control this, but we try to help educate you about what we don’t know during the inspection process. This is more difficult to convey in a report and one of many reasons why we recommend that you attend the inspection.

A property inspection is not an insurance policy

This report does not substitute for or serve as a warranty or guarantee of any kind. Home warranties can be purchased separately from insuring firms that provide this service.

A property inspection is visual and not destructive

The descriptions and observations in this report are based on a visual inspection of the structure. We inspect the aspects of the structure that can be viewed without dismantling, damaging or disfiguring the structure and without moving interior objects. Areas that are concealed, hidden or inaccessible to view are not covered by this inspection. Some systems cannot be tested during this inspection as testing risks damaging the building or those systems if they have been temporarily de-commissioned. Our procedures involve non-invasive investigation and non-destructive testing which will limit the scope of the inspection.

This is not an inspection for code compliance

This inspection and report are not intended for city / local code compliance. During the construction process structures are inspected for code compliance by municipal inspectors. Framing is open at this time and conditions can be fully viewed. Framing is typically not open during inspections of finished structures, and this limits the inspection. All structures fall out of code compliance shortly after they are built, as the codes continually change. National codes are augmented at least every three years for all of the varying disciplines. Municipalities can choose to adopt and phase in sections of the codes on their own timetables. There are generally no requirements to bring older structures into compliance unless substantial renovation is being done.

This is just our opinion

Construction techniques and standards vary. There is no one way to build a structure or install systems in a structure. The observations in this report are the opinions of the inspector. Other inspectors and contractors are likely to have some differing opinions. You are welcome to seek opinions from other professionals.

The scope of this inspection

This inspection will include the following systems: exterior, roof, structure, drainage, foundation, attic, interior, plumbing, electrical and heating. The evaluation will be based on limited observations that are primarily visual and non-invasive. This inspection and report are not intended to be technically exhaustive.

Your expectations

The overall goal of a property inspection is to help ensure that your expectations are appropriate with the structure you are proposing to buy. To this end we assist with discovery by showing and documenting observations during the structure inspection. This should not be mistaken for a technically exhaustive inspection designed to uncover every defect with a building. Such inspections are available but they are generally cost-prohibitive to most homebuyers.

Your participation is optional

Your presence is optional during this inspection. This written report will discuss concerns and potentially needed repairs on the property and the inspector is always available for in-depth discussions regarding the property once you have had time to read through and examine the report in detail.

How to Read This Report

Getting the Information to You

This report is designed to deliver important and technical information in a way that is easy for anyone to access and understand. If you are in a hurry, you can take a quick look at our "Summary Page” and quickly get critical information for important decision making. However, we strongly recommend that you take the time to read the full Report, which includes digital photographs, captions, diagrams, descriptions, videos and hot links to additional information.

The best way to get the layers of information that are presented in this report is to read your report online (the HTML version), which will allow you to expand your learning about your property. You will notice some words or series of words highlighted in blue and underlined – clicking on these will provide you with a link to additional information. The HTML version of this report also contains streaming videos. Short video clips often contain important information and critical context and sounds that can be difficult to capture in words and still pictures.

For the most reliable viewing experience, I recommend viewing the report on as large a screen as practical, as much detail can be lost on small devices like smart phones. For similar reasons, reports should only be printed in color to retain as much detail as possible and minimize misinterpretation of photographs.

This report can also be printed on paper or to a PDF document.

Chapters and Sections

This report is divided into chapters that parcel the structure into logical inspection components. Each chapter is broken into sections that relate to a specific system or component of the structure. You can navigate between chapters with the click of a button on the left side margin.

Most sections will contain some descriptive information done in black font. Observation narrative, done in colored boxes, will be included if a system or component is found to be significantly deficient in some way or if we wish to provide helpful additional information about the system or the scope of our inspection. If a system or component of the structure was deemed to be in satisfactory or serviceable condition, there may be no narrative observation comments in that section and it may simply say “tested,” or “inspected.”

Observation Labels

All narrative observations are colored, numbered and labeled to help you find, refer to, and understand the severity of the observation. Observation colors and labels used in this report are:

- Major Concern:Repair items that may cost significant money to correct now or in the near future, or items that require immediate attention to prevent additional damage or eliminate safety hazards.

- Repair:Repair and maintenance items noted during inspection. Please note that some repair items can be expensive to correct such as re-finishing hardwood floors, but are considered simply repair items due to their cosmetic nature.

- Recommended Maintenance:These are repair items that should be considered "routine home ownership items," such as servicing the furnace, cleaning the gutters or changing the air filters in the furnace.

- Improve:Observations that are not necessarily defects, but which could be improved for safety, efficiency, or reliability reasons.

- Monitor:Items that should be watched to see if correction may be needed in the future.

- Due Diligence:Observation such as a buried oil tank that may require further investigation to determine the severity and / or urgency of repair.

- Future Project:A repair that may be deferred for some time but should be on the radar for repair or replacement in the near future.

- Note:Refers to aside information and /or any comments elaborating on descriptions of systems in the home or limitations to the home inspection.

Pest Inspection

All items with the bug logo () are part of a structural pest inspection. If your inspector included a structural pest inspection as a part of the scope of your home inspection, you can distinguish pest inspection items by this logo. You can also go to the pest inspection summary page to see a summary of the items that are part of a pest inspection.

Summary Page

The Summary Page is designed as a bulleted overview of all the observations noted during inspection. This helpful overview is not a substitution for reading the entire inspection report. The entire report must be read to get a complete understanding of this inspection report as the Summary Page does not include photographs or photo captions.

Summary

Major Concerns

- ESGCDAF-1 ELECTRICAL SYSTEM, GROUNDING, CONNECTED DEVICES AND FIXTURES:

Live disconnected electrical wiring was found in at least one location and in order to reduce the risk for electrical shock and fire, all of the abandoned wiring in the structure should be located and removed or capped off and enclosed inside metal junction boxes by a qualified electrician.

- PSDFAV-1 PLUMBING SUPPLY, DRAINS, FIXTURES AND VENTS:

The left urinal in the men's restroom in the shop area was actively leaking at the time of the inspection when flushed. In order to reduce the potential for moisture related damage it is recommended that a qualified plumber evaluate and repair the urinal.

Repairs

- EWGCE-2 EXTERIOR WALLS< GROUNDS, CHIMNEYS. ETC:

The asphalt driveway and parkway is cracked and deteriorated and the open joints exacerbate further deterioration from moisture either saturating and softening the base or from freeze/thaw action in winter. In order to prolong the life of the driveway the severely deteriorated portions should be removed and patched and the entire driveway should then be seal coated. Evaluation and repair by a qualified asphalt contractor is recommended.

- EWGCE-3 EXTERIOR WALLS< GROUNDS, CHIMNEYS. ETC:

The existing caulking around the perimeter of the structure is cracked, missing and old. Exterior sealant performance is directly related to the joint preparation and application. For increased service life, performance and aesthetics, the exterior of the structure should be carefully examined and old deteriorated and/or improper caulking should be removed and the exterior of the structure caulked via appropriate means and materials. Proper joint preparation and the use of compliant exterior rated sealants of good quality is recommended .

All caulk joints should then be inspected annually and be repaired as needed. ALL exterior wall penetrations such as: piping, conduit, vent caps, exterior light fixtures and receptacles should be sealed against moisture intrusion through the use of the appropriate caulking methods and materials. An intentional opening/gap at the base of electrical fixtures should remain open to allow any moisture penetration an avenue of escape.

Several sources regarding caulking preparation can be found online, here is a link to one source: Caulking Basics

- EWGCE-4 EXTERIOR WALLS< GROUNDS, CHIMNEYS. ETC:

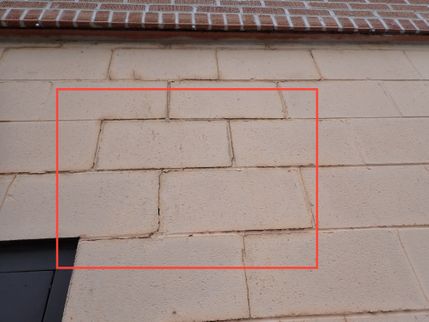

The exterior masonry walls are in overall good condition, however, areas of deterioration and damage were noted. The property owner should budget for repairs and maintenance and the exterior walls should be evaluated by a qualified masonry restoration contractor.

- EWGCE-5 EXTERIOR WALLS< GROUNDS, CHIMNEYS. ETC:

In order to prevent moisture penetration into the home and/or moisture contact with energized electrical equipment, caulking is recommended at the top and sides of the exterior electrical lighting fixtures. It should be noted that the bottom should remain unsealed for drainage purposes.

- EWGCE-6 EXTERIOR WALLS< GROUNDS, CHIMNEYS. ETC:

In order to provide protection against corrosion and also for proper appearance it is recommended that all of the steel window and door lintels be finish painted with a coating specifically formulated for exterior metal applications. Ideally these lintels would have been painted prior to their installation and this painting should comply with the paint manufacturers specifications for application.

- EWGCE-7 EXTERIOR WALLS< GROUNDS, CHIMNEYS. ETC:

In order to reduce the potential for moisture related damage, all exterior wall penetrations such as; piping, conduit, vent caps, etc. should be sealed against moisture intrusion, drafts, and energy losses through the use of the appropriate caulking methods and materials.

Also, many of the openings were rough penetrations. Penetrations through the exterior masonry walls should be configured with neatly cored openings that are slightly larger than the conduit or other item passing through the wall. This allows a consistent and uniform space for caulking/sealing which reduces the risk for moisture penetration and damage. It is recommended that all such exterior openings in the masonry walls be reconfigured in this manner.

- EWGCE-8 EXTERIOR WALLS< GROUNDS, CHIMNEYS. ETC:

Cracking was noted in the masonry joints between dissimilar materials and construction joints on the structure. All dissimilar elements on the exterior walls of the structure such as: brick-to-stone; brick-to-concrete block; concrete block-to-glass block, all interior corners and all construction joints should be joined one to the other and sealed against moisture through the use of backer rod and urethane caulk or its equivalent. These elements have either differing coefficients of expansion and contraction in relation to temperature and moisture and/or are subject to movement which can lead to cracking of the cladding material and/or of the mortar joints. In order to reduce the potential for moisture related damage, the existing cement mortar joints should be ground out and replaced with the appropriate backer rod and ASTM approved caulking by a qualified masonry repair contractor.

This procedure is in keeping with the standards set forth by the Brick Industry Association. Further information is available at the following link: Accommodating Expansion of Brickwork

- EWGCE-9 EXTERIOR WALLS< GROUNDS, CHIMNEYS. ETC:

The front public sidewalk is cracked, settled and uneven which creates potential trip hazards. In order to reduce the potential for injury, it is recommended that the homeowner contact the local municipality regarding any potential cost sharing sidewalk replacement program. Typically most municipalities will pay for up to half of the cost for sidewalk replacement for the portions of the walk that are determined to be unsafe.

- EWGCE-10 EXTERIOR WALLS< GROUNDS, CHIMNEYS. ETC:

The butt joints between the individual sections of clay tile coping have been sealed with cement mortar. The mortar is cracking and the joints are open which creates a risk for moisture saturation/damage to the masonry walls below. The coping tiles serve to protect the underlying brick masonry walls from wetting/drying and freezing/thawing damage and should be neatly joined and properly sealed in order to perform this function. The coping tiles should be repaired or replaced as needed by a qualified masonry or roofing contractor. It is recommended that the individual clay tiles be removed and reinstalled using backer rod and polyurethane caulk to seal the joints.

- EWGCE-11 EXTERIOR WALLS< GROUNDS, CHIMNEYS. ETC:

The aluminum parapet capping at the top of the masonry parapet walls and metal building does not conform with industry standards as published by the Sheet-Metal and Air Conditioning Contractors National Association (SMACNA). The aluminum wall cap does not promptly shed moisture; does not have sleeved and gasketed overlaps; and is composed of relatively thin aluminum which will expand and contract significantly from temperature changes. These defects greatly increase the risk for moisture penetration into and through the underlying masonry walls. It is recommended that plans be made for the near-term replacement of the existing parapet wall cap with one that reflects industry standards and best practices.

- GAO-1 GARAGES AND OUTBUILDINGS:

Portions of the garage and interior shop floors are badly damaged and uneven which creates potential trip hazards and instability with fork lift use. In order to reduce the potential for injury, it is recommended that a qualified concrete repair contractor remove and replace the badly deteriorated portions of concrete.

- RCRFRD-1 ROOF COVERINGS, ROOF FLASHING, ROOF DRAINAGE:

Several gutter sections on at least one of the roof areas was reverse pitched, other gutter sections on the structure appear to be leaking and a loose downspout was observed. For proper roof drainage and to reduce the potential for moisture related damage, the gutters and downspouts on the structure should be evaluated and repaired as needed by a qualified gutter installation contractor.

- RCRFRD-2 ROOF COVERINGS, ROOF FLASHING, ROOF DRAINAGE:

Loose and potentially unsealed areas of termination bar flashing and roofing membrane were noted in at least one area that creates the potential for the entry of moisture. In order to reduce the potential for moisture related damage It is recommended that a qualified roofing contractor evaluate and repair the flashing as needed.

- RCRFRD-3 ROOF COVERINGS, ROOF FLASHING, ROOF DRAINAGE:

Roof drains are part of a drainage system that removes excess rainwater from the roof. At least one of the drains was partially blocked and should be cleaned for proper roof drainage.

- ESGCDAF-3 ELECTRICAL SYSTEM, GROUNDING, CONNECTED DEVICES AND FIXTURES:

A spot check of the battery operated emergency lighting system/s revealed one or more non-functioning units. It is strongly recommended that these critical life safety devices be regularly evaluated and repaired as needed by a qualified electrician.

- ESGCDAF-4 ELECTRICAL SYSTEM, GROUNDING, CONNECTED DEVICES AND FIXTURES:

In order to help ensure the continuity of the bonding/grounding safety system, a bonding jumper should be installed across the water meter by a qualified electrician.

- ESGCDAF-5 ELECTRICAL SYSTEM, GROUNDING, CONNECTED DEVICES AND FIXTURES:

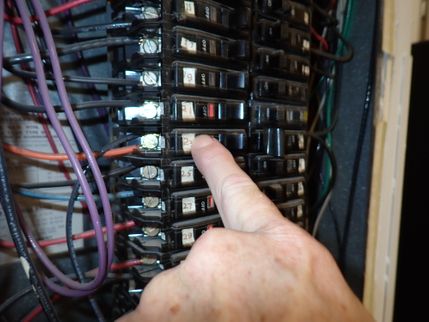

Pointed tipped screws are used to secure several of the service panel covers to the enclosure and the sharp ends have the potential to come into contact with wiring in the panel. This presents a risk for arcing/sparking, shock and fire and they should be replaced by a qualified electrician with blunt tipped screws specifically intended for use by the manufacturer of the panel.

- ESGCDAF-6 ELECTRICAL SYSTEM, GROUNDING, CONNECTED DEVICES AND FIXTURES:

While not all of the receptacles in the structure were tested, some loose and uncovered, electrical receptacles were noted in various areas of the structure. All of these conditions represent significant electrical safety defects. All of the electrical receptacles in the structure should be evaluated and repaired or replaced as necessary by a licensed and competent electrical contractor.

- ESGCDAF-7 ELECTRICAL SYSTEM, GROUNDING, CONNECTED DEVICES AND FIXTURES:

In order to reduce the risk for electrical shock from inadvertent contact with exposed current carrying equipment and in order to contain molten copper created by high temperature arcing and sparking of energized wiring, it is recommended that all electrical connections be concealed inside covered metal junction boxes by a qualified electrician.

- ESGCDAF-8 ELECTRICAL SYSTEM, GROUNDING, CONNECTED DEVICES AND FIXTURES:

Numerous double tapped breaker terminals were noted in several of the electrical service panels that were opened for examination. Double tapping can result in overloaded circuits and can increase the risk of electrical shock and/or fire. Evaluation and repair of all of the service panels in the structure by a licensed and competent electrical contractor is recommended.

- ESGCDAF-9 ELECTRICAL SYSTEM, GROUNDING, CONNECTED DEVICES AND FIXTURES:

At least one screw was missing from the cover for one of the electrical service panel. In order to reduce the potential for inadvertent contact with energized electric equipment, it is recommended that the missing electrical panel cover screw/s be replaced.

- PSDFAV-2 PLUMBING SUPPLY, DRAINS, FIXTURES AND VENTS:

The toilet in the office ladies room is not adequately secured to the floor. This can result in deformation of the wax ring seal, leaking and other damage. In order to reduce the potential for moisture related damage and to determine if removal and reinstallation is necessary, the toilet should be evaluated by a licensed and competent plumber.

- PSDFAV-3 PLUMBING SUPPLY, DRAINS, FIXTURES AND VENTS:

The flush mechanism in at least one of the toilets in the structure had to be held down to complete a flush. All toilets in the home should flush completely on a single depression of the flush lever and stop filling when the tank is full. If incomplete flushing and/or non-stop running of a toilet is noted at some point in the future, repair by a qualified plumber is recommended.

Many of these problems can be fixed with little or no experience and there are numerous helpful videos and article online. Here is a link to one such article that may provide useful information: Common Toilet Problems You Can Fix Yourself

- PSDFAV-4 PLUMBING SUPPLY, DRAINS, FIXTURES AND VENTS:

The utility sink is not adequately secured in place and is subject to excess motion which can result in damage to the water supply and/or drain piping. In order to reduce the potential for moisture related damage, repair by a qualified plumber is recommended.

- PSDFAV-5 PLUMBING SUPPLY, DRAINS, FIXTURES AND VENTS:

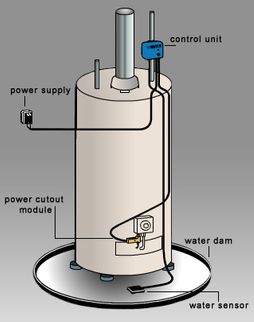

The water heater on the mezzanine by the Dayton space heater is located above other improved spaces and the lack of a nearby floor drain creates the potential for moisture related damage. Since a water heater defect or failure can result in catastrophic damage it is strongly recommended that a moisture management system be furnished and installed by a qualified contractor.

Options for flood prevention can be found in an article located at the following link: Water Heater Flooding Protection

- PSDFAV-6 PLUMBING SUPPLY, DRAINS, FIXTURES AND VENTS:

The gap between the toilet base and tile floors should be sealed using the appropriate materials and methods in order to reduce a "fouling area". If mop water, bathtub water or a less pleasant "bathroom liquid" gets underneath the toilet, there is no way to clean it up. In order to reduce this risk and promote proper sanitation in the bathroom, caulking around the base of the toilet is recommended.

- PSDFAV-7 PLUMBING SUPPLY, DRAINS, FIXTURES AND VENTS:

The water heater in the front portion of the mezzanine does not appear to have a shut-off within sight of the heater as the supply line disappears into a difficult to reach area. In order to safely isolate the water heater for servicing It is recommended that a qualified electrician install a safety switch if one is not already installed.

- HACVAGAS-2 HEATING, AIR CONDITIONING, VENTILATION, AND GAS APPLIANCE SYSTEMS:

Non-insulated and/or minimally insulated ductwork and/or plenums were noted in the unconditioned attic space above the office areas and there were stained ceiling tiles and signs of condensation leakage from the ductwork. The lack of insulation on this ductwork significantly reduces energy efficiency as the ducts are exposed to the extreme temperatures in the attic that the HVAC system is trying to overcome in the structure. The lack of insulation also dramatically increases the potential for the formation of condensation due to temperature differentials that would exist between the ductwork and the attic temperatures. In addition, the heat escaping from the ducts results in pre-mature melting of snow cover on the roof during winter that can result in icicle formation and subsequent ice damming. In order to reduce the potential for moisture related damage and for improved energy efficiency, it is recommended that a qualified HVAC contractor or insulation specialist evaluate and insulate the ductwork in the attic.

- HACVAGAS-3 HEATING, AIR CONDITIONING, VENTILATION, AND GAS APPLIANCE SYSTEMS:

Condensation resulting in leakage was observed on the A/C refrigerant lines on the HVAC unit in the mezzanine. The deteriorated/missing insulation on the A/C refrigerant lines can result in energy losses that promote the formation of condensation. In order to reduce the potential for moisture related damage and to reduce energy losses and maximize efficiency, the insulation should be replaced by a qualified HVAC contractor.

- IVAE-2 INSULATION, VENTILATION, ATTICS, ETC.:

The attic insulation above the office area has minimal and missing insulation with numerous areas having no insulation at all. Energy savings can be expected by blowing in additional cellulose insulation on top of the existing fiberglass insulation up to a level of approximately R-49 and evaluation by a qualified insulation specialist is recommended.

- IVAE-3 INSULATION, VENTILATION, ATTICS, ETC.:

The building has several large vent openings that do not appear to have dampers or louvers which allows unconditioned air to enter the shop area. The vents may be needed for the large exhaust fan structure in the shop, however, for improved energy efficiency self-closing louvers should be added to the vent.

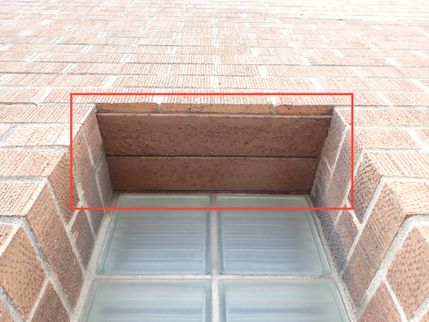

- WDS-1 WINDOWS, DOORS, SKYLIGHTS:

Several broken glazing blocks were noted on the glass block window installation(s). Repair by a qualified masonry contractor is recommended.

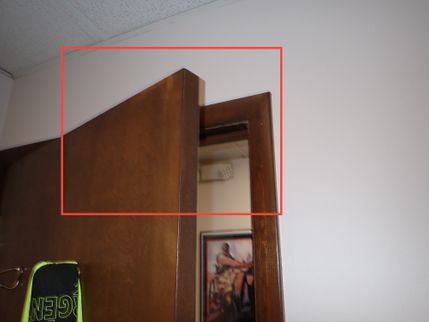

- WDS-2 WINDOWS, DOORS, SKYLIGHTS:

At least one of the doors in the structure failed to close or latch properly. For proper operation it is recommended that any non-functional doors be repaired or adjusted by a qualified carpenter or handyman.

- WDS-3 WINDOWS, DOORS, SKYLIGHTS:

The lower portion of the doorframe on the exterior entry door are deteriorated and elevated moisture levels were measured. In order to reduce the potential for further moisture related damage, it is recommended that a qualified carpenter evaluate and replace the deteriorated portions of the doorframe, possibly with materials that are less affected by moisture like PVC lumber.

- IA-1 INSTALLED APPLIANCES:

The dishwasher does not have a switched disconnect as required for electrical safety. In order to reduce the potential for electric shock, it is recommended that a qualified electrician install a 'kill switch' within sight of the dishwasher.

- O-1 OTHER:

Large devices typically associated with rats were noted around the perimeter of the property and larger droppings were noted near the home. Rats are extremely common in Cities and are typically attracted to waste and hidden nesting areas. Any areas that provide a safe haven for rats should be cleared of clutter that provides the ability for concealment and all waste should be kept in special waste containers.

- O-2 OTHER:

Evidence of a rodent problem was noted in and/or around the structure. Any openings in the exterior walls and door frames that are 1/4" or more in size could allow mice into the home. A comprehensive evaluation and sealing of the building exterior is recommended in addition to the elimination of any existing mice from inside the structure and further evaluation by a qualified pest control contractor is recommended.

- O-3 OTHER:

The floor tiling in the structure is of an age, size and style that is consistent with asbestos content. There is typically little risk for asbestos exposure with these tiles and it may be best to leave them in place, however, some flooring installers may be unwilling to install products over the making removal necessary. For more information on removing these tiles, here is a link to useful tips from a trusted home remodeling resource: All You Need to Know About Asbestos Floor Tiles

Also, the black mastic that was left behind has the potential to contain asbestos In order to determine if any hazard exists and what remedial steps may be prudent, further evaluation by a licensed and competent environmental remediation contractor is recommended.

In some cases encapsulation of the material by installing new flooring may be much more cost effective and potentially safer than hazardous removal of the mastic. Here is a link to an article that contains a discussion on this subject and provides options for this type of mastic: Black Mastic Floor Adhesive

Here is another link that provides additional information on black mastic: Black Mastic Floor Adhesive Information

- O-4 OTHER:

Fibrous panels were noted in the ceiling of some office areas above the drop ceiling. Portions of these panels are damaged and the presence of remaining sections of these panels suggests that, whatever material was previously removed was not done in accordance with existing safety standards. The improper removal of asbestos material can result in asbestos fibers in the dust and air in the home. If this material is made of asbestos, in order to assess any possible health risk posed by these conditions, further evaluation by a licensed and competent environmental remediation contractor would be recommended.

In order to determine if asbestos is present in this material, it may be possible for the buyer/property owner to carefully collect a small sample of the material to send to a lab for analysis.

Here is a link to a Chicago testing lab that may be able to perform this testing: Indoor Science Testing Lab

Here is a link to a Chicago suburban testing lab that may be able to perform this testing: UAS Laboratory Services

Recommended Maintenance Items

- PSDFAV-9 PLUMBING SUPPLY, DRAINS, FIXTURES AND VENTS:

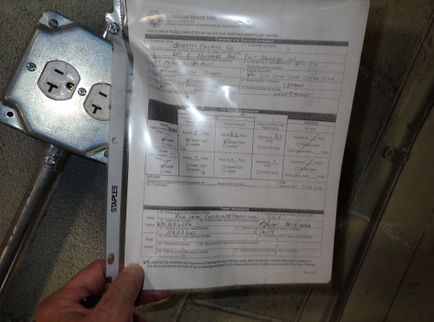

Backflow prevention devices typically require annual servicing. There is one such unit near the water meter on the west side of the building and it appears it was last serviced in 2019. In order to reduce the potential for backflow of undesirable materials into the water supply the unit should be evaluated and serviced as needed by a qualified service technician.

- PSDFAV-10 PLUMBING SUPPLY, DRAINS, FIXTURES AND VENTS:

FYI: Traps on floor drains without a continuous source of moisture can dry out and should be regularly monitored and re-filled with water as needed to prevent the migration of sewer gas into the home. The application of several drops of mineral oil can retard the evaporation of the water 'plug' in the floor drain trap.

Improves

- ESGCDAF-2 ELECTRICAL SYSTEM, GROUNDING, CONNECTED DEVICES AND FIXTURES:

There are no spare breaker spaces in some of the electrical service panels. Common sense and good practices call for the provision of at least 10% spare breaker spaces in a new service panel installation. In order to provide for future expansion and unforeseen demands, it is recommended that larger service panels be installed by a qualified electrician.

- PSDFAV-8 PLUMBING SUPPLY, DRAINS, FIXTURES AND VENTS:

Older style gate valve shut-offs were noted on supplies to many of the plumbing fixtures in the structure. These supplies can be prone to leakage when operated and they were not opened or closed at the time of the inspection. In order to be able to shut off water to service plumbing fixtures in the future, the valves should be replaced with 1/4 turn ball valves by a qualified plumber.

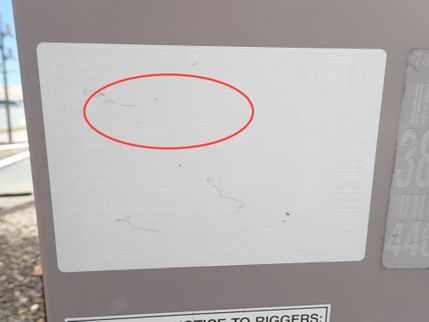

- IAF-1 INTERIORS AND FINISHES:

The interior finishes have some minor blemishes and in order for the interior to conform to accepted appearance standards, some repairs, re-finishing, drywall touch ups and repainting may be needed.

Persistent cracks in common areas for cracking like above doors and windows should be repaired with a flexible repair material. Here is a link to information regarding one such product: Applying Krack Kote

Monitors

- RCRFRD-6 ROOF COVERINGS, ROOF FLASHING, ROOF DRAINAGE:

There appears to have been roof leakage at some point as signs of interior leakage were observed in above the mezzanine and office areas. There were areas of the roof where the rock ballast appears to have been removed and some small cracks and openings were noted on the seams in some repairs and if leakage is noted at some point in the future the roof should be evaluated and repaired as needed by a qualified roofing contractor.

- PSDFAV-12 PLUMBING SUPPLY, DRAINS, FIXTURES AND VENTS:

Incipient leakage stains were noted on several water supply pipes in the structure and while no active leakage was observed at these locations at the time of the inspection, they should be monitored and repaired by a qualified plumber if leakage is noted at some point in the future or if other plumbing work is performed in the structure.

- PSDFAV-13 PLUMBING SUPPLY, DRAINS, FIXTURES AND VENTS:

Incipient leakage staining was noted on the drain/vent piping in the mezzanine area however no active leakage was noted at the time of the inspection. If active leakage is noted at some point in the future, repair by a qualified plumber is recommended.

Due Diligences

- ESGCDAF-10 ELECTRICAL SYSTEM, GROUNDING, CONNECTED DEVICES AND FIXTURES:

The evaluation of the low-voltage equipment in the home: alarm, communication, audiovisual, etc., is beyond the scope of the home inspection and should be performed by a qualified low-voltage electrical contractor. In order to reduce the potential for confusion and to reduce clutter around the home, any wiring, panels, cabinets, etc. for any equipment that is no longer in use should be removed.

- PSDFAV-11 PLUMBING SUPPLY, DRAINS, FIXTURES AND VENTS:

A video camera sewer scope is recommended. An evaluation of the sewer line below the ground is beyond the scope of this inspection. Due to the age and location of the building, a sewer scope is recommended to further evaluate the sewer line and the below ground connections between the structure and the municipal sewer line. Sewer scopes are done using video cameras and can reveal the materials, condition and reliability of the sewer line. If that has not been done recently, I recommend having a sewer scope performed.

- HACVAGAS-4 HEATING, AIR CONDITIONING, VENTILATION, AND GAS APPLIANCE SYSTEMS:

The age of the cast iron boiler in this structure could not be determined as there was not a legible data plate, however, it can provides decades of service if it is maintained properly. It is recommended that any available service records for the boiler be obtained from the seller and be compared to the manufacturers maintenance requirements. If proper maintenance is being followed, it is recommended that the property owner continue the ongoing service schedules.

- IVAE-1 INSULATION, VENTILATION, ATTICS, ETC.:

Traces of vermiculite insulation was noted in the attic space above the office area. This insulation is a mineral that is mined from the earth. Most of this insulation comes from a mine in Libby Montana that was contaminated with asbestos. A recent class action law suit alleged that this insulation is unsafe and could expose occupants to asbestos fibers. According to the EPA, there is no safe level of exposure to asbestos. At the time of inspection it appeared as though most of this material was removed. Inquire with the sellers for more information. For more information about vermiculite insulation go to the following link: Zonolite Attic Insulation Trust

Future Projects

- EWGCE-1 EXTERIOR WALLS< GROUNDS, CHIMNEYS. ETC:

Concrete/split faced block are highly porous building materials. The failure to maintain the exterior concrete block walls can lead to moisture intrusion, wood rot, mold growth, structural damage and (if severely neglected for a prolonged period) structural floor collapse. There was significant cracking in the exterior block wall areas on this structure and efflorescent material was noted on the interior which suggests moisture is moving through the building.

While building codes call for these materials to be pre-treated with water repellent at the factory and for the mortar used in their installation to also be water repellent. Even so, regular evaluation for moisture absorption and regular applications of surface-applied water repellent treatments are required every several years in order to protect against moisture intrusion into the interior spaces. The penetrating masonry sealants in common use appear to be providing five years or less of moisture resistance under field conditions in our area. High build coatings will typically provide longer lasting protection against moisture absorption when applied to concrete masonry units a.k.a. concrete block or split faced block.

The property owner should, in consultation with a qualified masonry restoration or painting contractor, assess the suitability of high build coatings on the exterior concrete block walls of this building. Any cracks in the mortar should be assessed and re-pointed if needed by a qualified masonry restoration contractor prior to applying any waterproofing coating.

Further information regarding high build coatings can be found in the article found at this link: High Build Coatings

- RCRFRD-4 ROOF COVERINGS, ROOF FLASHING, ROOF DRAINAGE:

Ponded areas were noted on the low slope roof. Ponding accelerates the rate of roof wear/deterioration and increases the risk for leaking. When a new roof covering is installed, plans should be made to re-pitch the roof using tapered roof insulation.

- RCRFRD-5 ROOF COVERINGS, ROOF FLASHING, ROOF DRAINAGE:

There appears to have been repairs performed on the chimney, however, much of the chimney is covered by roofing membrane. Best roofing practices call for the roof covering to be held back and terminated along masonry walls typically between 12" and 36". When the membrane is wrapped over masonry it prevents moisture from draining/evaporating at that side and will reduce mortar and brick life on the opposite side as moisture seeks pathways to drain or evaporate. It is recommended that the membrane be removed and terminated at an appropriate height on the parapet wall with appropriate base and counterflashing. Once the roofing has been removed the masonry chimney should be evaluated by a qualified masonry restoration contractor and mortar repairs should be expected where the roof material concealed masonry details.

- HACVAGAS-1 HEATING, AIR CONDITIONING, VENTILATION, AND GAS APPLIANCE SYSTEMS:

The air-conditioning condenser is close to the end of the expected service life and although the system was operational at the time of the inspection, cooling levels may be inadequate in the near future. The R-22 refrigerant that is used in the unit is being phased out and no new or imported R-22 is allowed in the U.S. and technicians will only be able to use recycled, reclaimed or previously produced R-22 to service equipment. Therefore, it will become more expensive to service the unit in the future. The cost to retrofit the HVAC system to use the new R-410 A replacement refrigerant is expensive and involves replacing the evaporator coils in the furnace.

The Full Report

GENERAL INFORMATION

TYPE OF STRUCTURE: Commercial Structure

APPROXIMATE AGE OF STRUCTURE: Over 100 Years, Online information suggests structure was built in 1915

STRUCTURE FACES: North

CLIENT PRESENT: No

RADON TEST: No

WATER QUALITY TEST: No

WEATHER CONDITIONS: Clear

AMBIENT TEMPERATURE: Over 60

NUMBER OF STORIES: One Story

EXTERIOR WALL CONSTRUCTION: Masonry, Steel

PRIMARY EXTERIOR WALL CLADDING MATERIAL: Brick

FOUNDATION: Foundation not Accessible

EXTERIOR WALLS< GROUNDS, CHIMNEYS. ETC

GAS SHUT-OFF LOCATION: Exterior Wall - North

WALKWAYS PATIOS DRIVEWAYS: Asphalt Driveway - Sealing and Patching Recommended

VEGETATION/GRADING/DRAINAGE: Improper Downspout Terminations

Concrete/split faced block are highly porous building materials. The failure to maintain the exterior concrete block walls can lead to moisture intrusion, wood rot, mold growth, structural damage and (if severely neglected for a prolonged period) structural floor collapse. There was significant cracking in the exterior block wall areas on this structure and efflorescent material was noted on the interior which suggests moisture is moving through the building.

While building codes call for these materials to be pre-treated with water repellent at the factory and for the mortar used in their installation to also be water repellent. Even so, regular evaluation for moisture absorption and regular applications of surface-applied water repellent treatments are required every several years in order to protect against moisture intrusion into the interior spaces. The penetrating masonry sealants in common use appear to be providing five years or less of moisture resistance under field conditions in our area. High build coatings will typically provide longer lasting protection against moisture absorption when applied to concrete masonry units a.k.a. concrete block or split faced block.

The property owner should, in consultation with a qualified masonry restoration or painting contractor, assess the suitability of high build coatings on the exterior concrete block walls of this building. Any cracks in the mortar should be assessed and re-pointed if needed by a qualified masonry restoration contractor prior to applying any waterproofing coating.

Further information regarding high build coatings can be found in the article found at this link: High Build Coatings

The asphalt driveway and parkway is cracked and deteriorated and the open joints exacerbate further deterioration from moisture either saturating and softening the base or from freeze/thaw action in winter. In order to prolong the life of the driveway the severely deteriorated portions should be removed and patched and the entire driveway should then be seal coated. Evaluation and repair by a qualified asphalt contractor is recommended.

The existing caulking around the perimeter of the structure is cracked, missing and old. Exterior sealant performance is directly related to the joint preparation and application. For increased service life, performance and aesthetics, the exterior of the structure should be carefully examined and old deteriorated and/or improper caulking should be removed and the exterior of the structure caulked via appropriate means and materials. Proper joint preparation and the use of compliant exterior rated sealants of good quality is recommended .

All caulk joints should then be inspected annually and be repaired as needed. ALL exterior wall penetrations such as: piping, conduit, vent caps, exterior light fixtures and receptacles should be sealed against moisture intrusion through the use of the appropriate caulking methods and materials. An intentional opening/gap at the base of electrical fixtures should remain open to allow any moisture penetration an avenue of escape.

Several sources regarding caulking preparation can be found online, here is a link to one source: Caulking Basics

The exterior masonry walls are in overall good condition, however, areas of deterioration and damage were noted. The property owner should budget for repairs and maintenance and the exterior walls should be evaluated by a qualified masonry restoration contractor.

In order to prevent moisture penetration into the home and/or moisture contact with energized electrical equipment, caulking is recommended at the top and sides of the exterior electrical lighting fixtures. It should be noted that the bottom should remain unsealed for drainage purposes.

In order to provide protection against corrosion and also for proper appearance it is recommended that all of the steel window and door lintels be finish painted with a coating specifically formulated for exterior metal applications. Ideally these lintels would have been painted prior to their installation and this painting should comply with the paint manufacturers specifications for application.

In order to reduce the potential for moisture related damage, all exterior wall penetrations such as; piping, conduit, vent caps, etc. should be sealed against moisture intrusion, drafts, and energy losses through the use of the appropriate caulking methods and materials.

Also, many of the openings were rough penetrations. Penetrations through the exterior masonry walls should be configured with neatly cored openings that are slightly larger than the conduit or other item passing through the wall. This allows a consistent and uniform space for caulking/sealing which reduces the risk for moisture penetration and damage. It is recommended that all such exterior openings in the masonry walls be reconfigured in this manner.

Cracking was noted in the masonry joints between dissimilar materials and construction joints on the structure. All dissimilar elements on the exterior walls of the structure such as: brick-to-stone; brick-to-concrete block; concrete block-to-glass block, all interior corners and all construction joints should be joined one to the other and sealed against moisture through the use of backer rod and urethane caulk or its equivalent. These elements have either differing coefficients of expansion and contraction in relation to temperature and moisture and/or are subject to movement which can lead to cracking of the cladding material and/or of the mortar joints. In order to reduce the potential for moisture related damage, the existing cement mortar joints should be ground out and replaced with the appropriate backer rod and ASTM approved caulking by a qualified masonry repair contractor.

This procedure is in keeping with the standards set forth by the Brick Industry Association. Further information is available at the following link: Accommodating Expansion of Brickwork

The front public sidewalk is cracked, settled and uneven which creates potential trip hazards. In order to reduce the potential for injury, it is recommended that the homeowner contact the local municipality regarding any potential cost sharing sidewalk replacement program. Typically most municipalities will pay for up to half of the cost for sidewalk replacement for the portions of the walk that are determined to be unsafe.

The butt joints between the individual sections of clay tile coping have been sealed with cement mortar. The mortar is cracking and the joints are open which creates a risk for moisture saturation/damage to the masonry walls below. The coping tiles serve to protect the underlying brick masonry walls from wetting/drying and freezing/thawing damage and should be neatly joined and properly sealed in order to perform this function. The coping tiles should be repaired or replaced as needed by a qualified masonry or roofing contractor. It is recommended that the individual clay tiles be removed and reinstalled using backer rod and polyurethane caulk to seal the joints.

The aluminum parapet capping at the top of the masonry parapet walls and metal building does not conform with industry standards as published by the Sheet-Metal and Air Conditioning Contractors National Association (SMACNA). The aluminum wall cap does not promptly shed moisture; does not have sleeved and gasketed overlaps; and is composed of relatively thin aluminum which will expand and contract significantly from temperature changes. These defects greatly increase the risk for moisture penetration into and through the underlying masonry walls. It is recommended that plans be made for the near-term replacement of the existing parapet wall cap with one that reflects industry standards and best practices.

GARAGES AND OUTBUILDINGS

Portions of the garage and interior shop floors are badly damaged and uneven which creates potential trip hazards and instability with fork lift use. In order to reduce the potential for injury, it is recommended that a qualified concrete repair contractor remove and replace the badly deteriorated portions of concrete.

ROOF COVERINGS, ROOF FLASHING, ROOF DRAINAGE

Roof Covering: Single Ply----Material Unknown, With Rock Ballast

Roof Viewed: Roof Was Walked

Several gutter sections on at least one of the roof areas was reverse pitched, other gutter sections on the structure appear to be leaking and a loose downspout was observed. For proper roof drainage and to reduce the potential for moisture related damage, the gutters and downspouts on the structure should be evaluated and repaired as needed by a qualified gutter installation contractor.

Loose and potentially unsealed areas of termination bar flashing and roofing membrane were noted in at least one area that creates the potential for the entry of moisture. In order to reduce the potential for moisture related damage It is recommended that a qualified roofing contractor evaluate and repair the flashing as needed.

Roof drains are part of a drainage system that removes excess rainwater from the roof. At least one of the drains was partially blocked and should be cleaned for proper roof drainage.

Ponded areas were noted on the low slope roof. Ponding accelerates the rate of roof wear/deterioration and increases the risk for leaking. When a new roof covering is installed, plans should be made to re-pitch the roof using tapered roof insulation.

There appears to have been repairs performed on the chimney, however, much of the chimney is covered by roofing membrane. Best roofing practices call for the roof covering to be held back and terminated along masonry walls typically between 12" and 36". When the membrane is wrapped over masonry it prevents moisture from draining/evaporating at that side and will reduce mortar and brick life on the opposite side as moisture seeks pathways to drain or evaporate. It is recommended that the membrane be removed and terminated at an appropriate height on the parapet wall with appropriate base and counterflashing. Once the roofing has been removed the masonry chimney should be evaluated by a qualified masonry restoration contractor and mortar repairs should be expected where the roof material concealed masonry details.

There appears to have been roof leakage at some point as signs of interior leakage were observed in above the mezzanine and office areas. There were areas of the roof where the rock ballast appears to have been removed and some small cracks and openings were noted on the seams in some repairs and if leakage is noted at some point in the future the roof should be evaluated and repaired as needed by a qualified roofing contractor.

STRUCTURE AND FOUNDATION

FLOOR STRUCTURE: Poured Concrete

CRAWLSPACE ACCESS: No Crawlspace

MAIN FLOOR BEAM AND POSTS: Structural Steel Posts and Beams, Wood Beams

A full evaluation of the foundation and structure of this commercial building is beyond the scope of this inspection, however, there was no cracking in the exterior masonry that would suggest unusual or excessive settlement has occurred in this structure.

ELECTRICAL SYSTEM, GROUNDING, CONNECTED DEVICES AND FIXTURES

ELECTRICAL SERVICE: 3 Phase Power, Copper Service Conductors, Overhead service

LOCATION OF MAIN SERVICE DISCONNECT: Interior Shut-offs

SERVICE PANEL AMPACITY: 400 AMP, 200 AMP

OVERCURRENT PROTECTION DEVICES: Circuit Breakers

SERVICE PANEL BRAND: SQUARE D, CUTLER HAMMER

BRANCH CIRCUIT CONDUCTORS: Copper, No Spare Breaker Spaces Are Available For Additional Circuitry

NUMBER OF CIRCUITS USED - NUMBER OF CIRCUITS AVAILABLE FOR USE: Numerous Panels - Varies per Panel

WIRING METHODS: Electrical Metallic Tubing EMT (Conduit), Armored Cable (BX)

ELECTRICAL GROUNDING CONDUCTOR/CLAMP LOCATION: Not Located: Further Evaluation of the Grounding/Bonding System by a Qualified Electrician is Recommended

Live disconnected electrical wiring was found in at least one location and in order to reduce the risk for electrical shock and fire, all of the abandoned wiring in the structure should be located and removed or capped off and enclosed inside metal junction boxes by a qualified electrician.

There are no spare breaker spaces in some of the electrical service panels. Common sense and good practices call for the provision of at least 10% spare breaker spaces in a new service panel installation. In order to provide for future expansion and unforeseen demands, it is recommended that larger service panels be installed by a qualified electrician.

A spot check of the battery operated emergency lighting system/s revealed one or more non-functioning units. It is strongly recommended that these critical life safety devices be regularly evaluated and repaired as needed by a qualified electrician.

In order to help ensure the continuity of the bonding/grounding safety system, a bonding jumper should be installed across the water meter by a qualified electrician.

Pointed tipped screws are used to secure several of the service panel covers to the enclosure and the sharp ends have the potential to come into contact with wiring in the panel. This presents a risk for arcing/sparking, shock and fire and they should be replaced by a qualified electrician with blunt tipped screws specifically intended for use by the manufacturer of the panel.

While not all of the receptacles in the structure were tested, some loose and uncovered, electrical receptacles were noted in various areas of the structure. All of these conditions represent significant electrical safety defects. All of the electrical receptacles in the structure should be evaluated and repaired or replaced as necessary by a licensed and competent electrical contractor.

In order to reduce the risk for electrical shock from inadvertent contact with exposed current carrying equipment and in order to contain molten copper created by high temperature arcing and sparking of energized wiring, it is recommended that all electrical connections be concealed inside covered metal junction boxes by a qualified electrician.

Numerous double tapped breaker terminals were noted in several of the electrical service panels that were opened for examination. Double tapping can result in overloaded circuits and can increase the risk of electrical shock and/or fire. Evaluation and repair of all of the service panels in the structure by a licensed and competent electrical contractor is recommended.

At least one screw was missing from the cover for one of the electrical service panel. In order to reduce the potential for inadvertent contact with energized electric equipment, it is recommended that the missing electrical panel cover screw/s be replaced.

The evaluation of the low-voltage equipment in the home: alarm, communication, audiovisual, etc., is beyond the scope of the home inspection and should be performed by a qualified low-voltage electrical contractor. In order to reduce the potential for confusion and to reduce clutter around the home, any wiring, panels, cabinets, etc. for any equipment that is no longer in use should be removed.

PLUMBING SUPPLY, DRAINS, FIXTURES AND VENTS

POTABLE WATER SOURCE: Public

WATER SERVICE PIPING MATERIAL: Copper, Not Fully Visible

MAIN WATER SHUT-OFF LOCATION: Interior - By water meter on west wall in shop area

WATER DISTRIBUTION PIPING MATERIAL: Copper, Not Fully Visible

WATER PRESSURE AND FLOW: Adequate

PLUMBING WASTE SYSTEM: Public Sewer

PLUMBING WASTE PIPING MATERIAL: Cast iron, PVC, Not Fully Visible

WATER HEATER SIZE AND POWER SOURCE: 3 Units, Electric Water Heater, 12 Gallons

BTU OR WATT INPUT RATING: 1500, 2000, 1650 Watts

WATER HEATER MANUFACTURER: Bradford White, Rheem, State Industries

APPROXIMATE AGE IN YEARS: Serial number suggests units were manufactured in: Rheem & State - 2012, Bradford White - 2019

The left urinal in the men's restroom in the shop area was actively leaking at the time of the inspection when flushed. In order to reduce the potential for moisture related damage it is recommended that a qualified plumber evaluate and repair the urinal.

The toilet in the office ladies room is not adequately secured to the floor. This can result in deformation of the wax ring seal, leaking and other damage. In order to reduce the potential for moisture related damage and to determine if removal and reinstallation is necessary, the toilet should be evaluated by a licensed and competent plumber.

The flush mechanism in at least one of the toilets in the structure had to be held down to complete a flush. All toilets in the home should flush completely on a single depression of the flush lever and stop filling when the tank is full. If incomplete flushing and/or non-stop running of a toilet is noted at some point in the future, repair by a qualified plumber is recommended.

Many of these problems can be fixed with little or no experience and there are numerous helpful videos and article online. Here is a link to one such article that may provide useful information: Common Toilet Problems You Can Fix Yourself

The utility sink is not adequately secured in place and is subject to excess motion which can result in damage to the water supply and/or drain piping. In order to reduce the potential for moisture related damage, repair by a qualified plumber is recommended.

The water heater on the mezzanine by the Dayton space heater is located above other improved spaces and the lack of a nearby floor drain creates the potential for moisture related damage. Since a water heater defect or failure can result in catastrophic damage it is strongly recommended that a moisture management system be furnished and installed by a qualified contractor.

Options for flood prevention can be found in an article located at the following link: Water Heater Flooding Protection

The gap between the toilet base and tile floors should be sealed using the appropriate materials and methods in order to reduce a "fouling area". If mop water, bathtub water or a less pleasant "bathroom liquid" gets underneath the toilet, there is no way to clean it up. In order to reduce this risk and promote proper sanitation in the bathroom, caulking around the base of the toilet is recommended.

The water heater in the front portion of the mezzanine does not appear to have a shut-off within sight of the heater as the supply line disappears into a difficult to reach area. In order to safely isolate the water heater for servicing It is recommended that a qualified electrician install a safety switch if one is not already installed.

Older style gate valve shut-offs were noted on supplies to many of the plumbing fixtures in the structure. These supplies can be prone to leakage when operated and they were not opened or closed at the time of the inspection. In order to be able to shut off water to service plumbing fixtures in the future, the valves should be replaced with 1/4 turn ball valves by a qualified plumber.

Backflow prevention devices typically require annual servicing. There is one such unit near the water meter on the west side of the building and it appears it was last serviced in 2019. In order to reduce the potential for backflow of undesirable materials into the water supply the unit should be evaluated and serviced as needed by a qualified service technician.

FYI: Traps on floor drains without a continuous source of moisture can dry out and should be regularly monitored and re-filled with water as needed to prevent the migration of sewer gas into the home. The application of several drops of mineral oil can retard the evaporation of the water 'plug' in the floor drain trap.

A video camera sewer scope is recommended. An evaluation of the sewer line below the ground is beyond the scope of this inspection. Due to the age and location of the building, a sewer scope is recommended to further evaluate the sewer line and the below ground connections between the structure and the municipal sewer line. Sewer scopes are done using video cameras and can reveal the materials, condition and reliability of the sewer line. If that has not been done recently, I recommend having a sewer scope performed.

Incipient leakage stains were noted on several water supply pipes in the structure and while no active leakage was observed at these locations at the time of the inspection, they should be monitored and repaired by a qualified plumber if leakage is noted at some point in the future or if other plumbing work is performed in the structure.

Incipient leakage staining was noted on the drain/vent piping in the mezzanine area however no active leakage was noted at the time of the inspection. If active leakage is noted at some point in the future, repair by a qualified plumber is recommended.

HEATING, AIR CONDITIONING, VENTILATION, AND GAS APPLIANCE SYSTEMS

COOLING EQUIPMENT STYLE: Split System (Outside Condenser w/ Inside Evaporator)

APPROXIMATE COOLING CAPACITY IN TONS: Rooftop unit 16 Tons, Smaller mini split 1.5 Tons

COOLING EQUIPMENT MANUFACTURER: CARRIER, Average Service Life of A/C Unit is 12-15 Years, The Air Conditioning Condensing Unit/s Are at or near the End of Their Useful Life, YORK

APPROXIMATE AGE OF CONDENSING UNIT: Serial number suggests rooftop unit was manufactured in 2006 and smaller mini split system in 2013

A/C REFRIGERANT: R 22 - Single system tested

HEAT TYPE: Circulating Hot Water Boiler, Copper Baseboard Convectors, Hydronic, Forced Air Ducted System, Space heater

HEATING ENERGY SOURCE: Natural Gas

BTU OR KW INPUT PER HOUR: Boiler unknown, Space Heater 200,000 BTU's

HEATING EQUIPMENT MANUFACTURER: BURNHAM, Average Service Life of Cast Iron Boiler is Approx. 35 years., Dayton Space Heater

APPROXIMATE AGE OF HEATING UNIT: Unknown

The air-conditioning condenser is close to the end of the expected service life and although the system was operational at the time of the inspection, cooling levels may be inadequate in the near future. The R-22 refrigerant that is used in the unit is being phased out and no new or imported R-22 is allowed in the U.S. and technicians will only be able to use recycled, reclaimed or previously produced R-22 to service equipment. Therefore, it will become more expensive to service the unit in the future. The cost to retrofit the HVAC system to use the new R-410 A replacement refrigerant is expensive and involves replacing the evaporator coils in the furnace.

Non-insulated and/or minimally insulated ductwork and/or plenums were noted in the unconditioned attic space above the office areas and there were stained ceiling tiles and signs of condensation leakage from the ductwork. The lack of insulation on this ductwork significantly reduces energy efficiency as the ducts are exposed to the extreme temperatures in the attic that the HVAC system is trying to overcome in the structure. The lack of insulation also dramatically increases the potential for the formation of condensation due to temperature differentials that would exist between the ductwork and the attic temperatures. In addition, the heat escaping from the ducts results in pre-mature melting of snow cover on the roof during winter that can result in icicle formation and subsequent ice damming. In order to reduce the potential for moisture related damage and for improved energy efficiency, it is recommended that a qualified HVAC contractor or insulation specialist evaluate and insulate the ductwork in the attic.

Condensation resulting in leakage was observed on the A/C refrigerant lines on the HVAC unit in the mezzanine. The deteriorated/missing insulation on the A/C refrigerant lines can result in energy losses that promote the formation of condensation. In order to reduce the potential for moisture related damage and to reduce energy losses and maximize efficiency, the insulation should be replaced by a qualified HVAC contractor.

The age of the cast iron boiler in this structure could not be determined as there was not a legible data plate, however, it can provides decades of service if it is maintained properly. It is recommended that any available service records for the boiler be obtained from the seller and be compared to the manufacturers maintenance requirements. If proper maintenance is being followed, it is recommended that the property owner continue the ongoing service schedules.

INSULATION, VENTILATION, ATTICS, ETC.

ATTIC INSULATION & VAPOR RETARDERS: Vermiculite Insulation (May Be Contaminated with Asbestos), Inadequate Insulation Present

Traces of vermiculite insulation was noted in the attic space above the office area. This insulation is a mineral that is mined from the earth. Most of this insulation comes from a mine in Libby Montana that was contaminated with asbestos. A recent class action law suit alleged that this insulation is unsafe and could expose occupants to asbestos fibers. According to the EPA, there is no safe level of exposure to asbestos. At the time of inspection it appeared as though most of this material was removed. Inquire with the sellers for more information. For more information about vermiculite insulation go to the following link: Zonolite Attic Insulation Trust

The attic insulation above the office area has minimal and missing insulation with numerous areas having no insulation at all. Energy savings can be expected by blowing in additional cellulose insulation on top of the existing fiberglass insulation up to a level of approximately R-49 and evaluation by a qualified insulation specialist is recommended.

The building has several large vent openings that do not appear to have dampers or louvers which allows unconditioned air to enter the shop area. The vents may be needed for the large exhaust fan structure in the shop, however, for improved energy efficiency self-closing louvers should be added to the vent.

INTERIORS AND FINISHES

The interior finishes have some minor blemishes and in order for the interior to conform to accepted appearance standards, some repairs, re-finishing, drywall touch ups and repainting may be needed.

Persistent cracks in common areas for cracking like above doors and windows should be repaired with a flexible repair material. Here is a link to information regarding one such product: Applying Krack Kote

WINDOWS, DOORS, SKYLIGHTS

WINDOW STYLES & MATERIALS: Glass Block

Several broken glazing blocks were noted on the glass block window installation(s). Repair by a qualified masonry contractor is recommended.

At least one of the doors in the structure failed to close or latch properly. For proper operation it is recommended that any non-functional doors be repaired or adjusted by a qualified carpenter or handyman.

The lower portion of the doorframe on the exterior entry door are deteriorated and elevated moisture levels were measured. In order to reduce the potential for further moisture related damage, it is recommended that a qualified carpenter evaluate and replace the deteriorated portions of the doorframe, possibly with materials that are less affected by moisture like PVC lumber.

INSTALLED APPLIANCES

The dishwasher does not have a switched disconnect as required for electrical safety. In order to reduce the potential for electric shock, it is recommended that a qualified electrician install a 'kill switch' within sight of the dishwasher.

OTHER

Large devices typically associated with rats were noted around the perimeter of the property and larger droppings were noted near the home. Rats are extremely common in Cities and are typically attracted to waste and hidden nesting areas. Any areas that provide a safe haven for rats should be cleared of clutter that provides the ability for concealment and all waste should be kept in special waste containers.

Evidence of a rodent problem was noted in and/or around the structure. Any openings in the exterior walls and door frames that are 1/4" or more in size could allow mice into the home. A comprehensive evaluation and sealing of the building exterior is recommended in addition to the elimination of any existing mice from inside the structure and further evaluation by a qualified pest control contractor is recommended.

The floor tiling in the structure is of an age, size and style that is consistent with asbestos content. There is typically little risk for asbestos exposure with these tiles and it may be best to leave them in place, however, some flooring installers may be unwilling to install products over the making removal necessary. For more information on removing these tiles, here is a link to useful tips from a trusted home remodeling resource: All You Need to Know About Asbestos Floor Tiles

Also, the black mastic that was left behind has the potential to contain asbestos In order to determine if any hazard exists and what remedial steps may be prudent, further evaluation by a licensed and competent environmental remediation contractor is recommended.

In some cases encapsulation of the material by installing new flooring may be much more cost effective and potentially safer than hazardous removal of the mastic. Here is a link to an article that contains a discussion on this subject and provides options for this type of mastic: Black Mastic Floor Adhesive

Here is another link that provides additional information on black mastic: Black Mastic Floor Adhesive Information

Fibrous panels were noted in the ceiling of some office areas above the drop ceiling. Portions of these panels are damaged and the presence of remaining sections of these panels suggests that, whatever material was previously removed was not done in accordance with existing safety standards. The improper removal of asbestos material can result in asbestos fibers in the dust and air in the home. If this material is made of asbestos, in order to assess any possible health risk posed by these conditions, further evaluation by a licensed and competent environmental remediation contractor would be recommended.

In order to determine if asbestos is present in this material, it may be possible for the buyer/property owner to carefully collect a small sample of the material to send to a lab for analysis.

Here is a link to a Chicago testing lab that may be able to perform this testing: Indoor Science Testing Lab

Here is a link to a Chicago suburban testing lab that may be able to perform this testing: UAS Laboratory Services

p20(3).jpg)

.jpg)