The Scope and Purpose of a Home Inspection

Inspection Overview

This home inspection is being conducted in accordance with the State of Illinois Home Inspector Licensing Act and following the American Society of Home Inspectors guidelines. No pest control, lead paint, asbestos, mold, or other types of testing are being performed. This is a visual inspection of readily accessible systems and components of the home. Some items or areas may not be inspected if they are blocked by furniture or stored items. The home inspector makes no guarantees regarding any of the home's systems or components. The inspection is performed in good faith and is a 'snapshot in time'; it does NOT constitute a prediction that the home will perform adequately in the future. Only non-invasive processes are used in the course of the inspection. Seasonal changes such as wind-driven rain, ice, and humidity may bring some defects to light that were not noted during your home inspection. Basements and attics that were dry at the time of the inspection can be damp or leak in later weeks or months. If you discover any adverse conditions in the home after your Domicile Consulting inspection, please call us immediately for a re-inspection and free consultation. No guarantees or warranties are provided in connection with the home inspection. Any disputes that cannot be resolved by the inspector and the client will be submitted jointly to the American Arbitration Association for a decision.

Purchasing property involves risk

The purpose of a home inspection is to help reduce the risk associated with the purchase of a structure by providing a professional opinion about the overall condition of the structure. A home inspection is a limited visual inspection and it cannot eliminate this risk. Some homes present more risks than others. We cannot control this, but we try to help educate you about what we don’t know during the inspection process. This is more difficult to convey in a report and one of many reasons why we recommend that you attend the inspection.

A home inspection is not an insurance policy

This report does not substitute for or serve as a warranty or guarantee of any kind. Home warranties can be purchased separately from insuring firms that provide this service.

A home inspection is visual and not destructive

The descriptions and observations in this report are based on a visual inspection of the structure. We inspect the aspects of the structure that can be viewed without dismantling, damaging or disfiguring the structure and without moving furniture and interior furnishings. Areas that are concealed, hidden or inaccessible to view are not covered by this inspection. Some systems cannot be tested during this inspection as testing risks damaging the building. For example, overflow drains on bathtubs are generally not tested because if they were found to be leaking they could damage the finishes below. Our procedures involve non-invasive investigation and non-destructive testing which will limit the scope of the inspection.

This is not an inspection for code compliance

This inspection and report are not intended for city / local code compliance. During the construction process structures are inspected for code compliance by municipal inspectors. Framing is open at this time and conditions can be fully viewed. Framing is not open during inspections of finished homes, and this limits the inspection. All houses fall out of code compliance shortly after they are built, as the codes continually change. National codes are augmented at least every three years for all of the varying disciplines. Municipalities can choose to adopt and phase in sections of the codes on their own timetables. There are generally no requirements to bring older homes into compliance unless substantial renovation is being done.

This is just our opinion

Construction techniques and standards vary. There is no one way to build a house or install a system in a house. The observations in this report are the opinions of the home inspector. Other inspectors and contractors are likely to have some differing opinions. You are welcome to seek opinions from other professionals.

The scope of this inspection

This inspection will include the following systems: exterior, roof, structure, drainage, foundation, attic, interior, plumbing, electrical and heating. The evaluation will be based on limited observations that are primarily visual and non-invasive. This inspection and report are not intended to be technically exhaustive.

Your expectations

The overall goal of a home inspection is to help ensure that your expectations are appropriate with the house you are proposing to buy. To this end we assist with discovery by showing and documenting observations during the home inspection. This should not be mistaken for a technically exhaustive inspection designed to uncover every defect with a building. Such inspections are available but they are generally cost-prohibitive to most homebuyers.

Your participation is requested

Your presence is requested during this inspection. A written report will not substitute for all the possible information that can be conveyed verbally by a shared visual observation of the conditions of the property.

How to Read This Report

Getting the Information to You

This report is designed to deliver important and technical information in a way that is easy for anyone to access and understand. If you are in a hurry, you can take a quick look at our "Summary Page” and quickly get critical information for important decision making. However, we strongly recommend that you take the time to read the full Report, which includes digital photographs, captions, diagrams, descriptions, videos and hot links to additional information.

The best way to get the layers of information that are presented in this report is to read your report online (the HTML version), which will allow you to expand your learning about your house. You will notice some words or series of words highlighted in blue and underlined – clicking on these will provide you with a link to additional information. The HTML version of this report also contains streaming videos. Short video clips often contain important information and critical context and sounds that can be difficult to capture in words and still pictures.

For the most reliable viewing experience, I recommend viewing the report on as large a screen as practical, as much detail can be lost on small devices like smart phones. For similar reasons, reports should only be printed in color to retain as much detail as possible and minimize misinterpretation of photographs.

This report can also be printed on paper or to a PDF document.

Chapters and Sections

This report is divided into chapters that parcel the home into logical inspection components. Each chapter is broken into sections that relate to a specific system or component of the home. You can navigate between chapters with the click of a button on the left side margin.

Most sections will contain some descriptive information done in black font. Observation narrative, done in colored boxes, will be included if a system or component is found to be significantly deficient in some way or if we wish to provide helpful additional information about the system or the scope of our inspection. If a system or component of the home was deemed to be in satisfactory or serviceable condition, there may be no narrative observation comments in that section and it may simply say “tested,” or “inspected.”

Observation Labels

All narrative observations are colored, numbered and labeled to help you find, refer to, and understand the severity of the observation. Observation colors and labels used in this report are:

- Major Concern:Repair items that may cost significant money to correct now or in the near future, or items that require immediate attention to prevent additional damage or eliminate safety hazards.

- Repair:Repair and maintenance items noted during inspection. Please note that some repair items can be expensive to correct such as re-finishing hardwood floors, but are considered simply repair items due to their cosmetic nature.

- Recommended Maintenance:These are repair items that should be considered "routine home ownership items," such as servicing the furnace, cleaning the gutters or changing the air filters in the furnace.

- Improve:Observations that are not necessarily defects, but which could be improved for safety, efficiency, or reliability reasons.

- Monitor:Items that should be watched to see if correction may be needed in the future.

- Due Diligence:Observation such as a buried oil tank that may require further investigation to determine the severity and / or urgency of repair.

- Future Project:A repair that may be deferred for some time but should be on the radar for repair or replacement in the near future.

- Efficiency:Denotes observations that are needed to make the home more energy efficient as well as to bring the home up to modern insulation standards. This category typically includes windows and insulation. Other items, such as lighting and appliances, are not inspected for their energy status.

- Note:Refers to aside information and /or any comments elaborating on descriptions of systems in the home or limitations to the home inspection.

Pest Inspection

All items with the bug logo () are part of a structural pest inspection. If your inspector included a structural pest inspection as a part of the scope of your home inspection, you can distinguish pest inspection items by this logo. You can also go to the pest inspection summary page to see a summary of the items that are part of a pest inspection.

Summary Page

The Summary Page is designed as a bulleted overview of all the observations noted during inspection. This helpful overview is not a substitution for reading the entire inspection report. The entire report must be read to get a complete understanding of this inspection report as the Summary Page does not include photographs or photo captions.

Moisture Meter Testing

Where moisture meter testing is indicated in this report a Protimiter Survey Master Dual Function was used.

Summary

Major Concerns

- HACVAGAS-10 HEATING, AIR CONDITIONING, VENTILATION, AND GAS APPLIANCE SYSTEMS:

There were older style gas valves present that have been known to leak over time. In order to reduce the potential for fire and explosion, it is recommended that the gas valves either be replaced with new valves if the gas line is to be used, otherwise the valves should be removed and the pipes capped by a qualified service technician.

- WDS-4 WINDOWS, DOORS, SKYLIGHTS:

The inspector was unable to find the etching in the corner of the shower doors or panels which typically indicates the presence of safety glazing. In order to reduce the potential for injury, evaluation and repair of all glass shower door panels by a qualified glazing specialist is recommended.

- O-1 OTHER:

The age of the smoke detectors noted in the home are unknown and they may be at or beyond the end of their service lives, typically taken to be 10 years for smoke detectors and 5 years for carbon monoxide detectors. It is recommended that the smoke detector and carbon monoxide detector systems be upgraded to reflect current life safety codes which include; smoke detectors on each level of living space and in each sleeping room, hard-wired 120 V smoke detectors that are interconnected in order to alarm simultaneously when any individual smoke detector responds, and carbon monoxide detectors and every level of living space and within 15 feet of a sleeping room. The installation of these critical life safety devices by a licensed and competent electrician is recommended.

Repairs

- EWGCE-1 EXTERIOR WALLS< GROUNDS, CHIMNEYS. ETC:

The rear stair/deck assembly does not conform to any standards and the following deficiencies were observed:

Stair/deck deficiencies

- Handrails non-graspable

- Handrails do not adequately resist lateral force

- Stair stringers single rail

- Foundation/s improper

- Bracing missing

- Step heights uneven

In order to reduce the potential for injury it is recommended that a qualified deck installation contractor evaluate and repair or replace the stairs/deck(s) as needed.

While local codes always govern, as a reference for proper construction practices that meet or exceed local building codes, here is a link to deck construction guidelines from the American Wood Council: Prescriptive Residential Wood Deck Construction Guide

- EWGCE-2 EXTERIOR WALLS< GROUNDS, CHIMNEYS. ETC:

The existing bushes, trees and landscaping installations are overgrown and/or dead and in need of trimming and/or removal. For proper appearance of the home the vegetation in the yard should be evaluated by a qualified arborist and/or landscaping contractor and be addressed as needed.

- EWGCE-3 EXTERIOR WALLS< GROUNDS, CHIMNEYS. ETC:

The masonry landscaping wall on the front of the home has stones that are loose and unstable. In order to reduce the potential for injury, It is recommended that a qualified landscaping contractor and/or masonry evaluate and repair the walls as needed.

NOTE: The walls do not have a foundation and are prone to movement and future deterioration from freeze/thaw movement in the ground. Rather than repair the walls via mortared joints, replacing the walls with segmented block walls that are intended for this purpose is recommended.

- EWGCE-4 EXTERIOR WALLS< GROUNDS, CHIMNEYS. ETC:

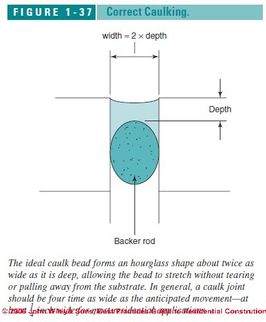

Cracking was noted in the masonry joints between dissimilar materials, stone features and stone coping on the structure. All dissimilar elements on the exterior walls of the structure such as: brick-to-stone; brick-to-concrete block; concrete block-to-glass block, all interior corners and all construction joints should be joined one to the other and sealed against moisture through the use of backer rod and urethane caulk or its equivalent. These elements have either differing coefficients of expansion and contraction in relation to temperature and moisture and/or are subject to movement which can lead to cracking of the cladding material and/or of the mortar joints. In order to reduce the potential for moisture related damage, the existing cement mortar joints should be ground out and replaced with the appropriate backer rod and ASTM approved caulking by a qualified masonry repair contractor.

This procedure is in keeping with the standards set forth by the Brick Industry Association. Further information is available at the following link: Accommodating Expansion of Brickwork

- EWGCE-5 EXTERIOR WALLS< GROUNDS, CHIMNEYS. ETC:

The existing caulking around the perimeter of the structure is cracked, old and missing. Exterior sealant performance is directly related to the joint preparation and application. For increased service life, performance and aesthetics, the exterior of the structure should be carefully examined and old deteriorated and/or improper caulking should be removed and the exterior of the structure caulked via appropriate means and materials. Proper joint preparation and the use of compliant exterior rated sealants of good quality is recommended .

All caulk joints should then be inspected annually and be repaired as needed. ALL exterior wall penetrations such as: piping, conduit, vent caps, exterior light fixtures and receptacles should be sealed against moisture intrusion through the use of the appropriate caulking methods and materials. An intentional opening/gap at the base of electrical fixtures should remain open to allow any moisture penetration an avenue of escape.

Several sources regarding caulking preparation can be found online, here is a link to one source: Caulking Basics

- EWGCE-6 EXTERIOR WALLS< GROUNDS, CHIMNEYS. ETC:

In order to reduce the potential for moisture related damage, all exterior wall penetrations such as; piping, conduit, vent caps, etc. should be sealed against moisture intrusion, drafts, and energy losses through the use of the appropriate caulking methods and materials.

- EWGCE-7 EXTERIOR WALLS< GROUNDS, CHIMNEYS. ETC:

Some of the painted wood surfaces have flaking paint or are exposed. In order to prolong the life of materials on the exterior of the home, all exposed wood surfaces should be professionally primed and painted by a qualified painting contractor or handyman.

- EWGCE-8 EXTERIOR WALLS< GROUNDS, CHIMNEYS. ETC:

Cracked glazing blocks were noted on the perimeter of some of the mortared glass block window installations. Mortar can transfer the stresses inherent in large masonry walls directly to the glass block which can lead to cracking of the glass block. Caulk, not mortar, should be used to seal the areas between the glass block windows and the brick walls. The broken glazing blocks should be removed and replaced and the existing mortar joints should be raked out and replaced with backer rod and urethane caulk or equivalent by a qualified masonry contractor.

- EWGCE-9 EXTERIOR WALLS< GROUNDS, CHIMNEYS. ETC:

Asphalt shingles have been used for siding on a portion of the home. These materials are generally not designed to have the full weight of the shingle hanging on the fasteners and if shingles are installed in this way additional fasteners must be added. Also. these shingles are prone to wind damage and should be monitored regularly for deterioration. In order to reduce the potential for moisture related damage, the material should not be replaced in kind and when it deteriorates to the point where replacement is required it is recommended that alternate proper siding materials be installed by a qualified siding installation contractor.

- EWGCE-10 EXTERIOR WALLS< GROUNDS, CHIMNEYS. ETC:

The exterior window lintels have been sealed and can no longer drain moisture which increases the potential for corrosion of the lintels. Over time the corroding steel will expand which can damage the adjacent masonry walls and allow moisture to penetrate to the interior of the living space. In order to reduce the potential for moisture related damage, the lintel drainage space should be repaired by a qualified masonry restoration contractor.

- EWGCE-11 EXTERIOR WALLS< GROUNDS, CHIMNEYS. ETC:

Some of the aluminum encasements that are sealing trim on the structure are loose and unsealed which exposes the older wood to become exposed to moisture. In order to reduce the potential for moisture related damage It is recommended that a qualified carpenter or handyman secure and seal all of the encasements.

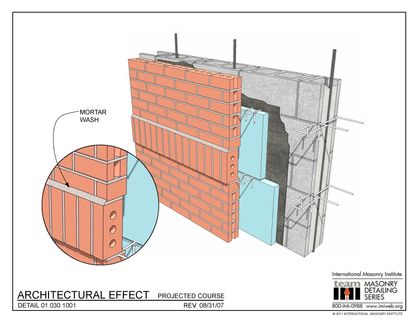

- EWGCE-12 EXTERIOR WALLS< GROUNDS, CHIMNEYS. ETC:

The presence of flat horizontal projections from the exterior masonry façade creates an increased risk for moisture accumulation, moisture saturation of the masonry and moisture penetration through the exterior wall to the interior. The most basic concept in exterior wall moisture management is to avoid flat surfaces and to ensure all exterior elements are properly sloped to promote the drainage of moisture. Therefore, it is recommended that a qualified masonry restoration contractor install an angled mortar wash, corrosion resistant metal flashing, or other methods and materials to reduce the risk for moisture related damage at these locations.

- EWGCE-13 EXTERIOR WALLS< GROUNDS, CHIMNEYS. ETC:

The exterior masonry walls are in overall good condition, however, general deterioration was noted with regard to the common brick exterior walls around the building. In order to reduce the potential for damaging and mold causing moisture to enter the home, it is recommended that plans be made for grinding out and repointing of the mortar joints in conjunction with spot replacement of individual damaged brick masonry units. Application of a penetrating masonry sealant is also recommended in order to reduce direct moisture absorption by the aged and deteriorated common bricks. The exterior walls should be evaluated and repaired by a qualified masonry restoration contractor.

.

- EWGCE-14 EXTERIOR WALLS< GROUNDS, CHIMNEYS. ETC:

The vent for the heater on the rear porch appears to be damaging the finish on the siding. The vent for the heater should be evaluated by a qualified HVAC service technician in order to see if it complies with the manufacturers installation instructions with regards to clearance to combustible materials. If the vent is installed properly, paints that can withstand high temperatures should be used on the siding adjacent to the vent.

- EWGCE-15 EXTERIOR WALLS< GROUNDS, CHIMNEYS. ETC:

The existing wooden deck/porch is weathered and deteriorating. In order to extend the service life of the deck materials, all exterior wooden deck surfaces should be professionally cleaned and sealed against weather.

Here is a link to some potentially useful information regarding deck sealing: How to Seal Your Deck & Best Deck Sealers

- EWGCE-16 EXTERIOR WALLS< GROUNDS, CHIMNEYS. ETC:

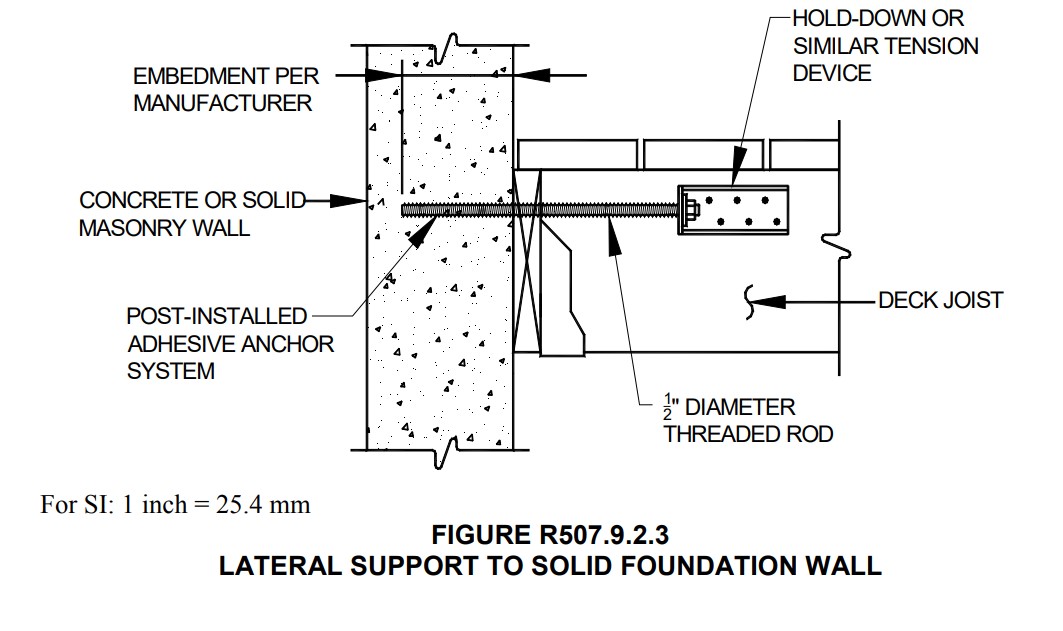

The deck ledger board is not properly secured to the exterior structural wall of the home. This creates a risk for structural motion of the deck, deck damage, and deck collapse. It is recommended that the deck ledger board be bolted to the exterior structural wall by a qualified carpenter or deck construction specialist.

- EWGCE-17 EXTERIOR WALLS< GROUNDS, CHIMNEYS. ETC:

There did not appear to be any lateral load resistance devices installed on the deck. While local municipal codes may not require these devices or may allow bracing, they are required in the International Building Code and can be critical in preventing the accidental detachment of the deck from the structure. These devices can be retro-fitted to the existing deck and in order to reduce the potential for deck collapse and resulting injury it is highly recommended that these devices be installed by a qualified carpenter or handyman.

- EWGCE-18 EXTERIOR WALLS< GROUNDS, CHIMNEYS. ETC:

The points of attachment between the rear porch and the exterior walls are concealed and it is unknown if they are properly sealed against moisture intrusion. In order to reduce the risk for ongoing moisture intrusion, mold growth, wood rot, etc. these critical areas should be protected by corrosion resistant metal flashing.

In order to determine the condition of the attachments it is recommended that decking, siding or interior wall coverings be removed so the band joist the structure is attached to can be examined and evaluation and potential repair by a qualified carpenter or handyman is recommended. If flashing is not present it should be retrofitted on the exterior walls wherever needed by a qualified contractor.

- GAO-2 GARAGES AND OUTBUILDINGS:

The trolley for the garage door opener appears to be bolted to a piece of wood that is only nailed in place which creates the potential for the opener to become loose. In order to reduce the potential for detachment of the opener trolley from the garage wall, the wood the door opener is bolted to should be securely fastened to the studs by a qualified garage door installation contractor.

- RCRFRD-1 ROOF COVERINGS, ROOF FLASHING, ROOF DRAINAGE:

In order to reduce the risk for moisture penetration and damage, it is recommended that a qualified roofing contractor install the missing overhanging drip edge flashing along all roof rake edges.

- RCRFRD-2 ROOF COVERINGS, ROOF FLASHING, ROOF DRAINAGE:

The sealant around the flashing on the metal roofs is cracked and deteriorated which can allow for the entry of moisture and signs of moisture related damage were observed in the ceiling of the living room. In order to reduce the potential for moisture related damage, It is recommended that a qualified roofing contractor or handyman repair the flashing joints as needed via appropriate means and materials.

- RCRFRD-3 ROOF COVERINGS, ROOF FLASHING, ROOF DRAINAGE:

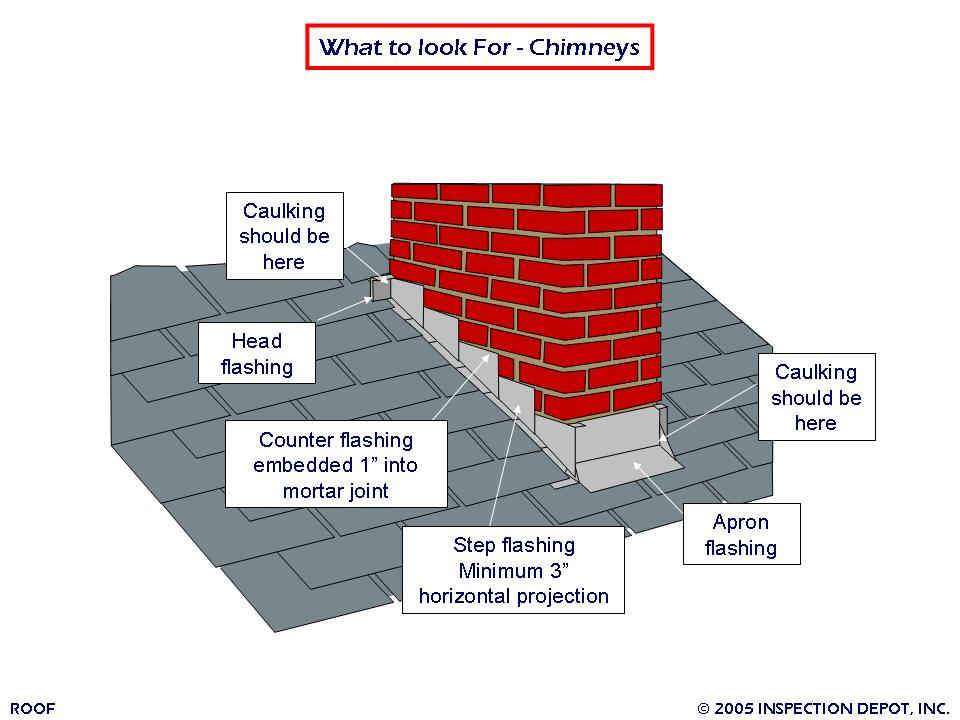

The flashing along the masonry chimney and/or roof to masonry wall transition has flush flashing that is sealed with caulk which is a low performance and high maintenance installation that creates the potential for moisture to enter the home. In order to reduce the potential for moisture related damage, it is recommended that step flashing be installed along the roof to masonry joint by a qualified roofing contractor.

- RCRFRD-4 ROOF COVERINGS, ROOF FLASHING, ROOF DRAINAGE:

The gutters on the home are clogged and overflowing with debris which can do more damage than discolor a home. The water that overflows out of the back side of the gutter can penetrate into the attic space causing damage to the internal structure and create holes large enough for invasive pests. Maintenance to keep gutters clear to prevent damage is recommended, especially in the fall when trees are losing their leaves.

- RCRFRD-5 ROOF COVERINGS, ROOF FLASHING, ROOF DRAINAGE:

The existing rooftop above the three season room appears to be able to be used as a deck. The roof does not have a walking surface and in order to reduce the potential for damage to the roof surface, a roof deck or some other walking or wearing surface should be added to the roof. When adding a roof deck, permitting through the City of Chicago is required and according to a recent memo from the City of Chicago, compliance with load and egress requirements is critical.

NOTE: The railing openings and height make the railing on the deck non-compliant and modifications to the railing if the roof is to be used.

Here is a link to a webpage that appears to contain current code information with regard to rooftop decks in Chicago: Rooftop Deck Code

Also, here is a link to a memorandum regarding roof deck replacements that may provide information relative to these installations: Replacement of roof decks installed before 10/1/2003

- RCRFRD-6 ROOF COVERINGS, ROOF FLASHING, ROOF DRAINAGE:

The modified bitumen roof covering on the rear addition roof is not properly secured to the back of the roof gutter. This defect presents an increased risk for damage from ice damming and from water backing up at the gutter. It is recommended that the roof/gutter interface be repaired by a qualified roofing contractor.

- RCRFRD-7 ROOF COVERINGS, ROOF FLASHING, ROOF DRAINAGE:

The roof on the rear three season room is older and was cracked and worn and plans should be made for roof replacement in the not too distant future. In order to extend the service life of the roofing and in order to reduce the cooling load on the rear porch, the application of a reflective coating is recommended over the surface of the modified bitumen roof covering. FYI: Aluminized coatings are, in general, far inferior to white roof coatings which are both more reflective and more emissive.

- SAF-1 STRUCTURE AND FOUNDATION:

Multiple foundation wall cracks were noted in the basement one of the cracks was actively leaking at the time of the inspection. The cracks may have been repaired by a professional foundation crack repair contractor and they will often provide lifetime warrantees against continued seepage and these warrantees are often transferable from owner to owner. All documentation regarding any crack repair performed during the current owners tenure should be provided to the buyer and in order to reduce the risk of seepage and to help prevent the cracks from becoming pathways for wood boring insects, these cracks should be evaluated and repaired by a licensed and competent basement waterproofing contractor.

Here is a link to an article that describes one potential type of crack sealing repair: Fixing Cracks in Concrete

- SAF-2 STRUCTURE AND FOUNDATION:

The rear three season room essentially has a crawlspace beneath it. Most vented crawlspaces are damp, moldy and inhabited with pests. They are typically connected to the air inside the home through many small un-intentional air leaks in the floors, partitions and ducts. Modern building science standards dictate that crawlspaces should not be vented unsealed to the exterior as this crawlspace is and it should be a conditioned space.

Therefore, to ensure durability, indoor air quality and save energy, a crawlspace must be kept dry, conditioned to control temperature and humidity and sealed tight to be pest free. It is recommended that the following improvements be made to the crawlspace:

- The door in the crawlspace be replaced with one that is insulated and should be completely sealed and the vent should also be sealed.

- The soil or gravel floor that is present in the crawlspace should be vapor-sealed with a minimum of a 6 mil plastic liner that has sealed joints, but preferably a high quality mesh reinforced liner.

- Floor insulation (if present) should be removed and the perimeter walls and rim joist areas should be insulated and air-sealed and the crawlspace air should be conditioned with small amounts of indoor air.

One potential use for accessible crawlspaces is storage. Here is a link to an article that discusses crawlspace improvements keeping that objective in mind: Convert Your Crawl Space into a Storage Area

- ESGCDAF-1 ELECTRICAL SYSTEM, GROUNDING, CONNECTED DEVICES AND FIXTURES:

The clamp securing the grounding wire to the driven ground rod is intended for a pipe connection and does not provide adequate connectivity to the ground rod. In order to ensure proper grounding of the electrical system, it is recommended that a qualified electrician evaluate and repair the grounding system by installing an acorn style grounding clamp or by other approved means.

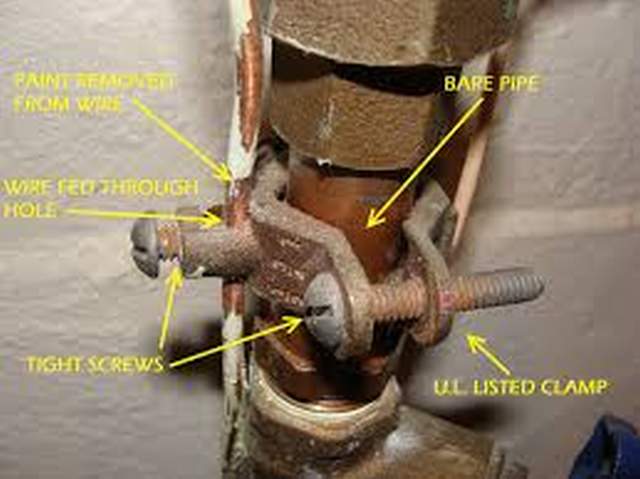

- ESGCDAF-3 ELECTRICAL SYSTEM, GROUNDING, CONNECTED DEVICES AND FIXTURES:

The grounding electrode conductor is not properly secured to the water piping system and grounding clamp. The stranded copper grounding conductor has been squeezed between the clamp and the piping which is not allowed and is unsafe since it makes the clamp prone to loosening. This can reduce the safety and effectiveness of the bonding and grounding system and the existing clamp should be replaced with one that can properly secure the grounding electrode conductor into a screw terminal. Further evaluation and repair by a licensed and competent electrical contractor is recommended.

- ESGCDAF-4 ELECTRICAL SYSTEM, GROUNDING, CONNECTED DEVICES AND FIXTURES:

There was a switch in the basement that was uncovered with represents a significant electrical safety defect. All of the electrical switches and receptacles in the structure should be evaluated and repaired as necessary by a licensed and competent electrical contractor.

- ESGCDAF-5 ELECTRICAL SYSTEM, GROUNDING, CONNECTED DEVICES AND FIXTURES:

Cold drafts can create condensation on the warm electrical components inside the service panel which can lead to corrosion and other deleterious conditions. The opening at the end of the service panel's feeder conduit should be sealed to stop the strong air drafts and energy losses at this location.

- ESGCDAF-6 ELECTRICAL SYSTEM, GROUNDING, CONNECTED DEVICES AND FIXTURES:

The existence of cloth insulated branch wiring was noted in the residence. Older cloth insulated wiring is often degraded and may have to be replaced during remodeling of the electrical system. In order to determine if it needs replacement, the cloth wiring in the building should be further evaluated and potentially replaced by a qualified electrician.

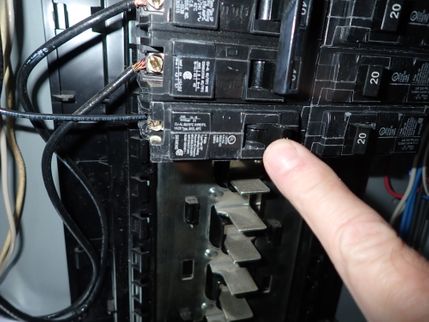

- ESGCDAF-7 ELECTRICAL SYSTEM, GROUNDING, CONNECTED DEVICES AND FIXTURES:

At least one over fused circuit was noted in the electrical service panel. Over fusing can cause overheating of the wires which could result in electric shock or fire. The service panel should be evaluated, repaired and certified as safe by licensed and competent electrical contractor.

- ESGCDAF-8 ELECTRICAL SYSTEM, GROUNDING, CONNECTED DEVICES AND FIXTURES:

At least one screw was missing from the cover for the electrical service panel. In order to reduce the potential for inadvertent contact with energized electric equipment, it is recommended that the missing electrical panel cover screw/s be replaced.

- ESGCDAF-10 ELECTRICAL SYSTEM, GROUNDING, CONNECTED DEVICES AND FIXTURES:

The bathroom light fixture in the primary bathroom is powered through the nearby GFCI receptacle. If the receptacle were to trip during a late night visit to the bath, or the receptacle were to become defective, the occupant could be left in the dark and would be subjected to an increased risk for falls and injuries. Repair by a qualified electrician is recommended.

- ESGCDAF-11 ELECTRICAL SYSTEM, GROUNDING, CONNECTED DEVICES AND FIXTURES:

In order to reduce the fire hazard associated with their hot surfaces and also to reduce the risk of bulb breakage, the bare bulb light fixtures in the closets should be replaced with low-profile fluorescent fixtures or their equivalent by a qualified electrician.

- ESGCDAF-12 ELECTRICAL SYSTEM, GROUNDING, CONNECTED DEVICES AND FIXTURES:

There was a missing and/or incomplete circuit directory for the electrical service panel/s. In order to allow for safe and efficient electrical circuit interruption when required for maintenance, repairs, or in emergencies, a complete and accurate electrical circuit directory should be provided to the buyer before closing.

- PSDFAV-2 PLUMBING SUPPLY, DRAINS, FIXTURES AND VENTS:

The water pressure and flow at some of the plumbing fixtures is marginal. For optimal flow and pressure during the use of multiple fixtures, it is recommended that the remaining galvanized water supply piping be removed and replaced with copper piping.

- PSDFAV-7 PLUMBING SUPPLY, DRAINS, FIXTURES AND VENTS:

The hot tap on the faucet on the laundry tub in the basement was leaking at the time of the inspection and the nozzle is stuck so it only fills one basin. For proper use of the laundry tub, repair or replacement of the faucet by a qualified plumber is recommended.

NOTE: While the old concrete tub was not leaking at the time of the inspection, cracks in the tub were noted and if signs of leakage from the sink are observed at some point in the future, replacement of the tub would be recommended.

- PSDFAV-8 PLUMBING SUPPLY, DRAINS, FIXTURES AND VENTS:

The pop-up drain assembly in the many of bathroom/s are not operating as intended and in order to be able to fill and/or drain the sink basin/s, they should be repaired or replaced by a qualified plumber or handyman.

- PSDFAV-9 PLUMBING SUPPLY, DRAINS, FIXTURES AND VENTS:

Several toilets in the home are not adequately secured to the floor. This can result in deformation of the wax ring seal, leaking and other damage. In order to reduce the potential for moisture related damage and to determine if removal and reinstallation is necessary, the toilets should be evaluated by a licensed and competent plumber.

- PSDFAV-11 PLUMBING SUPPLY, DRAINS, FIXTURES AND VENTS:

The flexible and corrugated drain piping at the main level bathroom should be replaced with rigid and smooth walled drain piping for optimal drain performance and clog prevention.

- HACVAGAS-2 HEATING, AIR CONDITIONING, VENTILATION, AND GAS APPLIANCE SYSTEMS:

The deteriorated/missing insulation on the A/C refrigerant lines can result in energy losses that promote the formation of condensation. In order to reduce the potential for moisture related damage and to reduce energy losses and maximize efficiency, the insulation should be replaced by a qualified HVAC contractor.

- HACVAGAS-4 HEATING, AIR CONDITIONING, VENTILATION, AND GAS APPLIANCE SYSTEMS:

Condensation staining and air gaps were noted on the air conditioning lines set entry points into the HVAC unit. In order to prevent further condensation and possible damage to the HVAC equipment, these entry points should be sealed a licensed and competent HVAC contractor.

- HACVAGAS-11 HEATING, AIR CONDITIONING, VENTILATION, AND GAS APPLIANCE SYSTEMS:

There is a junction box for the ductless min-split heat pump units in the attic and it appears there is leakage from some of the refrigerant lines. In order to ensure proper operation of the system and damage from fluid leakage It is recommended that a qualified HVAC service technician evaluate and repair the unit as needed.

- HACVAGAS-12 HEATING, AIR CONDITIONING, VENTILATION, AND GAS APPLIANCE SYSTEMS:

The space heater on the rear porch has a pilot light that needs to be lit to make the unit operational. The pilot light could not be lit and if the unit is operational, proper operation should be demonstrated at the final walk-through prior to closing. If the unit is not operational, the unit appears older and interior corrosion may exist that could affect performance and safety and it may be more cost effective to replace rather than repair this potentially older heater.

- FWE-2 FIREPLACES, WOODSTOVES, ETC.:

Both of the fireplaces in the home had broken dampers that were partially stuck open. Fireplaces can be a significant source of energy losses either when in use or not and care should be taken in order to reduce the impacts from fireplaces. Partially sealed flues allow conditioned air to escape creating a "stack effect" that can draw additional exterior air into the home.

In order to reduce the potential for a "stack effect" to occur, when not in use, dampers (if present) should be closed and insulated dampers should be inserted in the flues between fireplace uses with another possibility being to install a top sealing damper on the top of the flue that would reduce air from entering the chimney from the exterior. The flue on the decorative living room fireplace should be sealed completely, preferably with closed cell insulating foam just above the existing damper in order to eliminate air leakage as close to the fireplace opening as possible.

For a simple explanation of the "stack effect", here is a link to a webpage from NC State that explains this phenomena: Stack Effect – Defined

In order to further understand heat loss through a fireplace, here is a link to an article that may be useful: Is Your Fireplace Burning Through your Energy Bill?

For more information regarding chimney dampers, here is a link to a local supplier that provides examples of the types of products that are available: Top Sealing Chimney Damper Caps

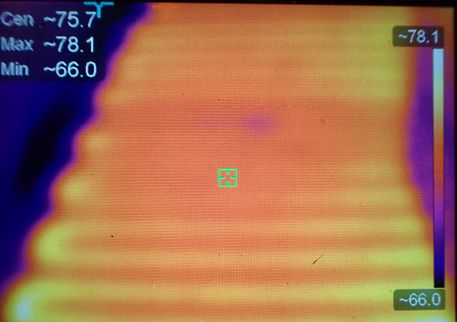

- IVAE-1 INSULATION, VENTILATION, ATTICS, ETC.:

The existing cheap plastic vent and/or dryer dampers are warped and are open to the exterior which creates the potential for cold air to enter and condense on warmer interior components and for flying pests to enter the open dryer venting. In order to reduce the potential for corrosion and moisture related damage and unwanted visitors, all dryer and exhaust vent dampers on the exterior walls should be replaced with high-quality, gasketed, vent dampers.

NOTE: In order to ensure proper performance of the dryer vents, regular examination and cleaning of dryer vents is recommended.

- IAF-3 INTERIORS AND FINISHES:

The existing handrails in the home have open ends that project from the wall, are non graspable and are non-continuous. Modern safety standards require that interior handrails be returned 90 degrees to the wall and in order to reduce the risk of snagging, falls and injuries and the handrails should be graspable and continuous and any non-conforming handrails should be modified or replaced by a qualified carpenter or handyman.

- IAF-5 INTERIORS AND FINISHES:

The interior finishes have some minor blemishes and in order for the interior to conform to accepted appearance standards, some repairs, re-finishing, drywall touch ups and repainting may be needed. The attached photo/s are representative, not all inclusive, of repairs that may be needed.

Persistent cracks in common areas for cracking like above doors and windows should be repaired with a flexible repair material. Here is a link to information regarding one such product: Applying Krack Kote

- IAF-6 INTERIORS AND FINISHES:

In order to reduce the potential for fungi growth and damage to the tile substrate, it is recommended that the gap between the tub spout and the tile wall be caulked or otherwise sealed via appropriate means and materials.

- IAF-7 INTERIORS AND FINISHES:

Portions of the caulk between the bathtub and tub/shower wall tile appear to have a mold like substance in/on it. Once mold has penetrated into the body of the caulk it typically cannot be successfully eliminated and for proper appearance the caulk should be removed and replaced by a qualified contractor.

Note - If grout is found in any corner areas beneath the caulk, these areas are prone to cracking and the presence of the grout does not allow for the formation of a proper caulk joint. In order to prolong the life of the caulk joints and reduce the potential for moisture to enter the cracks and damage the underlying sub-base, it is recommended that the grout be raked out completely prior to re-caulking.

- IAF-8 INTERIORS AND FINISHES:

The hardwood floors do not appear to have an adequate level of floor finish protection and could be easily damaged. It is recommended that the floors be protected by the application of at least two additional coats of a high-quality hardwood floor finish.

- WDS-2 WINDOWS, DOORS, SKYLIGHTS:

The weatherstripping around the exterior entry door/s is deteriorated and/or missing. In order to conserve energy, reduce cold drafts and reduce noise levels inside the living space, the installation of high quality rubber bulb weatherstripping by a qualified handyman is recommended at the top and sides of the exterior entry door(s).

- WDS-3 WINDOWS, DOORS, SKYLIGHTS:

Many of the doors in the home failed to close or latch properly and problems included: doors hitting doorframes, non-catching latches and non-locking door locks. For proper operation it is recommended that any non-functional doors be repaired or adjusted by a qualified carpenter or handyman.

- WDS-5 WINDOWS, DOORS, SKYLIGHTS:

Some of the windows in the home are older windows that may require maintenance and repair. While some older windows may have character that is worth retaining, potential improvements like adding storm windows or re-habilitating older windows with newer components can be performed. Repairs can be made on an as needed basis by a qualified window installation contractor, carpenter or handyman.

Examples of observations noted during inspection include:

- Some windows in the home are not operating and may be painted shut.

- Glazing is missing from some of the windows - this is used to secure the window pane to the wood frame of the window

- Many of the windows are single pane glass - these older windows do not comply with modern energy efficiency standards

- Windows are showing signs of leakage and moisture control problems.

- WDS-6 WINDOWS, DOORS, SKYLIGHTS:

Open gaps were noted on the bottom corners of the exterior entry door. In order to reduce energy losses and drafts, draft stopping self-adhesive pads should be installed at the exterior entry door(s).

- IA-1 INSTALLED APPLIANCES:

The kitchen range is unsecured and has the ability to tip under the right circumstances. In order to reduce the potential for scald and burn injuries related to the instability of the kitchen range, an anti-tipping device (Federally mandated and shipped with all ranges) should be installed behind the kitchen range.

- IA-2 INSTALLED APPLIANCES:

For increased insurance against leaks and water damage, it is recommended that the existing rubber water supply hoses for the washing machine be replaced with braided stainless steel hoses. The 'Watts' corporation produces hoses with a 'Flood-Stop' feature that will further reduce the risk for the free flow of water from the laundry outlet.

- IA-3 INSTALLED APPLIANCES:

The refrigerator appeared to be operational at the time of the inspection, however, this is no indication that the unit will be operational in the future. The inspector was unable to pull the refrigerator out of its recess due to inadequate perimeter clearance. Refrigerators should be readily removable so that the area in which they are located can be accessed for cleaning, servicing, repairs, etc.

- O-4 OTHER:

Exposed fiberglass was noted inside the side attics in the upper level and these areas appear to be in use as storage. Fiberglass fibers are an indoor air contaminant and are considered by the state of California to be carcinogenic. It is recommended that all reasonable attempts be made to isolate fiberglass fibers from the indoor air of the home. Therefore, it is recommended that all exposed fiberglass be concealed behind sealed surfaces such as drywall or other solid surfacing material.

- O-5 OTHER:

The home appeared to have cats living in the home. Many people are sensitive to cats and the removal of their byproducts is essential to being able to occupy a space formerly occupied by these residents. While professional cleaning and removal services are available, there are numerous applications that can be self applied.

Here is a link to an article regarding suggestions for removing cat byproducts: The 9 Best Cat Pee, Odor, and Stain-Removal Products of 2022, Tested and Reviewed

Recommended Maintenance Items

- PSDFAV-4 PLUMBING SUPPLY, DRAINS, FIXTURES AND VENTS:

FYI: Traps on floor drains without a continuous source of moisture can dry out and should be regularly monitored and re-filled with water as needed to prevent the migration of sewer gas into the home. The application of several drops of mineral oil can retard the evaporation of the water 'plug' in the floor drain trap.

Improves

- PSDFAV-3 PLUMBING SUPPLY, DRAINS, FIXTURES AND VENTS:

The existing outside hose bibb(s) should be replaced with new hose bibb(s) having both frost-proof and anti-siphon features. The anti-siphon feature reduces the risk for cross-contamination of the home's potable water supply; the frostproof feature virtually eliminates the risk for pipe freezing, bursting and flooding. Repair by a qualified plumbing contractor is recommended.

NOTE: There is a hose bibb in the garage and it was not operational at the time of the inspection and it is unknown if it can be turned on or how that is done. If the hose bibb is functional, proper operation should be demonstrated at the final walk-through prior to closing and also proper winterization methods should be discussed as the pipe cannot be left supplied with water through the winter.

- PSDFAV-5 PLUMBING SUPPLY, DRAINS, FIXTURES AND VENTS:

An expansion tank is recommended for the water heater; these are required if the house has a closed plumbing system. Expansion tanks help reduce pressure on the plumbing system by creating a buffer or a place for water to expand into as water swells during thermal expansion. Installation of expansion or pressure tanks is modern installation practice and will be required if a pressure reducing valve has been installed on a public water supply. Consult with a qualified plumber to install.

- PSDFAV-10 PLUMBING SUPPLY, DRAINS, FIXTURES AND VENTS:

The toilets in the home are connected by solid supply lines that are prone to leakage from movement. In order to reduce the potential for moisture related damage, it is highly recommended that the supply lines for all of the toilets be replaced with braided stainless toilet supplies.

- PSDFAV-12 PLUMBING SUPPLY, DRAINS, FIXTURES AND VENTS:

Older style gate valve shut-offs were noted on distribution piping to many of the plumbing fixtures in the residence. These valves can be prone to leakage when operated and they were not opened or closed at the time of the inspection. In order to be able to shut off water to service plumbing fixtures in the future, the valves should be replaced with 1/4 turn ball valves by a qualified plumber.

- WDS-1 WINDOWS, DOORS, SKYLIGHTS:

The aluminum framed vent window in the glass block window panel/s is prone to drafts and condensation. For energy efficiency and increased indoor comfort, it is recommended that it be replaced with a vinyl framed, insulated glass panel.

Monitors

- IAF-4 INTERIORS AND FINISHES:

Incipient leakage stains were noted around the lower portions of the upper level shower enclosure suggesting that moisture is leaking from the shower during usage. In order to reduce the potential for continued damage to adjacent finishes it is recommended that the shower enclosure be evaluated in order to determine if seals can be replaced or if the enclosure itself needs replacement.

Due Diligences

- GAO-1 GARAGES AND OUTBUILDINGS:

The code to the keyless remote overhead garage door opener should be provided to the buyer so that the unit can be tested prior to closing.

- ESGCDAF-2 ELECTRICAL SYSTEM, GROUNDING, CONNECTED DEVICES AND FIXTURES:

The evaluation of the low-voltage equipment in the home: alarm, communication, audiovisual, etc., is beyond the scope of the home inspection and should be performed by a qualified low-voltage electrical contractor. In order to reduce the potential for confusion and to reduce clutter around the home, any wiring, panels, cabinets, etc. for any equipment that is no longer in use should be removed.

- PSDFAV-6 PLUMBING SUPPLY, DRAINS, FIXTURES AND VENTS:

There is a pipe in the middle of the basement floor that is located near an unpainted shape in the floor. It is thought that the pipe is the stub for a drain that may have been connected to a wet bar in the basement. Further examination by a qualified plumber is needed in order to determine if a connection to the sewer exists or if this pipe served some other purpose like a fill pipe for an underground oil heating tank.

- PSDFAV-13 PLUMBING SUPPLY, DRAINS, FIXTURES AND VENTS:

A video camera sewer scope is recommended. An evaluation of the sewer line below the ground was performed as a separate operation during this home inspection. It was revealed that there is a blockage approximately 60 feet from the rear basin. It is unknown if the blockage can be removed by rodding and at this point it is recommended that a qualified plumber attempt to rod the pipe and re-televise the sewer to the main in order to determine the condition of the pipe.

- HACVAGAS-3 HEATING, AIR CONDITIONING, VENTILATION, AND GAS APPLIANCE SYSTEMS:

The ambient temperature did not allow for the safe operation of the air-conditioning system/s at the time of the inspection. In order to protect the purchaser in the event that the air-conditioning system/s is/are defective or inoperative, it is recommended that an escrow holdback be provided at closing. Further evaluation of the air-conditioning system/s by a licensed and competent HVAC contractor is recommended when the weather permits.

- FWE-1 FIREPLACES, WOODSTOVES, ETC.:

The National Fire Protection Agency recommends that wood-burning fireplaces be thoroughly evaluated when a home changes ownership. Evaluation of the fireplace(s) in the home by a qualified specialty contractor, preferably one who is a member of the Chimney Safety Institute of America, is recommended. Once the fireplace is approved for use, according to fireplace professionals, it should be cleaned after approximately every 30 fires.

NOTE: Both of the fireplaces in the home appeared to have significant concerns in that the dampers were not operational and some brick rubble appeared to be present on the dampers suggesting deterioration of the chimneys. Neither of the fireplaces should be used until they have been evaluated and determined to be safe for use by a qualified professional.

Future Projects

- HACVAGAS-1 HEATING, AIR CONDITIONING, VENTILATION, AND GAS APPLIANCE SYSTEMS:

The A/C condenser is close to the end of the expected service life and although the system was not tested at the time of the inspection, cooling levels may be inadequate in the near future. The R-22 refrigerant that is used in the unit is being phased out and no new or imported R-22 is allowed in the U.S. and technicians will only be able to use recycled, reclaimed, or previously produced R-22 to service equipment. Therefore it will become more expensive to service the unit in the future. The cost to retrofit the HVAC system to use the new R-410 A replacement refrigerant is expensive and involves replacing the evaporator coils in the furnace.

The furnace is also close to the end of the expected service life and in order to save on future costs and expensive retrofitting, if and when the furnace and/or the air conditioning unit in the structure is replaced, it is recommended that R-410 A equipment be installed and that budgeting for replacement of both the AC condenser unit and the furnace be be strongly considered.

- HACVAGAS-8 HEATING, AIR CONDITIONING, VENTILATION, AND GAS APPLIANCE SYSTEMS:

HVAC performance is critical to delivering efficiency, comfort and durability. When a new HVAC system is installed in this home it should be commissioned by an EPA certified Energy Star Contractor.

Here is a link regarding the importance of having this vital service performed: HVAC Design and Commissioning for ENERGY STAR

Efficiencies

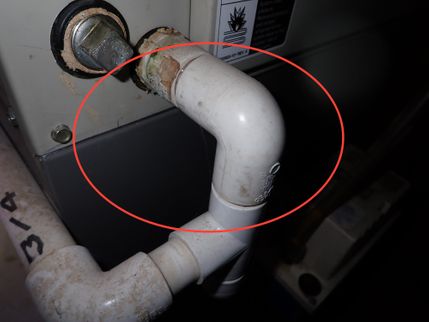

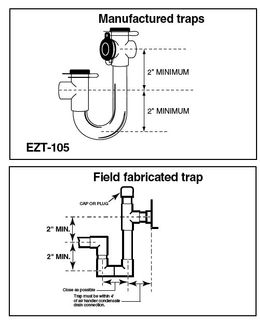

- HACVAGAS-5 HEATING, AIR CONDITIONING, VENTILATION, AND GAS APPLIANCE SYSTEMS:

Splashing, leaking and energy losses can occur in the evaporator drain pan from air backflow through the drain pipe for the A/C condensation. The installation of a trap on the condensate drain by a qualified HVAC contractor is recommended downstream of it's penetration from the furnace casing and upstream of the humidifier drain (if one is installed).

NOTE: The trap should be able to be cleaned and in order to reduce the potential for biological growth it should be cleaned at least annually.

- HACVAGAS-7 HEATING, AIR CONDITIONING, VENTILATION, AND GAS APPLIANCE SYSTEMS:

The use of one inch pleated cartridge filters can reduce the required airflow across the heat exchanger or the evaporator coil to a point where the capacity and efficiency of the HVAC equipment is significantly compromised. Therefore, it is recommended that, especially during the heating season when airflow is even more critical, a more open weave and less restrictive air filter be used. These less restrictive filters are sometimes derisively referred to as "rock catchers" since smaller particles may not be caught by these open weave filters. In order to enhance dust capture on this type of HVAC air filter, the homeowner can use a light spray coating of a non-stick cooking spray on the upstream side of the air filter.

However, the use of one inch thick HVAC air filters constitutes a low performance installation in what should be a high-performance home. Open weave filters (known in the vernacular as "rock catchers" due to the ability of particles to pass through the filter) will allow for proper flow of conditioned air and optimal energy transfer thereby allowing the heating and cooling equipment to operate as close as possible to its rated efficiency and capacity. However, these filters perform poorly at dust capture and in order to maintain even that low level of indoor air quality performance, they need to be changed frequently.

The use of thin pleated media filters can improve air quality for those with allergies, however, allergen filters will typically create a drastically reduced flow of air across the heating and cooling portions of the HVAC equipment, thereby significantly reducing the capacity and efficiency of the furnace and the air-conditioning system. Optimal air filtration is provided by 4 inch or 5 inch deep pleated filters since they allow for excellent dust capture and free conditioned air flow simultaneously. In order to determine the cost and feasibility for the installation of these high-performance HVAC air filters, it is recommended that the furnace/s in the home be further evaluated and potentially improved by a qualified HVAC contractor.

The Full Report

GENERAL INFORMATION

TYPE OF STRUCTURE: Single Family Detached Residence

NUMBER OF BEDROOMS: Four

APPROXIMATE AGE OF STRUCTURE: Over 50 Years, Online information suggests home was built in 1953

STRUCTURE FACES: South

CLIENT PRESENT: Yes

RADON TEST: Yes, Results to Follow

WATER QUALITY TEST: No

WEATHER CONDITIONS: Light Rain

AMBIENT TEMPERATURE: Below 60...A/C not operated due to risk of equipment damage

NUMBER OF STORIES: Two and a Half Story, With Basement

EXTERIOR WALLS< GROUNDS, CHIMNEYS. ETC

GAS SHUT-OFF LOCATION: Basement - East

WALKWAYS PATIOS DRIVEWAYS: Concrete Walks, Rear Masonry Paver Patio

VEGETATION/GRADING/DRAINAGE: Overgrown and Neglected Shrubery and/or Trees

EXTERIOR STEPS/STAIRWAYS/RAILINGS: Concrete/Masonry Front Porch, Wood Porch/Deck at Rear

EXTERIOR WALL CONSTRUCTION: Masonry

PRIMARY EXTERIOR WALL CLADDING MATERIAL: Brick

The rear stair/deck assembly does not conform to any standards and the following deficiencies were observed:

Stair/deck deficiencies

- Handrails non-graspable

- Handrails do not adequately resist lateral force

- Stair stringers single rail

- Foundation/s improper

- Bracing missing

- Step heights uneven

In order to reduce the potential for injury it is recommended that a qualified deck installation contractor evaluate and repair or replace the stairs/deck(s) as needed.

While local codes always govern, as a reference for proper construction practices that meet or exceed local building codes, here is a link to deck construction guidelines from the American Wood Council: Prescriptive Residential Wood Deck Construction Guide

The existing bushes, trees and landscaping installations are overgrown and/or dead and in need of trimming and/or removal. For proper appearance of the home the vegetation in the yard should be evaluated by a qualified arborist and/or landscaping contractor and be addressed as needed.

The masonry landscaping wall on the front of the home has stones that are loose and unstable. In order to reduce the potential for injury, It is recommended that a qualified landscaping contractor and/or masonry evaluate and repair the walls as needed.

NOTE: The walls do not have a foundation and are prone to movement and future deterioration from freeze/thaw movement in the ground. Rather than repair the walls via mortared joints, replacing the walls with segmented block walls that are intended for this purpose is recommended.

Cracking was noted in the masonry joints between dissimilar materials, stone features and stone coping on the structure. All dissimilar elements on the exterior walls of the structure such as: brick-to-stone; brick-to-concrete block; concrete block-to-glass block, all interior corners and all construction joints should be joined one to the other and sealed against moisture through the use of backer rod and urethane caulk or its equivalent. These elements have either differing coefficients of expansion and contraction in relation to temperature and moisture and/or are subject to movement which can lead to cracking of the cladding material and/or of the mortar joints. In order to reduce the potential for moisture related damage, the existing cement mortar joints should be ground out and replaced with the appropriate backer rod and ASTM approved caulking by a qualified masonry repair contractor.

This procedure is in keeping with the standards set forth by the Brick Industry Association. Further information is available at the following link: Accommodating Expansion of Brickwork

The existing caulking around the perimeter of the structure is cracked, old and missing. Exterior sealant performance is directly related to the joint preparation and application. For increased service life, performance and aesthetics, the exterior of the structure should be carefully examined and old deteriorated and/or improper caulking should be removed and the exterior of the structure caulked via appropriate means and materials. Proper joint preparation and the use of compliant exterior rated sealants of good quality is recommended .

All caulk joints should then be inspected annually and be repaired as needed. ALL exterior wall penetrations such as: piping, conduit, vent caps, exterior light fixtures and receptacles should be sealed against moisture intrusion through the use of the appropriate caulking methods and materials. An intentional opening/gap at the base of electrical fixtures should remain open to allow any moisture penetration an avenue of escape.

Several sources regarding caulking preparation can be found online, here is a link to one source: Caulking Basics

In order to reduce the potential for moisture related damage, all exterior wall penetrations such as; piping, conduit, vent caps, etc. should be sealed against moisture intrusion, drafts, and energy losses through the use of the appropriate caulking methods and materials.

Some of the painted wood surfaces have flaking paint or are exposed. In order to prolong the life of materials on the exterior of the home, all exposed wood surfaces should be professionally primed and painted by a qualified painting contractor or handyman.

Cracked glazing blocks were noted on the perimeter of some of the mortared glass block window installations. Mortar can transfer the stresses inherent in large masonry walls directly to the glass block which can lead to cracking of the glass block. Caulk, not mortar, should be used to seal the areas between the glass block windows and the brick walls. The broken glazing blocks should be removed and replaced and the existing mortar joints should be raked out and replaced with backer rod and urethane caulk or equivalent by a qualified masonry contractor.

Asphalt shingles have been used for siding on a portion of the home. These materials are generally not designed to have the full weight of the shingle hanging on the fasteners and if shingles are installed in this way additional fasteners must be added. Also. these shingles are prone to wind damage and should be monitored regularly for deterioration. In order to reduce the potential for moisture related damage, the material should not be replaced in kind and when it deteriorates to the point where replacement is required it is recommended that alternate proper siding materials be installed by a qualified siding installation contractor.

The exterior window lintels have been sealed and can no longer drain moisture which increases the potential for corrosion of the lintels. Over time the corroding steel will expand which can damage the adjacent masonry walls and allow moisture to penetrate to the interior of the living space. In order to reduce the potential for moisture related damage, the lintel drainage space should be repaired by a qualified masonry restoration contractor.

Some of the aluminum encasements that are sealing trim on the structure are loose and unsealed which exposes the older wood to become exposed to moisture. In order to reduce the potential for moisture related damage It is recommended that a qualified carpenter or handyman secure and seal all of the encasements.

The presence of flat horizontal projections from the exterior masonry façade creates an increased risk for moisture accumulation, moisture saturation of the masonry and moisture penetration through the exterior wall to the interior. The most basic concept in exterior wall moisture management is to avoid flat surfaces and to ensure all exterior elements are properly sloped to promote the drainage of moisture. Therefore, it is recommended that a qualified masonry restoration contractor install an angled mortar wash, corrosion resistant metal flashing, or other methods and materials to reduce the risk for moisture related damage at these locations.

The exterior masonry walls are in overall good condition, however, general deterioration was noted with regard to the common brick exterior walls around the building. In order to reduce the potential for damaging and mold causing moisture to enter the home, it is recommended that plans be made for grinding out and repointing of the mortar joints in conjunction with spot replacement of individual damaged brick masonry units. Application of a penetrating masonry sealant is also recommended in order to reduce direct moisture absorption by the aged and deteriorated common bricks. The exterior walls should be evaluated and repaired by a qualified masonry restoration contractor.

.

The vent for the heater on the rear porch appears to be damaging the finish on the siding. The vent for the heater should be evaluated by a qualified HVAC service technician in order to see if it complies with the manufacturers installation instructions with regards to clearance to combustible materials. If the vent is installed properly, paints that can withstand high temperatures should be used on the siding adjacent to the vent.

The existing wooden deck/porch is weathered and deteriorating. In order to extend the service life of the deck materials, all exterior wooden deck surfaces should be professionally cleaned and sealed against weather.

Here is a link to some potentially useful information regarding deck sealing: How to Seal Your Deck & Best Deck Sealers

The deck ledger board is not properly secured to the exterior structural wall of the home. This creates a risk for structural motion of the deck, deck damage, and deck collapse. It is recommended that the deck ledger board be bolted to the exterior structural wall by a qualified carpenter or deck construction specialist.

There did not appear to be any lateral load resistance devices installed on the deck. While local municipal codes may not require these devices or may allow bracing, they are required in the International Building Code and can be critical in preventing the accidental detachment of the deck from the structure. These devices can be retro-fitted to the existing deck and in order to reduce the potential for deck collapse and resulting injury it is highly recommended that these devices be installed by a qualified carpenter or handyman.

The points of attachment between the rear porch and the exterior walls are concealed and it is unknown if they are properly sealed against moisture intrusion. In order to reduce the risk for ongoing moisture intrusion, mold growth, wood rot, etc. these critical areas should be protected by corrosion resistant metal flashing.

In order to determine the condition of the attachments it is recommended that decking, siding or interior wall coverings be removed so the band joist the structure is attached to can be examined and evaluation and potential repair by a qualified carpenter or handyman is recommended. If flashing is not present it should be retrofitted on the exterior walls wherever needed by a qualified contractor.

GARAGES AND OUTBUILDINGS

The code to the keyless remote overhead garage door opener should be provided to the buyer so that the unit can be tested prior to closing.

The trolley for the garage door opener appears to be bolted to a piece of wood that is only nailed in place which creates the potential for the opener to become loose. In order to reduce the potential for detachment of the opener trolley from the garage wall, the wood the door opener is bolted to should be securely fastened to the studs by a qualified garage door installation contractor.

ROOF COVERINGS, ROOF FLASHING, ROOF DRAINAGE

Roof Covering: Composition (Asphalt or Fiberglass) Shingles

Roof Viewed: Via a Ladder Leaning Against the Eaves

In order to reduce the risk for moisture penetration and damage, it is recommended that a qualified roofing contractor install the missing overhanging drip edge flashing along all roof rake edges.

The sealant around the flashing on the metal roofs is cracked and deteriorated which can allow for the entry of moisture and signs of moisture related damage were observed in the ceiling of the living room. In order to reduce the potential for moisture related damage, It is recommended that a qualified roofing contractor or handyman repair the flashing joints as needed via appropriate means and materials.

The flashing along the masonry chimney and/or roof to masonry wall transition has flush flashing that is sealed with caulk which is a low performance and high maintenance installation that creates the potential for moisture to enter the home. In order to reduce the potential for moisture related damage, it is recommended that step flashing be installed along the roof to masonry joint by a qualified roofing contractor.

The gutters on the home are clogged and overflowing with debris which can do more damage than discolor a home. The water that overflows out of the back side of the gutter can penetrate into the attic space causing damage to the internal structure and create holes large enough for invasive pests. Maintenance to keep gutters clear to prevent damage is recommended, especially in the fall when trees are losing their leaves.

The existing rooftop above the three season room appears to be able to be used as a deck. The roof does not have a walking surface and in order to reduce the potential for damage to the roof surface, a roof deck or some other walking or wearing surface should be added to the roof. When adding a roof deck, permitting through the City of Chicago is required and according to a recent memo from the City of Chicago, compliance with load and egress requirements is critical.

NOTE: The railing openings and height make the railing on the deck non-compliant and modifications to the railing if the roof is to be used.

Here is a link to a webpage that appears to contain current code information with regard to rooftop decks in Chicago: Rooftop Deck Code

Also, here is a link to a memorandum regarding roof deck replacements that may provide information relative to these installations: Replacement of roof decks installed before 10/1/2003

The modified bitumen roof covering on the rear addition roof is not properly secured to the back of the roof gutter. This defect presents an increased risk for damage from ice damming and from water backing up at the gutter. It is recommended that the roof/gutter interface be repaired by a qualified roofing contractor.

The roof on the rear three season room is older and was cracked and worn and plans should be made for roof replacement in the not too distant future. In order to extend the service life of the roofing and in order to reduce the cooling load on the rear porch, the application of a reflective coating is recommended over the surface of the modified bitumen roof covering. FYI: Aluminized coatings are, in general, far inferior to white roof coatings which are both more reflective and more emissive.

STRUCTURE AND FOUNDATION

FLOOR STRUCTURE: 2x10, Dimensional Lumber

CRAWLSPACE ACCESS: Exterior Hatch

MAIN FLOOR BEAM AND POSTS: Structural Steel Posts and Beams

FOUNDATION: Concrete Foundation Walls, Crawlspace - Vented - Gravel or Soil Floor

Multiple foundation wall cracks were noted in the basement one of the cracks was actively leaking at the time of the inspection. The cracks may have been repaired by a professional foundation crack repair contractor and they will often provide lifetime warrantees against continued seepage and these warrantees are often transferable from owner to owner. All documentation regarding any crack repair performed during the current owners tenure should be provided to the buyer and in order to reduce the risk of seepage and to help prevent the cracks from becoming pathways for wood boring insects, these cracks should be evaluated and repaired by a licensed and competent basement waterproofing contractor.

Here is a link to an article that describes one potential type of crack sealing repair: Fixing Cracks in Concrete

The rear three season room essentially has a crawlspace beneath it. Most vented crawlspaces are damp, moldy and inhabited with pests. They are typically connected to the air inside the home through many small un-intentional air leaks in the floors, partitions and ducts. Modern building science standards dictate that crawlspaces should not be vented unsealed to the exterior as this crawlspace is and it should be a conditioned space.

Therefore, to ensure durability, indoor air quality and save energy, a crawlspace must be kept dry, conditioned to control temperature and humidity and sealed tight to be pest free. It is recommended that the following improvements be made to the crawlspace:

- The door in the crawlspace be replaced with one that is insulated and should be completely sealed and the vent should also be sealed.

- The soil or gravel floor that is present in the crawlspace should be vapor-sealed with a minimum of a 6 mil plastic liner that has sealed joints, but preferably a high quality mesh reinforced liner.

- Floor insulation (if present) should be removed and the perimeter walls and rim joist areas should be insulated and air-sealed and the crawlspace air should be conditioned with small amounts of indoor air.

One potential use for accessible crawlspaces is storage. Here is a link to an article that discusses crawlspace improvements keeping that objective in mind: Convert Your Crawl Space into a Storage Area

ELECTRICAL SYSTEM, GROUNDING, CONNECTED DEVICES AND FIXTURES

ELECTRICAL SERVICE: 240 volts, Overhead service, Copper Service Conductors

LOCATION OF MAIN SERVICE DISCONNECT: Electric service panel

SERVICE PANEL AMPACITY: 200 AMP

OVERCURRENT PROTECTION DEVICES: Circuit Breakers

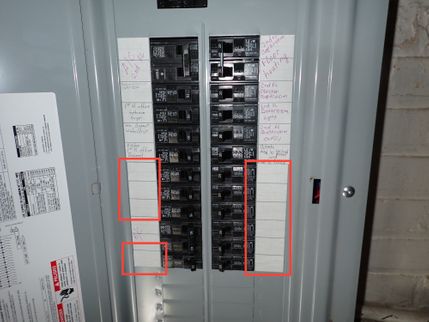

SERVICE PANEL BRAND: SIEMENS

BRANCH CIRCUIT CONDUCTORS: Copper

NUMBER OF CIRCUITS USED - NUMBER OF CIRCUITS AVAILABLE FOR USE: 24 Circuits used / 16 Circuits available

WIRING METHODS: Electrical Metallic Tubing EMT (Conduit), Armored Cable (BX)

ELECTRICAL GROUNDING CONDUCTOR/CLAMP LOCATION: Driven Ground Rod - Acorn Needed, North Exterior Wall

The clamp securing the grounding wire to the driven ground rod is intended for a pipe connection and does not provide adequate connectivity to the ground rod. In order to ensure proper grounding of the electrical system, it is recommended that a qualified electrician evaluate and repair the grounding system by installing an acorn style grounding clamp or by other approved means.

The evaluation of the low-voltage equipment in the home: alarm, communication, audiovisual, etc., is beyond the scope of the home inspection and should be performed by a qualified low-voltage electrical contractor. In order to reduce the potential for confusion and to reduce clutter around the home, any wiring, panels, cabinets, etc. for any equipment that is no longer in use should be removed.

The grounding electrode conductor is not properly secured to the water piping system and grounding clamp. The stranded copper grounding conductor has been squeezed between the clamp and the piping which is not allowed and is unsafe since it makes the clamp prone to loosening. This can reduce the safety and effectiveness of the bonding and grounding system and the existing clamp should be replaced with one that can properly secure the grounding electrode conductor into a screw terminal. Further evaluation and repair by a licensed and competent electrical contractor is recommended.

There was a switch in the basement that was uncovered with represents a significant electrical safety defect. All of the electrical switches and receptacles in the structure should be evaluated and repaired as necessary by a licensed and competent electrical contractor.

Cold drafts can create condensation on the warm electrical components inside the service panel which can lead to corrosion and other deleterious conditions. The opening at the end of the service panel's feeder conduit should be sealed to stop the strong air drafts and energy losses at this location.

The existence of cloth insulated branch wiring was noted in the residence. Older cloth insulated wiring is often degraded and may have to be replaced during remodeling of the electrical system. In order to determine if it needs replacement, the cloth wiring in the building should be further evaluated and potentially replaced by a qualified electrician.

At least one over fused circuit was noted in the electrical service panel. Over fusing can cause overheating of the wires which could result in electric shock or fire. The service panel should be evaluated, repaired and certified as safe by licensed and competent electrical contractor.

At least one screw was missing from the cover for the electrical service panel. In order to reduce the potential for inadvertent contact with energized electric equipment, it is recommended that the missing electrical panel cover screw/s be replaced.

At least one programmable light switch was noted in the home. These types of switches are typically used to control exterior lighting and any information regarding their operation should be provided to the buyer prior to closing.

The bathroom light fixture in the primary bathroom is powered through the nearby GFCI receptacle. If the receptacle were to trip during a late night visit to the bath, or the receptacle were to become defective, the occupant could be left in the dark and would be subjected to an increased risk for falls and injuries. Repair by a qualified electrician is recommended.

In order to reduce the fire hazard associated with their hot surfaces and also to reduce the risk of bulb breakage, the bare bulb light fixtures in the closets should be replaced with low-profile fluorescent fixtures or their equivalent by a qualified electrician.

There was a missing and/or incomplete circuit directory for the electrical service panel/s. In order to allow for safe and efficient electrical circuit interruption when required for maintenance, repairs, or in emergencies, a complete and accurate electrical circuit directory should be provided to the buyer before closing.

PLUMBING SUPPLY, DRAINS, FIXTURES AND VENTS

POTABLE WATER SOURCE: Public

WATER SERVICE PIPING MATERIAL: Lead Pipe (flush before drinking)

MAIN WATER SHUT-OFF LOCATION: Exterior - In front parkway

WATER DISTRIBUTION PIPING MATERIAL: Copper, Galvanized Pipe (30 to 50 year service life) - restricted flow, Not Fully Visible

WATER PRESSURE AND FLOW: Marginal

PLUMBING WASTE SYSTEM: Public Sewer