The Scope and Purpose of a Home Inspection

Inspection Overview

This home inspection is being conducted in accordance with the State of Illinois Home Inspector Licensing Act and following the American Society of Home Inspectors guidelines. No pest control, lead paint, asbestos, mold, or other types of testing are being performed. This is a visual inspection of readily accessible systems and components of the home. Some items or areas may not be inspected if they are blocked by furniture or stored items. The home inspector makes no guarantees regarding any of the home's systems or components. The inspection is performed in good faith and is a 'snapshot in time'; it does NOT constitute a prediction that the home will perform adequately in the future. Only non-invasive processes are used in the course of the inspection. Seasonal changes such as wind-driven rain, ice, and humidity may bring some defects to light that were not noted during your home inspection. Basements and attics that were dry at the time of the inspection can be damp or leak in later weeks or months. If you discover any adverse conditions in the home after your Domicile Consulting inspection, please call us immediately for a re-inspection and free consultation. No guarantees or warranties are provided in connection with the home inspection. Any disputes that cannot be resolved by the inspector and the client will be submitted jointly to the American Arbitration Association for a decision.

Purchasing property involves risk

The purpose of a home inspection is to help reduce the risk associated with the purchase of a structure by providing a professional opinion about the overall condition of the structure. A home inspection is a limited visual inspection and it cannot eliminate this risk. Some homes present more risks than others. We cannot control this, but we try to help educate you about what we don’t know during the inspection process. This is more difficult to convey in a report and one of many reasons why we recommend that you attend the inspection.

A home inspection is not an insurance policy

This report does not substitute for or serve as a warranty or guarantee of any kind. Home warranties can be purchased separately from insuring firms that provide this service.

A home inspection is visual and not destructive

The descriptions and observations in this report are based on a visual inspection of the structure. We inspect the aspects of the structure that can be viewed without dismantling, damaging or disfiguring the structure and without moving furniture and interior furnishings. Areas that are concealed, hidden or inaccessible to view are not covered by this inspection. Some systems cannot be tested during this inspection as testing risks damaging the building. For example, overflow drains on bathtubs are generally not tested because if they were found to be leaking they could damage the finishes below. Our procedures involve non-invasive investigation and non-destructive testing which will limit the scope of the inspection.

This is not an inspection for code compliance

This inspection and report are not intended for city / local code compliance. During the construction process structures are inspected for code compliance by municipal inspectors. Framing is open at this time and conditions can be fully viewed. Framing is not open during inspections of finished homes, and this limits the inspection. All houses fall out of code compliance shortly after they are built, as the codes continually change. National codes are augmented at least every three years for all of the varying disciplines. Municipalities can choose to adopt and phase in sections of the codes on their own timetables. There are generally no requirements to bring older homes into compliance unless substantial renovation is being done.

This is just our opinion

Construction techniques and standards vary. There is no one way to build a house or install a system in a house. The observations in this report are the opinions of the home inspector. Other inspectors and contractors are likely to have some differing opinions. You are welcome to seek opinions from other professionals.

The scope of this inspection

This inspection will include the following systems: exterior, roof, structure, drainage, foundation, attic, interior, plumbing, electrical and heating. The evaluation will be based on limited observations that are primarily visual and non-invasive. This inspection and report are not intended to be technically exhaustive.

Your expectations

The overall goal of a home inspection is to help ensure that your expectations are appropriate with the house you are proposing to buy. To this end we assist with discovery by showing and documenting observations during the home inspection. This should not be mistaken for a technically exhaustive inspection designed to uncover every defect with a building. Such inspections are available but they are generally cost-prohibitive to most homebuyers.

Your participation is requested

Your presence is requested during this inspection. A written report will not substitute for all the possible information that can be conveyed verbally by a shared visual observation of the conditions of the property.

How to Read This Report

Getting the Information to You

This report is designed to deliver important and technical information in a way that is easy for anyone to access and understand. If you are in a hurry, you can take a quick look at our "Summary Page” and quickly get critical information for important decision making. However, we strongly recommend that you take the time to read the full Report, which includes digital photographs, captions, diagrams, descriptions, videos and hot links to additional information.

The best way to get the layers of information that are presented in this report is to read your report online (the HTML version), which will allow you to expand your learning about your house. You will notice some words or series of words highlighted in blue and underlined – clicking on these will provide you with a link to additional information. The HTML version of this report also contains streaming videos. Short video clips often contain important information and critical context and sounds that can be difficult to capture in words and still pictures.

For the most reliable viewing experience, I recommend viewing the report on as large a screen as practical, as much detail can be lost on small devices like smart phones. For similar reasons, reports should only be printed in color to retain as much detail as possible and minimize misinterpretation of photographs.

This report can also be printed on paper or to a PDF document.

Chapters and Sections

This report is divided into chapters that parcel the home into logical inspection components. Each chapter is broken into sections that relate to a specific system or component of the home. You can navigate between chapters with the click of a button on the left side margin.

Most sections will contain some descriptive information done in black font. Observation narrative, done in colored boxes, will be included if a system or component is found to be significantly deficient in some way or if we wish to provide helpful additional information about the system or the scope of our inspection. If a system or component of the home was deemed to be in satisfactory or serviceable condition, there may be no narrative observation comments in that section and it may simply say “tested,” or “inspected.”

Observation Labels

All narrative observations are colored, numbered and labeled to help you find, refer to, and understand the severity of the observation. Observation colors and labels used in this report are:

- Major Concern:Repair items that may cost significant money to correct now or in the near future, or items that require immediate attention to prevent additional damage or eliminate safety hazards.

- Repair:Repair and maintenance items noted during inspection. Please note that some repair items can be expensive to correct such as re-finishing hardwood floors, but are considered simply repair items due to their cosmetic nature.

- Recommended Maintenance:These are repair items that should be considered "routine home ownership items," such as servicing the furnace, cleaning the gutters or changing the air filters in the furnace.

- Improve:Observations that are not necessarily defects, but which could be improved for safety, efficiency, or reliability reasons.

- Monitor:Items that should be watched to see if correction may be needed in the future.

- Due Diligence:Observation such as a buried oil tank that may require further investigation to determine the severity and / or urgency of repair.

- Future Project:A repair that may be deferred for some time but should be on the radar for repair or replacement in the near future.

- Note:Refers to aside information and /or any comments elaborating on descriptions of systems in the home or limitations to the home inspection.

Pest Inspection

All items with the bug logo () are part of a structural pest inspection. If your inspector included a structural pest inspection as a part of the scope of your home inspection, you can distinguish pest inspection items by this logo. You can also go to the pest inspection summary page to see a summary of the items that are part of a pest inspection.

Summary Page

The Summary Page is designed as a bulleted overview of all the observations noted during inspection. This helpful overview is not a substitution for reading the entire inspection report. The entire report must be read to get a complete understanding of this inspection report as the Summary Page does not include photographs or photo captions.

Moisture Meter Testing

Where moisture meter testing is indicated in this report a Protimiter Survey Master Dual Function was used.

Summary

Major Concerns

- EWGCE-1 EXTERIOR WALLS< GROUNDS, CHIMNEYS. ETC:

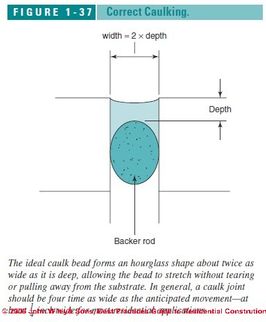

The upper portions of the masonry walls just below the clay tile caps are extremely deteriorated and portions were bulging suggesting that masonry is being displaced. The butt joints between the individual sections of clay tile coping have been sealed with cement mortar. The mortar is cracking and the joints are open which creates a risk for moisture saturation/damage to the masonry walls below. The coping tiles serve to protect the underlying brick masonry walls from wetting/drying and freezing/thawing damage and should be neatly joined and properly sealed in order to perform this function. The open joint have likely been allowing moisture to enter and the roofing wrapped over the parapet walls may be trapping moisture in the walls. It is highly recommended that the parapet walls be evaluated by a qualified masonry contractor and be repaired or rebuilt as needed. Also, when the coping tiles are repaired or replaced as needed, it is recommended that the individual clay tiles be reinstalled using backer rod and polyurethane caulk to seal the joints.

- ESGCDAF-1 ELECTRICAL SYSTEM, GROUNDING, CONNECTED DEVICES AND FIXTURES:

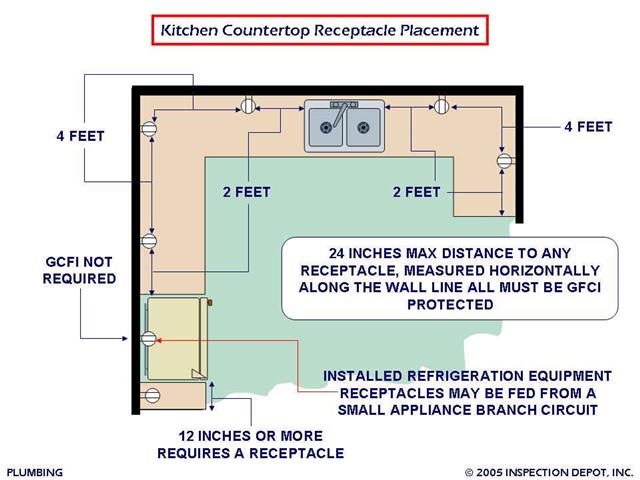

The kitchen countertop work areas in each unit are served by only one branch circuit. In order to provide adequate power to the high draw appliances often used at these locations, safety and convenience standards have long required two - 20 amp small appliance circuits for the kitchen countertop work areas. In order to determine the cost and feasibility for retrofitting a second small appliance circuit for the kitchen countertop work areas, further evaluation by a qualified electrician is recommended.

Also, an inadequate number of electric receptacles was noted for the structure. This is common in older buildings. This can present safety issues as tenants may have many more things to plug in than when the home was originally built. This can lead to overloading circuits which can lead to heat build-up and even fires. A logical improvement would be adding additional circuits and receptacles, especially in high-use areas such as media areas, kitchens and offices. Today's standards require no more than 24 inches from a receptacle in the kitchen and never more than 6 feet throughout the structure.

- PSDFAV-1 PLUMBING SUPPLY, DRAINS, FIXTURES AND VENTS:

The water pressure and flow at some of the plumbing fixtures is marginal. For optimal flow and pressure during the use of multiple fixtures, it is recommended that the remaining galvanized water supply piping be removed and replaced with copper piping.

- IAF-1 INTERIORS AND FINISHES:

The existing handrails in the structure are non-graspable, are non-continuous and have open ends that project from the wall. In order to reduce the risk of snagging, falls and injuries, modern safety standards require that interior handrails be returned 90 degrees to the wall and they be graspable and continuous. The handrails in the home should be modified, replaced or added as needed by a qualified carpenter or handyman.

- IAF-2 INTERIORS AND FINISHES:

The rear exterior doors to the stairs for the basement and upper level open into the stairways without the benefit of landings. This feature is required by residential building code and it's absence makes it extremely difficult and dangerous for someone trying to open the door while on the stairway. In order to reduce the potential for injury, it is recommended that a qualified carpenter or handyman reconfigure the doorways and/or stairs so they open into a landing area.

- IAF-3 INTERIORS AND FINISHES:

The rear porch porch stairs do not meet any standards and have one or more of the following characteristics: short and/or narrow tread widths, uneven step height and non-graspable handrails all of which create possible trip hazards. In order to reduce the potential for injury, it is recommended that the stairs be evaluated and repaired or reconstructed by a qualified carpenter.

Here is a link to a webpage that has a wealth of information regarding stair configurations: Stair Dimensions & Clearances for Stair Construction & Inspection

In order to understand the criteria for litigation regarding stair injuries, here is a link to the webpage from one of Chicago's leading injury litigating attorneys: Chicago Stairway Defect Injury Lawyers

- O-1 OTHER:

The age of the smoke detectors noted in the home are unknown and they may be at or beyond the end of their service lives, typically taken to be 10 years for smoke detectors and 5 years for carbon monoxide detectors. It is recommended that the smoke detector and carbon monoxide detector systems be upgraded to reflect current life safety codes which include; smoke detectors on each level of living space and in each sleeping room, hard-wired 120 V smoke detectors that are interconnected in order to alarm simultaneously when any individual smoke detector responds, and carbon monoxide detectors and every level of living space and within 15 feet of a sleeping room. The installation of these critical life safety devices by a licensed and competent electrician is recommended.

Repairs

- EWGCE-3 EXTERIOR WALLS< GROUNDS, CHIMNEYS. ETC:

Cracking was noted in the masonry joints between dissimilar materials, stone features and stone coping on the structure. All dissimilar elements on the exterior walls of the structure such as: brick-to-stone; brick-to-concrete block; concrete block-to-glass block, all interior corners and all construction joints should be joined one to the other and sealed against moisture through the use of backer rod and urethane caulk or its equivalent. These elements have either differing coefficients of expansion and contraction in relation to temperature and moisture and/or are subject to movement which can lead to cracking of the cladding material and/or of the mortar joints. In order to reduce the potential for moisture related damage, the existing cement mortar joints should be ground out and replaced with the appropriate backer rod and ASTM approved caulking by a qualified masonry repair contractor.

This procedure is in keeping with the standards set forth by the Brick Industry Association. Further information is available at the following link: Accommodating Expansion of Brickwork

- EWGCE-4 EXTERIOR WALLS< GROUNDS, CHIMNEYS. ETC:

The vinyl siding on the garage and porch has been installed using a "J" channel which traps moisture and increases the risk for moisture damage. The lowest and first course of vinyl siding should be installed using the appropriate starter strip as required by the vinyl siding manufacturer and it is recommended that the siding be repaired by a qualified siding installation contractor.

- EWGCE-5 EXTERIOR WALLS< GROUNDS, CHIMNEYS. ETC:

The existing wooden deck/porch is weathered and deteriorating. In order to extend the service life of the deck materials, all exterior wooden deck surfaces should be professionally cleaned and sealed against weather.

Here is a link to some potentially useful information regarding deck sealing: How to Seal Your Deck & Best Deck Sealers

- EWGCE-6 EXTERIOR WALLS< GROUNDS, CHIMNEYS. ETC:

The lower portions of the exterior masonry walls and the chimneys have been covered with a cement parging. The splotchy, thin, cement parging has been applied over deteriorated brick masonry. The coating appears to have been patched a number of times and will require regular upkeep and patching. The parge coating on this structure is lacking several features that would be present on a high-quality cement parging installation. These include a stainless steel mesh screen behind the cement parging that reduces the risk for delamination; corrosion resistant metal beading at the top and side terminations of the cement parging; and a proper movement joint at the base of the parging.

In order to allow for the best performance and optimal protection of the brick masonry walls, the parging would ideally be comprised of lime mortar and not Portland cement. The application of a clear masonry sealant over the existing cement parging may extend its service life and reduce its maintenance requirements. In order to develop a plan and budget for ongoing maintenance/repair of the protective cement parging, the condominium association or homeowner should engage the services of a qualified masonry restoration contractor with extensive experience in historic masonry repair.

- EWGCE-7 EXTERIOR WALLS< GROUNDS, CHIMNEYS. ETC:

In order to prevent ongoing and accelerating corrosion and for proper appearance, the exterior metal components should be prepared, primed and painted with a coating specifically formulated for exterior metal applications using procedures that follow the paint manufacturers specifications.

- EWGCE-8 EXTERIOR WALLS< GROUNDS, CHIMNEYS. ETC:

The railing on the front porch does not have sufficient strength to resist lateral force and is lower than the 42" guardrail height required by the City of Chicago for decks and porches. In order to reduce the potential for injury, It is recommended that a qualified ironworker modify or fabricate railings for the front porch

- EWGCE-9 EXTERIOR WALLS< GROUNDS, CHIMNEYS. ETC:

The historic metal façade is corroded and damaged in areas and at least one area appears to have become a home for pests. In order to reduce the potential for moisture related damage and the entry of pests, the façade should be evaluated and repaired by a qualified sheet metal contractor or historic façade renovation contractor.

- EWGCE-10 EXTERIOR WALLS< GROUNDS, CHIMNEYS. ETC:

The exterior window lintels have been sealed and can no longer drain moisture which increases the potential for corrosion of the lintels. Over time the corroding steel will expand which can damage the adjacent masonry walls and allow moisture to penetrate to the interior of the living space. In order to reduce the potential for moisture related damage, the lintel drainage space should be repaired by a qualified masonry restoration contractor.

- GAO-1 GARAGES AND OUTBUILDINGS:

The photo-electric safety sensors for the automatic overhead garage door should be placed within 4 to 6 inches of the garage slab in order to properly protect against crushing and entrapment. Repair by a licensed and competent garage door specialist is recommended.

- RCRFRD-1 ROOF COVERINGS, ROOF FLASHING, ROOF DRAINAGE:

The front gutter appears to be leaking in at least one location. In order to reduce the potential for moisture related damage It is recommended that a qualified gutter installation contractor evaluate and repair the gutter as needed.

- RCRFRD-3 ROOF COVERINGS, ROOF FLASHING, ROOF DRAINAGE:

The garage roof has a series of wood posts installed through the roof and the penetrations appear to be sealed with tar which is a low performance and high maintenance solution. In order to reduce the potential for moisture related damage, unless there is a reason for the posts to be present, they should be removed and the roof patched via appropriate means and materials.

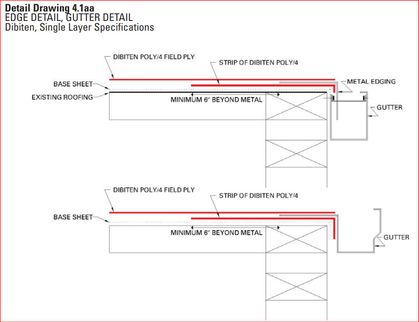

- RCRFRD-4 ROOF COVERINGS, ROOF FLASHING, ROOF DRAINAGE:

The modified bitumen roof covering is not properly secured to the back of the roof gutter. This defect presents an increased risk for damage from ice damming and from water backing up at the gutter. It is recommended that the roof/gutter interface be repaired by a qualified roofing contractor.

- RCRFRD-5 ROOF COVERINGS, ROOF FLASHING, ROOF DRAINAGE:

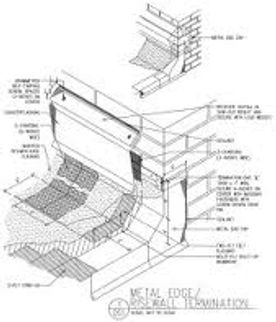

Best roofing practices call for the roof covering to be held back and terminated along the parapet wall typically between 12" and 36" depending on the height of the parapet wall itself. When the membrane is wrapped up and over the parapet top it prevents moisture from draining/evaporating at that side and will reduce mortar and brick life on the opposite side as moisture seeks pathways to drain or evaporate. It is recommended that the membrane be removed and terminated at an appropriate height on the parapet wall with appropriate base and counterflashing. Once the roofing has been removed the masonry parapet walls should be evaluated by a qualified masonry restoration contractor and mortar repairs should be expected where the roof concealed masonry details.

- RCRFRD-6 ROOF COVERINGS, ROOF FLASHING, ROOF DRAINAGE:

The existing rooftop on the front porch appears to be used as a deck. The roof does not have a walking surface and in order to reduce the potential for damage to the roof surface, a roof deck or some other walking or wearing surface should be added to the roof, also, secure and appropriate guardrails are needed. When adding a roof deck to this or the upper level roof, permitting through the City of Chicago is required and according to a recent memo from the City of Chicago, compliance with load and egress requirements is critical.

Here is a link to a webpage that appears to contain current code information with regard to rooftop decks in Chicago: Rooftop Deck Code

Also, here is a link to a memorandum regarding roof deck replacements that may provide information relative to these installations: Replacement of roof decks installed before 10/1/2003

- RCRFRD-7 ROOF COVERINGS, ROOF FLASHING, ROOF DRAINAGE:

Potential signs of moisture related damage were noted on the underside of the front porch roof and the roof deck was soft suggesting that the decking is deteriorated. Termination bar flashing should be installed at all areas where the modified bitumen roof covering is terminated. Failure to install the appropriate flashing at these areas can result in delamination, breaching, moisture intrusion and extensive damage. Evaluation and repair of the roof covering by a licensed and competent roofing contractor is recommended.

- ESGCDAF-2 ELECTRICAL SYSTEM, GROUNDING, CONNECTED DEVICES AND FIXTURES:

To guard against overheating and a risk for fire, the aluminum feeder cables in the service panel should be coated with an oxide inhibiting compound by a qualified electrician.

- ESGCDAF-3 ELECTRICAL SYSTEM, GROUNDING, CONNECTED DEVICES AND FIXTURES:

Multiple areas of loose armored electrical cable (commonly known as BX cable) were noted in the structure. A loose cable is subject to snagging and/or excess motion which can lead to arcing/sparking and the risk of fire and the armored electrical cables should be evaluated and repaired by a qualified electrician.

- ESGCDAF-5 ELECTRICAL SYSTEM, GROUNDING, CONNECTED DEVICES AND FIXTURES:

In order to reduce the risk for electrical shock when turning on the pull chain light, it is recommended that a non-conductive link be installed at the top of the light fixture pull chains.

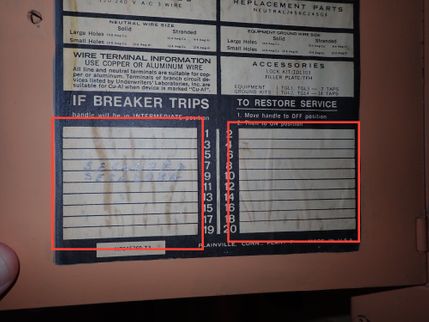

- ESGCDAF-6 ELECTRICAL SYSTEM, GROUNDING, CONNECTED DEVICES AND FIXTURES:

There was a missing and/or incomplete circuit directory for the electrical service panel/s. In order to allow for safe and efficient electrical circuit interruption when required for maintenance, repairs, or in emergencies, a complete and accurate electrical circuit directory should be provided to the buyer before closing.

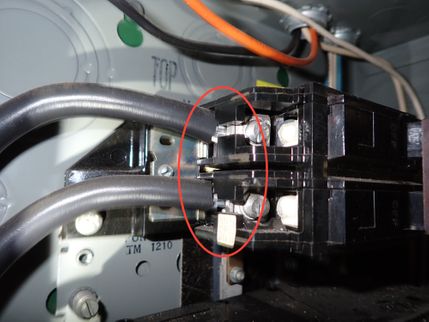

- ESGCDAF-7 ELECTRICAL SYSTEM, GROUNDING, CONNECTED DEVICES AND FIXTURES:

At least one double tapped breaker terminal was noted in the electrical service panel. Double tapping can result in overloaded circuits and can increase the risk of electrical shock and/or fire. Evaluation and repair of the service panel by a licensed and competent electrical contractor is recommended.

- ESGCDAF-8 ELECTRICAL SYSTEM, GROUNDING, CONNECTED DEVICES AND FIXTURES:

Pointed tipped screws are used to secure the service panel cover to the enclosure and the sharp ends have the potential to come into contact with wiring in the panel. This presents a risk for arcing/sparking, shock and fire and they should be replaced by a qualified electrician with blunt tipped screws specifically intended for use by the manufacturer of the panel.

Also, at least one screw was missing from the cover for the electrical service panel. In order to reduce the potential for inadvertent contact with energized electric equipment, it is recommended that the missing electrical panel cover screw/s be replaced.

- ESGCDAF-9 ELECTRICAL SYSTEM, GROUNDING, CONNECTED DEVICES AND FIXTURES:

Exposed wires were observed in at least one location in the residence. In order to reduce the risk for electrical shock from inadvertent contact with exposed current carrying equipment and in order to contain molten copper created by high temperature arcing and sparking of energized wiring, it is recommended that all electrical connections be concealed inside covered metal junction boxes by a qualified electrician.

- ESGCDAF-10 ELECTRICAL SYSTEM, GROUNDING, CONNECTED DEVICES AND FIXTURES:

While not all of the receptacles in the structure were tested, some loose, uncovered, mis-wired, two-pronged and painted, electrical receptacles were noted in various areas of the structure. All of these conditions represent significant electrical safety defects. All of the electrical receptacles in the structure should be evaluated and repaired or replaced as necessary by a licensed and competent electrical contractor.

- ESGCDAF-11 ELECTRICAL SYSTEM, GROUNDING, CONNECTED DEVICES AND FIXTURES:

There are switches throughout the residence that did not appear to control any light fixture or receptacle. Further investigation is required in order to determine what the functionality of these switches are.

- ESGCDAF-12 ELECTRICAL SYSTEM, GROUNDING, CONNECTED DEVICES AND FIXTURES:

In order to reduce the fire hazard associated with their hot surfaces and also to reduce the risk of bulb breakage, the bare bulb light fixtures in the closets should be replaced with low-profile fluorescent fixtures or their equivalent by a qualified electrician.

- PSDFAV-2 PLUMBING SUPPLY, DRAINS, FIXTURES AND VENTS:

Active leakage was noted on the drain pipe in the basement at the time of the inspection. In order to reduce the potential for damage and the development of mold and fungi, it is recommended that a qualified plumber evaluate and repair the piping as soon as practical.

Also, the drain for the basement bathroom sink does not keep pace with the incoming water causing it to fill to the point of overflowing if left unattended. In order to reduce the potential for moisture related damage it is recommended that a qualified plumber evaluate and repair the drain.

- PSDFAV-6 PLUMBING SUPPLY, DRAINS, FIXTURES AND VENTS:

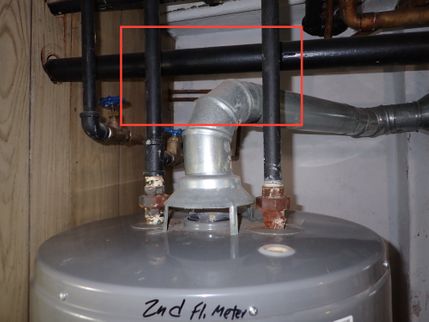

Melted plastic fittings were noted on the water heater supply connection pipes and moisture stains were observed on the vent piping and both of these suggest that hot exhaust gases are not being vented properly. The water heater exhaust pipe connects to the combined furnace/water heater exhaust pipe with a 'T' fitting instead of 'Y' fitting. Tee shaped fittings do not impart the desired directional flow to the exhaust gases and can increase the risk for back-drafting of exhaust gases. Repair by a qualified mechanical contractor or plumber is recommended.

- PSDFAV-7 PLUMBING SUPPLY, DRAINS, FIXTURES AND VENTS:

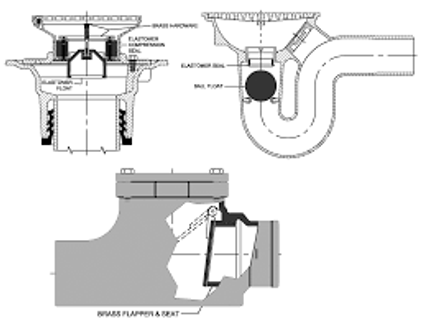

A standpipe is being utilized in one of the basement floor drains in the subject property and another one is plugged. The use of a standpipe or plug as sewage back-up prevention eliminates the utility of the floor drain in the event of a leak in the basement. In order for both functions to be performed, it is recommended that the standpipe be replaced with a floating ball style floor drain adapter.

- PSDFAV-10 PLUMBING SUPPLY, DRAINS, FIXTURES AND VENTS:

Several toilets in the structure are not adequately secured to the floor. This can result in deformation of the wax ring seal, leaking and other damage. In order to reduce the potential for moisture related damage and to determine if removal and reinstallation is necessary, the toilets should be evaluated by a licensed and competent plumber.

- PSDFAV-11 PLUMBING SUPPLY, DRAINS, FIXTURES AND VENTS:

The utility sink is not adequately secured in place and is subject to excess motion which can result in damage to the water supply and/or drain piping.

Also, the faucet on the sink did not have operational taps on the faucet and the faucet was frozen in place.

Finally the drain on the utility sink was clogged and standing water was observed in the sink at the time of the inspection. The drain pipe is repaired with tape and consists of improper proper piping. In order to reduce the potential for moisture related damage and for proper use of the sink, repair by a qualified plumber is recommended.

- PSDFAV-12 PLUMBING SUPPLY, DRAINS, FIXTURES AND VENTS:

The shower supply piping in the lower unit shower is loose and poorly secured. This piping can be subject to excess motion and physical damage which in turn can cause leaking and flooding in the residence. The shower supply piping should be evaluated and secured by a licensed and competent plumbing contractor.

- PSDFAV-13 PLUMBING SUPPLY, DRAINS, FIXTURES AND VENTS:

An improperly configured drain pipe was noted beneath the kitchen sink in the upper level unit. In order to reduce the potential for moisture related damage and for proper drainage, repair by a qualified plumber or handyman is recommended.

Also, incipient leakage staining was noted on the drain piping in the lower level unit bathroom, however no active leakage was noted at the time of the inspection. If active leakage is noted at some point in the future, repair by a qualified plumber is recommended.

- IVAE-1 INSULATION, VENTILATION, ATTICS, ETC.:

The kitchens in both units have exhaust ventilation fans, however, one of the units was unplugged and the other was non-functional. Cooking in the kitchen generates a great deal of heat, steam, grease, smoke and odors that need to be ventilated in order to maintain indoor air quality and proper housekeeping. It is the inspector's opinion that the failure to maintain ventilated exhaust fans will result in reduced indoor air quality, increased energy usage and more difficulty in keeping the units clean. A qualified service technician should evaluate the units in order to determine if they can be repaired or if replacement is needed.

- IVAE-2 INSULATION, VENTILATION, ATTICS, ETC.:

The existing cheap aluminum dryer damper is bent and stuck open which creates the potential for cold air to enter and condense on warmer interior components and for flying pests to enter the open dryer venting. In order to reduce the potential for corrosion and moisture related damage and unwanted visitors, all dryer and exhaust vent dampers on the exterior walls should be replaced with high-quality, gasketed, vent dampers.

NOTE: In order to ensure proper performance of the dryer vents, regular examination and cleaning of dryer vents is recommended.

- IVAE-3 INSULATION, VENTILATION, ATTICS, ETC.:

Open gaps were noted in the ceiling of the furnace closet that can allow smoke, carbon monoxide, and superheated gases to pass into other areas of the apartments in the event of a fire. In order to close off the gaps it is recommended that all opening be sealed with intumescent foam or other appropriate fireproofing materials.

- IVAE-4 INSULATION, VENTILATION, ATTICS, ETC.:

The bathroom ventilation fan is clogged with household dust. This affects it's ability to exhaust moisture and odors from the living space which, in turn, can lead to mold growth and moisture damage. A thorough cleaning of the vent cover and the accessible interior fan components is recommended.

- IAF-4 INTERIORS AND FINISHES:

The interior wall, floor, and ceiling finishes are aged and/or deteriorated. The interior trim and millwork is aged, defective and damaged in multiple locations. The kitchen and bathroom cabinetry, fixtures and appliances are also aged, deteriorated and neglected. Extensive remodeling of the condominium's interior is required in order to elevate it to modern standards of safety, convenience and appearance. Further evaluation by a qualified remodeling contractor is recommended in order to assist the buyer in developing a plan and budget for these repairs/upgrades.

- IAF-5 INTERIORS AND FINISHES:

Portions of the caulk between the bathtub and tub/shower wall tile appear to have a mold like substance in/on it. Once mold has penetrated into the body of the caulk it typically cannot be successfully eliminated and for proper appearance the caulk should be removed and replaced by a qualified contractor.

Note - If grout is found in any corner areas beneath the caulk, these areas are prone to cracking and the presence of the grout does not allow for the formation of a proper caulk joint. In order to prolong the life of the caulk joints and reduce the potential for moisture to enter the cracks and damage the underlying sub-base, it is recommended that the grout be raked out completely prior to re-caulking.

- IAF-6 INTERIORS AND FINISHES:

Moisture damage to the tub/shower surround was noted in the upper level unit bathroom. In order to reduce the potential for further moisture damage and fungi growth, the tile and tile backer should be repaired by a qualified tile setting contractor.

- WDS-1 WINDOWS, DOORS, SKYLIGHTS:

The lower portion of the doorframe on the ............. entry door are deteriorated and elevated moisture levels were measured. In order to reduce the potential for further moisture related damage, it is recommended that a qualified carpenter evaluate and replace the deteriorated portions of the doorframe, possibly with materials that are less affected by moisture like PVC lumber.

- WDS-2 WINDOWS, DOORS, SKYLIGHTS:

Many of the doors in the home failed to close or latch properly and problems included: doors hitting doorframes, non-catching latches and non-locking door locks. For proper operation it is recommended that any non-functional doors be repaired or adjusted by a qualified carpenter or handyman.

- WDS-3 WINDOWS, DOORS, SKYLIGHTS:

Caulk, not mortar, should be used to seal the areas between the glass block windows and the concrete block walls. Mortar can transfer the stresses inherent in these large masonry walls directly to the glass block; this can lead to cracking of the glass block. The existing mortar joints should be replaced with backer rod and urethane caulk or equivalent by a qualified masonry contractor.

- WDS-4 WINDOWS, DOORS, SKYLIGHTS:

A double-keyed deadbolt lock was noted on the rear door. No special tools or knowledge should be needed to exit the home in the event of an emergency and these locks present a risk of entrapment. Either a dedicated key needs to be left in the lock when the home is occupied, or the double keyed deadbolt lock should be replaced with one that utilizes a thumb latch.

- WDS-5 WINDOWS, DOORS, SKYLIGHTS:

The existing threshold at the exterior entry door/s is unsealed. In order to reduce the potential for the entry of pests, conserve energy, reduce cold drafts and reduce noise levels inside the living space, it is recommended that a weatherstripped threshold be installed at the bottom of the exterior entry door(s) by a qualified carpenter or handyman.

- WDS-6 WINDOWS, DOORS, SKYLIGHTS:

Some of the windows in the structure are older windows that may require maintenance and repair. While some older windows may have character that is worth retaining, potential improvements like adding storm windows or re-habilitating older windows with newer components can be performed. Repairs can be made on an as needed basis by a qualified window installation contractor, carpenter or handyman.

Examples of observations noted during inspection include:

- Cracked panes of glass were noted - glass replacement is needed in these windows.

- Condensation on interior of thermal panes

- Non-latching Windows

- Some of the windows are installed in locations that would require safety glazing today. Safety glazing is tempered or laminated glass and is required today in stairways, adjacent to operable doors, where large picture frames of glass are used and for windows in tub and shower enclosures.

- Windows are showing signs of leakage and moisture control problems.

- WDS-7 WINDOWS, DOORS, SKYLIGHTS:

The weatherstripping around the exterior entry door/s is deteriorated and/or missing. In order to conserve energy, reduce cold drafts and reduce noise levels inside the living space, the installation of high quality rubber bulb weatherstripping by a qualified handyman is recommended at the top and sides of the exterior entry door(s).

- WDS-8 WINDOWS, DOORS, SKYLIGHTS:

In order to prevent fire spread within the structure and also to prevent the blocking of emergency egress during a fire, the interior common area entry doors to this unit and to all living units in the building should be made self-closing, as required by fire safety codes.

- IA-1 INSTALLED APPLIANCES:

The kitchen ranges in both units are unsecured and have the ability to tip under the right circumstances. In order to reduce the potential for scald and burn injuries related to the instability of the kitchen ranges, anti-tipping devices (Federally mandated and shipped with all ranges) should be installed behind the kitchen ranges in both units.

NOTE: The kitchen range in the lower level unit was not plugged in at the time of the inspection so it's operation could not be verified.

- O-2 OTHER:

The heating pipes appear to be insulated with an asbestos-like material. Areas of this pipe insulation are damaged and the presence of remaining sections of this pipe insulation suggests that, whatever insulation was previously removed was not done in accordance with existing safety standards. The improper removal of asbestos pipe insulation can result in asbestos fibers in the dust and air in the home. If this material is made of asbestos, in order to assess any possible health risk posed by these conditions, further evaluation by a licensed and competent environmental remediation contractor would be recommended.

In order to determine if asbestos is present in this material, it may be possible for the buyer/homeowner to carefully collect a small sample of the material to send to a lab for analysis.

Here is a link to a Chicago testing lab that may be able to perform this testing: Indoor Science Testing Lab

Here is a link to a Chicago suburban testing lab that may be able to perform this testing: UAS Laboratory Services

Removal and remediation of asbestos can be expensive and it may be possible to repair and/or encapsulate the pipes, however, the long term performance and success of these products is unknown.

Here is a link to information regarding this process: The Four Steps to Asbestos Encapsulation

- O-3 OTHER:

Bird droppings can contain materials that are hazardous to the respiratory system and their nesting presence around the home should be discouraged. It is recommended that the existing nest/s be removed if not occupied and that openings be sealed and/or bird deterrent devices be installed to discourage further occurrences.

Here is a link to a site that has multiple options for bird deterrents: Bird Control Devices

Recommended Maintenance Items

- HACVAGAS-3 HEATING, AIR CONDITIONING, VENTILATION, AND GAS APPLIANCE SYSTEMS:

The boilers in this structure can provides decades of service if they are maintained properly. It is recommended that any available service records for the boilers be obtained from the seller and be compared to the manufacturers maintenance requirements. If proper maintenance is being followed, it is recommended that the buyer continue the ongoing service schedules.

NOTE: Neither of the boilers in the structure were operated as there can be operational concerns when turning these units on for the season and evaluation of these units by a qualified service technician before use is highly recommended. Units like the steam boiler require annual flushing for proper performance and adjustment of bleeder valves may be needed to reduce damage from leakage.

Improves

- ESGCDAF-4 ELECTRICAL SYSTEM, GROUNDING, CONNECTED DEVICES AND FIXTURES:

In order to reduce the risk of electrical shock and injury, it is recommended that all electrical receptacles in the bathrooms, garage, exterior and kitchen that are not already Ground Fault Circuit Interruption (GFCI) protected, be upgraded to GFCI receptacles by a licensed and competent electrician.

- PSDFAV-4 PLUMBING SUPPLY, DRAINS, FIXTURES AND VENTS:

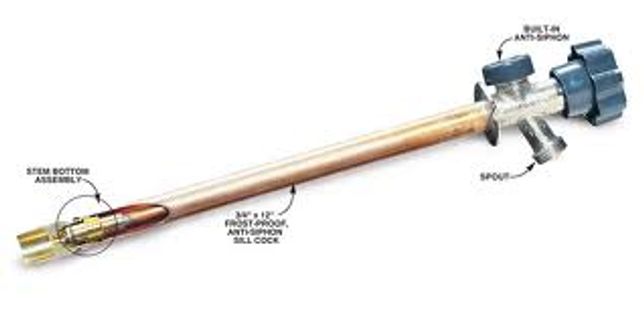

The existing outside hose bibb was not operational at the time of the inspection and if in use it should be replaced with new hose bibb(s) having both frost-proof and anti-siphon features. The anti-siphon feature reduces the risk for cross-contamination of the home's potable water supply; the frostproof feature virtually eliminates the risk for pipe freezing, bursting and flooding. Repair by a qualified plumbing contractor is recommended.

Also, the existing outside hose bibb/s is/are loose and subject to motion that can result in supply pipe leakage and flooding. In order to reduce the potential for moisture related damage the hose bibb/s should be secured by a qualified plumber or handyman using the tabs specifically designed for that purpose.

- PSDFAV-5 PLUMBING SUPPLY, DRAINS, FIXTURES AND VENTS:

An expansion tank is recommended for the water heater; these are required if the house has a closed plumbing system. Expansion tanks help reduce pressure on the plumbing system by creating a buffer or a place for water to expand into as water swells during thermal expansion. Installation of expansion or pressure tanks is modern installation practice and will be required if a pressure reducing valve has been installed on a public water supply. Consult with a qualified plumber to install.

- PSDFAV-14 PLUMBING SUPPLY, DRAINS, FIXTURES AND VENTS:

Older style gate valve shut-offs were noted on distribution piping to many of the plumbing fixtures in the residence. These valves can be prone to leakage when operated and they were not opened or closed at the time of the inspection. In order to be able to shut off water to service plumbing fixtures in the future, the valves should be replaced with 1/4 turn ball valves by a qualified plumber.

- IVAE-5 INSULATION, VENTILATION, ATTICS, ETC.:

Many of the bathroom ventilation fans in the structure are excessively and unnecessarily noisy. It is recommended that they be replaced with high quality, Energy Star rated, low noise bathroom ventilation fans.

- WDS-9 WINDOWS, DOORS, SKYLIGHTS:

The aluminum framed vent window in the glass block window panel is prone to drafts and condensation. For energy efficiency and increased indoor comfort, it is recommended that it be replaced with a vinyl framed, insulated glass panel.

Monitors

- SAF-1 STRUCTURE AND FOUNDATION:

The home has sloping floors and cracked walls suggesting that settlement has occurred. This settlement is most likely related to the slow deterioration of wood support posts that are resting on a dirt floor and/or subjected to continual saturation via capillary action through concrete. The existing posts were found to have elevated moisture levels and portions of the bottom of the posts are deteriorated making ongoing settlement possible. Additional cracking in walls or the inability to open doors and windows suggests additional settlement is occurring and if noted in the future, evaluation and repair by a qualified foundation repair contractor may be necessary.

Due Diligences

- GI-1 GENERAL INFORMATION:

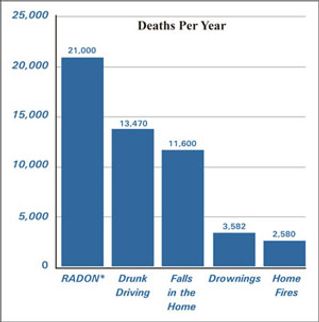

Radon is a colorless odorless gas that results from the natural decay of underground uranium deposits. The US EPA estimates that radon is responsible for approximately 22,000 deaths throughout the United States annually. The presence or absence of radon cannot be accurately inferred by the presence or absence of radon gas in adjoining or nearby properties. The only way to know for certain if the home has excess levels of radon levels is to perform a test. Testing is recommended to be performed during a residential real estate transaction not only for health reasons but also due to the fact that sellers will typically take responsibility for the cost of radon mitigation if excessive levels are found during the buyer's due diligence. It is strongly recommended that a radon test be performed at this property.

Here is a link to information from the EPA regarding Radon: Radon is a health hazard with a simple solution

- ESGCDAF-13 ELECTRICAL SYSTEM, GROUNDING, CONNECTED DEVICES AND FIXTURES:

The evaluation of the low-voltage equipment in the home: alarm, communication, audiovisual, etc., is beyond the scope of the home inspection and should be performed by a qualified low-voltage electrical contractor. In order to reduce the potential for confusion and to reduce clutter around the home, any wiring, panels, cabinets, etc. for any equipment that is no longer in use should be removed.

- PSDFAV-3 PLUMBING SUPPLY, DRAINS, FIXTURES AND VENTS:

A video camera sewer scope is recommended. An evaluation of the sewer line below the ground is beyond the scope of this inspection. Due to the age and location of the building, a sewer scope is recommended to further evaluate the sewer line and the below ground connections between the house and the municipal sewer line. Sewer scopes are done using video cameras and can reveal the materials, condition and reliability of the sewer line. If that has been done recently, I recommend having a sewer scope performed.

- PSDFAV-9 PLUMBING SUPPLY, DRAINS, FIXTURES AND VENTS:

A flood control system may have been installed in this structure. If one is present, in order to ensure that it is in proper operating condition when needed, flood control systems require regular evaluation and maintenance by a qualified plumbing or sewer contractor. It should be determined if a flood control system is present and it's operation should be established and it should be transferred to the new owner in fully operational condition.

Future Projects

- EWGCE-2 EXTERIOR WALLS< GROUNDS, CHIMNEYS. ETC:

The masonry exterior walls have been re-pointed in the 'European' style. This type of mortar configuration is characterized by rounded, convex mortar joints that are prone to saturation of the brick and mortar by collecting water as it flows down the exterior wall which exposes the exterior walls to freeze/thaw and wet/dry cycles that can accelerate aging and deterioration of the masonry.

Also, the structure has been surficially re-pointed in that the underlying old cracked mortar joints were not ground out and mortar was smeared over the joints. Areas of missing mortar were observed and loose of mortar could easily be removed from some joints which creates the potential for further deterioration and damage. The re-pointing may provide several years of protection, however, in order to reduce the potential for future moisture related damage, plans should be made for a proper re-pointing by a qualified masonry contractor in the not too distant future.

Here is a link to an article from the International Masonry Institute that discusses proper re-pointing methods: Re-pointing Masonry Walls

- RCRFRD-2 ROOF COVERINGS, ROOF FLASHING, ROOF DRAINAGE:

In order to extend the service life of the roofing on the garage and main structure and in order to reduce the cooling load on the upper unit, the application of a reflective coating is recommended over the surface of the modified bitumen roof covering. FYI: Aluminized coatings are, in general, far inferior to white roof coatings which are both more reflective and more emissive.

- HACVAGAS-1 HEATING, AIR CONDITIONING, VENTILATION, AND GAS APPLIANCE SYSTEMS:

If the basement becomes an occupied space, the mechanical equipment will need to be installed in an enclosed space and unless preventative measures are taken, the multiple boilers and water heater in the basement will have insufficient access to combustion/dilution air. In order to reduce the risk of equipment damage, inefficient combustion and infiltration of carbon monoxide into the living space, a controlled intake ventilation damper system that draws intake air from the outside of the structure should be installed by a qualified HVAC or mechanical contractor.

- HACVAGAS-2 HEATING, AIR CONDITIONING, VENTILATION, AND GAS APPLIANCE SYSTEMS:

The structure has boiler heating and no ductwork for air conditioning. Window air conditioning units may be used by tenants in the structure, however, these units can create the potential for water damage from poorly sealed openings and/or improperly draining condensate from the air conditioning unit. In order to be able to reduce the potential for moisture related damage in the structure, consideration should be given towards the installation of an air conditioning system by a qualified HVAC contractor.

Here is a link to an article that may provide some useful information with regards to ductless options: Is Ductless Heating and Cooling Right for You?

Here is a link to another article that discusses specific system options for ductless units: The Best Ductless Air Conditioners to Keep Your Home Cool

The Full Report

GENERAL INFORMATION

TYPE OF STRUCTURE: 2 Unit Multi-Family

APPROXIMATE AGE OF STRUCTURE: Over 100 Years, Online information suggests structure was built in 1910

STRUCTURE FACES: South

CLIENT PRESENT: Yes

RADON TEST: No, RADON TESTING STRONGLY RECOMMENDED

WATER QUALITY TEST: No

WEATHER CONDITIONS: Clear

AMBIENT TEMPERATURE: Below 60...A/C not operated due to risk of equipment damage

NUMBER OF STORIES: Two and a Half Story

Radon is a colorless odorless gas that results from the natural decay of underground uranium deposits. The US EPA estimates that radon is responsible for approximately 22,000 deaths throughout the United States annually. The presence or absence of radon cannot be accurately inferred by the presence or absence of radon gas in adjoining or nearby properties. The only way to know for certain if the home has excess levels of radon levels is to perform a test. Testing is recommended to be performed during a residential real estate transaction not only for health reasons but also due to the fact that sellers will typically take responsibility for the cost of radon mitigation if excessive levels are found during the buyer's due diligence. It is strongly recommended that a radon test be performed at this property.

Here is a link to information from the EPA regarding Radon: Radon is a health hazard with a simple solution

EXTERIOR WALLS< GROUNDS, CHIMNEYS. ETC

GAS SHUT-OFF LOCATION: Common Area Meter Room

WALKWAYS PATIOS DRIVEWAYS: Concrete Walks

VEGETATION/GRADING/DRAINAGE: No Obvious Defects Noted

EXTERIOR STEPS/STAIRWAYS/RAILINGS: Concrete/Masonry Front Porch

EXTERIOR WALL CONSTRUCTION: Masonry

PRIMARY EXTERIOR WALL CLADDING MATERIAL: Brick

The upper portions of the masonry walls just below the clay tile caps are extremely deteriorated and portions were bulging suggesting that masonry is being displaced. The butt joints between the individual sections of clay tile coping have been sealed with cement mortar. The mortar is cracking and the joints are open which creates a risk for moisture saturation/damage to the masonry walls below. The coping tiles serve to protect the underlying brick masonry walls from wetting/drying and freezing/thawing damage and should be neatly joined and properly sealed in order to perform this function. The open joint have likely been allowing moisture to enter and the roofing wrapped over the parapet walls may be trapping moisture in the walls. It is highly recommended that the parapet walls be evaluated by a qualified masonry contractor and be repaired or rebuilt as needed. Also, when the coping tiles are repaired or replaced as needed, it is recommended that the individual clay tiles be reinstalled using backer rod and polyurethane caulk to seal the joints.

The masonry exterior walls have been re-pointed in the 'European' style. This type of mortar configuration is characterized by rounded, convex mortar joints that are prone to saturation of the brick and mortar by collecting water as it flows down the exterior wall which exposes the exterior walls to freeze/thaw and wet/dry cycles that can accelerate aging and deterioration of the masonry.

Also, the structure has been surficially re-pointed in that the underlying old cracked mortar joints were not ground out and mortar was smeared over the joints. Areas of missing mortar were observed and loose of mortar could easily be removed from some joints which creates the potential for further deterioration and damage. The re-pointing may provide several years of protection, however, in order to reduce the potential for future moisture related damage, plans should be made for a proper re-pointing by a qualified masonry contractor in the not too distant future.

Here is a link to an article from the International Masonry Institute that discusses proper re-pointing methods: Re-pointing Masonry Walls

Cracking was noted in the masonry joints between dissimilar materials, stone features and stone coping on the structure. All dissimilar elements on the exterior walls of the structure such as: brick-to-stone; brick-to-concrete block; concrete block-to-glass block, all interior corners and all construction joints should be joined one to the other and sealed against moisture through the use of backer rod and urethane caulk or its equivalent. These elements have either differing coefficients of expansion and contraction in relation to temperature and moisture and/or are subject to movement which can lead to cracking of the cladding material and/or of the mortar joints. In order to reduce the potential for moisture related damage, the existing cement mortar joints should be ground out and replaced with the appropriate backer rod and ASTM approved caulking by a qualified masonry repair contractor.

This procedure is in keeping with the standards set forth by the Brick Industry Association. Further information is available at the following link: Accommodating Expansion of Brickwork

The vinyl siding on the garage and porch has been installed using a "J" channel which traps moisture and increases the risk for moisture damage. The lowest and first course of vinyl siding should be installed using the appropriate starter strip as required by the vinyl siding manufacturer and it is recommended that the siding be repaired by a qualified siding installation contractor.

The existing wooden deck/porch is weathered and deteriorating. In order to extend the service life of the deck materials, all exterior wooden deck surfaces should be professionally cleaned and sealed against weather.

Here is a link to some potentially useful information regarding deck sealing: How to Seal Your Deck & Best Deck Sealers

The lower portions of the exterior masonry walls and the chimneys have been covered with a cement parging. The splotchy, thin, cement parging has been applied over deteriorated brick masonry. The coating appears to have been patched a number of times and will require regular upkeep and patching. The parge coating on this structure is lacking several features that would be present on a high-quality cement parging installation. These include a stainless steel mesh screen behind the cement parging that reduces the risk for delamination; corrosion resistant metal beading at the top and side terminations of the cement parging; and a proper movement joint at the base of the parging.

In order to allow for the best performance and optimal protection of the brick masonry walls, the parging would ideally be comprised of lime mortar and not Portland cement. The application of a clear masonry sealant over the existing cement parging may extend its service life and reduce its maintenance requirements. In order to develop a plan and budget for ongoing maintenance/repair of the protective cement parging, the condominium association or homeowner should engage the services of a qualified masonry restoration contractor with extensive experience in historic masonry repair.

In order to prevent ongoing and accelerating corrosion and for proper appearance, the exterior metal components should be prepared, primed and painted with a coating specifically formulated for exterior metal applications using procedures that follow the paint manufacturers specifications.

The railing on the front porch does not have sufficient strength to resist lateral force and is lower than the 42" guardrail height required by the City of Chicago for decks and porches. In order to reduce the potential for injury, It is recommended that a qualified ironworker modify or fabricate railings for the front porch

The historic metal façade is corroded and damaged in areas and at least one area appears to have become a home for pests. In order to reduce the potential for moisture related damage and the entry of pests, the façade should be evaluated and repaired by a qualified sheet metal contractor or historic façade renovation contractor.

The exterior window lintels have been sealed and can no longer drain moisture which increases the potential for corrosion of the lintels. Over time the corroding steel will expand which can damage the adjacent masonry walls and allow moisture to penetrate to the interior of the living space. In order to reduce the potential for moisture related damage, the lintel drainage space should be repaired by a qualified masonry restoration contractor.

GARAGES AND OUTBUILDINGS

The photo-electric safety sensors for the automatic overhead garage door should be placed within 4 to 6 inches of the garage slab in order to properly protect against crushing and entrapment. Repair by a licensed and competent garage door specialist is recommended.

ROOF COVERINGS, ROOF FLASHING, ROOF DRAINAGE

Roof Covering: Modified Bitumen

Roof Viewed: Roof Was Walked, From a Raised Vantage Point Such as a Lower Roof

The front gutter appears to be leaking in at least one location. In order to reduce the potential for moisture related damage It is recommended that a qualified gutter installation contractor evaluate and repair the gutter as needed.

In order to extend the service life of the roofing on the garage and main structure and in order to reduce the cooling load on the upper unit, the application of a reflective coating is recommended over the surface of the modified bitumen roof covering. FYI: Aluminized coatings are, in general, far inferior to white roof coatings which are both more reflective and more emissive.

The garage roof has a series of wood posts installed through the roof and the penetrations appear to be sealed with tar which is a low performance and high maintenance solution. In order to reduce the potential for moisture related damage, unless there is a reason for the posts to be present, they should be removed and the roof patched via appropriate means and materials.

The modified bitumen roof covering is not properly secured to the back of the roof gutter. This defect presents an increased risk for damage from ice damming and from water backing up at the gutter. It is recommended that the roof/gutter interface be repaired by a qualified roofing contractor.

Best roofing practices call for the roof covering to be held back and terminated along the parapet wall typically between 12" and 36" depending on the height of the parapet wall itself. When the membrane is wrapped up and over the parapet top it prevents moisture from draining/evaporating at that side and will reduce mortar and brick life on the opposite side as moisture seeks pathways to drain or evaporate. It is recommended that the membrane be removed and terminated at an appropriate height on the parapet wall with appropriate base and counterflashing. Once the roofing has been removed the masonry parapet walls should be evaluated by a qualified masonry restoration contractor and mortar repairs should be expected where the roof concealed masonry details.

The existing rooftop on the front porch appears to be used as a deck. The roof does not have a walking surface and in order to reduce the potential for damage to the roof surface, a roof deck or some other walking or wearing surface should be added to the roof, also, secure and appropriate guardrails are needed. When adding a roof deck to this or the upper level roof, permitting through the City of Chicago is required and according to a recent memo from the City of Chicago, compliance with load and egress requirements is critical.

Here is a link to a webpage that appears to contain current code information with regard to rooftop decks in Chicago: Rooftop Deck Code

Also, here is a link to a memorandum regarding roof deck replacements that may provide information relative to these installations: Replacement of roof decks installed before 10/1/2003

Potential signs of moisture related damage were noted on the underside of the front porch roof and the roof deck was soft suggesting that the decking is deteriorated. Termination bar flashing should be installed at all areas where the modified bitumen roof covering is terminated. Failure to install the appropriate flashing at these areas can result in delamination, breaching, moisture intrusion and extensive damage. Evaluation and repair of the roof covering by a licensed and competent roofing contractor is recommended.

STRUCTURE AND FOUNDATION

FLOOR STRUCTURE: Unable to Determine

CRAWLSPACE ACCESS: No Crawlspace

MAIN FLOOR BEAM AND POSTS: Wood Columns - Deteriorated and/or Saturated, Wood Beams

FOUNDATION: Foundation not Accessible

The home has sloping floors and cracked walls suggesting that settlement has occurred. This settlement is most likely related to the slow deterioration of wood support posts that are resting on a dirt floor and/or subjected to continual saturation via capillary action through concrete. The existing posts were found to have elevated moisture levels and portions of the bottom of the posts are deteriorated making ongoing settlement possible. Additional cracking in walls or the inability to open doors and windows suggests additional settlement is occurring and if noted in the future, evaluation and repair by a qualified foundation repair contractor may be necessary.

Very little of the foundation was visible in the basement at the time of the inspection due to the finished lower level walls. There were visible signs of moisture intrusion and elevated moisture levels noted in the basement walls in several locations at the time of the inspection. It does not seem that there is bulk leakage as there were no stains on the floor suggesting that this type of infiltration was taking place. If improvement of this space is desired, it may be necessary to use finishing materials that do not react with moisture, here is a link to a webpage that discusses some available options: Three Basement Finishing Systems: An Introduction

ELECTRICAL SYSTEM, GROUNDING, CONNECTED DEVICES AND FIXTURES

ELECTRICAL SERVICE: 240 volts, Overhead service, Aluminum Service Conductors - Un-Coated

LOCATION OF MAIN SERVICE DISCONNECT: Electric service panels in basement

SERVICE PANEL AMPACITY: 3 Service Panels, 100 AMP

OVERCURRENT PROTECTION DEVICES: Circuit Breakers

SERVICE PANEL BRAND: GENERAL ELECTRIC

BRANCH CIRCUIT CONDUCTORS: Copper

NUMBER OF CIRCUITS USED - NUMBER OF CIRCUITS AVAILABLE FOR USE: Basement panel - 7 Circuits used / 5 Circuits available; Unit 1 panel - 4 Circuits used / 8 Circuits available; Unit 2 panel - 5 Circuits used / 7 Circuits available

WIRING METHODS: Electrical Metallic Tubing EMT (Conduit), Armored Cable (BX) - Loose

ELECTRICAL GROUNDING CONDUCTOR/CLAMP LOCATION: Water Pipe Grounding Clamp

The kitchen countertop work areas in each unit are served by only one branch circuit. In order to provide adequate power to the high draw appliances often used at these locations, safety and convenience standards have long required two - 20 amp small appliance circuits for the kitchen countertop work areas. In order to determine the cost and feasibility for retrofitting a second small appliance circuit for the kitchen countertop work areas, further evaluation by a qualified electrician is recommended.

Also, an inadequate number of electric receptacles was noted for the structure. This is common in older buildings. This can present safety issues as tenants may have many more things to plug in than when the home was originally built. This can lead to overloading circuits which can lead to heat build-up and even fires. A logical improvement would be adding additional circuits and receptacles, especially in high-use areas such as media areas, kitchens and offices. Today's standards require no more than 24 inches from a receptacle in the kitchen and never more than 6 feet throughout the structure.

To guard against overheating and a risk for fire, the aluminum feeder cables in the service panel should be coated with an oxide inhibiting compound by a qualified electrician.

Multiple areas of loose armored electrical cable (commonly known as BX cable) were noted in the structure. A loose cable is subject to snagging and/or excess motion which can lead to arcing/sparking and the risk of fire and the armored electrical cables should be evaluated and repaired by a qualified electrician.

In order to reduce the risk of electrical shock and injury, it is recommended that all electrical receptacles in the bathrooms, garage, exterior and kitchen that are not already Ground Fault Circuit Interruption (GFCI) protected, be upgraded to GFCI receptacles by a licensed and competent electrician.

In order to reduce the risk for electrical shock when turning on the pull chain light, it is recommended that a non-conductive link be installed at the top of the light fixture pull chains.

There was a missing and/or incomplete circuit directory for the electrical service panel/s. In order to allow for safe and efficient electrical circuit interruption when required for maintenance, repairs, or in emergencies, a complete and accurate electrical circuit directory should be provided to the buyer before closing.

At least one double tapped breaker terminal was noted in the electrical service panel. Double tapping can result in overloaded circuits and can increase the risk of electrical shock and/or fire. Evaluation and repair of the service panel by a licensed and competent electrical contractor is recommended.

Pointed tipped screws are used to secure the service panel cover to the enclosure and the sharp ends have the potential to come into contact with wiring in the panel. This presents a risk for arcing/sparking, shock and fire and they should be replaced by a qualified electrician with blunt tipped screws specifically intended for use by the manufacturer of the panel.

Also, at least one screw was missing from the cover for the electrical service panel. In order to reduce the potential for inadvertent contact with energized electric equipment, it is recommended that the missing electrical panel cover screw/s be replaced.

Exposed wires were observed in at least one location in the residence. In order to reduce the risk for electrical shock from inadvertent contact with exposed current carrying equipment and in order to contain molten copper created by high temperature arcing and sparking of energized wiring, it is recommended that all electrical connections be concealed inside covered metal junction boxes by a qualified electrician.

While not all of the receptacles in the structure were tested, some loose, uncovered, mis-wired, two-pronged and painted, electrical receptacles were noted in various areas of the structure. All of these conditions represent significant electrical safety defects. All of the electrical receptacles in the structure should be evaluated and repaired or replaced as necessary by a licensed and competent electrical contractor.

There are switches throughout the residence that did not appear to control any light fixture or receptacle. Further investigation is required in order to determine what the functionality of these switches are.

In order to reduce the fire hazard associated with their hot surfaces and also to reduce the risk of bulb breakage, the bare bulb light fixtures in the closets should be replaced with low-profile fluorescent fixtures or their equivalent by a qualified electrician.

The evaluation of the low-voltage equipment in the home: alarm, communication, audiovisual, etc., is beyond the scope of the home inspection and should be performed by a qualified low-voltage electrical contractor. In order to reduce the potential for confusion and to reduce clutter around the home, any wiring, panels, cabinets, etc. for any equipment that is no longer in use should be removed.

PLUMBING SUPPLY, DRAINS, FIXTURES AND VENTS

POTABLE WATER SOURCE: Public

WATER SERVICE PIPING MATERIAL: Galvanized, Not Fully Visible

MAIN WATER SHUT-OFF LOCATION: Exterior - In front parkway, Interior - By water meter in basement

WATER DISTRIBUTION PIPING MATERIAL: Galvanized Pipe (30 to 50 year service life) - restricted flow

WATER PRESSURE AND FLOW: Marginal

PLUMBING WASTE SYSTEM: Public Sewer

PLUMBING WASTE PIPING MATERIAL: Cast iron, PVC, Not Fully Visible

WATER HEATER SIZE AND POWER SOURCE: 50 Gallons, Gas-Fired Water Heater, Natural Draft Exhaust, Insufficiently Sized Water Heater

BTU OR WATT INPUT RATING: 38,000 BTU's

WATER HEATER MANUFACTURER: Rheem, Water Heater Statistical Service Life is 13 years.

APPROXIMATE AGE IN YEARS: Unit was manufactured in 2013

The water pressure and flow at some of the plumbing fixtures is marginal. For optimal flow and pressure during the use of multiple fixtures, it is recommended that the remaining galvanized water supply piping be removed and replaced with copper piping.

Active leakage was noted on the drain pipe in the basement at the time of the inspection. In order to reduce the potential for damage and the development of mold and fungi, it is recommended that a qualified plumber evaluate and repair the piping as soon as practical.

Also, the drain for the basement bathroom sink does not keep pace with the incoming water causing it to fill to the point of overflowing if left unattended. In order to reduce the potential for moisture related damage it is recommended that a qualified plumber evaluate and repair the drain.

A video camera sewer scope is recommended. An evaluation of the sewer line below the ground is beyond the scope of this inspection. Due to the age and location of the building, a sewer scope is recommended to further evaluate the sewer line and the below ground connections between the house and the municipal sewer line. Sewer scopes are done using video cameras and can reveal the materials, condition and reliability of the sewer line. If that has been done recently, I recommend having a sewer scope performed.

The existing outside hose bibb was not operational at the time of the inspection and if in use it should be replaced with new hose bibb(s) having both frost-proof and anti-siphon features. The anti-siphon feature reduces the risk for cross-contamination of the home's potable water supply; the frostproof feature virtually eliminates the risk for pipe freezing, bursting and flooding. Repair by a qualified plumbing contractor is recommended.

Also, the existing outside hose bibb/s is/are loose and subject to motion that can result in supply pipe leakage and flooding. In order to reduce the potential for moisture related damage the hose bibb/s should be secured by a qualified plumber or handyman using the tabs specifically designed for that purpose.

An expansion tank is recommended for the water heater; these are required if the house has a closed plumbing system. Expansion tanks help reduce pressure on the plumbing system by creating a buffer or a place for water to expand into as water swells during thermal expansion. Installation of expansion or pressure tanks is modern installation practice and will be required if a pressure reducing valve has been installed on a public water supply. Consult with a qualified plumber to install.

Melted plastic fittings were noted on the water heater supply connection pipes and moisture stains were observed on the vent piping and both of these suggest that hot exhaust gases are not being vented properly. The water heater exhaust pipe connects to the combined furnace/water heater exhaust pipe with a 'T' fitting instead of 'Y' fitting. Tee shaped fittings do not impart the desired directional flow to the exhaust gases and can increase the risk for back-drafting of exhaust gases. Repair by a qualified mechanical contractor or plumber is recommended.

A standpipe is being utilized in one of the basement floor drains in the subject property and another one is plugged. The use of a standpipe or plug as sewage back-up prevention eliminates the utility of the floor drain in the event of a leak in the basement. In order for both functions to be performed, it is recommended that the standpipe be replaced with a floating ball style floor drain adapter.

The water service pipe penetrating the floor slab appears to be galvanized piping. Typically this type of piping does not extend to the water main and unless there are records from the local municipality's water department that reveal a permit for water service replacement, most likely the service is made of lead. Lead is a neuro-toxic metal that can leach into the water especially during periods with no flow, such as commonly occurs overnight. Many municipalities are considering requiring property owners to replace the existing older lead water services. At a minimum, flushing of the water piping system prior to drinking is recommended after periods of supply piping inactivity. Many water filters are available that are capable of removing most of the lead from the drinking water.

For more information regarding the dangers of lead in water supplies, here is a link to a webpage from the EPA: Basic Information about Lead in Drinking Water

For residents in the City of Chicago, free lead testing kits (and potentially filters if eligible) are available. Here is a link to a webpage from the Department of Water Management regarding the testing program: Chicago Water Quality Study Program

A flood control system may have been installed in this structure. If one is present, in order to ensure that it is in proper operating condition when needed, flood control systems require regular evaluation and maintenance by a qualified plumbing or sewer contractor. It should be determined if a flood control system is present and it's operation should be established and it should be transferred to the new owner in fully operational condition.

Several toilets in the structure are not adequately secured to the floor. This can result in deformation of the wax ring seal, leaking and other damage. In order to reduce the potential for moisture related damage and to determine if removal and reinstallation is necessary, the toilets should be evaluated by a licensed and competent plumber.

The utility sink is not adequately secured in place and is subject to excess motion which can result in damage to the water supply and/or drain piping.

Also, the faucet on the sink did not have operational taps on the faucet and the faucet was frozen in place.

Finally the drain on the utility sink was clogged and standing water was observed in the sink at the time of the inspection. The drain pipe is repaired with tape and consists of improper proper piping. In order to reduce the potential for moisture related damage and for proper use of the sink, repair by a qualified plumber is recommended.

The shower supply piping in the lower unit shower is loose and poorly secured. This piping can be subject to excess motion and physical damage which in turn can cause leaking and flooding in the residence. The shower supply piping should be evaluated and secured by a licensed and competent plumbing contractor.

An improperly configured drain pipe was noted beneath the kitchen sink in the upper level unit. In order to reduce the potential for moisture related damage and for proper drainage, repair by a qualified plumber or handyman is recommended.