The Scope and Purpose of a Home Inspection

Purchasing property involves risk

The purpose of a home inspection is to help reduce the risk associated with the purchase of a structure by providing a professional opinion about the overall condition of the structure. A home inspection is a limited visual inspection and it cannot eliminate this risk. Some homes present more risks than others. We cannot control this, but we try to help educate you about what we don’t know during the inspection process. This is more difficult to convey in a report and one of many reasons why we recommend that you attend the inspection.

A home inspection is not an insurance policy

This report does not substitute for or serve as a warranty or guarantee of any kind. Home warranties can be purchased separately from insuring firms that provide this service.

A home inspection is visual and not destructive

The descriptions and observations in this report are based on a visual inspection of the structure. We inspect the aspects of the structure that can be viewed without dismantling, damaging or disfiguring the structure and without moving furniture and interior furnishings. Areas that are concealed, hidden or inaccessible to view are not covered by this inspection. Some systems cannot be tested during this inspection as testing risks damaging the building. For example, overflow drains on bathtubs are not tested because if they were found to be leaking they could damage the finishes below. Our procedures involve non-invasive investigation and non-destructive testing which will limit the scope of the inspection.

This is not an inspection for code compliance

This inspection and report are not intended for city / local code compliance. During the construction process structures are inspected for code compliance by municipal inspectors. Framing is open at this time and conditions can be fully viewed. Framing is not open during inspections of finished homes, and this limits the inspection. All houses fall out of code compliance shortly after they are built, as the codes continually change. National codes are augmented at least every three years for all of the varying disciplines. Municipalities can choose to adopt and phase in sections of the codes on their own timetables. There are generally no requirements to bring older homes into compliance unless substantial renovation is being done.

This is just our opinion

Construction techniques and standards vary. There is no one way to build a house or install a system in a house. The observations in this report are the opinions of the home inspector. Other inspectors and contractors are likely to have some differing opinions. You are welcome to seek opinions from other professionals.

The scope of this inspection

This inspection will include the following systems: exterior, roof, structure, drainage surrounding the primary residence and detached garage, foundation, attic, interior, plumbing, electrical and heating. The evaluation will be based on limited observations that are primarily visual and non-invasive. This inspection and report are not intended to be technically exhaustive.

Your expectations

The overall goal of a home inspection is to help ensure that your expectations are appropriate with the house you are proposing to buy. To this end we assist with discovery by showing and documenting observations during the home inspection. This should not be mistaken for a technically exhaustive inspection designed to uncover every defect with a building. Such inspections are available but they are generally cost-prohibitive to most home buyers. Any recommendations for further evaluation made in this report should be addressed during the inspection contingency period.

Your participation is requested

Your presence is requested during this inspection. A written report will not substitute for all the possible information that can be conveyed verbally by a shared visual observation of the conditions of the property.

How to Read This Report

Getting the Information to You

This report is designed to deliver important and technical information in a way that is easy for anyone to access and understand. If you are in a hurry, you can take a quick look at our "Summary Page” and quickly get critical information for important decision making. However, we strongly recommend that you take the time to read the full Report, which includes digital photographs, captions, diagrams, descriptions, videos and hot links to additional information.

The best way to get the layers of information that are presented in this report is to read your report online, which will allow you to expand your learning about your house. You will notice some words or series of words highlighted in blue and underlined – clicking on these will provide you with a link to additional information.

This report can also be printed on paper or to a PDF document.

Chapters and Sections

This report is divided into chapters that parcel the home into logical inspection components. Each chapter is broken into sections that relate to a specific system or component of the home. You can navigate between chapters with the click of a button on the left side margin.

Most sections will contain some descriptive information done in black font. Observation narrative, done in colored boxes, will be included if a system or component is found to be significantly deficient in some way or if we wish to provide helpful additional information about the system or the scope of our inspection. If a system or component of the home was deemed to be in satisfactory or serviceable condition, there may be no narrative observation comments in that section and it may simply say “tested,” or “inspected.”

Observation Labels

All narrative observations are colored, numbered and labeled to help you find, refer to, and understand the severity of the observation. Observation colors and labels used in this report are:

- Major Concern:Repair items that may cost significant money to correct now or in the near future, or items that require immediate attention to prevent additional damage or eliminate safety hazards.

- Repair:Repair and maintenance items noted during inspection. Please note that some repair items can be expensive to correct such as re-finishing hardwood floors, but are considered simply repair items due to their cosmetic nature.

- Recommended Maintenance:These are repair items that should be considered "routine home ownership items," such as servicing the furnace, cleaning the gutters or changing the air filters in the furnace.

- Improve:Observations that are not necessarily defects, but which could be improved for safety, efficiency, or reliability reasons.

- Monitor:Items that should be watched to see if correction may be needed in the future.

- Due Diligence:Observation such as a buried oil tank that may require further investigation to determine the severity and / or urgency of repair.

- Future Project:A repair that may be deferred for some time but should be on the radar for repair or replacement in the near future.

- Efficiency:Denotes observations that are needed to make the home more energy efficient as well as to bring the home up to modern insulation standards. This category typically includes windows and insulation. Other items, such as lighting and appliances, are not inspected for their energy status.

- Completed:Items that were initially an issue but have since been completed.

- Note:Refers to aside information and /or any comments elaborating on descriptions of systems in the home or limitations to the home inspection.

- Description:Detailed description of various aspects of the property noted during the inspection.

Summary Page

The Summary Page is designed as a bulleted overview of all the observations noted during inspection. This helpful overview is not a substitution for reading the entire inspection report. The entire report must be read to get a complete understanding of this inspection report as the Summary Page does not include photographs or photo captions.

Summary

Major Concerns

- E-3 Electrical:

The wiring to the sub panel is undersized. The wire is #4 AWG copper which has a maximum rating of 70 A and is connected to a 125 A circuit breaker. This is a fire hazard which requires correction by a qualified electrician at this time.

- E-6 Electrical:

Low voltage (doorbell) wiring is sharing an electrical enclosure with standard house wiring in this enclosure in the basement. This is a fire hazard which requires correction by a qualified electrician at this time.

Repairs

- GD-1 Grounds and Drainage:

Improved drainage is needed along the upper edge of the retaining wall between the back patio and hillside. It does not appear to be adequate provisions to remove for enough water and there are apparent corresponding signs of settlement to the masonry wall and paving. Have this corrected by a qualified general or drainage contractor.

- GD-7 Grounds and Drainage:

The fencing along the top of the retaining wall at at the back of the property here is suffering from localized areas of wood rot. The fence is also shorter than current standards for safety (42"). At a minimum, rotten wood should be replaced. It is recommended that the entirety of the fence be upgraded for improved safety. The masonry wall in the back yard can likely be simply extended.

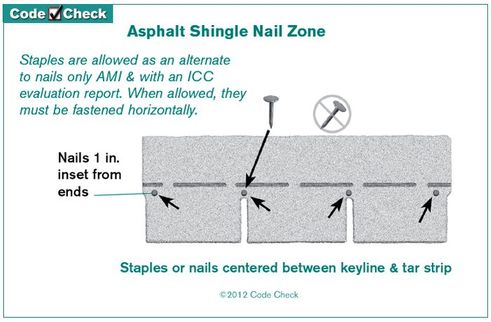

- RGC-1 Roof, Gutters, and Chimney:

Many locations were seen where nails were improperly placed on shingles and shingles are also placed too far apart. These are potential sources of water entry and should be further evaluated by a qualified roofing contractor. It may be possible to make repairs but be aware that these are installation defects which would require roof replacement in order to correct.

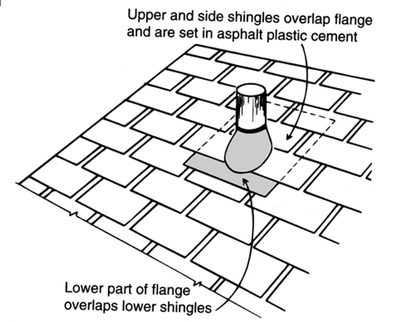

- RGC-2 Roof, Gutters, and Chimney:

Roof jack flashings are improperly integrated with the shingle surface which leaves them prone to water entry. These flashings should be installed in accordance with the attached illustration in order to properly shed water off the surface. Present installation is dependent on patching material which will require frequent maintenance to remain waterproof.

- RGC-3 Roof, Gutters, and Chimney:

Recommend removal or capping off of unused vent piping. These vents are open to the finished basement and will allow water and pest entry. Be aware that these are Transite pipe which likely contain asbestos and will need to be handled by an appropriate remediation specialist if removed or disturbed.

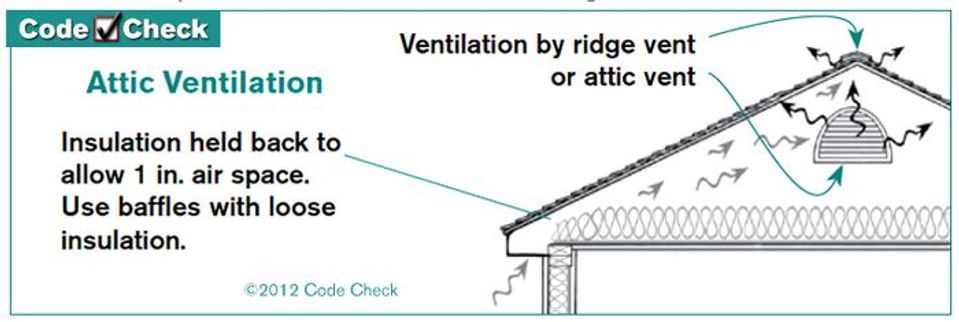

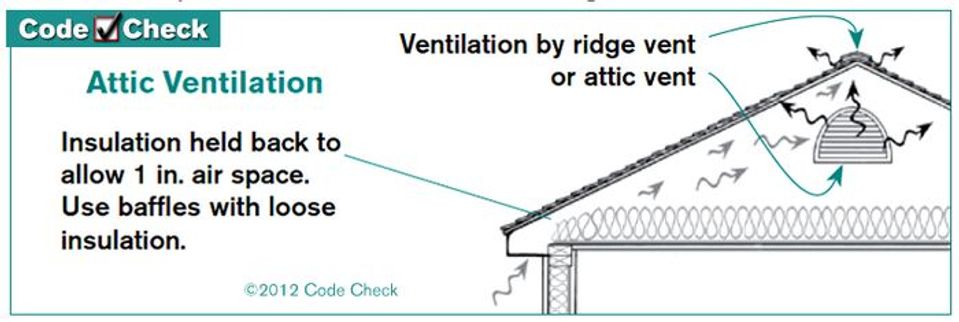

- RGC-4 Roof, Gutters, and Chimney:

Vent / flashing metal is rusted and corroded and unreliable. Recommend that as a solution in the short term that these be cleaned and painted to provide additional serviceable life. Have these replaced during the next roof replacement.

- RGC-7 Roof, Gutters, and Chimney:

One of the beams has been cut through to allow for the installation of a recessed light. Have this repaired by a qualified contractor to ensure reliable performance of the roof framing. In addition to supporting the interior finishes, the ceiling framing also serves to provide tension between the exterior walls.

- RGC-8 Roof, Gutters, and Chimney:

The attic and roof cavity ventilation looks to be inadequate. Standards recommend open ventilation levels in a ratio of 1 to 150 of the attic area. Proper attic ventilation is important for the roofing materials to perform as intended and to reduce chances for condensation problems and heat build-up in the attic. This is a common condition on older buildings that did not originally have composition roofs. As this building is made tighter and better insulated, and air-sealed for energy efficiency, it is important to improve roof cavity ventilation as well. Consult with a qualified general or roofing contractor about adding dormer or ridge vents for upper roof ventilation as needed.

- ED-1 Exterior and Decks:

Any objects which pass through the siding should be caulked or otherwise sealed to prevent water entry into the wall interior

- ED-3 Exterior and Decks:

The main entry door rubs against its frame. Trimming or adjustment needed for ease of use and to prevent damage to the finishes.

- ED-5 Exterior and Decks:

The deck surface is showing signs of age and localized decay. It is recommended that any damaged wood be further evaluated by a pest control professional and that any recommended repairs be completed as soon as possible for safety reasons. Also, secure any loose boards as needed to avoid a trip hazard.

- G-1 Garage:

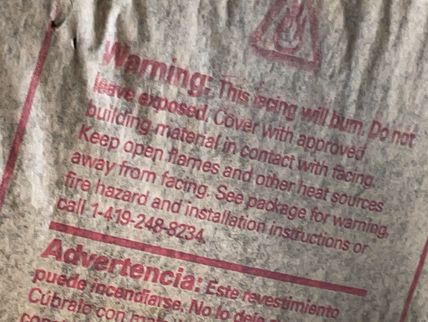

The insulation in the garage is installed upside down. The vapor barrier should be removed to prevent trapping moisture which can result in structural damage to the framing. The paper facing is also not treated for fire resistance and poses a hazard.

- G-3 Garage:

The laser eye safety mechanism for the overhead garage door has been set too high - this sensor should be no more than 6 inches off of the floor to perform as intended and prevent entrapment. Have this further evaluated and repaired by a garage door specialist.

- G-4 Garage:

The overhead garage door does not reverse under resistance to closing. Adjustment of the sensitivity by a qualified installer is recommended for improved safety. This typically involves adjusting a small plastic screw on the opener.

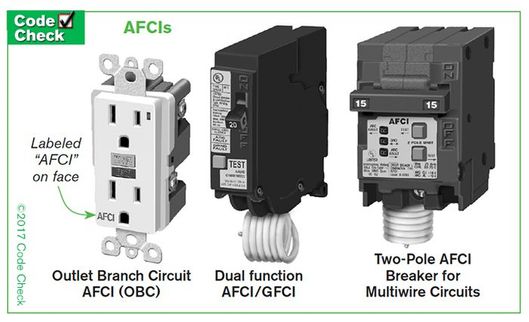

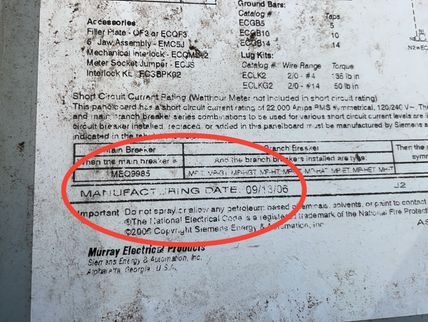

- E-1 Electrical:

This panel does not have AFCI (arc fault circuit interrupt) type breakers installed. These have been a requirement for circuits feeding sleeping areas since 2005 and more recently, for most all interior non dedicated circuits. This panel appears to have been recently installed (with a manufacture date of 2005) and these types of breakers should be present. Have this corrected by a qualified electrician

- E-2 Electrical:

There is damaged wiring in this panel where a connection is made to a circuit breaker. This should be repaired by a qualified electrician. Strands cut off like this reduce the effective wire gauge and can lead to an overheated situation.

- E-4 Electrical:

The wiring to the sub-panel requires repair. The neutrals should be on a floating bus bar and should be separated from the equipment grounds. Hire a licensed electrician to further evaluate and repair this condition.

- E-5 Electrical:

Corrosion was noted on one circuit inside the sub electric panel. This risks poor connections and should be further evaluated and repaired as recommended by a licensed electrician.

- E-7 Electrical:

There is improper wiring installed near the main electrical panel. This is an extension cord which should not be used as permanent wiring, has been left exposed and prone to damage, and the underground conduit which it is run through is open to the weather and will allow water entry. Have this improved by a qualified electrician.

- E-8 Electrical:

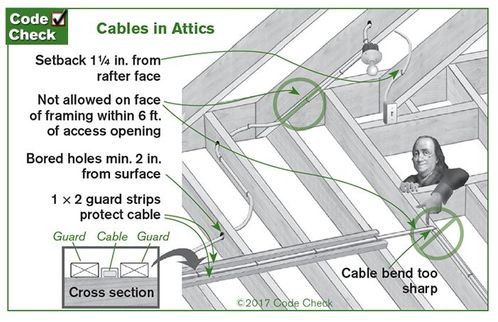

The open electrical junction boxes need to be covered for improved safety - see attic, crawl space, and basement ceiling. This is as simple as installing a cover plate over the box to protect the wiring. Sometimes, an extension ring is needed if finishes are covering the box. Repair as needed for improved safety.

- E-9 Electrical:

The non-metallic sheathed cable is poorly supported and requires staples or hangers for additional support and strain relief - see attic. This type of wiring should be supported every 4 feet and within 2 feet of junction boxes.

- E-11 Electrical:

Many of the receptacles tested as having open grounds. This is a common condition in older buildings (prior to 1962) where three prong receptacles have been installed on an older two wire system. This creates a safety hazard as appliances that rely on an equipment ground to discharge a fault can be plugged into ungrounded circuits. It is recommended that the older wiring present be updated to modern standards. Have a qualified electrician conduct further evaluation at this time.

- E-12 Electrical:

The exterior lights have broken or missing globes or covers - have an electrician repair or replace these old light fixtures.

- E-13 Electrical:

There is a light switch outside, that appears to be rated for interior use only. Have an electrician replace with a proper exterior rated electrical switch.

- E-14 Electrical:

The missing cover plates to electric receptacles, switches and junction boxes should be installed at this time to prevent entry.

- E-20 Electrical:

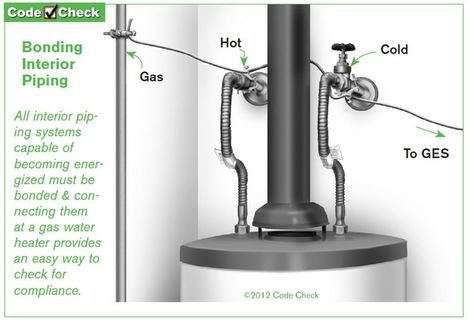

Have the electrical bonding system checked by a licensed electrician. Adequate bonding could not be verified at the main water pipe or the pipes by the water heater. This is an important safety feature to ensure safe control of stray voltage on metal systems in the house.

- P-1 Plumbing:

The static water pressure in the home tested above 80 PSI, the maximum allowed. High water pressure can put undue stress on the supply plumbing system and make it less reliable and vulnerable to leaks. A pressure reducing valve was noted in the home. This valve should be further evaluated and adjusted or repaired as needed so that water pressure inside the home is 80 PSI or less.

- P-2 Plumbing:

The galvanized steel supply pipe in this home looks to be at the end of its useful and reliable service life. Poor functional flow and multiple corrosion and leak points were noted. Hire a licensed plumbing contractor to further evaluate and replace this supply pipe.

- P-3 Plumbing:

Corrosion was seen on water piping in the crawlspace at the front of the house. This copper pipe appears to pass through a galvanized pipe or sleeve. Steel piping reacts with copper resulting in rapid deterioration. Have this repaired as recommended by a qualified plumbing contractor.

- P-5 Plumbing:

The discharge tube for the water heater temperature and pressure relief valve is missing and requires repair to eliminate a scald hazard. This is an important safety feature. Should the TPRV need to discharge, scalding water and steam would come out. This water and steam needs to be directed away from people. Hire a licensed plumber to further evaluate and repair. The discharge piping for the valve is required to terminate at the exterior and pointing downward within 6 inches of ground level

- P-6 Plumbing:

The condensate drain tube from this water heater is draining into the crawlspace. This needs to be extended to an approved location, such as the exterior, to avoid structural damage or deterioration. Have this corrected by a qualified plumbing contractor.

- LF-2 Laundry Facilities:

Foil or Mylar transition duct was noted in use to connect the dryer to the rigid vent. This product is not recommended as it has proven to be unreliable and a potential fire hazard. A corrugated metal flex duct is recommended.

- AP-1 Additional Plumbing:

The sprinkler valves are installed too close to grade. These valves are intended to be installed a certain height above the earth, generally 12", to ensure proper operation of the built-in backflow prevention devices. Failure of a backflow device can result in contamination of potable water with irrigation water which does carry some health risks. Recommend correction by a qualified plumbing or landscape contractor.

- FD-1 Fuel and Distribution:

The gas meter pressure regulator is too close to the furnace vent. It must be at least 3 feet away. Consult with your gas provider for an approved repair. This typically involves using an extension on the breather tube. Another solution would be to relocate the vent pipe for the furnace.

- FD-2 Fuel and Distribution:

Replacement of older style gas valves is recommended for reliability. There should also be a cap on any unused gas valves to ensure against leaks in the event of valve failure.

- HC4-1 Heating and Cooling:

There is evidence of a condensate leak which requires further investigation by a qualified HVAC technician. This condition could indicate internal corrosion or damage which may require repair.

- HC4-2 Heating and Cooling:

Gaps are present around the air return plenum which need to be better sealed. These will draw air in from the crawlspace and circulate it through the house.

- HC4-5 Heating and Cooling:

The insulation wrap around the refrigerant lines should be replaced. Damage is present which can result in condensate buildup which may then drip onto the structure beneath. At exterior locations, poor insulation will reduce overall efficiency of the system. Currently, 2 inch insulation is used to help maximize efficiency.

- HC4-6 Heating and Cooling:

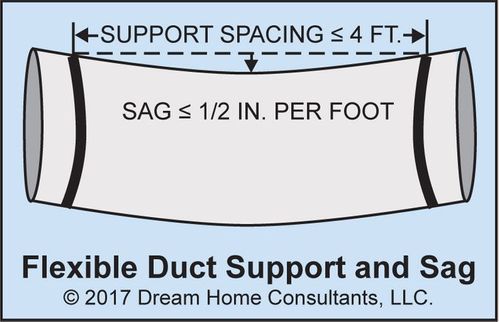

Some of the ductwork sags more than allowable. Improved support needed by a qualified HVAC technician

- FSF-1 Foundation and Structural Framing:

Efflorescence was seen on portions of the concrete footing indicating water saturation. This is typically the result of lack of ground slope away from the building and / or rain gutter downspout discharge too close to the foundation.

- CS-2 Crawl Space:

Damp soil was seen beneath the structure in the crawlspace. This is likely related to conditions discussed elsewhere regarding adjacent grade. This should be further evaluated by a drainage specialist who can advise regarding the best means of improvement to prevent ongoing issues with water entry and potential corresponding damage to the structure.

- I-1 Interior:

Stains were seen on the interior wall finish in the basement in the area shown here. This appears to be related to a plumbing leak from the bathroom above and is further discussed later in this report. Repair finishes following correction of the leak.

- I-5 Interior:

The sash springs that help the sash windows remain in the open position are damaged on several windows. These need to be replaced for proper operation of the windows.

- I-6 Interior:

Many of the wood windows are painted shut and are not performing as intended. Recommend cutting open all stuck windows and completing repairs to ensure reliable window performance.

- I-7 Interior:

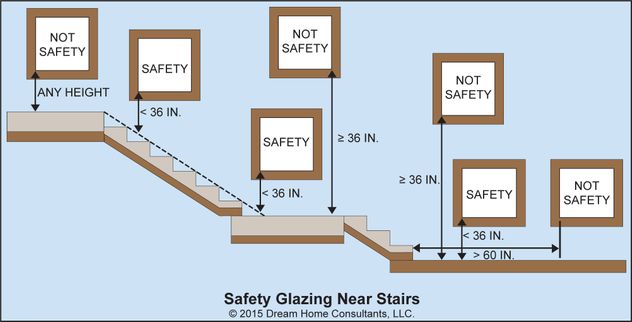

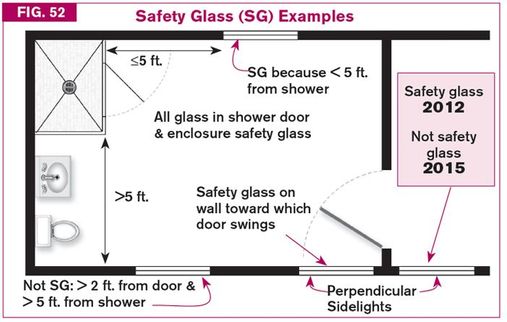

The window glass near the bathtubs should be safety glass according to current building standards. Updating this glazing is recommended.

- I-10 Interior:

Areas of apparent organic growth were noted on the interior of the basement storage cabinets at the back of the house. This should be further evaluated by a qualified environmental agency to determine the extent of repairs needed as well as cost. Be aware that health risks are associated with the presence of certain types of organic growth and that additional concealed damage could be present.

- K-2 Kitchen:

There is a leak where the kitchen sink faucet mounts to the plumbing within the wall. Have this further evaluated and repaired by a qualified plumbing contractor at this time. This condition risks damage to the finishes beneath and there is evidence of water entry to the cabinetry below

- K-3 Kitchen:

The kitchen sink faucet aerator is missing and should be installed.

- K-4 Kitchen:

Rust was seen on the flanges for the sink drain and disposer. Have a plumber replace parts as needed to ensure against leaks

- UB-2 Upstairs Bathroom:

The bathtub drain is leaking and requires immediate repair by a licensed plumber to prevent further water damage to the building.

- UB-4 Upstairs Bathroom:

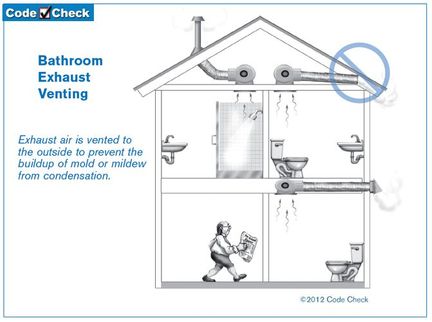

This exhaust fan is improperly venting into the attic. Have this extended to the exterior and terminate with use of a back draft damper. This repair may need to be coordinated with both a general and roofing contractor.

- DB-2 Downstairs Bathroom:

There is a leak where the angle shut off valve attaches to the plumbing coming from the wall which is in need of repair at this time by a qualified plumbing contractor. This would be a good opportunity to replace this older galvanized pipe.

- DB-3 Downstairs Bathroom:

The P-trap below the second downstairs bathroom sink is corroded. Although not currently leaking replacement is recommended now for improved reliability.

- DB-4 Downstairs Bathroom:

The escutcheons around the faucets are loose and should be sealed against the shower enclosure to prevent water seepage into the wall.

Recommended Maintenance Items

- GD-2 Grounds and Drainage:

Recommend cleaning and servicing the site drainage system to ensure all ground water and roof runoff is being reliably controlled and diverted away from the building.

- GD-4 Grounds and Drainage:

All trees, branches and vegetation should be pruned at least six feet away from the building to eliminate a condition conducive to wood destroying organisms and a path for pest entry. Branches in contact with the roof can also cause a significant amount of damage

- HC4-3 Heating and Cooling:

Annual servicing of the gas forced air furnaces is recommended for safe and reliable heat. The furnace was tested during inspection and was operational. The design life of these forced air furnaces is 15-20 years. Recommend having it serviced and keeping it on an annual service schedule.

- HC4-4 Heating and Cooling:

Heating and cooling contractors recommend annual servicing to ensure safe and reliable performance and to prolong the useful life of heating and cooling equipment. No recent service records were noted on this unit. Recommend having this system serviced and further evaluated by a qualified heating contractor if it has not been done in the last year. The system was tested during inspection and responded to normal operating controls.

Improves

- GD-5 Grounds and Drainage:

Some minor signs of settlement were noted to the retaining walls on this property which appears to be related to in adequate provisions for drainage. Improvements are needed at this time to prevent more serious structural damage and costly repairs. Weep holes were seen along the base of these walls to help alleviate hydrostatic pressure however there are no visible provisions for removing surface water. Have this improved by a qualified drainage contractor to ensure a long lifespan of the masonry walls

- GD-6 Grounds and Drainage:

The exterior stairs are missing a graspable handrail for safety. Have a qualified contractor build suitable railings to reduce the potential for falls.

- GD-8 Grounds and Drainage:

Cracking was seen on the masonry wall along the left side of the back patio. This appears to be related to issues with drainage discussed above. The wall is currently in serviceable condition however could require future repair of movement continues.

- ED-4 Exterior and Decks:

No tempered glass bug or logo was noted in the window - see adjacent to the walkways. Tempered or laminated glass is recommended in these locations for improved safety. Hire a glazing specialist to further evaluate and repair.

- ED-6 Exterior and Decks:

The openings for the deck guardrail are larger than modern standard of 4-inches. Caution should be used, especially around small children as they can often fit their head between this space of railing. Improving to modern standard is recommended.

- G-2 Garage:

The door between the house and the garage is not a listed fire resistant door and does not appear to meet the current recommended minimum requirements for a door between the house and the garage. Standards are for the door to be self closing, steel or solid wood - min 1 and 3/8 inches thick, or a 20-min rated door. This should be updated for improved safety.

- E-10 Electrical:

There is a portion of visible wiring present which is of an older type with cloth insulation. This insulation becomes brittle with age and breaks off leaving the metallic conductor exposed which is a shock and fire hazard. Have this older wiring further evaluated by a qualified electrician. Upgrading at this time is recommended.

- E-15 Electrical:

Updating the older two prong receptacles and the associated wiring is recommended. Most modern appliances require grounded circuits and the older wiring feeding these receptacles is not as safe as modern copper wiring. Have this older electrical system further evaluated by a qualified electrician at this time.

- E-16 Electrical:

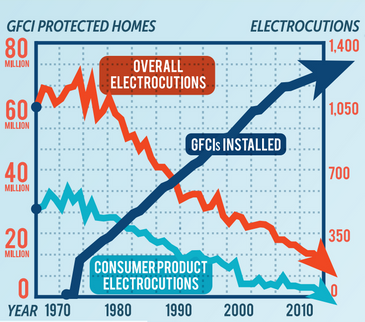

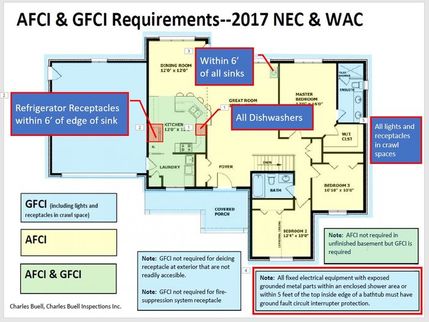

The use of GFCI (Ground Fault Circuit Interruption) protection is inconsistent with modern minimum standards for safety - see kitchen countertops. GFCI protection is recommended for the electrical receptacles in the following locations: the two dedicated kitchen appliance circuits, all receptacles within 6 feet of a sink, bathrooms, exterior, garage, unfinished basements, laundry and all wet and damp locations. GFCI's protect against electrocution by limiting the duration of an electrical shock. These are an important modern safety feature that have proven to save lives. Hire a licensed electrician to further evaluate and update GFCI protection for improved safety.

- P-4 Plumbing:

The cast iron and galvanized steel waste piping present is older and should be considered to be at or near the end of it serviceable life. No significant issues were currently noted however could develop at any time. Ideally this older material would be replaced in the near term as a preemptive measure to avoid the likely occurrence of clogs and leakage. Please note that with older material such as this no guarantee can be given regarding its ongoing performance. It is recommended that this older material be further evaluated by a qualified plumbing contractor.

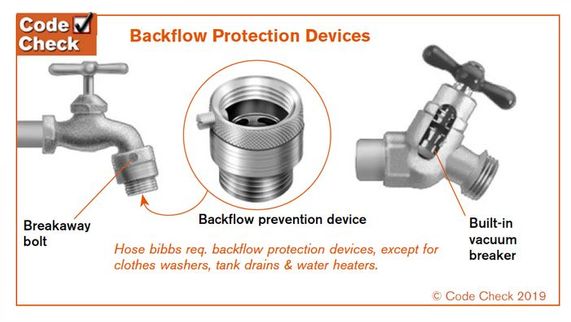

- P-7 Plumbing:

Backflow prevention devices are currently required at all hose bibs. Recommend installing as these devices are intended to minimize the chance of contamination of potable water.

- FD-3 Fuel and Distribution:

Gas meter lacks an automatic seismic shutoff valve. These are seismic protection that can automatically shut off the gas in the event of an earthquake and are required by current standards in most municipalities. Even if not required here, installation is recommended for additional safety to occupants.

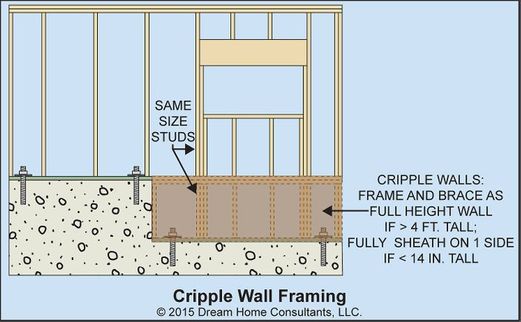

- FSF-2 Foundation and Structural Framing:

With older homes such as this, steps can be taken to improve seismic stability. Improvements include bolting the home to the foundation, adding sheer panels to cripple walls (if present) and installing positive connections between posts and beams. Consult with a licensed general contractor or company specializing in seismic retrofits to further evaluate and improve the structure.

It may be possible to qualify for financial assistance in this upgrade. Refer to the following link for further information regarding the earthquake brace and bolt program. https://www.earthquakebracebolt.com/

- CS-1 Crawl Space:

Recommend constructing a louvered cover for the crawlspace vent shown here. This will help prevent water entry from a wind driven rain as evidenced here.

- I-2 Interior:

There is an opening between the downstairs living area and crawlspace which will allow for loss of conditioned air and may reduce indoor air quality by allowing air into the interior from beneath the house. Recommend removal

- I-4 Interior:

The light fixture for the stairway is not situated in a location which provides illumination of the entirety of the stairs. Recommend relocation or addition of an additional fixture by a qualified electrician. This will help ensure safe use.

- I-8 Interior:

Recommend replacement of the missing locking hardware at this back facing window.

- UB-3 Upstairs Bathroom:

The tile grout is showing signs of absorbing moisture when running the shower. Tile and grout should be sealed and regularly maintained to minimize water penetration behind the tile. Plan on annual cleaning and sealing tile grout inside the shower surrounds to prolong the useful life of the tile. Prior to sealing, replace any failing grout and caulking at inside corners. At inside corners, sanded caulking works well and can be selected to match existing grout.

Due Diligences

- AP-2 Additional Plumbing:

An exterior irrigation system was noted for this home. Sprinkler systems are beyond the scope of this inspection. Irrigation systems often require annual attention / repair / servicing. Inquire with the seller for any information about this system. When testing the system, be sure sprinkler heads are adjusted so the system is not watering the side of the house. Hire a specialist to further evaluate this system as desired.

- I-9 Interior:

Evidence of animal entry into the attic and crawl space was discovered. Recommend inquiring with the seller regarding any history of animal problems and/or treatment. If no information is available, it is recommended that further evaluation be completed by a pest-control professional.

Efficiencies

- I-3 Interior:

Insulation is recommended on the dividing wall between the crawlspace and living space adjacent for both energy efficiency and interior comfort.

Notes

- GC-1 General Comments:

This home was occupied at the time of the inspection. Inspection of occupied homes presents some challenges as occupant belongings can obstruct visual inspection of and access to parts of the building. We do our best during inspection to work around belongings to discover as much as possible about the house without moving or damaging personal property, however, the presence of personal items does limit the inspection.

- GD-3 Grounds and Drainage:

Some of the subterranean drainage empties into what appears to be Orangeburg pipe. This type of pipe was created for sewage piping during wartime material shortages and has been found to be defective and prone to collapse. Updating this older pipe could be needed at any time.

- RGC-5 Roof, Gutters, and Chimney:

Some of the drip edge flashing has been cut where the gutters are fastened. This allows for a greater possibility of water damage to the wooden fascia however no damage was seen at the time of inspection.

- ED-2 Exterior and Decks:

Minor cracking was seen on the stucco finish in areas such as the back left corner shown here. This does not appear to be a structural defect.

- E-17 Electrical:

Some of the exterior lighting is controlled by either motion or daylight sensors which were not overridden to test.

- E-18 Electrical:

A mystery switch was found between the dining room and hallway. Inquire with the seller if desired.

- E-19 Electrical:

The link below includes important information about smoke alarms that could save lives in the event of a fire. There are two basic types of smoke alarms: ionization, which are better at detecting flaming fires and photoelectric, which are better at detecting smoldering fires. Standards in the building industry are moving toward recommending BOTH types of detectors in the home. It is nearly impossible to accurately test smoke alarms during a home inspection and testing is outside the scope of this evaluation. Recommend learning more about these important life saving devices and consider installing both types of smoke detectors in your home.

- LF-1 Laundry Facilities:

Repairs were seen on the wall surface behind the laundry appliances. Consult with the seller for any history of repair here if desired.

- FD-4 Fuel and Distribution:

The natural gas service piping appears to be constructed of plastic (polyethylene). This pipe can be easily damaged during excavation or drilling and precautions should be taken prior to any construction related work. There is no tracer wire attached would ideally be present to locate this pipe with specialized equipment.

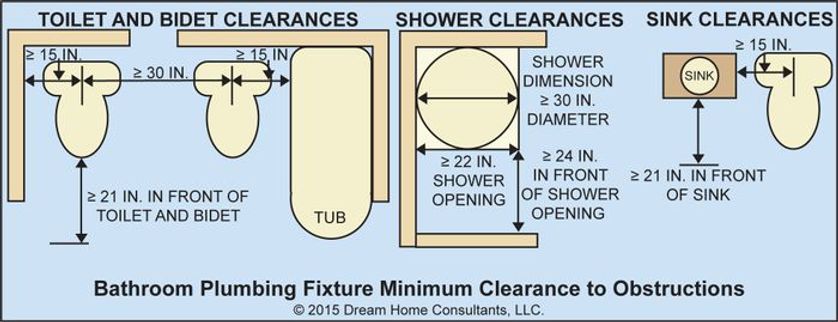

- UB-5 Upstairs Bathroom:

Less than standard clearances are present around the fixtures in this bathroom.

- DB-5 Downstairs Bathroom:

Less than standard clearances are present around the fixtures in this bathroom.

The Full Report

General Comments

Building Characteristics, Conditions and Limitations

Type of Building : Single Family (2-story)

Approximate Year of Original Construction: 1950

Unless the wiring in the building has been fully updated, this building likely has wiring that predates the late 1980's. Branch circuit wiring installed in buildings built prior to the late 1980s is typically rated for a maximum temperature of only 60 degrees Celsius. This includes non-metallic sheathed (Romex) wiring, and both BX and AC metal-clad flexible wiring. Knob and tube wiring, typically installed in homes built prior to 1950, may be rated for even lower maximum temperatures. Newer electric fixtures including lighting and fans typically require wiring rated for 90 degrees Celsius. Connecting newer fixtures to older, 60-degree-rated wiring is a potential fire hazard. Repairs for such conditions may involve replacing the last few feet of wiring to newer fixtures with new 90-degree-rated wire, and installing a junction box to join the old and new wiring. It is beyond the scope of this inspection to determine if any such incompatible components are installed. Based on the age of this building, be aware that such components may be present.

In 1978, federal laws were passed to prohibit use of lead and asbestos in building materials. Manufacturers of building materials were allowed to sell existing stocks of materials that were manufactured with lead and asbestos, so even buildings constructed as late as the mid-1980's could possibly contain lead or asbestos. Identification and testing for lead and asbestos and other environmental testing is beyond the scope of this home inspection. If you wish to seek additional information, recommend contacting an environmental lab or industrial hygienist.

Attending the Inspection: Buyer's Agent, Seller

Occupancy: Occupied

Weather during the inspection: Clear

Approximate temperature during the inspection: Over 70[F]

Ground/Soil surface conditions: Dry

For the Purposes of This Report, the Front Door Faces: Southwest

This home was occupied at the time of the inspection. Inspection of occupied homes presents some challenges as occupant belongings can obstruct visual inspection of and access to parts of the building. We do our best during inspection to work around belongings to discover as much as possible about the house without moving or damaging personal property, however, the presence of personal items does limit the inspection.

Grounds and Drainage

Drainage and Lot Location

Clearance to Grade: Standard

Downspout Discharge: Above grade

Site Description: Moderate slope

Improved drainage is needed along the upper edge of the retaining wall between the back patio and hillside. It does not appear to be adequate provisions to remove for enough water and there are apparent corresponding signs of settlement to the masonry wall and paving. Have this corrected by a qualified general or drainage contractor.

Recommend cleaning and servicing the site drainage system to ensure all ground water and roof runoff is being reliably controlled and diverted away from the building.

Driveways/Walkways/Paving

Driveway: Concrete

Walkways: Concrete

Patios: Concrete, Tile

Grounds, Trees and Vegetation

Trees/Vegetation too near building: Yes

Retaining Wall

Some minor signs of settlement were noted to the retaining walls on this property which appears to be related to in adequate provisions for drainage. Improvements are needed at this time to prevent more serious structural damage and costly repairs. Weep holes were seen along the base of these walls to help alleviate hydrostatic pressure however there are no visible provisions for removing surface water. Have this improved by a qualified drainage contractor to ensure a long lifespan of the masonry walls

Exterior Stairs

Fences, Gates, and Walls

The fencing along the top of the retaining wall at at the back of the property here is suffering from localized areas of wood rot. The fence is also shorter than current standards for safety (42"). At a minimum, rotten wood should be replaced. It is recommended that the entirety of the fence be upgraded for improved safety. The masonry wall in the back yard can likely be simply extended.

Roof, Gutters, and Chimney

Roof Materials

Method of Roof Inspection: Walked on roof

Roof Style: Hip

Flashings: Non-Standard

Roof Covering Materials: Architectural grade composition shingle

Approximate Age: 10+ years

Overlay Roof: No

Many locations were seen where nails were improperly placed on shingles and shingles are also placed too far apart. These are potential sources of water entry and should be further evaluated by a qualified roofing contractor. It may be possible to make repairs but be aware that these are installation defects which would require roof replacement in order to correct.

Roof jack flashings are improperly integrated with the shingle surface which leaves them prone to water entry. These flashings should be installed in accordance with the attached illustration in order to properly shed water off the surface. Present installation is dependent on patching material which will require frequent maintenance to remain waterproof.

Recommend removal or capping off of unused vent piping. These vents are open to the finished basement and will allow water and pest entry. Be aware that these are Transite pipe which likely contain asbestos and will need to be handled by an appropriate remediation specialist if removed or disturbed.

Vent / flashing metal is rusted and corroded and unreliable. Recommend that as a solution in the short term that these be cleaned and painted to provide additional serviceable life. Have these replaced during the next roof replacement.

Roof Drainage

Gutter and Downspout Materials: Galvanized

Roof Framing and Sheathing

Rafters: 2x6

Sheathing: Plywood

One of the beams has been cut through to allow for the installation of a recessed light. Have this repaired by a qualified contractor to ensure reliable performance of the roof framing. In addition to supporting the interior finishes, the ceiling framing also serves to provide tension between the exterior walls.

Attic Insulation

Insulation Type: Fiberglass

Attic and Roof Cavity Ventilation

Attic Ventilation Method: Soffit vents

Attic and roof cavity ventilation is a frequently-misunderstood element of residential construction. All roof cavities are required to have ventilation. The general default standard is 1 to 150 of the attic area and ideally, this comes from at least 60% lower roof cavity ventilation and 40% upper however this is an over-simplifications of the subject. As a good guiding principle the most important elements for healthy attic spaces, which are traditionally insulated and ventilated are:

- Make sure the ceiling between the living space and the attic is airtight

- Ventilate consistently across the whole lower part of the roof cavity with low, intake soffit venting

- Upper roof cavity venting is less important and if over-installed can exacerbate air migration into the attic from the living space.

- Avoid power ventilators which can depressurize the attic and exacerbate air migration from the house into the attic.

For more information, please see: Link

The attic and roof cavity ventilation looks to be inadequate. Standards recommend open ventilation levels in a ratio of 1 to 150 of the attic area. Proper attic ventilation is important for the roofing materials to perform as intended and to reduce chances for condensation problems and heat build-up in the attic. This is a common condition on older buildings that did not originally have composition roofs. As this building is made tighter and better insulated, and air-sealed for energy efficiency, it is important to improve roof cavity ventilation as well. Consult with a qualified general or roofing contractor about adding dormer or ridge vents for upper roof ventilation as needed.

Exterior and Decks

Siding and Trim

Any objects which pass through the siding should be caulked or otherwise sealed to prevent water entry into the wall interior

Eaves

Open rafters

Exterior Doors

Solid core

Exterior Windows

Balcony

Present

To see a prescriptive guide for residential wood deck construction click this link.

Deck Structure: Non-treated lumber

Deck Ledger Board: Not applicable

Guardrail: Non-standard

Decking Material: Softwood

The deck surface is showing signs of age and localized decay. It is recommended that any damaged wood be further evaluated by a pest control professional and that any recommended repairs be completed as soon as possible for safety reasons. Also, secure any loose boards as needed to avoid a trip hazard.

The openings for the deck guardrail are larger than modern standard of 4-inches. Caution should be used, especially around small children as they can often fit their head between this space of railing. Improving to modern standard is recommended.

Garage

Garage - General

The insulation in the garage is installed upside down. The vapor barrier should be removed to prevent trapping moisture which can result in structural damage to the framing. The paper facing is also not treated for fire resistance and poses a hazard.

The door between the house and the garage is not a listed fire resistant door and does not appear to meet the current recommended minimum requirements for a door between the house and the garage. Standards are for the door to be self closing, steel or solid wood - min 1 and 3/8 inches thick, or a 20-min rated door. This should be updated for improved safety.

Garage - Overhead Door and Opener

Automatic Garage Opener: Sensitivity (Inadequate - 1 Door), Laser Eyes (Too High)

Garage Door Type: Metal

The laser eye safety mechanism for the overhead garage door has been set too high - this sensor should be no more than 6 inches off of the floor to perform as intended and prevent entrapment. Have this further evaluated and repaired by a garage door specialist.

The overhead garage door does not reverse under resistance to closing. Adjustment of the sensitivity by a qualified installer is recommended for improved safety. This typically involves adjusting a small plastic screw on the opener.

Garage - Floor

Garage Slab: Concrete

Electrical

Electric Service

Service Entrance: Above Ground

Service Equipment

Main Panel Rating: 200 amps

Electric Service Amperage: 200 amps

Main Electric Panel Location: Exterior - Right Side

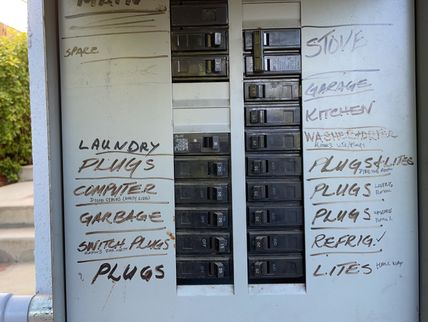

Panel Manufacturer: Murray

This panel does not have AFCI (arc fault circuit interrupt) type breakers installed. These have been a requirement for circuits feeding sleeping areas since 2005 and more recently, for most all interior non dedicated circuits. This panel appears to have been recently installed (with a manufacture date of 2005) and these types of breakers should be present. Have this corrected by a qualified electrician

Sub Panel

Service Conductor Size: Copper, #4, 60 amps

Sub Panel Amperage: 125 amps

Sub Panel Manufacturer: Crouse Hinds

The wiring to the sub panel is undersized. The wire is #4 AWG copper which has a maximum rating of 70 A and is connected to a 125 A circuit breaker. This is a fire hazard which requires correction by a qualified electrician at this time.

The wiring to the sub-panel requires repair. The neutrals should be on a floating bus bar and should be separated from the equipment grounds. Hire a licensed electrician to further evaluate and repair this condition.

Branch Wiring

Wire Material: Copper, Multi-strand Copper

Percentage Visible: 30-40%

Wiring Method: Non-metallic sheathed cable, Flex conduit

Low voltage (doorbell) wiring is sharing an electrical enclosure with standard house wiring in this enclosure in the basement. This is a fire hazard which requires correction by a qualified electrician at this time.

There is improper wiring installed near the main electrical panel. This is an extension cord which should not be used as permanent wiring, has been left exposed and prone to damage, and the underground conduit which it is run through is open to the weather and will allow water entry. Have this improved by a qualified electrician.

The open electrical junction boxes need to be covered for improved safety - see attic, crawl space, and basement ceiling. This is as simple as installing a cover plate over the box to protect the wiring. Sometimes, an extension ring is needed if finishes are covering the box. Repair as needed for improved safety.

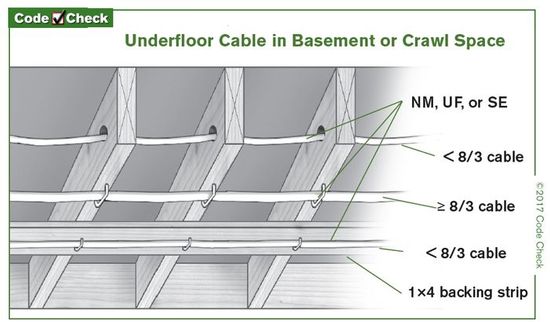

The non-metallic sheathed cable is poorly supported and requires staples or hangers for additional support and strain relief - see attic. This type of wiring should be supported every 4 feet and within 2 feet of junction boxes.

There is a portion of visible wiring present which is of an older type with cloth insulation. This insulation becomes brittle with age and breaks off leaving the metallic conductor exposed which is a shock and fire hazard. Have this older wiring further evaluated by a qualified electrician. Upgrading at this time is recommended.

Receptacles and Fixtures

Inspection Method: Random Testing

Electric Receptacles: Three wire and two wire receptacles

Many of the receptacles tested as having open grounds. This is a common condition in older buildings (prior to 1962) where three prong receptacles have been installed on an older two wire system. This creates a safety hazard as appliances that rely on an equipment ground to discharge a fault can be plugged into ungrounded circuits. It is recommended that the older wiring present be updated to modern standards. Have a qualified electrician conduct further evaluation at this time.

The exterior lights have broken or missing globes or covers - have an electrician repair or replace these old light fixtures.

There is a light switch outside, that appears to be rated for interior use only. Have an electrician replace with a proper exterior rated electrical switch.

The missing cover plates to electric receptacles, switches and junction boxes should be installed at this time to prevent entry.

Updating the older two prong receptacles and the associated wiring is recommended. Most modern appliances require grounded circuits and the older wiring feeding these receptacles is not as safe as modern copper wiring. Have this older electrical system further evaluated by a qualified electrician at this time.

The use of GFCI (Ground Fault Circuit Interruption) protection is inconsistent with modern minimum standards for safety - see kitchen countertops. GFCI protection is recommended for the electrical receptacles in the following locations: the two dedicated kitchen appliance circuits, all receptacles within 6 feet of a sink, bathrooms, exterior, garage, unfinished basements, laundry and all wet and damp locations. GFCI's protect against electrocution by limiting the duration of an electrical shock. These are an important modern safety feature that have proven to save lives. Hire a licensed electrician to further evaluate and update GFCI protection for improved safety.

Some of the exterior lighting is controlled by either motion or daylight sensors which were not overridden to test.

Smoke and Carbon Monoxide Alarm Systems

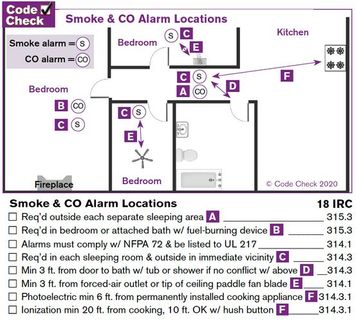

CO Alarms Noted: Outside all Sleeping Areas

Outside all Sleeping Areas

Smoke Alarms Noted: In All Bedrooms

In All Bedrooms

Smoke Alarms: Present

Present  Additional Info

Additional Info

For reliability, fire marshals recommended updating smoke alarms every 10 years and changing batters bi-annually. The latest data indicate that we should be using photo-electric technology in our smoke alarms for improved fire detection and to reduce problems with false alarms which can lead to disabling of this important safety system. Unfortunately, the alarms have to be removed to determine if they are photo-electric or ionization types. It is surprisingly complex to accurately test a smoke alarm system and determine the reliability, age, and type of sensor technology used, especially as many homes can have half a dozen or more alarms throughout the house. Evaluation of smoke alarms is beyond the scope of this inspection. For optimal fire safety, it is recommended to learn about how to service and maintain your smoke alarm system to keep the building occupants safe. For more information, please read this link. For more information, please read this link.

The link below includes important information about smoke alarms that could save lives in the event of a fire. There are two basic types of smoke alarms: ionization, which are better at detecting flaming fires and photoelectric, which are better at detecting smoldering fires. Standards in the building industry are moving toward recommending BOTH types of detectors in the home. It is nearly impossible to accurately test smoke alarms during a home inspection and testing is outside the scope of this evaluation. Recommend learning more about these important life saving devices and consider installing both types of smoke detectors in your home.

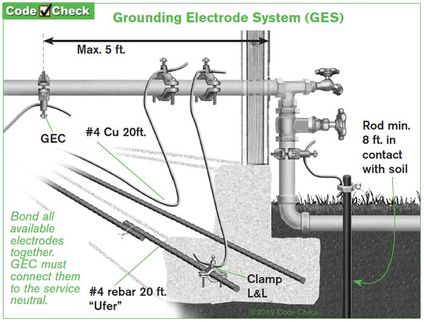

Electrical Grounding System

Present - Could Not Confirm

During a home or property inspection, every effort is made to inspect the visible components of the electrical system grounding. The grounding system is critical for safely discharging electrical surges, especially in the case of lightning strikes. There is no way in the context of a home inspection to verify the "effectiveness" of the grounding system as much of the system is not visible and there are not practical tests one can perform in the way we can test a furnace or a plumbing fixture. However, there are many things that can indicate the need for further evaluation of the grounding system by a licensed electrical contractor and they will be documented in the observations below if discovered.

Electrical Bonding System

Plumbing

Water Service Supply

Pipe Material: Copper

Water Supply: Public water

Water Pressure: 105 PSI

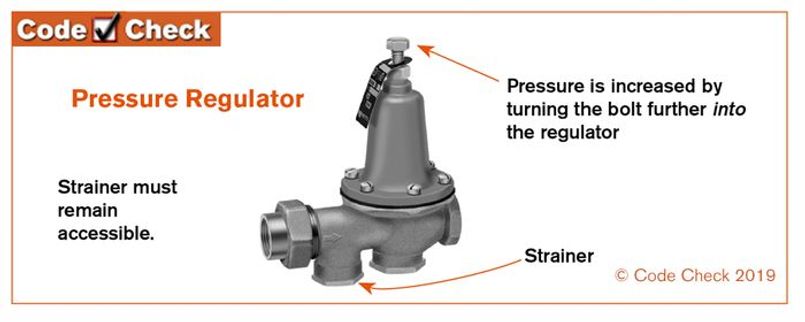

Pressure Reducing Valve: Present

This house has a pressure reducing valve to control high water pressure in the street.

The static water pressure in the home tested above 80 PSI, the maximum allowed. High water pressure can put undue stress on the supply plumbing system and make it less reliable and vulnerable to leaks. A pressure reducing valve was noted in the home. This valve should be further evaluated and adjusted or repaired as needed so that water pressure inside the home is 80 PSI or less.

Distribution Pipe

Supply Pipe Materials: Copper, Galvanized steel

Percentage Seen: 50-60%

Functional Flow: Average

Angle Stops Testing Note

Angle stops are the shut offs located below plumbing fixtures such as sinks and toilets. These are designed so that water can be shut off locally to a fixture without shutting off the water to the entire house so that localized fixtures can be serviced and repaired or replaced. Home inspectors do NOT test angle stops during inspection as there is a risk of leakage which could cause damage to the home.

The galvanized steel supply pipe in this home looks to be at the end of its useful and reliable service life. Poor functional flow and multiple corrosion and leak points were noted. Hire a licensed plumbing contractor to further evaluate and replace this supply pipe.

Waste Pipe and Discharge

Discharge Type: Unknown

Please note that there is the possibility that a system is not as it is listed; for example, a property could be listed as a public sewer system when in fact it is on a private septic system. This is unlikely, but is another reason why we recommend further evaluation of all sewage discharge systems.

Waste and Vent Pipe Materials: ABS plastic, Galvanized steel, Cast Iron

Percentage Seen: 40-50%

The cast iron and galvanized steel waste piping present is older and should be considered to be at or near the end of it serviceable life. No significant issues were currently noted however could develop at any time. Ideally this older material would be replaced in the near term as a preemptive measure to avoid the likely occurrence of clogs and leakage. Please note that with older material such as this no guarantee can be given regarding its ongoing performance. It is recommended that this older material be further evaluated by a qualified plumbing contractor.

Water Heater

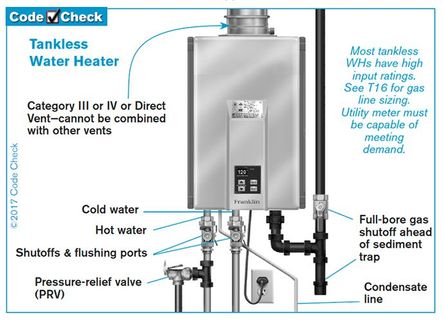

System Type: Tankless

This building has hot water provided by a tankless hot water heater. The typical lifespan of this type of water heater is 15 to 20 years however is installation and maintenance dependent. Annual flushing is typically recommended for these types of water heaters to ensure safe and reliable performance. Recommend having this water heater professionally serviced at this time and annually moving forward as a part of routine scheduled maintenance.

Manufacturer: Navien

Size: 150k btu/h

Age: 2020

Energy Source: Gas

Temperature Pressure Relief Value: Missing Tube

The discharge tube for the water heater temperature and pressure relief valve is missing and requires repair to eliminate a scald hazard. This is an important safety feature. Should the TPRV need to discharge, scalding water and steam would come out. This water and steam needs to be directed away from people. Hire a licensed plumber to further evaluate and repair. The discharge piping for the valve is required to terminate at the exterior and pointing downward within 6 inches of ground level

Laundry Facilities

Washer Hookups

Not tested

Dryer Hookups

Foil or Mylar transition duct was noted in use to connect the dryer to the rigid vent. This product is not recommended as it has proven to be unreliable and a potential fire hazard. A corrugated metal flex duct is recommended.

Laundry Sinks

Tested

Additional Plumbing

Landscape Irrigation

Common Observations: Too Close to Grade, Note for Buyer - Disclaim

The sprinkler valves are installed too close to grade. These valves are intended to be installed a certain height above the earth, generally 12", to ensure proper operation of the built-in backflow prevention devices. Failure of a backflow device can result in contamination of potable water with irrigation water which does carry some health risks. Recommend correction by a qualified plumbing or landscape contractor.

An exterior irrigation system was noted for this home. Sprinkler systems are beyond the scope of this inspection. Irrigation systems often require annual attention / repair / servicing. Inquire with the seller for any information about this system. When testing the system, be sure sprinkler heads are adjusted so the system is not watering the side of the house. Hire a specialist to further evaluate this system as desired.

Fuel and Distribution

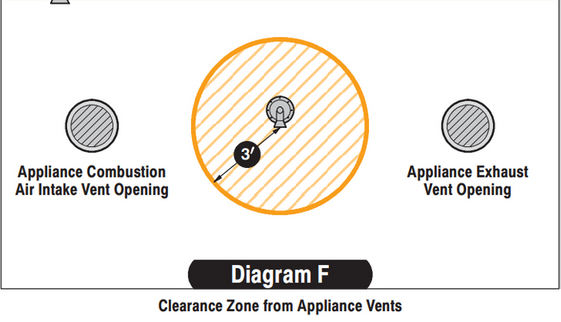

Gas Meter

Present

Gas Shutoff Location: South side of structure

Gas Pipe Materials: Steel and flex pipe

Seismic Shutoff: No

The gas meter pressure regulator is too close to the furnace vent. It must be at least 3 feet away. Consult with your gas provider for an approved repair. This typically involves using an extension on the breather tube. Another solution would be to relocate the vent pipe for the furnace.

Replacement of older style gas valves is recommended for reliability. There should also be a cap on any unused gas valves to ensure against leaks in the event of valve failure.

Gas meter lacks an automatic seismic shutoff valve. These are seismic protection that can automatically shut off the gas in the event of an earthquake and are required by current standards in most municipalities. Even if not required here, installation is recommended for additional safety to occupants.

Gas, Propane and Oil Piping

Gas Piping Materials Noted: Steel, Polyethylene

The natural gas service piping appears to be constructed of plastic (polyethylene). This pipe can be easily damaged during excavation or drilling and precautions should be taken prior to any construction related work. There is no tracer wire attached would ideally be present to locate this pipe with specialized equipment.

Heating and Cooling

Heating Element

Energy Source: Natural gas

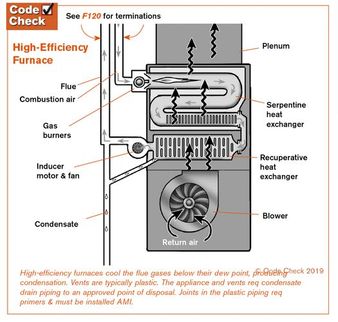

Heating Method: Gas forced air furnace - High efficiency

This house has a high efficiency gas forced air furnace. A critical component to all combustion equipment like this is the heat exchanger. This is the welded clam-shell piece of metal inside the furnace that contains the products of combustion so that moisture, carbon monoxide and other products of combustion do not mix with interior air and get safely vented to the exterior. Heat exchangers on modern furnaces have an average life expectancy of 15-20 years. Unfortunately, heat exchangers are buried inside of heating equipment; they are not visible and specifically excluded from a home inspection.

Manufacturer: Goodman

Capacity: 76,800 btu

Age: 2016

Last Service Record: None

There is evidence of a condensate leak which requires further investigation by a qualified HVAC technician. This condition could indicate internal corrosion or damage which may require repair.

Gaps are present around the air return plenum which need to be better sealed. These will draw air in from the crawlspace and circulate it through the house.

Annual servicing of the gas forced air furnaces is recommended for safe and reliable heat. The furnace was tested during inspection and was operational. The design life of these forced air furnaces is 15-20 years. Recommend having it serviced and keeping it on an annual service schedule.

Air Filters

Filtration Systems: Disposable

This heating and cooling system has disposable air filters installed. These should be changed every 30-45 days during regular use to ensure proper air flow at the furnace. Be sure to install the filters with the arrows pointing in the same direction as the air flow in the furnace.

Condenser

Manufacturer: Goodman

System Type: Split System

Size: 4 Tons

Energy Source: Electric

Age: 2016

Heating and cooling contractors recommend annual servicing to ensure safe and reliable performance and to prolong the useful life of heating and cooling equipment. No recent service records were noted on this unit. Recommend having this system serviced and further evaluated by a qualified heating contractor if it has not been done in the last year. The system was tested during inspection and responded to normal operating controls.

The insulation wrap around the refrigerant lines should be replaced. Damage is present which can result in condensate buildup which may then drip onto the structure beneath. At exterior locations, poor insulation will reduce overall efficiency of the system. Currently, 2 inch insulation is used to help maximize efficiency.

Foundation and Structural Framing

Foundation

% of Foundation Not Visible: 50%

Evidence of Seismic Protection: Some Signs

Building Configuration: Crawl space, Basement

Foundation Description: Poured concrete

Efflorescence was seen on portions of the concrete footing indicating water saturation. This is typically the result of lack of ground slope away from the building and / or rain gutter downspout discharge too close to the foundation.

With older homes such as this, steps can be taken to improve seismic stability. Improvements include bolting the home to the foundation, adding sheer panels to cripple walls (if present) and installing positive connections between posts and beams. Consult with a licensed general contractor or company specializing in seismic retrofits to further evaluate and improve the structure.

It may be possible to qualify for financial assistance in this upgrade. Refer to the following link for further information regarding the earthquake brace and bolt program. https://www.earthquakebracebolt.com/

Floor, Wall and Ceiling Framing

Wall Framing: Not visible

Wall Sheathing: Not visible

Floor Framing: Visible

Sub-Floor Material: Partly visible

Ceiling Framing: Partly visible

Crawl Space

Crawl Space Access

Method of Inspection: Walked

Crawl Space Ventilation

Ventilation Method: Exterior wall vents

Insulation

Insulation Type: None noted

Moisture Conditions

Damp soil was seen beneath the structure in the crawlspace. This is likely related to conditions discussed elsewhere regarding adjacent grade. This should be further evaluated by a drainage specialist who can advise regarding the best means of improvement to prevent ongoing issues with water entry and potential corresponding damage to the structure.

Interior

Floors and Floor Materials

Floor Materials: Hardwood, Tile

Floor Settlement: None noted

Walls, Ceilings, Trim and Closets

Wall and Ceiling Materials: Plaster, Wood paneling

Wall Insulation and Air Bypass

Wall Insulation: Not Visible

There is an opening between the downstairs living area and crawlspace which will allow for loss of conditioned air and may reduce indoor air quality by allowing air into the interior from beneath the house. Recommend removal

Stairs and Railings

Interior Doors

Hollow Core

Windows

Window Glazing: Single pane, Double pane

Interior Window Frame: Wood, Metal

Window Styles: Sliding, Single hung

The sash springs that help the sash windows remain in the open position are damaged on several windows. These need to be replaced for proper operation of the windows.

Many of the wood windows are painted shut and are not performing as intended. Recommend cutting open all stuck windows and completing repairs to ensure reliable window performance.

The window glass near the bathtubs should be safety glass according to current building standards. Updating this glazing is recommended.

Pests

Evidence of animal entry into the attic and crawl space was discovered. Recommend inquiring with the seller regarding any history of animal problems and/or treatment. If no information is available, it is recommended that further evaluation be completed by a pest-control professional.

Environmental

Areas of apparent organic growth were noted on the interior of the basement storage cabinets at the back of the house. This should be further evaluated by a qualified environmental agency to determine the extent of repairs needed as well as cost. Be aware that health risks are associated with the presence of certain types of organic growth and that additional concealed damage could be present.

Kitchen

Sinks and Faucets

There is a leak where the kitchen sink faucet mounts to the plumbing within the wall. Have this further evaluated and repaired by a qualified plumbing contractor at this time. This condition risks damage to the finishes beneath and there is evidence of water entry to the cabinetry below

Cabinets and Countertops

Countertop Material: Engineered Stone

Cabinet Material: Wood laminate

Ventilation Method

Fan Ducted to Exterior

Appliances

Refrigerator: Not inspected

Dishwasher: Operated

Dishwasher Air Gap: Present

Range/ Oven /Cook-tops: Gas

Disposer: Operated

General Kitchen Condition

Standard

Upstairs Bathroom

Sinks and Cabinets

Tested

Toilet

Tested

Bathtub / Shower

The bathtub drain is leaking and requires immediate repair by a licensed plumber to prevent further water damage to the building.

The tile grout is showing signs of absorbing moisture when running the shower. Tile and grout should be sealed and regularly maintained to minimize water penetration behind the tile. Plan on annual cleaning and sealing tile grout inside the shower surrounds to prolong the useful life of the tile. Prior to sealing, replace any failing grout and caulking at inside corners. At inside corners, sanded caulking works well and can be selected to match existing grout.

Bathroom Ventilation

Downstairs Bathroom

Sinks and Cabinets

There is a leak where the angle shut off valve attaches to the plumbing coming from the wall which is in need of repair at this time by a qualified plumbing contractor. This would be a good opportunity to replace this older galvanized pipe.

Toilet

Tested

Bathtub / Shower

Bathroom Ventilation

Type: Operable window

Checking Out Procedure

Check Out List

Oven: Off

Off

Lights: Off

Off Client and Realtor Still In House

Client and Realtor Still In House Client Still in House

Client Still in House Realtor Still in House

Realtor Still in House

Heating and Cooling: Restored to Pre-inspection temperatures

Restored to Pre-inspection temperatures

Appliances: Off / finishing cycle

Off / finishing cycle