The Scope and Purpose of a Home Inspection

Purchasing property involves risk

The purpose of a home inspection is to help reduce the risk associated with the purchase of a structure by providing a professional opinion about the overall condition of the structure. A home inspection is a limited visual inspection and it cannot eliminate this risk. Some homes present more risks than others. We cannot control this, but we try to help educate you about what we don’t know during the inspection process. This is more difficult to convey in a report and one of many reasons why we recommend that you attend the inspection.

A home inspection is not an insurance policy

This report does not substitute for or serve as a warranty or guarantee of any kind. Home warranties can be purchased separately from insuring firms that provide this service.

A home inspection is visual and not destructive

The descriptions and observations in this report are based on a visual inspection of the structure. We inspect the aspects of the structure that can be viewed without dismantling, damaging or disfiguring the structure and without moving furniture and interior furnishings. Areas that are concealed, hidden or inaccessible to view are not covered by this inspection. Some systems cannot be tested during this inspection as testing risks damaging the building. For example, overflow drains on bathtubs are not tested because if they were found to be leaking they could damage the finishes below. Our procedures involve non-invasive investigation and non-destructive testing which will limit the scope of the inspection.

This is not an inspection for code compliance

This inspection and report are not intended for city / local code compliance. During the construction process structures are inspected for code compliance by municipal inspectors. Framing is open at this time and conditions can be fully viewed. Framing is not open during inspections of finished homes, and this limits the inspection. All houses fall out of code compliance shortly after they are built, as the codes continually change. National codes are augmented at least every three years for all of the varying disciplines. Municipalities can choose to adopt and phase in sections of the codes on their own timetables. There are generally no requirements to bring older homes into compliance unless substantial renovation is being done.

This is just our opinion

Construction techniques and standards vary. There is no one way to build a house or install a system in a house. The observations in this report are the opinions of the home inspector. Other inspectors and contractors are likely to have some differing opinions. You are welcome to seek opinions from other professionals.

The scope of this inspection

This inspection will include the following systems: exterior, roof, structure, drainage surrounding the primary residence and detached garage, foundation, attic, interior, plumbing, electrical and heating. The evaluation will be based on limited observations that are primarily visual and non-invasive. This inspection and report are not intended to be technically exhaustive.

Your expectations

The overall goal of a home inspection is to help ensure that your expectations are appropriate with the house you are proposing to buy. To this end we assist with discovery by showing and documenting observations during the home inspection. This should not be mistaken for a technically exhaustive inspection designed to uncover every defect with a building. Such inspections are available but they are generally cost-prohibitive to most home buyers. Any recommendations for further evaluation made in this report should be addressed during the inspection contingency period.

Your participation is requested

Your presence is requested during this inspection. A written report will not substitute for all the possible information that can be conveyed verbally by a shared visual observation of the conditions of the property.

How to Read This Report

Getting the Information to You

This report is designed to deliver important and technical information in a way that is easy for anyone to access and understand. If you are in a hurry, you can take a quick look at our "Summary Page” and quickly get critical information for important decision making. However, we strongly recommend that you take the time to read the full Report, which includes digital photographs, captions, diagrams, descriptions, videos and hot links to additional information.

The best way to get the layers of information that are presented in this report is to read your report online, which will allow you to expand your learning about your house. You will notice some words or series of words highlighted in blue and underlined – clicking on these will provide you with a link to additional information.

This report can also be printed on paper or to a PDF document.

Chapters and Sections

This report is divided into chapters that parcel the home into logical inspection components. Each chapter is broken into sections that relate to a specific system or component of the home. You can navigate between chapters with the click of a button on the left side margin.

Most sections will contain some descriptive information done in black font. Observation narrative, done in colored boxes, will be included if a system or component is found to be significantly deficient in some way or if we wish to provide helpful additional information about the system or the scope of our inspection. If a system or component of the home was deemed to be in satisfactory or serviceable condition, there may be no narrative observation comments in that section and it may simply say “tested,” or “inspected.”

Observation Labels

All narrative observations are colored, numbered and labeled to help you find, refer to, and understand the severity of the observation. Observation colors and labels used in this report are:

- Major Concern:Repair items that may cost significant money to correct now or in the near future, or items that require immediate attention to prevent additional damage or eliminate safety hazards.

- Repair:Repair and maintenance items noted during inspection. Please note that some repair items can be expensive to correct such as re-finishing hardwood floors, but are considered simply repair items due to their cosmetic nature.

- Recommended Maintenance:These are repair items that should be considered "routine home ownership items," such as servicing the furnace, cleaning the gutters or changing the air filters in the furnace.

- Improve:Observations that are not necessarily defects, but which could be improved for safety, efficiency, or reliability reasons.

- Monitor:Items that should be watched to see if correction may be needed in the future.

- Due Diligence:Observation such as a buried oil tank that may require further investigation to determine the severity and / or urgency of repair.

- Future Project:A repair that may be deferred for some time but should be on the radar for repair or replacement in the near future.

- Efficiency:Denotes observations that are needed to make the home more energy efficient as well as to bring the home up to modern insulation standards. This category typically includes windows and insulation. Other items, such as lighting and appliances, are not inspected for their energy status.

- Completed:Items that were initially an issue but have since been completed.

- Note:Refers to aside information and /or any comments elaborating on descriptions of systems in the home or limitations to the home inspection.

- Description:Detailed description of various aspects of the property noted during the inspection.

Summary Page

The Summary Page is designed as a bulleted overview of all the observations noted during inspection. This helpful overview is not a substitution for reading the entire inspection report. The entire report must be read to get a complete understanding of this inspection report as the Summary Page does not include photographs or photo captions.

Summary

Repairs

- RGC-1 Roof, Gutters, and Chimney:

The HVAC condenser platform is of a type intended for installation on earth or paved surfaces. When a condenser is installed on the rooftop, there is typically a raised platform built into the roof surface and finished with a sheet-metal top. There are also raised platforms with feet which similarly integrate to the roof surface which can also be used. Improvements are recommended as the existing platform will likely result in premature wear to the roof surface

- RGC-2 Roof, Gutters, and Chimney:

There is a missing sheet metal cover over the refrigerant line opening through the roof. Have this cover properly installed by a roofing contractor to prevent leaks and damage

- ED-1 Exterior and Decks:

The cement fiberboard insulation is in need of further evaluation by a qualified installer. Several errors were noted with the installation of this material that can result in water entry and damage to the wooden sheathing or wall interior. Some of the issues noted include:

- Loose planks

- Missing Z flashing

- Missing mounting block

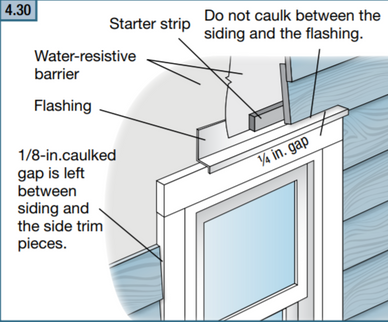

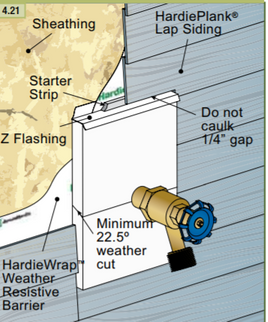

- This diagram shows a proper flashed mounting block.

These issues are indication of unprofessional or inexperienced installation and additional defects may be present.

- ED-2 Exterior and Decks:

Some of the stucco is in need of repair. There is damage along some of the corners, particularly around the upstairs balcony, leaving the wire lath visible. This lath will likely rust and deteriorate when exposed to the weather and is in imperfect cosmetic appearance. Have this corrected by a qualified stucco installer

- ED-4 Exterior and Decks:

The door from the garage to the back patio is difficult to lock. Adjustment of the deadbolt or strike plate hardware needed

- ED-6 Exterior and Decks:

The underside of the balconies is enclosed. The installation does not have a means to ventilate and or drain the enclosed space. This type of installation is inherently problematic. Current construction standards require the enclosed area to be ventilated both to prevent condensation and to allow any leakage to drain out. No opinions are offered regarding the conditions in concealed areas. This can create conditions conducive to concealed damage. It is recommended that the area be made accessible and further evaluated. The installation of drainage/ventilation is recommended. Please consult with a qualified general contractor and or appropriate registered design professional for further evaluation. Any necessary service should be completed by a qualified general contractor in accordance with approved design.

- G-1 Garage:

The auto-close hinges on the garage door have been disabled. This safety device is required to ensure the door is closed to keep pollutants and even fire from spreading into the house. Repair as needed.

- G-2 Garage:

Sheetrock is in contact with the concrete slab in the garage. This can lead to organic growth and water damage at the base of the sheetrock. Generally, a 1/2 inch clearance is recommended. Cutting back the sheetrock is advised.

- E-2 Electrical:

Installation of a light switch for the garage lights in the area of the house entry door is recommended. There is a switch and motion sensor for these lights however they are not activated until the steps are descended which poses a safety hazard. The switch is located adjacent to the side exit door.

- HC4-2 Heating and Cooling:

There seemed to be a significantly larger volume of air coming from the registers in the living room and kitchen. It was also louder in this room than in other rooms. This is, in part, due to the fact that the air return is located here however it also appears to be related to airflow from the registers. Recommend having this further evaluated by a qualified HVAC contractor as it is possible that the distribution system is in need of adjustment or repair. There are dampers which can be used to slow the airflow to specific areas and diverted elsewhere.

- I-1 Interior:

Openings in the lower flight of stair railings appears to be greater than 6 inches. Reduce gaps at the interior stair landing to 6 inches or less to bring this up to current safety standards for child safety.

- DBB-3 Downstairs Bedroom Bathroom:

Use sanded caulking that matches grout to seal cracking inside corners at tile. Grout should not be used at corners or other changes of plane as it will crack and fall free as seen here.

Recommended Maintenance Items

- ED-3 Exterior and Decks:

This building has no eaves. Keeping all exterior penetrations well-sealed is important for a building with this design as gutter leaks can run down the siding and cause water damage. Expect the need for more vigilant maintenance for exposed sections of the building.

Improves

- RGC-3 Roof, Gutters, and Chimney:

One of the downspouts is draining onto a balcony surface. Having this extended to ground level is recommended as this can result in premature deterioration of the balcony surface.

- I-2 Interior:

The doors should be trimmed to provide a minimum 1 inch air gap between the door and the floor. This is of greater importance on doors to bedrooms in homes with central forced air heat to allow air to flow evenly through the home.

- I-3 Interior:

Some of the window tracks are in need of cleaning to allow for smooth operation.

- UB-2 Upstairs Bathroom:

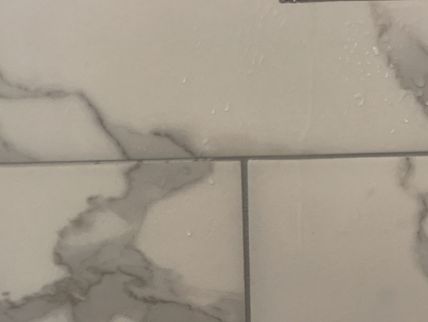

The tile grout is showing signs of absorbing moisture when running the shower. Tile and grout should be sealed and regularly maintained to minimize water penetration behind the tile. Plan on annual cleaning and sealing tile grout inside the shower surrounds to prolong the useful life of the tile. Prior to sealing, replace any failing grout and caulking at inside corners. At inside corners, sanded caulking works well and can be selected to match existing grout.

- DBB-4 Downstairs Bedroom Bathroom:

The tile grout is showing signs of absorbing moisture when running the shower. Tile and grout should be sealed and regularly maintained to minimize water penetration behind the tile. Plan on annual cleaning and sealing tile grout inside the shower surrounds to prolong the useful life of the tile. Prior to sealing, replace any failing grout and caulking at inside corners. At inside corners, sanded caulking works well and can be selected to match existing grout.

- DHB-2 Downstairs Hall Bathroom:

The tile grout is showing signs of absorbing moisture when running the shower. Tile and grout should be sealed and regularly maintained to minimize water penetration behind the tile. Plan on annual cleaning and sealing tile grout inside the shower surrounds to prolong the useful life of the tile. Prior to sealing, replace any failing grout and caulking at inside corners. At inside corners, sanded caulking works well and can be selected to match existing grout.

Due Diligences

- GC-1 General Comments:

As this is a newer construction building, there is a chance that building plans, permits, drainage plans, construction records, a list of sub-contractors and warranty information may be available. Recommend obtaining and keeping this information for your records and for future re-sale.

- GC-2 General Comments:

This property is a part of a common interest development, often referred to as a Home Owners Association- HOA. Buyer should be aware that purchase of this individual unit also includes buying into a larger entity which typically owns the structure and surrounding common areas. These elements maintained by the HOA are not the responsibility of the individual homeowner and as such, are not commented on in this report. Comments here are limited to the systems and components present within the dwelling unit inspected. Any mentions made of common elements in relation to this unit are done as a courtesy and do not imply that a thorough evaluation has occurred. If present in this report, it is suggested that they be discussed with the HOA.

Client is advised to thoroughly review HOA documents prepared in accordance with California civil code sections 1365-1365.5; those relating to financial, legal, and operational matters. This should involve review of the HOA Bylaws, Reserve Study, Financial Statements and Budgets, and Insurance Master Policy. Client is also advised to review seller's disclosures or contact the HOA regarding any past defects and corrective action relating to this unit. This could involve a more in depth investigation than review of information present in documents provided by minimum disclosure requirements. If available, review of HOA board meeting minutes and/or newsletters may provide additional valuable information.

- ED-5 Exterior and Decks:

One of the back facing window frames is damaged. Have this further evaluated by a qualified glazing contractor. This may simply be a cosmetic defect however was not able to be seen up close. Have this further evaluated by a qualified contractor.

- P-2 Plumbing:

It was not apparent or disclosed, if this house is on a public sewer connection or on a private on-site septic system. Recommend inquiring with the seller for additional inspection and have the system inspected or video-scoped as desired to ensure reliable performance from this important system. Please note that evaluation of sewer and septic connections are beyond the scope of this home inspection.

- AP-1 Additional Plumbing:

A sump pump system was noted for this building / site. Inquire with the builder or seller for more information about this pump system and any ongoing maintenance requirements as well as responsibility.

- AP-2 Additional Plumbing:

An interior fire sprinkler system was noted in this building. Fire suppression systems are beyond the scope of this inspection. Inquire with the seller for any additional information and maintenance requirements.

- AP-3 Additional Plumbing:

An exterior irrigation system was noted for this home. Sprinkler systems are beyond the scope of this inspection. Irrigation systems often require annual attention / repair / servicing. Inquire with the seller for any information about this system. When testing the system, be sure sprinkler heads are adjusted so the system is not watering the side of the house. Hire a specialist to further evaluate this system as desired.

- HC4-1 Heating and Cooling:

There is an open pipe terminating beneath the sink in the main floor powder room. This may be an abandoned pipe however it is recommended that this be brought to the attention of the builder. Any water dripping from the slight may result in serious damage to the finishes surrounding

- I-4 Interior:

There appears to be a methane mitigation system installed. Consult with the seller for further information regarding this system and any ongoing maintenance requirements. This type of system is outside of the scope of a general home inspection.

- K-2 Kitchen:

The refrigerator and dish washer were not yet fully installed and operational at the time of inspection. Verify operation during the final walk through.

Notes

- RGC-4 Roof, Gutters, and Chimney:

Note that this house is mostly all vaulted ceiling - there is no attic space and no access to inspect roof framing, thermal barriers or ductwork.

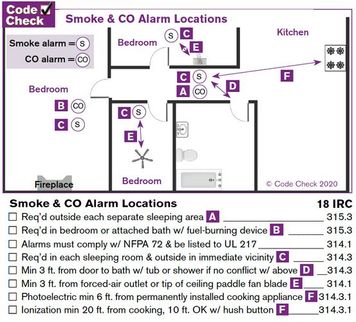

- E-3 Electrical:

The link below includes important information about smoke alarms that could save lives in the event of a fire. There are two basic types of smoke alarms: ionization, which are better at detecting flaming fires and photoelectric, which are better at detecting smoldering fires. Standards in the building industry are moving toward recommending BOTH types of detectors in the home. It is nearly impossible to accurately test smoke alarms during a home inspection and testing is outside the scope of this evaluation. Recommend learning more about these important life saving devices and consider installing both types of smoke detectors in your home.

- LF-1 Laundry Facilities:

The plumbing and electrical connections for these appliances are not visible due to the method of installation.

- UB-3 Upstairs Bathroom:

During inspection, all plumbing fixtures in bathrooms were operated. Bathtub overflow drains are not tested as this risks damaging finishes around the tub. Monitor tubs while filling and avoid pushing water into the overflow. Even well-installed overflow drains can leak as the gaskets that seal the overflow will dry out over time and may no longer provide a watertight seal. Monitor plumbing after moving into a new home as testing during inspection presents less stress on plumbing than daily use. Please note that vacant homes present additional risk as it can be difficult to distinguish how the plumbing system will respond to daily use. Any defects uncovered during inspection are listed in this report.

The Full Report

General Comments

Building Characteristics, Conditions and Limitations

Type of Building : Single Family (3-story)

Approximate Year of Original Construction: New Construction

Attending the Inspection: Buyer's Agent

Occupancy: Unoccupied

Weather during the inspection: Clear

Approximate temperature during the inspection: Over 70[F]

Ground/Soil surface conditions: Dry

For the Purposes of This Report, the Front Door Faces: Southeast

As this is a newer construction building, there is a chance that building plans, permits, drainage plans, construction records, a list of sub-contractors and warranty information may be available. Recommend obtaining and keeping this information for your records and for future re-sale.

This property is a part of a common interest development, often referred to as a Home Owners Association- HOA. Buyer should be aware that purchase of this individual unit also includes buying into a larger entity which typically owns the structure and surrounding common areas. These elements maintained by the HOA are not the responsibility of the individual homeowner and as such, are not commented on in this report. Comments here are limited to the systems and components present within the dwelling unit inspected. Any mentions made of common elements in relation to this unit are done as a courtesy and do not imply that a thorough evaluation has occurred. If present in this report, it is suggested that they be discussed with the HOA.

Client is advised to thoroughly review HOA documents prepared in accordance with California civil code sections 1365-1365.5; those relating to financial, legal, and operational matters. This should involve review of the HOA Bylaws, Reserve Study, Financial Statements and Budgets, and Insurance Master Policy. Client is also advised to review seller's disclosures or contact the HOA regarding any past defects and corrective action relating to this unit. This could involve a more in depth investigation than review of information present in documents provided by minimum disclosure requirements. If available, review of HOA board meeting minutes and/or newsletters may provide additional valuable information.

This house was vacant / unoccupied at the time of inspection. Vacant and unoccupied houses present unique challenges for home inspection, particularly relating to the piping and wiring systems which have not be subject to regular use prior to the inspection. While these systems can be tested during inspection, this one-time test is different than regular use and it is difficult to know how these systems will respond to regular use after the inspection. For example, septic systems may initially function and then fail under regular daily use. Plumbing traps may operate with no signs of leaks and then let go when being actively used for a few days. Shower pans may only leak when someone is standing in the shower and taking a shower. Seals for plumbing fixtures can dry up and leak when not is use. Sewer lines with roots may allow water flow, but then fail when waste and tissue are flushed; it can take a few days for that to backup. Please understand we are trying our best to look for clues of past or existing problems to paint a realistic best-guess as to the reliability of these systems during inspection.

Grounds and Drainage

Drainage and Lot Location

Clearance to Grade: Standard

Downspout Discharge: Above grade

Site Description: Flat

Driveways/Walkways/Paving

Driveway: Concrete

Walkways: Concrete

Patios: Concrete

Grounds, Trees and Vegetation

Trees/Vegetation too near building: No

Retaining Wall

Retaining Wall Material: Concrete

Fences, Gates, and Walls

Present

Roof, Gutters, and Chimney

Roof Materials

Method of Roof Inspection: Walked on roof

Roof Style: Low slope

Flashings: Present and Visually Standard

Roof flashings are used to keep a roofing system water proof where the roofing material starts, stops, changes direction or is penetrated. During inspection, we look for standard flashing techniques that could be considered normal or standard in our region. Damaged, incomplete or non-standard flashings can be a sign of an older or less reliable roofing system and may require repair. Any non-standard flashings noted during inspection will be reported on below if found.

Roof Covering Materials: TPO membrane

Approximate Remaining Life Expectancy: 10+ years

The HVAC condenser platform is of a type intended for installation on earth or paved surfaces. When a condenser is installed on the rooftop, there is typically a raised platform built into the roof surface and finished with a sheet-metal top. There are also raised platforms with feet which similarly integrate to the roof surface which can also be used. Improvements are recommended as the existing platform will likely result in premature wear to the roof surface

Roof Drainage

Gutter and Downspout Materials: Aluminum

Attic Access

No access. Vaulted ceiling

Note that this house is mostly all vaulted ceiling - there is no attic space and no access to inspect roof framing, thermal barriers or ductwork.

Roof Framing and Sheathing

Rafters: Not visible

Attic Insulation

Insulation Type: Not visible

Exterior and Decks

Siding and Trim

Siding Material: Stucco, Fiber-cement

This building has a Hardcoat stucco siding system. When installed over a wood building, stucco should be installed with two layers of underlayment below the plaster and a weep screed system which allows air to dry any accumulated water behind the plaster. Stucco is one of the nicest and lowest maintenance siding systems but it is installation sensitive. Poor installation can lead to expensive repairs. The most critical element to a stucco siding system, the weather barrier, is not visible to inspection, which limits the inspectors' ability to see how the system is performing. During the inspection, we look for clues in the installation to make an educated guess about the future reliability of this system. More detailed information can be gained through destructive testing. This involves drilling holes in the plaster and using a moisture probe to determine if any sections of the building have failed moisture control. Destructive testing like this is beyond the scope of this inspection.

Manufacturers of fiber cement siding have done a poor job helping inspectors and consumers distinguish their products after installation; these products have few if any distinguishing characteristics. This report will site James Hardie manufacturers installation requirements for reference because they are the most common manufacturer of fiber cement siding and the various manufactures seem to share similar installation guidelines. However, reference of these guidelines in this report does not ensure that the fiber cement siding here is a James Hardie product.

The cement fiberboard insulation is in need of further evaluation by a qualified installer. Several errors were noted with the installation of this material that can result in water entry and damage to the wooden sheathing or wall interior. Some of the issues noted include:

- Loose planks

- Missing Z flashing

- Missing mounting block

- This diagram shows a proper flashed mounting block.

These issues are indication of unprofessional or inexperienced installation and additional defects may be present.

Some of the stucco is in need of repair. There is damage along some of the corners, particularly around the upstairs balcony, leaving the wire lath visible. This lath will likely rust and deteriorate when exposed to the weather and is in imperfect cosmetic appearance. Have this corrected by a qualified stucco installer

Eaves

This building has no eaves. Keeping all exterior penetrations well-sealed is important for a building with this design as gutter leaks can run down the siding and cause water damage. Expect the need for more vigilant maintenance for exposed sections of the building.

Exterior Doors

Exterior Windows

Balcony

Present

To see a prescriptive guide for residential wood deck construction click this link.

Deck Structure: Not visible

Deck Ledger Board: Not applicable

Guardrail: Standard

Decking Material: Elastomeric over concrete

The underside of the balconies is enclosed. The installation does not have a means to ventilate and or drain the enclosed space. This type of installation is inherently problematic. Current construction standards require the enclosed area to be ventilated both to prevent condensation and to allow any leakage to drain out. No opinions are offered regarding the conditions in concealed areas. This can create conditions conducive to concealed damage. It is recommended that the area be made accessible and further evaluated. The installation of drainage/ventilation is recommended. Please consult with a qualified general contractor and or appropriate registered design professional for further evaluation. Any necessary service should be completed by a qualified general contractor in accordance with approved design.

Garage

Garage - General

Attached

The auto-close hinges on the garage door have been disabled. This safety device is required to ensure the door is closed to keep pollutants and even fire from spreading into the house. Repair as needed.

Garage - Overhead Door and Opener

Automatic Garage Opener: Present

Garage Door Type: Metal

Garage - Floor

Garage Slab: Concrete

Electrical

Sub Panel - Garage

Branch Wiring

Wire Material: Copper, Multi-strand Copper

Percentage Visible: 0-10%

Wiring Method: Non-metallic sheathed cable

Visible portions of the electrical wiring system were inspected and no material defects were observed.

Receptacles and Fixtures

Inspection Method: Random Testing

Electric Receptacles: Three wire receptacles

Installation of a light switch for the garage lights in the area of the house entry door is recommended. There is a switch and motion sensor for these lights however they are not activated until the steps are descended which poses a safety hazard. The switch is located adjacent to the side exit door.

Smoke and Carbon Monoxide Alarm Systems

CO Alarms Noted: Outside all Sleeping Areas

Outside all Sleeping Areas

Smoke Alarms Noted: In All Bedrooms

In All Bedrooms

Smoke Alarms: Present

Present  Additional Info

Additional Info

For reliability, fire marshals recommended updating smoke alarms every 10 years and changing batters bi-annually. The latest data indicate that we should be using photo-electric technology in our smoke alarms for improved fire detection and to reduce problems with false alarms which can lead to disabling of this important safety system. Unfortunately, the alarms have to be removed to determine if they are photo-electric or ionization types. It is surprisingly complex to accurately test a smoke alarm system and determine the reliability, age, and type of sensor technology used, especially as many homes can have half a dozen or more alarms throughout the house. Evaluation of smoke alarms is beyond the scope of this inspection. For optimal fire safety, it is recommended to learn about how to service and maintain your smoke alarm system to keep the building occupants safe. For more information, please read this link. For more information, please read this link.

The link below includes important information about smoke alarms that could save lives in the event of a fire. There are two basic types of smoke alarms: ionization, which are better at detecting flaming fires and photoelectric, which are better at detecting smoldering fires. Standards in the building industry are moving toward recommending BOTH types of detectors in the home. It is nearly impossible to accurately test smoke alarms during a home inspection and testing is outside the scope of this evaluation. Recommend learning more about these important life saving devices and consider installing both types of smoke detectors in your home.

Electrical Grounding System

UFER Ground Noted

A UFER ground connection was noted for the electrical grounding system. These are required and standard on newer construction houses. These grounds connect the electrical system to Rebar in the house foundation and make a reliable path to the earth for "earthing" or grounding the electrical system.

Electrical Bonding System

Present - Could Not Confirm

During the inspection, visual evaluation of the electrical system bonding is completed. There is no way in the context of a home inspection to verify the "effectiveness" of system bonding. All metallic systems in the building are required to be "bonded" (connected) to the the building's electrical grounding system. Bonding creates a pathway to shunt static charges (that would otherwise build up on the system) to earth, and to provide a pathway to trip a breaker in the event that these bonded metallic components became energized. There are many things that can indicate the need for further evaluation of this system by a licensed electrical contractor and they will be documented as repair items in the observations below if discovered.

Plumbing

Water Service Supply

Pipe Material: Copper

Water Supply: Public water

Pressure Reducing Valve: Present

This house has a pressure reducing valve to control high water pressure in the street.

Main Water Shut-off Location: Exterior - Left side

Distribution Pipe

Supply Pipe Materials: Copper

Percentage Seen: 0-10%

Functional Flow: Average

Angle Stops Testing Note

Angle stops are the shut offs located below plumbing fixtures such as sinks and toilets. These are designed so that water can be shut off locally to a fixture without shutting off the water to the entire house so that localized fixtures can be serviced and repaired or replaced. Home inspectors do NOT test angle stops during inspection as there is a risk of leakage which could cause damage to the home.

Visible portions of the supply piping were in satisfactory condition with no material defects noted.

Waste Pipe and Discharge

Discharge Type: Unknown

Please note that there is the possibility that a system is not as it is listed; for example, a property could be listed as a public sewer system when in fact it is on a private septic system. This is unlikely, but is another reason why we recommend further evaluation of all sewage discharge systems.

Waste and Vent Pipe Materials: ABS plastic, Cast Iron, Galvanized steel

Percentage Seen: 0-10%

It was not apparent or disclosed, if this house is on a public sewer connection or on a private on-site septic system. Recommend inquiring with the seller for additional inspection and have the system inspected or video-scoped as desired to ensure reliable performance from this important system. Please note that evaluation of sewer and septic connections are beyond the scope of this home inspection.

Water Heater

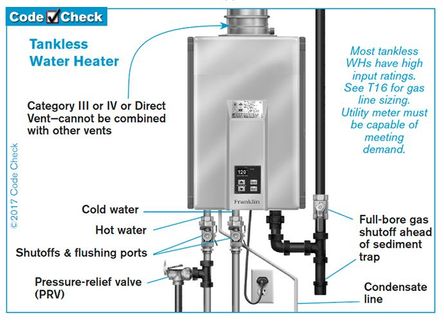

System Type: Tankless

This building has hot water provided by a tankless hot water heater. The typical lifespan of this type of water heater is 15 to 20 years however is installation and maintenance dependent. Annual flushing is typically recommended for these types of water heaters to ensure safe and reliable performance. Recommend having this water heater professionally serviced at this time and annually moving forward as a part of routine scheduled maintenance.

Manufacturer: Rinnai

Size: 199 MBTU

Age: New

Energy Source: Gas

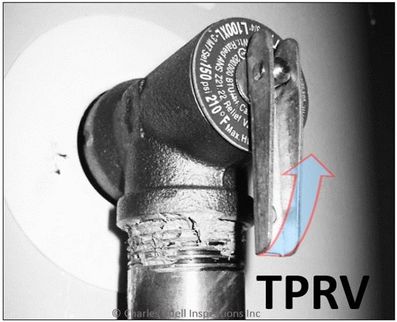

Temperature Pressure Relief Value: Present - Not Tested

The temperature and pressure relief valve is arguably one of the most important safety devices in your house. Should the thermostats fail inside your water heater, the TPRV allows excess pressure to "blow off," which will prevent catastrophic build up of temperature and pressure which can make water heaters explosive. These valves are not tested during inspection as there is a risk it could stick open and testing could cause the need for a repair. Manufacturers of these relief valves recommend that these be tested annually.

Exterior Hose Bibs

Operating

Laundry Facilities

Washer Hookups

Not tested

Dryer Hookups

Not tested

Power Source: Gas

Exhaust Duct: Ducted to Exterior

Additional Plumbing

Sump Pumps and Drains

Sump Pumps: Present

Fire Suppression

An interior fire sprinkler system was noted in this building. Fire suppression systems are beyond the scope of this inspection. Inquire with the seller for any additional information and maintenance requirements.

Landscape Irrigation

Common Observations: Note for Buyer - Disclaim

An exterior irrigation system was noted for this home. Sprinkler systems are beyond the scope of this inspection. Irrigation systems often require annual attention / repair / servicing. Inquire with the seller for any information about this system. When testing the system, be sure sprinkler heads are adjusted so the system is not watering the side of the house. Hire a specialist to further evaluate this system as desired.

Fuel and Distribution

Gas Meter

Gas, Propane and Oil Piping

Gas Piping Materials Noted: Steel

Visible portions of the fuel piping were in satisfactory condition with no material defects noted. This inspection does not verify sizing in accordance with appliance needs or engineering of distribution.

Heating and Cooling

Fan Coil

Energy Source: Electricity

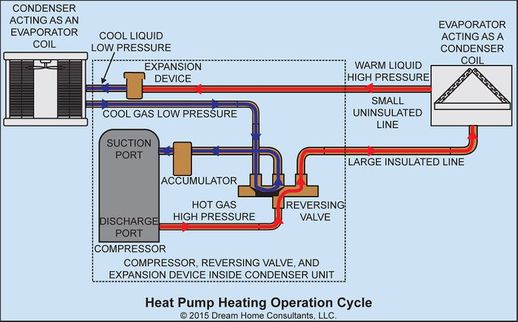

Heating Method: Heat pump

Heating and cooling for this dwelling is provided by an electrically operated heat pump. These systems typically have a serviceable life of 12-15 years or more depending on maintenance. Recommend keeping the heating and cooling system on an annual service schedule. Heating and cooling contractors recommend annual servicing to ensure safe and reliable performance and to prolong the useful life of this equipment.

Manufacturer: International Comfort

Capacity: 60,000 btu

Age: 2019

There is an open pipe terminating beneath the sink in the main floor powder room. This may be an abandoned pipe however it is recommended that this be brought to the attention of the builder. Any water dripping from the slight may result in serious damage to the finishes surrounding

Air Filters

Filtration Systems: Disposable

This heating and cooling system has disposable air filters installed. These should be changed every 30-45 days during regular use to ensure proper air flow at the furnace. Be sure to install the filters with the arrows pointing in the same direction as the air flow in the furnace.

Condenser

Manufacturer: Tempstar

System Type: Split System

Size: 5 Tons

Energy Source: Electric

Age: 2019

Heating and Cooling Distribution Systems

Heat Source in Each Room: Present

Distribution Method: Forced Air / Ducts

There seemed to be a significantly larger volume of air coming from the registers in the living room and kitchen. It was also louder in this room than in other rooms. This is, in part, due to the fact that the air return is located here however it also appears to be related to airflow from the registers. Recommend having this further evaluated by a qualified HVAC contractor as it is possible that the distribution system is in need of adjustment or repair. There are dampers which can be used to slow the airflow to specific areas and diverted elsewhere.

Foundation and Structure

Foundation

% of Foundation Not Visible: 70%

Evidence of Seismic Protection: Not visible

Building Configuration: Slab on grade (garage slab)

Foundation Description: Poured concrete

Floor, Wall and Ceiling Framing

Wall Framing: Not visible

Wall Sheathing: Not visible

Floor Framing: Not visible

Sub-Floor Material: Not visible

Ceiling Framing: Not visible

Interior

Floors and Floor Materials

Floor Materials: Hardwood

Floor Settlement: None noted

Walls, Ceilings, Trim and Closets

Wall and Ceiling Materials: Drywall

Stairs and Railings

Interior Doors

Windows

Window Glazing: Double pane

Interior Window Frame: Metal

Window Styles: Sliding

Kitchen

Sinks and Faucets

Tested

Cabinets and Countertops

Countertop Material: Engineered Stone

Cabinet Material: Wood laminate

Ventilation Method

Fan Ducted to Exterior

Appliances

Refrigerator: Not inspected

Dishwasher Air Gap: Present

Range/ Oven /Cook-tops: Gas

Disposer: Operated

Built in Microwave: Tested

General Kitchen Condition

Standard

Upstairs Bathroom

Sinks and Cabinets

Tested

Toilet

Tested

Bathtub / Shower

The tile grout is showing signs of absorbing moisture when running the shower. Tile and grout should be sealed and regularly maintained to minimize water penetration behind the tile. Plan on annual cleaning and sealing tile grout inside the shower surrounds to prolong the useful life of the tile. Prior to sealing, replace any failing grout and caulking at inside corners. At inside corners, sanded caulking works well and can be selected to match existing grout.

Bathroom Ventilation

Type: Bath fan

General Bath Condition

Standard

During inspection, all plumbing fixtures in bathrooms were operated. Bathtub overflow drains are not tested as this risks damaging finishes around the tub. Monitor tubs while filling and avoid pushing water into the overflow. Even well-installed overflow drains can leak as the gaskets that seal the overflow will dry out over time and may no longer provide a watertight seal. Monitor plumbing after moving into a new home as testing during inspection presents less stress on plumbing than daily use. Please note that vacant homes present additional risk as it can be difficult to distinguish how the plumbing system will respond to daily use. Any defects uncovered during inspection are listed in this report.

Sinks and Cabinets

Tested

Toilet

Tested

Bathroom Ventilation

Type: Bath fan

General Bath Condition

Standard

Primary Bathroom

Sinks and Cabinets

Tested

Toilet

Tested

Bathtub / Shower

Tested

Bathroom Ventilation

Type: Fan and window

General Bath Condition

Standard

Downstairs Bedroom Bathroom

Sinks and Cabinets

Tested

Toilet

Tested

Bathtub / Shower

Tested

Use sanded caulking that matches grout to seal cracking inside corners at tile. Grout should not be used at corners or other changes of plane as it will crack and fall free as seen here.

The tile grout is showing signs of absorbing moisture when running the shower. Tile and grout should be sealed and regularly maintained to minimize water penetration behind the tile. Plan on annual cleaning and sealing tile grout inside the shower surrounds to prolong the useful life of the tile. Prior to sealing, replace any failing grout and caulking at inside corners. At inside corners, sanded caulking works well and can be selected to match existing grout.

Bathroom Ventilation

Type: Bath fan

General Bath Condition

Standard

Downstairs Hall Bathroom

Toilet

Tested

Bathtub / Shower

The tile grout is showing signs of absorbing moisture when running the shower. Tile and grout should be sealed and regularly maintained to minimize water penetration behind the tile. Plan on annual cleaning and sealing tile grout inside the shower surrounds to prolong the useful life of the tile. Prior to sealing, replace any failing grout and caulking at inside corners. At inside corners, sanded caulking works well and can be selected to match existing grout.

Checking Out Procedure

Check Out List

Oven: Off

Off

Lights: Off

Off Client and Realtor Still In House

Client and Realtor Still In House Client Still in House

Client Still in House Realtor Still in House

Realtor Still in House

Heating and Cooling: Restored to Pre-inspection temperatures

Restored to Pre-inspection temperatures

Appliances: Off / finishing cycle

Off / finishing cycle