The Full Report

Inspection Information

Inspection Information

Information: Information

All comments and observations made by the inspector should be considered and actions taken prior to the close of escrow. This includes any recommendation to employ a professional plumber to further evaluate any anomalous findings noted during this inspection. All recommendations for repair, replacement, remediation of limitations and any follow-up re-inspection should be considered and actions taken prior to the close of escrow. Your best interests are your inspector's primary concern however, your inspector is not an expert, licensed plumber. A qualified, experienced professional plumber can provide options, insights and costing estimates that are unknown to your inspector. All costs associated with further inspection fees, and the repair or replacement of any component should be considered prior to the close of escrow.

NOTE ABOUT SMOKE TESTING:

It is important to know that sanitary sewer utility providers conduct routine smoke testing of the sanitary sewer systems within their domain. Smoke testing reveals deficiencies within the main system, the side sewer systems feeding into the main and the drain, waste and vent systems within the structure. Smoke testing can identify deficiencies that are potentially harmful to you and those that are potentially harmful to the overall sewer system. (The smoke itself is non-toxic to you, your pets and your house plants.) The utility company can mandate you repair, at your expense, deficient systems within the side sewer serving this property as a condition of continued service. If this sewer scope inspection reveals any deficiency, it is important to understand the future ramifications of deferring a repair that may be identified during utility company smoke testing.

Sewer Inspection Report

Access Point

Side Sewer Type (Public/On-Site)

Side Sewer Type: Public Sewer System

Public Sewer System

PUBLIC SEWER SYSTEM

The side sewer serving this property is connected to a public sewer system.

Scope Findings

PIPE MATERIAL(S): PIPE MATERIAL(S)

PIPE MATERIAL(S) Concrete

Concrete Cast Iron

Cast Iron

PIPE MATERIAL(S)

I noted the presence of the following type(s) of pipe material(s): The materials are listed below in the order that I encountered them, moving from the point of access toward the main sewer line.

- Cast Iron

- Concrete

APPROXIMATE DEPTH OF TIE-IN TO MAIN OR SEPTIC TANK: Approximate Depth of Tie-In to Main Sewer Line or Septic Tank

Approximate Depth of Tie-In to Main Sewer Line or Septic Tank

ROOT INTRUSION: Minor

Minor Moderate

Moderate

OFFSET JOINTS: Moderate

Moderate

DEBRIS/GREASE: Minor

Minor

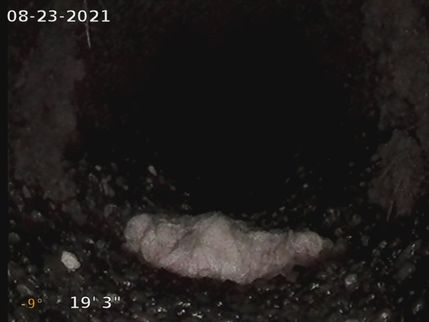

MODERATE ROOT INTRUSION

The root intrusion seen during your sewer scope inspection is MODERATE and it is located *Distance in Feet* feet from the access point. Root intrusion is considered moderate if they are blocking 25 to 50 percent of the pipe. The moderate root intrusion seen here may or may not be impacting the performance of the side sewer. This root intrusion is likely to increase in size and/or severity over time. Moderate root growth may be treated with a commercially available sewer root control product such as Root-X, or they can be mechanically removed using a rotary cutter. Whether treated or not, the side sewer should be re-inspected every, one to two years to determine if the roots have increased in size and/or severity.

Roots are another common problem within side sewers, especially older concrete and clay pipe side sewers that weren’t constructed with watertight joints. Once roots seek out a water source in sewer pipes, they continue to thrive and grow. This results in cracked pipes and sewer backups when debris isn’t able to pass through the roots. Pipes that are cracked from roots should be repaired in a manner that doesn’t allow the roots to grow back into the sewer system. Roots that are coming into joints that aren’t cracked may be routinely removed by cleaning the sewer pipes. The frequency of removal will depend on how aggressive the root growth is. The only way to permanently remove roots from a side sewer is to construct a watertight sewer pipe either through replacement or rehabilitation.

MODERATE OFFSET

The offset joint(s) seen during your sewer scope inspection are MODERATE and are located 43 feet from the access point. Moderate offsets may cause some buildup of debris but typically would not cause a backup. I do not see any exposed soil at the noted offset(s). I recommend further evaluation by a qualified licensed sewer plumbing contractor and correction as recommended. This work should be completed prior to the close of escrow.

Side sewers are built using multiple segments of pipe that are connected together at joints. Offset joints occur when the pipes don’t perfectly match up and one of the pipes sits lower or off to the side of the connecting pipe.

Offset joints can cause debris to build up on the joint that can eventually lead to backups. Additionally, an offset is a location where roots can easily grow into the sewer line. Also, if the joint is offset enough that soil is exposed around the edges of the pipes, the surrounding soil can erode into the pipe and be washed away, eventually causing voids to occur around the outside of the pipe and possibly become sink holes. Offset joints are not watertight and can allow infiltration of clean groundwater into the wastewater sewer system.

MINOR DEBRIS/GREASE

The debris seen during your sewer scope inspection is MINOR and it is located *Distance in Feet* feet from the access point. Debris accumulation is considered minor if it occludes the sewer pipe by 25 percent or less. Minor accumulations of debris may be flushed away during periods of high-water usage. However, you may wish to have the pipes professionally power jetted to ensure optimal performance of the side sewer. I recommend further evaluation by a qualified licensed sewer plumbing contractor and repair as required. This work should be completed prior to the close of escrow.

Debris can build up in a side sewer if there are structural defects or obstructions in the pipe (such as sags, roots or offset joints) that obstruct the flow of the sewer and if inappropriate items are flushed or poured down the drains. Or, if pipes are constructed at slopes less than the recommended ¼-inch drop per foot of pipe, the liquids won’t be moving fast enough to carry away the solids in the pipe. If debris build up is severe enough, it can eventually fill a pipe and cause backups or slow-draining side sewers.

Examples of items that do not degrade like toilet paper and should not be flushed down a drain (even though they may be advertised as flushable) include baby wipes, disinfectant wipes, paper towels, egg shells, coffee grounds, dental floss, toilet bowl scrub pads, feminine hygiene products and grease. Even very hot grease cools quickly once it reaches an underground pipe and sticks to the walls of the side sewer. Over time, grease can cause a side sewer to either drain very slowly or cause a complete blockage of the side sewer. Grease is one of the more common causes of backups and slow-draining side sewers.

Videos

VIDEO: Video

SEWER SCOPE VIDEO LINK

Here is the video and audio recorded during your sewer scope inspection. Please contact our office if you have any questions or need assistance viewing the video.

The Sterling Inspection Group Inc

253-841-1128

info@sterlinginspections.com

Common Side Sewer Repair Processes

Common Side Sewer Repair Processes

Repair Description: Description

Construction Methods to Eliminate Defects in Side Sewers

This section describes various methods available for repairing, replacing, or rehabilitating an existing side sewer. Every side sewer is unique and not all methods are suitable for all circumstances. It is always important to work with a sewer contractor experienced with the particular kind of construction to determine the suitability for each side sewer on an individual basis and to obtain cost estimates for the various methods as they may vary greatly for each project.

Open cut construction

This method of construction is the typical dig and replace that most people are familiar with. This is the most common method of repairing side sewers and consists of digging up the old pipe and replacing it with new pipe. Open cut may be less suitable for areas where there are significant surface improvements that a property owner wants to avoid disturbing and that are costly to replace or when side sewers are fairly deep.

Pipe bursting

This method of construction consists of inserting a new flexible pipe into the old pipe. This method requires digging an installation pit and a receiving pit at each end of the side sewer to allow for the pipe to be inserted and to make final connections at each end. This method is beneficial for sites where there are surface improvements that an owner either chooses not to disturb or that would be expensive to replace. Pipe bursting is not suitable for pipes that are no longer round enough to allow for the bursting machine to penetrate, in pipes with multiple bends, or in pipes that need to have sags corrected as the new pipe will follow the vertical alignment of the old pipe.

Cured In Place Pipe (CIPP) lining

CIPP consists of rehabilitating an existing pipe with a new pipe. A resin-soaked felt tube liner is inserted into the existing pipe, inflated to expand to the shape of the existing pipe, and then cured until the resin hardens to form a pipe within the old pipe. CIPP is also beneficial for sites where there are surface improvements than an owner either chooses not to disturb or that would be expensive to replace. The liner can be inserted through cleanouts in the side sewer and requires no other digging unless needed to install a cleanout. Since CIPP forms to the shape of the existing pipe it is not suitable for pipes that are collapsing or egg-shaped, nor can it be installed in pipes with multiple bends or in pipes that need to have sags corrected as the new pipe will follow the vertical alignment of the old pipe.

Spot repairs

If the majority of a pipe is good condition with little or no defects, a spot repair may be the most suitable and cost effective method for repair. The property owner should consider a full side sewer replacement or rehabilitation if there are multiple defects throughout the pipe. It is generally less costly to hire a contractor once than to have a contractor mobilize to a site multiple times with repeated spot repairs.