The Scope and Purpose of this Inspection

The scope of this inspection

INSPECTION AGREEMENT

Major Structural and Electromechanical Inspection

HomePro Inspection, Inc. agrees to conduct an inspection for the purpose of informing the CLIENT of major deficiencies in the condition of the property in accordance with the Standards as set forth by the American Society of Home Inspectors (ASHI) and the State of Tennessee. The inspection and written report are performed and prepared for the sole, confidential and exclusive use and possession of the CLIENT; the report is nontransferable.

The written report will include the following only:

- general exterior, including roof, siding, windows, chimney, drainage and grading

- structural condition of foundation & frame

- electrical, plumbing, hot water heater, heating and air conditioning

- general interior, including ceilings, walls, floors, windows, insulation and ventilation

Maintenance and other items may be discussed but they are not a part of the inspection. The report is not a compliance inspection or certification for past or present governmental codes or regulations of any kind and is only based on the inspector’s opinions.

It is understood and agreed that the inspection will be of readily accessible areas of the building and is limited to visual observations of apparent conditions existing at the time of the inspection only. Latent and concealed defects and deficiencies are excluded from the inspection; equipment, items and systems will not be moved or dismantled. When the inspection is for only one or a limited number of systems or components, the inspection is limited to only those systems or components that were inspected. Detached structures are not included. HomePro Inspection, Inc. will be under no obligation under any circumstances for any further follow-up inspection.

ENVIRONMENTAL HAZARDS including Asbestos, Mold, Fungus, Lead, Radon, Cockroaches, Rodents, Pesticides, Treated Lumber, Mercury, Carbon Monoxide, Urea Formaldehyde, Toxic Wastes, Polluted Water, Contaminants and all Pollutants and Hazardous Materials or other similar environmental hazards are not part of this Home Inspection. In addition, no inspection for household insects or unwanted animals will be done.

This report does not address Subterranean Systems or system components for Sewage Disposal, Water Supply, or Fuel Storage or Delivery. Auxiliary systems such as Alarm, Security, Intercom, other low voltage wiring, Generator, Private Water, Sprinkler, Elevator, Central Vacuum, Refrigerators, Laundry Equipment, Solar, Swimming Pools, Hot Tubs, Saunas, Space Heaters, Window Air Conditioners and or any system not considered a part of the major building systems are not a part of the inspection process.

The parties agree that the HomePro Inspection, Inc., and its employees and agents, assume no liability or responsibility for the cost of repairing or replacing any unreported defects or deficiencies, either current or arising in the future, or for any property damage, consequential damage or bodily injury of any nature. THE INSPECTION AND REPORT ARE NOT INTENDED AS A GUARANTEE OR WARRANTY, EXPRESSED OR IMPLIED INCLUDING REGARDING THE ADEQUACY, OR PERFORMANCE OF ANY INSPECTED STRUCTURE, ITEM OR SYSTEM. THE HOMEPRO INSPECTION, INC. IS NOT AN INSURER OF ANY INSPECTED CONDITIONS.

It is understood and agreed that should HomePro Inspection, Inc. and/or its agents or employees be found liable for any loss or damages resulting from a failure to perform any of its obligations, including but not limited to negligence, breach of contract or otherwise, then the liability of HomePro Inspection, Inc. and/or its agents or employees, shall be limited to a sum equal to the amount of the fee paid by the CLIENT for the Inspection and Report.

The parties agree that the faxed or digital copy of the agreement is to be relied upon in lieu of the original.

Acceptance and understanding of this agreement are hereby acknowledged:

How to Read This Report

This digital report or a printed version of this report should only be viewed in full color where the photos are discernible and on a device where the report page width is no less than 8.5" wide. Please note, Right and Left of the building are determined as facing the front of building shown on the report cover. The client has the duty and obligation to read the entire report. Feel free to reach out to the inspector should you have any questions or concerns.

This report is designed to inform the client of obvious major structural deficiencies, inoperative conditions and the presence of noticeable, detrimental moisture issues for areas inspected. Additionally, the inspection report may advise regarding notable safety concerns and appropriate upgrades recommended by the inspector that you should consider and act on when appropriate. Please note, undesirable conditions pertaining to this inspection may be present and unreported for concealed areas and areas with limited or blocked access.

Photos

Photos included in this report are intended to help describe a reported item or area only. The photos, while representative, may not encompass the full scope of work required to correct the item or area listed. Repairs should be based on actual condition of property and not solely on the photos included in this report.

Repairs

Repairs or corrections needed at the inspected property should be completed by competent qualified professions familiar with the type of work being performed. Obtain competitive bids as needed. Obtain further evaluation when needed.

Getting the Information to You

This report is designed to deliver important and technical information in a way that is easy to access and understand. The best way to get the layers of information that are presented in this report is to read your report online in the HTML format, which will allow you to expand your learning about the inspected property. You will notice some words or series of words highlighted in blue and underlined – clicking on these will provide you with a link to additional information, if desired. Other text colors, if present, have no real meaning. Please read all written text.

This report can also be printed on paper or to a PDF document.

Chapters and Sections

This report is divided into chapters that parcel the home into logical inspection components. Each chapter is broken into sections that relate to a specific system or component of the home. You can navigate between chapters with the click of a button on the left side margin when viewing the report online.

Observation Labels

Narrative observation labels are defined here. Some of the following observation labels may not appear in all reports. Hazardous, Key Concerns and Further Evaluation observation label types, if used, will appear in the report and in the summary. All other observation labels, when used, appear only in the report and will not appear in the summary. All narrative observation label types are labeled, and numbered to help differentiate each reported narrative observation. When narrative observation labels are given a color, the specific color used has no meaning. Some observation labels are given a specific icon to group the observation types. The specific icon used also has no meaning.

Observation labels and colors used for reporting are:

- Hazardous:Observations listed as hazardous pose imminent danger to the inspected property or occupants. Hazardous observations should be properly corrected before occupying the property. When used, this observation will appear in the report and in the summary.

- Key Concerns:Observations listed as key concerns will typically include inoperative equipment, common and significant corrections needed for plumbing, electrical, heating/cooling, structure, interior and exterior areas including the roof covering. When used, this observation will appear in the report and in the summary.

- Further Evaluation:Observations listed as further evaluation need a more extensive or technically exhaustive evaluation. For areas where corrections may not be straight forward or where a proper plan should be developed to implement corrections, then further evaluation is recommended. To obtain further evaluation is to hire a specialist that is highly experienced in the repair or correction of a specific item or area. Some observations listed under other labels that also require further evaluation will appear under the other label only. When used, this observation will appear in the report and in the summary.

- Periodic Maintenance Needed:Observations listed as periodic maintenance needed are items or areas that are expected to have maintenance performed at some interval. Maintenance neglect may be from lack of maintenance knowledge or lack of adequate funding for periodic maintenance. Some irregular or substandard installations may need more frequent maintenance until properly replaced. Start dates and intervals for periodic maintenance are a matter of personal judgment. When used, this observation will appear only in the report.

- Safety Concerns:Observations listed as safety concerns are items or areas listed to help reduce the risk of personal injury. Safety standards and expectations change. Consideration should be given to evaluate and act upon your risk exposure to help reduce the risk of personal injury. Some observations listed under other labels that are also safety concerns will appear under the other label only, such as electrical repairs, which almost always pose some safety risk. Some safety concerns may also be considered improvements but will fall under the safety concerns label if deemed more appropriate. When used, this observation will appear only in the report.

- Routine Correction Needed:Observations listed as routine correction are not unusual for the type and age property inspected. These routine items are typically not recurring and once properly corrected should not require repetitive correction. When used, this observation will appear only in the report.

- Monitor:Observations listed as monitor are typically items or areas that need subsequent observations and should be monitored over time to obtain historical data. These items may or may not require correction in the future based upon their performance over time. If you are unable to do the monitoring, the inspector recommends you appropriately schedule monitoring by a qualified competent contractor. Some observations listed under other labels that also may require monitoring will appear under the other label only. When used, this observation will appear only in the report.

- Improve:Observations listed as improve are items or areas that were ready for improvement or upgrade. This label is used for predictable expected opportunities to better the property condition or installation deficiencies that may or may not affect equipment function. Some observations listed under other labels that also may be considered improvements will appear under the other label only. When used, this observation will appear only in the report.

- New Construction Builder Punch List Item:Builder punch list items are routine and incomplete items and areas observed at a new construction property that likely would not be listed in the summary of the report if it were not a new construction property. Builder punch list items appear in the summary of the report to help the client remind the builder of an incomplete or routine item or area that should be properly addressed.

- Note:Notes are general remarks or comments elaborating on descriptions of systems, limitations, restrictions, or other similar conditions present during the inspection. Notes do not appear in the summary.

- Inspector Informational Note:Inspector informational note regarding inspection process.

- Description:Descriptive information for various aspects of the property, equipment, items, or areas noted during the inspection. Descriptions do not appear in the summary.

- Deck Description:Description of observed deck conditions and issues.

- Bathroom Description:Description of Bathroom features. When used, this observation will appear only in the report.

- Central Heating/Cooling Description:Description of Central Heating/Cooling. When used, this observation will appear only in the report.

- Kitchen Description:Description of Kitchen features. When used, this observation will appear only in the report.

Summary Page

For convenience, the report contains a summary. Be advised, the summary contains only the observations listed as Key Concerns, Further Evaluation Needed, and Hazardous. The summary alone is available at our "Summary Page”. Please understand that you have a duty and obligation to read the full report which contains all of the information and is available at Report. The full report includes full descriptions, digital photographs, captions, and when applicable, diagrams, videos and hot links to additional information.

This report can also be printed on paper or to a PDF document.

Summary

Key Concerns

- B-1 Bathroom:

Bathing Area Main Level at Hall ──── Duplex Right Side

Tub finish was observed damaged. Properly repair to meet your needs and prevent leakage.

- B-2 Bathroom:

Escutcheon was missing at tub faucet at right bathroom. Properly correct where needed.

- B-3 Bathroom:

Bathing Faucet Main Level ──── ──── Duplex Left Side

Faucet was loose. Properly secure faucet as needed.

- B-4 Bathroom:

Sink Faucet Main Level ──── ──── Duplex Left Side

Faucet was loose. Properly secure faucet as needed.

- P2-1 Plumbing:

Water Heater ──── Duplex Right Side

Water heater did not appear to meet manufacturer installation standards for proper installation when inspected. Refer to installation instructions and have a competent contractor correct as needed for function and safety.

- P2-2 Plumbing:

Exterior hose faucet was observed inoperative when inspected. Properly correct or replace as needed.

- Hose faucet at right exterior was inoperative when tested

- CHC-1 Central Heating/Cooling:

Heating System ──── Duplex Right Side

Proper servicing of system is recommended. Due to the condition of the heating system, it is recommended that a qualified competent heating contractor service this system properly repairing as needed for function and safety.

- When operating heat pump system in heating mode, the insulated refrigerant line should be warm to the touch. Refrigerant piping was frosting over rather than being warm to the touch.

- CHC-2 Central Heating/Cooling:

Service walkway to furnace in attic was missing or incomplete.

Furnaces installed inside attic areas should have a secured 24" wide walkway and a 30" deep service platform running the length of the control side of the furnace to provide minimum reasonable access for maintenance of the furnace. Correction was needed for safety of service personnel and to reduce property owner liability exposure. Properly correct to meet your needs.

- CHC-3 Central Heating/Cooling:

Heating System ──── Duplex Left Side

Proper servicing of system is recommended. Due to the condition of the heating system, it is recommended that a qualified competent heating contractor service this system properly repairing as needed for function and safety.

- Condensing unit failed to engage when heat pump system was calling for normal heating using the condensing unit at exterior.

- CHC-4 Central Heating/Cooling:

Irregular duct installation was observed and further evaluation of system is recommended. Properly correct heating and cooling system installation to meet your needs.

- Installed ductwork was irregular

- Installed ductwork was damaged at multiple areas

- Representative photos provided

- Replace or repair ductwork as needed

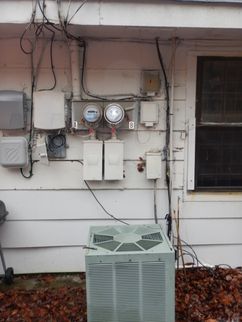

- E4-1 Electrical:

Electrical Service

Observed electrical service should have unobstructed, dedicated safe service access area of no less than 30" in width and 36" depth as measured out from the inspected electrical panel. This clear area is needed for safe access to this type of equipment. Consider relocating equipment or obstruction as needed to provide minimum safe working access to electrical service.

- E4-2 Electrical:

Electrical Panel Exterior near Meter

Corrections were needed at electrical distribution panel. Make proper corrections as needed for safety and function now. Refer to the full report for additional information and photos regarding obvious corrections recommended for this electrical panel.

- E4-3 Electrical:

Electrical Panel Exterior near Cooling unit

Corrections were needed at electrical distribution panel. Make proper corrections as needed for safety and function now. Refer to the full report for additional information and photos regarding obvious corrections recommended for this electrical panel.

- Inner cover was missing at fuse panel

- Fuse panel did not have reasonable access as fuse panel was blocked by cooling unit

- E4-4 Electrical:

Clothes dryer receptacle at right unit was not secured in place. Properly correct for safety before use.

- E4-5 Electrical:

Some lighting was inoperative when inspected. Some light fixtures were damaged. Check all lighting/fans making functional and safe where needed.

- Representative photos provided

- R-1 Roof:

Roofing was ready for corrections now. A competent roofing contractor should check entire roof system and associated flashings. Repair or replace roof covering system as needed.

- Moss observed at roofing

- Damaged shingles observed at right rear

- Representative photos provided

General Comments

Building Characteristics, Conditions and Limitations

Type of Building : Duplex

Approximate Square Footage: 1888

Approximate Year of Original Construction: 1968

Weather during the inspection: Cloudy, Light Rain

Approximate temperature range during the inspection: 32-59[F]

Ground/Soil surface conditions: Wet

Interior

Access

Furnishings, Personal Property

Access and visibility was limited at interior areas as furnishings were present.

Access and visibility was limited for some interior areas as personal property was present.

Walls

Wall Materials: Drywall

Wear and damage noted. Budget reconditioning.

Recondition Your Standard

Properly recondition area to your standard.

Ceilings

Flooring

Floor Covering Materials: Carpet, Engineered Flooring, Tile

Serviceable, fulfilling its function.

Doors at Interior

Doors at Interior: Some doors were missing or not installed

Doors Replace Repair

Replace, repair or upgrade interior doors to meet your needs. Properly correct any affected adjacent areas, if present.

Doors to Exterior

Replace, Repair, Check All

Glazing/Glass

Insulated glass was present.

Visibility Obscured

Obscured visibility was observed at insulated glass at some windows. Obscured visibility at insulated glass can be caused by failure of the seal between the layers of glass, failure of the UV protective film or other cause. Replacement of the glass is typically the best method to cure this problem. Check all areas. Properly replace or repair all obscured or damaged glass as needed.

Windows

Metal framed windows were present.

Escape and Rescue

Consider upgrade for escape and rescue window openings. Window for one or more possible sleeping areas did not appear to meet modern safety standards for an emergency escape or a rescue opening from a sleeping room. Evaluate your risk exposure correcting or making contingency measures as needed. Consider this area for appropriate upgrade or improvement.

Improve Operation

Some window operation could be improved. Check all windows. Correct to your standard.

- Window

Some Blocked

Furniture or stored items blocked some windows. Blocked windows were not operated.

Consider Replacement

Consider replacement windows as a more cost effective long term solution than repairing existing windows now and performing future periodic maintenance.

Kitchen

Kitchen Inspection Process

Kitchen Inspection Process

Kitchen Inspection Process

Kitchen inspection was of the readily accessible and visible portions of the kitchen. The kitchen inspection includes the countertops and a representative number of cabinets. Kitchen faucets, when functional, are run for longer than one minute checking for observable leaks and hot/cold orientation.

The following builtin kitchen appliances, where installed, were inspected and on/off operated testing the main function of each appliance using the normal operating controls:

- Cooktop / Oven / Range (cook surface with integral oven)

- Microwave

- Garbage Disposal

- Trash Compactor

Installed dishwashers are run through a normal cycle. Obvious functional issues and leaks observed around the dishwasher are reported, if present.

Ventilation equipment, such as range hoods, are inspected, on/off operated and are reported as ductless, ducted or recirculating. It is beyond the scope of this inspection to determine the effectiveness of the kitchen exhaust fan, such as to verify air flow quantity or discharge location.

Appliance inspection does not cover clocks, timers, self cleaning function, calibration, automatic functions or optional equipment on appliances. Refrigerators are considered personal property and are not evaluated. Refrigerator presence or absence is noted.

Equipment that appears to be shut down, inoperable or intentionally taken out of service is noted but will not be operated by the inspector. Shut down equipment may be unplugged, breaker off, water off, gas off or otherwise taken out of service.

Installation conditions and functional issues for this area requiring correction should be performed by a competent qualified contractor.

Kitchen

Kitchen Area: Right

Duplex Right Side

Countertop: Laminate

Wear noted, recondition as desired

Cabinets: Wood

Some wear noted, recondition as desired

Floor Covering: Tile

Serviceable, fulfilling its function

────

Sink: Double Bowl Stainless Steel

No leaks were viewed at faucet or visible supply lines or waste drain just beneath the sink.

Signs of past leakage observed, maintain area to meet your needs

Disposal: Not Present

Dishwasher: Not Present

Range: Range (Electric Top/Oven)

Present and On/Off Tested functional

Microwave: Portable unit not evaluated

Kitchen Exhaust: Ductless unit appeared functional

Refrigerator: Present but not evaluated

Trash Compactor: Not Present

Kitchen

Kitchen Area: Left

Duplex Left Side

Countertop: Laminate

Some wear noted, recondition as desired

Cabinets: Wood Some Painted

Some wear noted, recondition as desired

Floor Covering: Engineered Flooring

Serviceable, fulfilling its function

Flooring was not level. Consider for correction.

Sink: Double Bowl Stainless Steel

No leaks were viewed at faucet or visible supply lines or waste drain just beneath the sink.

Signs of past leakage observed, maintain area to meet your needs

Disposal: Not Present

Dishwasher: Not Present

Range: Range (Electric Top/Oven)

Present and On/Off Tested functional

Microwave: Portable unit not evaluated

Kitchen Exhaust: Ductless unit appeared functional

Refrigerator: Present but not evaluated

Trash Compactor: Not Present

Kitchen Exhaust: Exhaust Filter Missing

Exhaust Duplex Left Side

Fan filter was missing from kitchen exhaust. Properly service kitchen exhaust correcting as needed for function and safety.

Bathroom

Testing Plumbing at Bathroom Areas

Testing Limitations

Bathroom Inspection Process

The following opinion was based on an inspection of the readily accessible and visible portions of bathroom areas.

Hand washing faucets, when functional, are run for longer than one minute checking for observable leaks at the faucet and beneath the sink as well as checking Hot/Cold orientation.

Bathing area faucets, when functional, are run for longer than five minutes checking for observable leaks and Hot/Cold orientation.

Toilets, when functional, are flushed no less than two times. Inspector checks for leaks around toilet, checks that toilet fills and shuts off, and checks to see if toilet appears securely mounted.

Effectiveness and discharge locations for mechanical bathroom exhaust vents are not confirmed during inspection.

Installation conditions and functional issues for this area requiring correction should be performed by a competent, qualified contractor.

Bathroom 1

Full Bathroom

Main Level at Hall ──── Duplex Right Side

Bathing Area: Combination tub and shower

────

────

────

Hand Washing: Vanity with basin ────

No leaks were observed around faucet, visible supply lines or waste drain just beneath the sink.

Signs of past leakage observed, maintain area to meet your needs.

────

Toilet: Water tank type ────

No Leaks were observed around toilet and it appeared secured in place.

Ventilation: ────

Fan on/off tested operative - Consider exhausting to exterior if needed.

Floor Covering: Tile

Serviceable, fulfilling its function

────

Bathing Area: Periodic Maintenance Needed (Leak at Shower Head)

Bathing Area Main Level at Hall ──── Duplex Right Side

Tub finish was observed damaged. Properly repair to meet your needs and prevent leakage.

Bathroom 2

Full Bathroom

Main Level ──── ──── Duplex Left Side

Bathing Area: Combination tub and shower

Properly maintain shower enclosure to meet your needs.

────

Hand Washing: Vanity with basin ────

Signs of past leakage observed, maintain area to meet your needs.

────

────

Toilet: Water tank type ────

No Leaks were observed around toilet and it appeared secured in place.

Ventilation: ────

────

Floor Covering: Engineered Flooring

Serviceable, fulfilling its function

────

Bathing Faucet Main Level ──── ──── Duplex Left Side

Faucet was loose. Properly secure faucet as needed.

Sink Faucet Main Level ──── ──── Duplex Left Side

Faucet was loose. Properly secure faucet as needed.

Plumbing

Plumbing Supply Piping - Main Water Shut Off Valve - Apparent Location - Note Such Valves are Not Operated

Water Utility Owned - Plumbing Supply Piping - Shut Off Valve Location: At Meter

Property Owner - Plumbing Supply Piping - Shut Off Valve Location: Not Observed, Unknown

Water Heater

Water Heater

Water Heater

Water Heater

Size: Unknown / Location: Laundry Area Duplex Left Side

Age unknown ──── / Fuel: Electric

Water Heater was observed functional during inspection

Typical service life of a water heater is 8-12 years.

────

Access: Excessively Restricted

Water Heater ──── Duplex Left Side

Water heater likely area had excessively restricted access when inspected. The water heater installation was not observed by inspector nor was area around the water heater observed for leaks. The age and size of the water heater were not determined when it was inspected. Create proper access to water heater area. Have system installation evaluated properly correcting as needed.

Discharge Piping: Short

Water Heater ──── Duplex Right Side

Water heater relief valve had a discharge extension pipe that appeared too short. This pipe should extend to within 6" above floor level for safety. The pipe should be rated for hot water and the diameter of the pipe should match that of the valve.

Installation Issue: Questionable Installation, Leak Pan Drained to Interior

Water Heater ──── Duplex Right Side

Leak pan was observed beneath water heater that drained to an interior area defeating the function of the leak pan. The leak pan should drain to an exterior area. Proper correction is recommended to prevent damage to interior areas should the water heater leak pan receive water such as from a water heater leak.

Water Heater ──── Duplex Right Side

Water heater did not appear to meet manufacturer installation standards for proper installation when inspected. Refer to installation instructions and have a competent contractor correct as needed for function and safety.

Supply Piping

Supply Piping: Copper, PEX, CPVC

Water Flow at Supply Piping: Adequate

Adequate functional supply water flow was observed during inspection for water outlets operated.

Waste Piping

Waste Piping: Plastic

Functional waste water flow observed during inspection for water outlets operated.

Apparent Plumbing Vent Piping

Plastic - No Adverse

Material: Plastic

No adverse conditions were observed, maintain to meet your needs.

Laundry Connections

Laundry: Appliances Present

Laundry appliances were present during inspection. Duplex Both Units

Laundry appliances restricted view of laundry connections. Laundry appliances typically do not convey with property. Laundry appliances are not evaluated during inspection. Laundry faucets are not operated when appliances are connected to faucets. Verify your clothes dryer exhaust is functional, safe and properly installed to meet the requirements of clothes dryer manufacturer in use.

Exterior Hose Faucets

Performance: Inoperative

Performance: Loose

Hose Faucet at left exterior

Hose faucet observed loose. Properly correct hose faucet installation as needed.

Plumbing Equipment Observed Present But Not Tested or Evaluated

Thermal Expansion: About Thermal Expansion, Tank Missing

Regarding Plumbing System Thermal Expansion:

Thermal expansion occurs when a tanked water heater operates without any plumbing valves open for a period of time. If the property water meter has a check or backflow preventer valve installed it will prevent the expanding contained water from flowing backwards through the water meter. This expansion causes the water heater pressure relief valve to open briefly releasing a small amount of water if an expansion control device is not present or not working properly. If the pressure relief valve on the water heater opens and does not seal closed properly then active leaks and subsequent damage may occur.

A plumbing thermal expansion tank was not observed near the water heater. Duplex Both Units

Monitor this area for leaks adding an expansion tank if needed.

________________________________________________________________________________________________________________________________________________________________

Pressure Reducer: About Pressure Reducing Valves

Regarding Plumbing System Pressure Reducing Valves:

The pressure reducer or pressure regulator in a plumbing system is designed to reduce the water pressure to a reasonable level in an effort to help prevent damage to the plumbing system. For most areas if the utility water pressure is greater than 80 PSI (pounds per square inch) a pressure reducer is needed. For some areas with extremely high utility pressure multiple pressure reducers may be needed installed in series. Pressure reducers are typically factory set for 50 PSI and property water pressure is expected to be between 30 PSI and 80 PSI. Inspector notes presence of pressure reducer when observed. Pressure readings for plumbing system are not part of the inspection performed.

Pressure Reducer Location: For Both Units, Unknown

A plumbing system pressure reducer was not located. Verify location of installed pressure reducer or add as needed, if needed.

Plumbing Other

Older Plumbing

Inspected plumbing system appeared older and portions may be outdated. Monitor plumbing system for unusual performance or leakage making proper corrections if necessary.

Central Heating/Cooling

Central Heating /Cooling

Split System - Heat Pump

Split Heat Pump System served: System served entire home Duplex Right Side

Brand Furnace: Brand not listed / Location: Attic / Fuel: Electric Heat Pump

Size: 2.5 ton / Age unknown ────

Heat pumps typically have a service life of 12-18 years when properly maintained

Filter Type: Disposable / Thermostat Type: Digital

Cooling Brand: Corsaire / Location: Exterior / Fuel: Electric

Year of Manufacture: 1998

Heat pumps typically have a service life of 12-18 years when properly maintained

Condensate disposal method: Gravity drain piping - service annually

Consider properly replacing older central system as preventative maintenance.

Cooling Function: Below 60 Degrees

Cooling System Not Operated Cool Day

Outdoor temperature was below 60 degrees f. The central cooling system was not operated in cooling mode due to low exterior ambient temperatures. To test the cooling unit without causing possible damage to the compressor the ambient outdoor temperature should be above 60 degrees.

Cooling Issue: Insulate Refrigerant Lines

Cooling system refrigerant lines need insulation. Sections of the insulation on the compressor lines appeared to be missing. These lines should be suitably insulated to prevent sweating lines from dripping moisture to finished areas and to improve efficiency of the cooling system.

Heating System Location Issue: Attic Walkway

Heating System ──── Duplex Right Side

Proper servicing of system is recommended. Due to the condition of the heating system, it is recommended that a qualified competent heating contractor service this system properly repairing as needed for function and safety.

- When operating heat pump system in heating mode, the insulated refrigerant line should be warm to the touch. Refrigerant piping was frosting over rather than being warm to the touch.

Service walkway to furnace in attic was missing or incomplete.

Furnaces installed inside attic areas should have a secured 24" wide walkway and a 30" deep service platform running the length of the control side of the furnace to provide minimum reasonable access for maintenance of the furnace. Correction was needed for safety of service personnel and to reduce property owner liability exposure. Properly correct to meet your needs.

Central Heating /Cooling cont

Split System - Heat Pump

Split Heat Pump System served: System served entire home Duplex Left Side

Brand Furnace: Nortek formerly Nordyne / Location: Attic / Fuel: Electric Heat Pump

Size: 2.5 ton / Year of Manufacture: 2014

Heat pumps typically have a service life of 12-18 years when properly maintained

Filter Type: Disposable / Thermostat Type: Digital

Cooling Brand: Brand not listed / Location: Exterior / Fuel: Electric

Age unknown: ID plate not legible ────

Heat pumps typically have a service life of 12-18 years when properly maintained

Condensate disposal method: Gravity drain piping - service annually

Consider properly replacing older portion of central system as preventative maintenance.

Cooling Function: Below 60 Degrees

Cooling System Not Operated Cool Day

Outdoor temperature was below 60 degrees f. The central cooling system was not operated in cooling mode due to low exterior ambient temperatures. To test the cooling unit without causing possible damage to the compressor the ambient outdoor temperature should be above 60 degrees.

Heating System ──── Duplex Left Side

Proper servicing of system is recommended. Due to the condition of the heating system, it is recommended that a qualified competent heating contractor service this system properly repairing as needed for function and safety.

- Condensing unit failed to engage when heat pump system was calling for normal heating using the condensing unit at exterior.

Distribution Ductwork

Ductwork: Irregular Further Evaluate

Irregular duct installation was observed and further evaluation of system is recommended. Properly correct heating and cooling system installation to meet your needs.

- Installed ductwork was irregular

- Installed ductwork was damaged at multiple areas

- Representative photos provided

- Replace or repair ductwork as needed

Electrical

Electrical System Inspection

Electrical System Inspection

What is an electrical system?

The electrical system consists of an electrical service, distribution equipment and branch wiring. The electric metering equipment is usually at the electrical service. Distribution equipment is most often one or more installed breaker panels and the branch wiring runs to all equipment, receptacles, lighting outlets and devices such as the light switches. The inspection report focuses on wiring operating between 100-250 Volts. Most low voltage wiring is excluded from the performed inspection. Low voltage items such as a heating and cooling thermostat are operated in order to determine the function of such equipment.

There are now a wide variety of lighting bulbs or lamps that will fit into lighting fixtures. Some choices may not be appropriate for some lighting fixtures. It is beyond the scope of this inspection to verify each lamp or bulb is appropriate for the installed lighting fixture. The inspector recommends that you review the bulb or lamp installations for each fixture correcting as needed for safety and function. Common errors include 100 watt bulbs installed in fixtures rated for 60 watt max bulbs and interior rated bulbs installed at exterior or damp locations. Other types of errors also exist.

The following opinion was based on an inspection of the readily accessible and visible portions of the electrical system. The Inspector is responsible for checking a representative number of installed lighting fixtures, switches, and receptacles. Electrical installation conditions and functional issues requiring correction should be performed by a competent licensed electrical contractor. Most, if not all, electrical corrections should be considered a safety concern.

System Amps / Volts

System Amperage: 200 Amps

System Voltage: 120/240 Volts

Electrical Service

Electrical Service Type: Overhead

Access: Electrical Service Working Access

Electrical Service

Observed electrical service should have unobstructed, dedicated safe service access area of no less than 30" in width and 36" depth as measured out from the inspected electrical panel. This clear area is needed for safe access to this type of equipment. Consider relocating equipment or obstruction as needed to provide minimum safe working access to electrical service.

Main Electrical Distribution Panel

Service Entrance Conductors: Aluminum, Stranded

Electrical Panel Type: Multiple Breaker Panels at One Location

Corrections Needed

Access: Working Access

Electrical Panel Exterior near Meter

Observed electrical equipment panel should have unobstructed dedicated safe service access area of no less than 30" in width and 36" depth as measured out from the inspected electrical panel. This clear area is needed for safe access to this type of equipment. Consider relocating equipment or obstruction as needed to provide minimum safe working access to the electrical panel.

Access: Relocate Cooling Unit or Electrical Panel

Electrical Panel Exterior near Meter

Cooling unit installation restricted safe access to electrical panel. Budget relocation of cooling unit or electrical panel in order to have safe working access to electrical panel. Properly correct now or no later than when replacing cooling unit.

Electrical Panel Exterior near Meter

Corrections were needed at electrical distribution panel. Make proper corrections as needed for safety and function now. Refer to the full report for additional information and photos regarding obvious corrections recommended for this electrical panel.

Sub Electrical Distribution Panel

Sub Electrical Panel Type: Sub Breaker Panel

Index: Index

Access: Panel Cover SEALED in Place

Sub Electrical Distribution Panel

Sub Electrical Panel Type: Sub Breaker Panel

Access: Panel Access BLOCKED

Electrical Panel Laundry Area Duplex Left Side

The electrical distribution panel was inspected and restricted access was found. Reasonable access was blocked at the distribution panel cover. The inspector did not remove the panel cover and evaluate the interior of the electrical panel. The inspector recommends this condition be corrected and the interior of breaker panel be evaluated making corrections if needed.

- Laundry room door was blocked closed by excess laundry.

- Floor area in front of breaker panel was concealed by excess laundry.

Sub Electrical Distribution Panel

Corrections Needed

Electrical Panel Exterior near Cooling unit

Corrections were needed at electrical distribution panel. Make proper corrections as needed for safety and function now. Refer to the full report for additional information and photos regarding obvious corrections recommended for this electrical panel.

- Inner cover was missing at fuse panel

- Fuse panel did not have reasonable access as fuse panel was blocked by cooling unit

Branch Wiring

Material: Copper

Wiring Method: Non Metallic Sheathed Cable

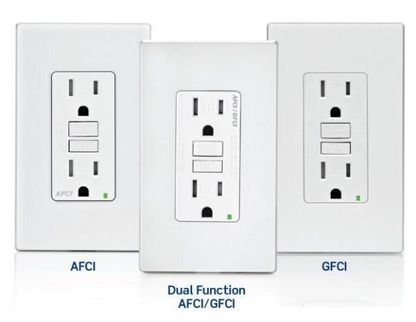

AFCI - Arc Fault Circuit Interrupter

AFCI Residential

What is Arc Fault Circuit Interrupter (AFCI) Protection?

AFCI protection is designed to help reduce the chance of fire when a specific type of malfunction occurs at installed electrical outlets. This protection detects unintended electrical arcs and disconnects the power before the arc starts a fire.

Most, but not all, homes will have a need for additional AFCI protection based on varied municipal enforcement and the numerous changes for which areas require AFCI protection. Evaluate your risk exposure. Consider adding AFCI protection where needed for improved safety, particularly where construction was completed 2002 or later.

Modern Locations Where AFCI Protection is Known to Improve Safety for 15 and 20 Amp Electrical Circuits:

For all 15 and 20 ampere single phase residential electrical circuits serving outlets and devices in Kitchens, Family Rooms, Dining Rooms, Living Rooms, Parlors, Libraries, Dens, Bedrooms, Sunrooms, Recreation Rooms, Closets, Hallways, Laundry Areas, or similar rooms or areas.

Testing AFCI Function

The inspector uses push button at AFCI breakers, where installed, to confirm AFCI protection trips. Once tripped, the inspector checks indexed electrical circuits to determine where AFCI protection is present or missing.

Obvious locations lacking AFCI protection are listed in the body of the report.

Obvious broken, non working and improperly wired AFCI receptacles or breakers are listed in the summary of the report. Evaluate your risk exposure.

No AFCI Built Before 2002

Areas That Did Not Appear AFCI Protected

No AFCI protection was observed at inspected property. AFCI protection is not expected for homes built before 2002. If installation of AFCI protection is desired, consult a competent electrical contractor.

GFCI - Ground Fault Circuit Interrupter

GFCI Residential

What is Ground Fault Circuit Interrupter (GFCI) Protection?

GFCI protection is designed to help reduce the risk of being shocked when using electricity in certain areas.

Most, but not all, buildings will have a need for additional GFCI protection based on varied municipal enforcement and the numerous changes for which areas require this type of protection. Evaluate your risk exposure. Consider adding GFCI protection for 15 and 20 ampere electrical circuits where needed for improved safety.

Modern Locations Where GFCI Protection is Known to Improve Safety for 15 and 20 Amp Electrical Circuits:

- all electrical receptacles at Bathrooms, Crawl Spaces, Exterior Areas, Garages, Unfinished Basements

- all electrical receptacles serving Kitchen Counter Surfaces

- all electrical circuits for Dishwashers

- all electrical circuits for Hydro Massage Tubs

- all 120 V electrical receptacles at Laundry Areas

- all electrical receptacles near Showers or plumbing Sinks (within 6 feet/arms reach)

- all 3 wire electrical receptacles installed on 2 wire circuits (such as at older homes)

- all electrical receptacles at accessory buildings (OUTBUILDINGS) that have a floor located at or below grade level not intended as habitable rooms

Testing GFCI Function

The inspector uses an electrical tester at receptacles that simulates a remote ground fault current to confirm which areas lack proper GFCI protection at electrical receptacles.

Obvious locations lacking GFCI protection are listed in the body of the report.

Obvious broken, non working and improperly wired GFCI receptacles or breakers are listed in the summary of the report.

GFCI Some

Some GFCI protection was present. Multiple areas would benefit from adding further GFCI protection. Consider modernizing electrical installation adding this shock protection, where missing, for all electrical areas where GFCI protection is known to improve safety.

Electrical Receptacle Outlets

Receptacle Appeared Missing: Cooling Unit

Electrical Receptacle Outlet ──── Duplex Both Units

An electrical receptacle was not observed near the cooling condensing unit at exterior. Equipment requiring periodic servicing should have a permanent electrical receptacle installed close by. Consider properly adding an electrical receptacle at exterior ground level within 25 feet of cooling condensing unit to service this equipment.

Two Wire 120 Volt Electrical Receptacle Outlets Commonly Found in Older Buildings

3 Corrections 2 Wire Receptacle Circuits, Preferred Method 2 Wire Receptacles

Regarding Two Wire Electrical Receptacle Outlets ────

Inspector informational note regarding proper wiring of 120V electrical receptacles on two wire electrical circuits such as in older homes and in the inspected property.

There are three proper wiring methods for older two wire receptacle circuits:

- Two wire receptacle circuits may have two wire receptacles, if properly installed.

- Two wire receptacle circuits may have replacement three wire receptacles, if properly installed, GFCI protected and appropriately marked 'NO EQUIPMENT GROUND'. GFCI protected receptacles without test/reset buttons should also be appropriately marked 'GFCI PROTECTED OUTLET'.

- Two wire receptacle circuits may be properly replaced with three wire receptacle circuits and three wire receptacles.

Two Wire Electrical Receptacle Outlets ────

Inspector informational note regarding personal preferred wiring method for 120 V two wire electrical receptacles circuits found in older homes.

There are multiple ways to properly address electrical receptacles on two wire circuits. The inspector has developed a personal preference for your consideration. This preference eliminates the need for stickers on most of the receptacles. This preference eliminates confusion regarding which receptacles have a grounding wire and which do not.

INSPECTOR PREFERRED METHOD

Newer two wire receptacles are used on two wire receptacle circuits.

Replace any two wire receptacles that are damaged or where a plug is loose when plugged into receptacle.

For two wire receptacle circuits needing GFCI protection, GFCI breakers are utilized rather than GFCI receptacles.

Where three wire receptacles are necessary or desired, three wire receptacle circuits are either confirmed existing already or a new three wire circuit is added.

Areas where three wire receptacles are beneficial include:

Exterior, Garages and circuits that serve refrigerator, freezer, microwave, clothes washer, garage door operator, computers and other electronics, appliances or tools with a three wire cord. Adding grounded electrical receptacles for electronics, appliances or tools that have a two wire cord is not necessary.

Mixed Circuits, Correct Where Needed, Label Where Needed

Two Wire Electrical Receptacle Outlets ────

The inspector observed some electrical circuits that appeared to have a grounding conductor and some circuits that did not appear to have a grounding conductor. This is not unusual for the age of the property inspected. Monitor your electrical need and consider upgrading wiring as appropriate.

Two Wire Electrical Receptacle Outlets ────

Properly correct two wire receptacle circuits where needed to improve safety.

Two Wire Electrical Receptacle Outlets ────

Properly identify 3 wire receptacles installed on 2 wire circuits as 'GFCI Protected' and 'No Equipment Ground' where needed.

Three Wire 240Volt Electrical Receptacle Outlets Commonly Found in Older Buildings

Three Wire 240V Receptacles Observed

Some older 240V 3 wire electrical receptacle circuits were observed. Typically, these circuits would serve electric clothes dryers or electric kitchen ranges but may also serve other areas. Evaluate your risk exposure and consider upgrade replacement of any 240V 3 wire receptacle circuits where present with a modern 240V 4 wire receptacle circuits for improved safety. Properly maintain older 240V 3 wire receptacle circuits to meet your needs and for safety, if not upgrading older circuits now.

Electrical Lighting Outlets and Ceiling Fans

Exposed Closet

Exposed incandescent type light fixture was observed at closet. Stored items should be kept away from surface mounted incandescent closet lights to reduce the risk of fire. Use caution with this type fixture. Install low wattage LED light bulbs or fixture with a globe to help reduce heat transfer risk.

Inoperative/Damaged

Switches

Switch Location Informational Note

Regarding Lighting Switch Locations:

While exact placement of lighting switches is considered a design issue, installing lighting switches at appropriate locations is useful to improve safety. Generally, a light switch would be located within arms length of the entry point of a room so that the lighting for the room you are entering may be switched on from an area near the doorway. Installing a switch at an inconvenient location, such as on the hinge side of a door, would not be desirable. Where the stairway between floor levels has six risers or more, a wall switch would be located at each floor level and at each landing level that includes an entryway to control the lighting for the stairway. Evaluate your need in regard to lighting switch locations. Consider updating switch locations for improved safety if desired.

Smoke Alarms

Modernize, Test After Installation

Consider Upgrade Modernizing Smoke Alarm Installation:

Consider modernizing smoke alarm installation to improve safety as changes have occurred as to where smoke alarms should be installed. Modern smoke alarm systems typically are hardwired to the electrical system and will have battery backup so that they will function when the power is off to the building. Modern smoke alarm systems typically have all smoke alarms interconnected so that when one alarm sounds then all smoke alarms will sound simultaneously. This is useful for heavy sleepers and in larger homes.

Modern smoke alarm systems typically have smoke alarms installed at the following locations:

- Outside sleeping areas

- Inside sleeping areas

- At least one per floor level including basements

- Near stairs

- In garages

- In unfinished basements

- (some installations will require additional smoke alarms)

It is important to note that a single smoke alarm can satisfy multiple areas if carefully placed.

It is common to have a single smoke alarm near the top of the stairs and just outside multiple sleeping areas.

Evaluate your risk exposure. Upgrade smoke alarms to meet your needs.

Read and follow the smoke alarm manufacturer installation and operating instructions.

Contact your local Fire Marshal if need be.

Regarding Testing Smoke Alarms:

After installing smoke alarms, test weekly and replace batteries when needed. Properly replace smoke alarms when not functioning correctly and at least every ten years. Smoke alarms should be at least the photoelectric type and dual sensor photoelectric and ionization smoke alarms are available, and preferred. Refer to installation and care instructions for proper locations and periodic maintenance.

Structure

Attic Access

Attic Access: Scuttle Hole

Attic Access: Floored

Attic area viewed from areas where secured, floored, continuous, walkway was present. Some areas of attic may not have been viewed.

Attic Area

Draft Stop: Not Present

Not Present

No draft stop or fire wall was observed at attic area between dwelling units for multi family dwelling. Properly installed drywall at attic areas between attached dwelling is used to create a draft stop. In case of fire a properly installed draft stop can offer some protection slowing the spread of smoke and fire from one dwelling unit to another. Consider this area for appropriate upgrade or improvement.

Roof Framing

Framing: Rafters

Sheathing: Wood

Roof Framing: Older Typical

Ceiling Framing

Framing Access: Finished Restricted

Finished areas restricted view of structural components. Some areas were not observed by inspector.

Wall Framing

Framing Access: Finished Prevented

Finished areas prevented view of structural components. Structural areas were not observed by inspector.

Underfloor Access

Slab: Finished Areas

Finished areas prevented view of structural components. Structural components were not observed by inspector at such areas.

Underfloor Description

Slab: On Grade

Underfloor Area

Access:

Slab construction no underfloor area present

Construction Type:

Concrete Slab on Grade

Foundation:

Poured in Place Concrete

Columns or Piers:

Not Applicable

Floor Structure:

Concrete Slab Floor

Floor Insulation:

Not Applicable

Foundation

Cracked Monitor Repair if Worsens

Concrete Block Foundation Observed Cracked

Cracked areas were observed when inspected. Monitor area budgeting repairs as needed should condition worsen.

- Obvious cracking and displacement was observed at front exterior. Consider for correction now or closely monitor area to determine if movement is active. Budget immediate correction should condition worsen.

Insulation

Above Ceiling Insulation

Recommended Insulation

Recommended attic insulation depth above living spaces for this area of the country is R-38 to R-60 to help lower utility costs. This recommendation comes from the US Department of Energy. Evaluate your comfort level and utility costs correcting insulation depth if needed.

Insulation Type: Blown In

Observed Insulation Approximate Depth: R - 13

Consider Improving Insulation: Missing, Energy Audit Recommended

Consider obtaining evaluation by an energy auditor for home to improve energy efficiency and occupant comfort at home.

Wall Insulation

Insulation: Wall Insulation Not Observed, Undetermined

Ventilation

Attic Ventilation

Attic Exhaust Vents: Ridge Roof Vent, Gable End Vent

Attic Intake Vents: Soffit Vents Where Installed

Moisture

Moisture Indications at Interior

Interior: Moisture Stains Observed Dry

Dry moisture stains were observed. Stains are evidence of a prior undesirable moisture condition. Monitor area to verify cause of stain is not still present. Further evaluation may be needed if cause of stains persists. Properly correct cause of stain if needed. Properly repair affected areas as needed.

- Dry moisture stain observed at multiple areas at ceilings

- Representative photos provided

Roof

Roof Covering

Method of Roof Inspection: Walked on roof

Common Limitations: Dead Vegetation

Roof Style: Gable

Roofing Material: Composition Three Tab Shingle

Observation: Roofing Corrections Needed

Gutters and Downspouts

Gutter and Downspout Materials: None

Exterior Surfaces

Siding

Siding: Composition Siding

Eaves: Painted Wood

Trim: Wood

Irregularity: Low

The inspector noted that portions of the siding or trim are too close to ground level, making the siding or substrate subject to damage. Siding and untreated substrate should be a minimum of 6" above soil and 2" above pavement. Properly provide separation at siding/trim and untreated substrate from soil and pavement. If it is not cost effective to lower the soil grade or raise the siding and substrate area then you should budget periodic replacement of affected areas.

Siding: Deferred Maintenance, Flashing With Replacement, Paint Failing, Physical Damage, Rot, Temporary Repairs, Refurbish, Replace/Repair, Consider Complete Replacement

Siding - ────

The inspected item suffered from deferred maintenance and was ready for reconditioning.

Older siding installation may not have modern flashing details for all areas where expected. Correct any flashings where needed now in conjunction with predictable siding replacement at older home needed now.

Siding - ────

One or more layers of paint did not appear to be properly bonded to painted surface. This can be caused by age, poor preparation, excessive thickness or moisture. Properly correct as needed before repainting.

Siding - ────

Physical damage was noted and should be properly repaired.

Siding - ────

Rotting and damage was observed. Check all exterior areas subject to decay properly correcting damage and affected adjacent areas as needed.

Siding - ────

Temporary repairs, where present, should be considered for permanent corrections to reduce periodic maintenance.

Siding - ────

Refurbish area before painting. A quality paint or stain job will include washing/cleaning all areas to be painted, repair/replacement of damaged siding and trim, seal all gaps, prime all unpainted areas and sufficient paint coverage to achieve desired color without bleed through.

Siding - ────

Properly replace or repair exterior siding and trim as needed. Properly correct any adjacent affected areas damaged by deferred maintenance.

- Representative photos provided

Consider complete replacement of siding and trim now as a more cost effective long term solution rather than replacing portions of damaged siding and trim now then replacing additional portions of damaged siding as it continues to age.

Brick

Brickwork: Requires Maintenance

Siding - Stucco

Stucco Over Concrete Block

Siding: Requires Maintenance, Physical Damage, Replace/Repair, Upgrade or Maintain

Stucco

Stucco requires periodic maintenance and appeared ready for corrections when inspected. Check all areas properly reconditioning siding to meet your needs.

Stucco

Physical damage was noted and should be properly repaired.

Stucco

Properly replace or repair exterior siding and trim as needed. Properly correct any adjacent affected areas damaged by deferred maintenance.

Stucco

Upgrade or maintain stucco to meet your needs.

Lots and Grounds

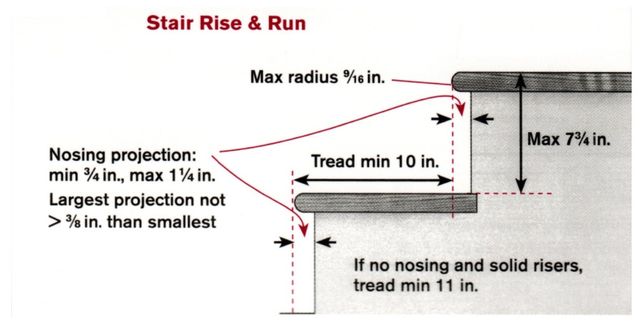

Landing

Stairs and Railings at Exterior

Stairs at Front

Diagram: Correction Needed Stairs

Stairs: Staggered

Walkway

Driveway

Asphalt

Driveway: Recondition

Driveway was ready for reconditioning. Deferred maintenance was observed. Properly correct or upgrade area to meet your needs.

Vegetation

Vegetation Maintenance, Dead Limbs

Properly maintain vegetation to meet your needs. Vegetation should not touch building exterior or overhang roof. Vegetation should not interfere with access or servicing of electrical, gas or heating/cooling equipment.

Dead tree limbs were noted and should be properly removed.

Site

Site: Adjust Grade Slab

Adjust exterior grade for concrete slab floor construction. Some exterior grade work may improve storm water runoff away from foundation. Slope grade minimum ten feet away from and around structure so that water does not collect near foundation. Be sure that exterior soil grade and landscaping is below interior floor level at perimeter of foundation to help prevent unwanted moisture entry into interior areas.

Receipt -- HomePro Inspection Report

02B New Investor Chattanooga TN 37424

| Home Inspection Fee | $410.00 |

| Discount Scheduling | $-20.00 |

| Duplex Fee | $40.00 |

| $430.00 | |

| PAID |

HomePro Inspection Inc

C/O Roger Williamson

2409 Haven Crest Drive

Chattanooga, TN 37421

423-301-1000

.jpg)

.jpg)

.png)